NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2371 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual INSTRUMENT PANEL ASSEMBLY

IP-5

C

D

E

F

G

H

J

K

L

MA

B

IP

Removal and InstallationEIS0 00 NI

TA B L E O F W O R K I T E M

[ ]: The number shows the removal order.

ComponentsInstrument

panelCombination

NISSAN X-TRAIL 2003 Electronic Repair Manual INSTRUMENT PANEL ASSEMBLY

IP-5

C

D

E

F

G

H

J

K

L

MA

B

IP

Removal and InstallationEIS0 00 NI

TA B L E O F W O R K I T E M

[ ]: The number shows the removal order.

ComponentsInstrument

panelCombination](/img/5/57402/w960_57402-2370.png)

INSTRUMENT PANEL ASSEMBLY

IP-5

C

D

E

F

G

H

J

K

L

MA

B

IP

Removal and InstallationEIS0 00 NI

TA B L E O F W O R K I T E M

[ ]: The number shows the removal order.

ComponentsInstrument

panelCombination

meterNavigation

DisplayAudio

Console

Up Down

Front speaker grille [1]

Instrument finisher A, B [2] [1]

Cup holder [3]

Instrument cluster lid A [4] [2]

Combination meter [5] [3]

Pocket [6]

Key cylinder escutcheon and steer-

ing column cover[7]

Instrument lower driver panel [8]

Mirror control switch [9]

GPS antenna [10]

Cluster lid C [11] [1] [1]

Audio unit and pocket [12] [2] [2]

Cluster lid finisher [13] [1] [1]

Heater control finisher [14] [2]

CD auto–changer and pocket [15] [3]

Heater controller [16]

A/T(M/T,CVT) finisher [17] [2]

Console mask [18] [3]

Center console [19] [4]

Lower instrument cover [20]

instrument lower center panel [21]

Glove box [22]

Lower instrument panel [23]

Glove box cover [24]

Front passenger air bag module [25]

Instrument reinforcement [26]

Instrument mask [27]

Front pillar garnish [28]

Instrument panel [29]

Page 2372 of 3066

IP-6

INSTRUMENT PANEL ASSEMBLY

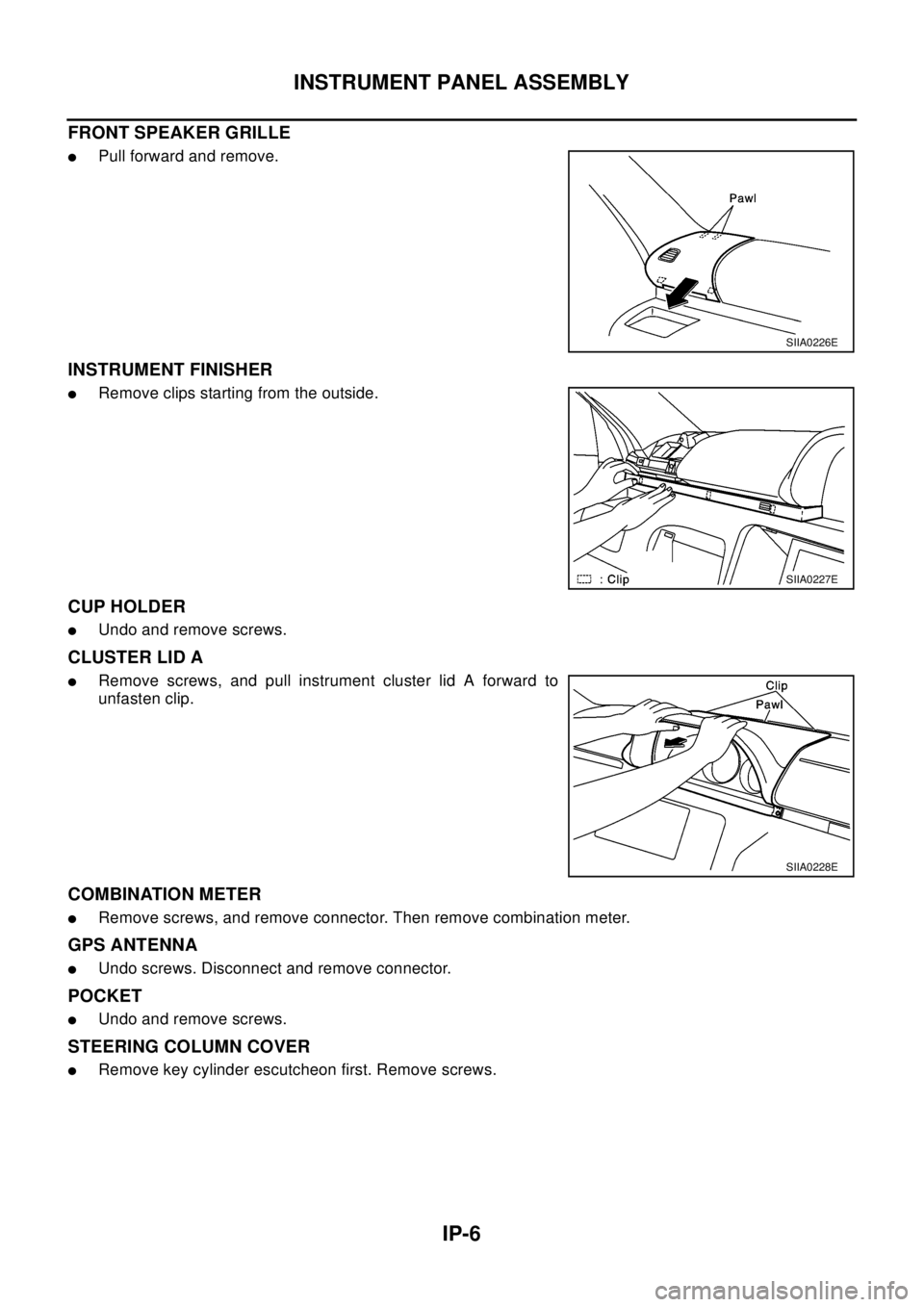

FRONT SPEAKER GRILLE

lPull forward and remove.

INSTRUMENT FINISHER

lRemove clips starting from the outside.

CUP HOLDER

lUndo and remove screws.

CLUSTER LID A

lRemove screws, and pull instrument cluster lid A forward to

unfasten clip.

COMBINATION METER

lRemove screws, and remove connector. Then remove combination meter.

GPS ANTENNA

lUndo screws. Disconnect and remove connector.

POCKET

lUndo and remove screws.

STEERING COLUMN COVER

lRemove key cylinder escutcheon first. Remove screws.

SIIA0226E

SIIA0227E

SIIA0228E

Page 2373 of 3066

INSTRUMENT PANEL ASSEMBLY

IP-7

C

D

E

F

G

H

J

K

L

MA

B

IP

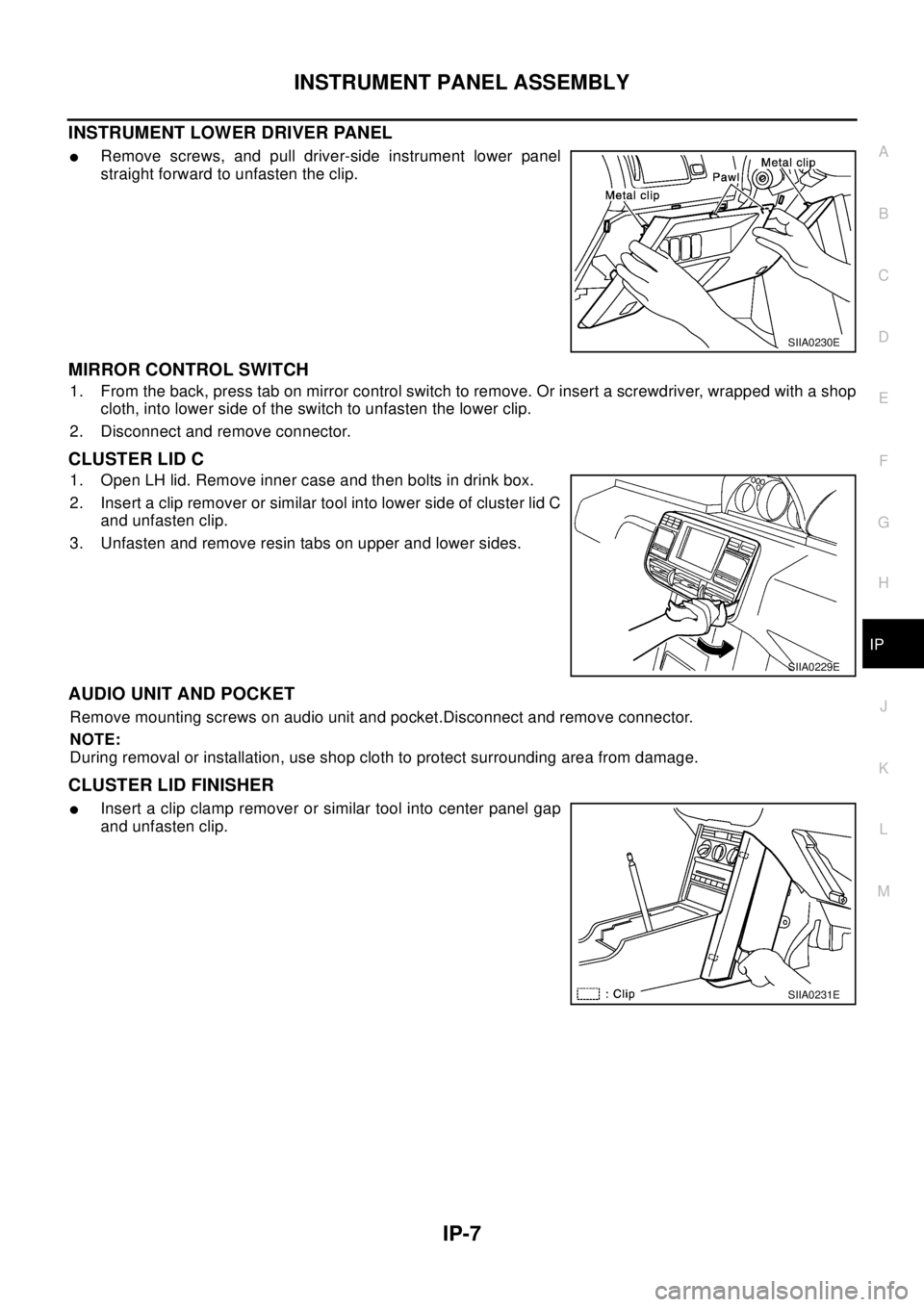

INSTRUMENT LOWER DRIVER PANEL

lRemove screws, and pull driver-side instrument lower panel

straight forward to unfasten the clip.

MIRROR CONTROL SWITCH

1. From the back, press tab on mirror control switch to remove. Or insert a screwdriver, wrapped with a shop

cloth, into lower side of the switch to unfasten the lower clip.

2. Disconnect and remove connector.

CLUSTER LID C

1. Open LH lid. Remove inner case and then bolts in drink box.

2. Insert a clip remover or similar tool into lower side of cluster lid C

and unfasten clip.

3. Unfasten and remove resin tabs on upper and lower sides.

AUDIO UNIT AND POCKET

Remove mounting screws on audio unit and pocket.Disconnect and remove connector.

NOTE:

During removal or installation, use shop cloth to protect surrounding area from damage.

CLUSTER LID FINISHER

lInsert a clip clamp remover or similar tool into center panel gap

and unfasten clip.

SIIA0230E

SIIA0229E

SIIA0231E

Page 2374 of 3066

IP-8

INSTRUMENT PANEL ASSEMBLY

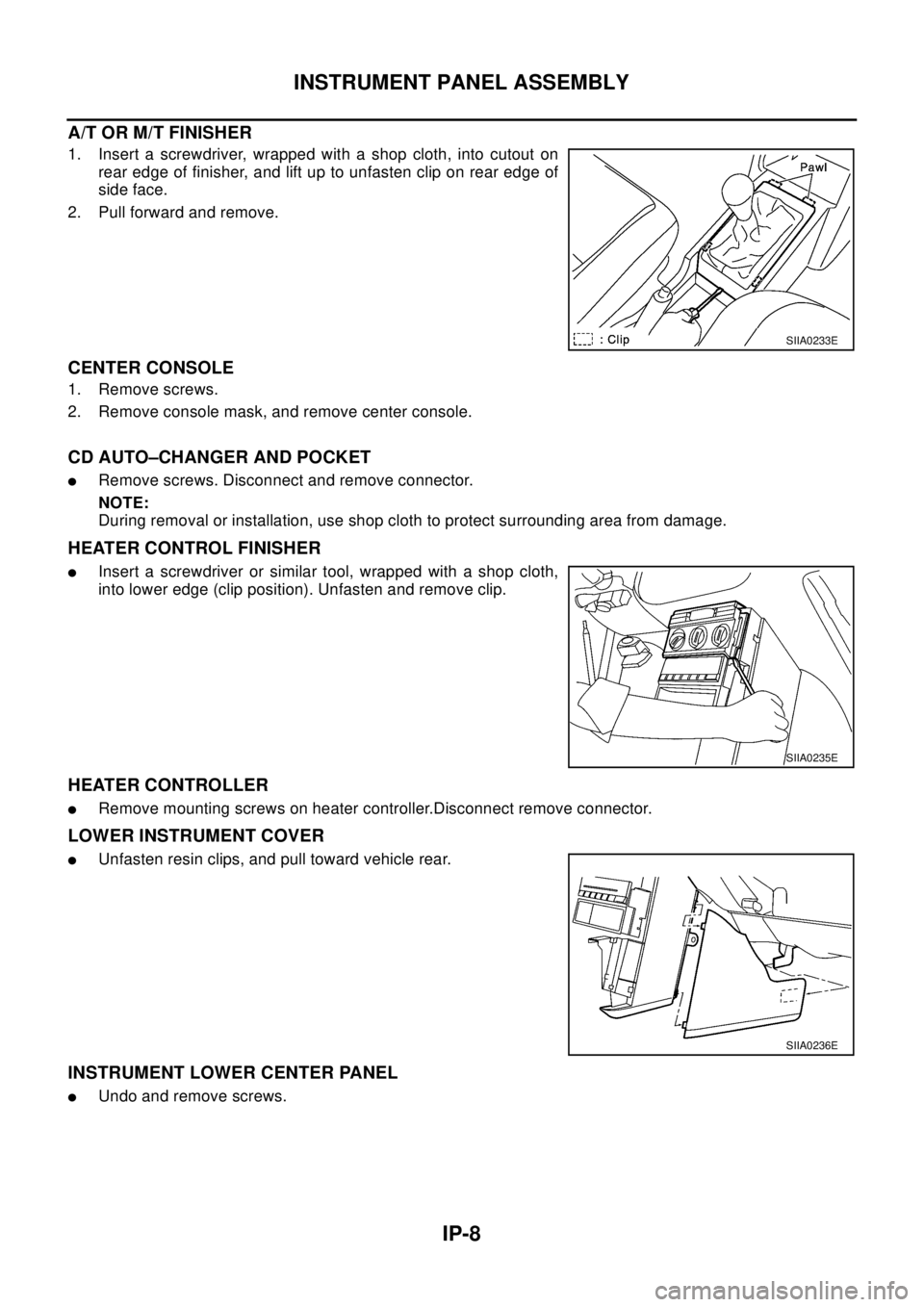

A/T OR M/T FINISHER

1. Insert a screwdriver, wrapped with a shop cloth, into cutout on

rear edge of finisher, and lift up to unfasten clip on rear edge of

side face.

2. Pull forward and remove.

CENTER CONSOLE

1. Remove screws.

2. Remove console mask, and remove center console.

CD AUTO–CHANGER AND POCKET

lRemove screws. Disconnect and remove connector.

NOTE:

During removal or installation, use shop cloth to protect surrounding area from damage.

HEATER CONTROL FINISHER

lInsert a screwdriver or similar tool, wrapped with a shop cloth,

into lower edge (clip position). Unfasten and remove clip.

HEATER CONTROLLER

lRemove mounting screws on heater controller.Disconnect remove connector.

LOWER INSTRUMENT COVER

lUnfasten resin clips, and pull toward vehicle rear.

INSTRUMENT LOWER CENTER PANEL

lUndo and remove screws.

SIIA0233E

SIIA0235E

SIIA0236E

Page 2375 of 3066

INSTRUMENT PANEL ASSEMBLY

IP-9

C

D

E

F

G

H

J

K

L

MA

B

IP

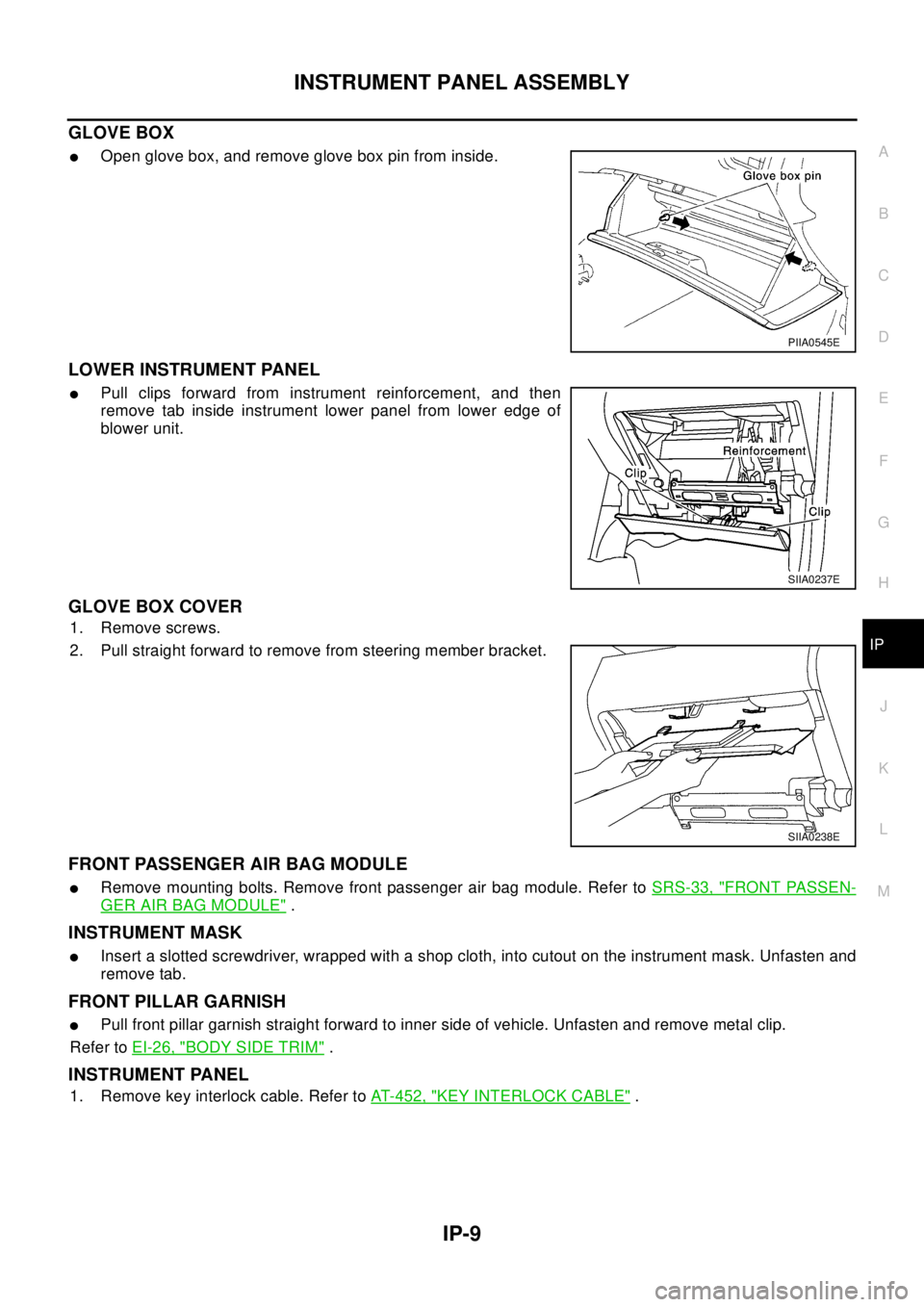

GLOVE BOX

lOpen glove box, and remove glove box pin from inside.

LOWER INSTRUMENT PANEL

lPull clips forward from instrument reinforcement, and then

remove tab inside instrument lower panel from lower edge of

blower unit.

GLOVE BOX COVER

1. Remove screws.

2. Pull straight forward to remove from steering member bracket.

FRONT PASSENGER AIR BAG MODULE

lRemove mounting bolts. Remove front passenger air bag module. Refer toSRS-33, "FRONT PASSEN-

GER AIR BAG MODULE".

INSTRUMENT MASK

lInsert a slotted screwdriver, wrapped with a shop cloth, into cutout on the instrument mask. Unfasten and

remove tab.

FRONT PILLAR GARNISH

lPull front pillar garnish straight forward to inner side of vehicle. Unfasten and remove metal clip.

Refer toEI-26, "

BODY SIDE TRIM".

INSTRUMENT PANEL

1. Remove key interlock cable. Refer toAT-452, "KEY INTERLOCK CABLE".

PIIA0545E

SIIA0237E

SIIA0238E

Page 2376 of 3066

IP-10

INSTRUMENT PANEL ASSEMBLY

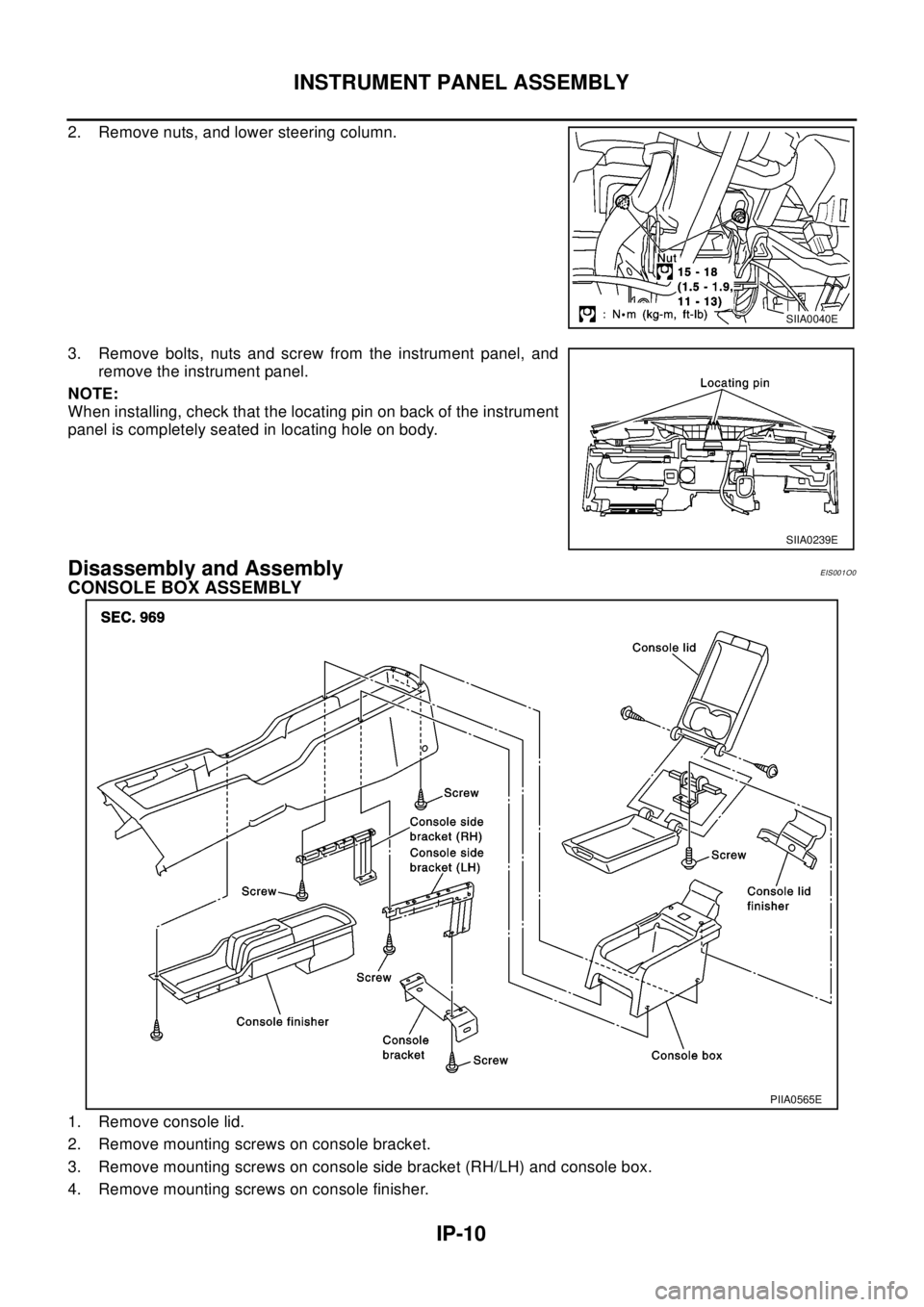

2. Remove nuts, and lower steering column.

3. Remove bolts, nuts and screw from the instrument panel, and

remove the instrument panel.

NOTE:

When installing, check that the locating pin on back of the instrument

panel is completely seated in locating hole on body.

Disassembly and AssemblyEIS001O0

CONSOLE BOX ASSEMBLY

1. Remove console lid.

2. Remove mounting screws on console bracket.

3. Remove mounting screws on console side bracket (RH/LH) and console box.

4. Remove mounting screws on console finisher.

SIIA0040E

SIIA0239E

PIIA0565E

Page 2377 of 3066

LAN-1

LAN SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTION

A

B

LAN

LAN SYSTEM

CAN

PRECAUTIONS .......................................................... 2

Precautions for Supplemental Restraint System

(SRS) “AIR BAG” and “SEAT BELT PRE-TEN-

SIONER” .................................................................. 2

Precautions For Trouble Diagnosis .......................... 2

CAN SYSTEM ....................................................... 2

Precautions For Harness Repair .............................. 2

CAN SYSTEM ....................................................... 2

CAN COMMUNICATION ............................................ 3

System Description .................................................. 3

FOR A/T MODELS ................................................ 3

FOR M/T MODELS ............................................... 3

CAN SYSTEM (FOR A/T MODELS) ........................... 5

System Description .................................................. 5

Component Parts and Harness Connector Location..... 5

Wiring Diagram — CAN — ....................................... 6

Work Flow ................................................................ 7

CHECK SHEET ..................................................... 8

CHECK SHEET RESULTS (EXAMPLE) ............... 9

INSPECTION ........................................................ 9CAN Communication Circuit Check .......................... 9

Component Inspection ............................................ 10

ECM/TCM INTERNAL CIRCUIT INSPECTION... 10

CAN SYSTEM (FOR M/T MODELS) ........................ 11

System Description ................................................. 11

Component Parts and Harness Connector Location... 11

Wiring Diagram — CAN — ..................................... 12

Work Flow ............................................................... 13

CHECK SHEET ................................................... 14

CHECK SHEET RESULTS (EXAMPLE) ............. 15

INSPECTION ...................................................... 16

Circuit Check Between Steering Wheel Angle Sen-

sor and 4WD Control Unit ....................................... 16

ECM Circuit Check ................................................. 17

4WD Control Unit Circuit Check ............................. 18

Steering Wheel Angle Sensor Circuit Check .......... 18

ESP/TCS/ABS Control Unit Circuit Check .............. 19

CAN Communication Circuit Check ........................ 20

Component Inspection ............................................ 22

ECM / ESP/TCS/ABS CONTROL UNIT INTER-

NAL CIRCUIT INSPECTION ............................... 22

Page 2378 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-2

[CAN]

PRECAUTIONS

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS001U0

The Supplemental Restraint System such as NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-2

[CAN]

PRECAUTIONS

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS001U0

The Supplemental Restraint System such as](/img/5/57402/w960_57402-2377.png)

LAN-2

[CAN]

PRECAUTIONS

[CAN]PRECAUTIONSPFP:00001

Precautions for Supplemental Restraint System (SRS) “AIR BAG” and “SEAT

BELT PRE-TENSIONER”

EKS001U0

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WAR NIN G:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

Precautions For Trouble DiagnosisEKS001U1

CAN SYSTEM

lDo not apply voltage of 7.0V or higher to the measurement terminals.

lUse the tester with its open terminal voltage being 7.0V or less.

Precautions For Harness RepairEKS001U2

CAN SYSTEM

lSolder the repaired parts, and wrap with tape. [Frays of twisted

line must be within 110 mm (4.33 in)]

lDo not perform bypass wire connections for the repair

parts.(The spliced wire will become separated and the charac-

teristics of twisted line will be lost.)

PKIA0306E

PKIA0307E

Page 2379 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual CAN COMMUNICATION

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

CAN COMMUNICATIONPFP:23710

System DescriptionEKS001U3

CAN (Controller Area Network) is a serial communication line for real time application. I NISSAN X-TRAIL 2003 Electronic Repair Manual CAN COMMUNICATION

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

CAN COMMUNICATIONPFP:23710

System DescriptionEKS001U3

CAN (Controller Area Network) is a serial communication line for real time application. I](/img/5/57402/w960_57402-2378.png)

CAN COMMUNICATION

LAN-3

[CAN]

C

D

E

F

G

H

I

J

L

MA

B

LAN

CAN COMMUNICATIONPFP:23710

System DescriptionEKS001U3

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication speed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CAN communication, control units are connected with 2

communication lines (CAN H line, CAN L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only.

FOR A/T MODELS

System diagram

Input/output signal chart

T: Transmit R: Receive

FOR M/T MODELS

System diagram

Input/output signal chart

T: Transmit R: Receive

SKIA0884E

Signals ECM TCM

Engine speed signal T R

Engine coolant temperature signal T R

Accelerator pedal position signal T R

A/T self-diagnosis signal R T

SKIA0885E

Signals ECMSteering wheel

angle sensor4WD control unitESP/ TCS / ABS

control unit

Engine speed signal T R R

Accelerator pedal position signal T R

ESP operation signal R R T

TCS operation signal R R T

ABS operation signal R R T

Stop lamp switch signalRT

Page 2380 of 3066

![NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-4

[CAN]

CAN COMMUNICATION

Steering wheel angle sensor signal T R

ESP-OFFSW signalRT

Wheel speed sensor signalRT

4WD Mode signalTR Signals ECMSteering wheel

angle sensor4WD control unitESP/ TCS / A NISSAN X-TRAIL 2003 Electronic Repair Manual LAN-4

[CAN]

CAN COMMUNICATION

Steering wheel angle sensor signal T R

ESP-OFFSW signalRT

Wheel speed sensor signalRT

4WD Mode signalTR Signals ECMSteering wheel

angle sensor4WD control unitESP/ TCS / A](/img/5/57402/w960_57402-2379.png)

LAN-4

[CAN]

CAN COMMUNICATION

Steering wheel angle sensor signal T R

ESP-OFFSW signalRT

Wheel speed sensor signalRT

4WD Mode signalTR Signals ECMSteering wheel

angle sensor4WD control unitESP/ TCS / ABS

control unit