PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1671 of 1825

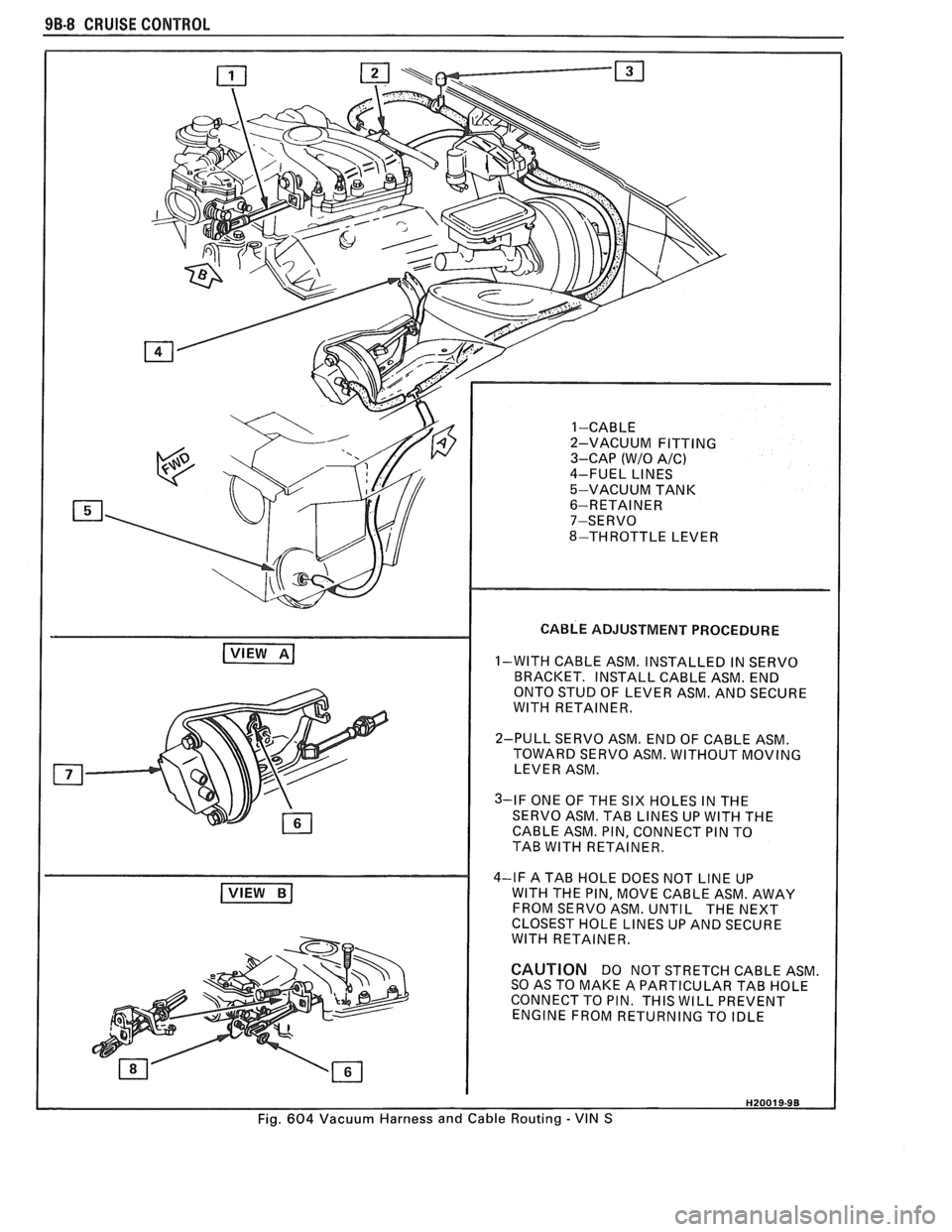

9B-8 CRUISE CONTROL

( VIEW BI

CABLE ADJUSTMENT PROCEDURE

1-WITH CABLE ASM. INSTALLED IN SERVO

BRACKET. INSTALL CABLE ASM. END

ONTO STUD OF LEVER ASM. AND SECURE

WlTH RETAINER.

2-PULL SERVO ASM. END OF CABLE ASM.

TOWARD SERVO ASM. WITHOUT MOVING

LEVER ASM.

3-IF ONE OF THE SIX HOLES IN THE

SERVO ASM. TAB LINES UP WlTH THE

CABLE ASM. PIN, CONNECT PIN TO

TAB WlTH RETAINER.

4-IF A TAB HOLE DOES NOT LINE UP

WlTH THE PIN, MOVE CABLE ASM. AWAY

FROM SERVO ASM. UNTIL THE NEXT

CLOSEST HOLE LINES UP AND SECURE

WlTH RETAINER.

CAUTION DO NOT STRETCH CABLE ASM

SO AS TO MAKE A PARTICULAR TAB HOLE

CONNECT TO PIN. THIS WILL PREVENT

ENGINE FROM RETURNING TO IDLE

Fig. 604 Vacuum Harness and Cable Routing - VIN S

Page 1672 of 1825

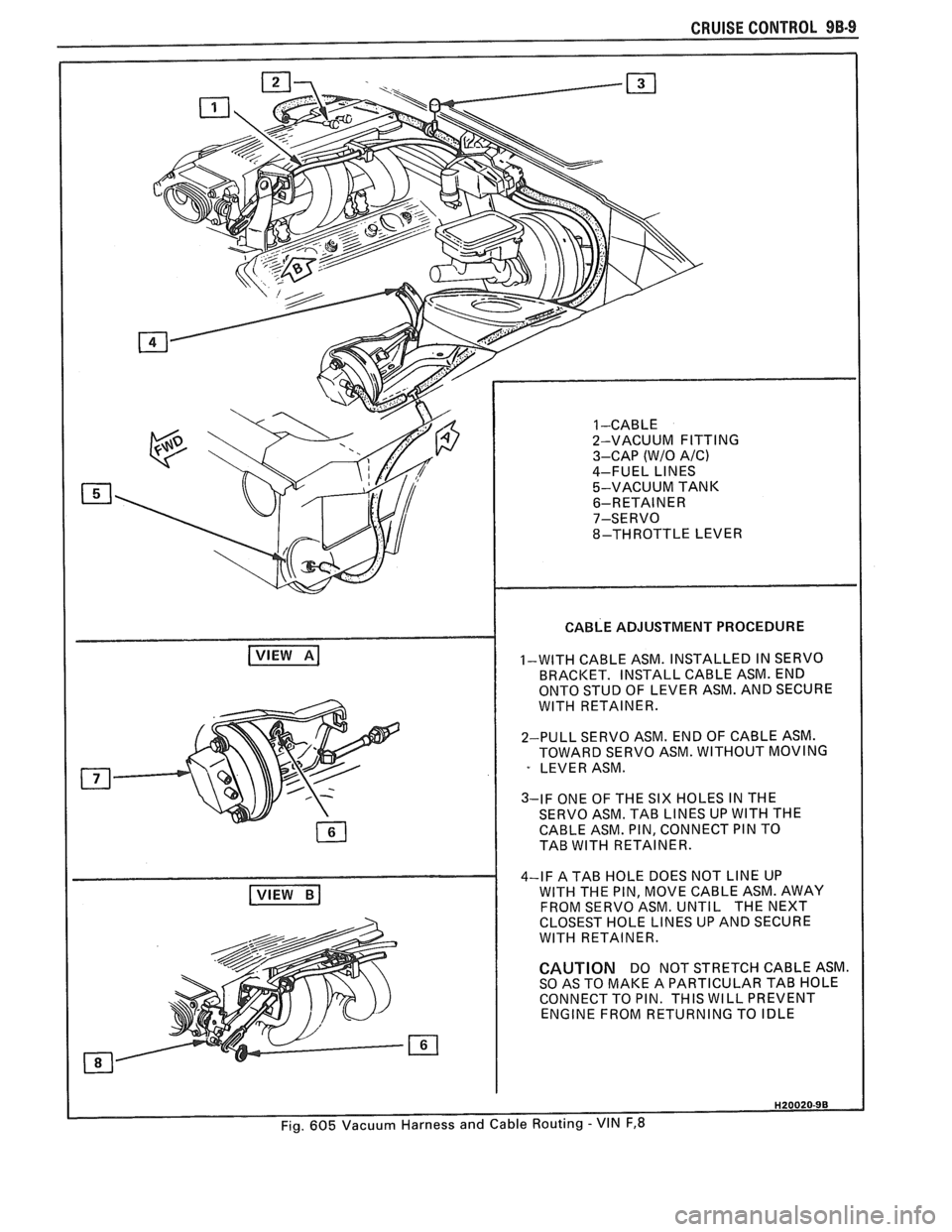

CABLE ADJUSTMENT PROCEDURE

1-WITH CABLE ASM. INSTALLED IN SERVO

BRACKET. INSTALL CABLE ASM. END

ONTO STUD OF LEVER ASM. AND SECURE

WlTH RETAINER.

2-PULL SERVO ASM. END OF CABLE ASM.

TOWARD SERVO ASM. WITHOUT MOVING

LEVER ASM.

3-IF ONE OF THE SIX HOLES IN THE

SERVO ASM. TAB LINES UP WlTH THE

CABLE ASM. PIN, CONNECT PIN TO

TAB WITH RETAINER.

4-IF A TAB HOLE DOES NOT

LINE UP

WITH THE PIN, MOVE CABLE ASM. AWAY

FROM SERVO ASM.

UNTl L THE NEXT

CLOSEST HOLE LINES UP AND SECURE

WlTH RETAINER.

CAUTION DO NOT STRETCH CABLE ASM.

SO AS TO MAKE A PARTICULAR TAB HOLE

CONNECT TO PIN. THIS WILL PREVENT

ENGINE FROM RETURNING TO IDLE

Page 1673 of 1825

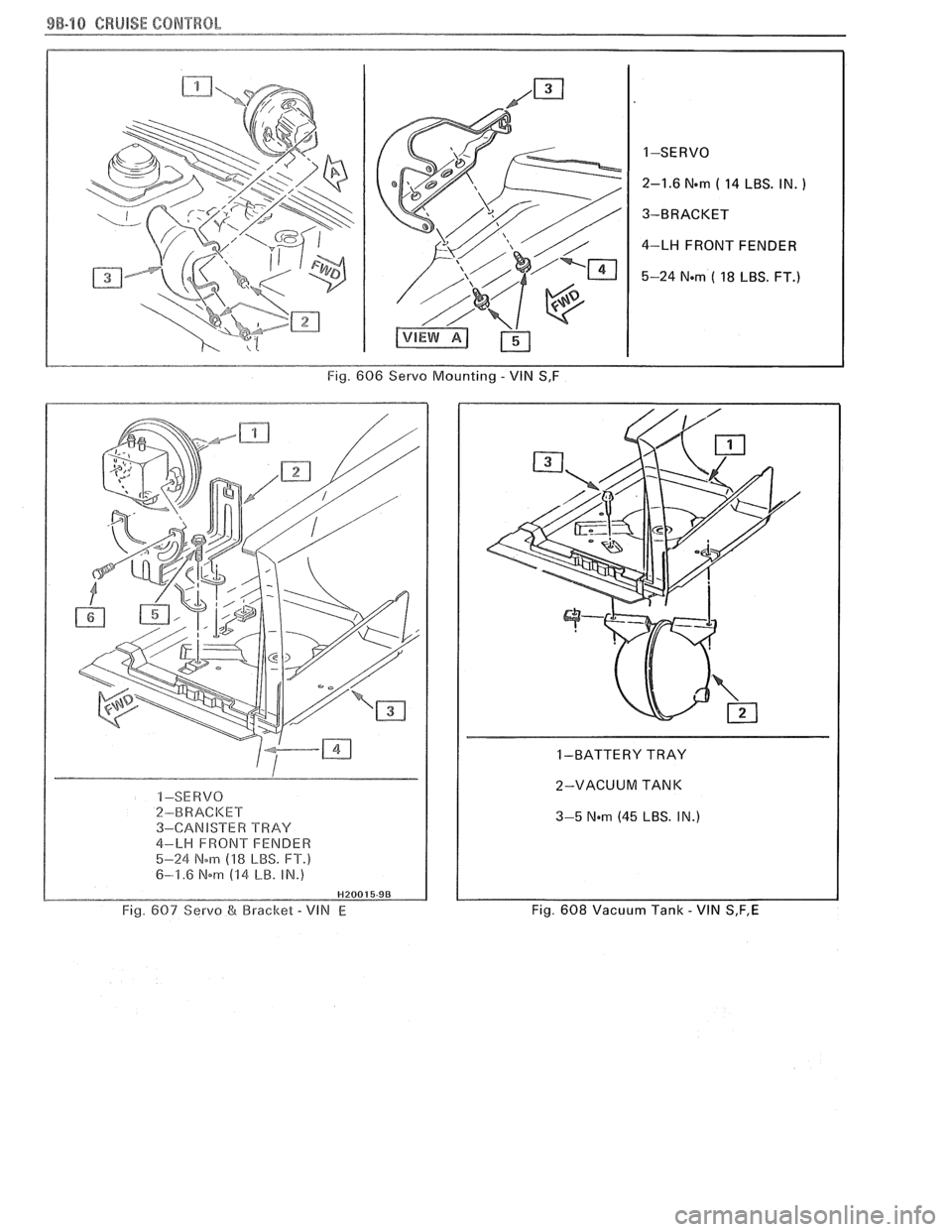

9B-10 CRUISE CONTROL

1-SERVO

2-1.6

Nem ( 14 LBS. IN. )

3-BRACKET

4-LH FRONT FENDER

5-24

Nom ( 18 LBS. FT.)

Fig. 606 Servo Mounting - VlN S,F

I -SE RVO 2-BRACI

4-LH FRONT FENDER

5-24 Nom (18 LBS. FT.)

6-1.6 Nm (14 LB. IN.)

Fig. 607 Servo &I Bracket - VIN E

1 -BATTERY TRAY

2-VACUUM TANK

I 3-5 Nem (45 LBS. IN.)

Fig. 608 Vacuum Tank - VIN S,F,E

Page 1674 of 1825

MISCELLANEOUS ACCESSORIES 96-4

SCELLANEOUS ACCESSOR

General Description ................................. 9G-1

Rally Gages .................................................. 9G- 1

Tachometer ................................................. 9G- 1

Trip Odometer

............................................. 9G- 1

Electric Rear Window Defogger ................. 9G-2

Power Remote Control Rearview

Mirror ........................................................ 9G-2

Diagnosis .................................................... 9G-2

Rally Gages ............................................... 9G-2

Tachometer .................................... .... .... 9G-2

Electric Rear Window Defogger ................. 9G-2

Power Remote Control Rearview

Mirror ........................................................ 96-2

Dash and Console Mounted

Accessory Switches

................................. 9G-4

General Description .................................. 9G-4

Electronic Glare Control Mirror ................. 9G-4

On-Car Service ............................................. 9G-4

Rally Gages, Tach ....................................... 96-4.

Rear Window Defogger ............................ 96-4.

Power Remote Control Mirror .................... 9G-4

GENERAL BESCRIP"T0N

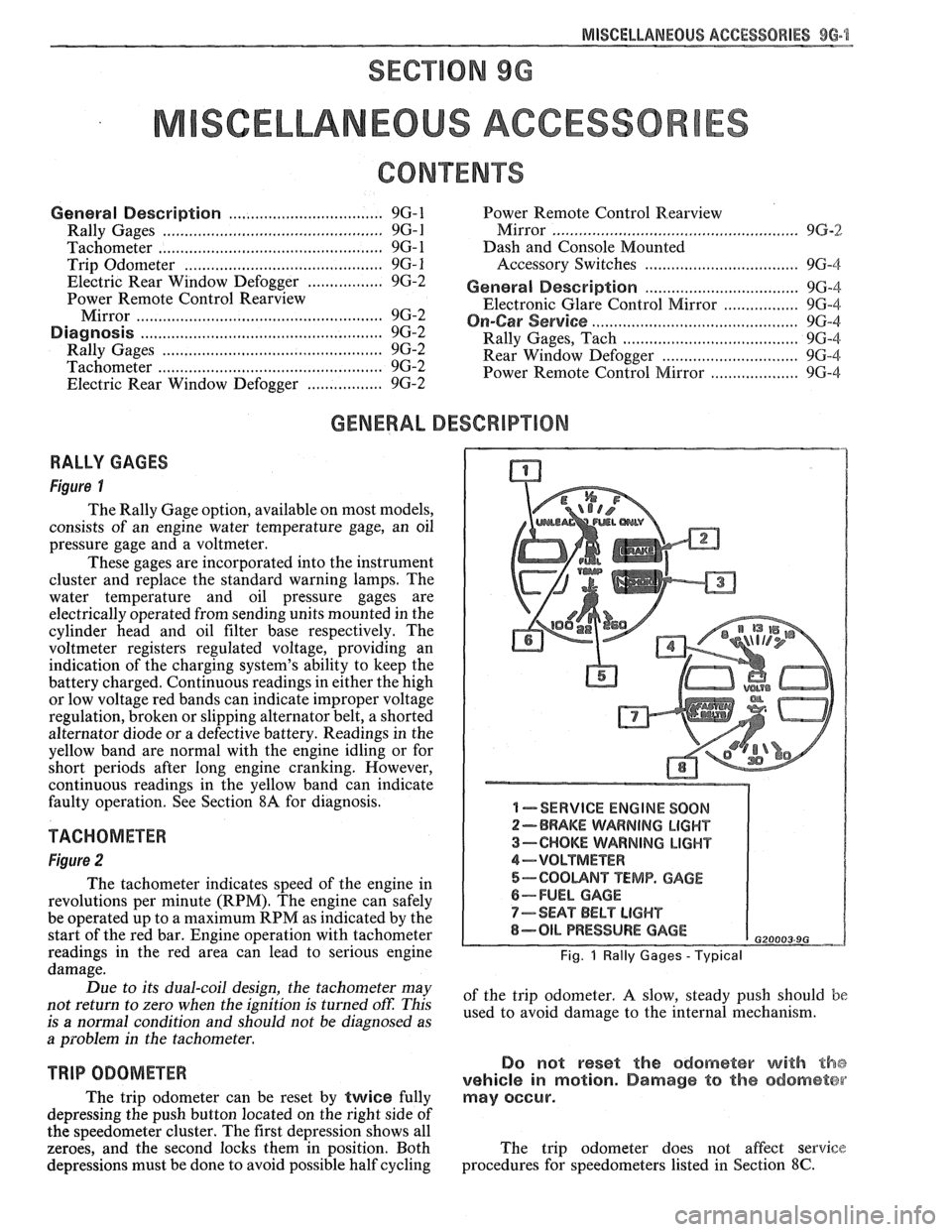

RALLY GAGES

Figure I

The Rally Gage option, available on most models,

consists of an engine water temperature gage, an oil

pressure gage and a voltmeter.

These gages are incorporated into the instrument

cluster and replace the standard warning lamps. The

water temperature and oil pressure gages are

electrically operated from sending units mounted in the

cylinder head and oil filter base respectively. The

voltmeter registers regulated voltage, providing an

indication of the charging system's ability to keep the

battery charged. Continuous readings in either the high

or low voltage red bands can indicate improper voltage

regulation, broken or slipping alternator belt,

a shorted

alternator diode

or a defective battery. Readings in the

yellow band are normal with the engine idling or for

short periods after long engine cranking. However,

continuous readings in the yellow band can indicate

faulty operation. See Section

8A for diagnosis.

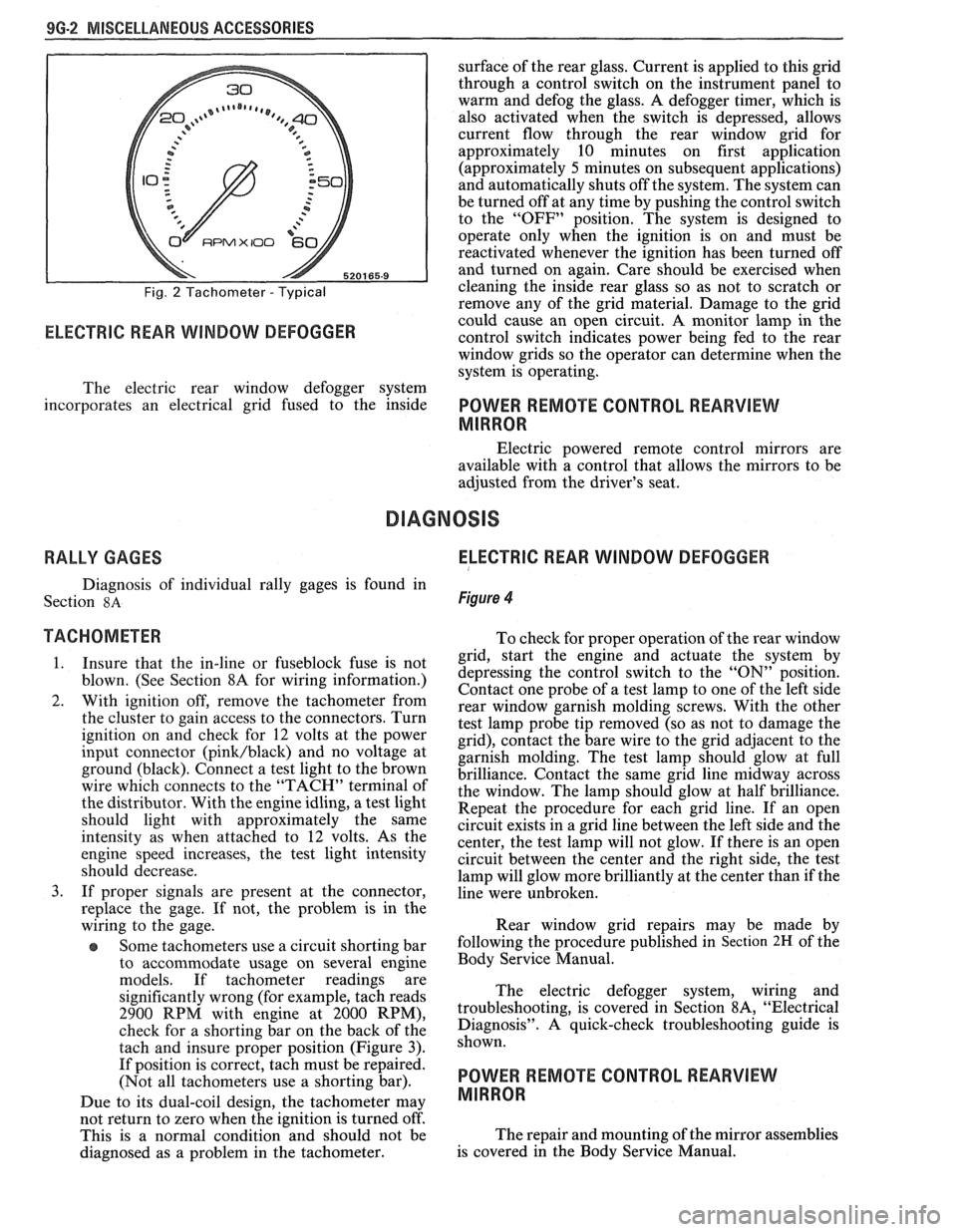

TACHOMETER

Figure 2

The tachometer indicates speed of the engine in

revolutions per minute (RPM). The engine can safely

be operated up to a maximum RPM as indicated by the

start of the red bar. Engine operation with tachometer

readings in the red area can lead to serious engine

damage.

Due to its dual-coil design, the tachometer may

not return to zero when the ignition

is turned oft: This

is

a normal condition and should not be diagnosed as

a problem in the tachometer.

TRIP ODOMETER

The trip odometer can be reset by twice fully

depressing the push button located on the right side of

the speedometer cluster. The first depression shows all

zeroes, and the second locks them in position. Both

depressions must be done to avoid possible half cycling

I -SERVICE ENGINE SOON

2-BRAKE WARNING LIGHT

3-CHOKE WARNING LIGHT

4-VOLTMETER

5-COOUNT TEMP. GAGE

6-FUEL GAGE

7-SEAT BELT LIGHT

8-OIL PRESSURE GAGE G20003 9G

Fig. 1 Rally Gages - Typical

of the trip odometer. A slow, steady push should be

used to avoid damage to the internal mechanism.

Do not reset the odometer with the

vehicle in motion. Damage to the odometer

may occur.

The trip odometer does not affect service

procedures for speedometers listed in Section

8C.

Page 1675 of 1825

9G-2 MISCELLANEOUS ACCESSORIES

Fig. 2 Tachometer - Typical

RPMX I00 €31-

ELECTRIC REAR WINDOW DEFOGGER

surface of the rear glass. Current is applied to this grid

through a control switch on the instrument panel to

warm and defog the glass. A defogger timer, which is

also activated when the switch is depressed, allows

current flow through the rear window grid

for

approximately 10 minutes on first application

(approximately

5 minutes on subsequent applications)

and automatically shuts off the system. The system can

be turned off at any time by pushing the control switch

to the "OFF" position. The system is designed to

operate only when the ignition is on and must be

reactivated whenever the ignition has been turned off

and turned on again. Care should be exercised when

cleaning the inside rear glass so as not to scratch or

remove any of the grid material. Damage to the grid

could cause an open circuit. A monitor lamp in-the

control switch indicates power being fed to the rear

window grids so the operator can determine when the

system is operating.

The electric rear window defogger system

incorporates an electrical grid fused to the inside

POWER REMOTE CONTROL REARVIEW

MIRROR

Electric powered remote control mirrors are

available with a control that allows the mirrors to be

adjusted from the driver's seat.

RALLY GAGES ELECTRIC REAR WINDOW DEFOGGER

Diagnosis of individual rally gages is found in

Section

8A Figure 4

TACHOMETER To check for moper o~eration of the rear window

1. Insure that the in-line or fuseblock fuse is not

blown. (See Section 8A for wiring information.)

2. With ignition off, remove the tachometer from

the cluster to gain access to the connectors. Turn

ignition on and check for

12 volts at the power

input connector

(pink/black) and no voltage at

ground (black). Connect a test light to the brown

wire which connects to the "TACH" terminal of

the distributor. With the engine idling, a test light

should light with approximately the same

intensity as when attached to

12 volts. As the

engine speed increases, the test light intensity

should decrease.

3. If proper signals are present at the connector,

replace the gage. If not, the problem is in the

wiring to the gage.

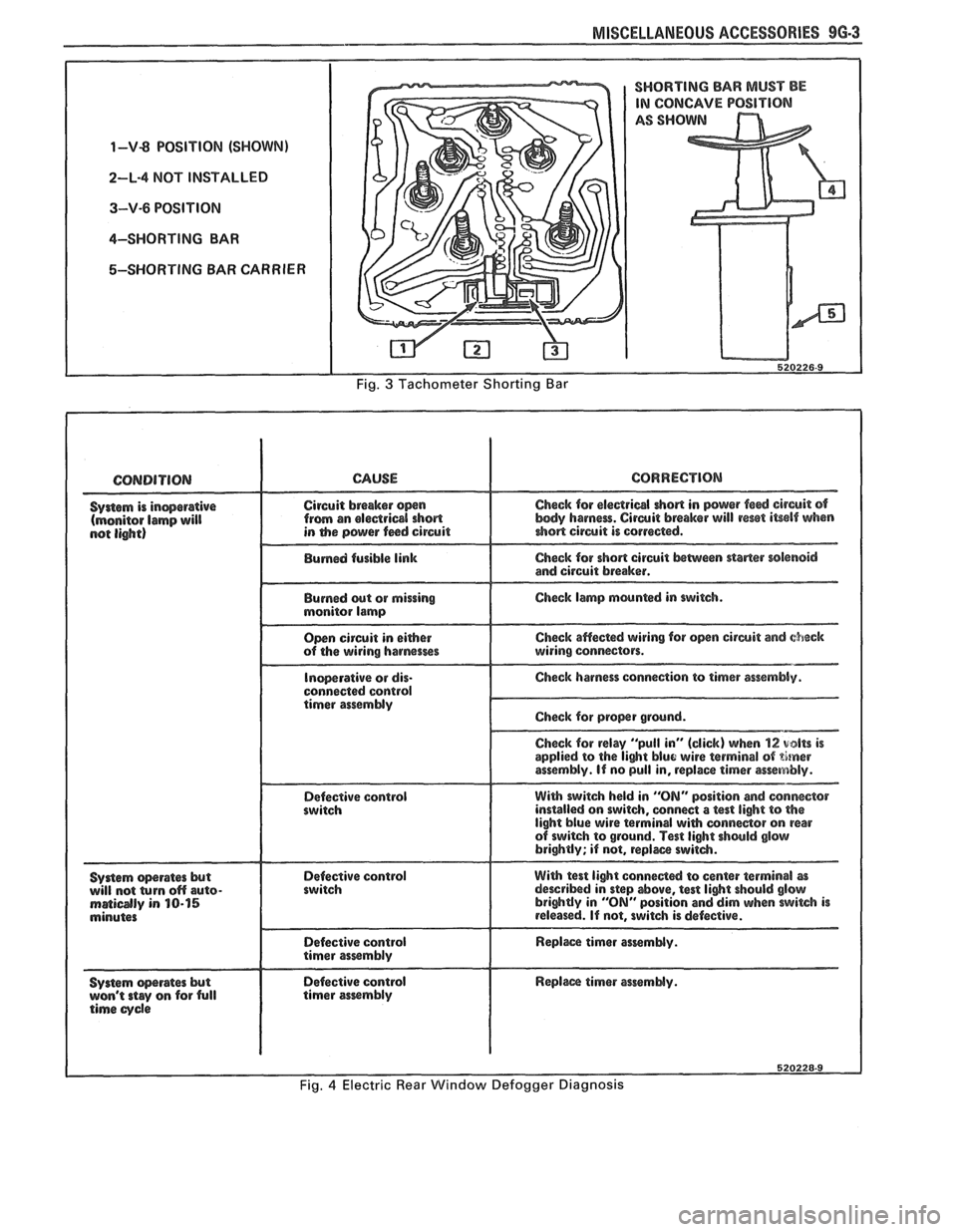

Some tachometers use a circuit shorting bar

to accommodate usage on several engine

models. If tachometer readings are

significantly wrong (for example, tach reads

2900 RPM with engine at 2000 RPM),

check for a shorting bar on the back of the

tach and insure proper position (Figure

3).

If position is correct, tach must be repaired.

(Not all tachometers use a shorting bar).

Due to its dual-coil design, the tachometer

may

- grid, start the engine a& actuate the system by

depressing the control switch to the

"ON" position.

Contact one probe of a test lamp to one of the left side

rear window garnish molding screws. With the other

test lamp probe tip removed (so as not to damage the

grid), contact the bare wire to the grid adjacent to the

garnish molding. The test lamp should glow at full

brilliance. Contact the same grid line midway across

the window. The lamp should glow at half brilliance.

Repeat the procedure for each grid line. If an open

circuit exists in a grid line between the left side and the

center, the test lamp will not glow. If there is an open

circuit between the center and the right side, the test

lamp will glow more brilliantly at the center than if the

line were unbroken.

Rear window grid repairs may be made by

following the procedure published in

Section 2H of the

Body Service Manual.

The electric defogger system, wiring and

troubleshooting, is covered in Section

8A, "Electrical

Diagnosis". A quick-check troubleshooting guide is

shown.

POWER REMOTE CONTROL REARVIEW

MIRROR

not return to zero when tvhe ignition is turned off'.

This is a normal condition and should not be The

repair and mounting of the mirror assemblies

diagnosed as a problem in the tachometer. is

covered in the Body Service Manual.

Page 1676 of 1825

MISCELLANEOUS ACCESSORIES 96-3

1-V-8 POSITION (SHOWN)

2-L-4 NOT INSTALLED

3-V-6 POSITION

4-SHORTING BAR

5-SHORTING BAR CARRIER

I SHORTING BAR MUST BE

CONCAVE POSITION

SHO

520226-9

Fig. 3 Tachometer Shorting Bar

Syrlem operates but Defective control will not (urn off auto- maidly in 10-15 minutes

System

-rates but Defective control Replm timer essemMy. won't stay on for full timer assmbly time cycle

Page 1677 of 1825

96.4 MISCELLANEOUS ACCESSORIES

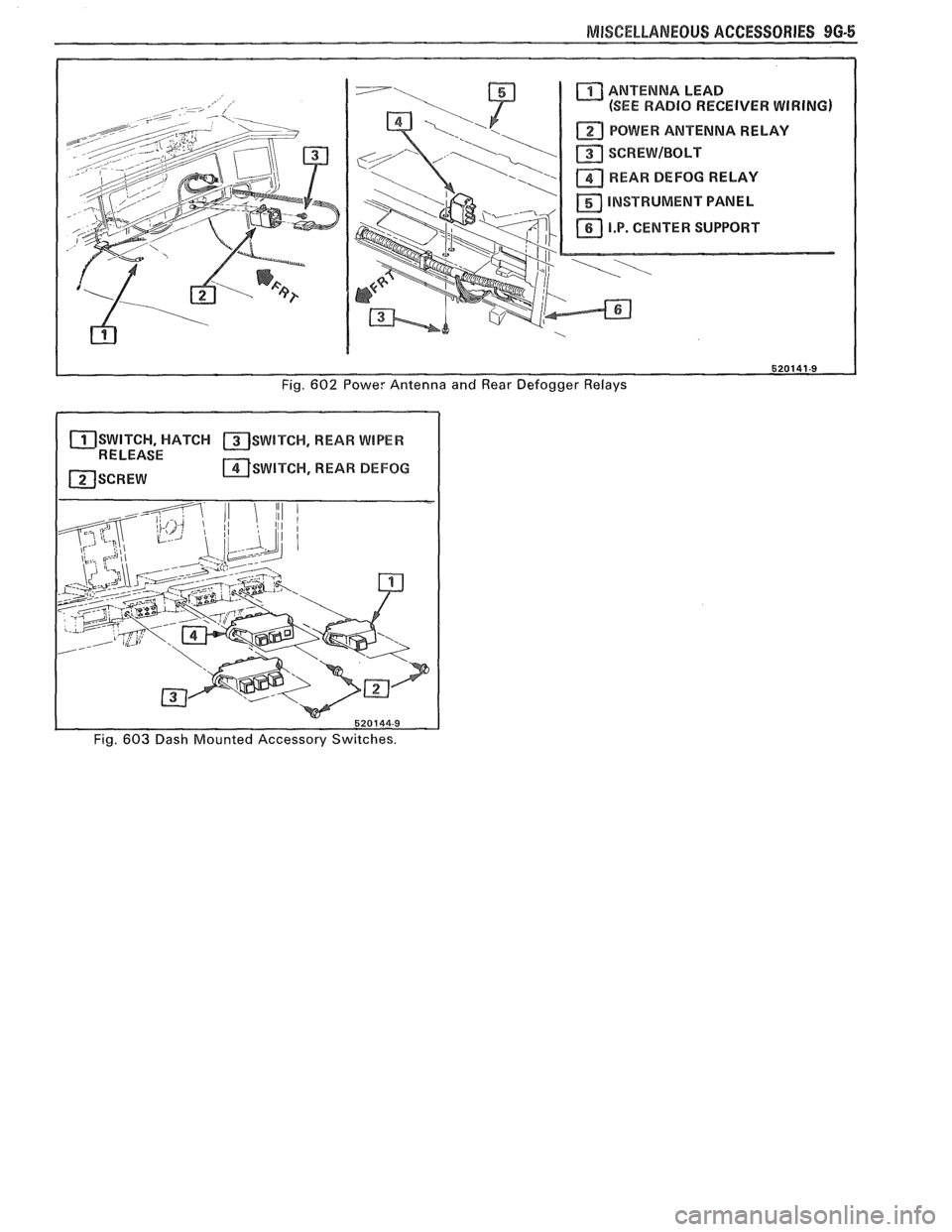

DASH AND CONSOLE MOUNTED ACCESSORY

SWITCHES

Installation for various dash and console

mounted accessory switches is shown in Section

8C.

GENERAL DESCRIPIIOM

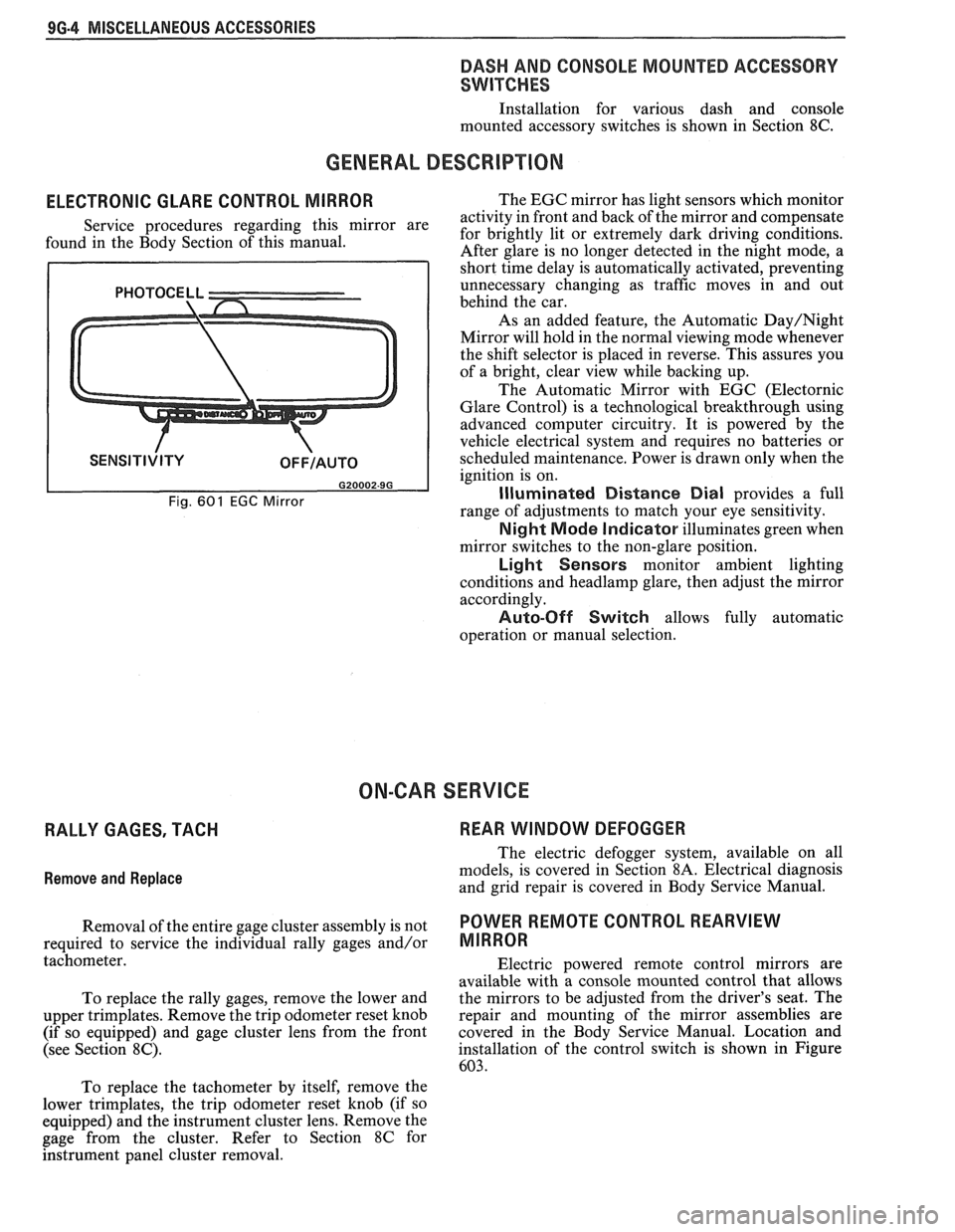

ELECTRONIC GLARE CONTROL MIRROR

Service procedures regarding this mirror are

found in the Body Section of this manual.

Fig. 601 EGC Mirror

The EGC mirror has light sensors which monitor

activity in front and back of the mirror and compensate

for brightly lit or extremely dark driving conditions.

After glare is no longer detected in the night mode, a

short time delay is automatically activated, preventing

unnecessary changing as traffic moves in and out

behind the car.

As an added feature, the Automatic

Day/Night

Mirror will hold in the normal viewing mode whenever

the shift selector is placed in reverse. This assures you

of a bright, clear view while backing up.

The Automatic Mirror with EGC (Electornic

Glare Control) is a technological breakthrough using

advanced computer circuitry. It is powered by the

vehicle electrical system and requires no batteries or

scheduled maintenance. Power is drawn only when the

ignition is on.

Illuminated Distance Dial provides a full

range of adjustments to match your eye sensitivity.

Night Mode Indicator illuminates green when

mirror switches to the non-glare position.

Light Sensors monitor ambient lighting

conditions and

headlamp glare, then adjust the mirror

accordingly.

Auto-Off Switch allows fully automatic

operation or manual selection.

ON-CAR SERVICE

RALLY GAGES, TACH REAR WINDOW DEFOGGER

Remove

and Replace

The electric defogger system, available on all

models, is covered in Section

8A. Electrical diagnosis

and grid repair is covered in Body Service Manual.

Removal of the entire gage cluster assembly is not

POWER RmOTE CONTROL REARVIEW

required to service the individual rally gages and/or MIRROR

tachometer.

Electric powered remote control mirrors are

available with a console mounted control that allows

To replace the rally gages, remove the lower and the

mirrors to be adjusted from the driver's seat. The

upper trimplates. Remove the trip odometer reset knob repair

and mounting of the mirror assemblies are

(if so equipped) and gage cluster lens from the front covered in

the Body Service Manual. Location and

(see Section

8C). installation of the control switch is shown in Figure

603.

To replace the tachometer by itself, remove the

lower trimplates, the trip odometer reset knob (if so

equipped) and the instrument cluster lens. Remove the

gage from the cluster. Refer to Section

8C for

hstrument panel cluster removal.

Page 1678 of 1825

MISCELLANEOUS ACCESSORIES 9G-5

ANTENNA LEAD

(SEE RADIO RECEIVER WIRING)

POWER ANTENNA RELAY

SCREWIBOLT

REARD DEFOG RELAY

INSTRUMENT PANEL

11 I.P. CENTER SUPPORT XJ I

Fig. 602 Powe: Antenna and Rear Defogger Relays

SWITCH, HATCH SWITCH, REAR WIPER 1 RELEASE - I ~SWITCW, REAR BEFOG

I

1 520144-9

Fig. 603 Dash Mounted Accessory Switches.

Page 1679 of 1825

Page 1680 of 1825

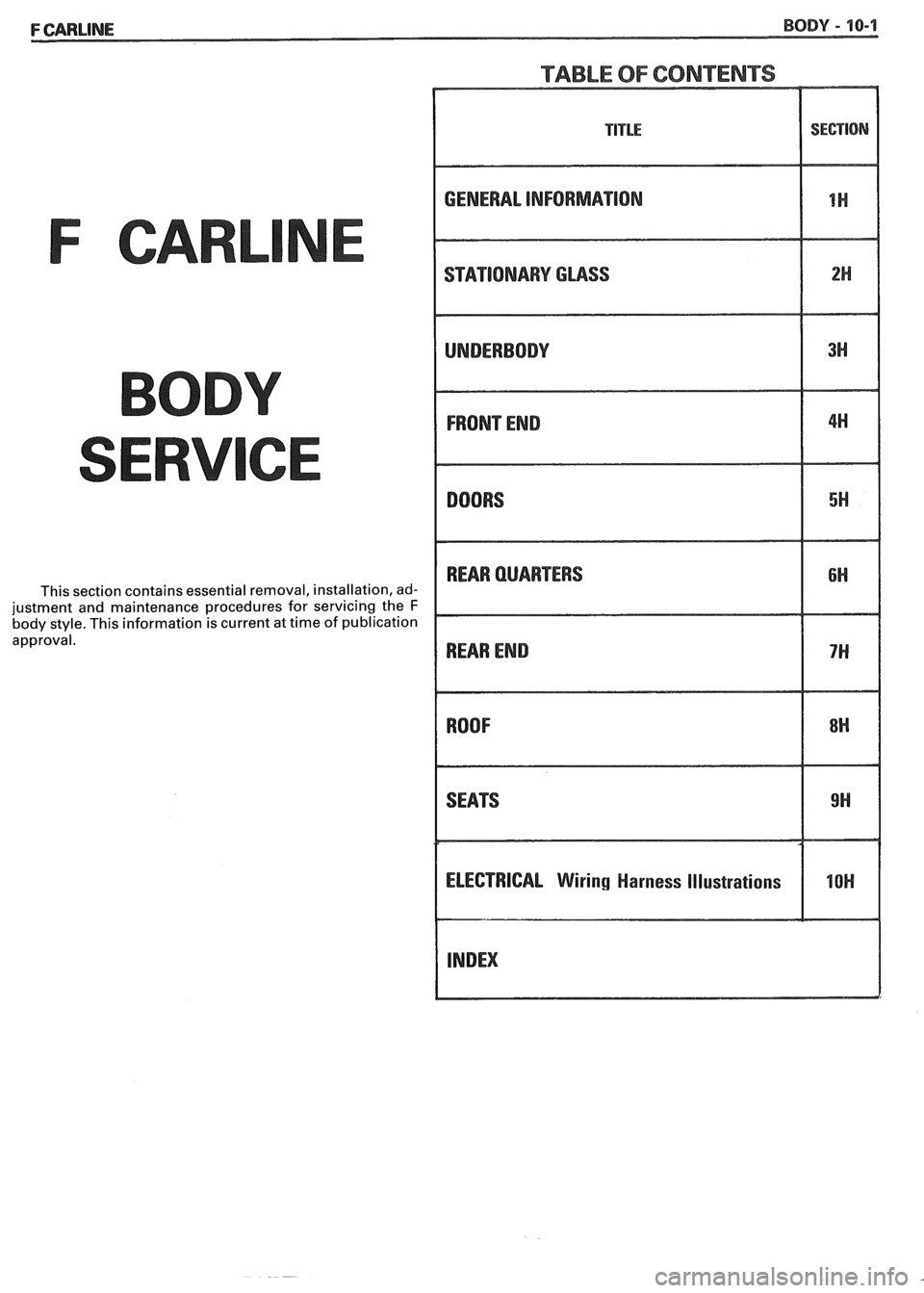

TABLE OF CONTENTS

F CARL

This section contains essential removal, installation, ad-

justment and maintenance procedures for servicing the

F body style. This information is current at time of publication

approval.

GENERAL INFORMATION

STATlONARV GLASS

REAR QUARTERS

ELECTRICAL

Wiring Harness Illustrations

I -IoH I