DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999,

Model line: NEON,

Model: DODGE NEON 1999

Pages: 1200, PDF Size: 35.29 MB

DODGE NEON 1999 Service Repair Manual

NEON 1999

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56911/w960_56911-0.png

DODGE NEON 1999 Service Repair Manual

Trending: set clock, engine overheat, brake, wheel, fuse box, display, wiper blades

Page 1021 of 1200

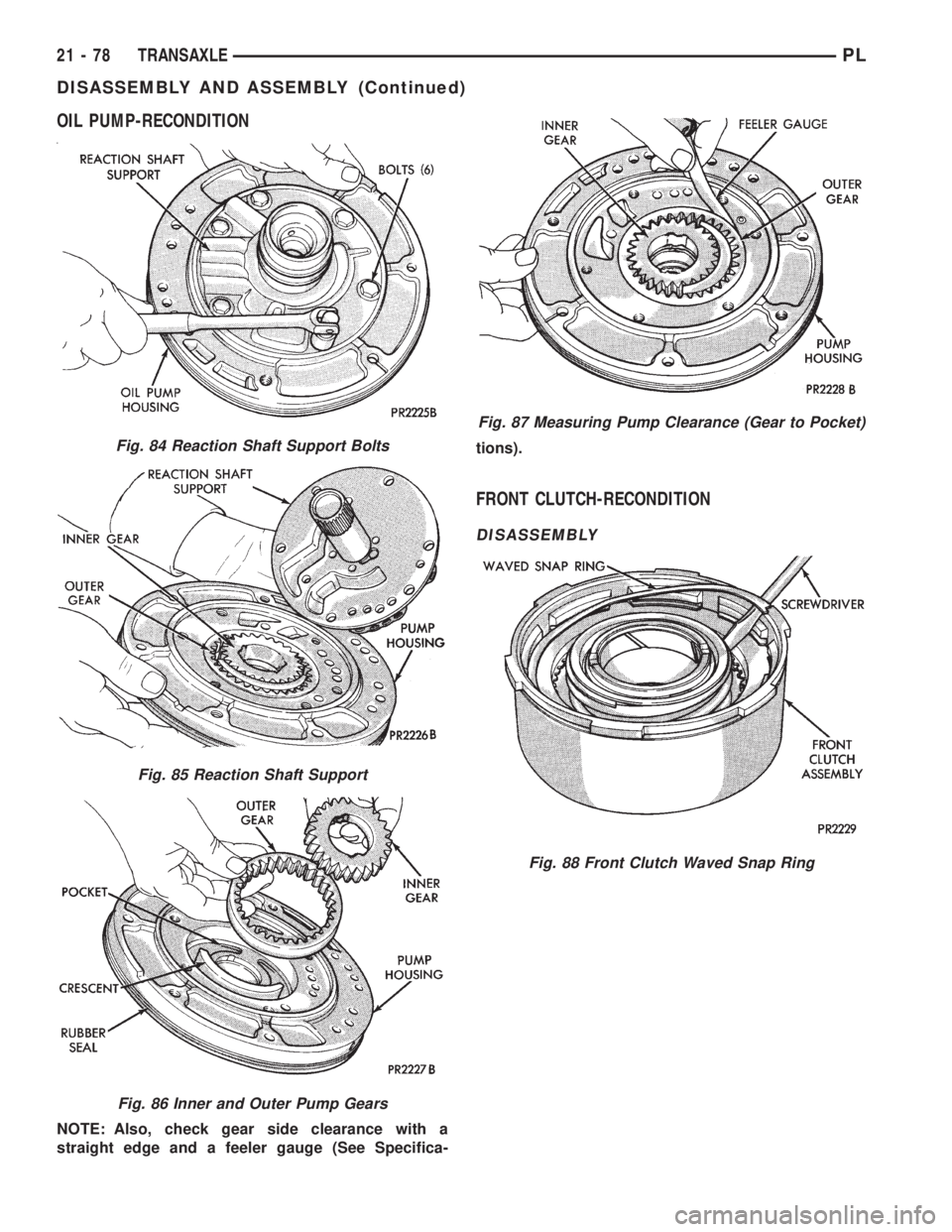

OIL PUMP-RECONDITION

NOTE: Also, check gear side clearance with a

straight edge and a feeler gauge (See Specifica-tions).

FRONT CLUTCH-RECONDITION

DISASSEMBLY

Fig. 84 Reaction Shaft Support Bolts

Fig. 85 Reaction Shaft Support

Fig. 86 Inner and Outer Pump Gears

Fig. 87 Measuring Pump Clearance (Gear to Pocket)

Fig. 88 Front Clutch Waved Snap Ring

21 - 78 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1022 of 1200

ASSEMBLY

To reassemble, reverse the above procedure.MEASURING PLATE CLEARANCE

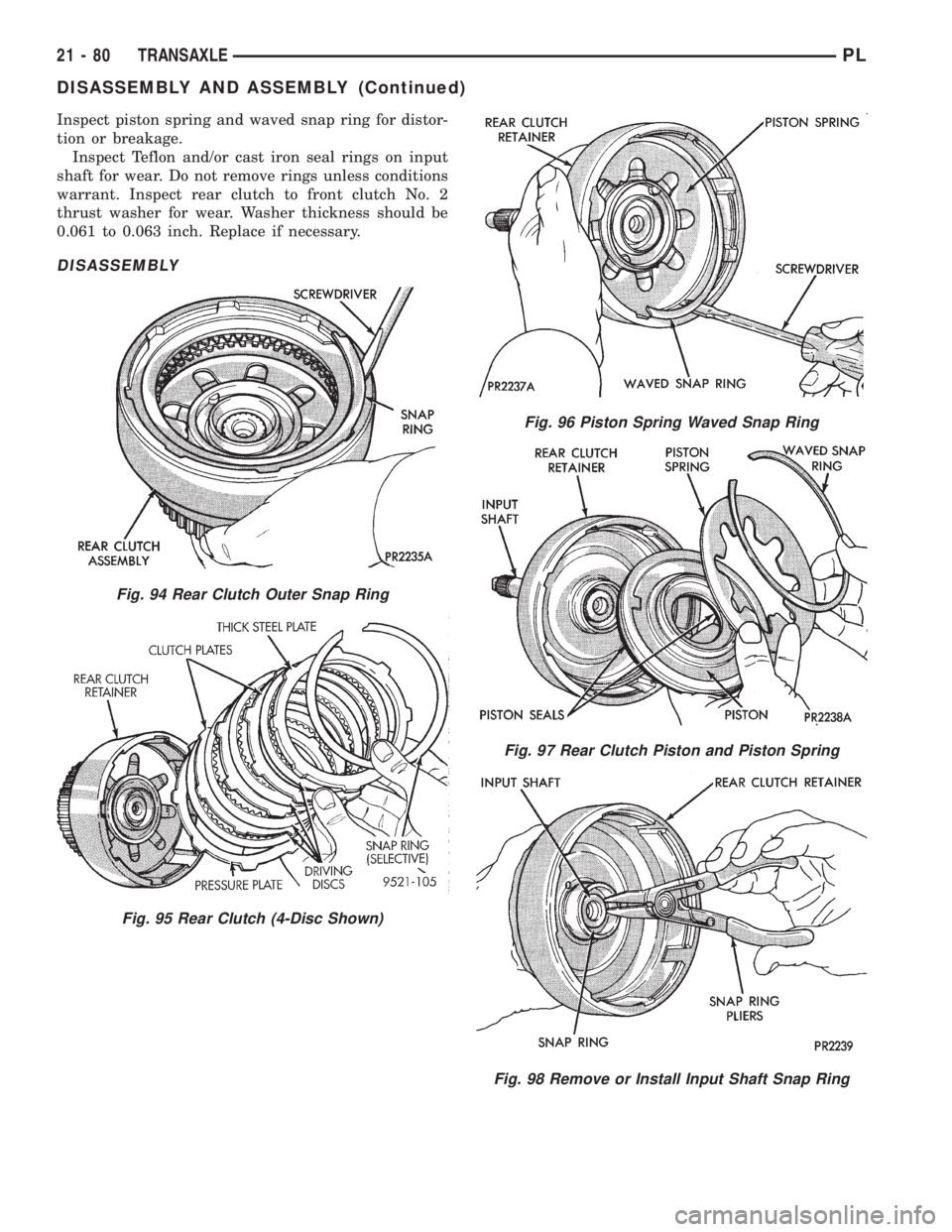

REAR CLUTCH-RECONDITION

INSPECTION

Inspect facing material on all driving discs.

Replace discs that are charred, glazed, or heavily pit-

ted. Discs should also be replaced if they show evi-

dence of material flaking off, or if facing material can

be scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate and pres-

sure plate surface for burning, scoring, or damaged

driving lugs. Replace if necessary. Inspect plates and

discs for flatness; they must not be warped or cone-

shaped.

Inspect steel plate lug grooves in clutch retainer

for smooth surfaces; plates must travel freely in the

grooves. Note ball check in piston; be sure ball moves

freely. Inspect seal rings surfaces in clutch retainer

for nicks or deep scratches; light scratches will not

interfere with sealing of the seals. Inspect Neoprene

seal rings for deterioration, wear, and hardness.

Fig. 89 Thick Steel Plate and Waved Snap Ring

Fig. 90 Front Clutch (4-Disc Shown)

Fig. 91 Front Clutch Return Spring Snap Ring

Fig. 92 Front Clutch Return Spring and Piston

Fig. 93 Measuring Front Clutch Plate Clearance

PLTRANSAXLE 21 - 79

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1023 of 1200

Inspect piston spring and waved snap ring for distor-

tion or breakage.

Inspect Teflon and/or cast iron seal rings on input

shaft for wear. Do not remove rings unless conditions

warrant. Inspect rear clutch to front clutch No. 2

thrust washer for wear. Washer thickness should be

0.061 to 0.063 inch. Replace if necessary.

DISASSEMBLY

Fig. 94 Rear Clutch Outer Snap Ring

Fig. 95 Rear Clutch (4-Disc Shown)

Fig. 96 Piston Spring Waved Snap Ring

Fig. 97 Rear Clutch Piston and Piston Spring

Fig. 98 Remove or Install Input Shaft Snap Ring

21 - 80 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1024 of 1200

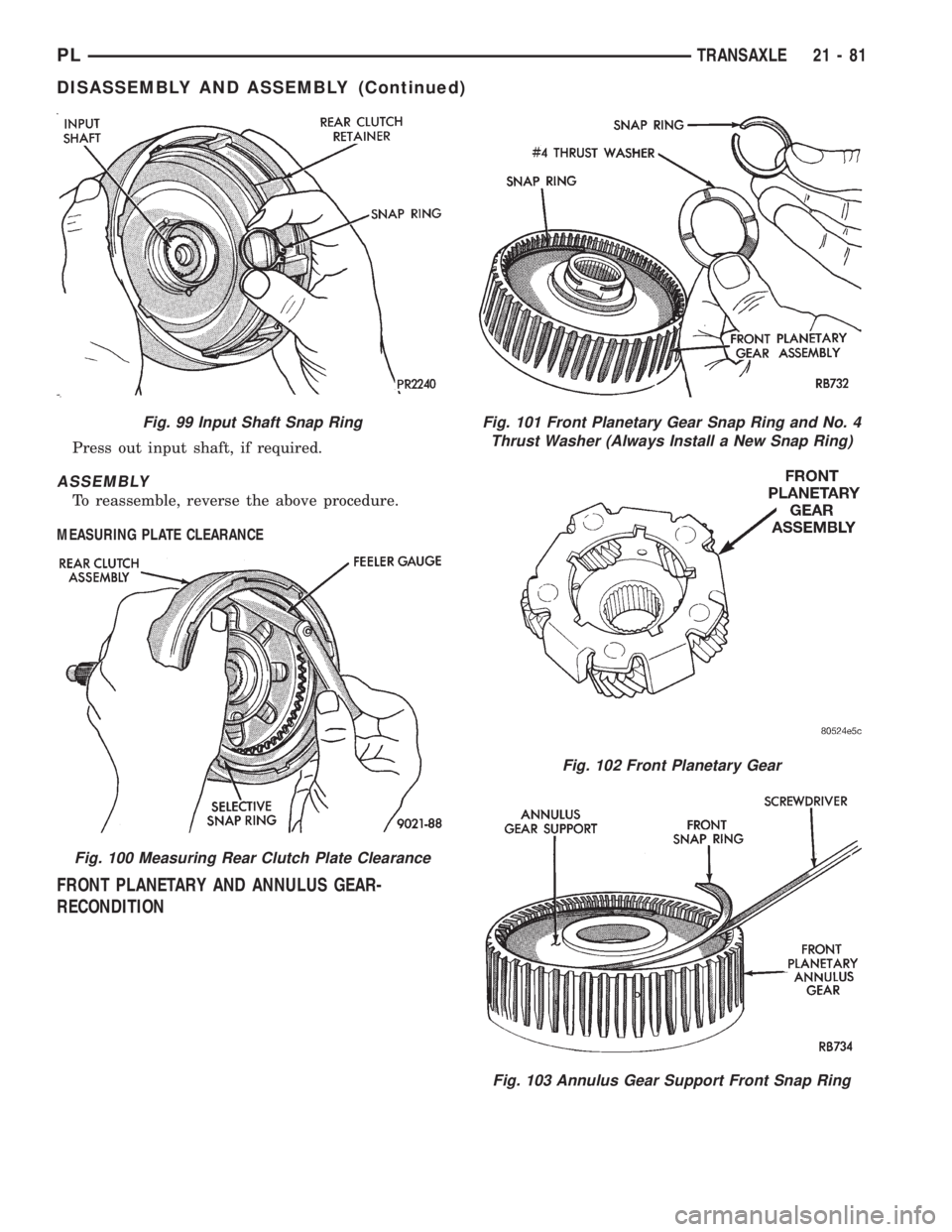

Press out input shaft, if required.

ASSEMBLY

To reassemble, reverse the above procedure.

MEASURING PLATE CLEARANCE

FRONT PLANETARY AND ANNULUS GEAR-

RECONDITION

Fig. 99 Input Shaft Snap Ring

Fig. 100 Measuring Rear Clutch Plate Clearance

Fig. 101 Front Planetary Gear Snap Ring and No. 4

Thrust Washer (Always Install a New Snap Ring)

Fig. 102 Front Planetary Gear

Fig. 103 Annulus Gear Support Front Snap Ring

PLTRANSAXLE 21 - 81

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1025 of 1200

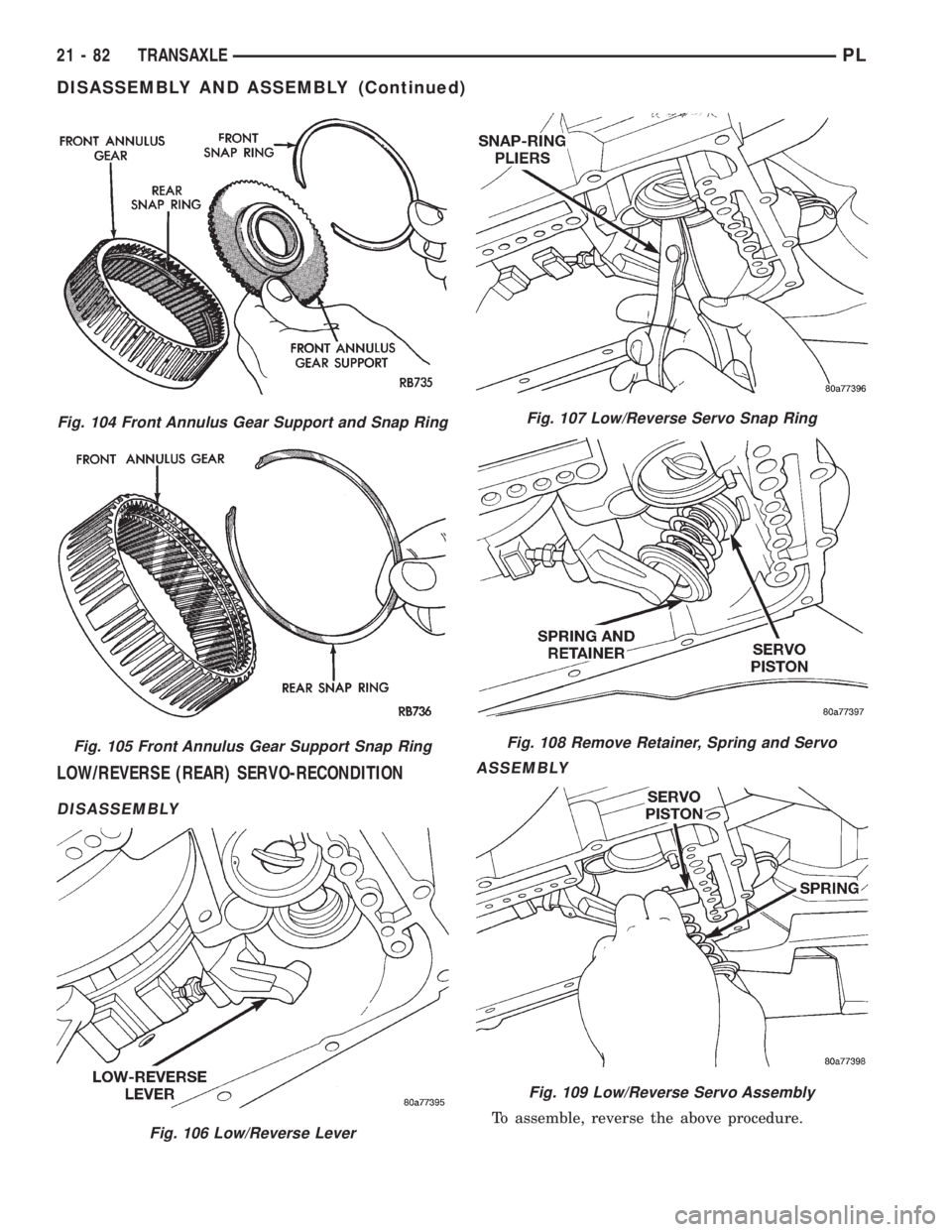

LOW/REVERSE (REAR) SERVO-RECONDITION

DISASSEMBLYASSEMBLY

To assemble, reverse the above procedure.

Fig. 104 Front Annulus Gear Support and Snap Ring

Fig. 105 Front Annulus Gear Support Snap Ring

Fig. 106 Low/Reverse Lever

Fig. 107 Low/Reverse Servo Snap Ring

Fig. 108 Remove Retainer, Spring and Servo

Fig. 109 Low/Reverse Servo Assembly

21 - 82 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1026 of 1200

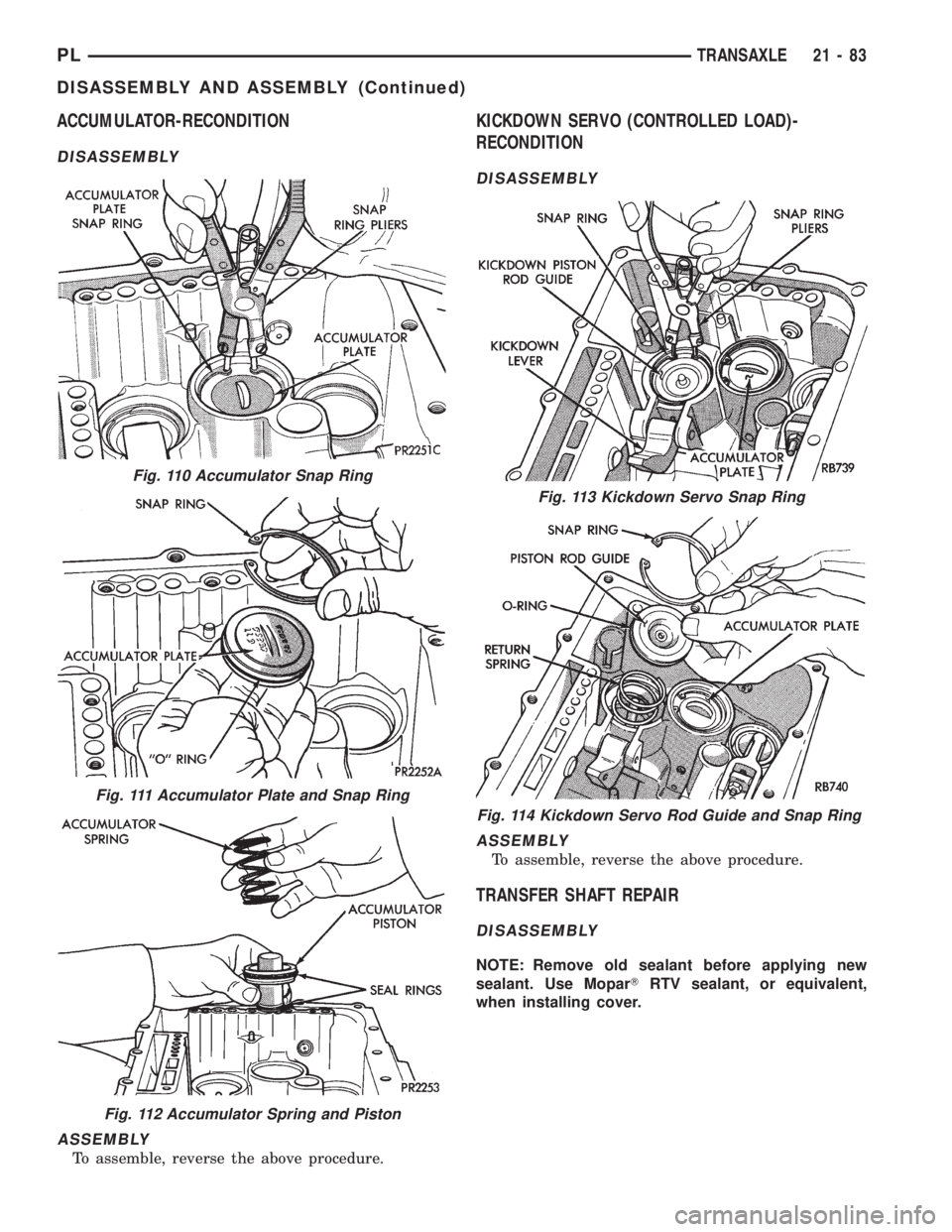

ACCUMULATOR-RECONDITION

DISASSEMBLY

ASSEMBLY

To assemble, reverse the above procedure.

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION

DISASSEMBLY

ASSEMBLY

To assemble, reverse the above procedure.

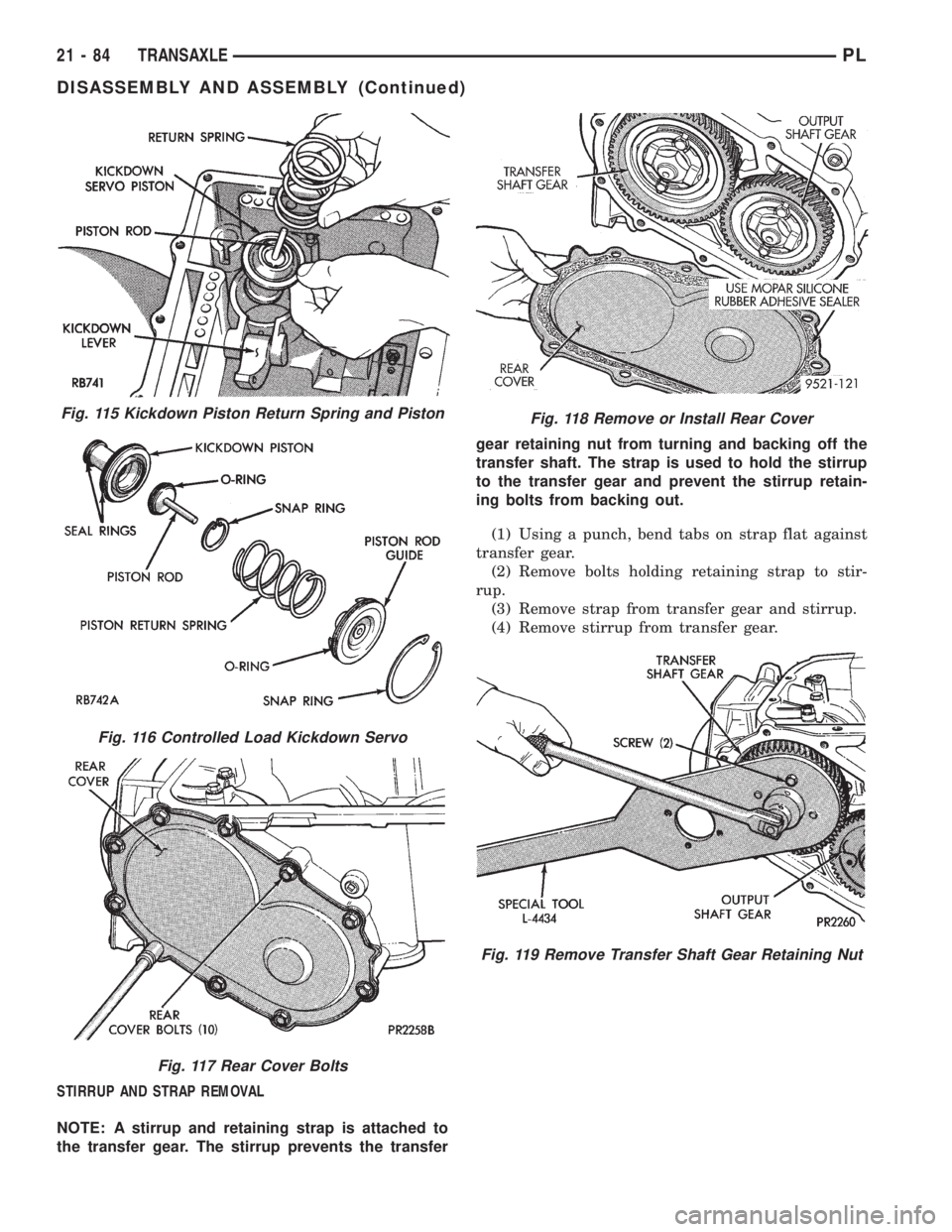

TRANSFER SHAFT REPAIR

DISASSEMBLY

NOTE: Remove old sealant before applying new

sealant. Use MoparTRTV sealant, or equivalent,

when installing cover.

Fig. 110 Accumulator Snap Ring

Fig. 111 Accumulator Plate and Snap Ring

Fig. 112 Accumulator Spring and Piston

Fig. 113 Kickdown Servo Snap Ring

Fig. 114 Kickdown Servo Rod Guide and Snap Ring

PLTRANSAXLE 21 - 83

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1027 of 1200

STIRRUP AND STRAP REMOVAL

NOTE: A stirrup and retaining strap is attached to

the transfer gear. The stirrup prevents the transfergear retaining nut from turning and backing off the

transfer shaft. The strap is used to hold the stirrup

to the transfer gear and prevent the stirrup retain-

ing bolts from backing out.

(1) Using a punch, bend tabs on strap flat against

transfer gear.

(2) Remove bolts holding retaining strap to stir-

rup.

(3) Remove strap from transfer gear and stirrup.

(4) Remove stirrup from transfer gear.

Fig. 115 Kickdown Piston Return Spring and Piston

Fig. 116 Controlled Load Kickdown Servo

Fig. 117 Rear Cover Bolts

Fig. 118 Remove or Install Rear Cover

Fig. 119 Remove Transfer Shaft Gear Retaining Nut

21 - 84 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1028 of 1200

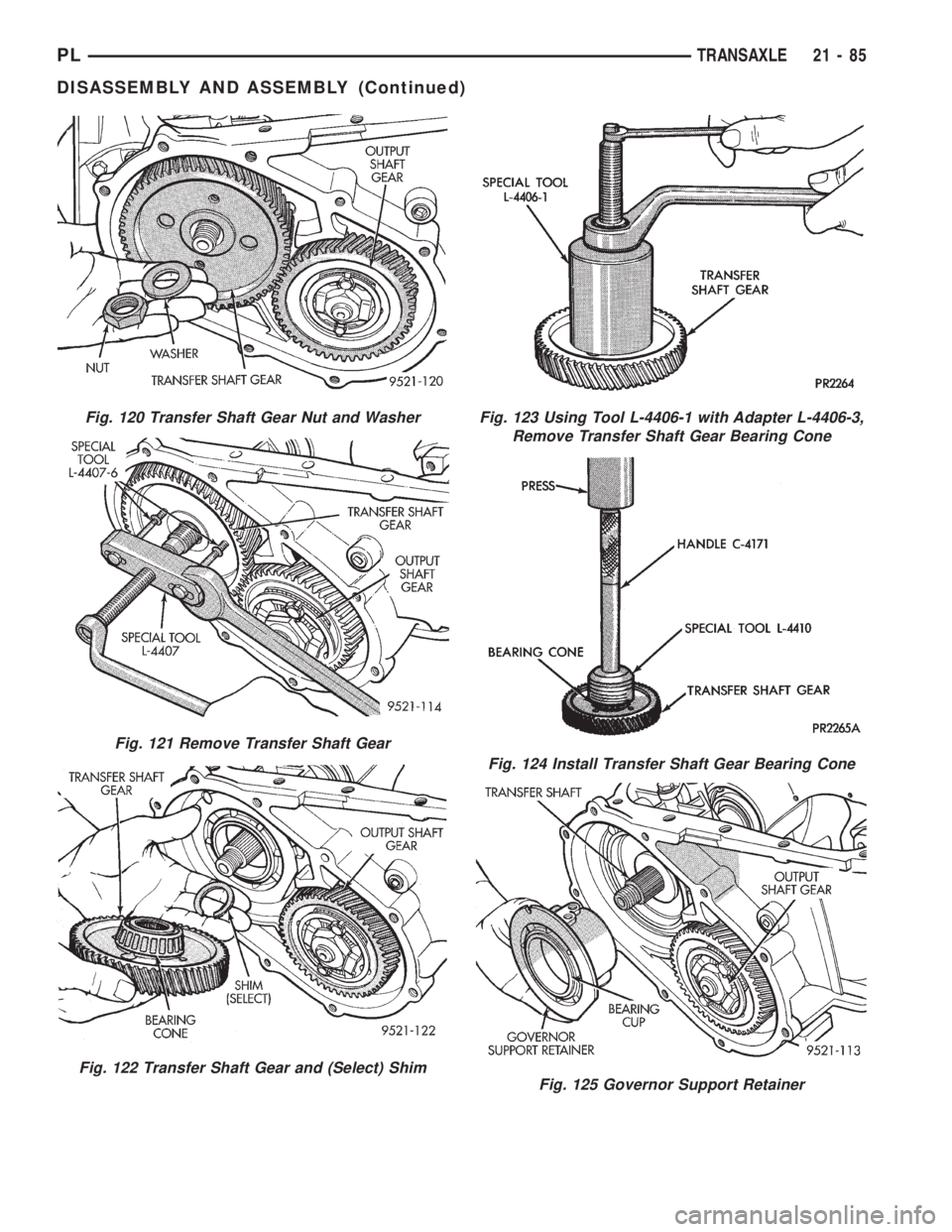

Fig. 120 Transfer Shaft Gear Nut and Washer

Fig. 121 Remove Transfer Shaft Gear

Fig. 122 Transfer Shaft Gear and (Select) Shim

Fig. 123 Using Tool L-4406-1 with Adapter L-4406-3,

Remove Transfer Shaft Gear Bearing Cone

Fig. 124 Install Transfer Shaft Gear Bearing Cone

Fig. 125 Governor Support Retainer

PLTRANSAXLE 21 - 85

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1029 of 1200

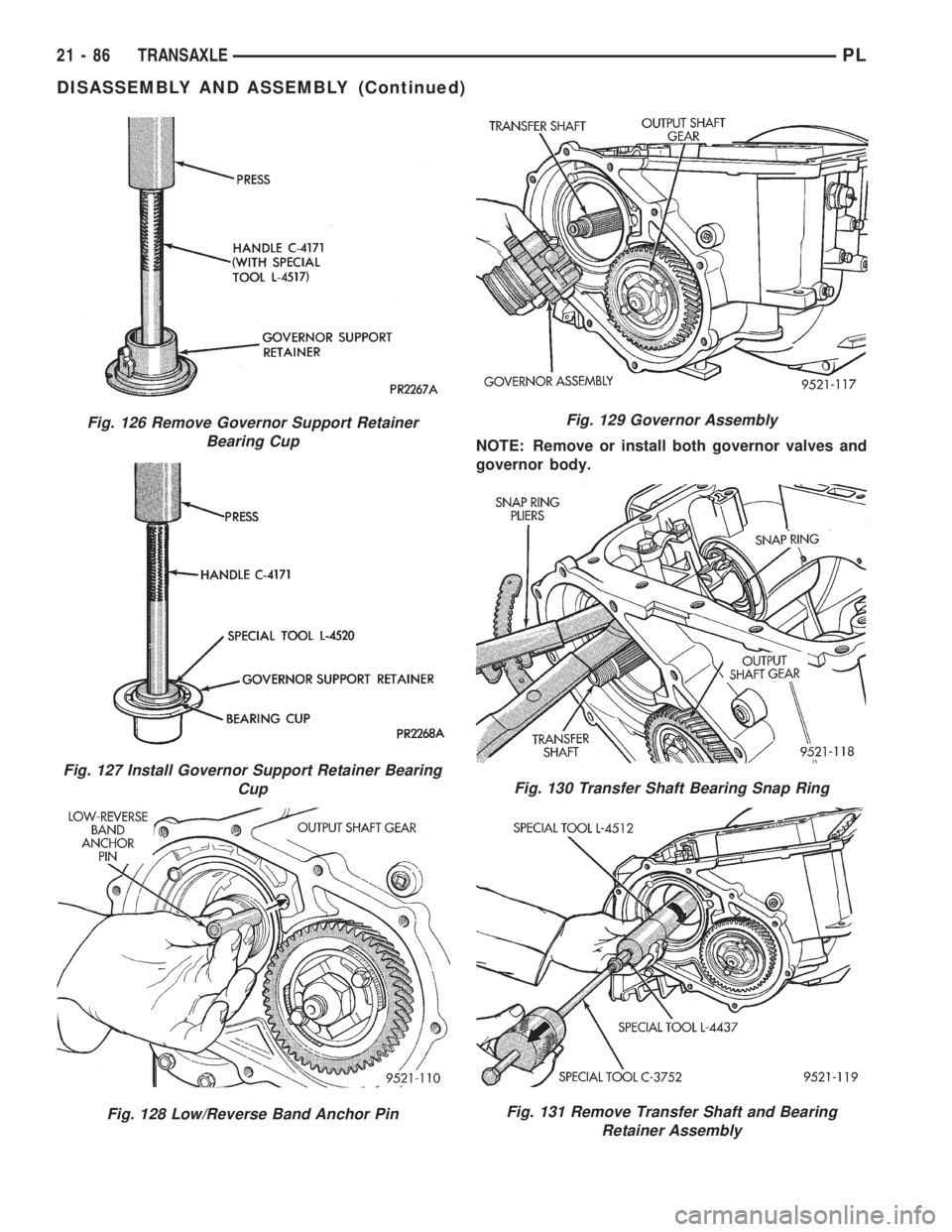

NOTE: Remove or install both governor valves and

governor body.

Fig. 126 Remove Governor Support Retainer

Bearing Cup

Fig. 127 Install Governor Support Retainer Bearing

Cup

Fig. 128 Low/Reverse Band Anchor Pin

Fig. 129 Governor Assembly

Fig. 130 Transfer Shaft Bearing Snap Ring

Fig. 131 Remove Transfer Shaft and Bearing

Retainer Assembly

21 - 86 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1030 of 1200

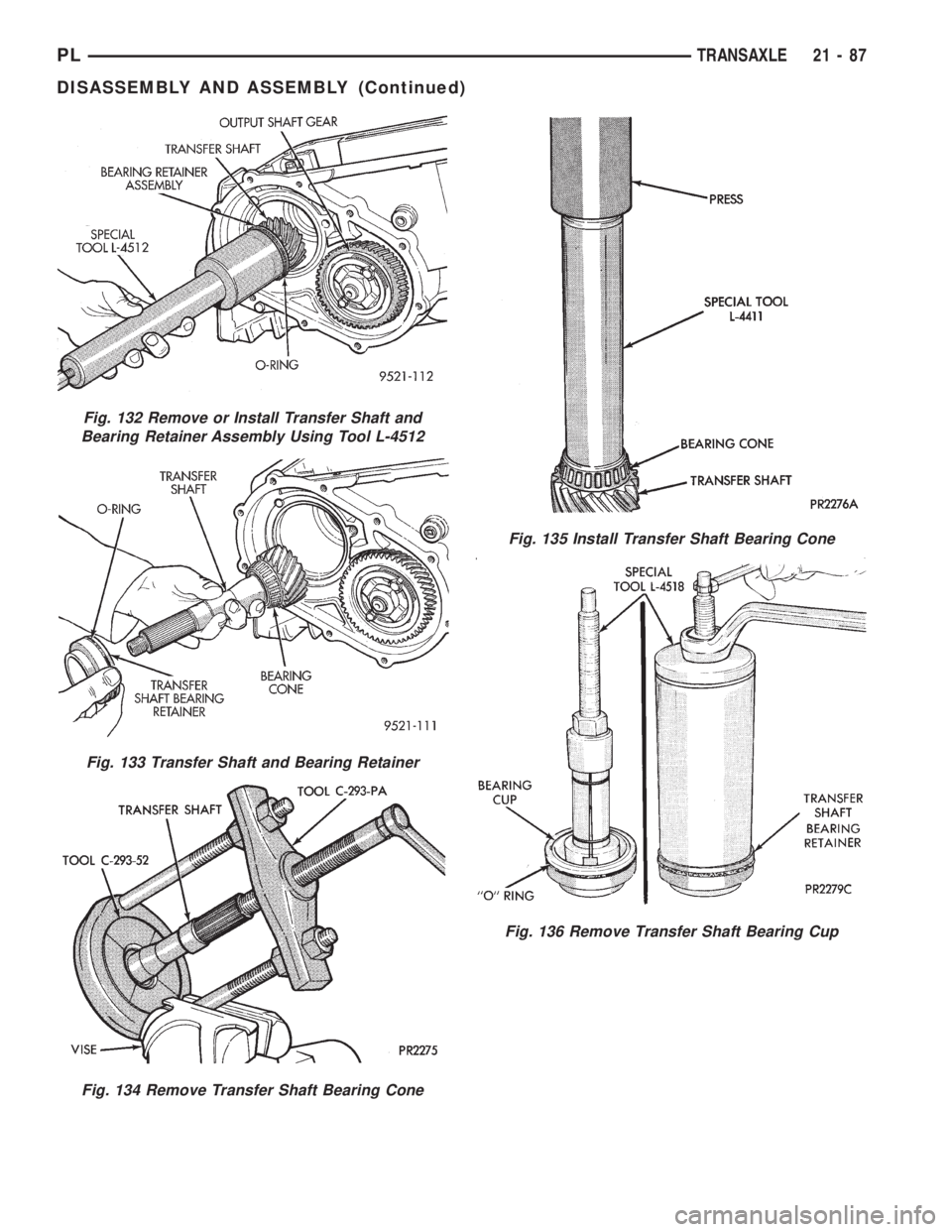

Fig. 132 Remove or Install Transfer Shaft and

Bearing Retainer Assembly Using Tool L-4512

Fig. 133 Transfer Shaft and Bearing Retainer

Fig. 134 Remove Transfer Shaft Bearing Cone

Fig. 135 Install Transfer Shaft Bearing Cone

Fig. 136 Remove Transfer Shaft Bearing Cup

PLTRANSAXLE 21 - 87

DISASSEMBLY AND ASSEMBLY (Continued)

Trending: fuel cap release, octane, key, rear view mirror, key fob battery, recommended oil, check engine