NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2341 of 3066

GW-38

POWER WINDOW SYSTEM

Trouble Diagnoses

EIS001SF

3 R/W Power window DOWN signalPower window switch DOWN

operation.Approx. 0

Power window switch

UP operation.Approx. 0

Power window switch DOWN

operation.Battery voltage

Power window switch

UP operation.Battery voltage

Other than above. Approx. 0

4 L/OR Power window UP signalPower window switch

UP operation.Approx. 0

Power window switch DOWN

operation.Approx. 0

Power window switch

UP operation.Battery voltage

Power window switch DOWN

operation.Battery voltage

Other than above. Approx. 0

5W/RPower window switch power

supply— Battery voltage TERMINALWIRE

COLORITEM CONDITION VOLTAGE (V)

Symptom Possible cause Repair order

None of the power windows can be

operated using any switch.1. 10A fuse, 40A fusible link

2. M4 circuit breaker

3. Power window relay

4. M4 circuit breaker

5. Ground circuit

6. Power window main switch1. Check 10A fuse [No. 5, located in fuse block (J/B)]

Turn ignition switch “ON” and verify positive battery

voltage is present at terminal 1 (G) of power window

relay.

2. Check 40A fusible link (letterB, located in fuse and

fusible link box) and M4 circuit breaker. Verify positive

battery voltage is present at terminal 3 (W) of power

window relay.

3. Check M4 circuit breaker.

4. Check power window relay.

5. Check the following:

–Check harness between M4 circuit breaker and 40A

fusible link (letterB,located in fuse and fusible link

box).

–Check harness between M4 circuibt breaker and

power window main switch terminal 5 (LHD models)

or 3 (RHD models)

6. Check the following

–Check ground circuit of power window main switch.

–Check power window relay ground circuit.

–Check power window main switch.

Driver side power window cannot be

operated but other windows can be

operated.1. Driver side power window regula-

tor circuit

2. Driver side power window regula-

tor

3. Power window main switch1. Check harness between power window main switch

and driver side power window regulator for open or

short circuit.

2. Check driver side power window regulator.

3. Check power window main switch.

Page 2342 of 3066

POWER WINDOW SYSTEM

GW-39

C

D

E

F

G

H

J

K

L

MA

B

GW

Encoder and Limit Switch CheckEIS000M4

1.CHECK DOOR WINDOW SLIDE MECHANISM

Check the following.

lObstacles in window, glass molding, etc.

lWorn or deformed glass molding.

lDoor sash tilted too far inward or outward.

lDoor window regulator.

OK or NG?

OK >> GO TO 2.

Not OK >> Remove obstacles or repair door window slide mechanism.

One or more power windows except

driver's side window cannot be

operated.1. Power window sub-switches

2. Power window regulators

3. Power window main switch

4. Power window circuit1. Check power window sub-switch.

2. Check power window regulator.

3. Check power window main switch.

4. Check the following.

–Check harness between the power window relay ter-

minal 12 (W/R) and power window relay.

–Check harnesses between power window main switch

and power window sub-switch for open/short circuit.

–Check harnesses between power window sub-switch

and power window regulator for open/short circuit.

Power windows except driver's side

window cannot be operated using

power window main switch but can

be operated by power window sub-

switch.1. Power window main switch 1. Check power window main switch.

Driver side power window automatic

operation does not function prop-

erly.1. Power window main switch

2. Encoder and limit switch1. Check power window main switch.

2. Check encoder and limit switch.Refer toGW-39,

"Encoder and Limit Switch Check". Symptom Possible cause Repair order

Page 2343 of 3066

GW-40

POWER WINDOW SYSTEM

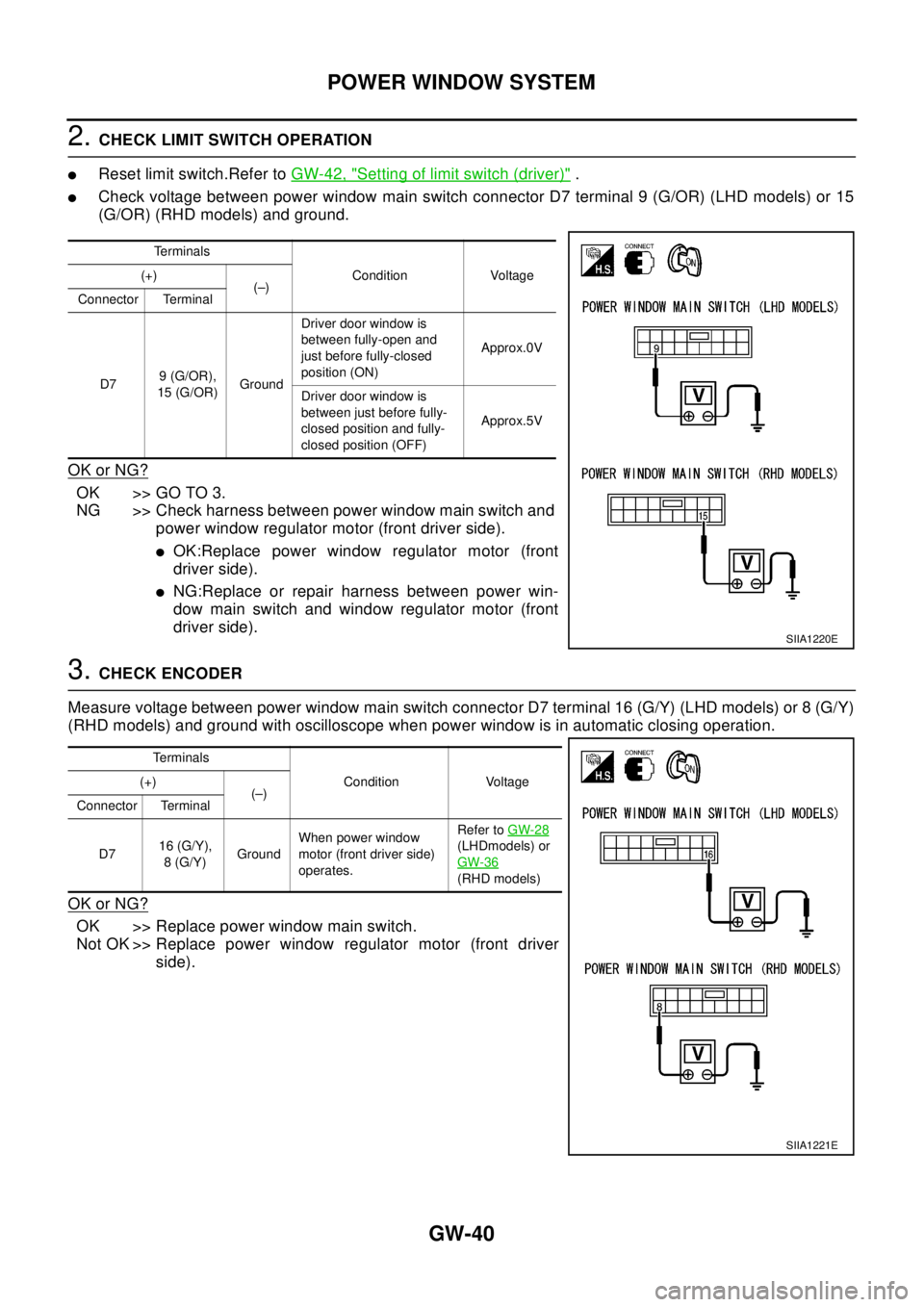

2.CHECK LIMIT SWITCH OPERATION

lReset limit switch.Refer toGW-42, "Setting of limit switch (driver)".

lCheck voltage between power window main switch connector D7 terminal 9 (G/OR) (LHD models) or 15

(G/OR) (RHD models) and ground.

OK or NG?

OK >> GO TO 3.

NG >> Check harness between power window main switch and

power window regulator motor (front driver side).

lOK:Replace power window regulator motor (front

driver side).

lNG:Replace or repair harness between power win-

dow main switch and window regulator motor (front

driver side).

3.CHECK ENCODER

Measure voltage between power window main switch connector D7 terminal 16 (G/Y) (LHD models) or 8 (G/Y)

(RHD models) and ground with oscilloscope when power window is in automatic closing operation.

OK or NG?

OK >> Replace power window main switch.

Not OK >> Replace power window regulator motor (front driver

side).

Te r m i n a l s

Condition Voltage (+)

(–)

Connector Terminal

D79 (G/OR),

15 (G/OR)GroundDriver door window is

between fully-open and

just before fully-closed

position (ON)Approx.0V

Driver door window is

between just before fully-

closed position and fully-

closed position (OFF)Approx.5V

SIIA1220E

Te r m i n a l s

Condition Voltage (+)

(–)

Connector Terminal

D716 (G/Y),

8(G/Y)GroundWhen power window

motor(frontdriverside)

operates.Refer toGW-28

(LHDmodels) or

GW-36

(RHD models)

SIIA1221E

Page 2344 of 3066

FRONT DOOR GLASS AND REGULATOR

GW-41

C

D

E

F

G

H

J

K

L

MA

B

GW

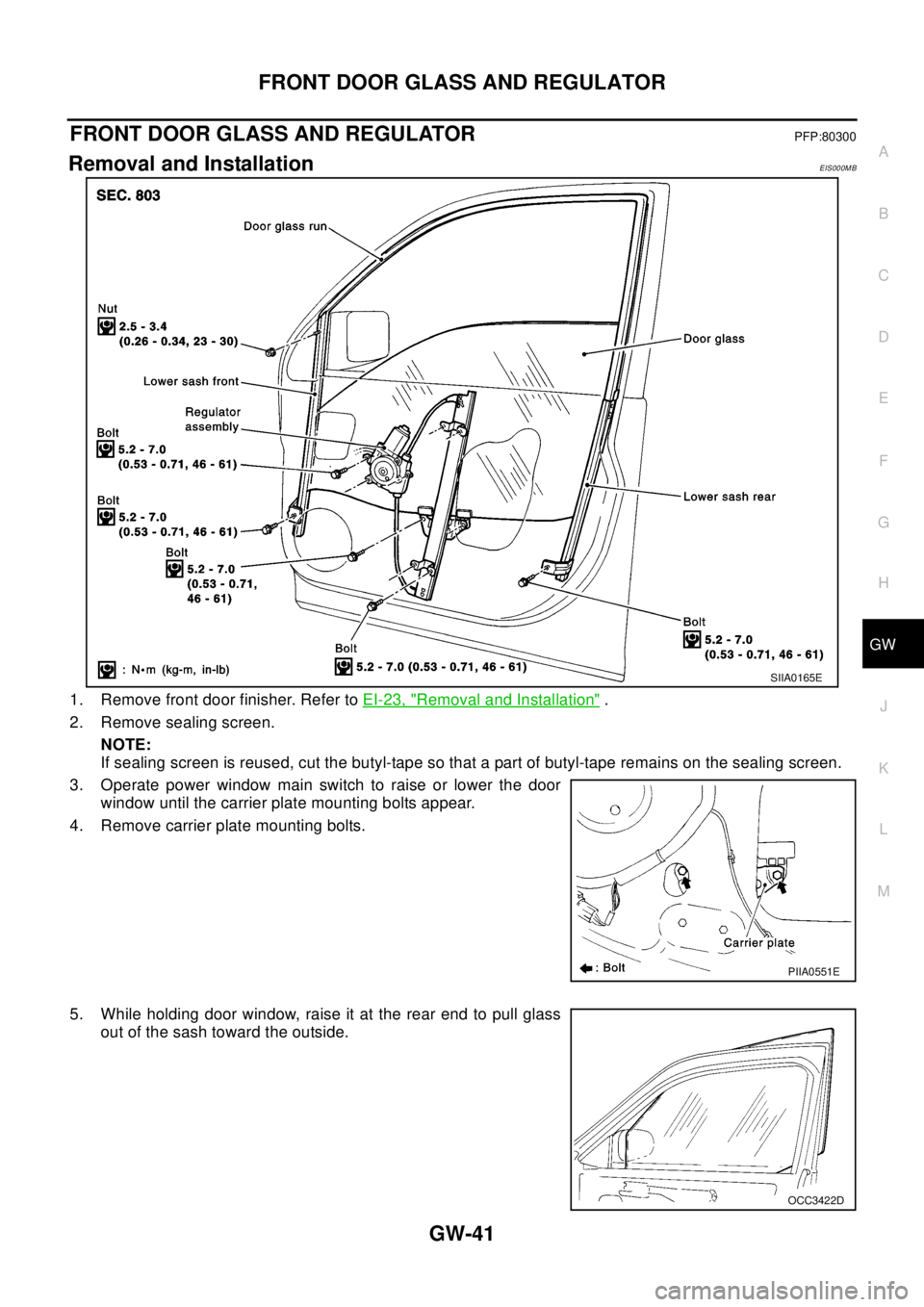

FRONTDOORGLASSANDREGULATORPFP:80300

Removal and InstallationEIS000MB

1. Remove front door finisher. Refer toEI-23, "Removal and Installation".

2. Remove sealing screen.

NOTE:

If sealing screen is reused, cut the butyl-tape so that a part of butyl-tape remains on the sealing screen.

3. Operate power window main switch to raise or lower the door

window until the carrier plate mounting bolts appear.

4. Remove carrier plate mounting bolts.

5. While holding door window, raise it at the rear end to pull glass

out of the sash toward the outside.

SIIA0165E

PIIA0551E

OCC3422D

Page 2345 of 3066

GW-42

FRONT DOOR GLASS AND REGULATOR

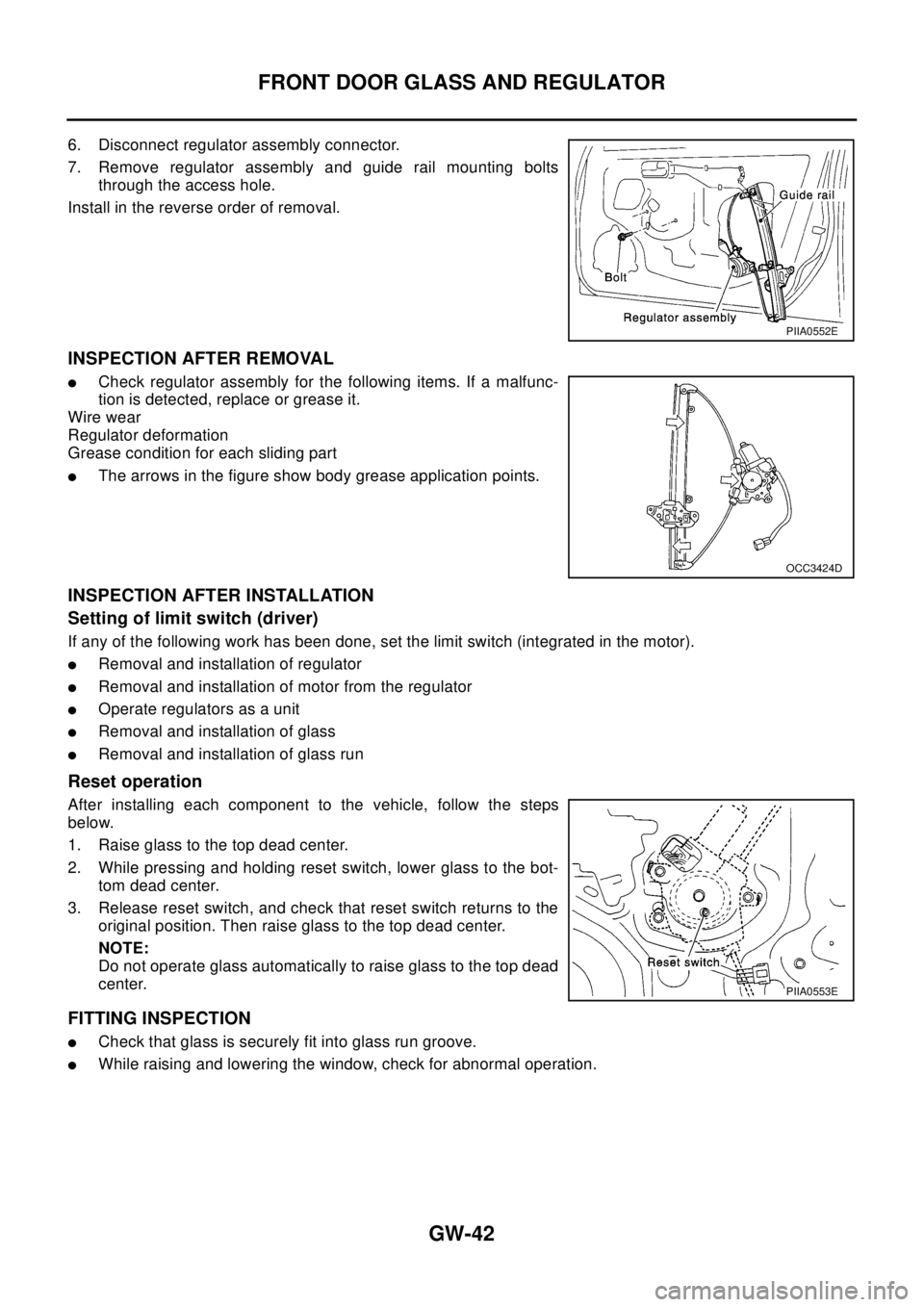

6. Disconnect regulator assembly connector.

7. Remove regulator assembly and guide rail mounting bolts

through the access hole.

Install in the reverse order of removal.

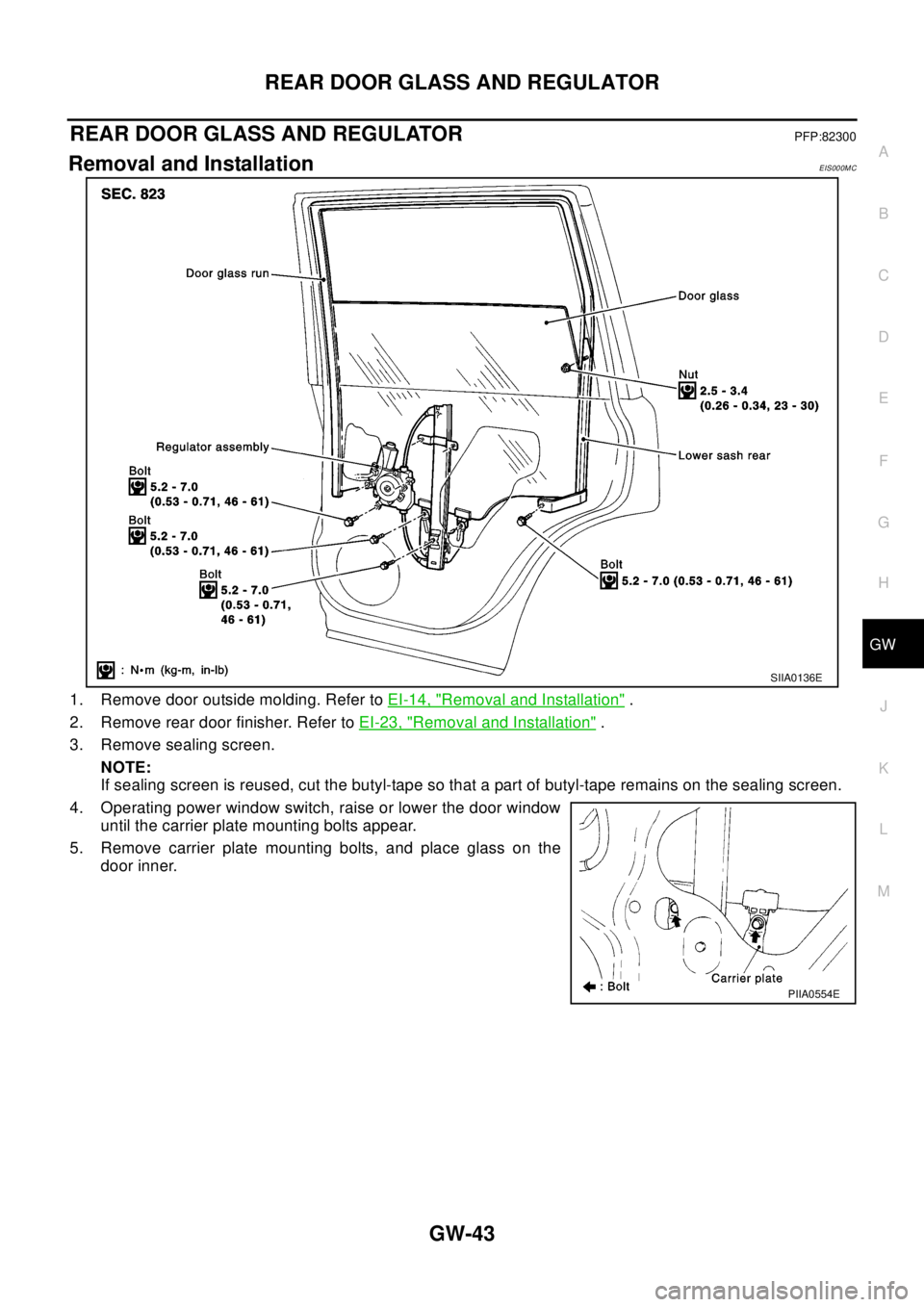

INSPECTION AFTER REMOVAL

lCheck regulator assembly for the following items. If a malfunc-

tion is detected, replace or grease it.

Wire wear

Regulator deformation

Grease condition for each sliding part

lThe arrows in the figure show body grease application points.

INSPECTION AFTER INSTALLATION

Setting of limit switch (driver)

If any of the following work has been done, set the limit switch (integrated in the motor).

lRemoval and installation of regulator

lRemoval and installation of motor from the regulator

lOperate regulators as a unit

lRemoval and installation of glass

lRemoval and installation of glass run

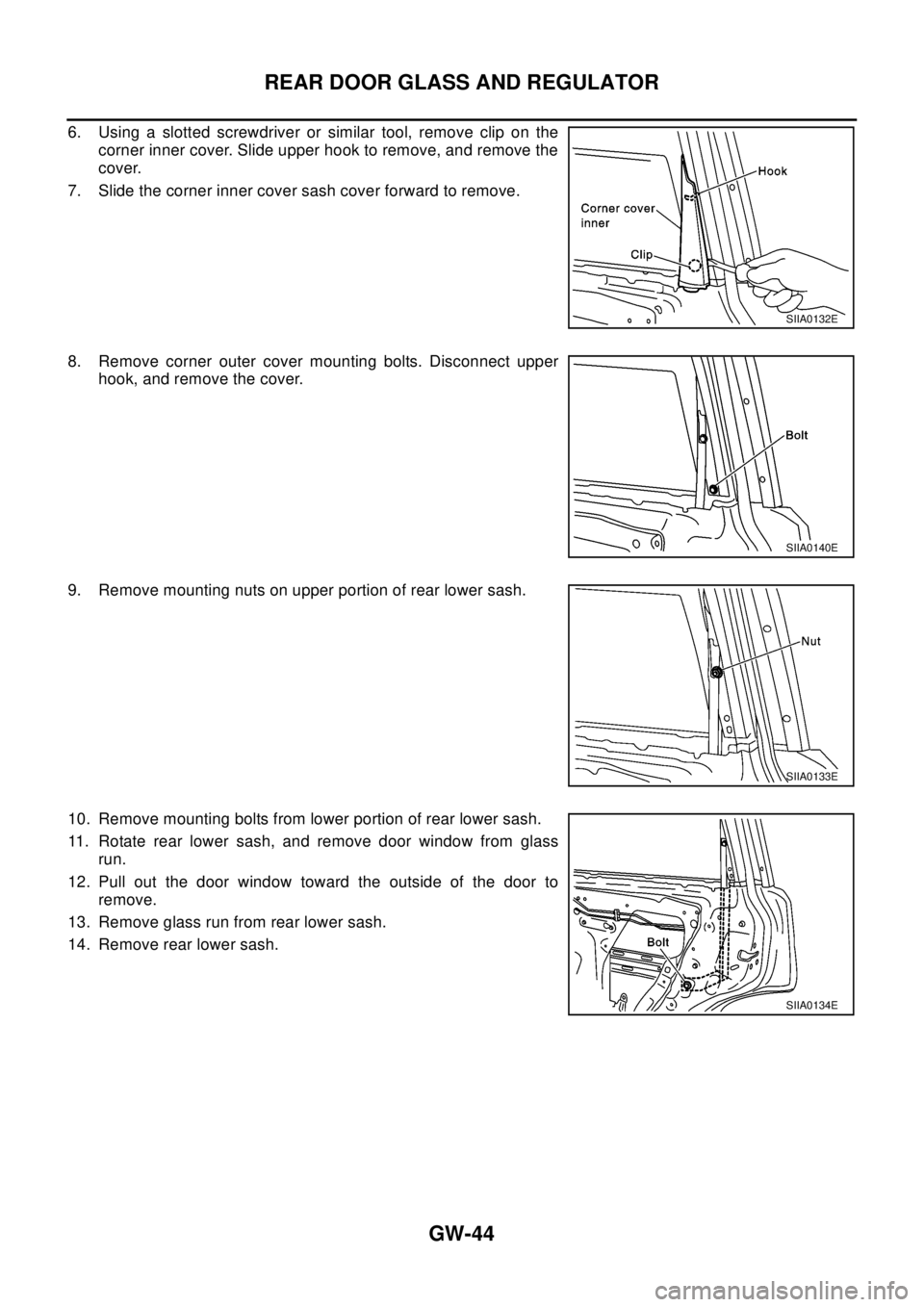

Reset operation

After installing each component to the vehicle, follow the steps

below.

1. Raise glass to the top dead center.

2. While pressing and holding reset switch, lower glass to the bot-

tom dead center.

3. Release reset switch, and check that reset switch returns to the

original position. Then raise glass to the top dead center.

NOTE:

Do not operate glass automatically to raise glass to the top dead

center.

FITTING INSPECTION

lCheck that glass is securely fit into glass run groove.

lWhile raising and lowering the window, check for abnormal operation.

PIIA0552E

OCC3424D

PIIA0553E

Page 2346 of 3066

REAR DOOR GLASS AND REGULATOR

GW-43

C

D

E

F

G

H

J

K

L

MA

B

GW

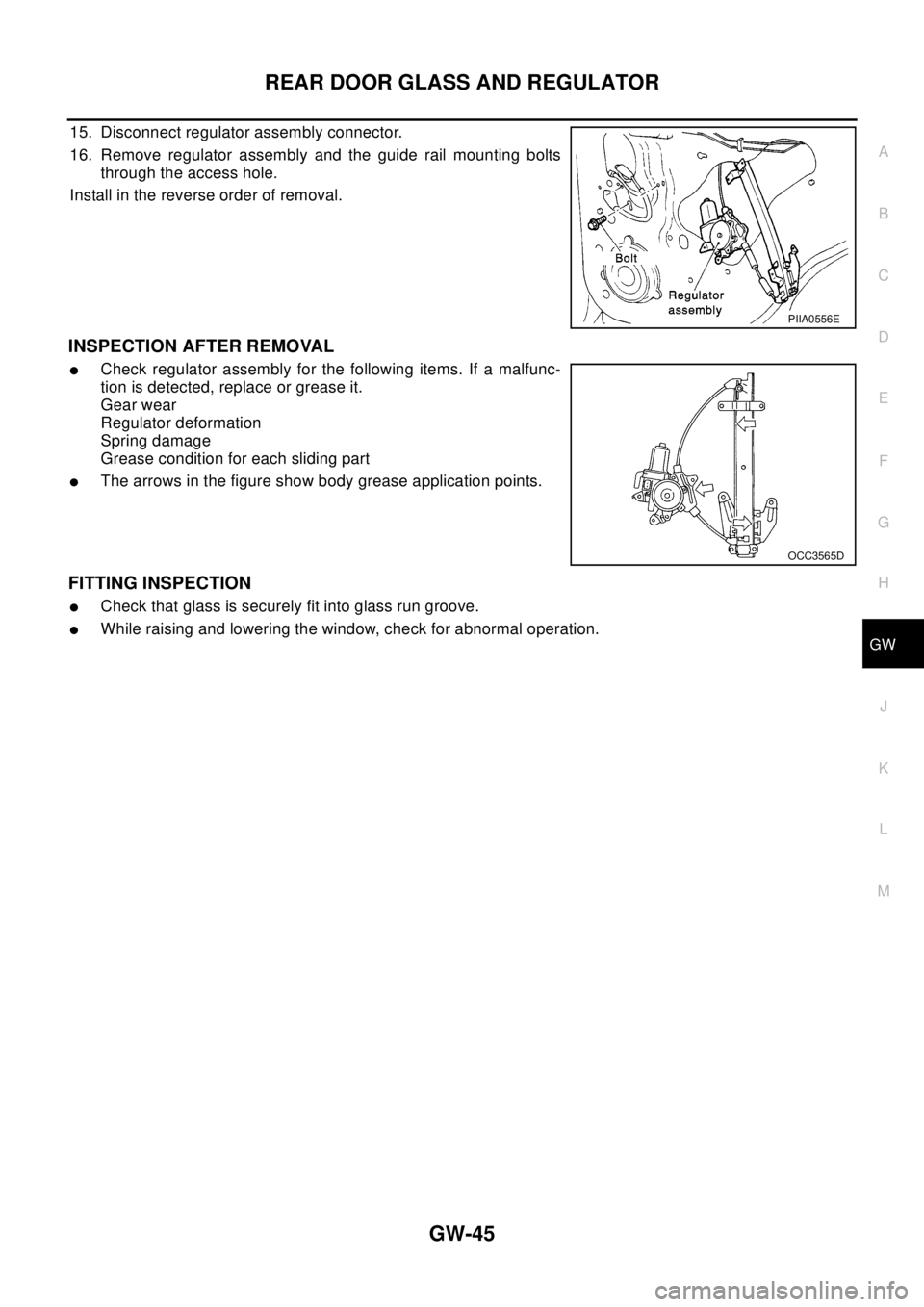

REAR DOOR GLASS AND REGULATORPFP:82300

Removal and InstallationEIS000MC

1. Remove door outside molding. Refer toEI-14, "Removal and Installation".

2. Remove rear door finisher. Refer toEI-23, "

Removal and Installation".

3. Remove sealing screen.

NOTE:

If sealing screen is reused, cut the butyl-tape so that a part of butyl-tape remains on the sealing screen.

4. Operating power window switch, raise or lower the door window

until the carrier plate mounting bolts appear.

5. Remove carrier plate mounting bolts, and place glass on the

door inner.

SIIA0136E

PIIA0554E

Page 2347 of 3066

GW-44

REAR DOOR GLASS AND REGULATOR

6. Using a slotted screwdriver or similar tool, remove clip on the

corner inner cover. Slide upper hook to remove, and remove the

cover.

7. Slide the corner inner cover sash cover forward to remove.

8. Remove corner outer cover mounting bolts. Disconnect upper

hook, and remove the cover.

9. Remove mounting nuts on upper portion of rear lower sash.

10. Remove mounting bolts from lower portion of rear lower sash.

11. Rotate rear lower sash, and remove door window from glass

run.

12. Pull out the door window toward the outside of the door to

remove.

13. Remove glass run from rear lower sash.

14. Remove rear lower sash.

SIIA0132E

SIIA0140E

SIIA0133E

SIIA0134E

Page 2348 of 3066

REAR DOOR GLASS AND REGULATOR

GW-45

C

D

E

F

G

H

J

K

L

MA

B

GW

15. Disconnect regulator assembly connector.

16. Remove regulator assembly and the guide rail mounting bolts

through the access hole.

Install in the reverse order of removal.

INSPECTION AFTER REMOVAL

lCheck regulator assembly for the following items. If a malfunc-

tion is detected, replace or grease it.

Gear wear

Regulator deformation

Spring damage

Grease condition for each sliding part

lThe arrows in the figure show body grease application points.

FITTING INSPECTION

lCheck that glass is securely fit into glass run groove.

lWhile raising and lowering the window, check for abnormal operation.

PIIA0556E

OCC3565D

Page 2349 of 3066

GW-46

DOOR MIRROR

DOOR MIRROR

PFP:96301

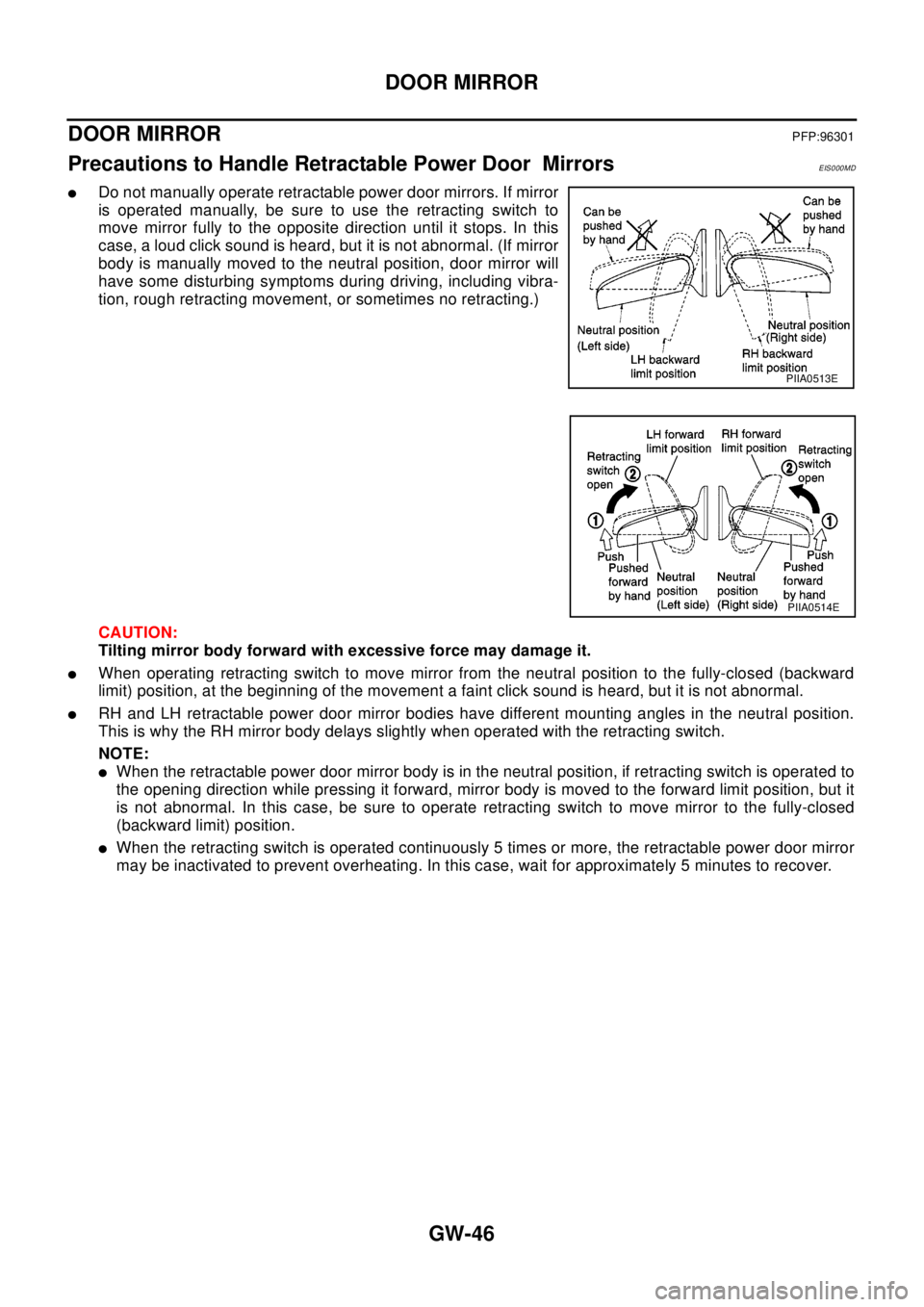

Precautions to Handle Retractable Power Door MirrorsEIS000MD

lDo not manually operate retractable power door mirrors. If mirror

is operated manually, be sure to use the retracting switch to

move mirror fully to the opposite direction until it stops. In this

case, a loud click sound is heard, but it is not abnormal. (If mirror

body is manually moved to the neutral position, door mirror will

have some disturbing symptoms during driving, including vibra-

tion, rough retracting movement, or sometimes no retracting.)

CAUTION:

Tilting mirror body forward with excessive force may damage it.

lWhen operating retracting switch to move mirror from the neutral position to the fully-closed (backward

limit) position, at the beginning of the movement a faint click sound is heard, but it is not abnormal.

lRH and LH retractable power door mirror bodies have different mounting angles in the neutral position.

This is why the RH mirror body delays slightly when operated with the retracting switch.

NOTE:

lWhen the retractable power door mirror body is in the neutral position, if retracting switch is operated to

the opening direction while pressing it forward, mirror body is moved to the forward limit position, but it

is not abnormal. In this case, be sure to operate retracting switch to move mirror to the fully-closed

(backward limit) position.

lWhen the retracting switch is operated continuously 5 times or more, the retractable power door mirror

may be inactivated to prevent overheating. In this case, wait for approximately 5 minutes to recover.

PIIA0513E

PIIA0514E

Page 2350 of 3066

DOOR MIRROR

GW-47

C

D

E

F

G

H

J

K

L

MA

B

GW

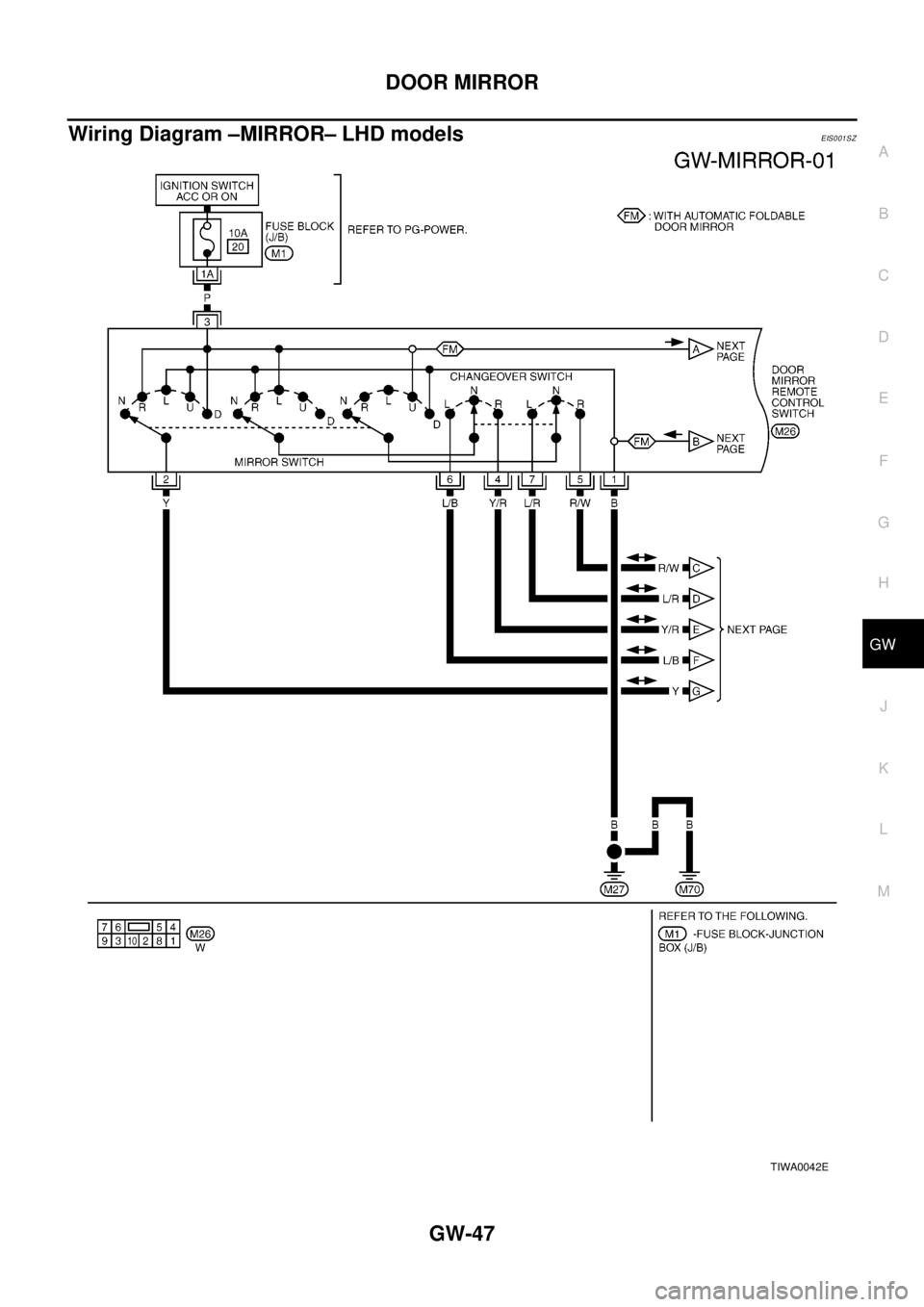

Wiring Diagram –MIRROR– LHD modelsEIS001SZ

TIWA0042E