PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 1661 of 1825

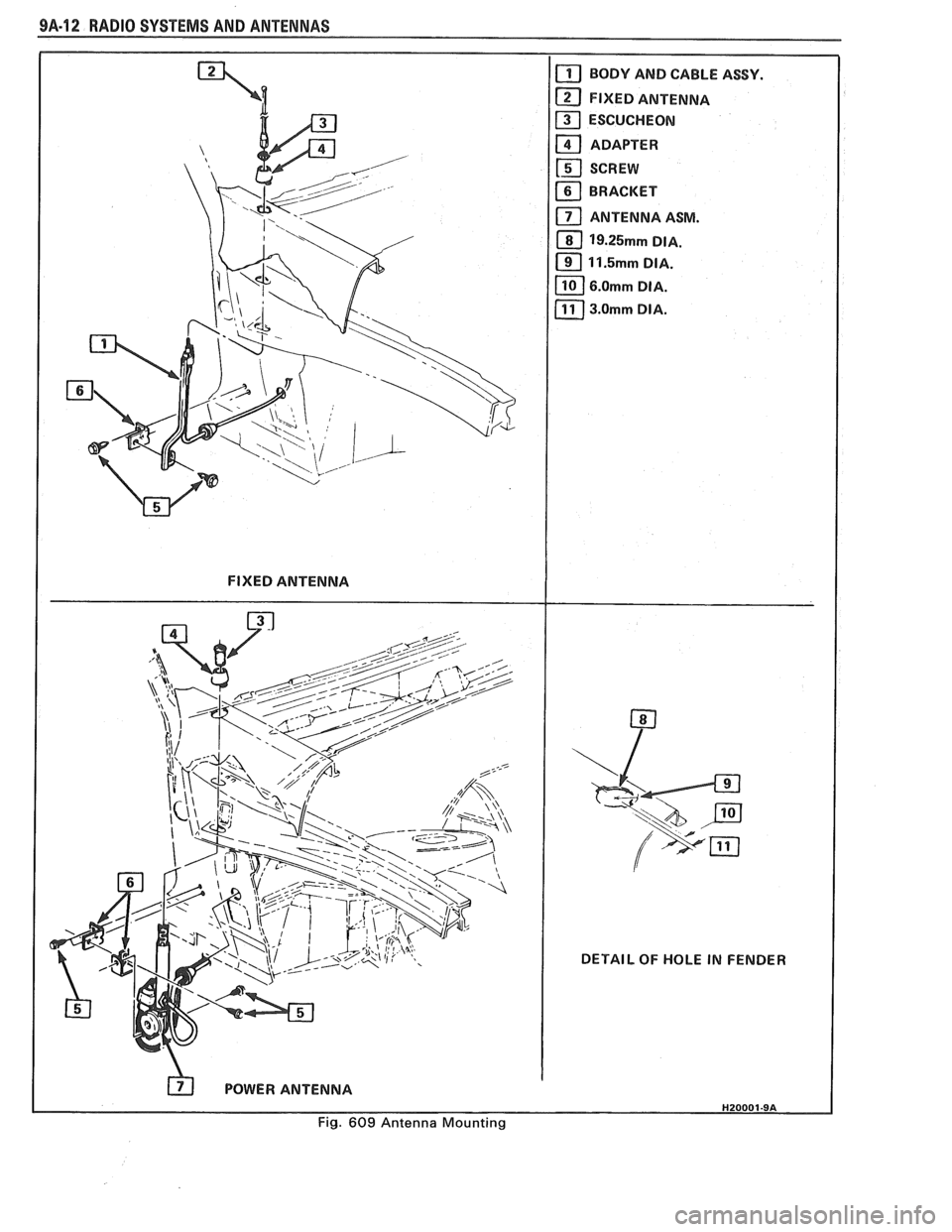

9A-12 RADIO SYSTEMS AND ANENNAS

FIXED ANTENNA

POWER ANTENNA DETAIL OF

HOLE IN FENDER

Fig. 609 Antenna Mounting

Page 1662 of 1825

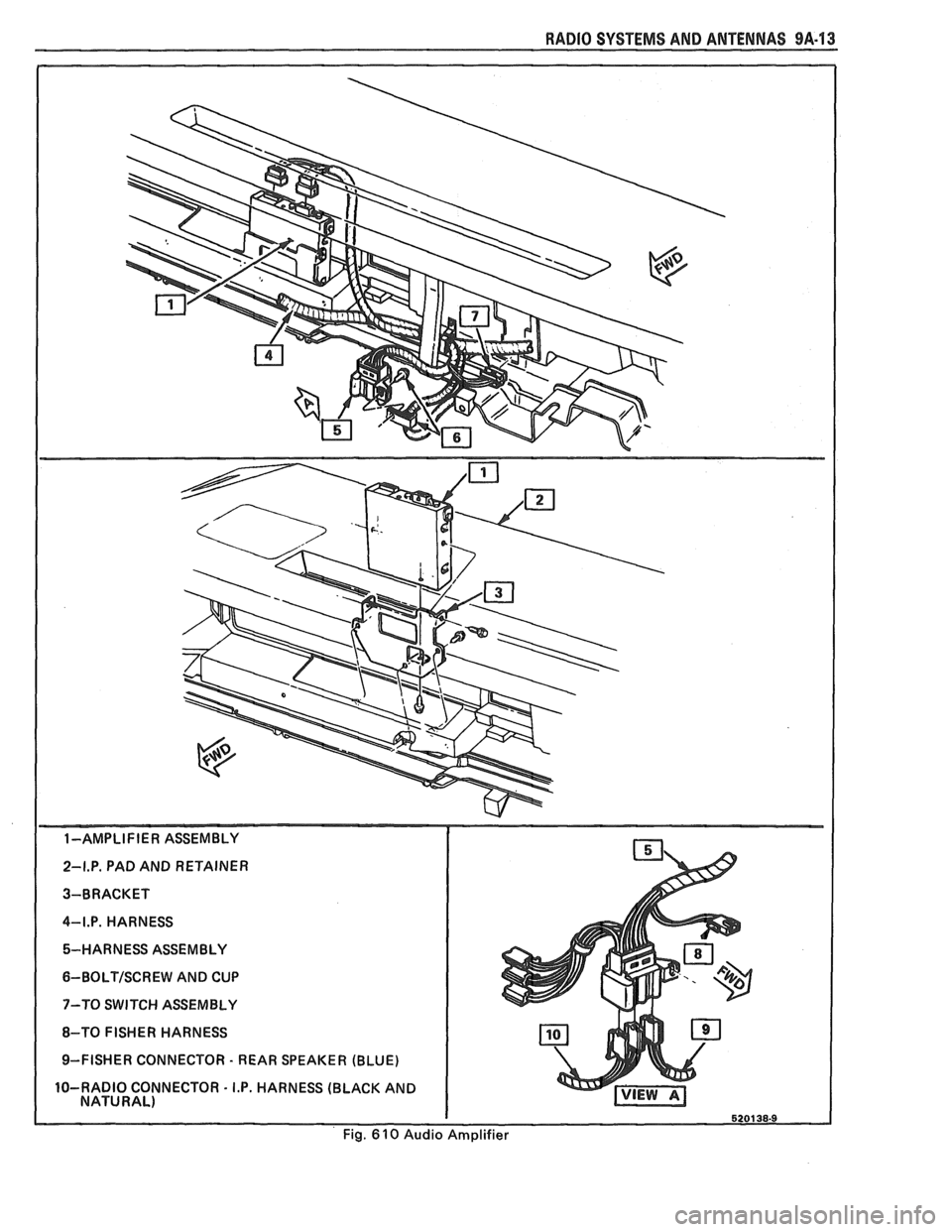

RADIO SYSTEMS AND ANTENNAS 9A.13

1-AMPLIFIER ASSEMBLY

2-I.P. PAD AND RETAINER

3-BRACKET

4-I.P. HARNESS 5-HARNESS ASSEMBLY

6-BOLTISCREW AND CUP

7-TO SWITCH ASSEMBLY

8-TO FISHER HARNESS

9-FISHER CONNECTOR

- REAR SPEAKER (BLUE)

10-RADIO CONNECTOR

- I.P. HARNESS (BLACK AND

NATURAL)

Fig.

6 10 Audio Amplifier

Page 1663 of 1825

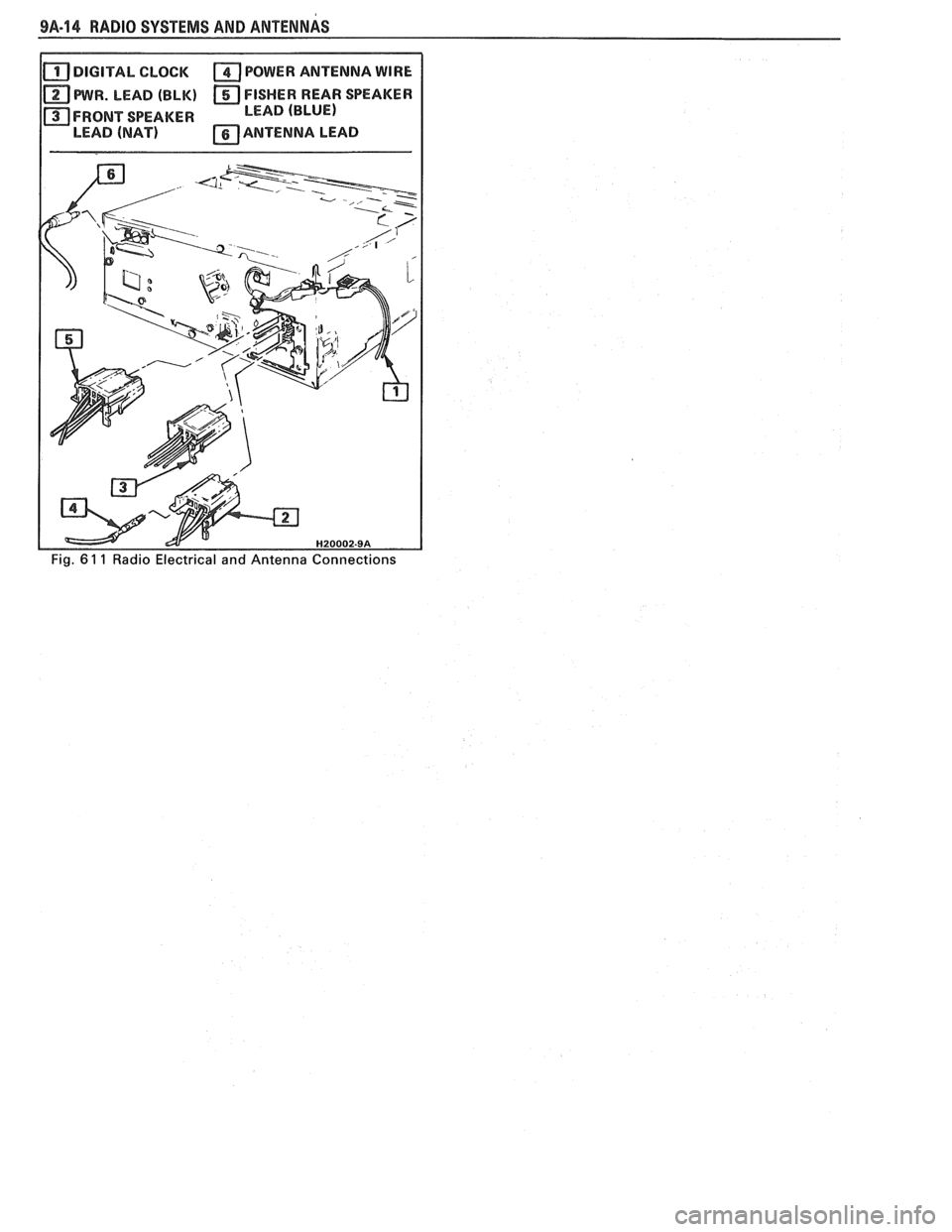

9A-14 RADIO SYSTEMS AND ANTENNAS

DIGITAL CLOCK POWER ANTENNA WIRE

PWR. LEAD (BLK) FISHER REAR SPEAKER

FRONT SPEAKER LEAD (BLUE)

LEAD

(NAT) ANTENNA LEAD

Page 1664 of 1825

CRUISE CONTROL 9B-1

SECTION 9B

SE CONTROL

CONTENTS

General Description ................................... 9B-1

Off/On/Resume/Accel Switch

Operation

................................................ 9B- 1

Set/Coast Button Switch .............................. 9B- 1

Electronic Controller (Module) .................... 9B-2

Servo Unit ..................................................... 9B-2

Speed Sensors ............................................. 9B-3

VSS Buffer Amplifier ................................ 9B-3

PM Generator Speed Signal ..................... 9B-3

Vacuum Supply ............................................. 9B -4

Electrical and Vacuum Release

Switches

..................................................... 9B-4

Electrical Harness ...................................... 9B-4

Diagnosis .................................................. 9B-4

Cruise System Surges .................................... 9B-4

Cruise Set Speed High or Low ..................... 9B-4

Excessive Cruise Speed Loss on Hills .......... 9B-4

Cruise Tap-Up and Tap-Down .................... 9B-4

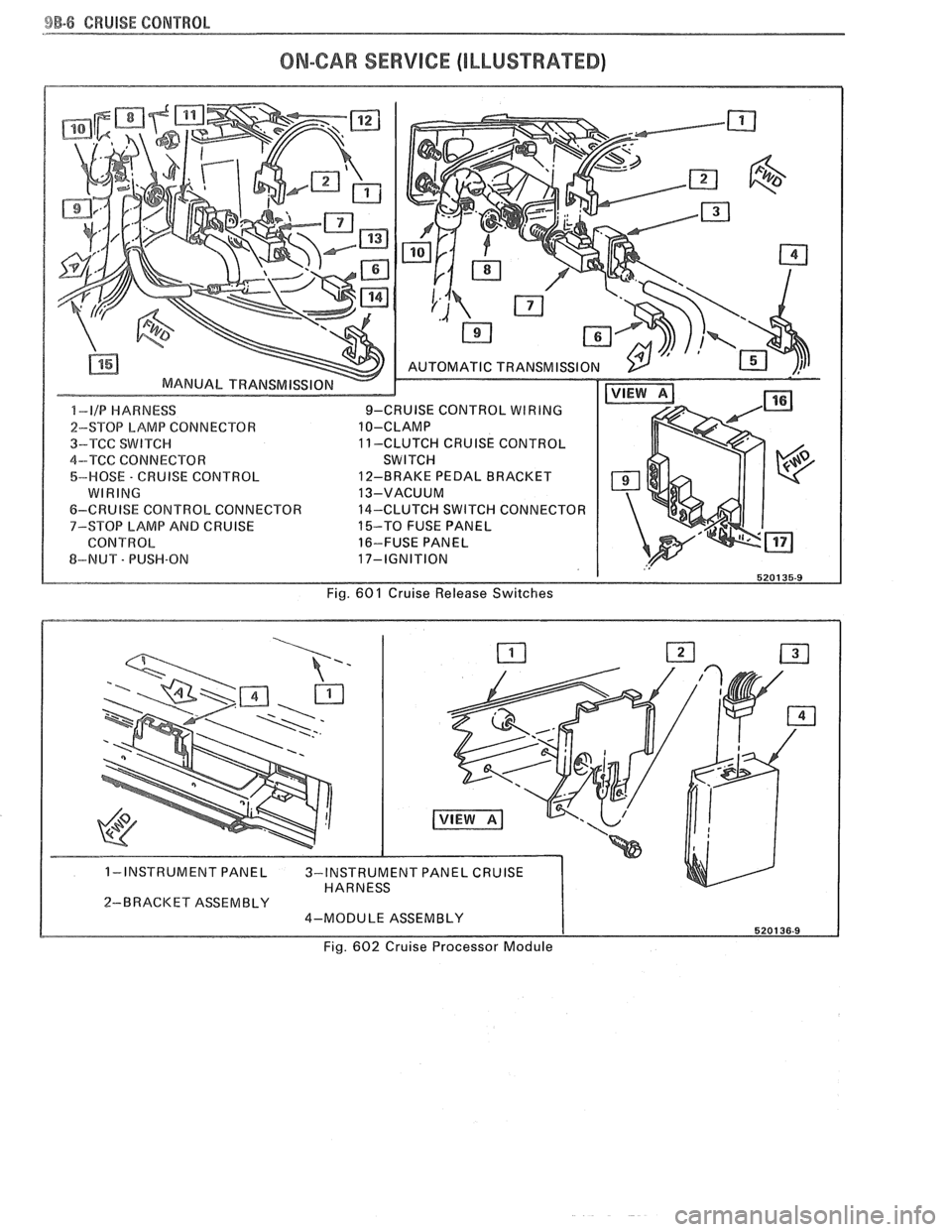

On-Gar Service (Illustrated) ..................... 9B-6

Cruise Release Switches ............................... 9B-6

............................. Cruise Processor Module 9B-6

Vacuum Harness and Cable Routing -

VIN E ..................................................... 9B-7

Vacuum Harness and Cable Routing -

VIN S ......................................................... 9B-8

Vacuum Harness and Cable Routing -

VIN F,8 ..................................................... 9B-9

Servo Mounting - VIN S,F .......................... 9B-10

....................... Servo and Bracket - VIN E 9B-10

Vacuum Tank - VIN S,F,E ....................... 9B-10

GENERAL DESCRIPTION

Cruise control is a speed control system which

maintains a desired car speed under normal driving

conditions. However, steep grades up or down may

cause variations in the selected speeds. The electronic

cruise control system has the capability to cruise, coast,

resume speed, accelerate, and "tap-up" and

" tap-down" .

The main parts of the cruise control system are

the mode control switches, controller (module), servo

unit, speed sensor, vacuum supply, electrical and

vacuum release switches, and electrical harness.

The cruise control system uses vacuum to operate

a throttle servo unit. The servo unit maintains a desired

car speed by trapping vacuum in the servo unit at the

proper servo position. The controller monitors vehicle

speed and servo position and operates the vacuum and

vent valves in the servo to maintain desired speed. The

controller contains a low speed limit which will prevent

system engagement below a minimum speed of about

25 mph. The operation of the controller is controlled

by mode control switches located in the end of the

directional signal lever. To disengage the system, two

release switches are provided. An electrical release

switch mounted on the brake pedal bracket (brake and

clutch pedal bracket on cars equipped with manual

transmission) disengages the system electrically when

the brake pedal (or clutch pedal) is depressed. A

vacuum release valve, mounted on the brake pedal

bracket, vents the trapped vacuum in the servo to

atmosphere when the brake pedal is depressed,

allowing the servo unit to quickly return the throttle

to idle position.

.

OFF/ON/RESUME/ACCEL SWITCH

(OPERATION)

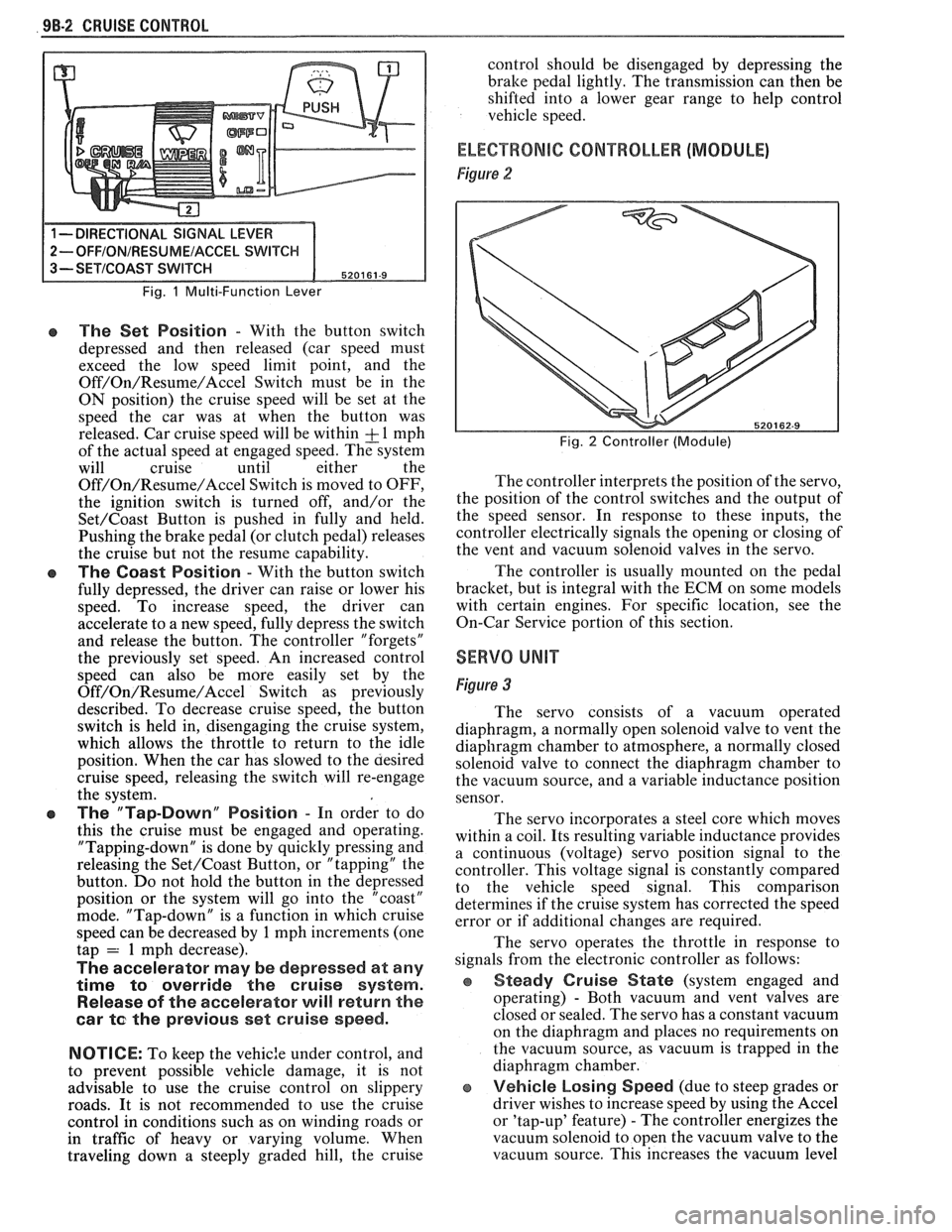

Figure 1

The Off/On/Resume/Accel Switch has three

positions. This switch turns the cruise control system

ON and OFF and also returns cruise control operation

to the last speed setting when MOMENTARILY

moved towards the R/A position after braking. (Do

not hold the slider in the R/A position

... release it

immediately.) If the slider is held in the R/A position

for more than one second, the system goes into the

Accel mode. To accelerate the car, move the slider

switch to the R/A position and hold it there until the

car reaches the desired speed. When the slider switch

is released, the system will maintain the new cruise

speed. In order to use the Accel mode, the cruise

OFF/ON/Resume/Accel switch must be in the "ON"

position and the car must be above the low speed limit

of

25 mph.

The slide switch can also be used to "tap-up" car

speed. In order to do this the cruise must be engaged

and operating. "Tapping-up" is done by quickly

pressing the slide switch toward the R/A position and

quickly releasing it, or "tapping" the lever. Do not hold

the lever in the R/A position or the system will go into

the Accel mode. "Tap-up" is a function in which cruise

speed can be increased by

1 mph increments (one tap

= 1 mph increase).

SET/COAST BUTTON SWITCH

Figure 1

The cruise control Set/Coast Switch (located in

the end of the turn signal lever) has two positions

-

"Normal" and "Depressed".

Page 1665 of 1825

98-2 CRUISE CONTROL

Fig. 1 Multi-Function Lever

e The Set Position - With the button switch

depressed and then released (car speed must

exceed the low speed limit point, and the

Off/On/Resume/Accel Switch must be in the

ON position) the cruise speed will be set at the

speed the car was at when the button was

released. Car cruise speed will be within

& 1 mph

of the actual speed at engaged speed. The system

will cruise until either the

Off/On/Resume/Accel Switch is moved to OFF,

the ignition switch is turned off, and/or the

Set/Coast Button is pushed in fully and held.

Pushing the brake pedal (or clutch pedal) releases

the cruise but not the resume capability.

The Coast Position - With the button switch

fully depressed, the driver can raise or lower his

speed. To increase speed, the driver can

accelerate to a new speed, fully depress the switch

and release the button. The controller "forgets"

the previously set speed. An increased control

speed can also be more easily set by the

Off/On/Resume/Accel Switch as previously

described. To decrease cruise speed, the button

switch is held in, disengaging the cruise system,

which allows the throttle to return to the idle

position. When the car has slowed to the aesired

cruise speed, releasing the switch will re-engage

the system.

e The "Tap-Down" Position - In order to do

this the cruise must be engaged and operating.

"Tapping-down" is done by quickly pressing and

releasing the

Set/Coast Button, or "tapping" the

button. Do not hold the button in the depressed

position or the system will go into the "coast"

mode. "Tap-down" is a function in which cruise

speed can be decreased by

1 mph increments (one

tap = 1 mph decrease).

The accelerator may be depressed at any

time

to override the cruise system.

Release of the accelerator will return the

car

te the previous set cruise speed.

NOTICE:

To keep the vehic:e under control, and

to prevent possible vehicle damage, it is not

advisable to use the cruise control on slippery

roads. It is not recommended to use the cruise

control in conditions such as on winding roads or

in traffic of heavy or varying volume. When

traveling down

a steeply graded hill, the cruise control

should be disengaged by depressing the

bralte pedal lightly. The transmission can then be

shifted into a lower gear range to help control

vehicle speed.

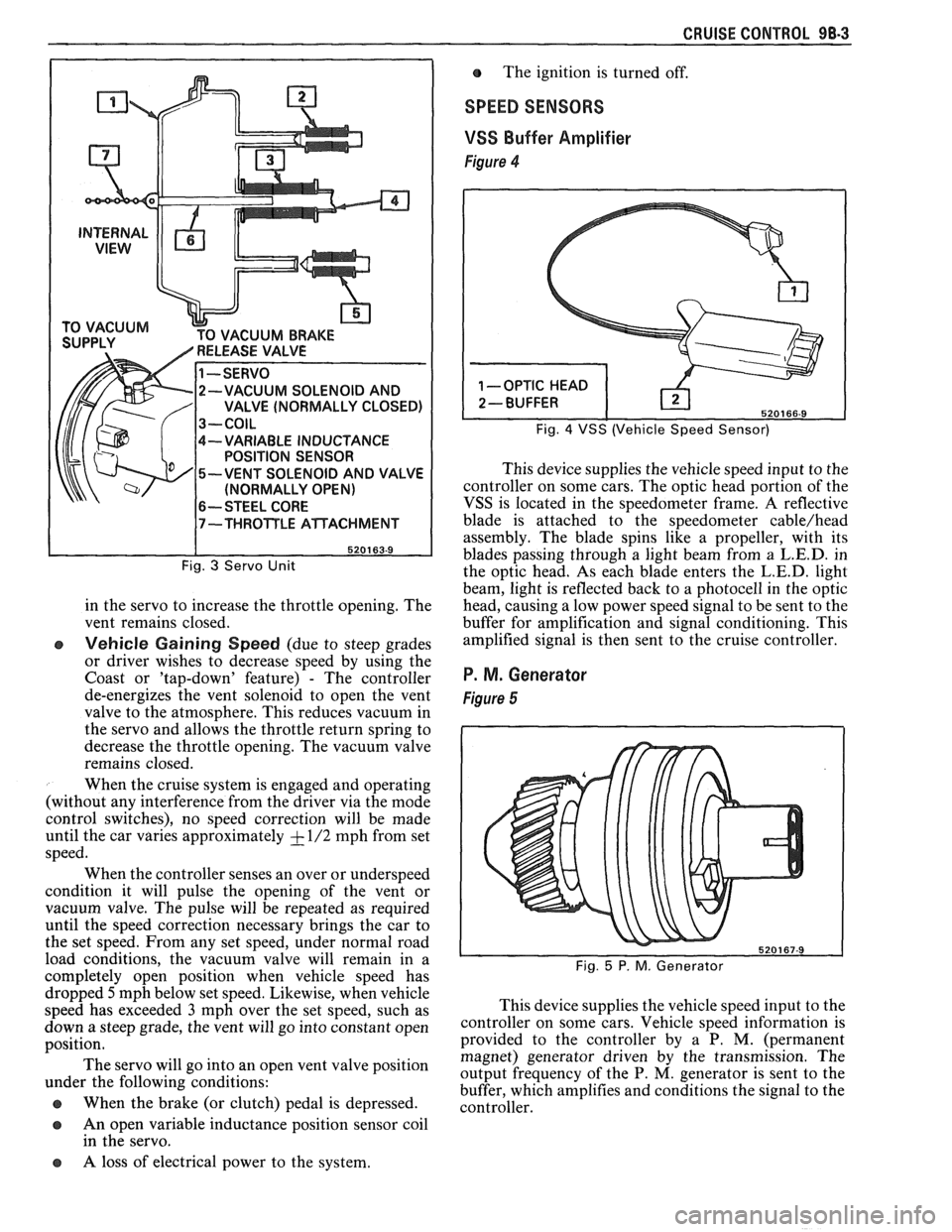

ELECTRONIC CONTROLLER (MODULE)

Figure 2

Fig. 2 Controller (Module)

The controller interprets the position of the servo,

the position of the control switches and the output of

the speed sensor. In response to these inputs, the

controller electrically signals the opening or closing of

the vent and vacuum solenoid valves in the servo.

The controller is usually mounted on the pedal

bracket, but is integral with the ECM on some models

with certain engines. For specific location, see the

On-Car Service portion of this section.

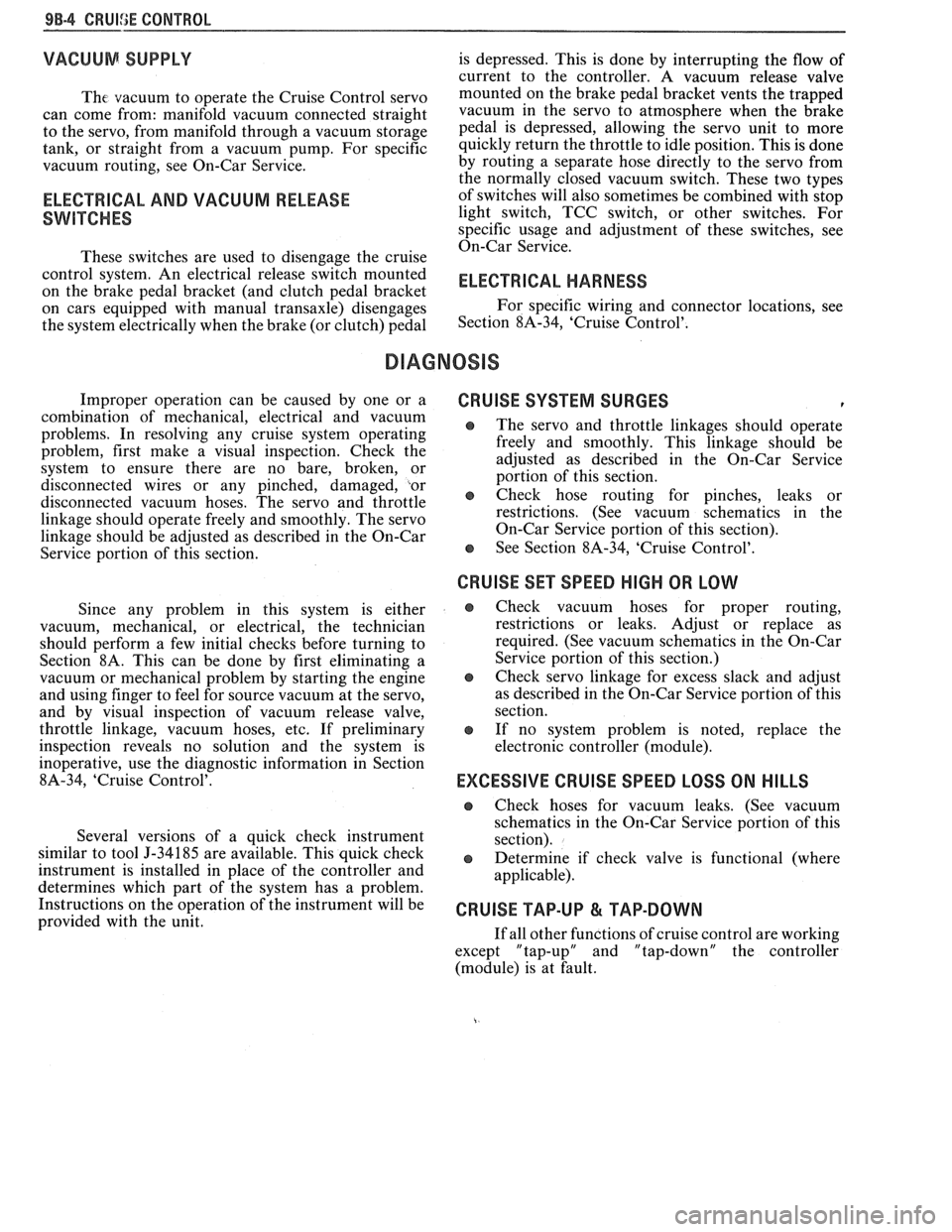

SERVO UNIT

Figure 3

The servo consists of a vacuum operated

diaphragm, a normally open solenoid valve to vent the

diaphragm chamber to atmosphere, a normally closed

solenoid valve to connect the diaphragm chamber to

the vacuum source, and a variable inductance position

sensor.

The servo incorporates a steel core which moves

within a coil. Its resulting variable inductance provides

a continuous (voltage) servo position signal to the

controller. This voltage signal is constantly compared

to the vehicle speed signal. This comparison

determines if the cruise system has corrected the speed

error or if additional changes are required.

The servo operates the throttle in response to

signals from the electronic controller as follows:

Steady Cruise State (system engaged and

operating)

- Both vacuum and vent valves are

closed or sealed. The servo has a constant vacuum

on the diaphragm and places no requirements on

the vacuum source, as vacuum is trapped in the

diaphragm chamber.

e Vehicle Losing Speed (due to steep grades or

driver wishes to increase speed by using the Accel

or 'tap-up' feature)

- The controller energizes the

vacuum solenoid to open the vacuum valve to the

vacuum source. This increases the vacuum level

Page 1666 of 1825

CRUISE CONTROL 98-3

CUUM BRAKE

-VARIABLE INDUCTANCE

POSITION SENSOR

-VENT SOLENOID AND VALVE

(NORMALLY OPEN)

6-- STEEL CORE

Fig. 3 Servo Unit

in the servo to increase the throttle opening. The

vent remains closed.

e Vehicle Gaining Speed (due to steep grades

or driver wishes to decrease speed by using the

Coast or 'tap-down' feature)

- The controller

de-energizes the vent solenoid to open the vent

valve to the atmosphere. This reduces vacuum in

the servo and allows the throttle return spring to

decrease the throttle opening. The vacuum valve

remains closed.

When the cruise system is engaged and operating

(without any interference from the driver via the mode

control switches), no speed correction will be made

until the car varies approximately

+ - 1/2 mph from set

speed.

When the controller senses an over or underspeed

condition it will pulse the opening of the vent or

vacuum valve. The pulse will be repeated as required

until the speed correction necessary brings the car to

the set speed. From any set speed, under normal road

load conditions, the vacuum valve will remain in a

completely open position when vehicle speed has The

ignition is turned off.

SPEED SENSORS

VSS

Buffer Amplifier

Figure 4

Fig. 4 VSS (Vehicle Speed Sensor)

This device supplies the vehicle speed input to the

controller on some cars. The optic head portion of the

VSS is located in the speedometer frame. A reflective

blade is attached to the speedometer

cable/head

assembly. The blade spins like a propeller, with its

blades passing through a light beam from a

L.E.D. in

the optic head. As each blade enters the

L.E.D. light

beam, light is reflected back to a photocell in the optic

head, causing a low power speed signal to be sent to the

buffer for amplification and signal conditioning. This

amplified signal is then sent to the cruise controller.

P. M. Generator

Figure 5

dropped 5mph below set speed. Likewise, when vehicle

speed has exceeded

3 mph over the set speed, such as This

device supplies the vehicle speed input to the

down a steep grade, the vent will go into ,-onstant open ~0ntI-011er on some cars. Vehicle speed information is

position. provided

to the controller by a P. M. (permanent

magnet) generator driven by the transmission. The

The servo go into an 'Pen vent position output frequency of the P. M, generator is sent to the under the following conditions:

buffer, which amplifies and conditions the signal to the

@ When the brake (or clutch) pedal is depressed. controller.

a An open variable inductance position sensor coil

in the servo.

a A loss of electrical power to the system.

Page 1667 of 1825

VACUUM SUPPLY

Tht vacuum to operate the Cruise Control servo

can come from: manifold vacuum connected straight

to the servo, from manifold through a vacuum storage

tank, or straight from a vacuum pump. For specific

vacuum routing, see On-Car Service.

ELECTRICAL AND VACUUM RELEASE

SWITCHES

These switches are used to disengage the cruise

control system. An electrical release switch mounted

on the brake pedal bracket (and clutch pedal bracket

on cars equipped with manual transaxle) disengages

the system electrically when the brake (or clutch) pedal is

depressed. This is done by interrupting the flow of

current to the controller. A vacuum release valve

mounted on the brake pedal bracket vents the trapped

vacuum in the servo to atmosphere when the brake

pedal is depressed, allowing the servo unit to more

quickly return the throttle to idle position. This is done

by routing a separate hose directly to the servo from

the normally closed vacuum switch. These two types

of switches will also sometimes be combined with stop

light switch, TCC switch, or other switches. For

specific usage and adjustment of these switches, see

On-Car Service.

ELECTRICAL HARNESS

For specific wiring and connector locations, see

Section

8A-34, 'Cruise Control'.

Improper operation can be caused by one or a

CRUISE SYSTEM SURGES t combination of mechanical, electrical and vacuum The servo and throttle linkages should operate problems. In resolving any cruise system operating

problem, first make a visual inspection. Check the freely

and smoothly. This linkage should be

system to ensure there are no bare, broken, or adjusted

as described in the On-Car Service

disconnected wires or any pinched, damaged,

-or portion of this section.

disconnected vacuum hoses. The servo and throttle

e Check hose routing for pinches, leaks or

linkage should operate freely and smoothly. The servo restrictions.

(See vacuum schematics in the

linkage should be adjusted as described in the On-Car On-Car

Service portion of this section).

Service portion of this section. See

Section

8A-34, 'Cruise Control'.

CRUISE SET SPEED HIGH OR LOW

Since any problem in this system is either

vacuum, mechanical, or electrical, the technician

should perform a few initial checks before turning to

Section

8A. This can be done by first eliminating a

vacuum or mechanical problem by starting the engine

and using finger to feel for source vacuum at the servo,

and by visual inspection of vacuum release valve,

throttle linkage, vacuum hoses, etc. If preliminary

inspection reveals no solution and the system is

inoperative, use the diagnostic information in Section

8A-34, 'Cruise Control'.

Several versions of a quick check instrument

similar to tool 5-34185 are available. This quick check

instrument is installed in place of the controller and

determines which part of the system has a problem.

Instructions on the operation of the instrument will be

provided with the unit. Check vacuum hoses for

proper routing,

restrictions or leaks. Adjust or replace as

required. (See vacuum schematics in the On-Car

Service portion of this section.)

e Check servo linkage for excess slack and adjust

as described in the On-Car Service portion of this

section.

s If no system problem is noted, replace the

electronic controller (module).

EXCESSIVE CRUISE SPEED LOSS ON HILLS

e Check hoses for vacuum leaks. (See vacuum

schematics in the On-Car Service portion of this

section).

e Determine if check valve is functional (where

applicable).

CRUISE TAP-UP & TAP-DOWN

If all other functions of cruise control are working

except "tap-up" and "tap-down" the controller

(module) is at fault.

Page 1668 of 1825

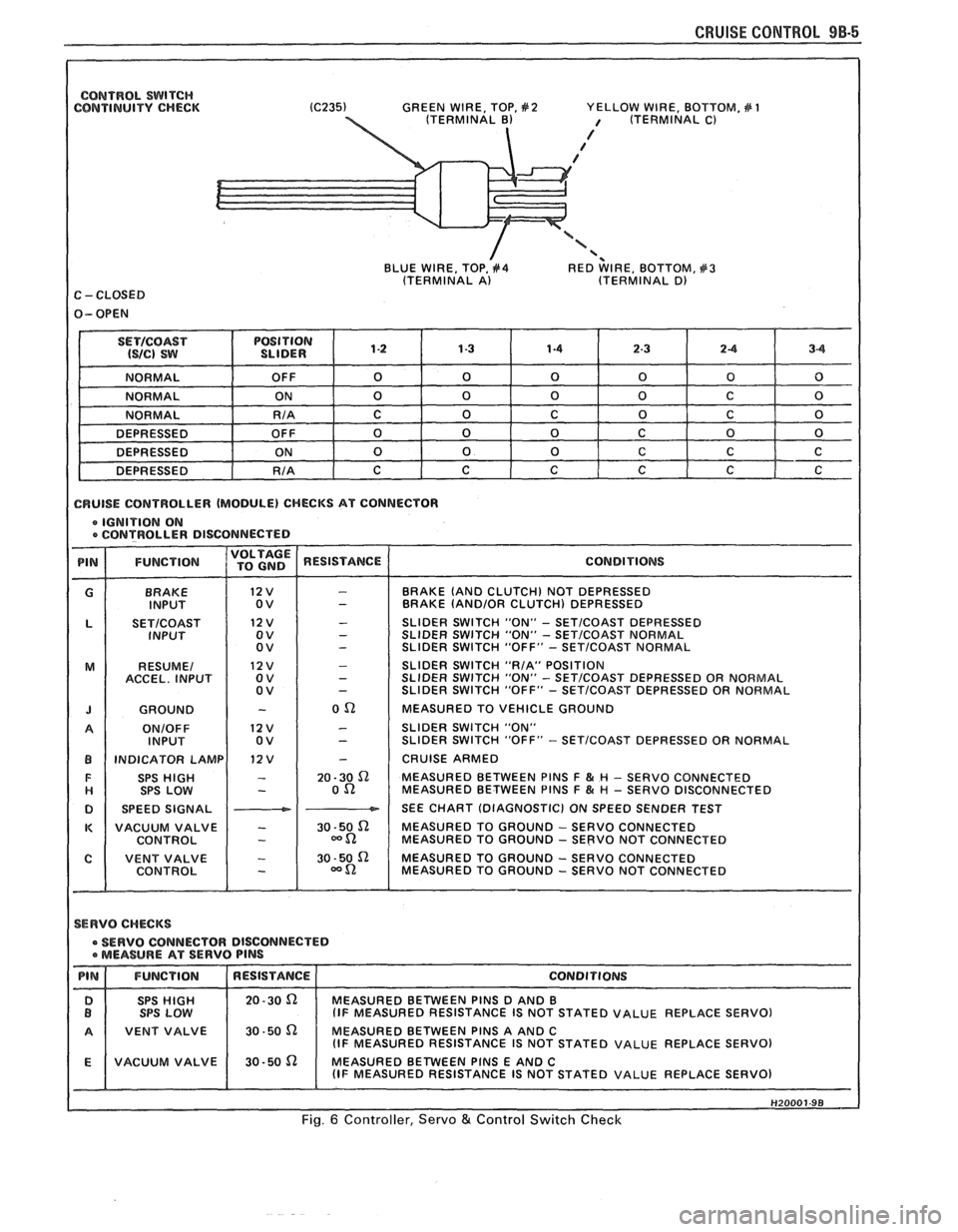

CONTROL SWITCH CONTINUITY CHECK GREEN

WIRE, TOP, #2 YELLOW WIRE, BOTTOM, # 1 / (TERMINAL C)

/ / /

'< BLUE WIRE, TOP, #4 RED WIRE, BOTTOM, #3 (TERMINAL A) (TERMINAL D) C - CLOSED

1 CRUISE CONTROLLER (MODULE) CHECKS AT CONNECTOR

e IGNITION ON e CONTROLLER DISCONNECTE D

BRAKE

INPUT

SETICOAST INPUT

RESUME1

ACCEL. INPUT

GROUND

ONIOFF INPUT

INDICATOR LAMP SPS

HIGH SPS LOW

SPEED SIGNAL

VACUUM VALVE

CONTROL

I

BRAKE (AND CLUTCH) NOT DEPRESSED

BRAKE (AND/OR CLUTCH) DEPRESSED

SLIDER SWITCH "ON"

- SETICOAST DEPRESSED

SLIDER SWITCH "ON" - SET/COAST NORMAL

SLIDER SWITCH "OFF" - SETICOAST NORMAL

SLIDER SWITCH "RIA" POSITION

SLIDER

SWITCH "ON" - SET/COAST DEPRESSED OR NORMAL

SLIDER SWITCH "OFF" - SETICOAST DEPRESSED OR NORMAL

MEASURED TO VEHICLE GROUND

SLIDER SWITCH "ON"

SLIDER SWITCH "OFF"

- SETICOAST DEPRESSED OR NORMAL

CRUISE ARMED

MEASURED BETWEEN PlNS

F & H - SERVO CONNECTED

MEASURED BETWEEN PlNS F & # - SERVO DISCONNECTED

SEE CHART (DIAGNOSTIC) ON SPEED SENDER TEST

MEASURED TO GROUND

- SERVO CONNECTED

MEASURED TO GROUND - SERVO NOT CONNECTED

MEASURED TO GROUND

- SERVO CONNECTED

MEASURED TO GROUND - SERVO NOT CONNECTED

1 SERVO CHECKS

SERVO CONNECTOR DISCONNECTED a MEASURE AT SERVO PlNS

STATED VALUE REPLACE SERVO)

1 A 1 VENT VALVE 1 30-50 n MEASURED BETWEEN PINS A AND C I (IF MEASURED RESISTANCE IS NOT STATED VALUE REPLACE SERVO)

Fig. 6 Controller, Servo & Control Switch Check

Page 1669 of 1825

BB-8 CRUISE CONTROL

ON-CAR SERVICE (ILLUSTRAEED)

2-BRACKET ASSEMBLY 4-MODULE ASSEMBLY

Fig. 602 Cruise Processor Module

Page 1670 of 1825

CRUISE CONTROL 9B-7

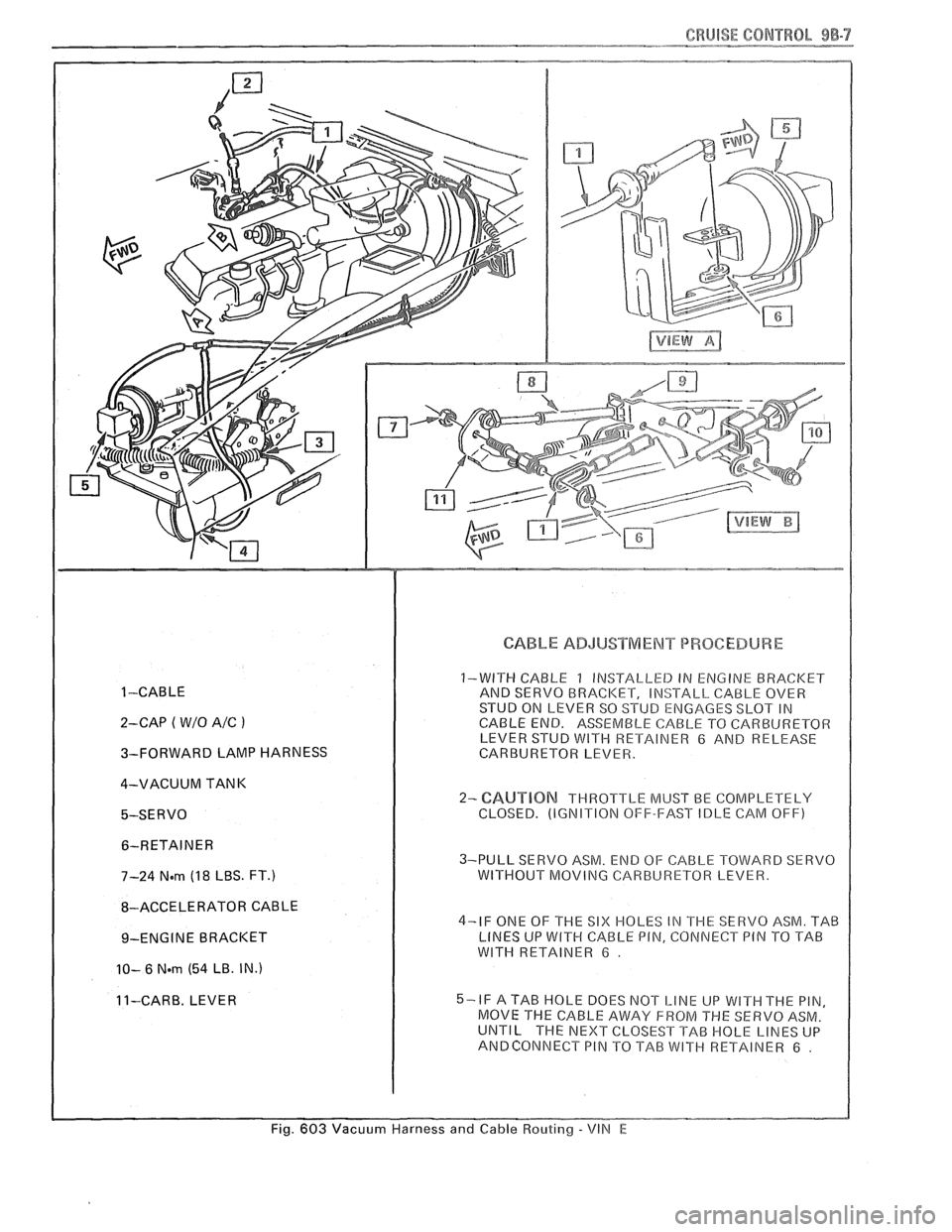

1 -CABLE

2-CAP

( W/O A/C )

3-FORWARD LAMP HARNESS

4-VACUUM TANK

5-SERVO 6-RETAINER

7-24

N.m (1 8 LBS. FT.)

8-ACCELERATOR CABLE

9-ENGINE BRACKET

10- 6 Nern (54 LB. IN.)

11-CARE. LEVER

CABLE ADJUSTMENT PROCEDURE

1-WITH CABLE 1 INSTALLED IN ENGINE BRACI

CABLE END. ASSEMBLE CABLE TO CARBIJRETOR LEVER STUB WITH RETAINER 6 AND RELEASE

CARBURETOR LEVER.

2- CAUT1BN THROTTLE MUST BE COMPLETELY

CLOSED. (IGNITION OFF-FAST IDLE CAM OFF)

3-PULL SERVO ASM. END OF CABLE TOWARD SERVO

WITHOUT MOVING CARBURETOR LEVER.

4-IF ONE OF THE

SIX HOLES IN THE SERVO ASM. TAB

LINES UP WlTH CABLE PIN, CONNECT PIN TO TAB

WlTH RETAINER 6 .

5-IF A TAB HOLE DOES NOT LINE UP WITH THE PIN,

MOVE THE CABLE AWAY FROM

THE SERVO ASM. UNTIL THE NEXT CLOSEST TAB HOLE LINES UP

ANBCONNECT PIN TO TAB WITH RETAINER 6 .

Fig. 603 Vacuum Harness and Cable Routing - VIN E