DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999,

Model line: NEON,

Model: DODGE NEON 1999

Pages: 1200, PDF Size: 35.29 MB

DODGE NEON 1999 Service Repair Manual

NEON 1999

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56911/w960_56911-0.png

DODGE NEON 1999 Service Repair Manual

Trending: transmission fluid, engine oil capacity, open hood, drain bolt, key fob, battery capacity, clock

Page 1031 of 1200

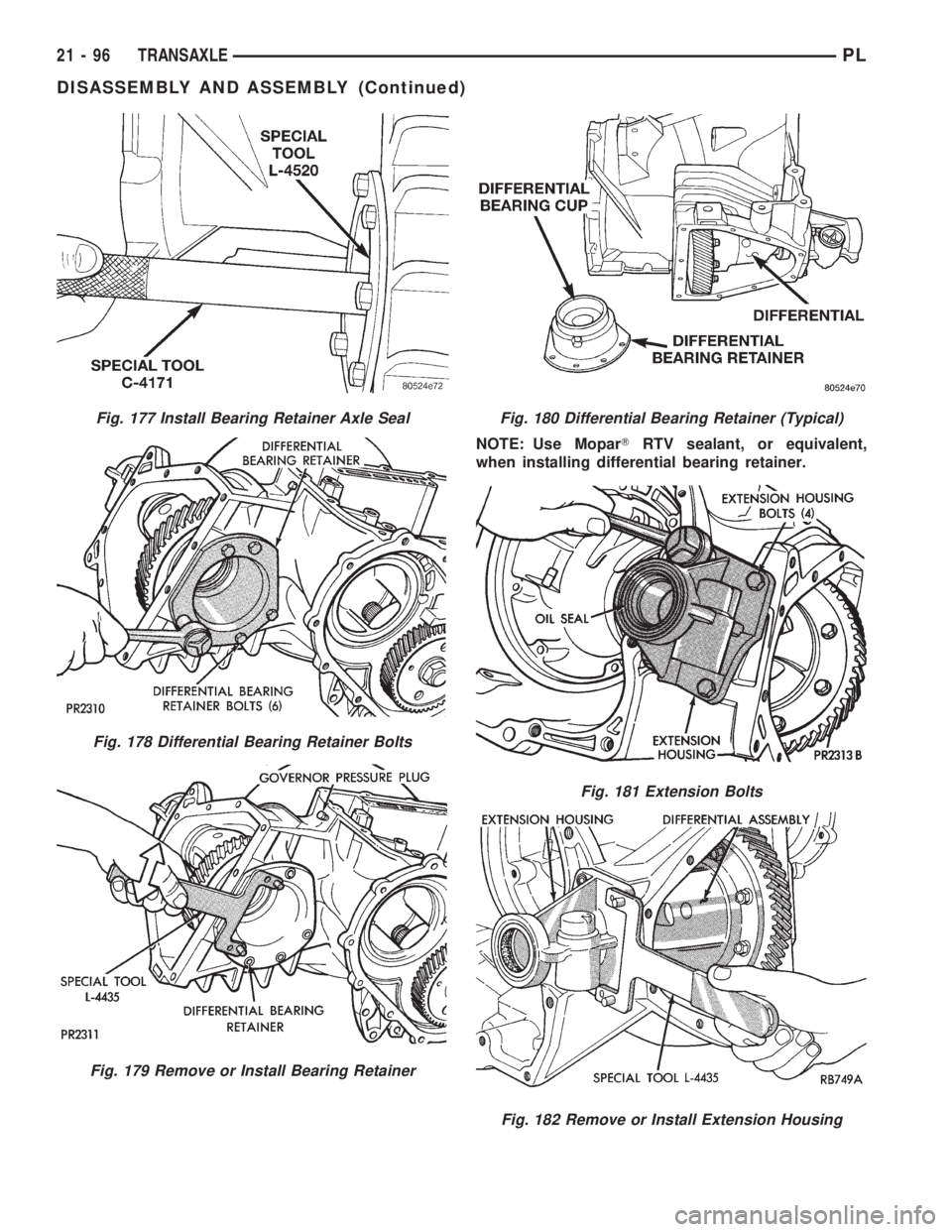

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Transfer shaft

²Transfer shaft gear

²Transfer shaft bearings

²Governor support retainer

²Transfer shaft bearing retainer

²Retainer snap ring

²Governor support

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.STIRRUP AND STRAP INSTALLATION

Once bearing shim selection has been adjusted,

install stirrup and strap assembly onto transfer gear.

NOTE: Once the stirrup assembly is positioned

onto the transfer gear, it is necessary to ªclockº the

stirrup against the flats of the transfer gear retain-

ing nut.

(1) Position the stirrup on the transfer gear.

(2) Position strap.

(3) Install retaining bolts into transfer gear. Fin-

ger±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

transfer gear retaining nut.

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

ASSEMBLY

To install transfer shaft, reverse the above proce-

dure.

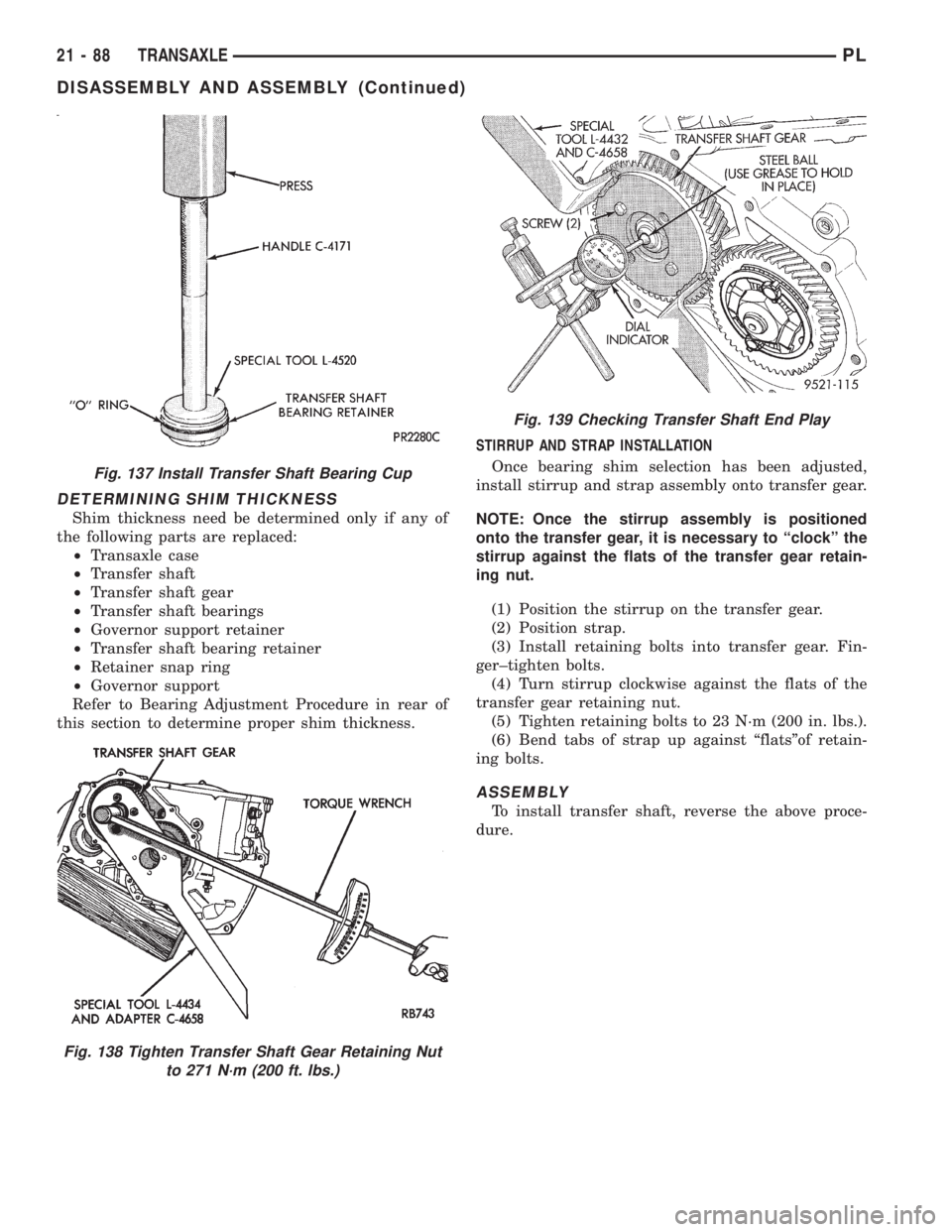

Fig. 137 Install Transfer Shaft Bearing Cup

Fig. 138 Tighten Transfer Shaft Gear Retaining Nut

to 271 N´m (200 ft. lbs.)

Fig. 139 Checking Transfer Shaft End Play

21 - 88 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1032 of 1200

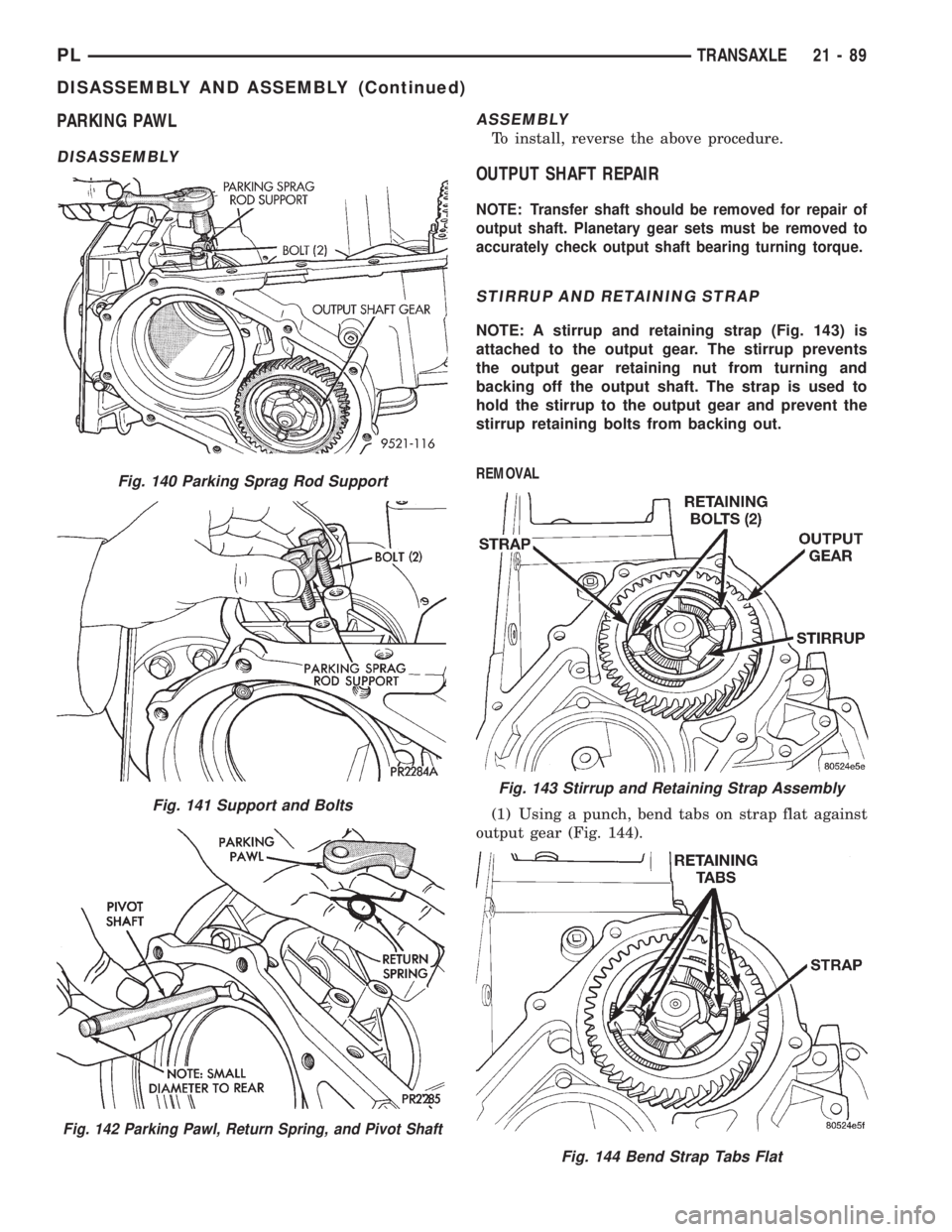

PARKING PAWL

DISASSEMBLYASSEMBLY

To install, reverse the above procedure.

OUTPUT SHAFT REPAIR

NOTE: Transfer shaft should be removed for repair of

output shaft. Planetary gear sets must be removed to

accurately check output shaft bearing turning torque.

STIRRUP AND RETAINING STRAP

NOTE: A stirrup and retaining strap (Fig. 143) is

attached to the output gear. The stirrup prevents

the output gear retaining nut from turning and

backing off the output shaft. The strap is used to

hold the stirrup to the output gear and prevent the

stirrup retaining bolts from backing out.

REMOVAL

(1) Using a punch, bend tabs on strap flat against

output gear (Fig. 144).

Fig. 140 Parking Sprag Rod Support

Fig. 141 Support and Bolts

Fig. 142 Parking Pawl, Return Spring, and Pivot Shaft

Fig. 143 Stirrup and Retaining Strap Assembly

Fig. 144 Bend Strap Tabs Flat

PLTRANSAXLE 21 - 89

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1033 of 1200

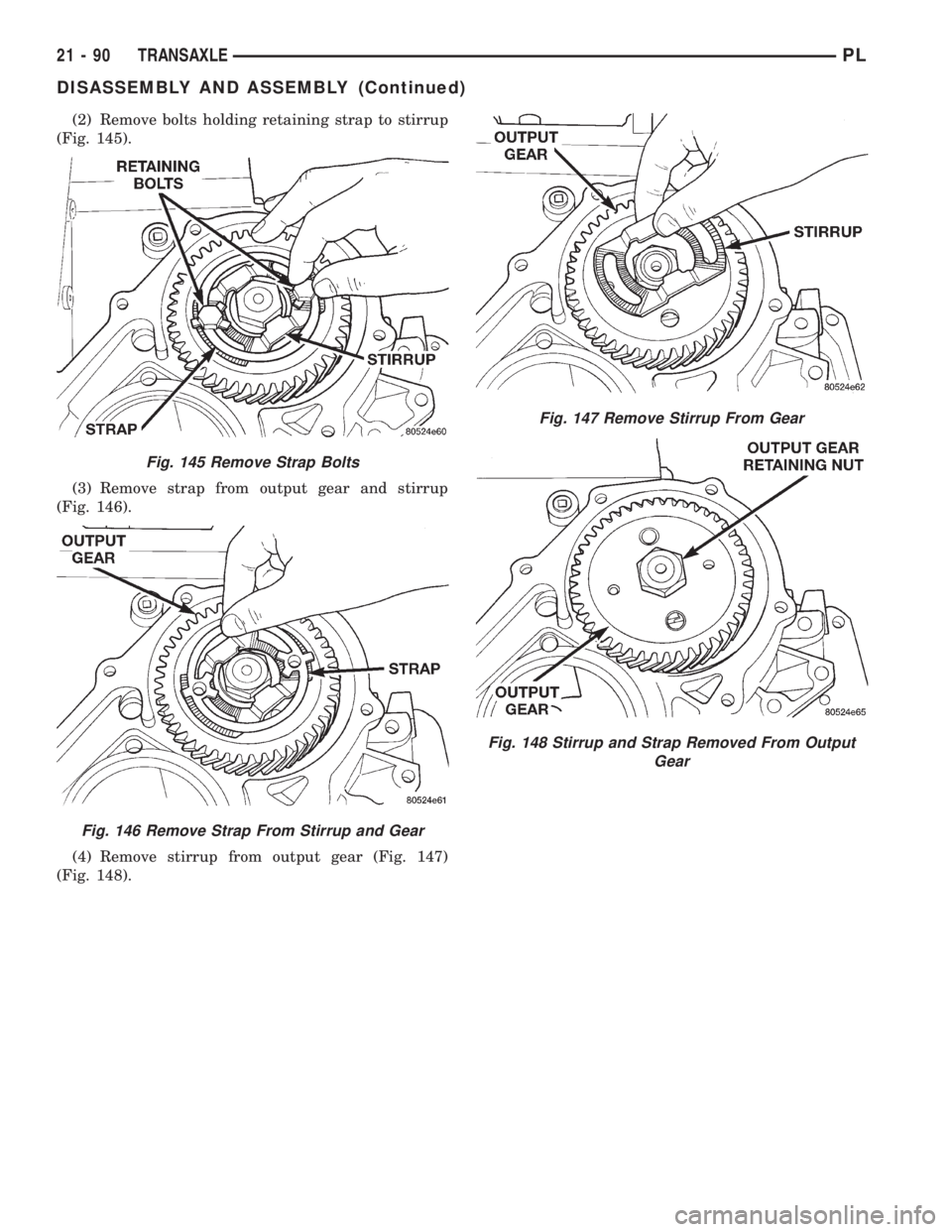

(2) Remove bolts holding retaining strap to stirrup

(Fig. 145).

(3) Remove strap from output gear and stirrup

(Fig. 146).

(4) Remove stirrup from output gear (Fig. 147)

(Fig. 148).

Fig. 145 Remove Strap Bolts

Fig. 146 Remove Strap From Stirrup and Gear

Fig. 147 Remove Stirrup From Gear

Fig. 148 Stirrup and Strap Removed From Output

Gear

21 - 90 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1034 of 1200

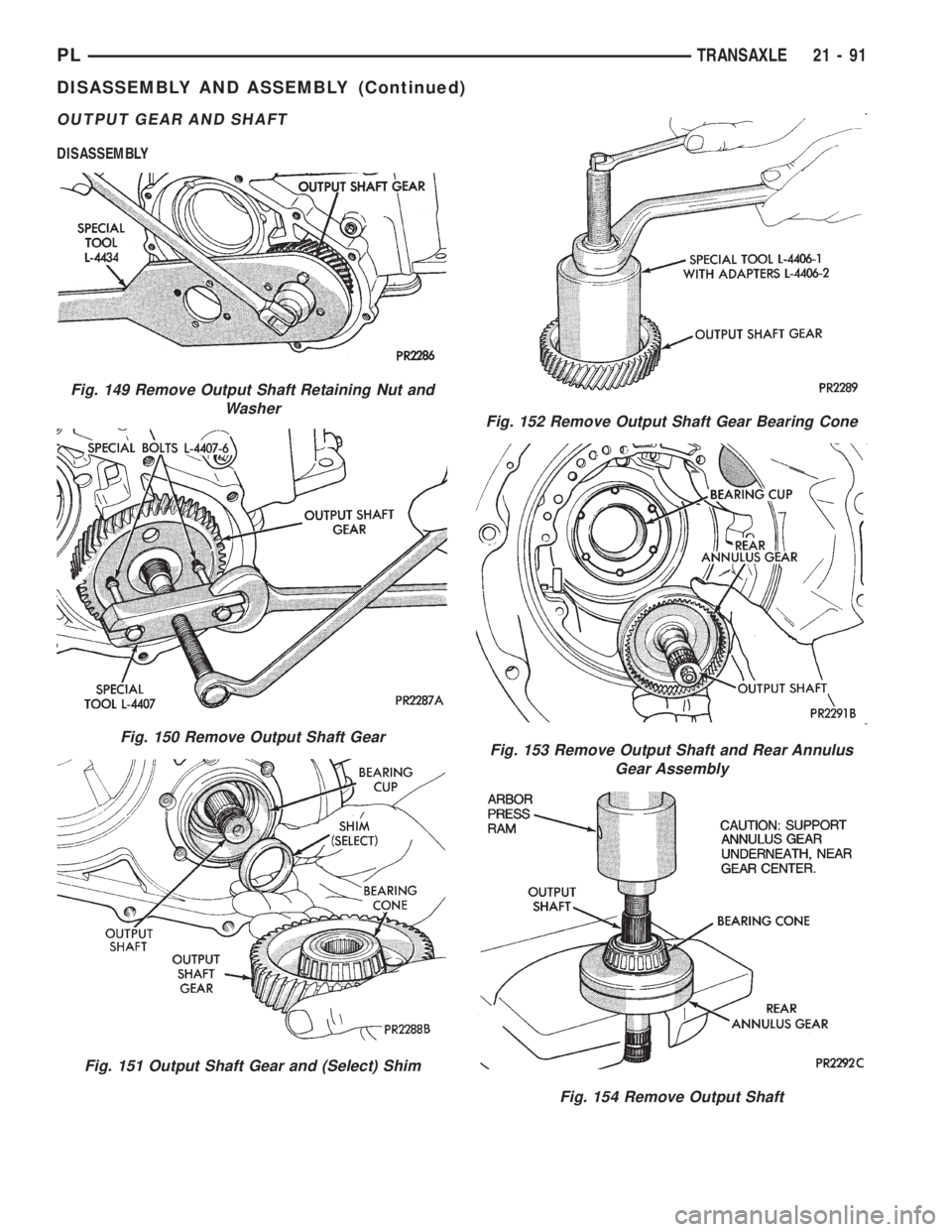

OUTPUT GEAR AND SHAFT

DISASSEMBLY

Fig. 149 Remove Output Shaft Retaining Nut and

Washer

Fig. 150 Remove Output Shaft Gear

Fig. 151 Output Shaft Gear and (Select) Shim

Fig. 152 Remove Output Shaft Gear Bearing Cone

Fig. 153 Remove Output Shaft and Rear Annulus

Gear Assembly

Fig. 154 Remove Output Shaft

PLTRANSAXLE 21 - 91

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1035 of 1200

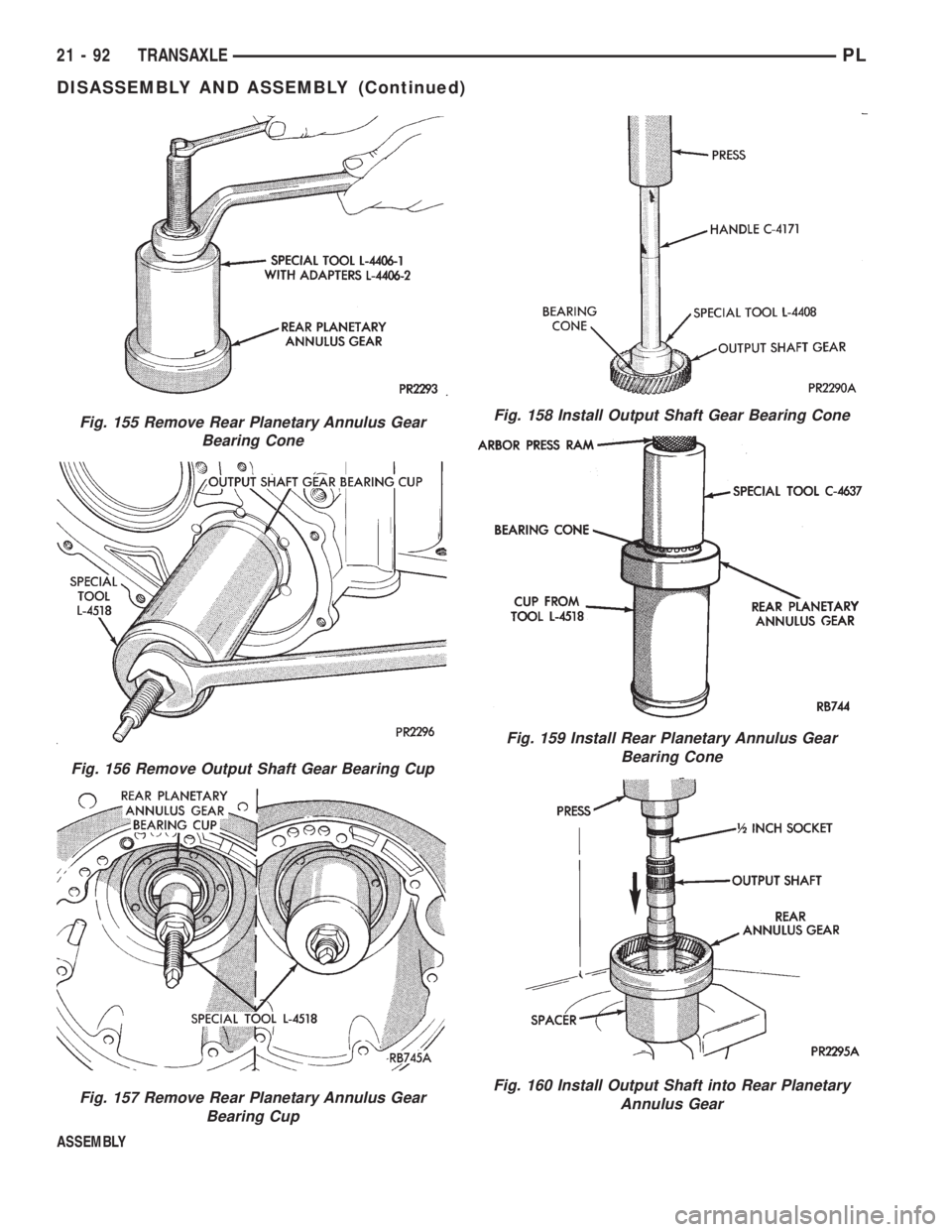

ASSEMBLY

Fig. 155 Remove Rear Planetary Annulus Gear

Bearing Cone

Fig. 156 Remove Output Shaft Gear Bearing Cup

Fig. 157 Remove Rear Planetary Annulus Gear

Bearing Cup

Fig. 158 Install Output Shaft Gear Bearing Cone

Fig. 159 Install Rear Planetary Annulus Gear

Bearing Cone

Fig. 160 Install Output Shaft into Rear Planetary

Annulus Gear

21 - 92 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1036 of 1200

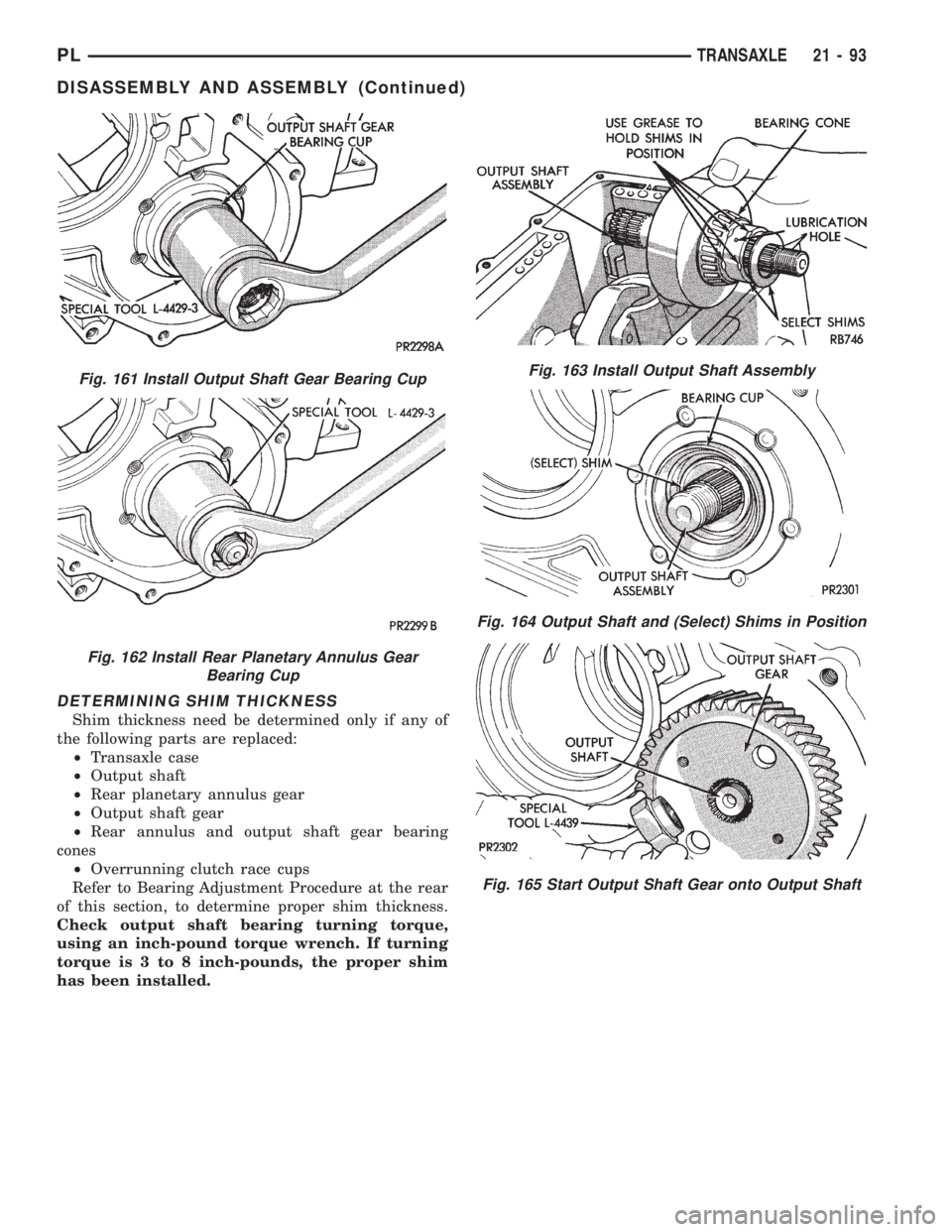

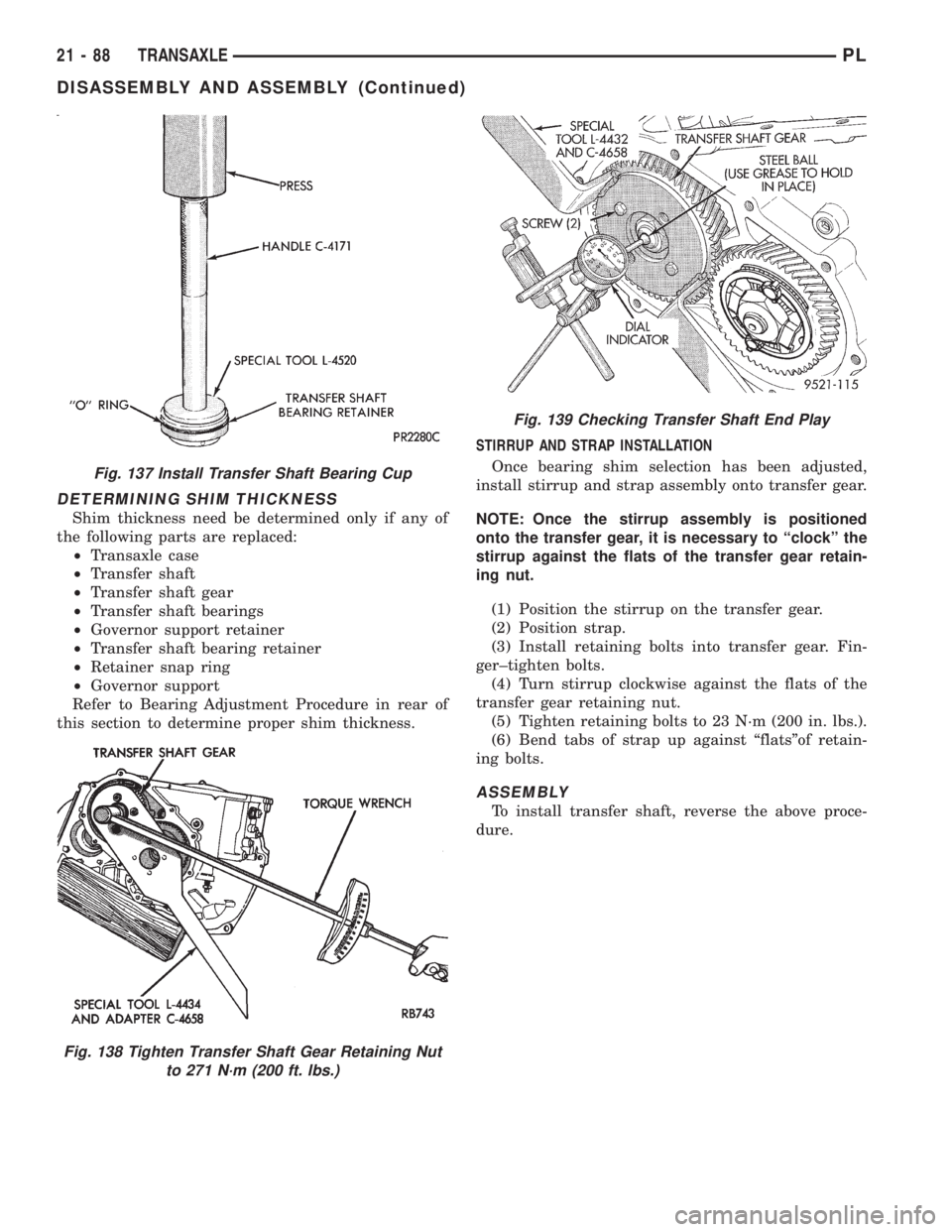

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Output shaft

²Rear planetary annulus gear

²Output shaft gear

²Rear annulus and output shaft gear bearing

cones

²Overrunning clutch race cups

Refer to Bearing Adjustment Procedure at the rear

of this section, to determine proper shim thickness.

Check output shaft bearing turning torque,

using an inch-pound torque wrench. If turning

torque is 3 to 8 inch-pounds, the proper shim

has been installed.

Fig. 161 Install Output Shaft Gear Bearing Cup

Fig. 162 Install Rear Planetary Annulus Gear

Bearing Cup

Fig. 163 Install Output Shaft Assembly

Fig. 164 Output Shaft and (Select) Shims in Position

Fig. 165 Start Output Shaft Gear onto Output Shaft

PLTRANSAXLE 21 - 93

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1037 of 1200

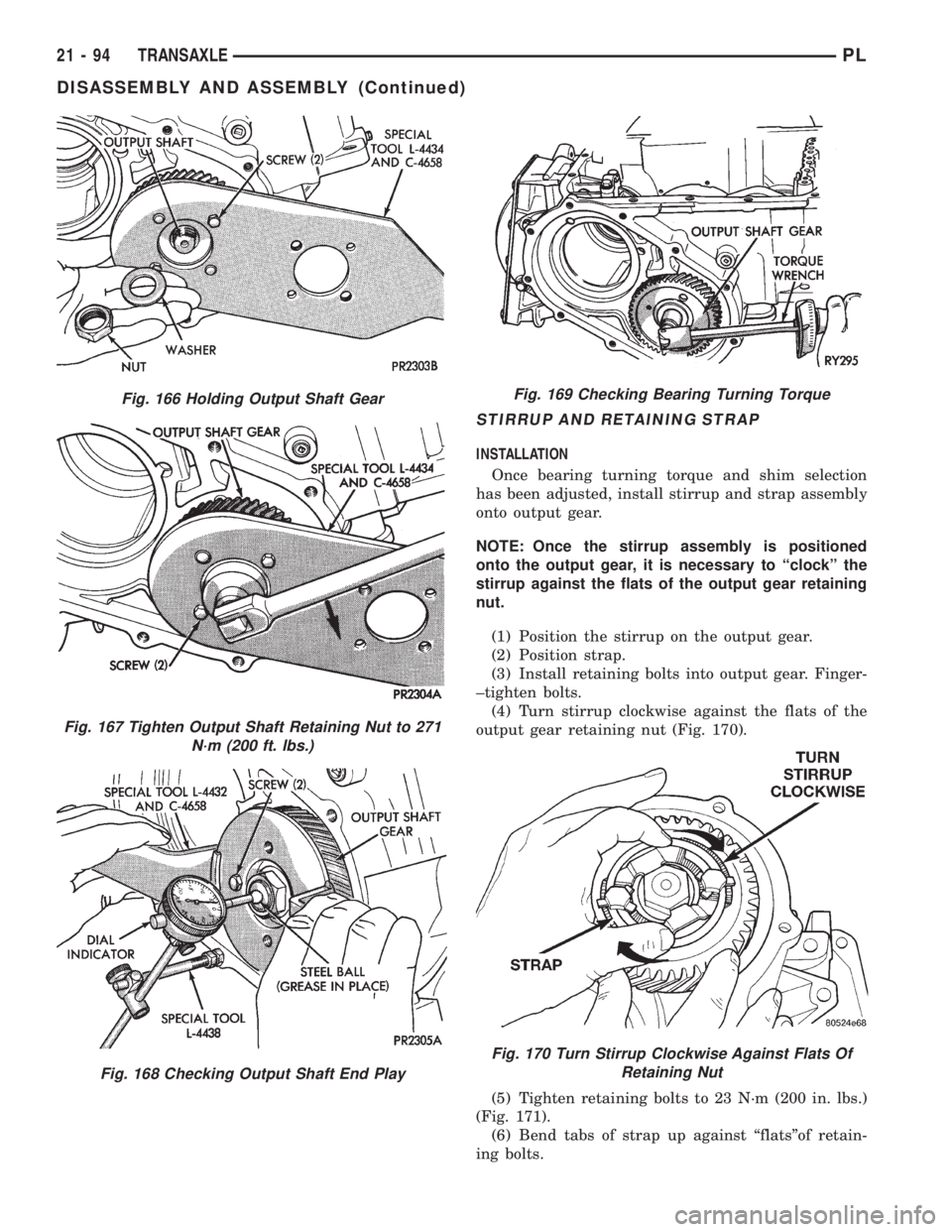

STIRRUP AND RETAINING STRAP

INSTALLATION

Once bearing turning torque and shim selection

has been adjusted, install stirrup and strap assembly

onto output gear.

NOTE: Once the stirrup assembly is positioned

onto the output gear, it is necessary to ªclockº the

stirrup against the flats of the output gear retaining

nut.

(1) Position the stirrup on the output gear.

(2) Position strap.

(3) Install retaining bolts into output gear. Finger-

±tighten bolts.

(4) Turn stirrup clockwise against the flats of the

output gear retaining nut (Fig. 170).

(5) Tighten retaining bolts to 23 N´m (200 in. lbs.)

(Fig. 171).

(6) Bend tabs of strap up against ªflatsºof retain-

ing bolts.

Fig. 166 Holding Output Shaft Gear

Fig. 167 Tighten Output Shaft Retaining Nut to 271

N´m (200 ft. lbs.)

Fig. 168 Checking Output Shaft End Play

Fig. 169 Checking Bearing Turning Torque

Fig. 170 Turn Stirrup Clockwise Against Flats Of

Retaining Nut

21 - 94 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1038 of 1200

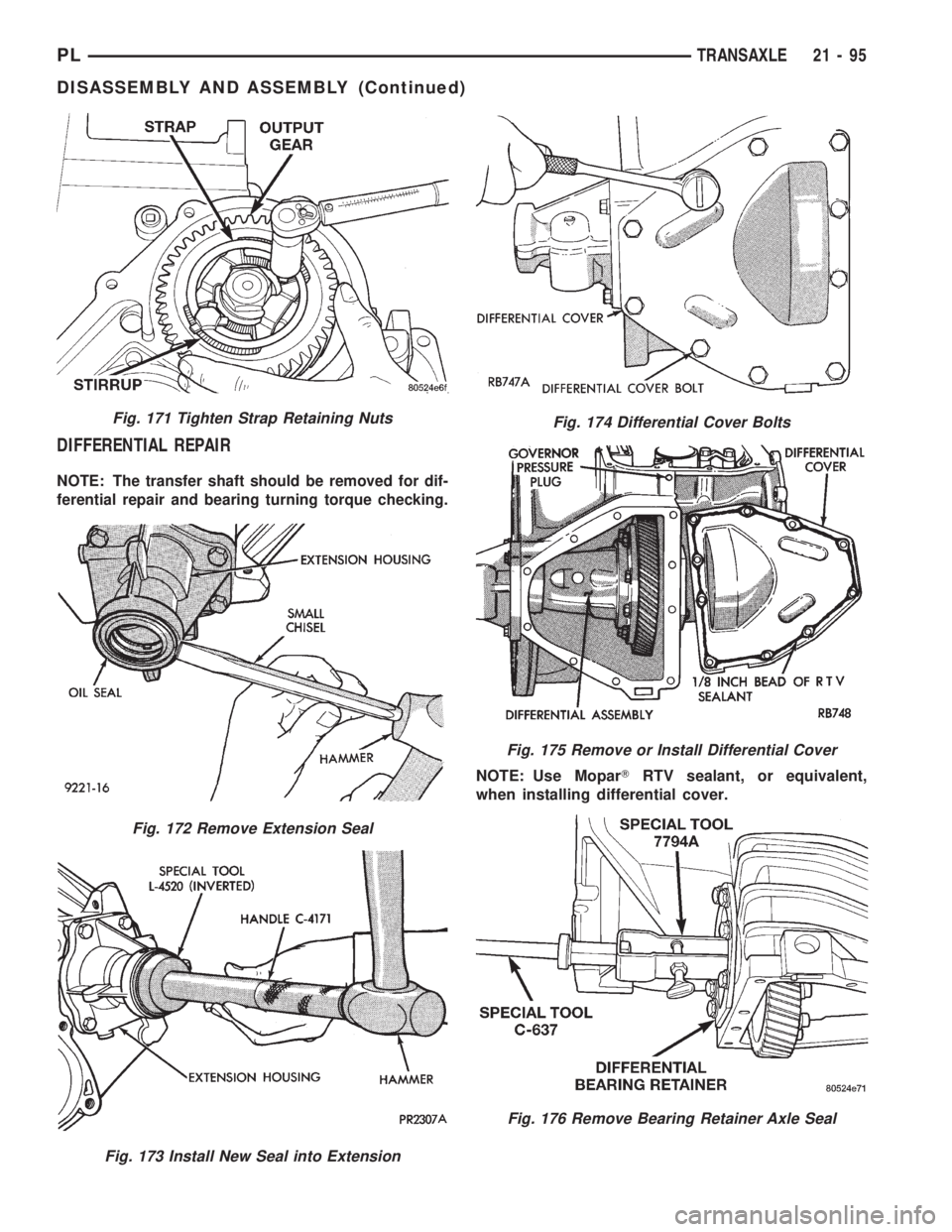

DIFFERENTIAL REPAIR

NOTE: The transfer shaft should be removed for dif-

ferential repair and bearing turning torque checking.

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential cover.

Fig. 171 Tighten Strap Retaining Nuts

Fig. 172 Remove Extension Seal

Fig. 173 Install New Seal into Extension

Fig. 174 Differential Cover Bolts

Fig. 175 Remove or Install Differential Cover

Fig. 176 Remove Bearing Retainer Axle Seal

PLTRANSAXLE 21 - 95

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1039 of 1200

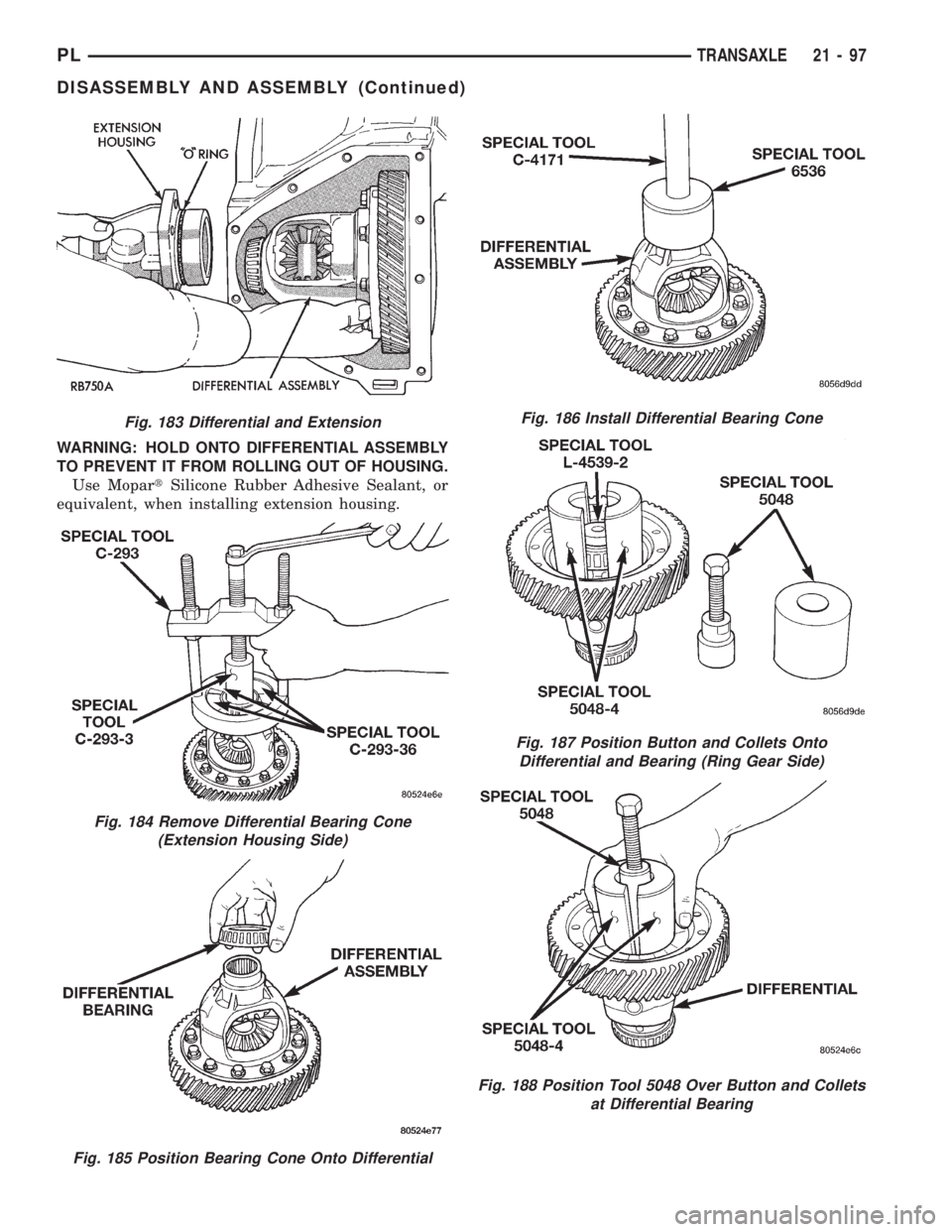

NOTE: Use MoparTRTV sealant, or equivalent,

when installing differential bearing retainer.

Fig. 177 Install Bearing Retainer Axle Seal

Fig. 178 Differential Bearing Retainer Bolts

Fig. 179 Remove or Install Bearing Retainer

Fig. 180 Differential Bearing Retainer (Typical)

Fig. 181 Extension Bolts

Fig. 182 Remove or Install Extension Housing

21 - 96 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1040 of 1200

WARNING: HOLD ONTO DIFFERENTIAL ASSEMBLY

TO PREVENT IT FROM ROLLING OUT OF HOUSING.

Use MopartSilicone Rubber Adhesive Sealant, or

equivalent, when installing extension housing.

Fig. 183 Differential and Extension

Fig. 184 Remove Differential Bearing Cone

(Extension Housing Side)

Fig. 185 Position Bearing Cone Onto Differential

Fig. 186 Install Differential Bearing Cone

Fig. 187 Position Button and Collets Onto

Differential and Bearing (Ring Gear Side)

Fig. 188 Position Tool 5048 Over Button and Collets

at Differential Bearing

PLTRANSAXLE 21 - 97

DISASSEMBLY AND ASSEMBLY (Continued)

Trending: ignition, coolant reservoir, key fob, four wheel drive, fuel cap, spare wheel, low beam