NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2191 of 3066

EX-1

EXHAUST SYSTEM

B ENGINE

CONTENTS

C

D

E

F

G

H

I

J

K

L

M

SECTION

A

EX

EXHAUST SYSTEM

EXHAUST SYSTEM ................................................... 2

Checking Exhaust System ....................................... 2

Removal and Installation .......................................... 2

QR20DE ................................................................ 2

YD22DDTI ............................................................. 3RREMOVAL ........................................................... 3

INSTALLATION ..................................................... 3

Inspection After Installation ...................................... 4

SERVICE DATA AND SPECIFICATIONS (SDS) ........ 5

Tightening Torque ..................................................... 5

Page 2192 of 3066

EX-2

EXHAUST SYSTEM

EXHAUST SYSTEM

PFP:20100

Checking Exhaust SystemEBS00AZ6

Check exhaust pipes, muffler and mounting for improper attachment,

leaks, cracks, damage or deterioration.

Removal and InstallationEBS003DN

CAUTION:

lBe sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance and shape.

lPerform the operation with the exhaust system fully cooled down because the system will be hot

just after the engine stops.

lBe careful not to cut your hand on the insulator edge.

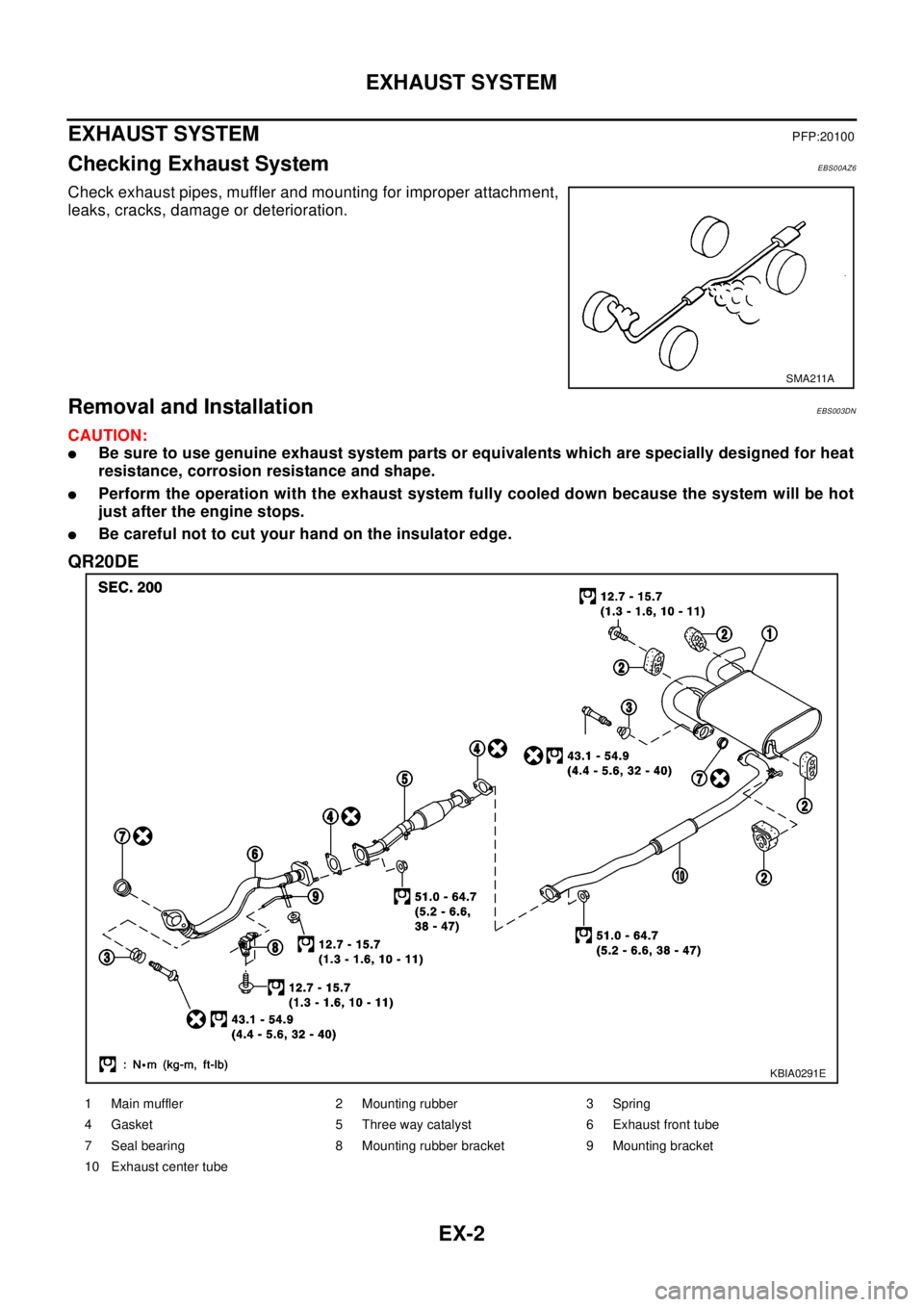

QR20DE

SMA211A

KBIA0291E

1 Main muffler 2 Mounting rubber 3 Spring

4 Gasket 5 Three way catalyst 6 Exhaust front tube

7 Seal bearing 8 Mounting rubber bracket 9 Mounting bracket

10 Exhaust center tube

Page 2193 of 3066

EXHAUST SYSTEM

EX-3

C

D

E

F

G

H

I

J

K

L

MA

EX

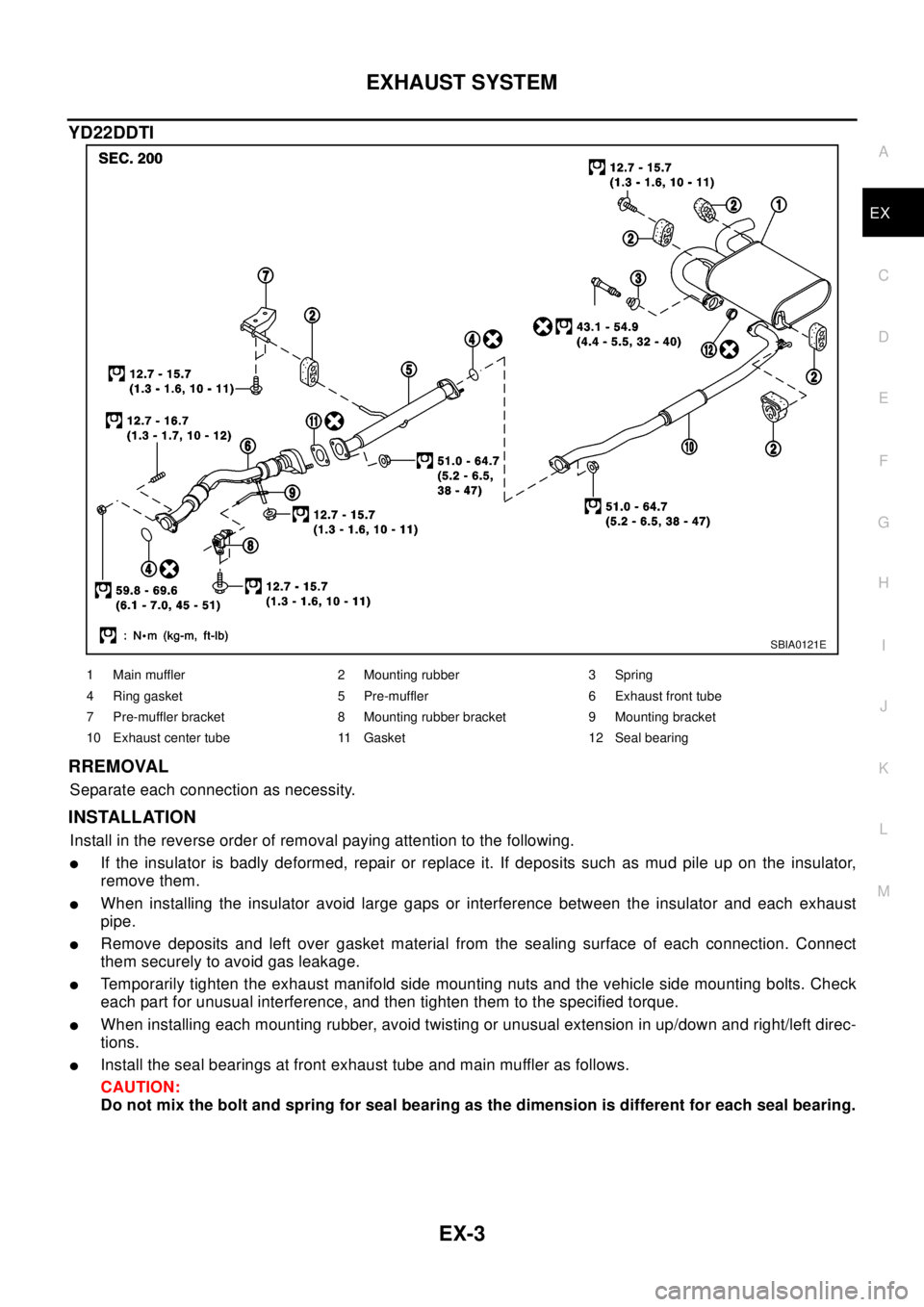

YD22DDTI

RREMOVAL

Separate each connection as necessity.

INSTALLATION

Install in the reverse order of removal paying attention to the following.

lIf the insulator is badly deformed, repair or replace it. If deposits such as mud pile up on the insulator,

remove them.

lWhen installing the insulator avoid large gaps or interference between the insulator and each exhaust

pipe.

lRemove deposits and left over gasket material from the sealing surface of each connection. Connect

them securely to avoid gas leakage.

lTemporarily tighten the exhaust manifold side mounting nuts and the vehicle side mounting bolts. Check

each part for unusual interference, and then tighten them to the specified torque.

lWhen installing each mounting rubber, avoid twisting or unusual extension in up/down and right/left direc-

tions.

lInstall the seal bearings at front exhaust tube and main muffler as follows.

CAUTION:

Do not mix the bolt and spring for seal bearing as the dimension is different for each seal bearing.

SBIA0121E

1 Main muffler 2 Mounting rubber 3 Spring

4 Ring gasket 5 Pre-muffler 6 Exhaust front tube

7 Pre-muffler bracket 8 Mounting rubber bracket 9 Mounting bracket

10 Exhaust center tube 11 Gasket 12 Seal bearing

Page 2194 of 3066

EX-4

EXHAUST SYSTEM

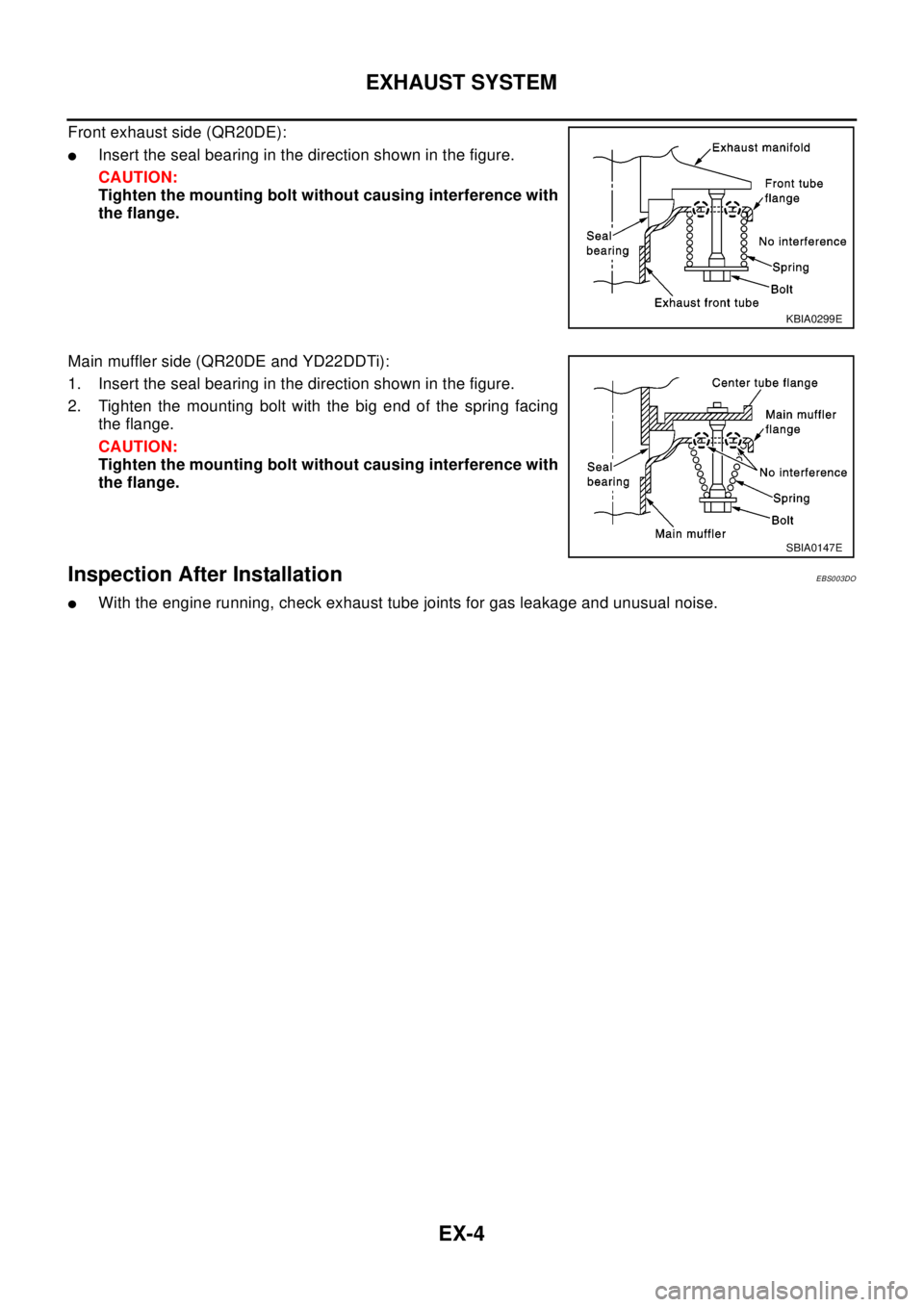

Front exhaust side (QR20DE):

lInsert the seal bearing in the direction shown in the figure.

CAUTION:

Tighten the mounting bolt without causing interference with

the flange.

Main muffler side (QR20DE and YD22DDTi):

1. Insert the seal bearing in the direction shown in the figure.

2. Tighten the mounting bolt with the big end of the spring facing

the flange.

CAUTION:

Tighten the mounting bolt without causing interference with

the flange.

Inspection After InstallationEBS003DO

lWith the engine running, check exhaust tube joints for gas leakage and unusual noise.

KBIA0299E

SBIA0147E

Page 2195 of 3066

SERVICE DATA AND SPECIFICATIONS (SDS)

EX-5

C

D

E

F

G

H

I

J

K

L

MA

EX

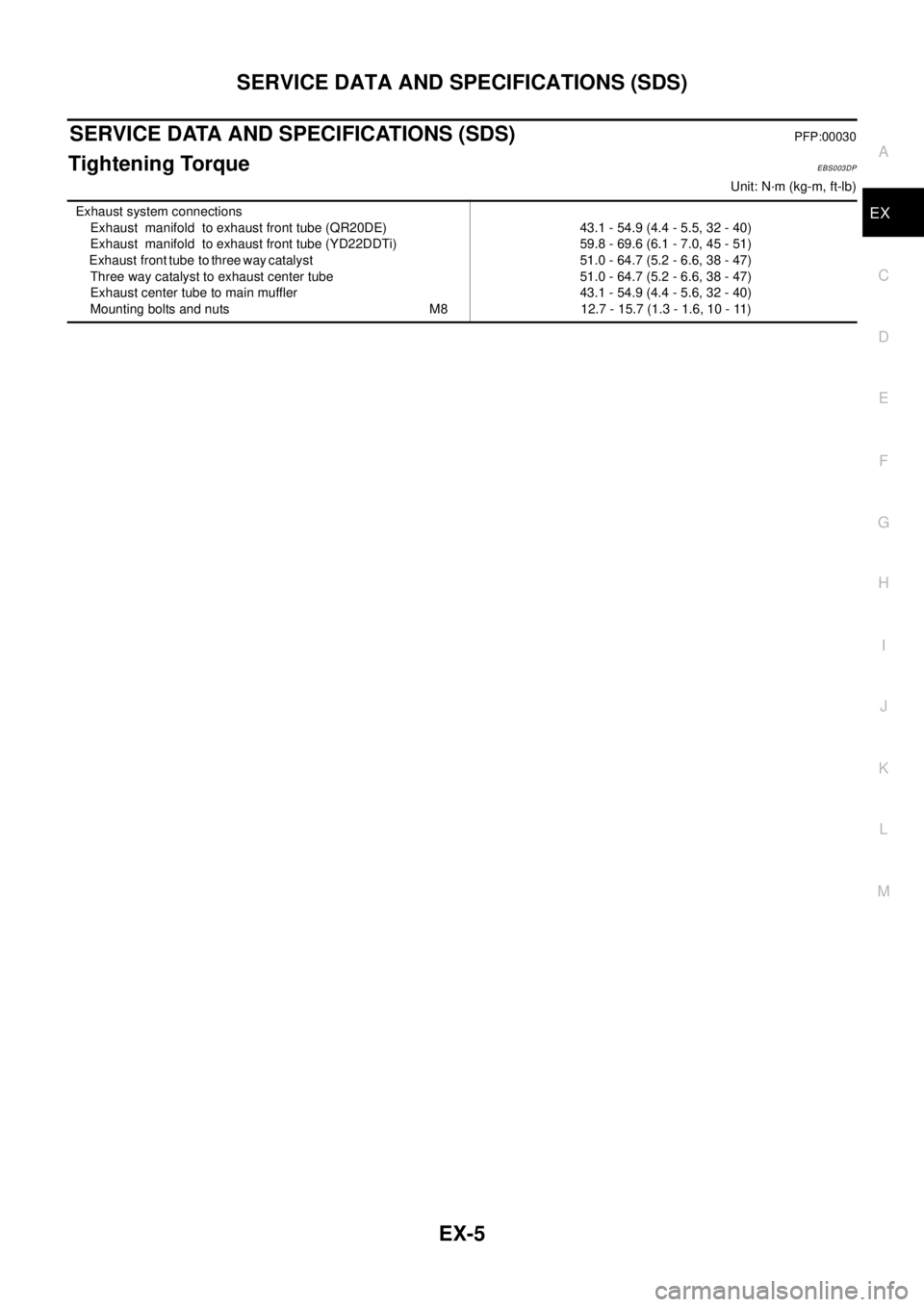

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

Tightening TorqueEBS003DP

Unit: N·m (kg-m, ft-lb)

Exhaust system connections

Exhaust manifold to exhaust front tube (QR20DE)

Exhaust manifold to exhaust front tube (YD22DDTi)

Exhaust front tube to three way catalyst

Three way catalyst to exhaust center tube

Exhaust center tube to main muffler

Mounting bolts and nuts M843.1 - 54.9 (4.4 - 5.5, 32 - 40)

59.8 - 69.6 (6.1 - 7.0, 45 - 51)

51.0 - 64.7 (5.2 - 6.6, 38 - 47)

51.0 - 64.7 (5.2 - 6.6, 38 - 47)

43.1 - 54.9 (4.4 - 5.6, 32 - 40)

12.7 - 15.7 (1.3 - 1.6, 10 - 11)

Page 2196 of 3066

EX-6

SERVICE DATA AND SPECIFICATIONS (SDS)

Page 2197 of 3066

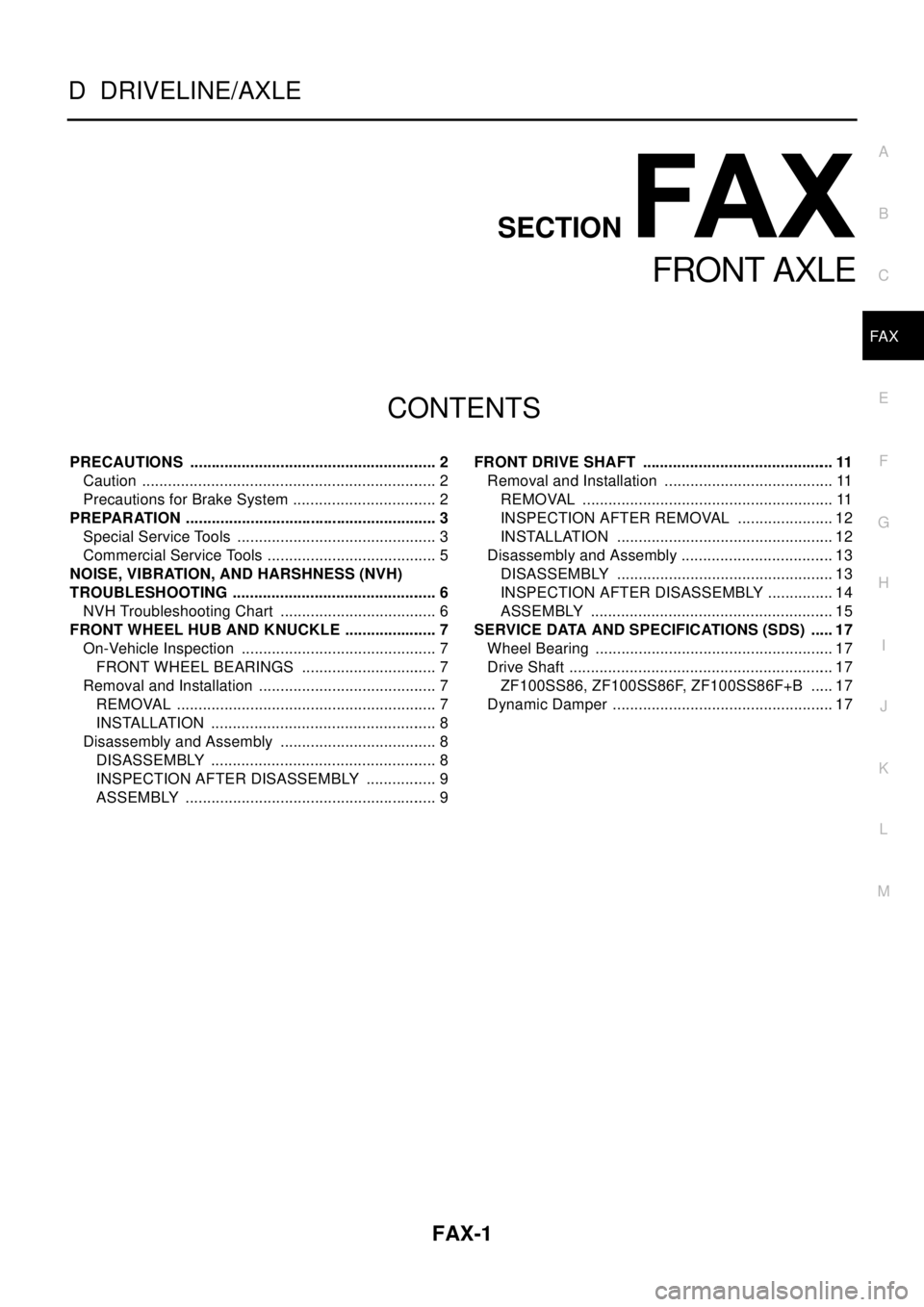

FAX-1

FRONT AXLE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION

A

B

FA X

FRONT AXLE

PRECAUTIONS .......................................................... 2

Caution ..................................................................... 2

Precautions for Brake System .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 5

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 6

NVH Troubleshooting Chart ..................................... 6

FRONT WHEEL HUB AND KNUCKLE ...................... 7

On-Vehicle Inspection .............................................. 7

FRONT WHEEL BEARINGS ................................ 7

Removal and Installation .......................................... 7

REMOVAL ............................................................. 7

INSTALLATION ..................................................... 8

Disassembly and Assembly ..................................... 8

DISASSEMBLY ..................................................... 8

INSPECTION AFTER DISASSEMBLY ................. 9

ASSEMBLY ........................................................... 9FRONT DRIVE SHAFT ............................................. 11

Removal and Installation ........................................ 11

REMOVAL ........................................................... 11

INSPECTION AFTER REMOVAL ....................... 12

INSTALLATION ................................................... 12

Disassembly and Assembly .................................... 13

DISASSEMBLY ................................................... 13

INSPECTION AFTER DISASSEMBLY ................ 14

ASSEMBLY ......................................................... 15

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 17

Wheel Bearing ........................................................ 17

Drive Shaft .............................................................. 17

ZF100SS86, ZF100SS86F, ZF100SS86F+B ...... 17

Dynamic Damper .................................................... 17

Page 2198 of 3066

FAX-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEDS0005P

Observe the following precautions when disassembling and servicing drive shaft.

lThe wheel joint cannot be disassembled. Do not attempt to disassemble it.

lPerform work in a location which is as dust-free and dirt-free as possible.

lBefore disassembling and servicing, clean the outside of parts.

lThe disassembly and service location must be clean. Care must be taken to prevent parts from becoming

dirty and to prevent the entry of foreign objects.

lDisassembled parts must be carefully reassembled in the correct order. If work is interrupted, a clean

cover must be placed over parts.

lPaper shop cloths must be used. Fabric shop cloths must not be used because of the danger of lint adher-

ing to parts.

lDisassembled parts (except for rubber parts) should be cleaned with kerosene which shall be removed by

blowing with air or wiping with paper shop cloths.

Precautions for Brake SystemEDS0 00 I0

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake tubes.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lAlways torque brake lines when installing.

SBR686C

Page 2199 of 3066

PREPARATION

FAX-3

C

E

F

G

H

I

J

K

L

MA

B

FA X

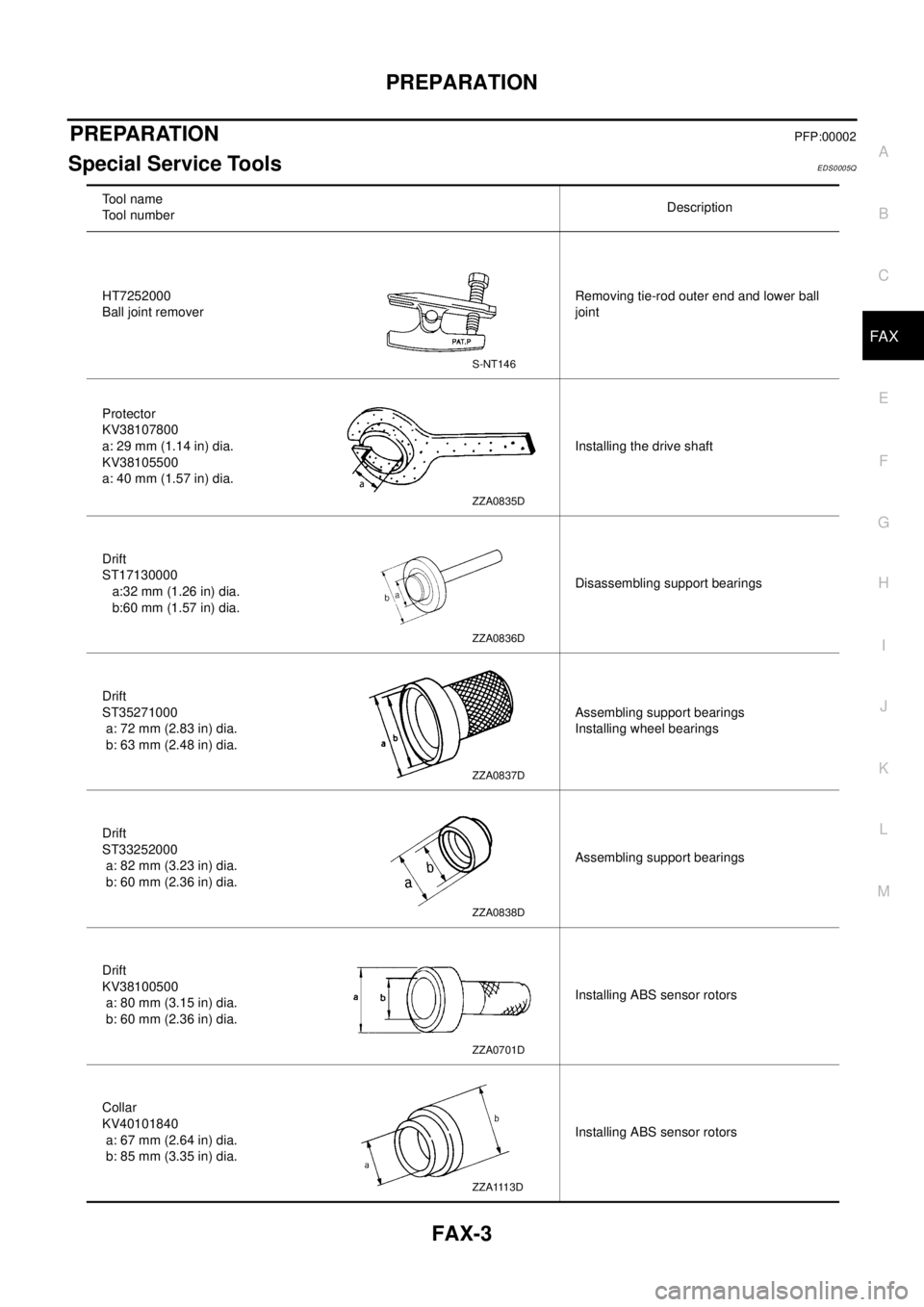

PREPARATIONPFP:00002

Special Service ToolsEDS0005Q

To o l n a m e

Tool numberDescription

HT7252000

Ball joint removerRemoving tie-rod outer end and lower ball

joint

Protector

KV38107800

a: 29 mm (1.14 in) dia.

KV38105500

a: 40 mm (1.57 in) dia.Installing the drive shaft

Drift

ST17130000

a:32 mm (1.26 in) dia.

b:60 mm (1.57 in) dia.Disassembling support bearings

Drift

ST35271000

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.Assembling support bearings

Installing wheel bearings

Drift

ST33252000

a: 82 mm (3.23 in) dia.

b: 60 mm (2.36 in) dia.Assembling support bearings

Drift

KV38100500

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.Installing ABS sensor rotors

Collar

KV40101840

a: 67 mm (2.64 in) dia.

b: 85 mm (3.35 in) dia.Installing ABS sensor rotors

S-NT146

ZZA0835D

ZZA0836D

ZZA0837D

ZZA0838D

ZZA0701D

ZZA1113D

Page 2200 of 3066

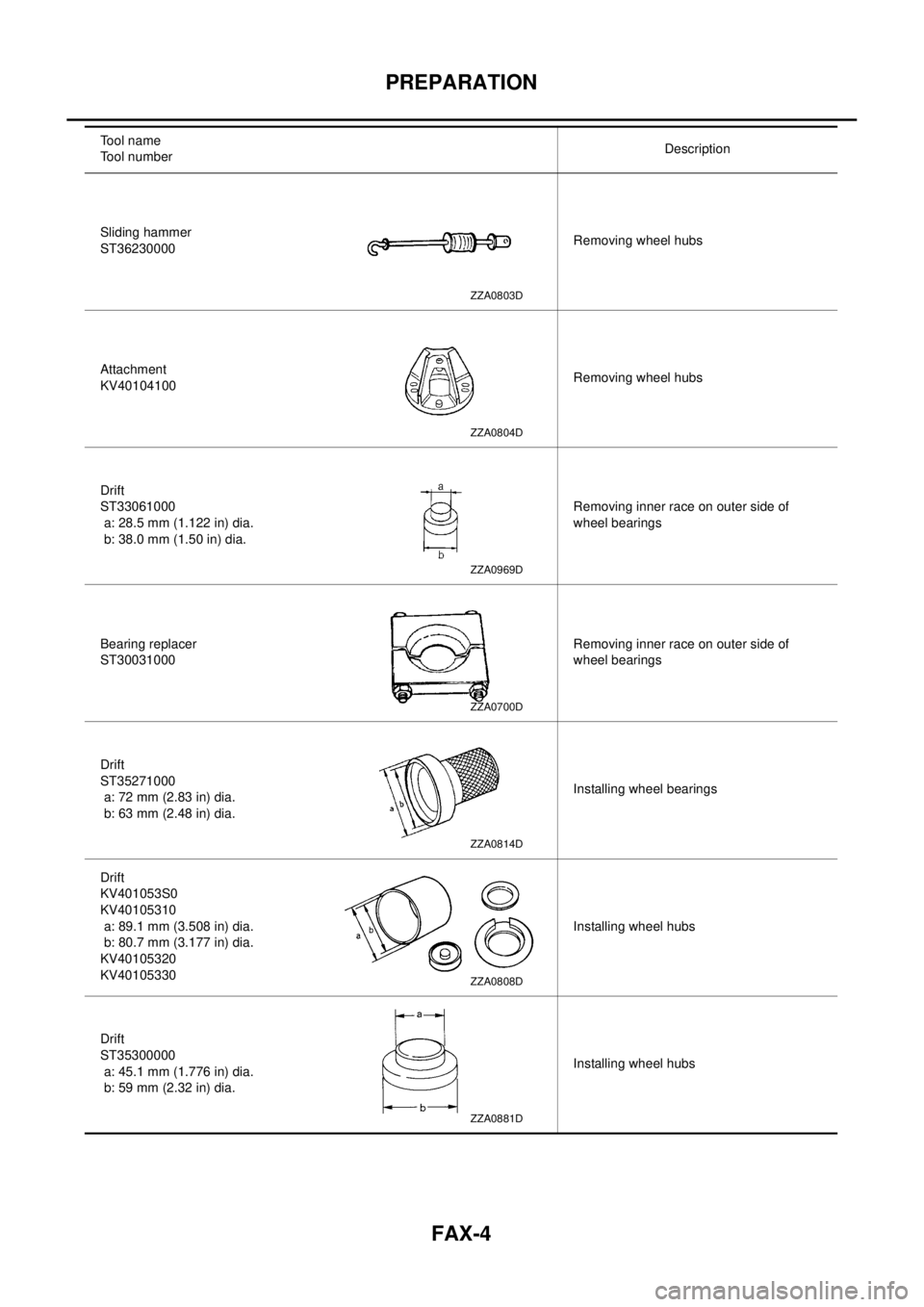

FAX-4

PREPARATION

Sliding hammer

ST36230000Removing wheel hubs

Attachment

KV40104100Removing wheel hubs

Drift

ST33061000

a: 28.5 mm (1.122 in) dia.

b: 38.0 mm (1.50 in) dia.Removing inner race on outer side of

wheel bearings

Bearing replacer

ST30031000Removing inner race on outer side of

wheel bearings

Drift

ST35271000

a: 72 mm (2.83 in) dia.

b: 63 mm (2.48 in) dia.Installing wheel bearings

Drift

KV401053S0

KV40105310

a: 89.1 mm (3.508 in) dia.

b: 80.7 mm (3.177 in) dia.

KV40105320

KV40105330Installing wheel hubs

Drift

ST35300000

a: 45.1 mm (1.776 in) dia.

b: 59 mm (2.32 in) dia.Installing wheel hubs Tool name

Tool numberDescription

ZZA0803D

ZZA0804D

ZZA0969D

ZZA0700D

ZZA0814D

ZZA0808D

ZZA0881D