ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1491 of 1771

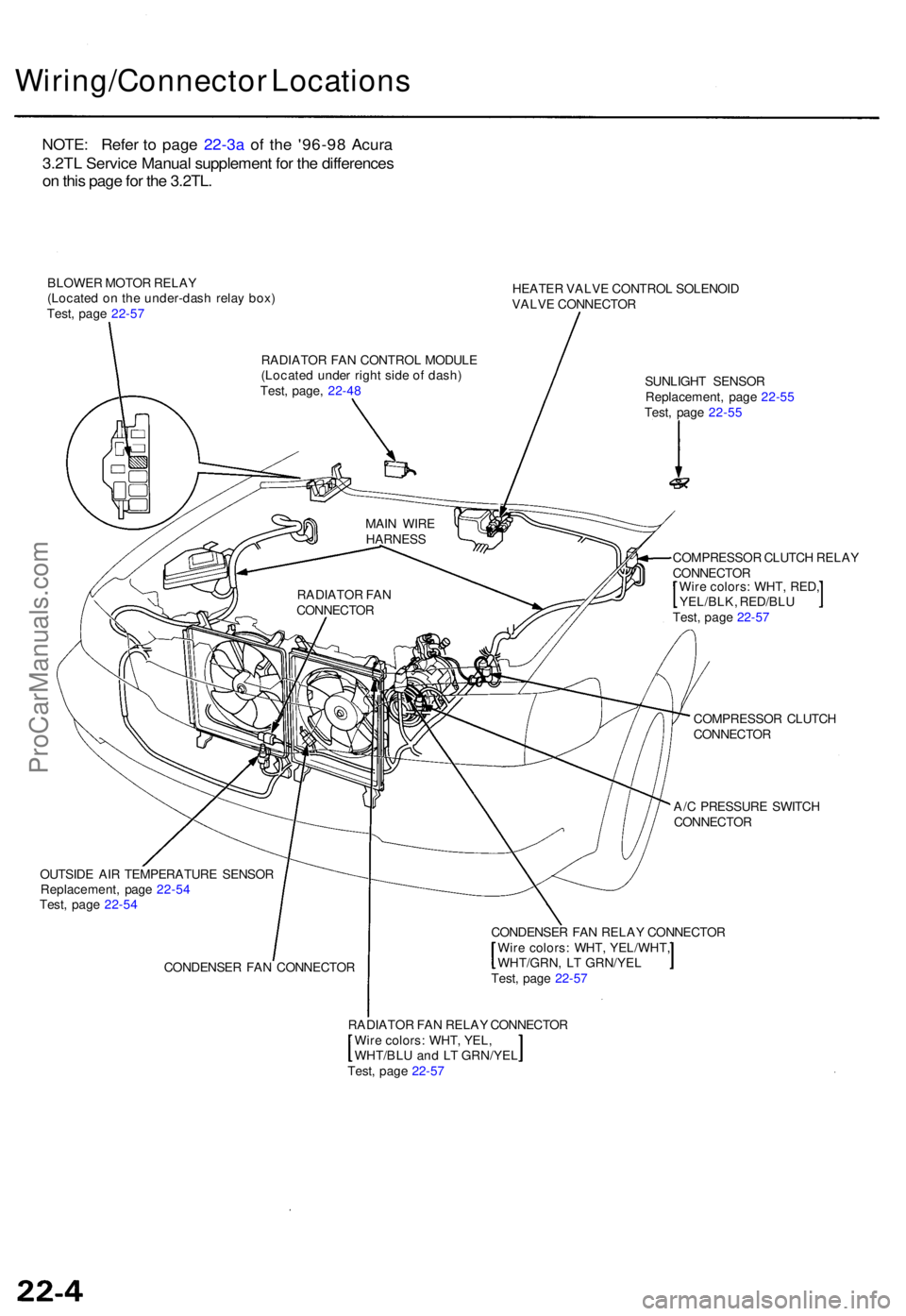

Wiring/Connector Location s

BLOWER MOTO R RELA Y

(Locate d o n th e under-das h rela y box )

Test , pag e 22-5 7 HEATE

R VALV E CONTRO L SOLENOI D

VALV E CONNECTO R

SUNLIGH T SENSO R

Replacement , pag e 22-5 5

Test , pag e 22-5 5

COMPRESSO R CLUTC H RELA Y

CONNECTO R

Wir e colors : WHT , RED ,

YEL/BLK , RED/BL U

Test , pag e 22-5 7

COMPRESSO R CLUTC H

CONNECTO R

A/ C PRESSUR E SWITC H

CONNECTO R

OUTSID E AI R TEMPERATUR E SENSO R

Replacement , pag e 22-5 4

Test , pag e 22-5 4

CONDENSE R FA N CONNECTO R CONDENSE

R FA N RELA Y CONNECTO R

Wir e colors : WHT , YEL/WHT ,

WHT/GRN, L T GRN/YE L

Test , pag e 22-5 7

RADIATO R FA N RELA Y CONNECTO R

Wir e colors : WHT , YEL ,

WHT/BL U an d L T GRN/YE L

Test , pag e 22-5 7

RADIATO

R FA N

CONNECTO RMAI

N WIR E

HARNES S

RADIATO R FA N CONTRO L MODUL E

(Locate d unde r righ t sid e o f dash )

Test , page , 22-4 8

NOTE : Refe r t o page 22-3a of the '96-9 8 Acura

3.2TL Servic e Manual supplement for the differences

on this page for the 3.2TL.

ProCarManuals.com

Page 1492 of 1771

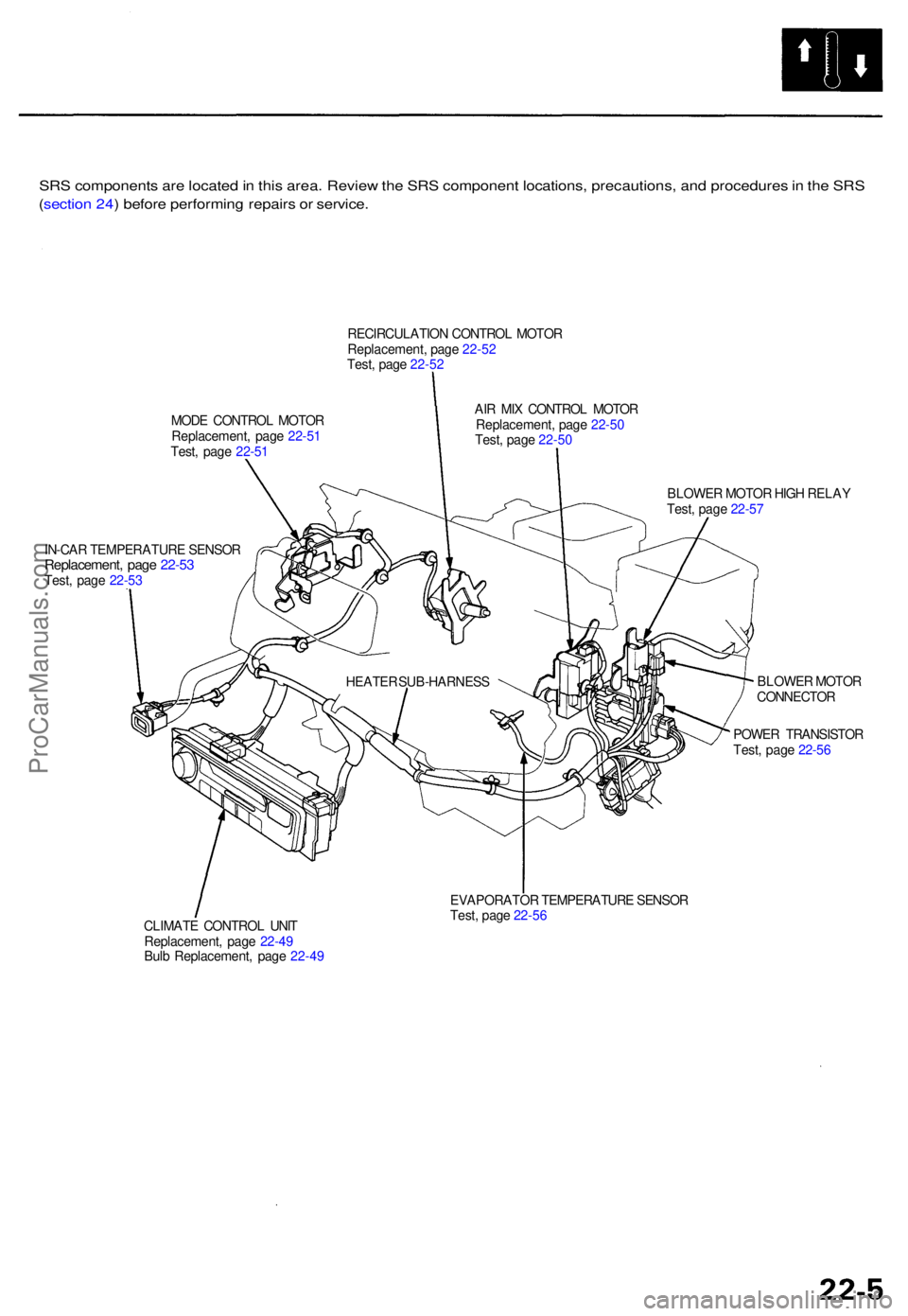

SRS component s ar e locate d in thi s area . Revie w th e SR S componen t locations , precautions , an d procedure s in th e SR S

( sectio n 24 ) befor e performin g repair s o r service .

RECIRCULATIO N CONTRO L MOTO R

Replacement , pag e 22-5 2

Test , pag e 22-5 2

MOD E CONTRO L MOTO R

Replacement , pag e 22-5 1

Test , pag e 22-5 1 AI

R MI X CONTRO L MOTO R

Replacement , pag e 22-5 0

Test , pag e 22-5 0

IN-CA R TEMPERATUR E SENSO R

Replacement , pag e 22-5 3Test, pag e 22-5 3 BLOWE

R MOTO R HIG H RELA Y

Test , pag e 22-5 7

BLOWE R MOTO R

CONNECTO R

POWE R TRANSISTO R

Test , pag e 22-5 6

CLIMAT E CONTRO L UNI T

Replacement , pag e 22-4 9

Bul b Replacement , pag e 22-4 9 EVAPORATO

R TEMPERATUR E SENSO R

Test , pag e 22-5 6

HEATE

R SUB-HARNES S

ProCarManuals.com

Page 1493 of 1771

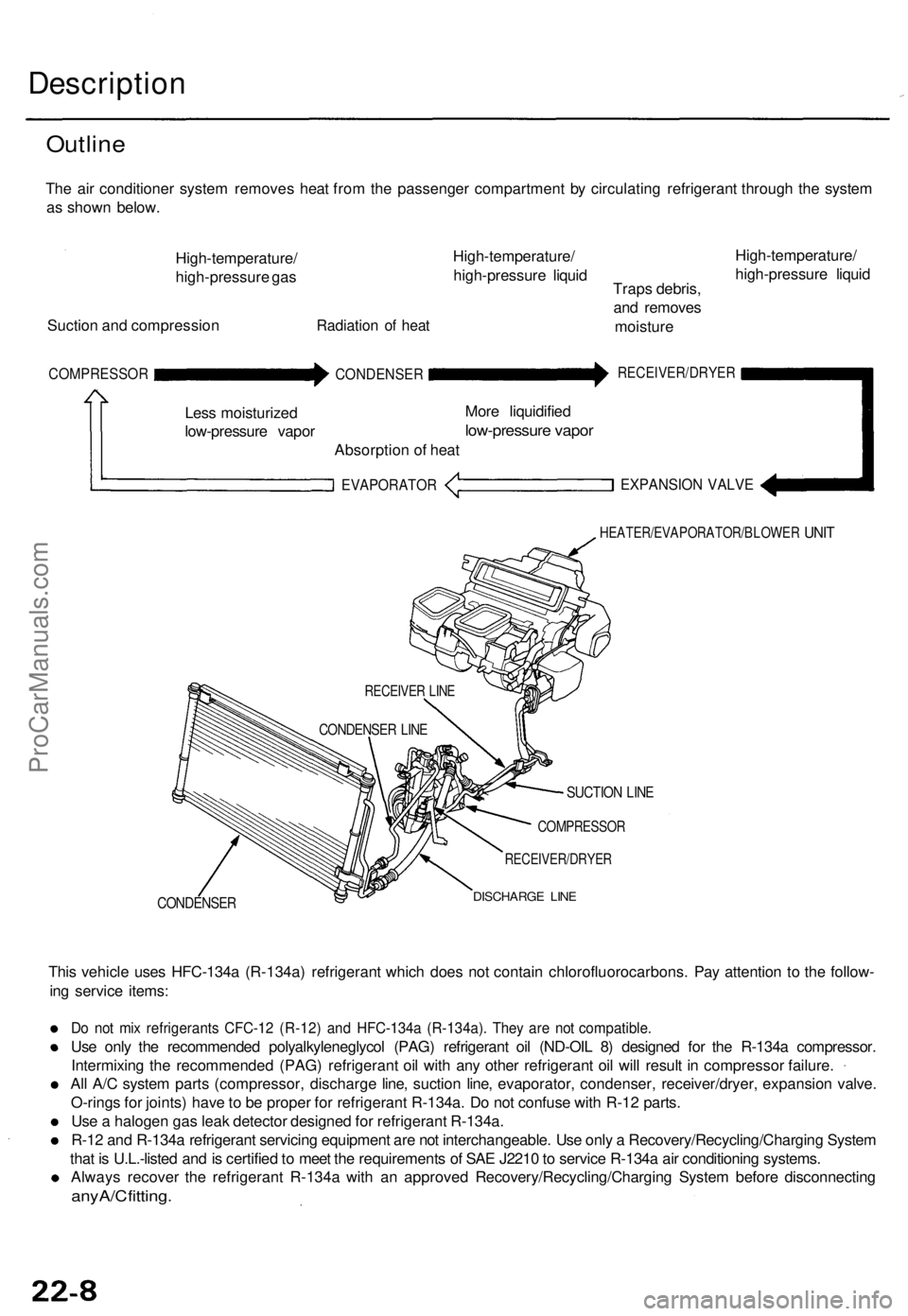

Description

Outline

The air conditioner system removes heat from the passenger compartment by circulating refrigerant through the system

as shown below.

High-temperature/

high-pressure gas

Suction and compression

Radiation of heat

High-temperature/

high-pressure liquid

Traps debris,

and removes

moisture

High-temperature/

high-pressure liquid

COMPRESSOR

Less moisturized

low-pressure vapor

CONDENSER

Absorption of heat

EVAPORATOR

More liquidified

low-pressure vapor

RECEIVER/DRYER

EXPANSION VALVE

HEATER/EVAPORATOR/BLOWER

UNIT

CONDENSER

SUCTION LINE

COMPRESSOR

RECEIVER/DRYER

DISCHARGE LINE

This vehicle uses HFC-134a (R-134a) refrigerant which does not contain chlorofluorocarbons. Pay attention to the follow-

ing service items:

Do not mix refrigerants CFC-12 (R-12) and HFC-134a (R-134a). They are not compatible.

Use only the recommended polyalkyleneglycol (PAG) refrigerant oil (ND-OIL 8) designed for the R-134a compressor.

Intermixing the recommended (PAG) refrigerant oil with any other refrigerant oil will result in compressor failure.

All A/C system parts (compressor, discharge line, suction line, evaporator, condenser, receiver/dryer, expansion valve.

O-rings for joints) have to be proper for refrigerant R-134a. Do not confuse with R-12 parts.

Use a halogen gas leak detector designed for refrigerant R-134a.

R-12 and R-134a refrigerant servicing equipment are not interchangeable. Use only a Recovery/Recycling/Charging System

that is U.L.-listed and is certified to meet the requirements of SAE J2210 to service R-134a air conditioning systems.

Always recover the refrigerant R-134a with an approved Recovery/Recycling/Charging System before disconnecting

any A/C fitting.

RECEIVER LINE

CONDENSER LINEProCarManuals.com

Page 1494 of 1771

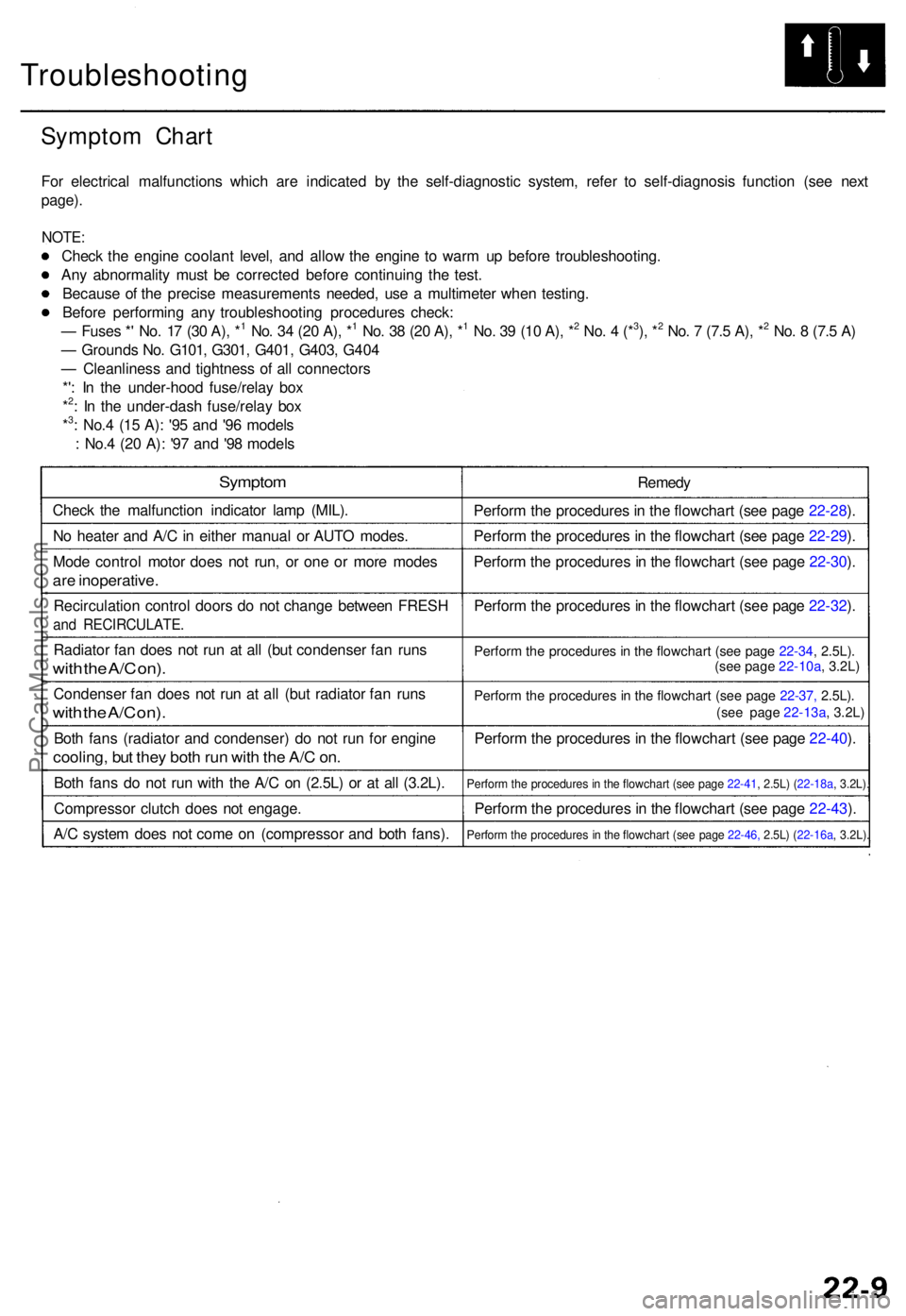

Troubleshooting

Symptom Char t

For electrica l malfunction s whic h ar e indicate d b y th e self-diagnosti c system , refe r t o self-diagnosi s functio n (se e nex t

page) .

NOTE :

Check th e engin e coolan t level , an d allo w th e engin e t o war m u p befor e troubleshooting .

An y abnormalit y mus t b e correcte d befor e continuin g th e test .

Becaus e o f th e precis e measurement s needed , us e a multimete r whe n testing .

Befor e performin g an y troubleshootin g procedure s check :

— Fuse s * ' No . 1 7 (3 0 A) , *

1 No . 3 4 (2 0 A) , *1 No . 3 8 (2 0 A) , *1 No . 3 9 (1 0 A) , *2 No . 4 (*3), *2 No . 7 (7. 5 A) , *2 No . 8 (7. 5 A )

— Ground s No . G101 , G301 , G401 , G403 , G40 4

— Cleanlines s an d tightnes s o f al l connector s

*' : I n th e under-hoo d fuse/rela y bo x

*

2: I n th e under-das h fuse/rela y bo x

*3: No. 4 (1 5 A) : '9 5 an d '9 6 model s

: No. 4 (2 0 A) : '9 7 an d '9 8 model s

Sympto m

Check th e malfunctio n indicato r lam p (MIL) .

N o heate r an d A/ C in eithe r manual or AUT O modes .

Mod e contro l moto r doe s no t run , o r on e o r mor e mode s

are inoperative .

Recirculatio n contro l door s d o no t chang e betwee n FRES H

and RECIRCULATE .

Radiator fa n doe s no t ru n a t al l (bu t condense r fa n run s

with th e A/ C on) .

Condense r fa n doe s no t ru n a t al l (bu t radiato r fa n run s

with th e A/ C on) .

Both fan s (radiato r an d condenser ) d o no t ru n fo r engin e

cooling , bu t the y bot h ru n wit h th e A/ C on .

Bot h fan s d o no t ru n wit h th e A/ C on (2.5L) or at all (3.2L) .

Compresso r clutc h doe s no t engage .

A/ C syste m doe s no t com e o n (compresso r an d bot h fans) . Remed

y

Perfor m th e procedure s in th e flowchar t (se e pag e 22-28 ).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-29 ).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-30 ).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-32 ).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-34 , 2.5L) .

Perfor m th e procedure s i n th e flowchar t (se e pag e 22-37, 2.5L).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-40 ).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-41 , 2.5L) ( 22-18a, 3.2L).

Perfor m th e procedure s in th e flowchar t (se e pag e 22-43 ).

Perfor m th e procedure s i n th e flowchar t (se e pag e 22-46, 2.5L) (22-16a , 3.2L).

(see page 22-10a, 3.2L)

(see page 22-13a , 3.2L)

ProCarManuals.com

Page 1495 of 1771

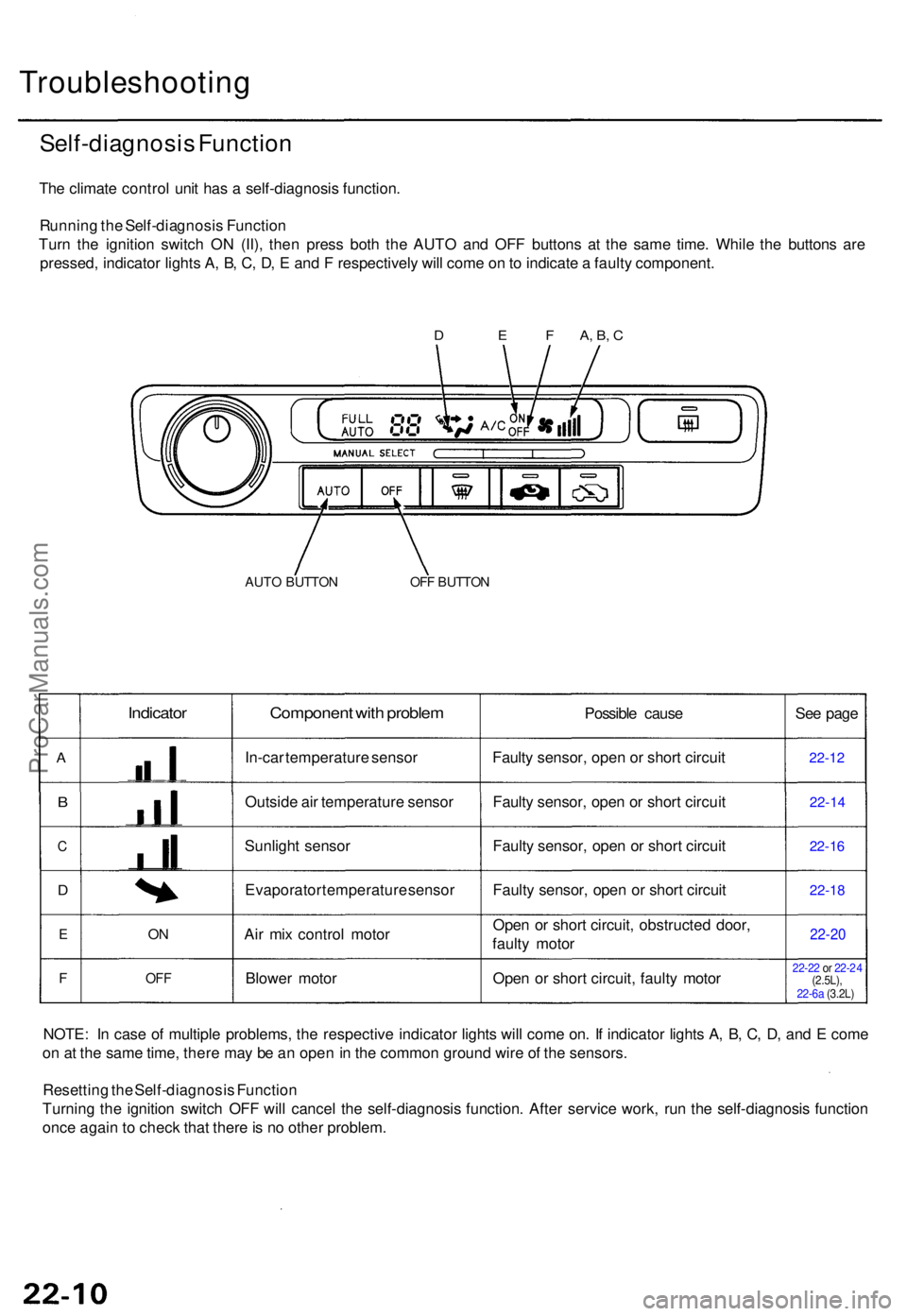

Troubleshooting

Self-diagnosis Functio n

The climat e contro l uni t ha s a self-diagnosi s function .

Runnin g th e Self-diagnosi s Functio n

Tur n th e ignitio n switc h O N (II) , the n pres s bot h th e AUT O an d OF F button s a t th e sam e time . Whil e th e button s ar e

pressed , indicato r light s A , B , C , D , E an d F respectivel y wil l com e o n to indicat e a fault y component .

AUTO BUTTO NOFF BUTTO N

A

B

C

D

E

F

Indicator

ON

OF F

Componen t wit h proble m

In-car temperatur e senso r

Outsid e ai r temperatur e senso r

Sunligh t senso r

Evaporato r temperatur e senso r

Ai r mi x contro l moto r

Blowe r moto r Possibl

e caus e

Fault y sensor , ope n o r shor t circui t

Fault y sensor , ope n o r shor t circui t

Fault y sensor , ope n o r shor t circui t

Fault y sensor , ope n o r shor t circui t

Ope n o r shor t circuit , obstructe d door ,

fault y moto r

Ope n o r shor t circuit , fault y moto r Se

e pag e22-1 2

22-1 4

22-16

22-1 8

22-2 0

22-22 or 22- 24

(2.5L),

NOTE : I n cas e o f multipl e problems , th e respectiv e indicato r light s wil l com e on . I f indicato r light s A , B , C , D , an d E com e

o n a t th e sam e time , ther e ma y b e a n ope n in th e commo n groun d wir e o f th e sensors .

Resettin g th e Self-diagnosi s Functio n

Turnin g th e ignitio n switc h OF F wil l cance l th e self-diagnosi s function . Afte r servic e work , ru n th e self-diagnosi s functio n

onc e agai n to chec k tha t ther e is n o othe r problem.

D E F A, B , C

22-6a (3.2L)

ProCarManuals.com

Page 1496 of 1771

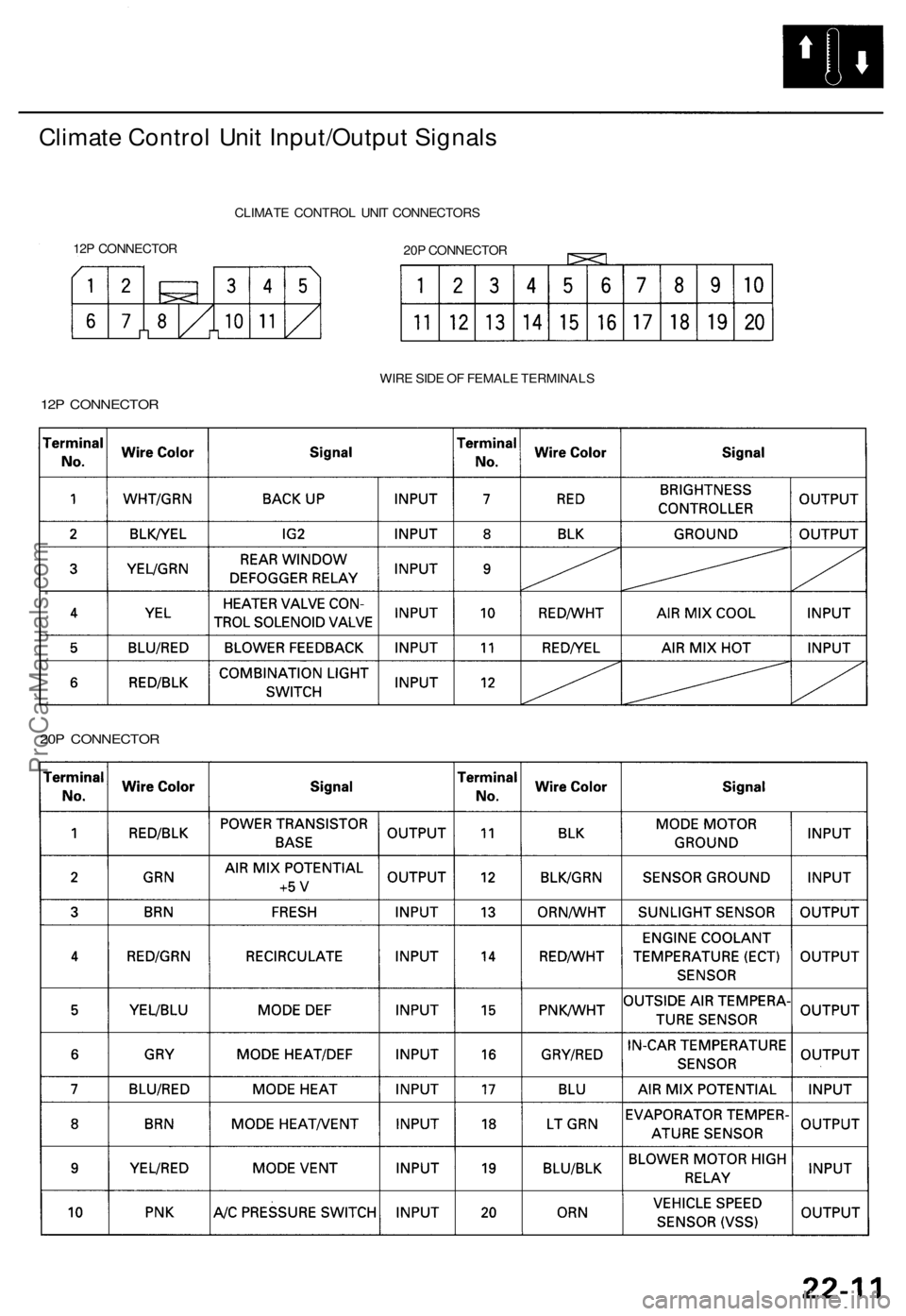

Climate Contro l Uni t Input/Outpu t Signal s

12P CONNECTO RCLIMAT

E CONTRO L UNI T CONNECTOR S

20 P CONNECTO R

WIR E SID E O F FEMAL E TERMINAL S

12P CONNECTO R

20 P CONNECTO R

ProCarManuals.com

Page 1497 of 1771

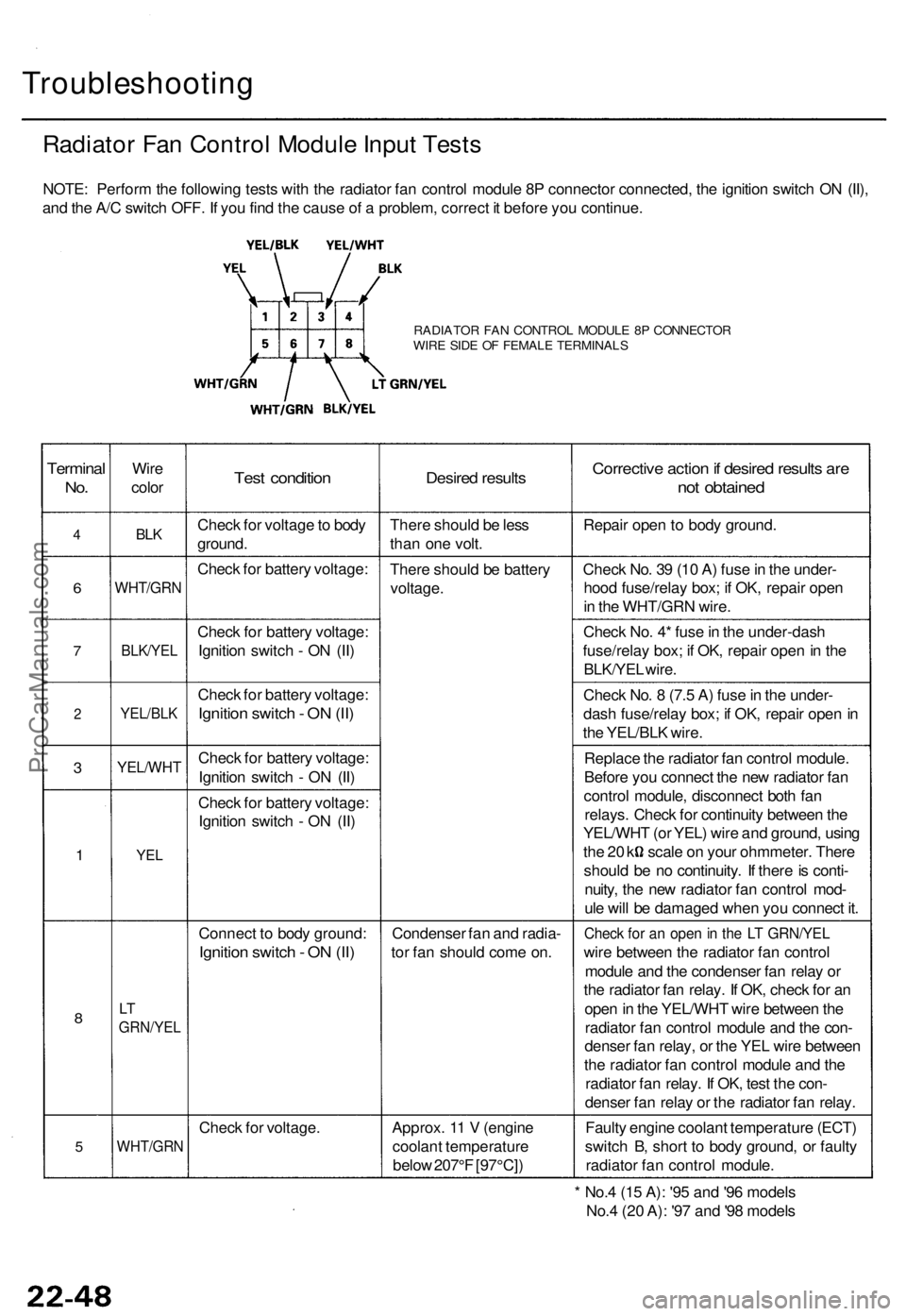

Troubleshooting

Radiator Fan Control Module Input Tests

NOTE: Perform the following tests with the radiator fan control module 8P connector connected, the ignition switch ON (II),

and the A/C switch OFF. If you find the cause of a problem, correct it before you continue.

RADIATOR FAN CONTROL MODULE 8P CONNECTOR

WIRE SIDE OF FEMALE TERMINALS

Terminal

No.

4

6

7

2

3

1

8

5

Wire

color

BLK

WHT/GRN

BLK/YEL

YEL/BLK

YEL/WHT

YEL

LT

GRN/YEL

WHT/GRN

Test condition

Check for voltage to body

ground.

Check for battery voltage:

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Check for battery voltage:

Ignition switch - ON (II)

Connect to body ground:

Ignition switch - ON (II)

Check for voltage.

Desired results

There should be less

than one volt.

There should be battery

voltage.

Condenser fan and radia-

tor fan should come on.

Approx. 11 V (engine

coolant temperature

below 207°F [97°C])

Corrective action if desired results are

not obtained

Repair open to body ground.

Check No. 39 (10 A) fuse in the under-

hood fuse/relay box; if OK, repair open

in the WHT/GRN wire.

Check No. 4* fuse in the under-dash

fuse/relay box; if OK, repair open in the

BLK/YEL wire.

Check No. 8 (7.5 A) fuse in the under-

dash fuse/relay box; if OK, repair open in

the YEL/BLK wire.

Replace the radiator fan control module.

Before you connect the new radiator fan

control module, disconnect both fan

relays. Check for continuity between the

YEL/WHT (or YEL) wire and ground, using

the 20 k scale on your ohmmeter. There

should be no continuity. If there is conti-

nuity, the new radiator fan control mod-

ule will be damaged when you connect it.

Check for an open in the LT GRN/YEL

wire between the radiator fan control

module and the condenser fan relay or

the radiator fan relay. If OK, check for an

open in the YEL/WHT wire between the

radiator fan control module and the con-

denser fan relay, or the YEL wire between

the radiator fan control module and the

radiator fan relay. If OK, test the con-

denser fan relay or the radiator fan relay.

Faulty engine coolant temperature (ECT)

switch B, short to body ground, or faulty

radiator fan control module.

* No.4 (15 A): '95 and '96 models

No.4 (20 A): '97 and '98 modelsProCarManuals.com

Page 1498 of 1771

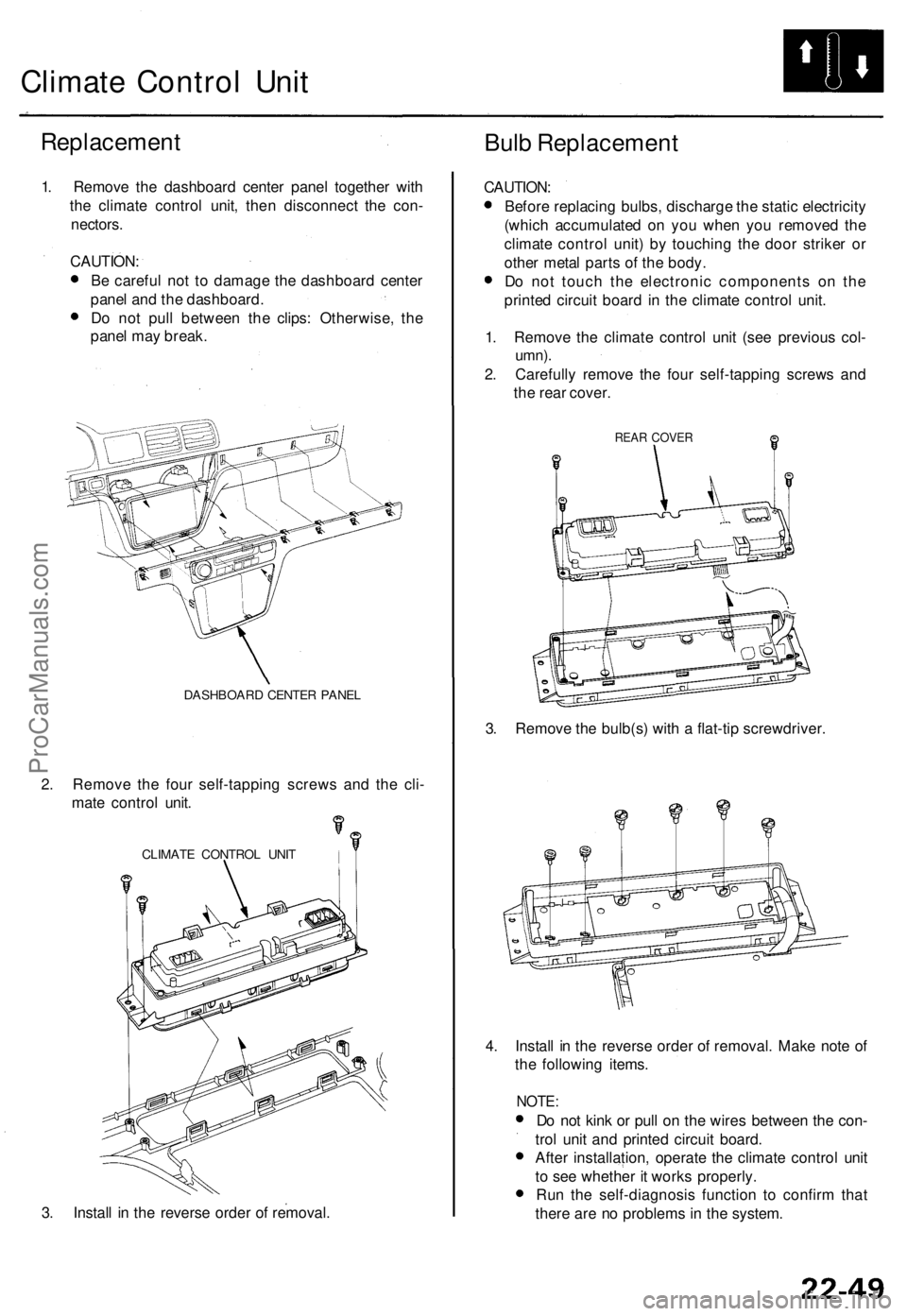

Climate Contro l Uni t

Replacemen t

Bulb Replacemen t

1. Remov e th e dashboar d cente r pane l togethe r wit h

th e climat e contro l unit , the n disconnec t th e con -

nectors .

CAUTION :

B e carefu l no t t o damag e th e dashboar d cente r

pane l an d th e dashboard .

D o no t pul l betwee n th e clips : Otherwise , th e

pane l ma y break .

DASHBOAR D CENTE R PANE L

2. Remov e th e fou r self-tappin g screw s an d th e cli -

mat e contro l unit .

CLIMAT E CONTRO L UNI T

3. Instal l i n th e revers e orde r o f removal . CAUTION

:

Befor e replacin g bulbs , discharg e th e stati c electricit y

(whic h accumulate d o n yo u whe n yo u remove d th e

climat e contro l unit ) b y touchin g th e doo r strike r o r

othe r meta l part s o f th e body .

D o no t touc h th e electroni c component s o n th e

printe d circui t boar d in th e climat e contro l unit .

1 . Remov e th e climat e contro l uni t (se e previou s col -

umn) .

2. Carefull y remov e th e fou r self-tappin g screw s an d

th e rea r cover .

REAR COVE R

3. Remov e th e bulb(s ) wit h a flat-ti p screwdriver .

4 . Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

NOTE:

Do no t kin k o r pul l o n th e wire s betwee n th e con -

tro l uni t an d printe d circui t board .

Afte r installation , operat e th e climat e contro l uni t

t o se e whethe r i t work s properly .

Ru n th e self-diagnosi s functio n t o confir m tha t

ther e ar e n o problem s i n th e system .

ProCarManuals.com

Page 1499 of 1771

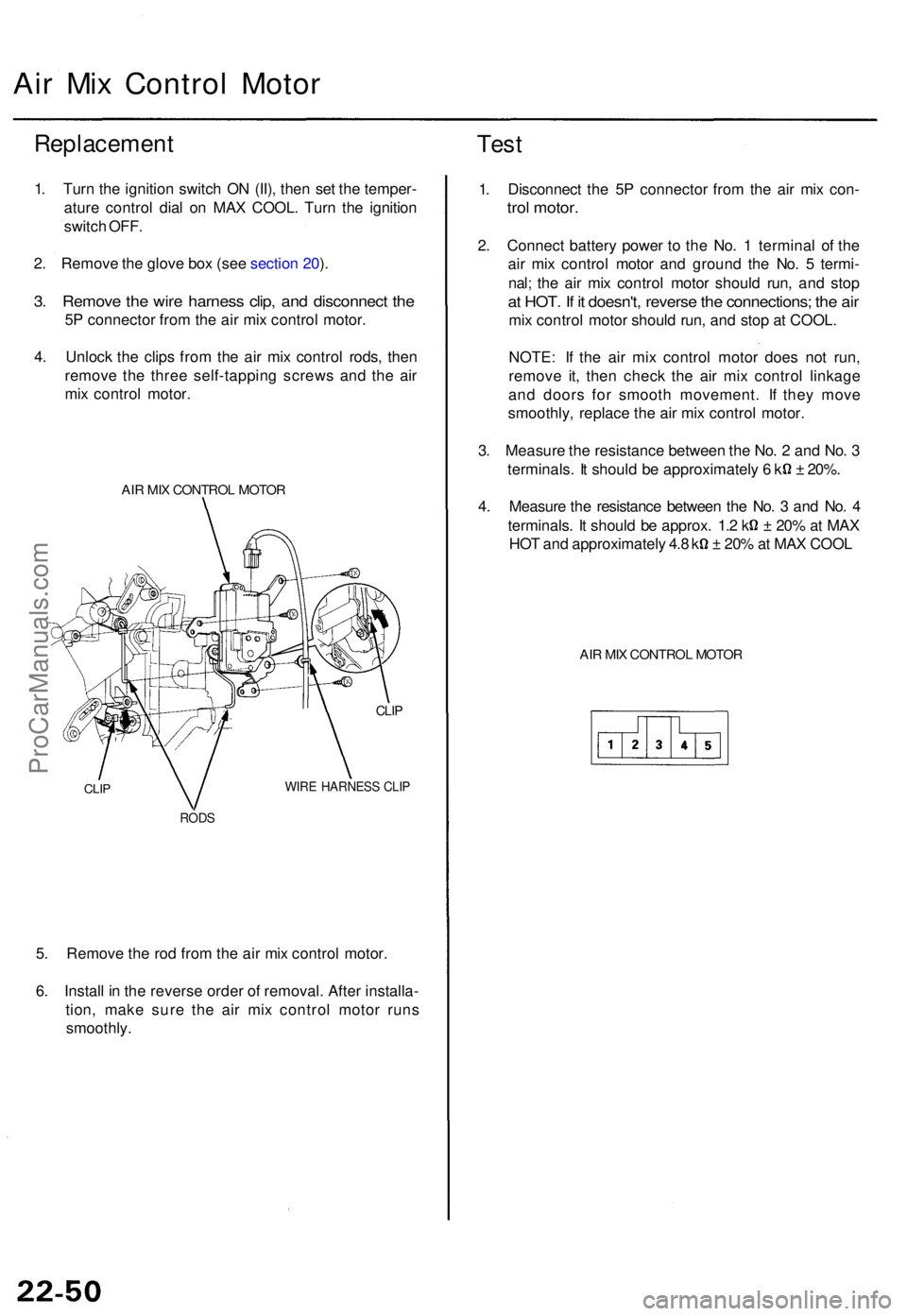

Air Mi x Contro l Moto r

Replacemen t

1. Tur n th e ignitio n switc h O N (II) , the n se t th e temper -

atur e contro l dia l o n MA X COOL . Tur n th e ignitio n

switc h OFF .

2 . Remov e th e glov e bo x (se e sectio n 20 ).

3 . Remov e th e wir e harnes s clip , an d disconnec t th e

5P connecto r fro m th e ai r mi x contro l motor .

4 . Unloc k th e clip s fro m th e ai r mi x contro l rods , the n

remov e th e thre e self-tappin g screw s an d th e ai r

mi x contro l motor .

AIR MI X CONTRO L MOTO R

CLIP

CLIP

WIR E HARNES S CLI P

ROD S

5. Remov e th e ro d fro m th e ai r mi x contro l motor .

6 . Instal l i n th e revers e orde r o f removal . Afte r installa -

tion , mak e sur e th e ai r mi x contro l moto r run s

smoothly .

Test

1. Disconnec t th e 5 P connecto r fro m th e ai r mi x con -

trol motor .

2. Connec t batter y powe r t o th e No . 1 termina l o f th e

ai r mi x contro l moto r an d groun d th e No . 5 termi -

nal ; th e ai r mi x contro l moto r shoul d run , an d sto p

at HOT . I f i t doesn't , revers e th e connections ; th e ai r

mi x contro l moto r shoul d run , an d sto p a t COOL .

NOTE : I f th e ai r mi x contro l moto r doe s no t run ,

remov e it , the n chec k th e ai r mi x contro l linkag e

an d door s fo r smoot h movement . I f the y mov e

smoothly , replac e th e ai r mi x contro l motor .

3 . Measur e th e resistanc e betwee n th e No . 2 an d No . 3

terminals . I t shoul d b e approximatel y 6 k ± 20% .

4 . Measur e th e resistanc e betwee n th e No . 3 an d No . 4

terminals . I t shoul d b e approx . 1. 2 k ± 20% at MA X

HOT an d approximatel y 4. 8 k ± 20% at MA X COO L

AIR MI X CONTRO L MOTO R

ProCarManuals.com

Page 1500 of 1771

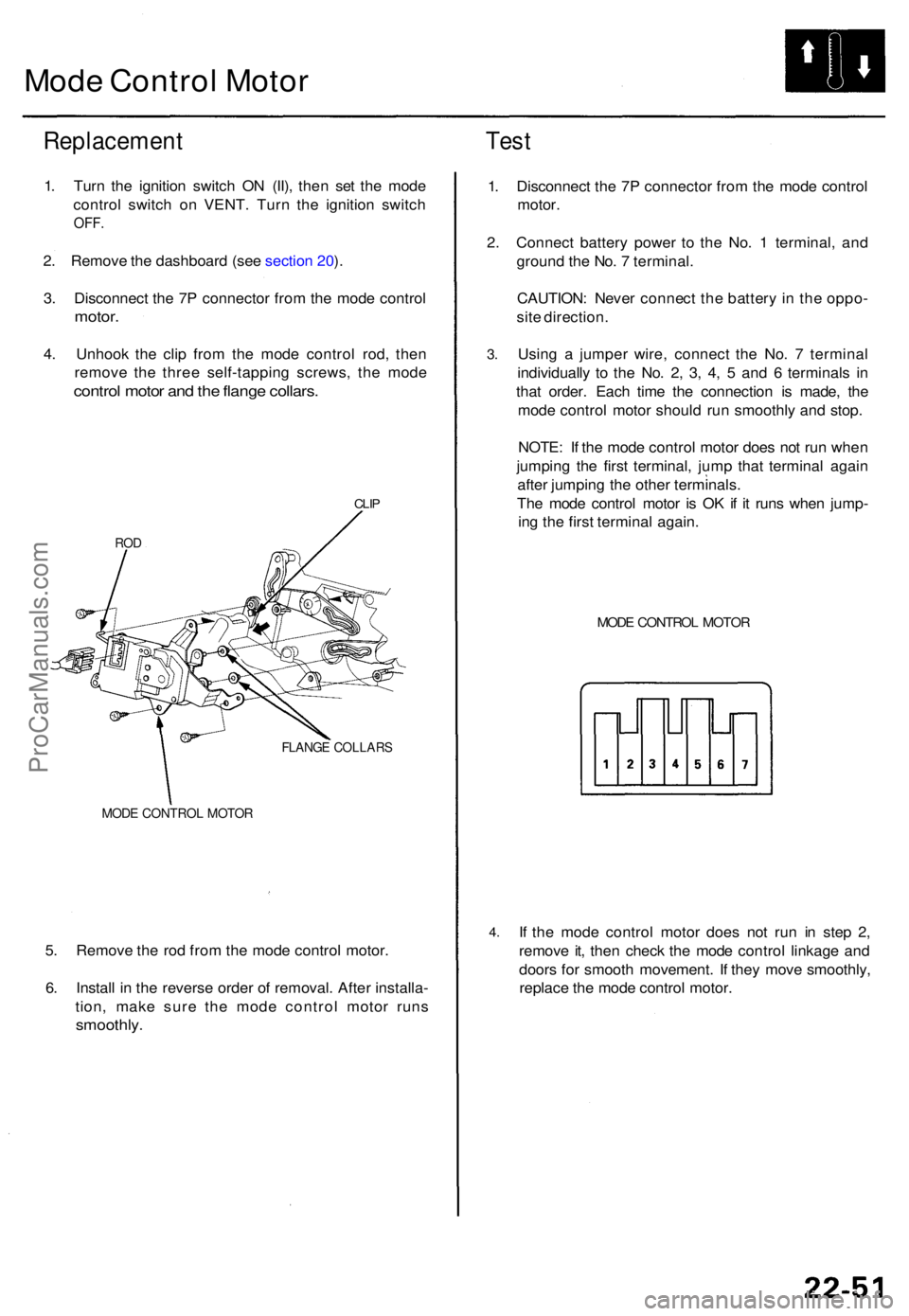

Mode Contro l Moto r

Replacemen t

1. Tur n th e ignitio n switc h O N (II) , the n se t th e mod e

contro l switc h o n VENT . Tur n th e ignitio n switc h

OFF.

2. Remov e th e dashboar d (se e sectio n 20 ).

3 . Disconnec t th e 7 P connecto r fro m th e mod e contro l

motor.

4. Unhoo k th e cli p fro m th e mod e contro l rod , the n

remov e th e thre e self-tappin g screws , th e mod e

contro l moto r an d th e flang e collars .

CLIP

RO D

FLANG E COLLAR S

MODE CONTRO L MOTO R

5. Remov e th e ro d fro m th e mod e contro l motor .

6 . Instal l i n th e revers e orde r o f removal . Afte r installa -

tion , mak e sur e th e mod e contro l moto r run s

smoothly .

Test

1. Disconnec t th e 7 P connecto r fro m th e mod e contro l

motor .

2 . Connec t batter y powe r t o th e No . 1 terminal , an d

groun d th e No . 7 terminal .

CAUTION : Neve r connec t th e batter y in th e oppo -

sit e direction .

3.

4 .

Usin g a jumpe r wire , connec t th e No . 7 termina l

individuall y t o th e No . 2 , 3 , 4 , 5 an d 6 terminal s i n

tha t order . Eac h tim e th e connectio n i s made , th e

mod e contro l moto r shoul d ru n smoothl y an d stop .

NOTE : I f th e mod e contro l moto r doe s no t ru n whe n

jumpin g th e firs t terminal , jum p tha t termina l agai n

afte r jumpin g th e othe r terminals .

Th e mod e contro l moto r i s O K if i t run s whe n jump -

in g th e firs t termina l again .

MODE CONTRO L MOTO R

If th e mod e contro l moto r doe s no t ru n i n ste p 2 ,

remov e it , the n chec k th e mod e contro l linkag e an d

door s fo r smoot h movement . I f the y mov e smoothly ,

replac e th e mod e contro l motor .

ProCarManuals.com