PONTIAC FIERO 1988 Service Repair Manual

Manufacturer: PONTIAC, Model Year: 1988, Model line: FIERO, Model: PONTIAC FIERO 1988Pages: 1825, PDF Size: 99.44 MB

Page 321 of 1825

Page 322 of 1825

DISC BRAKE CALIPER ASSEMBLY 586-1

SEC"619RI 5B6

SC BRAKE CAL PER ASSEMBLY

3548 SERIES

CONTENTS

General Description ................................. 5B6-2 Unit Repair ........................................... 5B6-5

On-Car Service ........................................ 5B6-2 Caliper Overhaul ....................................... 5B6-5

Caliper Assembly ....................................... 5B6-2

Parking Brake Adjustment ......................... 5B6-3

Shoe and Lining Assembly ......................... 5B6-4

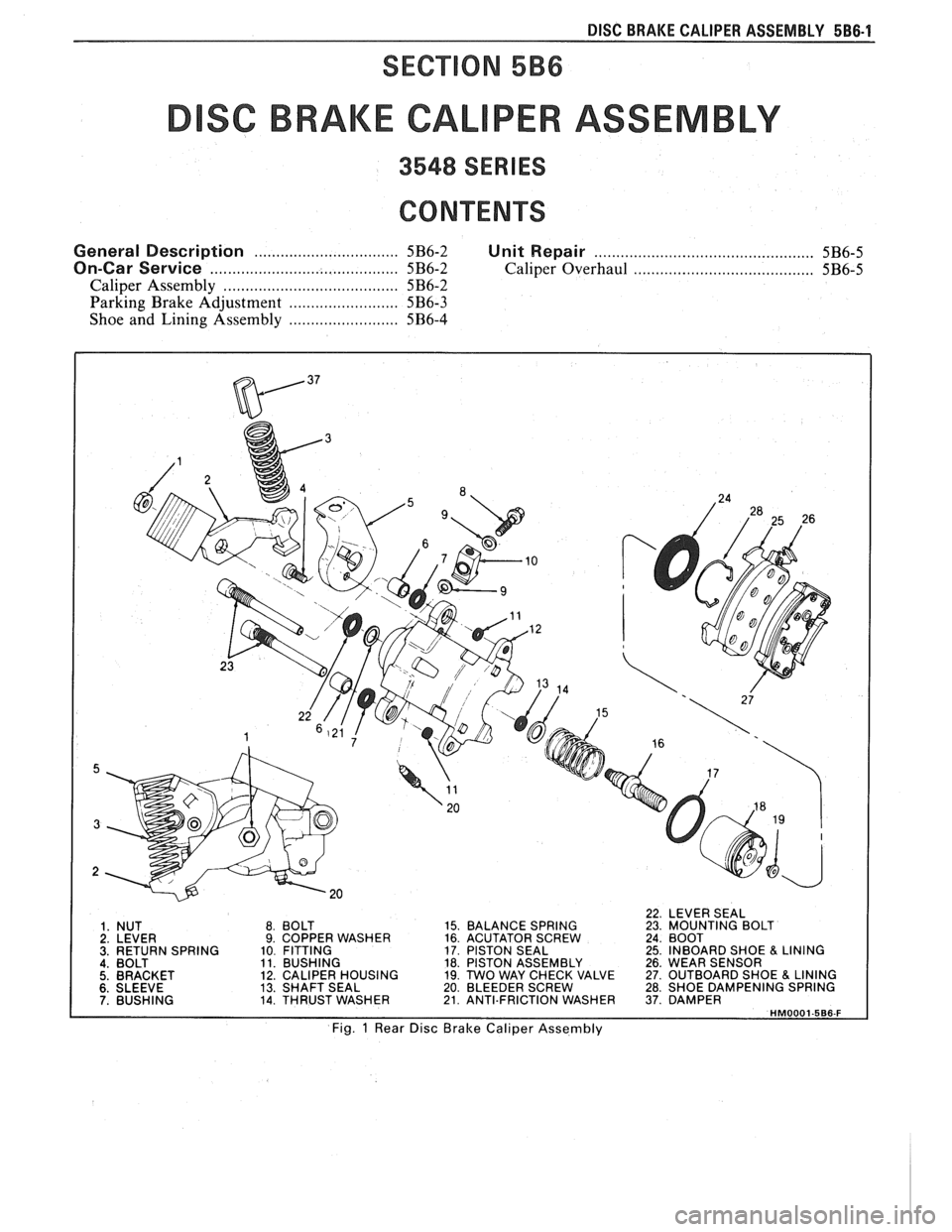

22 LEVER SEAL

1. NUT

2. LEVER

3. RETURN SPRING 4. BOLT 5. BRACKET 8.

BOLT 15.

BALANCE SPRING

23. MOUNT~NG BOLT 9. COPPER WASHER 16. ACUTATOR SCREW 24. BOOT

10 FITTING 17.

PISTON SEAL 25. INBOARD SHOE & LINING 11. BUSHING 18. PISTON ASSEMBLY 26. WEAR SENSOR

12. CALIPER HOUSING 19. TWO

WAY CHECK VALVE 27. OUTBOARD SHOE & LINING 6. SLEEVE 13. SHAFT SEAL 20. BLEEDER SCREW 28. SHOE DAMPENING SPRING 7. BUSHING 14. THRUST WASHER 21. ANTI.FRICTION WASHER 37. DAMPER HM0001-566-F

Fig. 1 Rear Disc Brake Caliper Assembly

Page 323 of 1825

586.2 DISC BRAKE CALIPER ASSEMBLY

GENERAL DESCRIPUON

This caliper has a single bore and is mounted to

the support bracket with two mounting bolts.

Hydraulic pressure, created by applying force to the

brake pedal, is converted by the caliper to a stopping

force. This force acts equally against the piston and the

bottom of the caliper bore to move the piston outward

and to move (slide) the caliper inward resulting in a

clamping action on the rotor. This clamping action

forces the linings against the rotor, creating friction to

stop the vehicle.

When the parking brake is applied, the lever turns

the actuator screw which is threaded into a nut in the

piston assembly. This causes the piston to move

outward and the caliper to slide inward mechanically,

forcing the linings against the rotor. The piston

assembly contains a self-adjusting mechanism to keep

the parking brake in proper adjustment.

NOTICE: Replace all components included in

repair kits used to service this caliper. Lubricate

rubber parts with clean brake fluid to ease

assembly. Do not

uhe lubricated shop air on brake

parts as damage to rubber components may result.

If any hydraulic

coniponent is removed or

disconnected,

it may he necessary to bleed all or

part of the brake system. Replace shoe and linings

in axle sets only. The torque values specified are

for dry,

unlubricated fasteners. Perform service

operations

011 a clean bench free from all mineral

oil materials.

ON-CAR SERVICE

CALIPER ASSEMBLY

Figures 2 thru 4

Remove or Disconnect

1. 2/3 of brake fluid from master cylinder assembly.

2. Raise car and suitably support.

e Mark relationship of wheel at axle flange.

3. Wheel and tire.

e Reinstall two lug liuts to retain rotor.

4. Loosen tension on parking brake cable at

equalizer.

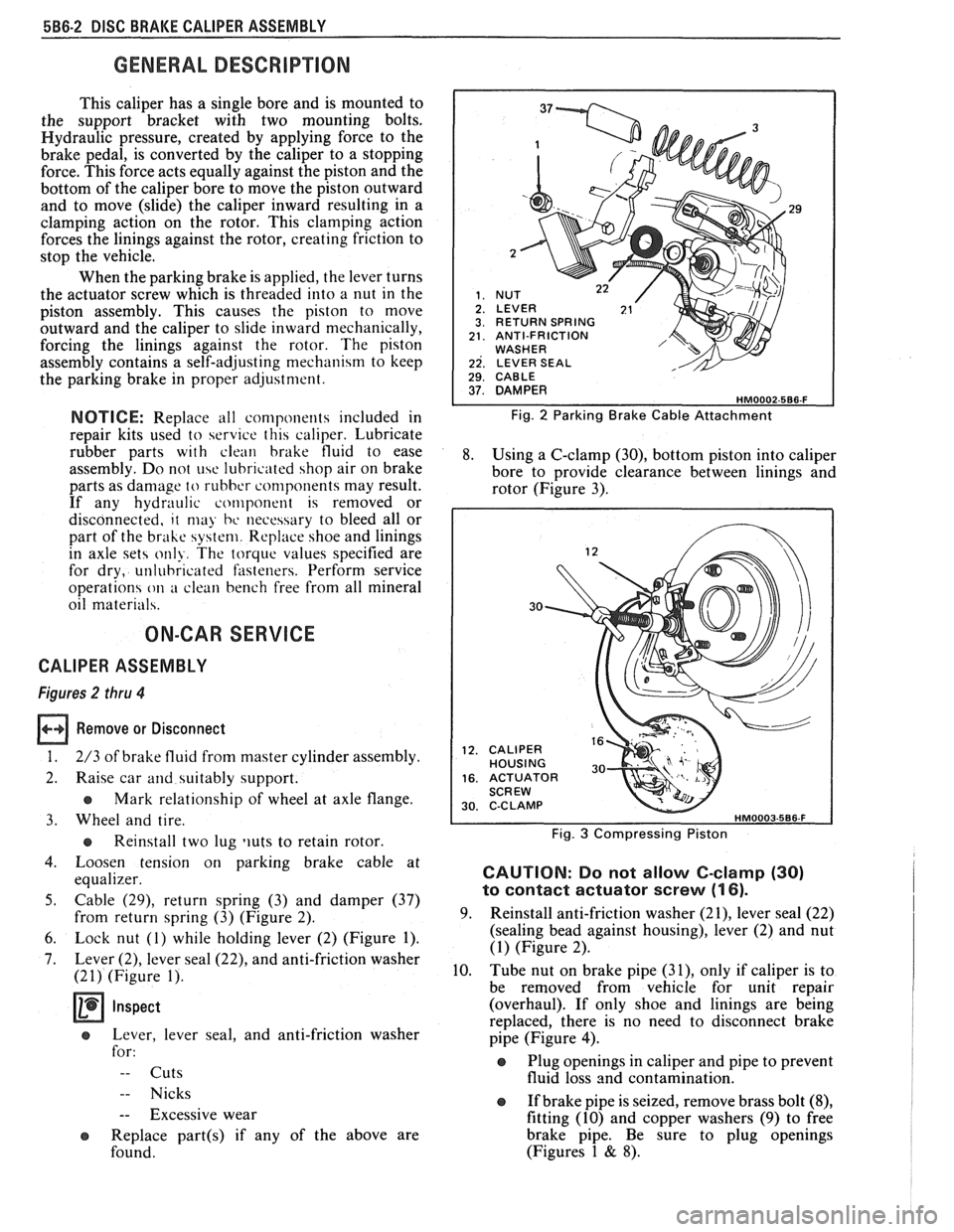

5. Cable (29), return spring (3) and damper (37)

from return spring (3) (Figure 2).

6. Lock nut (1) while holding lever (2) (Figure 1).

7. Lever (2), lever seal (22), and anti-friction washer

(21) (Figure 1).

Inspect

e Lever, lever seal, and anti-friction washer

for:

-- Cuts

-- Nicks

-- Excessive wear

e Replace part(s) if any of the above are

found.

29

RETURN SPRING ANTI-FRICTION WASHER LEVER SEAL 1 29. CABLE I

Fig. 2 Parking Brake Cable Attachment

8. Using a C-clamp (30), bottom piston into caliper

bore to provide clearance between linings and

rotor (Figure 3).

30

CALIPER HOUSING ACTUATOR SCREW C-C LAMP

Fig. 3 Compressing Piston

CAUTION: Do not allow C-clamp (30)

to contact actuator screw (1 6).

9. Reinstall anti-friction washer (21), lever seal (22)

(sealing bead against housing), lever (2) and nut

(1) (Figure 2).

10. Tube nut on brake pipe

(31), only if caliper is to

be removed from vehicle for unit repair

(overhaul). If only shoe and linings are being

replaced, there is no need to disconnect brake

pipe (Figure

4).

Plug openings in caliper and pipe to prevent

fluid loss and contamination.

If brake pipe is seized, remove brass bolt

(8),

fitting (10) and copper washers (9) to free

brake pipe. Be sure to plug openings

(Figures 1

& 8).

Page 324 of 1825

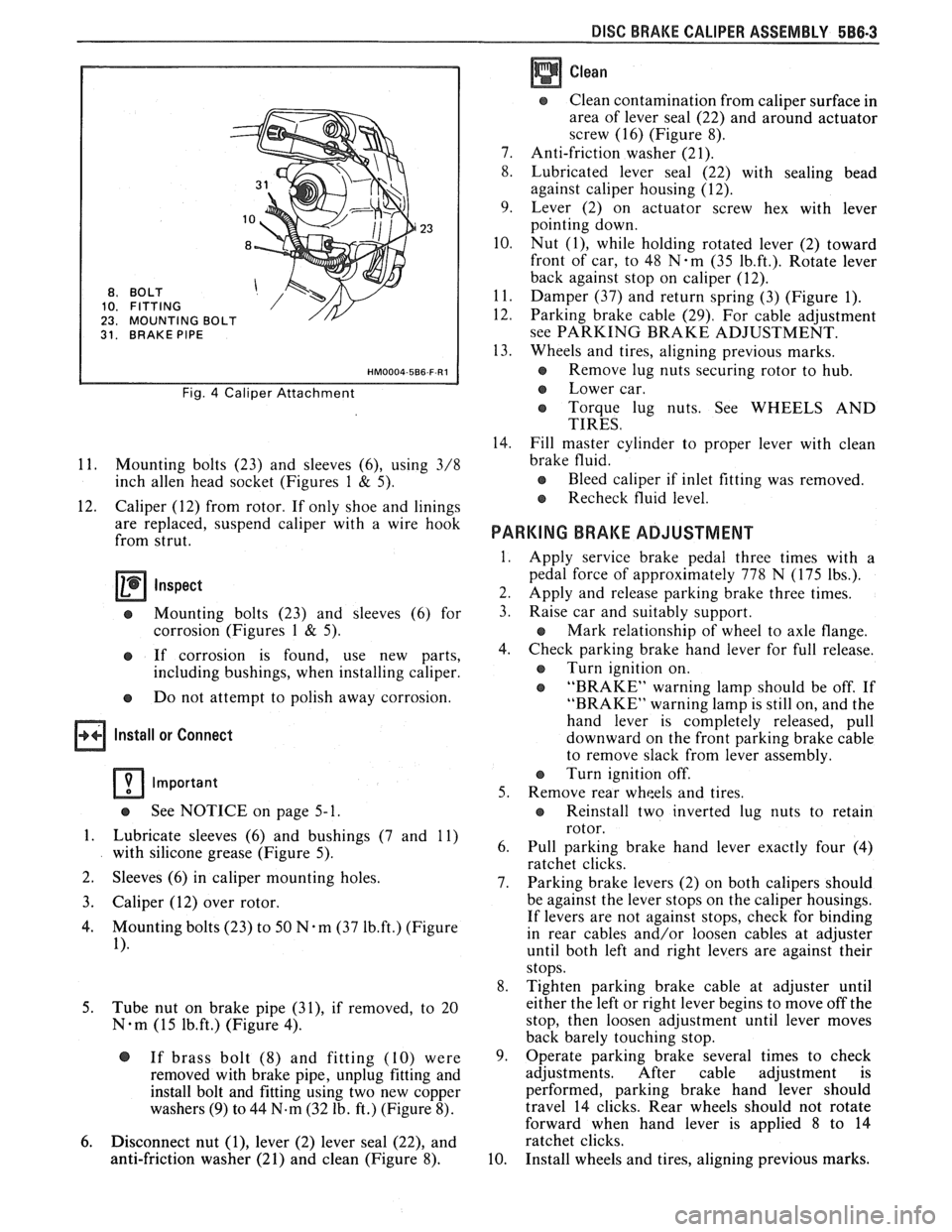

DISC BRAKE CALIPER ASSEMBLY 588-3

BO LT

FITTING

MOUNTING

31. BRAKE PIPE

Fig. 4 Caliper Attachment

11. Mounting bolts (23) and sleeves (6), using 3/8

inch

allen head socket (Figures 1 & 5).

12. Caliper (12) from rotor. If only shoe and linings

are replaced, suspend caliper with a wire hook

from strut.

Inspect

e Mounting bolts (23) and sleeves (6) for

corrosion (Figures

1 & 5).

e If corrosion is found, use new parts,

including bushings, when installing caliper.

e Do not attempt to polish away corrosion.

Install or Connect

Important

See NOTICE on page 5- 1.

1. Lubricate sleeves (6) and bushings (7 and 11)

with silicone grease (Figure 5).

2. Sleeves

(6) in caliper mounting holes.

3. Caliper (12) over rotor.

4. Mounting bolts (23) to 50 N-m (37 1b.ft.) (Figure

1).

5.

Tube nut on brake pipe (31), if removed, to 20

N-m (15 1b.ft.) (Figure 4).

@ If brass bolt (8) and fitting (10) were

removed with brake pipe, unplug fitting and

install bolt and fitting using two new copper

washers

(9) to 44 N.m (32 lb. ft.) (Figure 8).

6. Disconnect nut (I), lever (2) lever seal (22), and

anti-friction washer (21) and clean (Figure 8).

Clean

Clean contamination from caliper surface in

area of lever seal (22) and around actuator

screw (16) (Figure 8).

7. Anti-friction washer (21).

8. Lubricated lever seal (22) with sealing bead

against caliper housing (12).

9. Lever (2) on actuator screw hex with lever

pointing down.

10. Nut

(I), while holding rotated lever (2) toward

front of car, to 48

N-m (35 1b.ft.). Rotate lever

back against stop on caliper (12).

11. Damper (37) and return spring (3) (Figure 1).

12. Parking brake cable (29). For cable adjustment

see PARKING BRAKE ADJUSTMENT.

13. Wheels and tires, aligning previous marks.

s Remove lug nuts securing rotor to hub.

e Lower car.

e Torque lug nuts. See WHEELS AND

TIRES.

14. Fill master cylinder to proper lever with clean

brake fluid.

e Bleed caliper if inlet fitting was removed.

Recheck fluid level.

PARKING BRAKE ADJUSTMENT

Apply service brake pedal three times with a

pedal force of approximately 778 N (175 lbs.).

Apply and release parking brake three times.

Raise car and suitably support.

e Mark relationship of wheel to axle flange.

Check parking brake hand lever for full release.

e Turn ignition on.

e "BRAKE" warning lamp should be off. If

"BRAKE" warning lamp is still on, and the

hand lever is completely released, pull

downward on the front parking brake cable

to remove slack from lever assembly.

Turn ignition off.

Remove rear wheels and tires.

e Reinstall two inverted lug nuts to retain

rotor.

Pull parking brake hand lever exactly four (4)

ratchet clicks.

Parking brake levers (2) on both calipers should

be against the lever stops on the caliper housings.

If levers are not against stops, check for binding

in rear cables and/or loosen cables at adjuster

until both left and right levers are against their

stops.

Tighten parking brake cable at adjuster until

either the left or right lever begins to move off the

stop, then loosen adjustment until lever moves

back barely touching stop.

Operate parking brake several times to check

adjustments. After cable adjustment is

performed, parking brake hand lever should

travel 14 clicks. Rear wheels should not rotate

forward when hand lever is applied

8 to 14

ratchet clicks.

Install wheels and tires, aligning previous marks.

Page 325 of 1825

e Remove lug nuts securing rotor to hub.

e Lower car.

o Torque lug nuts. See WHEELS AND

TIRES.

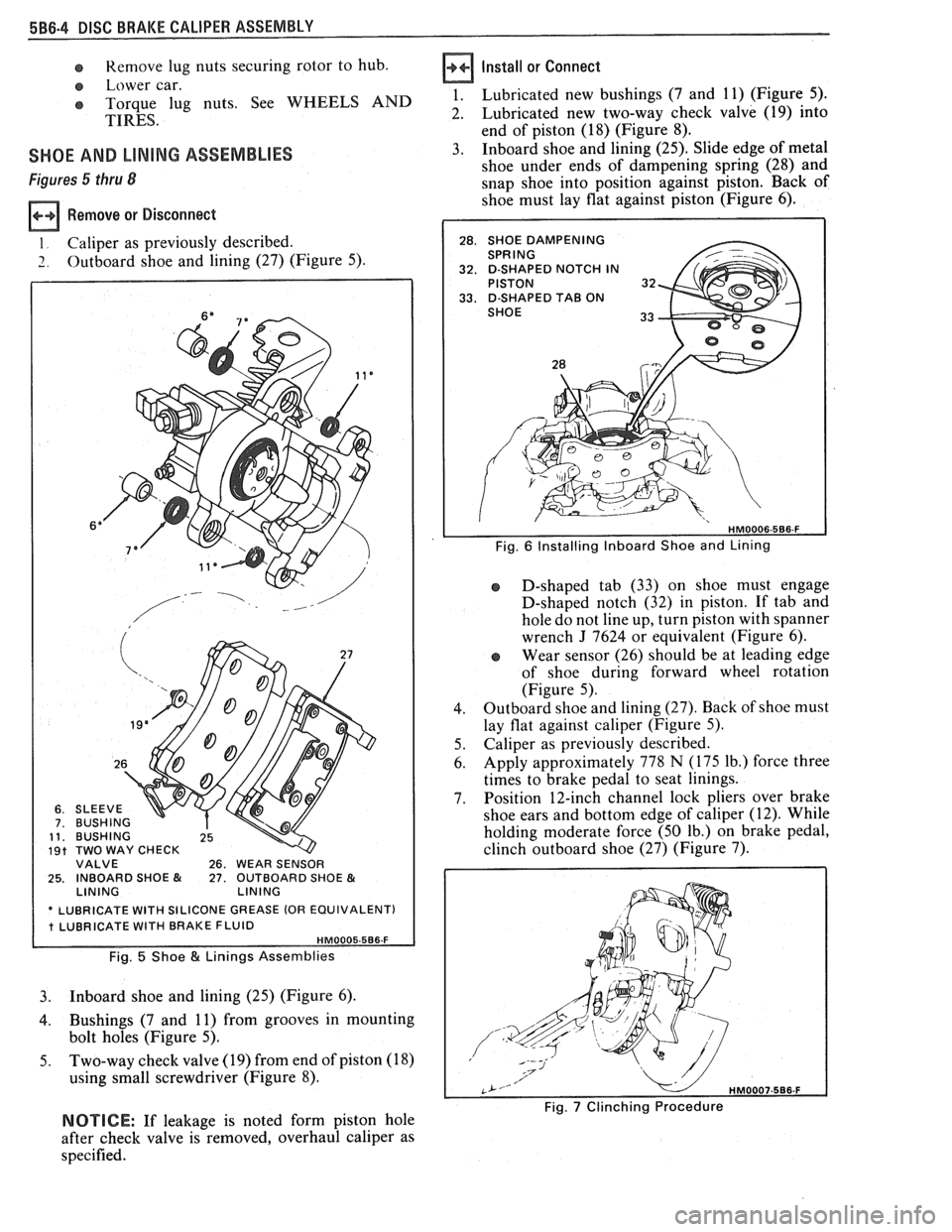

SHOE AND LINING ASSEMBLIES

Figures 5 thru 8

Remove or Disconnect

1. Caliper as previously described.

2 Outboard shoe and lining (27) (Figure 5).

Install or Connect

1. Lubricated new bushings (7 and 11) (Figure 5).

2. Lubricated new two-way check valve (19) into

end of piston (18) (Figure 8).

3. Inboard shoe and lining (25). Slide edge of metal

shoe under ends of dampening spring (28) and

snap shoe into position against piston. Back of

shoe must lay flat against piston (Figure 6).

Fig. 6 Installing Inboard Shoe and Lining

26. WEAR SENSOR 25. INBOARD SHOE & 27. OUTBOARD SHOE & LINING

ASE (OR EQUIVALENT)

Fig. 5 Shoe & Linings Assemblies

3. Inboard shoe and lining (25) (Figure 6).

4. Bushings (7 and 11) from grooves in mounting

bolt holes (Figure 5).

5. Two-way check valve (19) from end of piston (18)

using small screwdriver (Figure 8). D-shaped

tab (33) on shoe must engage

D-shaped notch (32) in piston. If tab and

hole do not line up, turn piston with spanner

wrench

J 7624 or equivalent (Figure 6).

r, Wear sensor (26) should be at leading edge

of shoe during forward wheel rotation

(Figure 5).

4. Outboard

shoe and lining (27). Back of shoe must

lay flat against caliper (Figure

5).

5. Caliper as previously described.

6. Apply approximately 778

N (175 lb.) force three

times to brake pedal to seat linings.

7. Position

12-inch channel lock pliers over brake

shoe ears and bottom edge of caliper (12). While

holding moderate force

(50 lb.) on brake pedal,

clinch outboard shoe (27) (Figure 7).

NOTICE: If leakage is noted form piston hole

after check valve is removed, overhaul caliper as

specified.

Page 326 of 1825

DISC BRAKE CALIPER ASSEMBLY 586.5 --

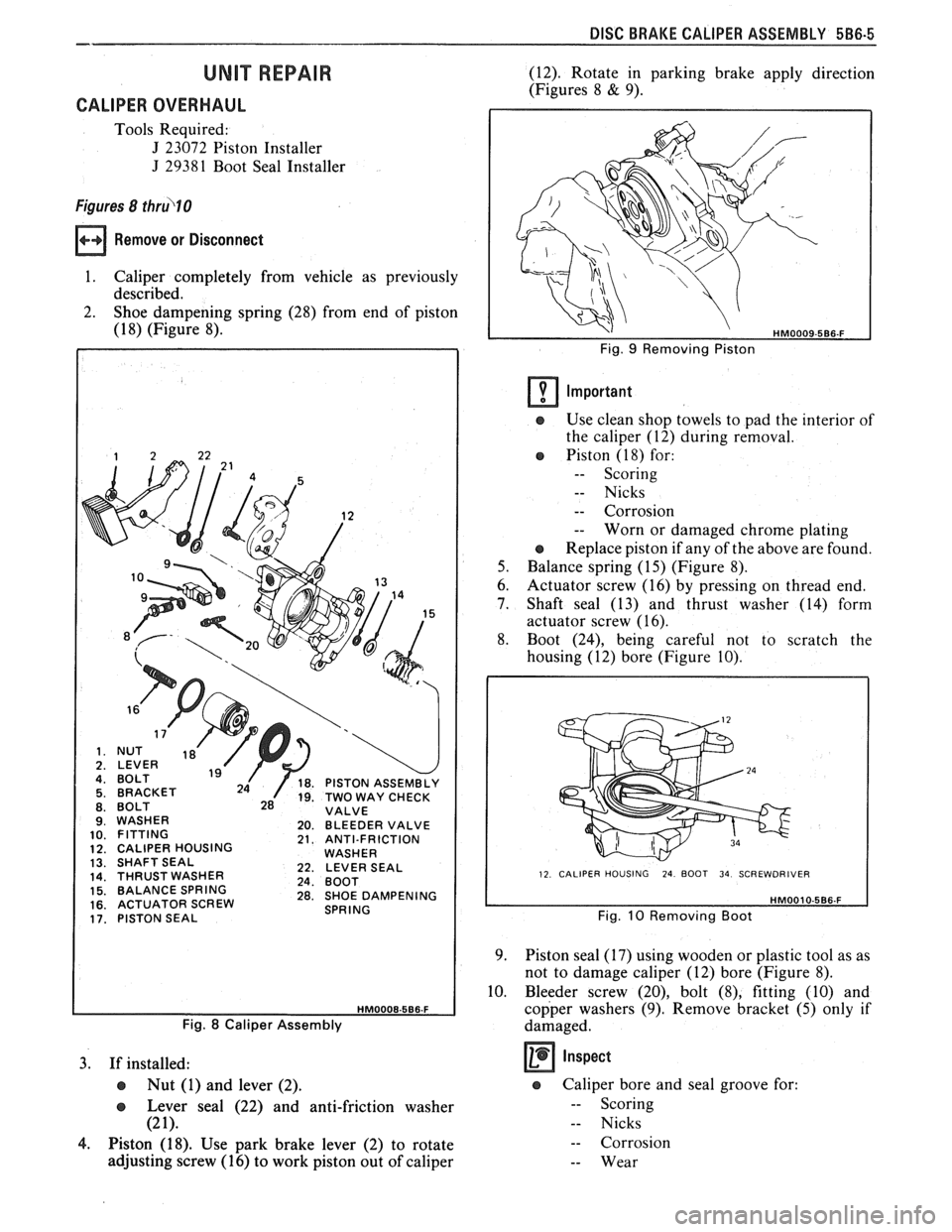

UNIT REPAIR

CALIPER OVERHAUL

Tools Required:

J 23072 Piston Installer

J 2938 1 Boot Seal Installer

Figures 8 thru'l0

Remove or Disconnect

1. Caliper completely from vehicle as previously

described.

2. Shoe dampening spring (28) from end of piston

(18) (Figure 8).

2. LEVER 4. BOLT

5. BRACKET

8. BOLT

9. WASHER

20. BLEEDER VALVE

10. FITTING

21. ANTI-FRICTION

12. CALIPER HOUSING

WASHER

13. SHAFT SEAL

22. LEVER SEAL

14. THRUST WASHER

15. BALANCE SPRING 24. BOOT

16. ACTUATOR SCREW 28.

SHOE DAMPENING

17. PISTON SEAL SPRING

Fig. 8 Caliper

Assembly

3. If installed:

a Nut (1) and lever (2).

a Lever seal (22) and anti-friction washer

(21).

4. Piston (18). Use park brake lever (2) to rotate

adjusting screw (16) to work piston out of caliper (12).

Rotate in parking brake apply direction

(Figures 8

& 9).

Fig. 9 Removing Piston

Important

a Use clean shop towels to pad the interior of

the caliper (12) during removal.

Piston (18) for:

-- Scoring

-- Nicks

-- Corrosion -- Worn or damaged chrome plating

e Replace piston if any of the above are found.

5. Balance spring (15) (Figure 8).

6. Actuator screw (16) by pressing on thread end.

7. Shaft seal (13) and thrust washer (14) form

actuator screw (16).

8. Boot

(24), being careful not to scratch the

housing (12) bore (Figure 10).

1

12 CALIPER HOUSING 24 BOOT 34 SCREWDRIVER

I

Fig. 10 Removing Boot

9.

Piston seal (17) using wooden or plastic tool as as

not to damage caliper (12) bore (Figure 8).

10. Bleeder screw

(20), bolt (8), fitting (10) and

copper washers (9). Remove bracket

(5) only if

damaged.

Inspect

Caliper bore and seal groove for:

-- Scoring

-- Nicks

-- Corrosion

-- Wear

Page 327 of 1825

5B6-6 DISC BRAKE CALIPER ASSEMBLY

e Use crocus cloth to polish out light

corrosion.

e Replace caliper housing if corrosion in and

around seal groove will not clean up with

crocus cloth.

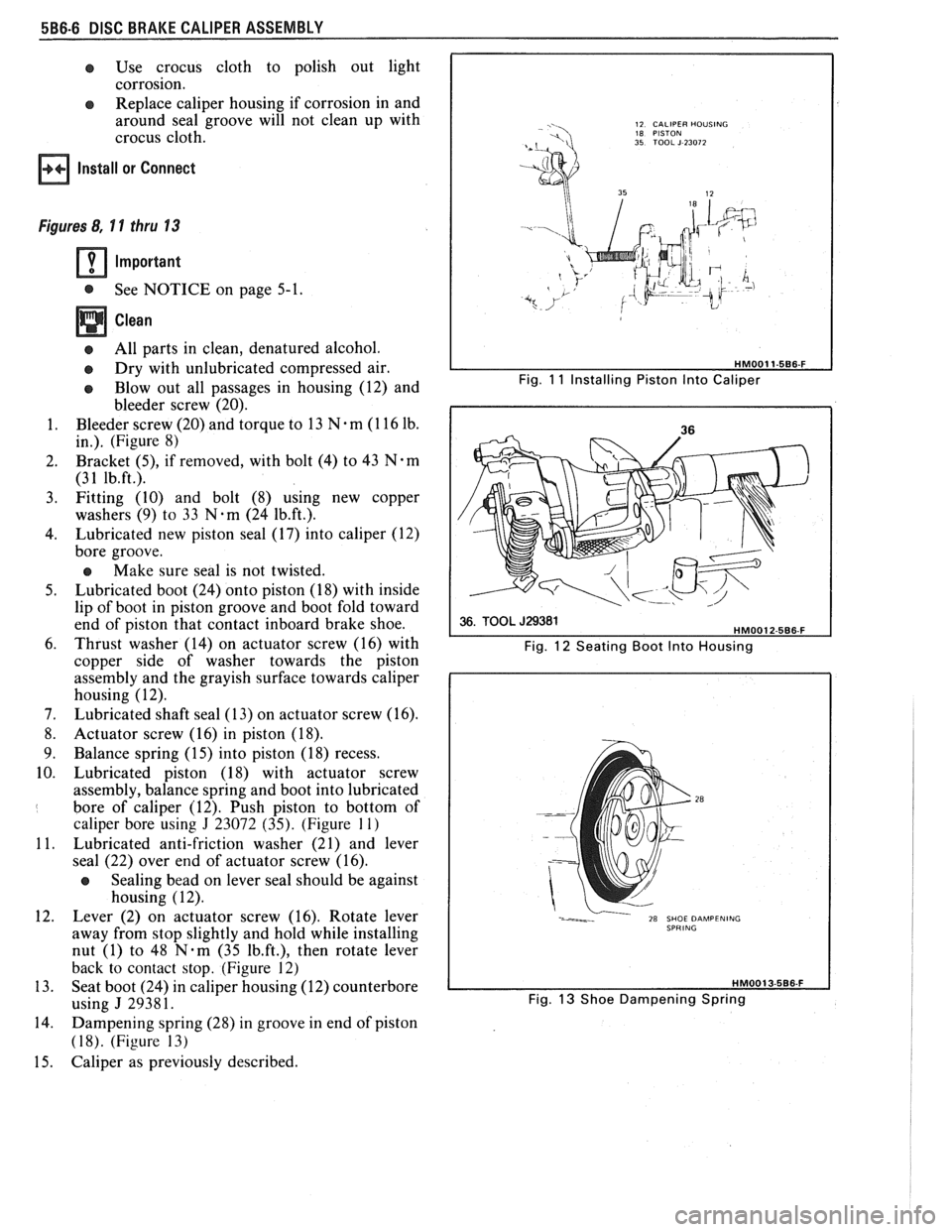

Install or Connect

Figures 8, 1 1 thru 13

Important - @ See NOTICE on page 5-1,

e All parts in clean, denatured alcohol.

e Dry with unlubricated compressed air.

e Blow out all passages in housing (12) and

bleeder screw (20).

Bleeder screw (20) and torque to 13 N

. m (1 16 lb.

in.). (Figure

8)

Bracket (5), if removed, with bolt (4) to 43 N-m

(3 1 1b.ft.).

Fitting (10) and bolt (8) using new copper

washers (9) to 33

N-m (24 1b.ft.).

Lubricated new piston seal (17) into caliper (12)

bore groove.

a Make sure seal is not twisted.

Lubricated boot (24) onto piston (1 8) with inside

lip of boot in piston groove and boot fold toward

end of piston that contact inboard brake shoe.

Thrust washer (14) on actuator screw (16) with

copper side of washer towards the piston

assembly and the grayish surface towards caliper

housing (12).

Lubricated shaft seal (13) on actuator screw (16).

Actuator screw (16) in piston (18).

Balance spring (15) into piston (18) recess.

Lubricated piston (18) with actuator screw

assembly, balance spring and boot into lubricated

bore of caliper (12). Push piston to bottom of

caliper bore using

J 23072 (35). (Figure 11)

Lubricated anti-friction washer (2 1) and lever

seal (22) over end of actuator screw (16).

a Sealing bead on lever seal should be against

housing

( 12).

Lever (2) on actuator screw (16). Rotate lever

away from stop slightly and hold while installing

nut (1) to 48

N-m (35 Ib.ft.), then rotate lever

back to contact stop. (Figure 12)

Seat boot (24) in caliper housing (12) counterbore

using

J 29381.

Dampening spring (28) in groove in end of piston

(1 8). (Figure 13)

Caliper as previously described.

12 CALIPER HOUSING

18 PISTON

35 TOOL J 23072

Fig. 11 Installing Piston lnto Caliper

Fig.

12 Seating Boot lnto Housing

Fig.

13 Shoe Dampening Spring

Page 328 of 1825

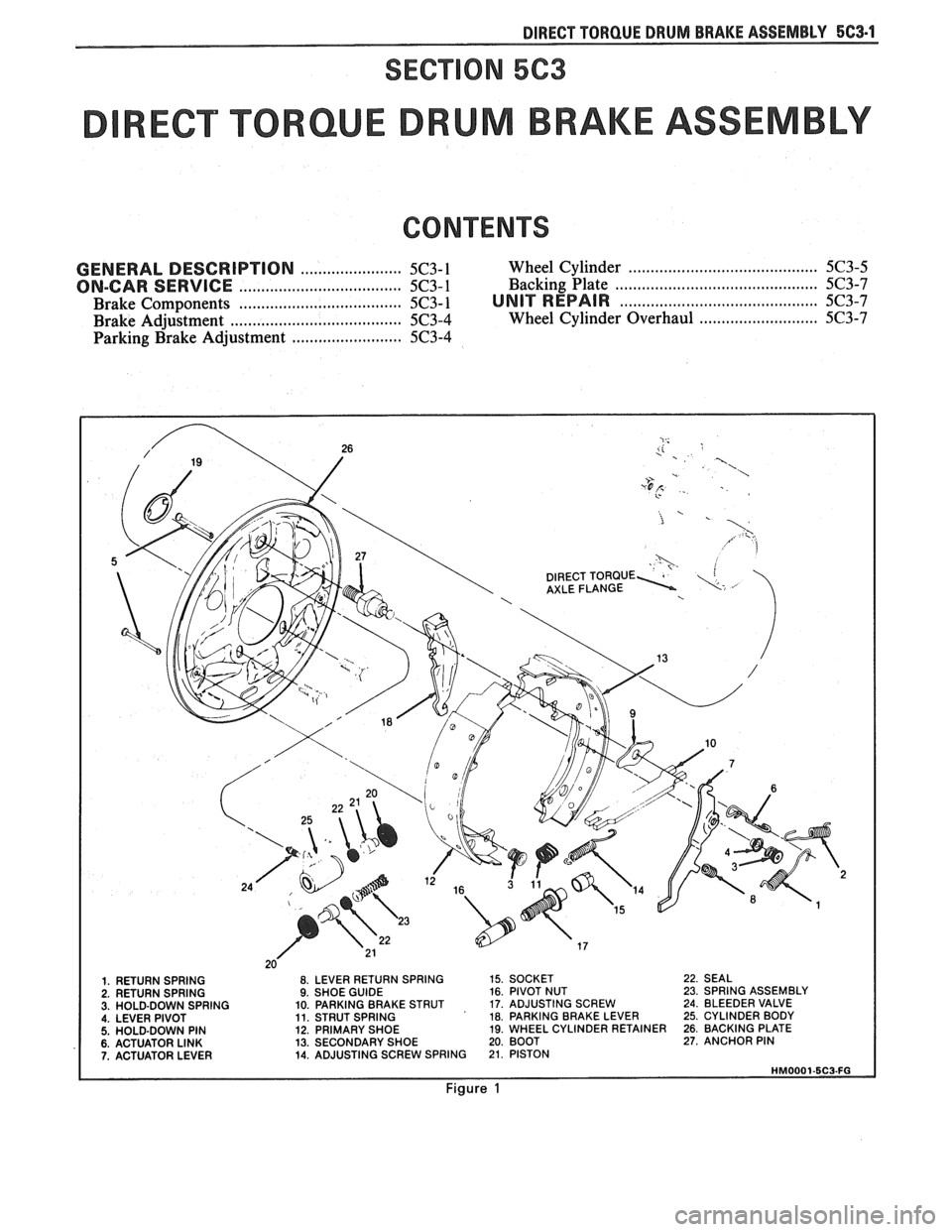

DIRECT TORQUE DRUM BRAKE ASSEMBLY 5C3-1

SECTION 5C3

RECT TORQUE DRUM BRAKE ASSEMBLY

CONTENTS

GENERAL DESCRIPTION ....................... 5C3-1 Wheel Cylinder ........................................ 5C3-5

ON-CAR SERVICE ................................... 5C3-1 Backing Plate ............................................ 5C3-7

Brake Components ................... .... ......... 5C3- 1 UNIT REPAIR ........................................... 5C3-7

Brake Adjustment ..................................... 5C3-4 Wheel Cylinder Overhaul .......................... 5C3-7

Parking Brake Adjustment ......................... 5C3-4

1. RETURN SPRING 8. LEVER RETURN SPRING 15. SOCKET 22. SEAL 2. RETURN SPRING 9. SHOE GUIDE 16. PIVOT NUT 23. SPRING ASSEMBLY 3. HOLD-DOWN SPRING 10. PARKING BRAKE STRUT . 17. ADJUSTING SCREW 24. BLEEDER VALVE 4. LEVER PIVOT 11. STRUT SPRING 18. PARKING BRAKE LEVER 25. CYLINDER BODY 5. HOLD.DOWN PIN 12. PRIMARY SHOE 19. WHEEL CYLINDER RETAINER 26. BACKING PLATE 6. ACTUATOR LINK 13. SECONDARY SHOE 20. BOOT 27. ANCHOR PIN 7. ACTUATOR LEVER 14. ADJUSTING SCREW SPRING 21. PISTON HM0001.5C3-FG

Figure 1

Page 329 of 1825

5C3-2 DIRECT TORQUE DRUM BRAKE ASSEMBLY

GENERAL DESCRIPTION

This drum brake asembly is a duo-servo, direct

torque design. In the duo-servo brake, the force which

the wheel cylinder applies to the primary shoe is

multiplied by the primary lining friction to provide a

very large force applied to the secondary shoe. With

the direct torque design, torque from the brake shoes

is transferred directly through the anchor pin to the

axle flange. Adjustment for both the primary and

secondary shoe and linings is automatic during reverse

brake applications.

Important

a Replace all components included in repair kits

used to service this drum brake.

a Lubricate parts as specified.

e Do not use lubricated shop air on brake parts as

damage to rubber components may result.

a If any hydraulic components is removed or

disconnected, it will be necessary to bleed all or

part of the brake system.

s Replace shoe and linings in axle sets only.

e The torque values specified are for dry,

unlubricated fasteners.

e Perform service operations on a clean bench free

from all mineral oil materials.

CAUTION: When servicing brake

parts, do not create dust by grinding or

sanding brake linings or by cleaning

wheel brake parts with a dry brush or

with compressed air.

A water

dampened cloth should be used.

Many

brake parts contain asbestos fibers

which can become airborne if dust is

created during servicing. Breathing

dust containing asbestos fibers may

cause serious bodily harm.

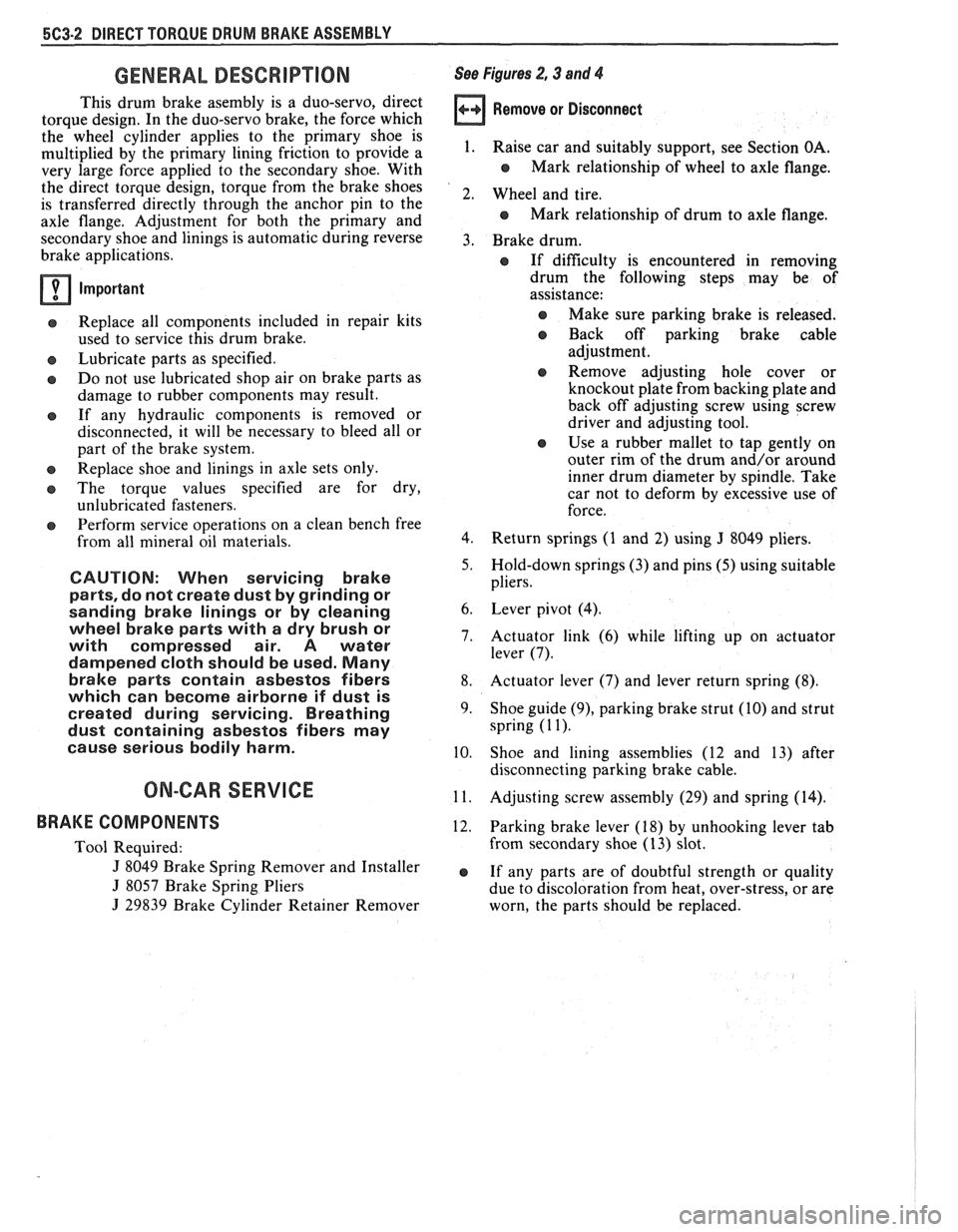

ON-CAR SERVICE

BRAKE COMPONENTS

Tool Required:

J 8049 Brake Spring Remover and Installer

J 8057 Brake Spring Pliers

J 29839 Brake Cylinder Retainer Remover

See Figures 2,3 and 4

Remove or Disconnect

1.

Raise car and suitably support, see Section OA.

e Mark relationship of wheel to axle flange.

2. Wheel and tire.

e Mark relationship of drum to axle flange.

3. Brake drum.

a If dificulty is encountered in removing

drum the following steps may be of

assistance:

@ Make sure parking brake is released.

a Back off parking brake cable

adjustment.

a Remove adjusting hole cover or

knockout plate from backing plate and

back off adjusting screw using screw

driver and adjusting tool.

a Use a rubber mallet to tap gently on

outer rim of the drum and/or around

inner drum diameter by spindle. Take

car not to deform by excessive use of

force.

4. Return springs (1 and 2) using

J 8049 pliers.

5. Hold-down springs (3) and pins (5) using suitable

pliers.

6. Lever pivot (4).

7. Actuator link (6) while lifting up on actuator

lever

(7).

8. Actuator lever (7) and lever return spring (8).

9.

Shoe guide (9), parking brake strut (10) and strut

spring

(1 1).

10. Shoe and lining assemblies (12 and 13) after

disconnecting parking brake cable.

11. Adjusting screw assembly (29) and spring (14).

12. Parking brake lever (18) by unhooking lever tab

from secondary shoe (13) slot.

e If any parts are of doubtful strength or quality

due to discoloration from heat, over-stress, or are

worn, the parts should be replaced.

Page 330 of 1825

DIRECT TORQUE DRUM BRAKE ASSEMBLY 5C3-3

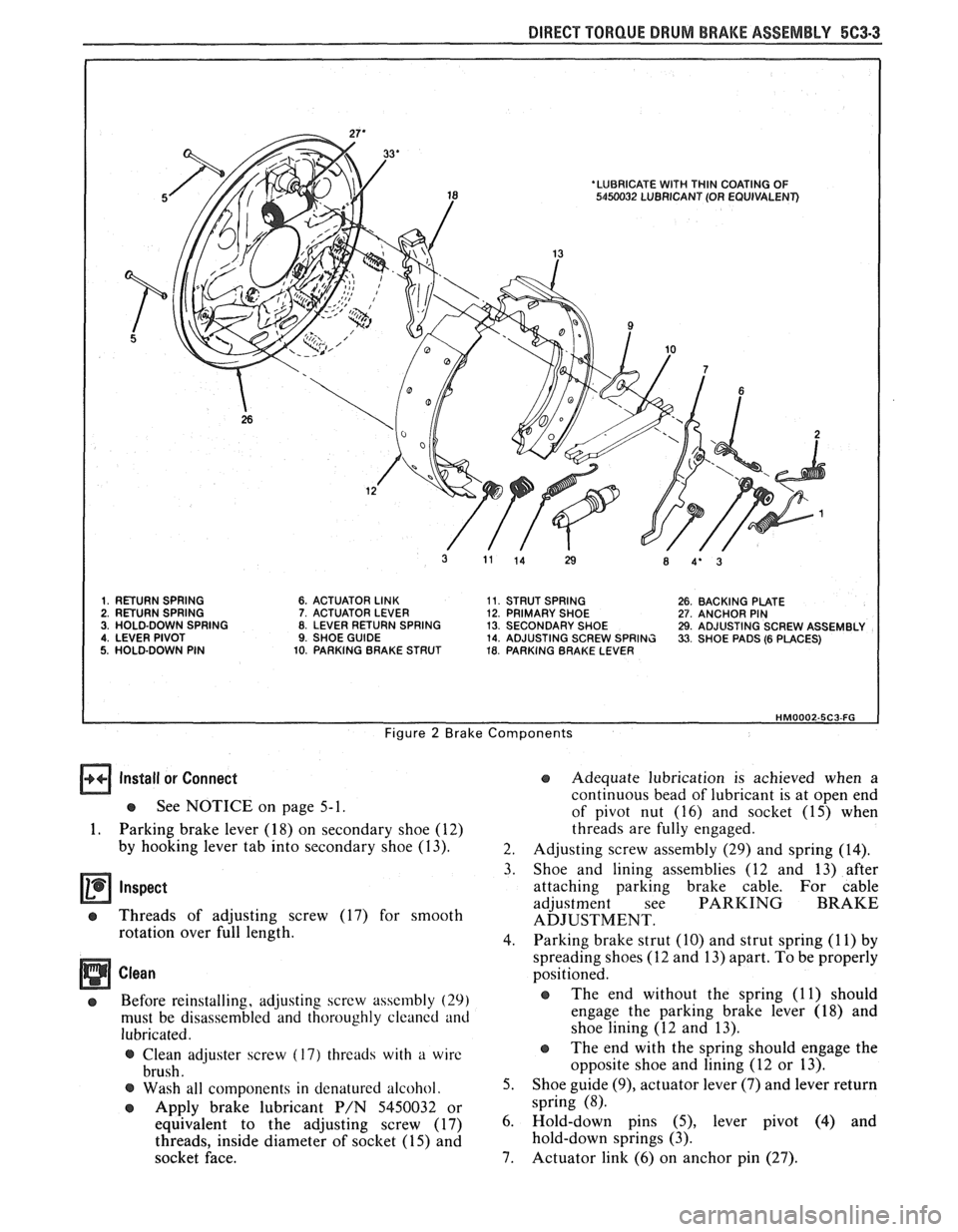

1. RETURN SPRING 6. ACTUATOR LINK 11. STRUT SPRING 26. BACKING PLATE 2. RETURN SPRING 7. ACTUATOR LEVER 12. PRIMARY SHOE 27. ANCHOR PIN 3. HOLD-DOWN SPRING 8. LEVER RETURN SPRING 13. SECONDARY SHOE 29. ADJUSTING SCREW ASSEMBLY 4. LEVER PIVOT 9. SHOE GUIDE 14. ADJUSTING SCREW SPRING 37 SHOE PADS (6 PLACES) 5. HOLD-DOWN PIN 10. PARKING BRAKE STRUT 18. PARKING BRAKE LEVER

Figure 2 Brake Components

Install or Connect

e See NOTICE on page 5-1.

1. Parking brake lever (18) on secondary shoe (12)

by hooking lever tab into secondary shoe (13).

o Threads of adjusting screw (17) for smooth

rotation over full length.

Clean

e Before reinstalling, adjusting screw asse~nbly (29)

must be disassembled and thoroughly cleaned and

lubricated.

@ Clean adjuster screw ( 17) threads with a wire

brush.

@ Wash all components in denatured alcohol.

o Apply brake lubricant P/N 5450032 or

equivalent to the adjusting screw (17)

threads, inside diameter of socket (15) and

socket face.

e Adequate lubrication is achieved when a

continuous bead of lubricant is at open end

of pivot nut (16) and socket (15) when

threads are fully engaged.

2. Adjusting screw assembly (29) and spring

(14).

3. Shoe and lining assemblies (12 and 13) after

attaching parking brake cable. For cable

adjustment see

PARKING BRAKE

ADJUSTMENT.

4. Parking brake strut (10) and strut spring

(1 1) by

spreading shoes (12 and 13) apart. To be properly

positioned.

o The end without the spring (11) should

engage the parking brake lever (18) and

shoe lining (12 and 13).

e~ The end with the spring should engage the

opposite shoe and lining (12 or 13).

5. Shoe guide

(9), actuator lever (7) and lever return

spring

(8).

6. Hold-down pins (5), lever pivot (4) and

hold-down springs (3).

7. Actuator link (6) on anchor pin (27).