NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2401 of 3066

PRECAUTION

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT

PRECAUTIONPFP:00011

Precautions for Supplemental Restraint System (SRS) ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT

BELT PRE-TENSIONERŌĆØ

EKS003KR

The Supplemental Restraint System such as ŌĆ£AIR BAGŌĆØ and ŌĆ£SEAT BELT PRE-TENSIONERŌĆØ, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SRS and SB section of

this Service Manual.

WA RN ING:

lTo avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance must be per-

formed by an authorized NISSAN/INFINITI dealer.

lImproper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the SRS section.

lDo not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connectors.

PrecautionEKS003KS

lDo not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it. Do not

touch bulb by hand while it is lit or right after being turned off. Burning may result.

lDo not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc. may affect

the performance of the headlamp. When replacing the bulb, be sure to replace it with a new one.

lAdjust aiming by tightening aiming screw. (To adjust it toward loosening side, first loosen adjusting screw,

and then make adjustment by tightening.)

lTo remove soil or sealant of bulbs, do not use organic solvent (thinner, gasoline, etc.)

lWhen replacing bulb, be sure to hold bulb socket and pull it out straight. If wiring harness of the bulb is

pulled at an angle, the bulb may be caught in the lamp, making it difficult to take out.

Wiring Diagrams and Trouble DiagnosisEKS003KT

Whenyoureadwiringdiagrams,refertothefollowings:

lRefer toGI-14, "How to Read Wiring Diagrams"in GI section

lRefer toPG-2, "POWER SUPPLY ROUTING"for power distribution circuit in PG section

When you perform trouble diagnosis, refer to the followings:

lRefer toGI-11, "HOW TO FOLLOW TEST GROUPS IN TROUBLE DIAGNOSES"in GI section

lRefer toGI-24, "How to Perform Efficient Diagnosis for an Electrical Incident"in GI section

Page 2402 of 3066

LT-4

HEADLAMP

HEADLAMP

PFP:26010

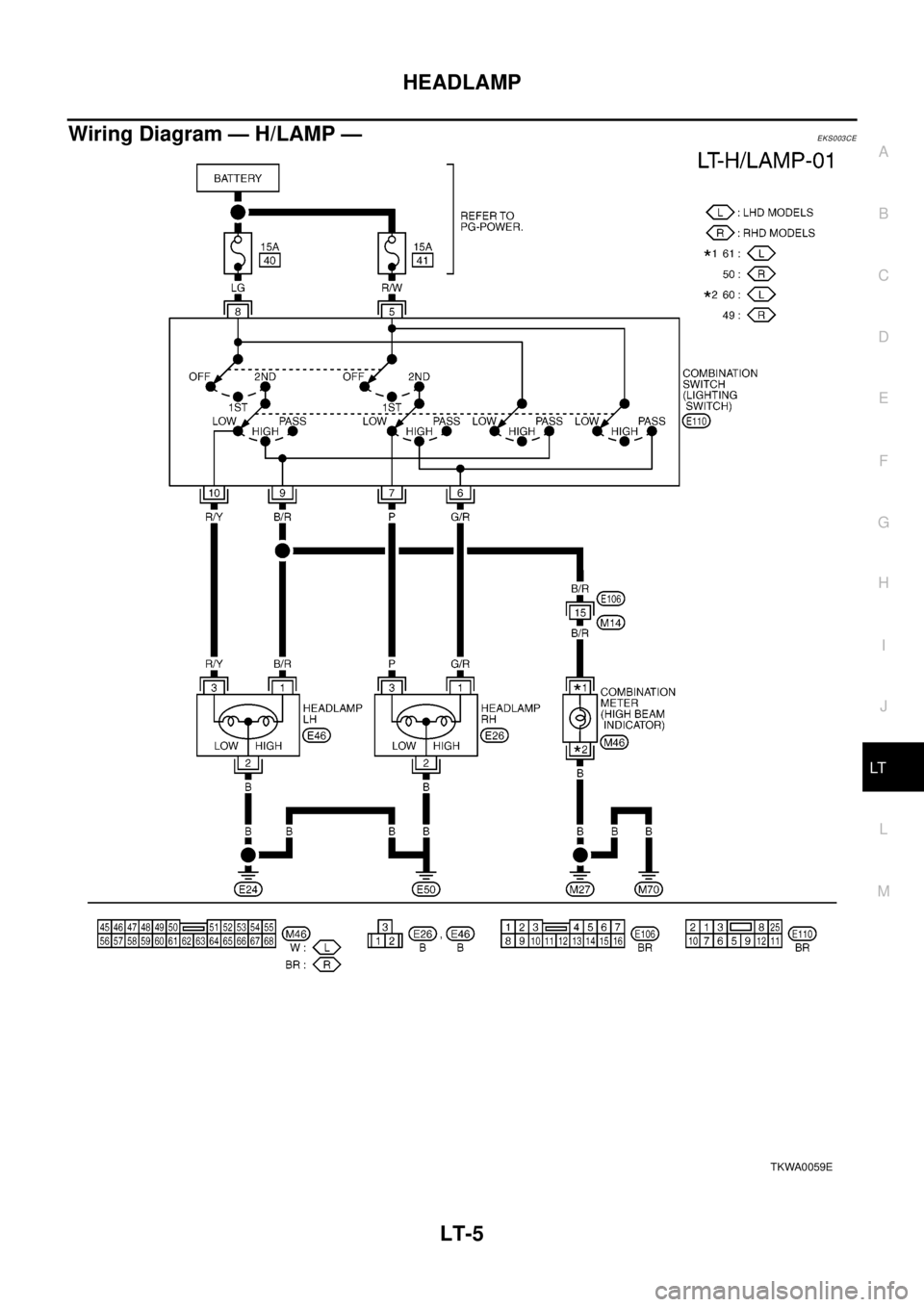

System DescriptionEKS003CD

DESCRIPTION

The headlamps are controlled by the lighting switch which is built into the combination switch.

Power is supplied at all times

lto lighting switch terminal 8

lthrough 15A fuse (No. 40, located in the fuse and fusible link box), and

lto lighting switch terminal 5

lthrough 15A fuse (No. 41, located in the fuse and fusible link box).

LOW BEAM OPERATION

When the lighting switch is turned to the 2ND position and placed in LOW (ŌĆ£BŌĆØ) position, power is supplied

lfrom lighting switch terminal 10

lto terminal 3 of the headlamp LH, and

lfrom lighting switch terminal 7

lto terminal 3 of the headlamp RH.

Terminal 2 of each headlamp supplies ground through body grounds E24 and E50.

With power and ground supplied, the low beams will illuminate.

HIGH BEAM OPERATION/FLASH-TO-PASS OPERATION

When the lighting switch is turned to the 2ND position and placed in HIGH (ŌĆ£AŌĆØ) position or PASS (ŌĆ£CŌĆØ) posi-

tion, power is supplied

lfrom lighting switch terminal 6

lto terminal 1 of headlamp RH, and

lfrom lighting switch terminal 9

lto terminal 1 of headlamp LH, and

lto combination meter terminal 61 (LHD models) or 50 (RHD models) for the HIGH BEAM indicator.

Ground is supplied to terminal 60 (LHD models) or 49 (RHD models) of the combination meter through body

grounds M27 and M70.

Ground is supplide to terminal 2 of each headlamp through body grounds E24 and E50.

With power and ground supplied, the high beams and the HIGH BEAM indicator illuminate.

Page 2403 of 3066

HEADLAMP

LT-5

C

D

E

F

G

H

I

J

L

MA

B

LT

Wiring Diagram ŌĆö H/LAMP ŌĆöEKS003CE

TKWA0059E

Page 2404 of 3066

LT-6

HEADLAMP

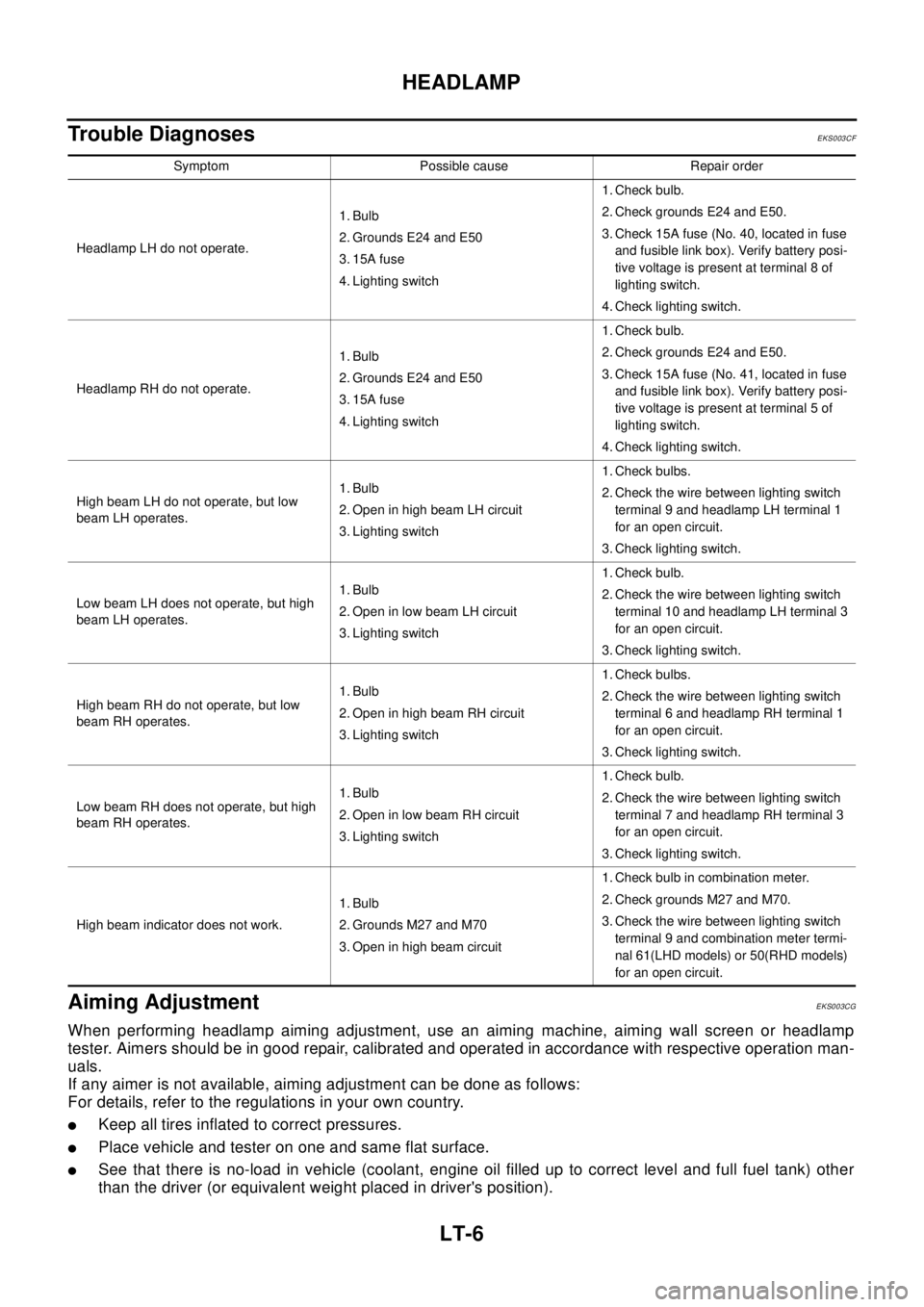

Trouble Diagnoses

EKS003CF

Aiming AdjustmentEKS003CG

When performing headlamp aiming adjustment, use an aiming machine, aiming wall screen or headlamp

tester. Aimers should be in good repair, calibrated and operated in accordance with respective operation man-

uals.

If any aimer is not available, aiming adjustment can be done as follows:

For details, refer to the regulations in your own country.

lKeep all tires inflated to correct pressures.

lPlace vehicle and tester on one and same flat surface.

lSee that there is no-load in vehicle (coolant, engine oil filled up to correct level and full fuel tank) other

than the driver (or equivalent weight placed in driver's position).

Symptom Possible cause Repair order

Headlamp LH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 40, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 8 of

lighting switch.

4. Check lighting switch.

Headlamp RH do not operate.1. Bulb

2. Grounds E24 and E50

3. 15A fuse

4. Lighting switch1. Check bulb.

2. Check grounds E24 and E50.

3. Check 15A fuse (No. 41, located in fuse

and fusible link box). Verify battery posi-

tive voltage is present at terminal 5 of

lighting switch.

4. Check lighting switch.

High beam LH do not operate, but low

beam LH operates.1. Bulb

2. Open in high beam LH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 9 and headlamp LH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam LH does not operate, but high

beam LH operates.1. Bulb

2. Open in low beam LH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 10 and headlamp LH terminal 3

for an open circuit.

3. Check lighting switch.

High beam RH do not operate, but low

beam RH operates.1. Bulb

2. Open in high beam RH circuit

3. Lighting switch1. Check bulbs.

2. Check the wire between lighting switch

terminal 6 and headlamp RH terminal 1

for an open circuit.

3. Check lighting switch.

Low beam RH does not operate, but high

beam RH operates.1. Bulb

2. Open in low beam RH circuit

3. Lighting switch1. Check bulb.

2. Check the wire between lighting switch

terminal 7 and headlamp RH terminal 3

for an open circuit.

3. Check lighting switch.

High beam indicator does not work.1. Bulb

2. Grounds M27 and M70

3. Open in high beam circuit1. Check bulb in combination meter.

2. Check grounds M27 and M70.

3. Check the wire between lighting switch

terminal 9 and combination meter termi-

nal 61(LHD models) or 50(RHD models)

for an open circuit.

Page 2405 of 3066

HEADLAMP

LT-7

C

D

E

F

G

H

I

J

L

MA

B

LT

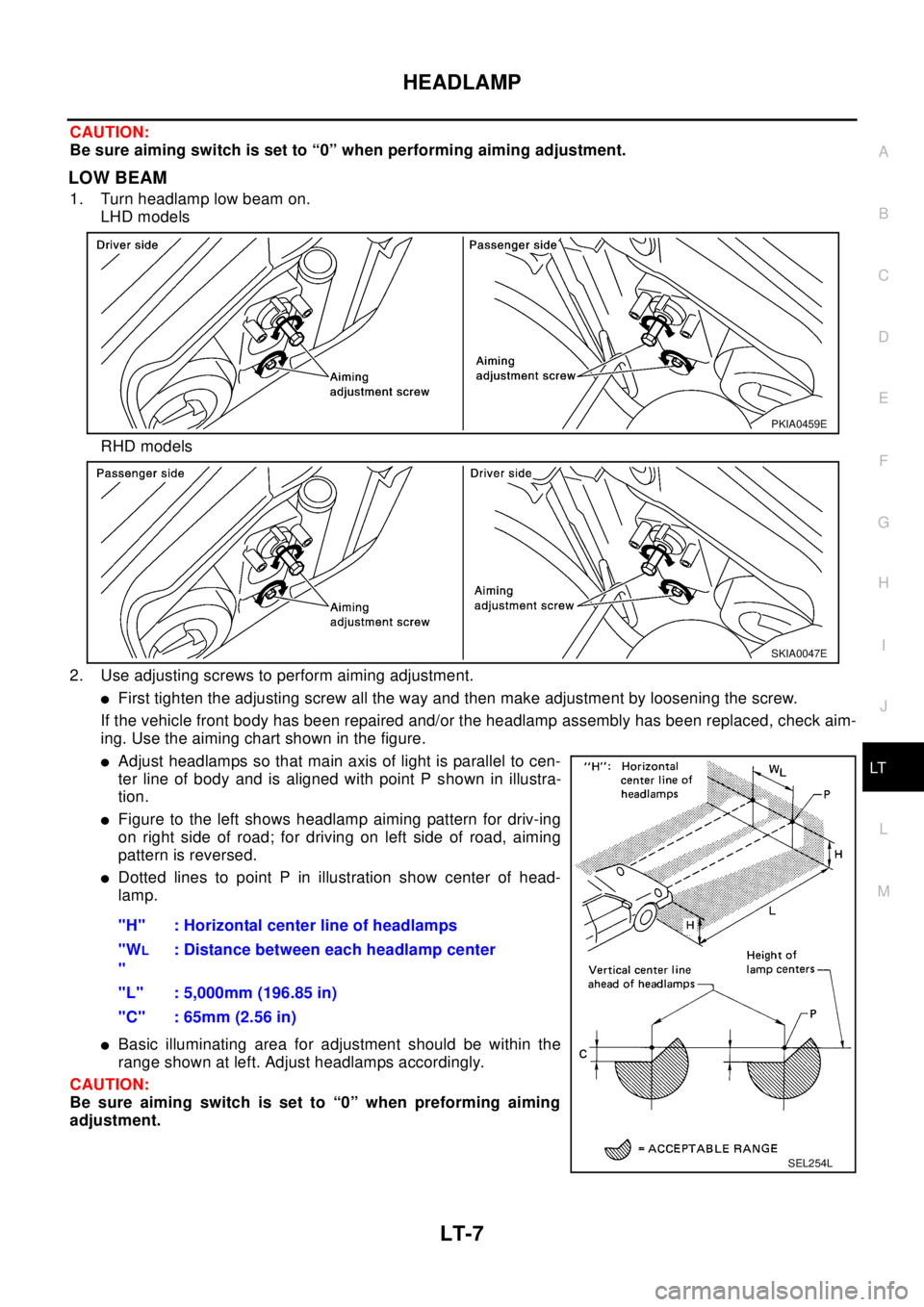

CAUTION:

Be sure aiming switch is set to ŌĆ£0ŌĆØ when performing aiming adjustment.

LOW BEAM

1. Turn headlamp low beam on.

LHD models

RHD models

2. Use adjusting screws to perform aiming adjustment.

lFirst tighten the adjusting screw all the way and then make adjustment by loosening the screw.

If the vehicle front body has been repaired and/or the headlamp assembly has been replaced, check aim-

ing. Use the aiming chart shown in the figure.

lAdjust headlamps so that main axis of light is parallel to cen-

ter line of body and is aligned with point P shown in illustra-

tion.

lFigure to the left shows headlamp aiming pattern for driv-ing

on right side of road; for driving on left side of road, aiming

pattern is reversed.

lDotted lines to point P in illustration show center of head-

lamp.

lBasic illuminating area for adjustment should be within the

range shown at left. Adjust headlamps accordingly.

CAUTION:

Be sure aiming switch is set to ŌĆ£0ŌĆØ when preforming aiming

adjustment."H" : Horizontal center line of headlamps

"W

L

": Distance between each headlamp center

"L" : 5,000mm (196.85 in)

"C" : 65mm (2.56 in)

PKIA0459E

SKIA0047E

SEL254L

Page 2406 of 3066

LT-8

HEADLAMP

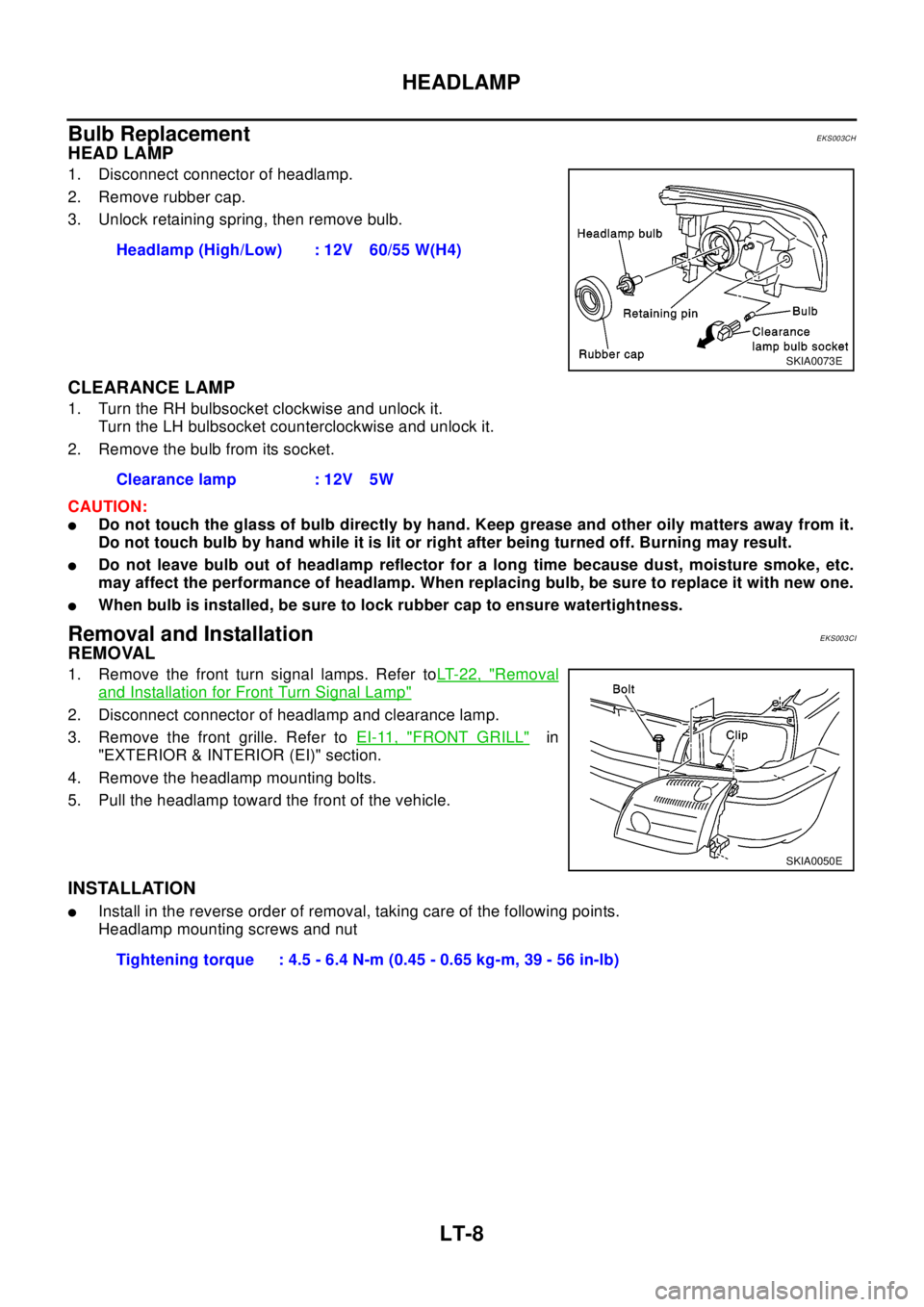

Bulb Replacement

EKS003CH

HEAD LAMP

1. Disconnect connector of headlamp.

2. Remove rubber cap.

3. Unlock retaining spring, then remove bulb.

CLEARANCE LAMP

1. Turn the RH bulbsocket clockwise and unlock it.

Turn the LH bulbsocket counterclockwise and unlock it.

2. Remove the bulb from its socket.

CAUTION:

lDo not touch the glass of bulb directly by hand. Keep grease and other oily matters away from it.

Do not touch bulb by hand while it is lit or right after being turned off. Burning may result.

lDo not leave bulb out of headlamp reflector for a long time because dust, moisture smoke, etc.

may affect the performance of headlamp. When replacing bulb, be sure to replace it with new one.

lWhen bulb is installed, be sure to lock rubber cap to ensure watertightness.

Removal and InstallationEKS003CI

REMOVAL

1. Remove the front turn signal lamps. Refer toLT-22, "Removal

and Installation for Front Turn Signal Lamp"

2. Disconnect connector of headlamp and clearance lamp.

3. Remove the front grille. Refer toEI-11, "

FRONT GRILL"in

"EXTERIOR & INTERIOR (EI)" section.

4. Remove the headlamp mounting bolts.

5. Pull the headlamp toward the front of the vehicle.

INSTALLATION

lInstall in the reverse order of removal, taking care of the following points.

Headlamp mounting screws and nutHeadlamp (High/Low) : 12V 60/55 W(H4)

SKIA0073E

Clearance lamp : 12V 5W

SKIA0050E

Tightening torque : 4.5 - 6.4 N-m (0.45 - 0.65 kg-m, 39 - 56 in-lb)

Page 2407 of 3066

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-9

C

D

E

F

G

H

I

J

L

MA

B

LT

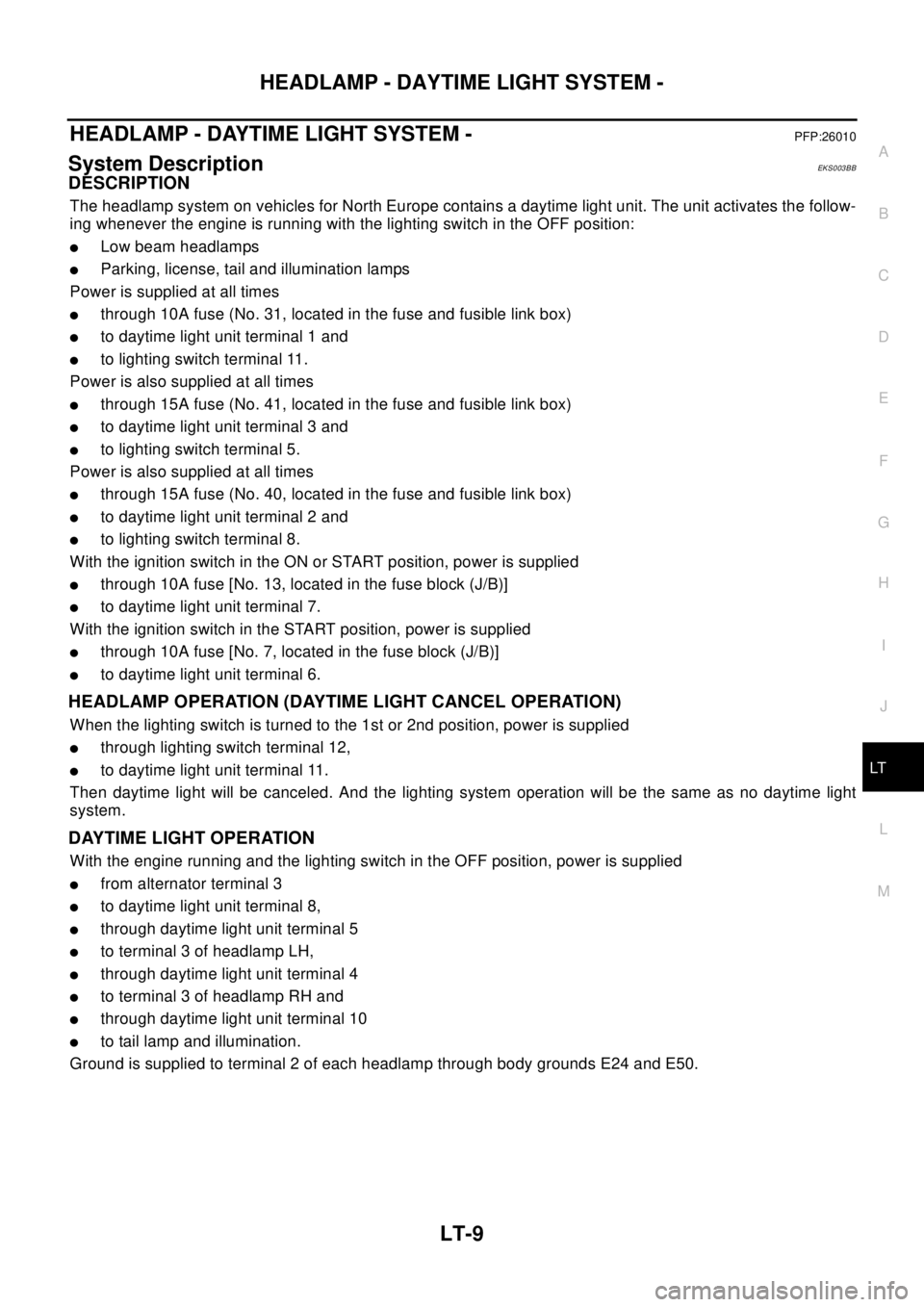

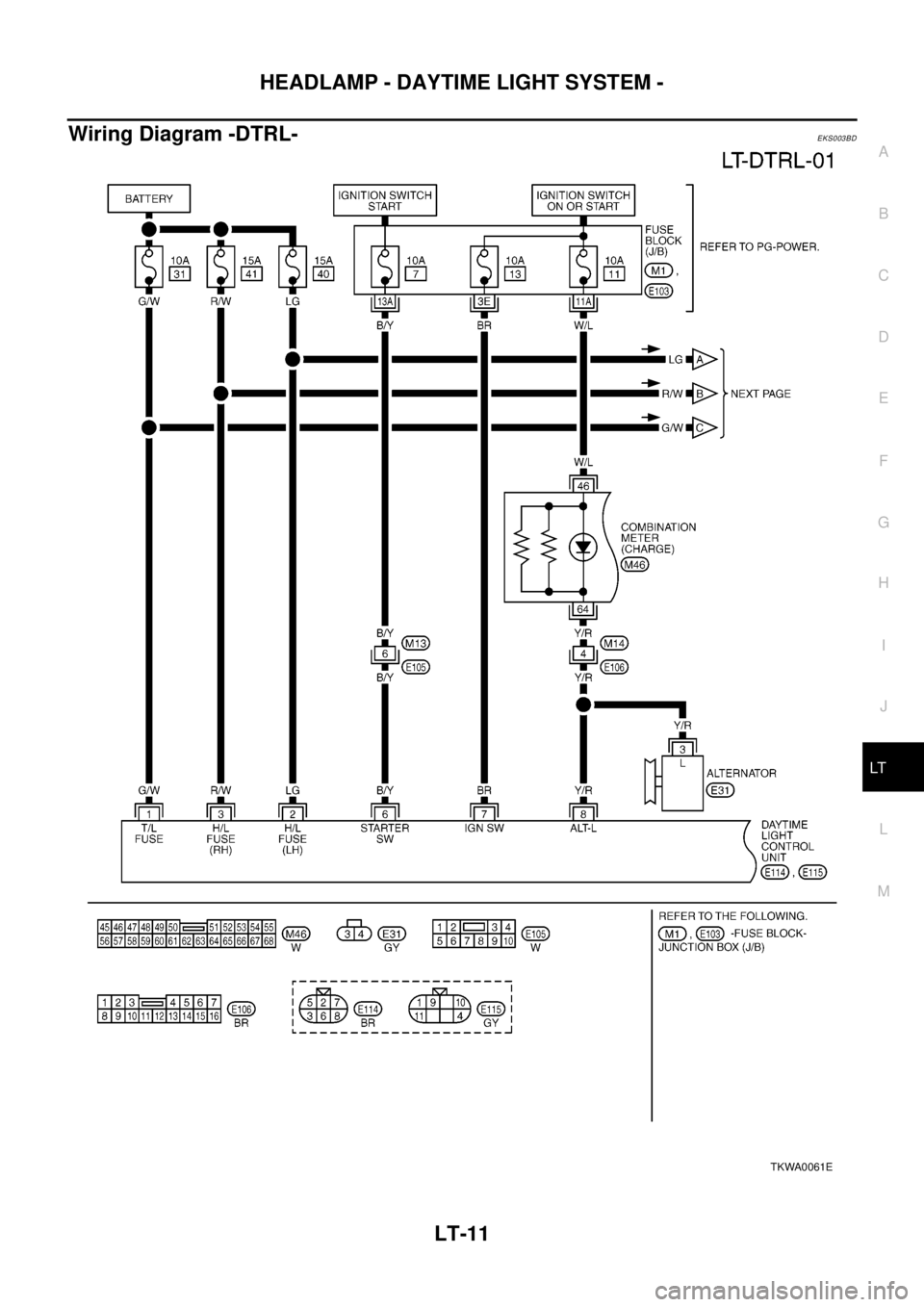

HEADLAMP - DAYTIME LIGHT SYSTEM -PFP:26010

System DescriptionEKS003BB

DESCRIPTION

The headlamp system on vehicles for North Europe contains a daytime light unit. The unit activates the follow-

ing whenever the engine is running with the lighting switch in the OFF position:

lLow beam headlamps

lParking, license, tail and illumination lamps

Power is supplied at all times

lthrough 10A fuse (No. 31, located in the fuse and fusible link box)

lto daytime light unit terminal 1 and

lto lighting switch terminal 11.

Power is also supplied at all times

lthrough 15A fuse (No. 41, located in the fuse and fusible link box)

lto daytime light unit terminal 3 and

lto lighting switch terminal 5.

Power is also supplied at all times

lthrough 15A fuse (No. 40, located in the fuse and fusible link box)

lto daytime light unit terminal 2 and

lto lighting switch terminal 8.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No. 13, located in the fuse block (J/B)]

lto daytime light unit terminal 7.

With the ignition switch in the START position, power is supplied

lthrough 10A fuse [No. 7, located in the fuse block (J/B)]

lto daytime light unit terminal 6.

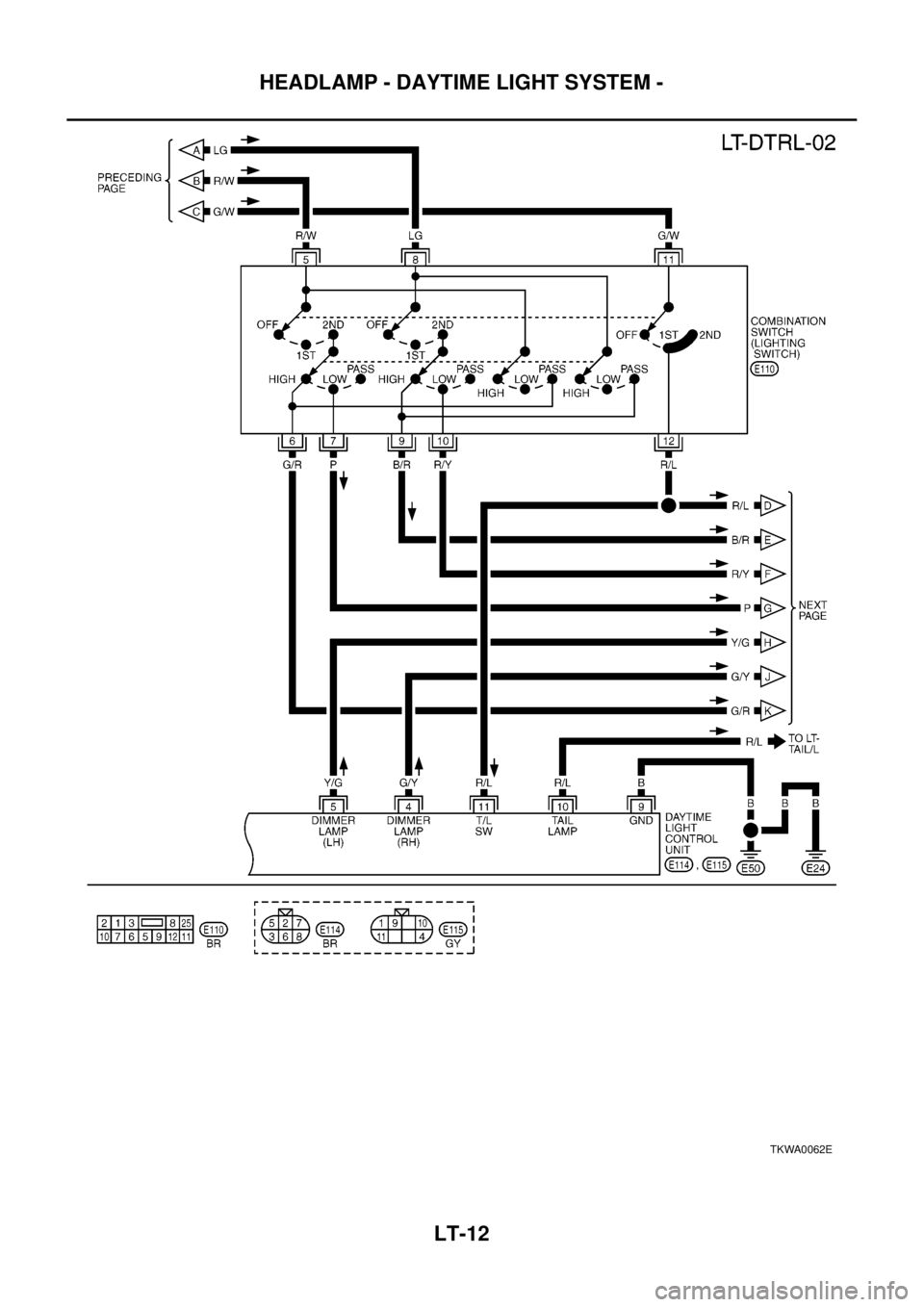

HEADLAMP OPERATION (DAYTIME LIGHT CANCEL OPERATION)

When the lighting switch is turned to the 1st or 2nd position, power is supplied

lthrough lighting switch terminal 12,

lto daytime light unit terminal 11.

Then daytime light will be canceled. And the lighting system operation will be the same as no daytime light

system.

DAYTIME LIGHT OPERATION

With the engine running and the lighting switch in the OFF position, power is supplied

lfrom alternator terminal 3

lto daytime light unit terminal 8,

lthrough daytime light unit terminal 5

lto terminal 3 of headlamp LH,

lthrough daytime light unit terminal 4

lto terminal 3 of headlamp RH and

lthrough daytime light unit terminal 10

lto tail lamp and illumination.

Ground is supplied to terminal 2 of each headlamp through body grounds E24 and E50.

Page 2408 of 3066

LT-10

HEADLAMP - DAYTIME LIGHT SYSTEM -

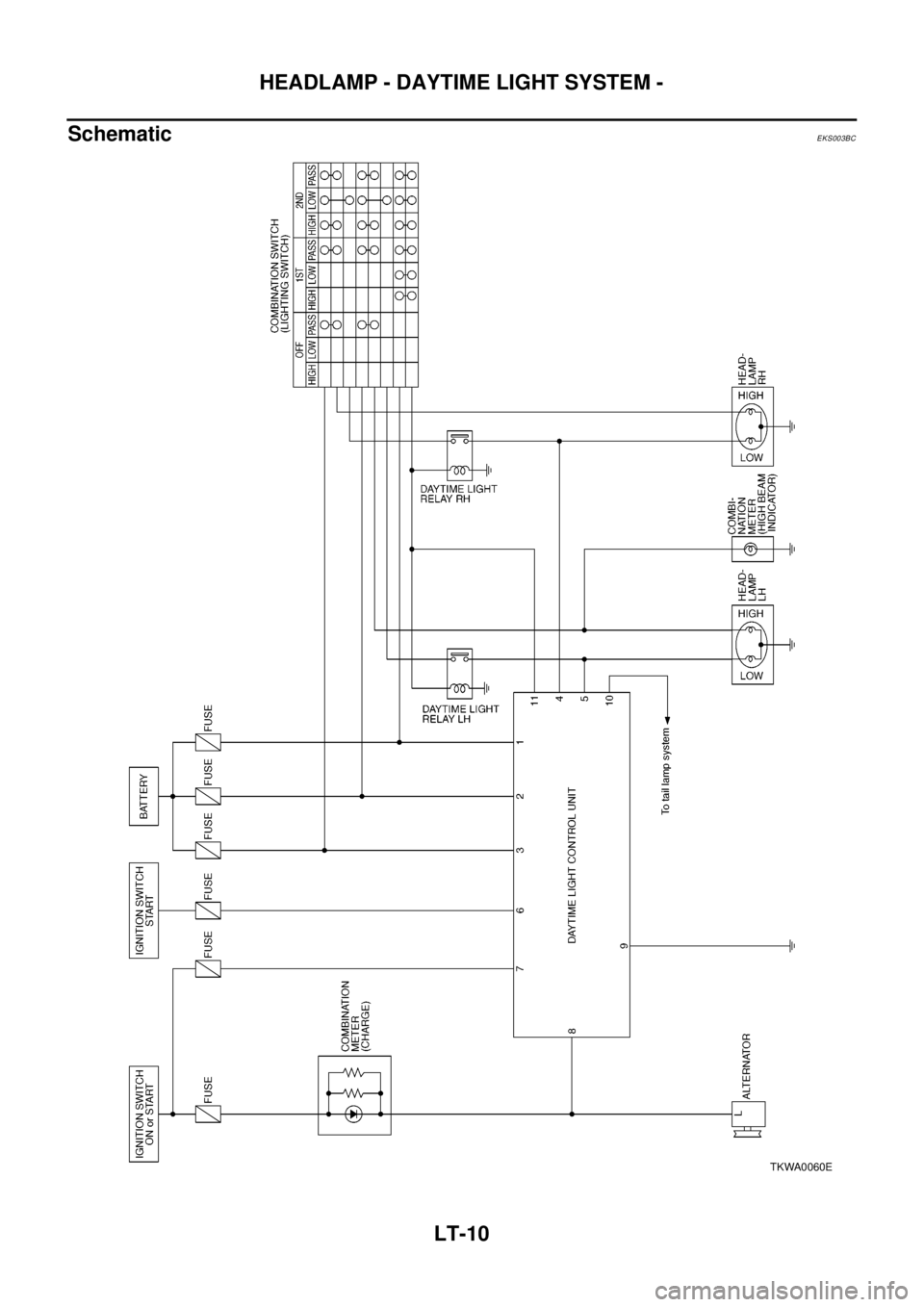

Schematic

EKS003BC

TKWA0060E

Page 2409 of 3066

HEADLAMP - DAYTIME LIGHT SYSTEM -

LT-11

C

D

E

F

G

H

I

J

L

MA

B

LT

Wiring Diagram -DTRL-EKS003BD

TKWA0061E

Page 2410 of 3066

LT-12

HEADLAMP - DAYTIME LIGHT SYSTEM -

TKWA0062E