ACURA TL 1995 Service Repair Manual

Manufacturer: ACURA, Model Year: 1995, Model line: TL, Model: ACURA TL 1995Pages: 1771, PDF Size: 62.49 MB

Page 1511 of 1771

Blower Uni t

Replacemen t

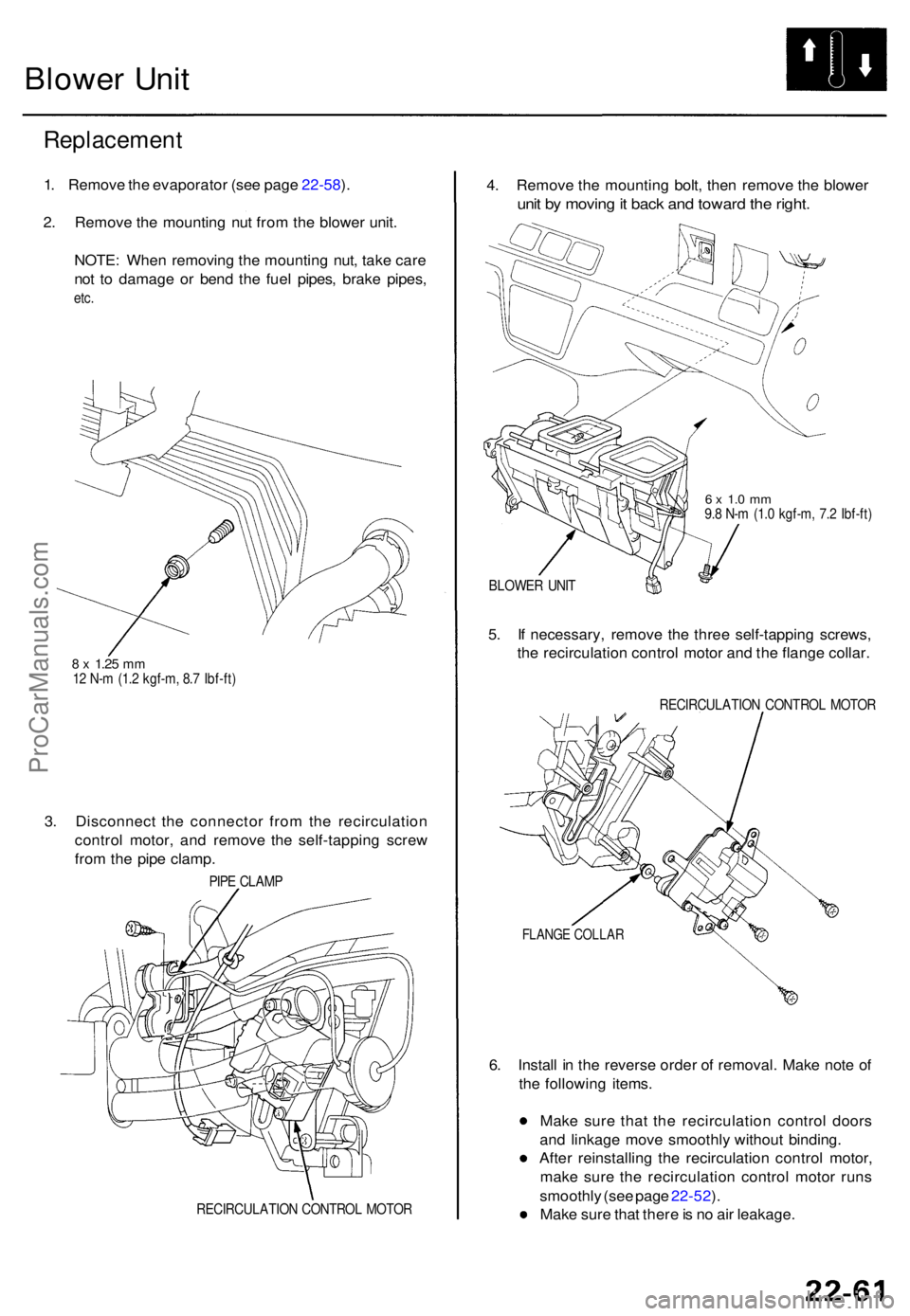

1. Remov e th e evaporato r (se e pag e 22-58 ).

2 . Remov e th e mountin g nu t fro m th e blowe r unit .

NOTE : Whe n removin g th e mountin g nut , tak e car e

no t t o damag e o r ben d th e fue l pipes , brak e pipes ,

etc.

8 x 1.2 5 mm12 N- m (1. 2 kgf-m , 8. 7 Ibf-ft )

3. Disconnec t th e connecto r fro m th e recirculatio n

contro l motor , an d remov e th e self-tappin g scre w

fro m th e pip e clamp .

PIPE CLAM P

RECIRCULATIO N CONTRO L MOTO R

4. Remov e th e mountin g bolt , the n remov e th e blowe r

unit b y movin g it bac k an d towar d th e right .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

BLOWE R UNI T

5. I f necessary , remov e th e thre e self-tappin g screws ,

th e recirculatio n contro l moto r an d th e flang e collar .

RECIRCULATIO N CONTRO L MOTO R

FLANG E COLLA R

6. Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

Mak e sur e tha t th e recirculatio n contro l door s

an d linkag e mov e smoothl y withou t binding .

Afte r reinstallin g th e recirculatio n contro l motor ,

mak e sur e th e recirculatio n contro l moto r run s

smoothl y (se e pag e 22-52 ).

Mak e sur e tha t ther e is n o ai r leakage .

ProCarManuals.com

Page 1512 of 1771

Blower Unit

Overhaul

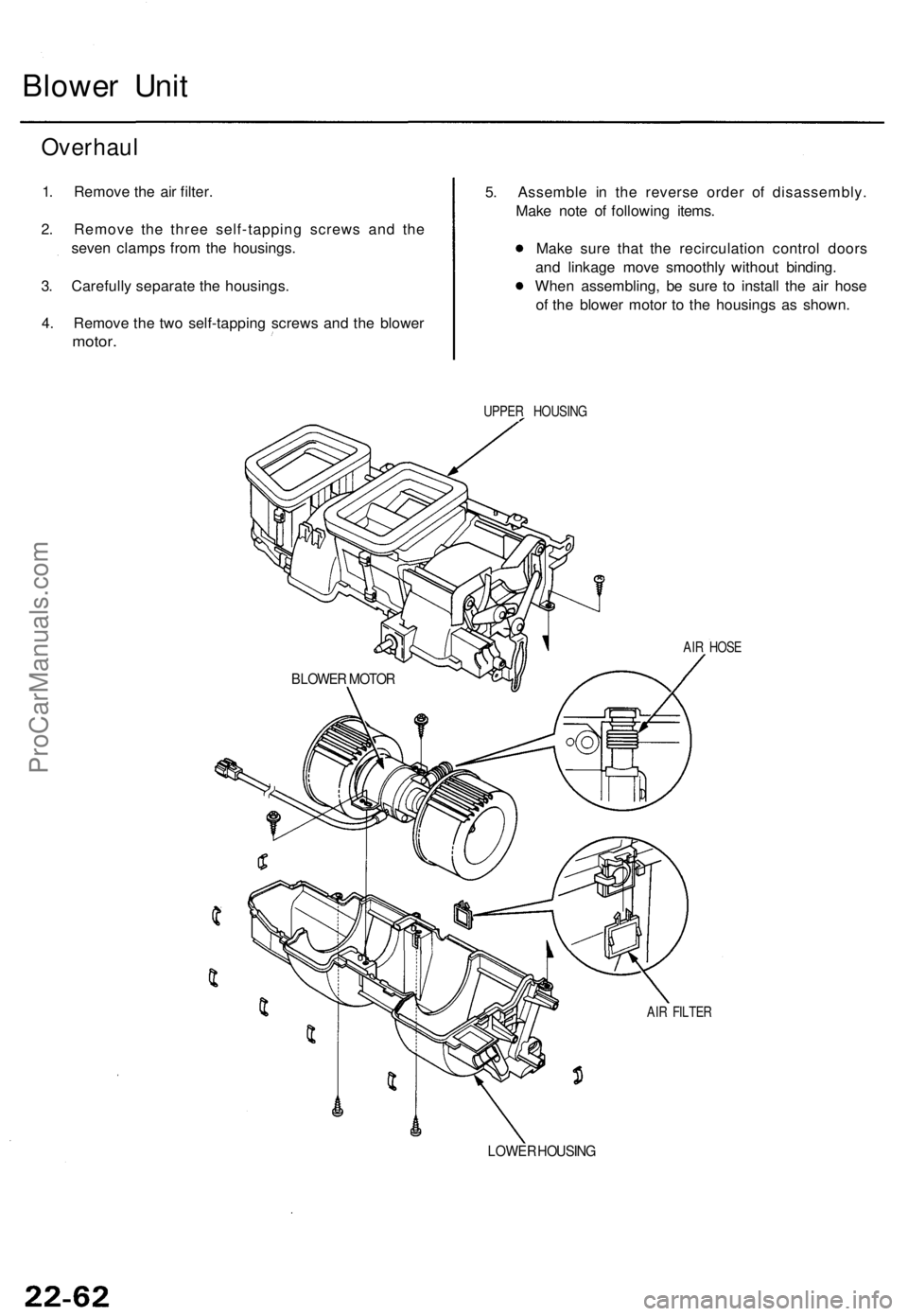

1. Remove the air filter.

2. Remove the three self-tapping screws and the

seven clamps from the housings.

3. Carefully separate the housings.

4. Remove the two self-tapping screws and the blower

motor.

5. Assemble in the reverse order of disassembly.

Make note of following items.

Make sure that the recirculation control doors

and linkage move smoothly without binding.

When assembling, be sure to install the air hose

of the blower motor to the housings as shown.

UPPER HOUSING

AIR HOSE

AIR FILTER

LOWER HOUSING

BLOWER MOTORProCarManuals.com

Page 1513 of 1771

Heater Uni t

Replacemen t

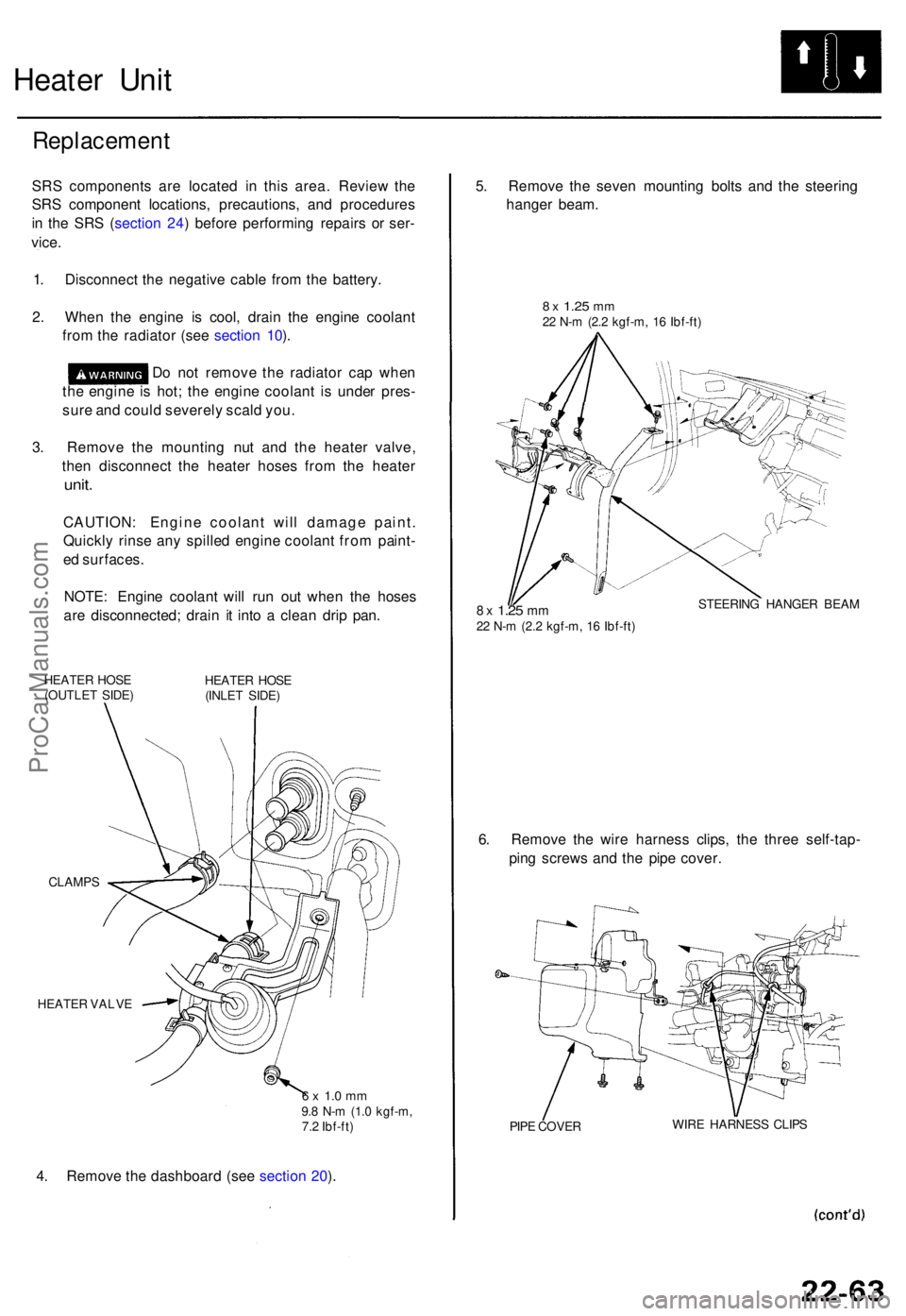

SRS component s ar e locate d i n thi s area . Revie w th e

SR S componen t locations , precautions , an d procedure s

i n th e SR S ( sectio n 24 ) befor e performin g repair s o r ser -

vice .

1 . Disconnec t th e negativ e cabl e fro m th e battery .

2 . Whe n th e engin e i s cool , drai n th e engin e coolan t

fro m th e radiato r (se e sectio n 10 ).

D o no t remov e th e radiato r ca p whe n

th e engin e i s hot ; th e engin e coolan t i s unde r pres -

sur e an d coul d severel y scal d you .

3 . Remov e th e mountin g nu t an d th e heate r valve ,

the n disconnec t th e heate r hose s fro m th e heate r

unit.

CAUTION : Engin e coolan t wil l damag e paint .

Quickl y rins e an y spille d engin e coolan t fro m paint -

e d surfaces .

NOTE : Engin e coolan t wil l ru n ou t whe n th e hose s

ar e disconnected ; drai n i t int o a clea n dri p pan .

HEATE R HOS E

(OUTLE T SIDE ) HEATE

R HOS E

(INLE T SIDE )

CLAMP S

HEATE R VALV E

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m ,

7. 2 Ibf-ft )

4. Remov e th e dashboar d (se e sectio n 20 ). 5

. Remov e th e seve n mountin g bolt s an d th e steerin g

hange r beam .

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

8 x 1.2 5 mm22 N- m (2. 2 kgf-m , 1 6 Ibf-ft ) STEERIN

G HANGE R BEA M

6. Remov e th e wir e harnes s clips , th e thre e self-tap -

pin g screw s an d th e pip e cover .

PIPE COVE R WIR

E HARNES S CLIP S

ProCarManuals.com

Page 1514 of 1771

Heater Uni t

Replacemen t (cont'd )

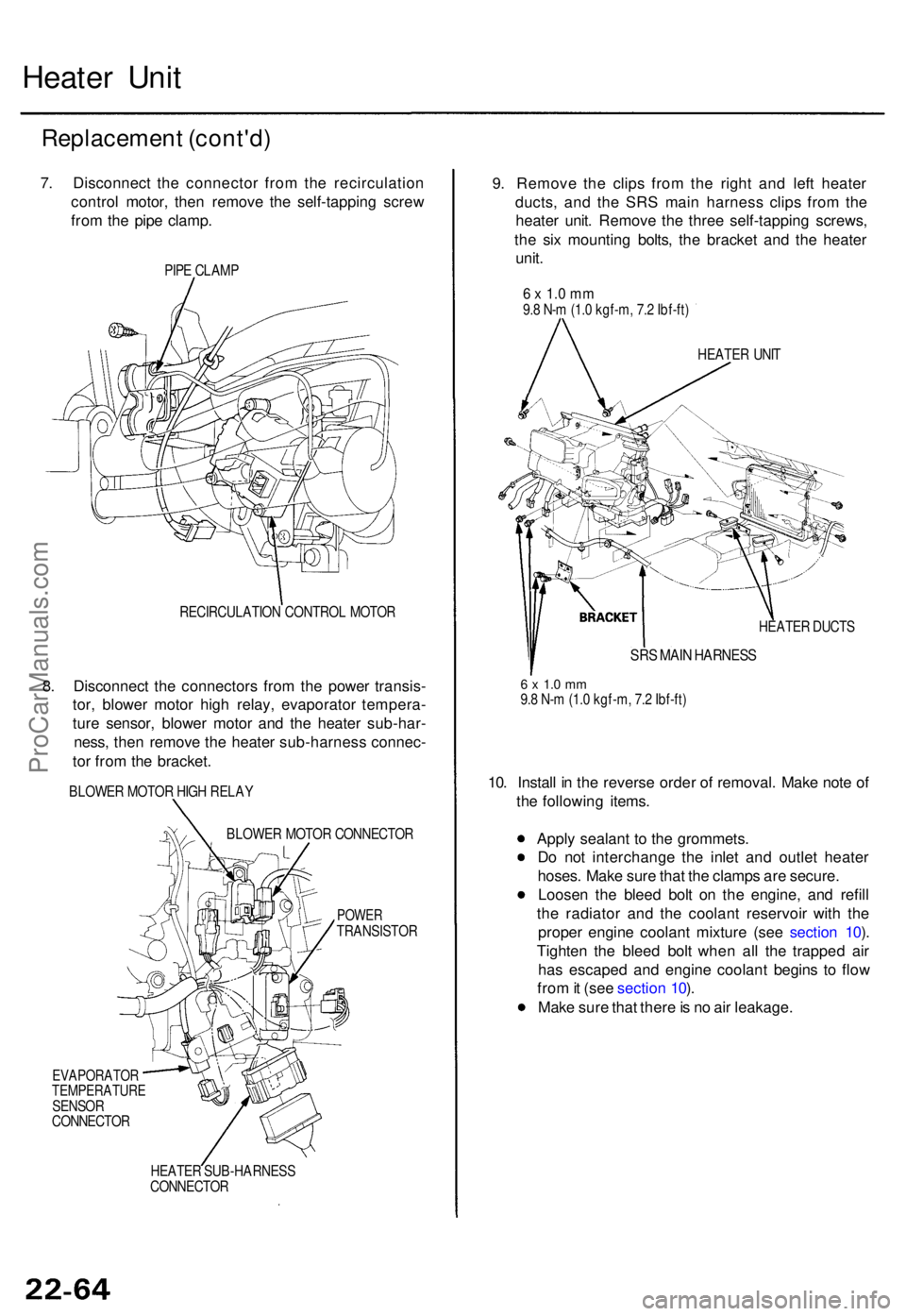

7. Disconnec t th e connecto r fro m th e recirculatio n

contro l motor , the n remov e th e self-tappin g scre w

fro m th e pip e clamp .

PIPE CLAM P

RECIRCULATIO N CONTRO L MOTO R

8. Disconnec t th e connector s fro m th e powe r transis -

tor , blowe r moto r hig h relay , evaporato r tempera -

tur e sensor , blowe r moto r an d th e heate r sub-har -

ness , the n remov e th e heate r sub-harnes s connec -

to r fro m th e bracket .

BLOWER MOTO R HIG H RELA Y

BLOWE R MOTO R CONNECTO R

POWERTRANSISTO R

EVAPORATO RTEMPERATUR ESENSORCONNECTO R

HEATE R SUB-HARNES S

CONNECTO R

9. Remov e th e clip s fro m th e righ t an d lef t heate r

ducts , an d th e SR S mai n harnes s clip s fro m th e

heate r unit . Remov e th e thre e self-tappin g screws,

th e si x mountin g bolts , th e bracke t an d th e heate r

unit .

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

HEATE R UNI T

HEATE R DUCT S

SRS MAI N HARNES S

6 x 1. 0 m m9.8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

10. Instal l i n th e revers e orde r o f removal . Mak e not e o f

th e followin g items .

Appl y sealan t t o th e grommets .

D o no t interchang e th e inle t an d outle t heate r

hoses . Mak e sur e tha t th e clamp s ar e secure .

Loose n th e blee d bol t o n th e engine , an d refil l

th e radiato r an d th e coolan t reservoi r wit h th e

prope r engin e coolan t mixtur e (se e sectio n 10 ).

Tighte n th e blee d bol t whe n al l th e trappe d ai r

ha s escape d an d engin e coolan t begin s t o flo w

fro m it (se e sectio n 10 ).

Mak e sur e tha t ther e is n o ai r leakage .

ProCarManuals.com

Page 1515 of 1771

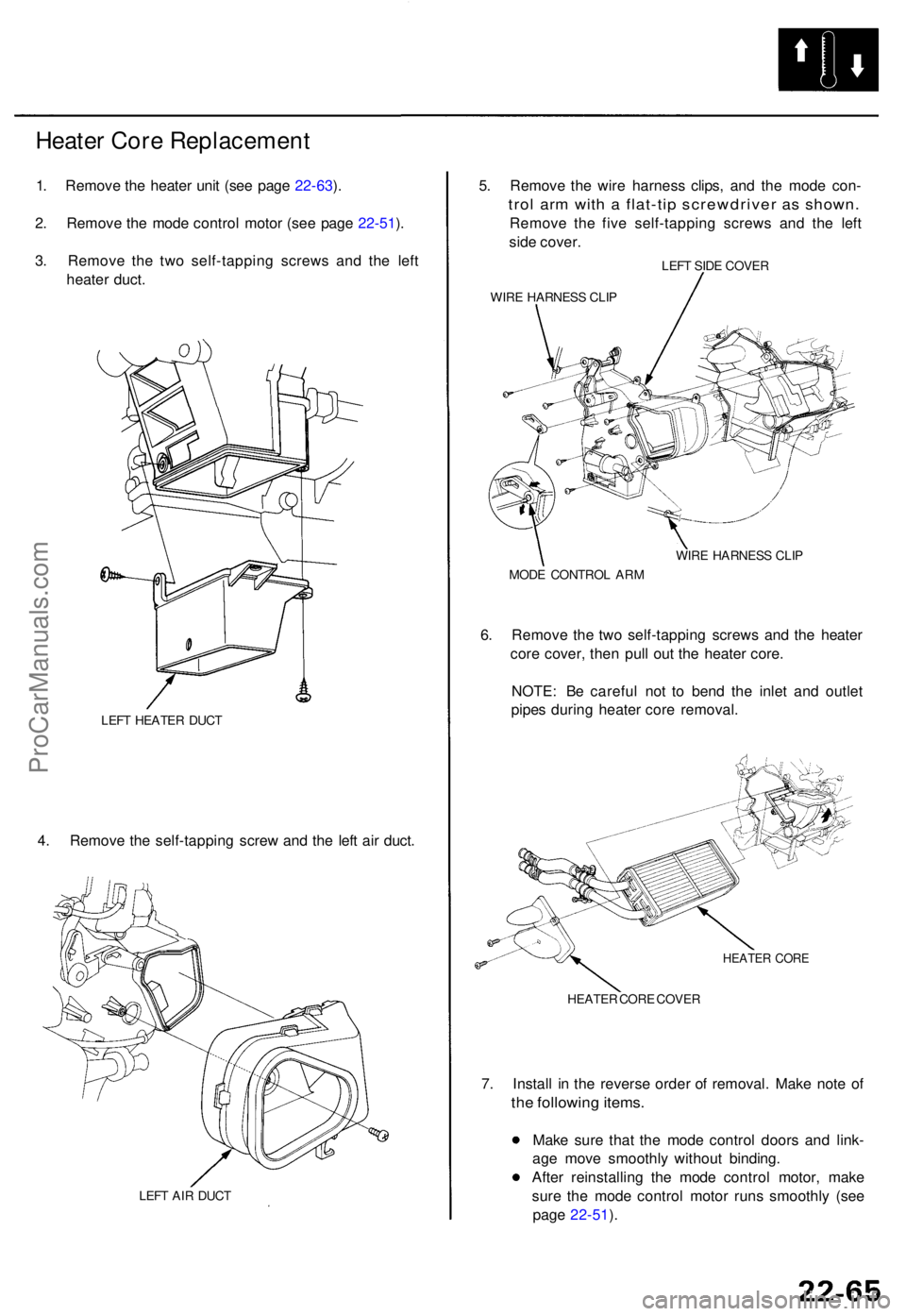

Heater Cor e Replacemen t

1. Remov e th e heate r uni t (se e pag e 22-63 ).

2 . Remov e th e mod e contro l moto r (se e pag e 22-51 ).

3 . Remov e th e tw o self-tappin g screw s an d th e lef t

heate r duct .

LEFT HEATE R DUC T

4. Remov e th e self-tappin g scre w an d th e lef t ai r duct .

LEFT AI R DUC T

5. Remov e th e wir e harnes s clips , an d th e mod e con -

trol ar m wit h a flat-ti p screwdrive r a s shown .

Remove th e fiv e self-tappin g screw s an d th e lef t

sid e cover .

LEFT SID E COVE R

WIR E HARNES S CLI P

WIRE HARNES S CLI P

MOD E CONTRO L AR M

6. Remov e th e tw o self-tappin g screw s an d th e heate r

cor e cover , the n pul l ou t th e heate r core .

NOTE : B e carefu l no t t o ben d th e inle t an d outle t

pipe s durin g heate r cor e removal .

HEATER COR E

HEATE R COR E COVE R

7. Instal l i n th e revers e orde r o f removal . Mak e not e o f

the followin g items .

Make sur e tha t th e mod e contro l door s an d link -

ag e mov e smoothl y withou t binding .

Afte r reinstallin g th e mod e contro l motor , mak e

sur e th e mod e contro l moto r run s smoothl y (se e

pag e 22-51 ).

ProCarManuals.com

Page 1516 of 1771

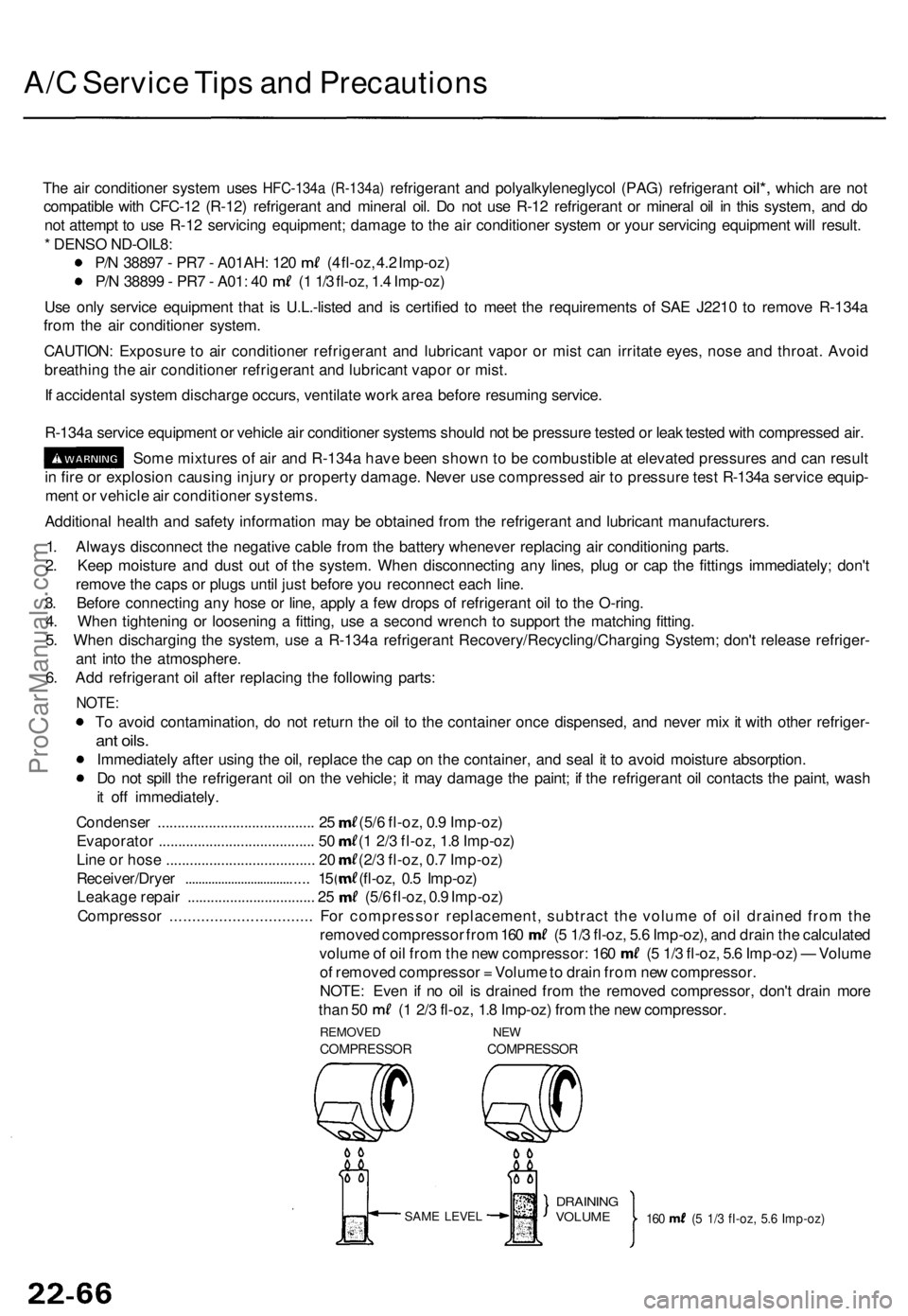

A/C Servic e Tip s an d Precaution s

The ai r conditione r syste m use s HFC-134 a (R-134a) refrigeran t and polyalkyleneglyco l (PAG ) refrigeran t oil*, whic h are no t

compatibl e wit h CFC-1 2 (R-12 ) refrigeran t an d minera l oil . D o no t us e R-1 2 refrigeran t o r minera l oi l i n thi s system , an d d o

no t attemp t t o us e R-1 2 servicin g equipment ; damag e t o th e ai r conditione r syste m o r you r servicin g equipmen t wil l result .

* DENS O ND-OIL8 :

P/N 3889 7 - PR 7 - A01AH : 12 0 ( 4 fl-oz , 4. 2 Imp-oz )

P/N 3889 9 - PR 7 - A01 : 4 0 ( 1 1/ 3 fl-oz , 1. 4 Imp-oz )

Us e onl y servic e equipmen t tha t i s U.L.-liste d an d i s certifie d t o mee t th e requirement s o f SA E J221 0 t o remov e R-134 a

fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d throat . Avoi d

breathin g th e ai r conditione r refrigeran t an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r system s shoul d no t b e pressur e teste d o r lea k teste d wit h compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n show n to b e combustibl e a t elevate d pressure s an d ca n resul t

i n fir e o r explosio n causin g injur y o r propert y damage . Neve r us e compresse d ai r t o pressur e tes t R-134 a servic e equip -

men t o r vehicl e ai r conditione r systems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d fro m th e refrigeran t an d lubrican t manufacturers .

1 . Alway s disconnec t th e negativ e cabl e fro m th e batter y wheneve r replacin g ai r conditionin g parts .

2 . Kee p moistur e an d dus t ou t o f th e system . Whe n disconnectin g an y lines , plu g o r ca p th e fitting s immediately ; don' t

remov e th e cap s o r plug s unti l jus t befor e yo u reconnec t eac h line .

3 . Befor e connecting any hos e o r line , appl y a fe w drop s o f refrigeran t oi l t o th e O-ring .

4 . Whe n tightenin g o r loosenin g a fitting , us e a secon d wrenc h t o suppor t th e matchin g fitting .

5 . Whe n dischargin g th e system , us e a R-134 a refrigeran t Recovery/Recycling/Chargin g System ; don' t releas e refriger -

an t int o th e atmosphere .

6 . Ad d refrigeran t oi l afte r replacin g th e followin g parts :

NOTE :

To avoi d contamination , d o no t retur n th e oi l t o th e containe r onc e dispensed , an d neve r mi x i t wit h othe r refriger -

ant oils .

Immediatel y afte r usin g th e oil , replac e th e ca p o n th e container , an d sea l i t t o avoi d moistur e absorption .

D o no t spil l th e refrigeran t oi l o n th e vehicle ; i t ma y damag e th e paint ; i f th e refrigeran t oi l contact s th e paint , was h

i t of f immediately .

Condense r ....................................... . 2 5 (5/ 6 fl-oz , 0. 9 Imp-oz )

Evaporato r ....................................... . 5 0 ( 1 2/ 3 fl-oz , 1. 8 Imp-oz )

Lin e o r hos e ..................................... . 2 0 (2/ 3 fl-oz , 0. 7 Imp-oz )

Receiver/Drye r ................................ ..... 15(1/ 2(fl-oz , 0. 5 Imp-oz )

Leakag e repai r ................................ . 2 5 (5/ 6 fl-oz , 0. 9 Imp-oz )

Compresso r ............................... . Fo r compresso r replacement , subtrac t th e volum e o f oi l draine d fro m th e

remove d compresso r fro m 16 0 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz) , an d drai n th e calculate d

volume o f oi l fro m th e ne w compressor : 16 0 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz ) — Volum e

o f remove d compresso r = Volum e to drai n fro m ne w compressor .

NOTE : Eve n i f n o oi l i s draine d fro m th e remove d compressor , don' t drai n mor e

than 5 0 ( 1 2/ 3 fl-oz , 1. 8 Imp-oz ) fro m th e ne w compressor .

REMOVED NE W

COMPRESSOR COMPRESSO R

SAME LEVE LDRAININ GVOLUME160 ( 5 1/ 3 fl-oz , 5. 6 Imp-oz )

ProCarManuals.com

Page 1517 of 1771

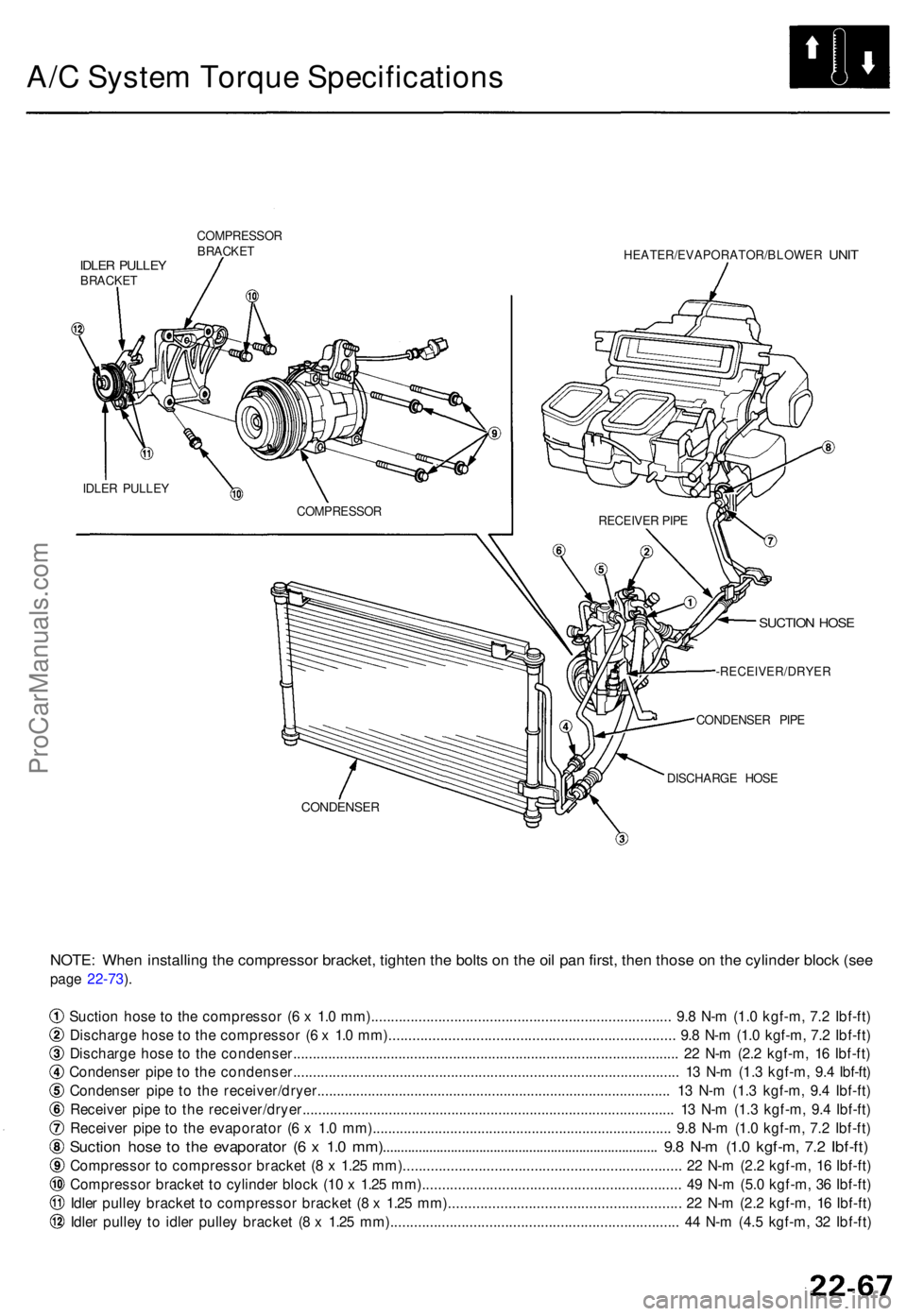

A/C Syste m Torqu e Specification s

COMPRESSO R

BRACKE T

IDLER PULLE YBRACKE T HEATER/EVAPORATOR/BLOWE

R

UNIT

SUCTIO N HOS E

-RECEIVER/DRYE R

CONDENSE R PIP E

DISCHARG E HOS E

CONDENSE R

NOTE: Whe n installin g th e compresso r bracket , tighte n th e bolt s o n th e oi l pa n first , the n thos e o n th e cylinde r bloc k (se e

page 22-73 ).

Suctio n hos e t o th e compresso r ( 6 x 1. 0 mm)...................................................................\

........ . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Discharg e hos e t o th e compresso r ( 6 x 1. 0 mm)...................................................................\

.... . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Discharg e hos e t o th e condenser..............................................................\

.................................... . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Condense r pip e t o th e condenser..............................................................\

................................... . 1 3 N- m (1. 3 kgf-m , 9. 4 Ibf-ft )

Condense r pip e t o th e receiver/dryer.........................................................\

................................. . 1 3 N- m (1. 3 kgf-m , 9. 4 Ibf-ft )

Receive r pip e t o th e receiver/dryer.........................................................\

..................................... . 1 3 N- m (1. 3 kgf-m , 9. 4 Ibf-ft )

Receive r pip e t o th e evaporato r ( 6 x 1. 0 mm)...................................................................\

......... . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Suctio n hos e t o th e evaporato r ( 6 x 1. 0 mm)...................................................................\

......... . 9. 8 N- m (1. 0 kgf-m , 7. 2 Ibf-ft )

Compresso r t o compresso r bracke t ( 8 x 1.2 5 mm)...................................................................\

.. . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Compresso r bracke t t o cylinde r bloc k (1 0 x 1.2 5 mm)................................................................ . 4 9 N- m (5. 0 kgf-m , 3 6 Ibf-ft )

Idle r pulle y bracke t t o compresso r bracke t ( 8 x 1.2 5 mm)......................................................... . 2 2 N- m (2. 2 kgf-m , 1 6 Ibf-ft )

Idle r pulle y t o idle r pulle y bracke t ( 8 x 1.2 5 mm)...................................................................\

..... . 4 4 N- m (4. 5 kgf-m , 3 2 Ibf-ft )

IDLER PULLE Y

COMPRESSOR

RECEIVER PIP E

ProCarManuals.com

Page 1518 of 1771

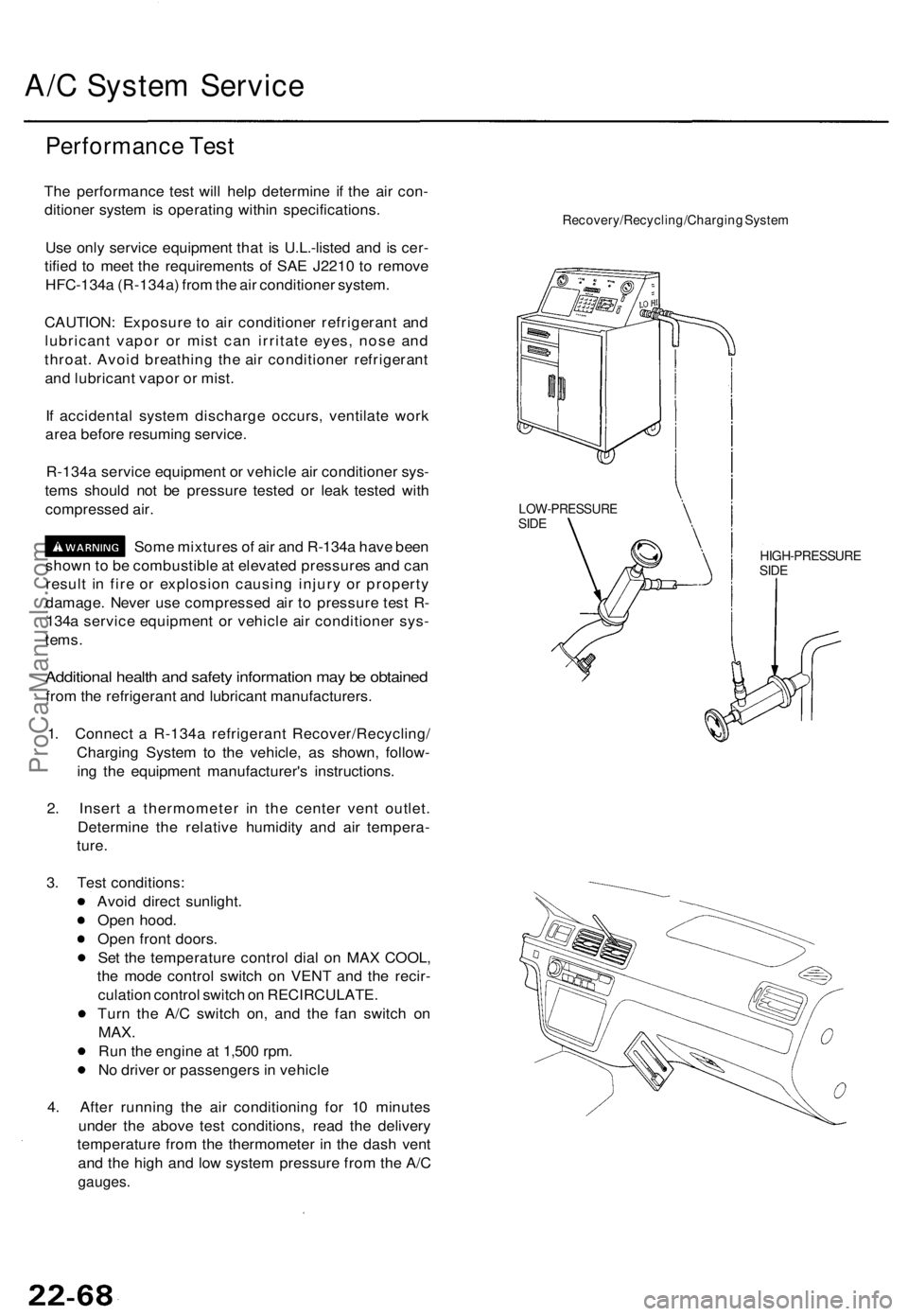

A/C Syste m Servic e

Performanc e Tes t

The performanc e tes t wil l hel p determin e i f th e ai r con -

ditione r syste m is operatin g withi n specifications .

Us e onl y servic e equipmen t tha t i s U.L.-liste d an d is cer -

tifie d t o mee t th e requirement s o f SA E J221 0 t o remov e

HFC-134 a (R-134a ) fro m th e ai r conditione r system .

CAUTION : Exposur e t o ai r conditione r refrigeran t an d

lubrican t vapo r o r mis t ca n irritat e eyes , nos e an d

throat . Avoi d breathin g th e ai r conditione r refrigeran t

an d lubrican t vapo r o r mist .

I f accidenta l syste m discharg e occurs , ventilat e wor k

are a befor e resumin g service .

R-134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tem s shoul d no t b e pressur e teste d o r lea k teste d wit h

compresse d air .

Som e mixture s o f ai r an d R-134 a hav e bee n

show n to b e combustibl e a t elevate d pressure s an d ca n

resul t i n fir e o r explosio n causin g injur y o r propert y

damage . Neve r us e compresse d ai r t o pressur e tes t R -

134 a servic e equipmen t o r vehicl e ai r conditione r sys -

tems .

Additiona l healt h an d safet y informatio n ma y b e obtaine d

from th e refrigeran t an d lubrican t manufacturers .

1 . Connec t a R-134 a refrigeran t Recover/Recycling /

Chargin g Syste m to th e vehicle , a s shown , follow -

in g th e equipmen t manufacturer' s instructions .

2 . Inser t a thermomete r i n th e cente r ven t outlet .

Determin e th e relativ e humidit y an d ai r tempera -

ture .

Recovery/Recycling/Chargin g Syste m

HIGH-PRESSUR ESIDE

3. Tes t conditions :

Avoi d direc t sunlight .

Ope n hood .

Ope n fron t doors .

Se t th e temperatur e contro l dia l o n MA X COOL ,

th e mod e contro l switc h o n VEN T an d th e recir -

culatio n contro l switc h o n RECIRCULATE .

Tur n th e A/ C switc h on , an d th e fa n switc h o n

MAX .

Run th e engin e a t 1,50 0 rpm .

N o drive r o r passenger s in vehicl e

4 . Afte r runnin g th e ai r conditionin g fo r 1 0 minute s

unde r th e abov e tes t conditions , rea d th e deliver y

temperatur e fro m th e thermomete r i n th e das h ven t

an d th e hig h an d lo w syste m pressur e fro m th e A/ C

gauges .

LOW-PRESSUR ESIDE

ProCarManuals.com

Page 1519 of 1771

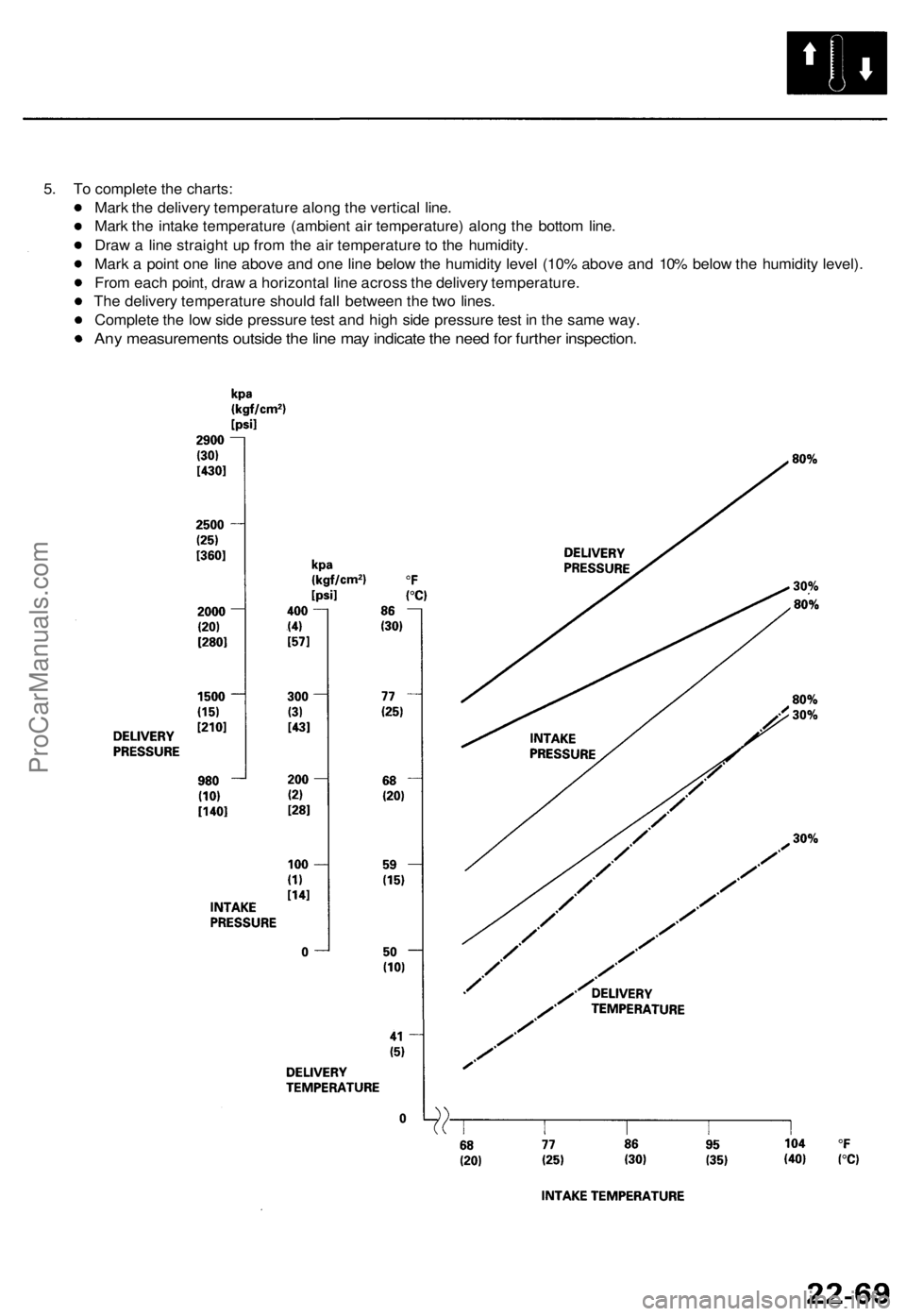

5. To complete the charts:

Mark the delivery temperature along the vertical line.

Mark the intake temperature (ambient air temperature) along the bottom line.

Draw a line straight up from the air temperature to the humidity.

Mark a point one line above and one line below the humidity level (10% above and 10% below the humidity level).

From each point, draw a horizontal line across the delivery temperature.

The delivery temperature should fall between the two lines.

Complete the low side pressure test and high side pressure test in the same way.

Any measurements outside the line may indicate the need for further inspection.ProCarManuals.com

Page 1520 of 1771

A/C Syste m Servic e

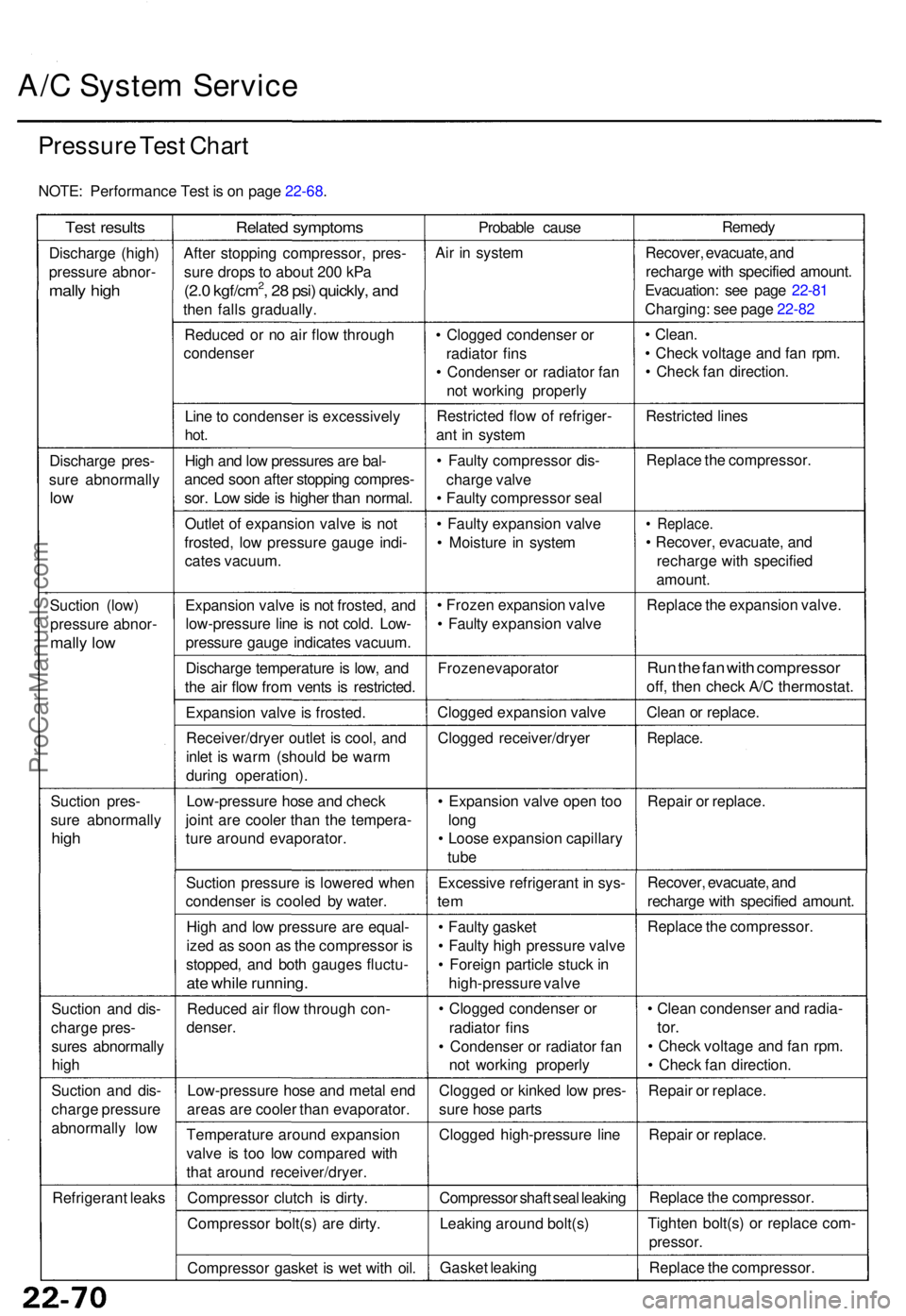

Pressur e Tes t Char t

NOTE : Performanc e Tes t i s o n pag e 22-68 .

Test result s

Discharg e (high )

pressur e abnor -

mally hig h

Discharg e pres -

sur e abnormall y

low

Suctio n (low )

pressur e abnor -

mally lo w

Suctio n pres -

sur e abnormall y

high

Suctio n an d dis -

charg e pres -

sure s abnormall y

hig h

Suctio n an d dis -

charg e pressur e

abnormall y lo w

Refrigeran t leak s

Relate d symptom s

After stoppin g compressor, pres-

sur e drop s t o abou t 20 0 kP a

(2.0 kgf/cm2, 2 8 psi ) quickly , an d

the n fall s gradually .

Reduce d o r n o ai r flo w throug h

condense r

Lin e to condense r i s excessivel y

hot.

Hig h an d lo w pressure s ar e bal -

ance d soo n afte r stoppin g compres -

sor . Lo w sid e is highe r tha n normal .

Outle t o f expansio n valv e is no t

frosted , lo w pressur e gaug e indi -

cate s vacuum .

Expansio n valv e is no t frosted , an d

low-pressur e lin e is no t cold . Low -

pressur e gaug e indicate s vacuum .

Discharg e temperatur e is low , an d

th e ai r flo w fro m vent s i s restricted .

Expansio n valv e is frosted .

Receiver/drye r outle t i s cool , an d

inle t i s war m (shoul d b e war m

durin g operation) .

Low-pressur e hos e an d chec k

join t ar e coole r tha n th e tempera -

tur e aroun d evaporator .

Suctio n pressur e is lowere d whe n

condense r i s coole d b y water .

Hig h an d lo w pressur e ar e equal -

ize d a s soo n a s th e compresso r i s

stopped , an d bot h gauge s fluctu -

ate whil e running .

Reduced ai r flo w throug h con -

denser .

Low-pressur e hos e an d meta l en d

area s ar e coole r tha n evaporator .

Temperatur e aroun d expansio n

valv e i s to o lo w compare d wit h

tha t aroun d receiver/dryer .

Compresso r clutc h i s dirty .

Compresso r bolt(s ) ar e dirty .

Compresso r gaske t i s we t wit h oil . Probabl

e caus e

Ai r i n syste m

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Restricte d flo w o f refriger -

an t i n syste m

• Fault y compresso r dis -

charg e valv e

• Fault y compresso r sea l

• Fault y expansio n valv e

• Moistur e i n syste m

• Froze n expansio n valv e

• Fault y expansio n valv e

Froze n evaporato r

Clogge d expansio n valv e

Clogge d receiver/drye r

• Expansio n valv e ope n to o

lon g

• Loos e expansio n capillar y

tub e

Excessiv e refrigeran t i n sys -

tem

• Fault y gaske t

• Fault y hig h pressur e valv e

• Foreig n particl e stuc k in

high-pressur e valv e

• Clogge d condense r o r

radiato r fin s

• Condense r o r radiato r fa n

no t workin g properl y

Clogge d o r kinke d lo w pres -

sur e hos e part s

Clogge d high-pressur e lin e

Compresso r shaf t sea l leakin g

Leakin g aroun d bolt(s )

Gaske t leakin g Remed

y

Recover , evacuate , an d

recharg e wit h specifie d amount .

Evacuation : se e pag e 22-8 1

Charging : se e pag e 22-8 2

• Clean .

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Restricte d line s

Replac e th e compressor .

• Replace .

• Recover , evacuate , an d

recharg e wit h specifie d

amount .

Replac e th e expansio n valve .

Run th e fa n wit h compresso r

off, the n chec k A/ C thermostat .

Clea n o r replace .

Replace .

Repair o r replace .

Recover , evacuate , an d

recharg e wit h specifie d amount .

Replac e th e compressor .

• Clea n condense r an d radia -

tor.

• Chec k voltag e an d fa n rpm .

• Chec k fa n direction .

Repai r o r replace .

Repai r o r replace .

Replac e th e compressor .

Tighte n bolt(s ) o r replac e com -

pressor .

Replac e th e compressor .

ProCarManuals.com