DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 981 of 1200

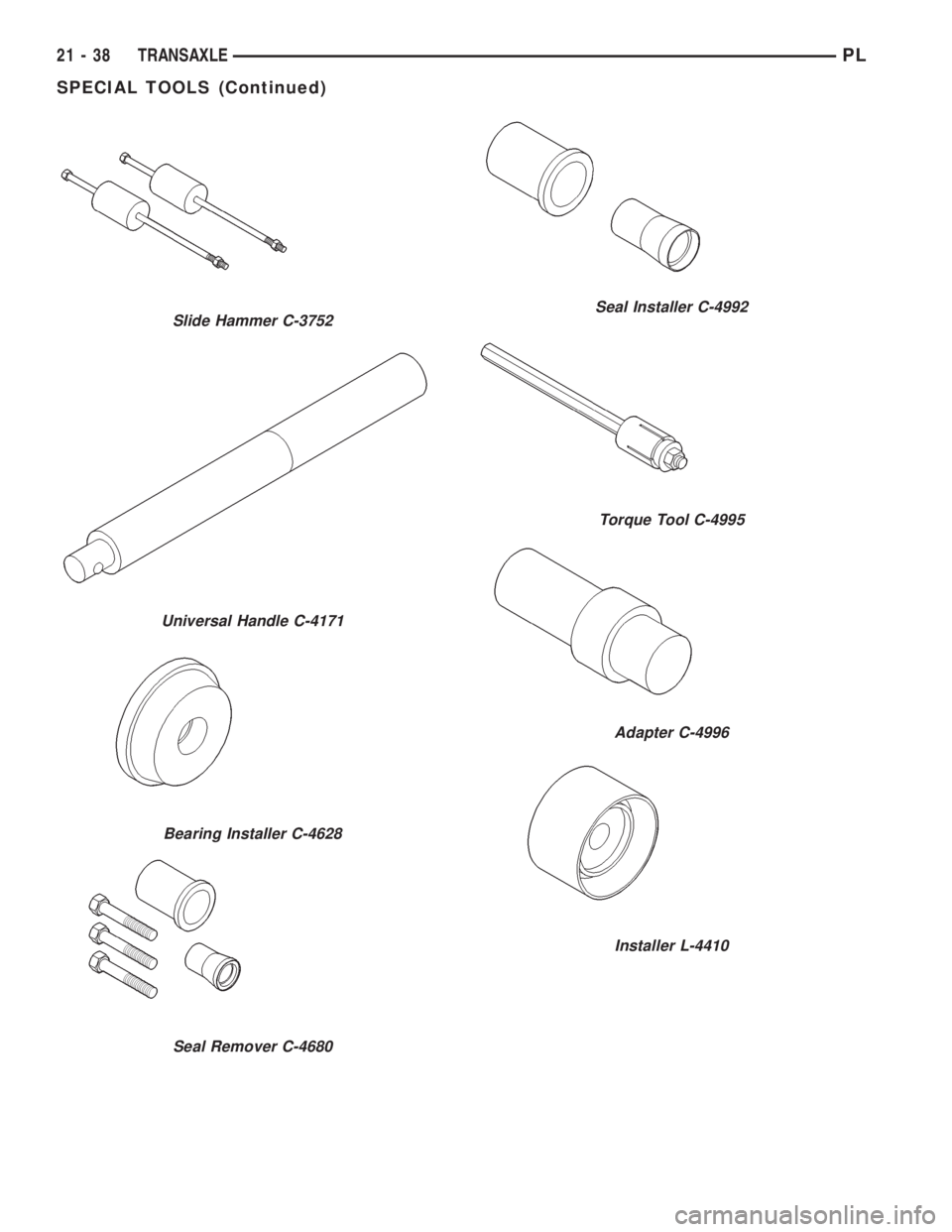

Slide Hammer C-3752

Universal Handle C-4171

Bearing Installer C-4628

Seal Remover C-4680

Seal Installer C-4992

Torque Tool C-4995

Adapter C-4996

Installer L-4410

21 - 38 TRANSAXLEPL

SPECIAL TOOLS (Continued)

Page 982 of 1200

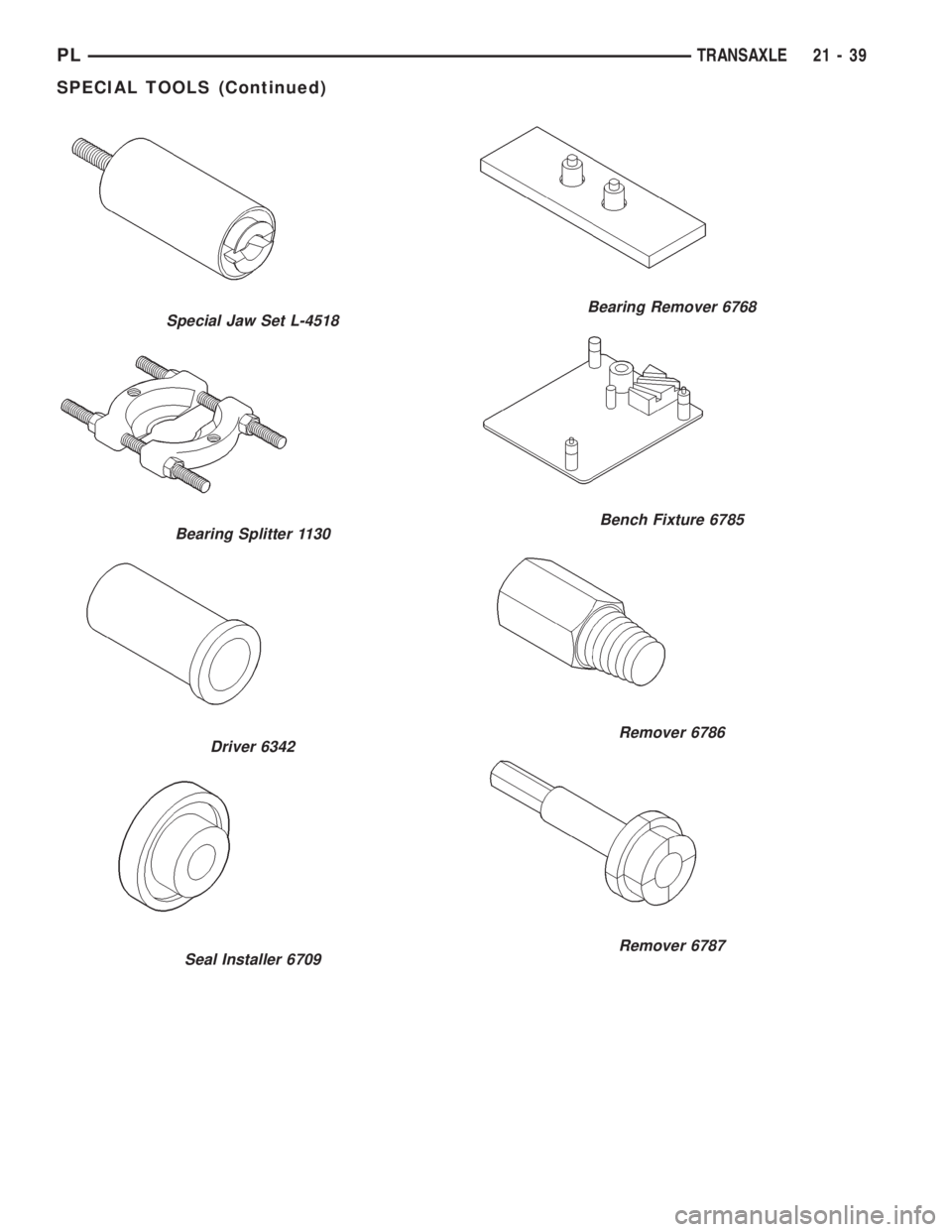

Special Jaw Set L-4518

Bearing Splitter 1130

Driver 6342

Seal Installer 6709

Bearing Remover 6768

Bench Fixture 6785

Remover 6786

Remover 6787

PLTRANSAXLE 21 - 39

SPECIAL TOOLS (Continued)

Page 983 of 1200

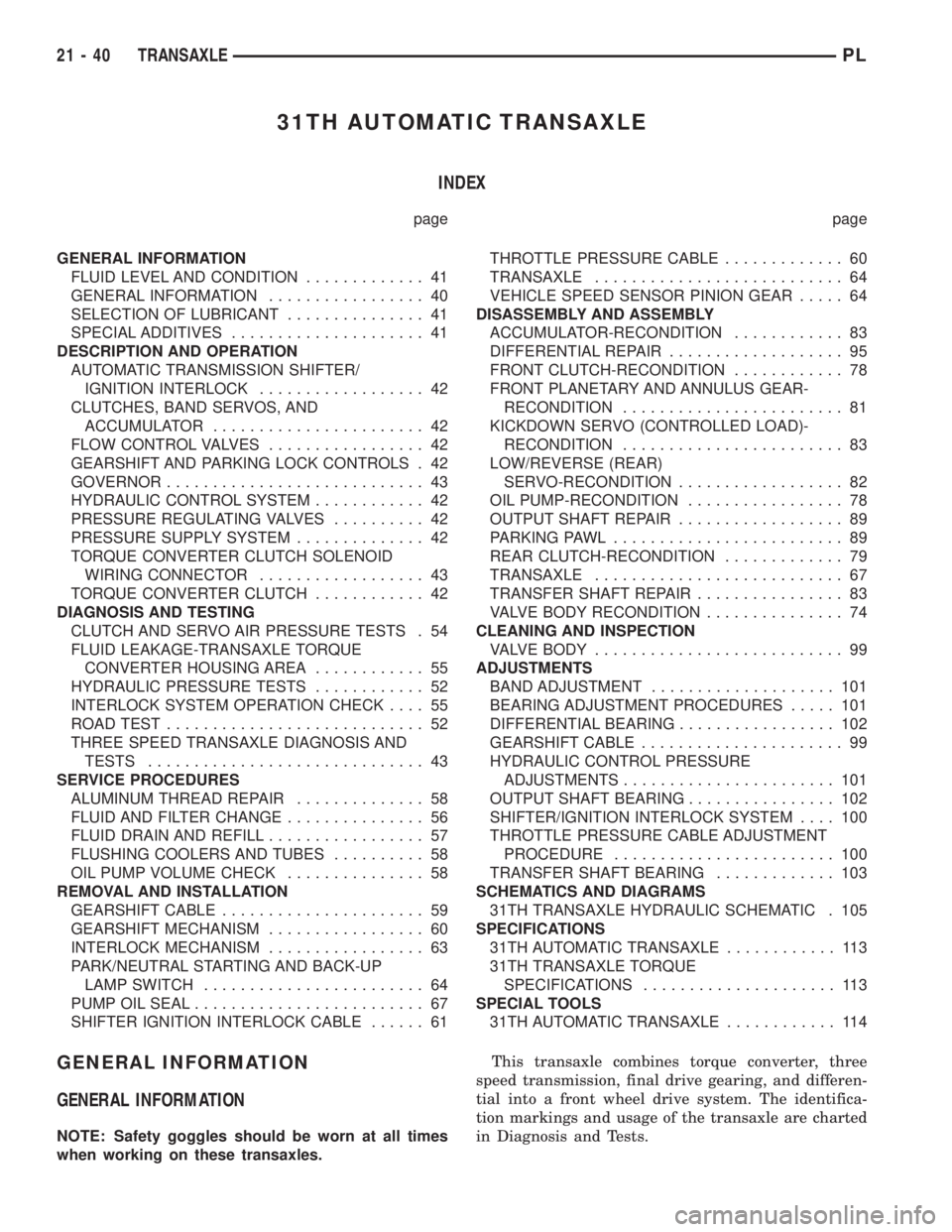

31TH AUTOMATIC TRANSAXLE

INDEX

page page

GENERAL INFORMATION

FLUID LEVEL AND CONDITION............. 41

GENERAL INFORMATION................. 40

SELECTION OF LUBRICANT............... 41

SPECIAL ADDITIVES..................... 41

DESCRIPTION AND OPERATION

AUTOMATIC TRANSMISSION SHIFTER/

IGNITION INTERLOCK.................. 42

CLUTCHES, BAND SERVOS, AND

ACCUMULATOR....................... 42

FLOW CONTROL VALVES................. 42

GEARSHIFT AND PARKING LOCK CONTROLS . 42

GOVERNOR............................ 43

HYDRAULIC CONTROL SYSTEM............ 42

PRESSURE REGULATING VALVES.......... 42

PRESSURE SUPPLY SYSTEM.............. 42

TORQUE CONVERTER CLUTCH SOLENOID

WIRING CONNECTOR.................. 43

TORQUE CONVERTER CLUTCH............ 42

DIAGNOSIS AND TESTING

CLUTCH AND SERVO AIR PRESSURE TESTS . 54

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA............ 55

HYDRAULIC PRESSURE TESTS............ 52

INTERLOCK SYSTEM OPERATION CHECK.... 55

ROAD TEST............................ 52

THREE SPEED TRANSAXLE DIAGNOSIS AND

TESTS.............................. 43

SERVICE PROCEDURES

ALUMINUM THREAD REPAIR.............. 58

FLUID AND FILTER CHANGE............... 56

FLUID DRAIN AND REFILL................. 57

FLUSHING COOLERS AND TUBES.......... 58

OIL PUMP VOLUME CHECK............... 58

REMOVAL AND INSTALLATION

GEARSHIFT CABLE...................... 59

GEARSHIFT MECHANISM................. 60

INTERLOCK MECHANISM................. 63

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH........................ 64

PUMP OIL SEAL......................... 67

SHIFTER IGNITION INTERLOCK CABLE...... 61THROTTLE PRESSURE CABLE............. 60

TRANSAXLE........................... 64

VEHICLE SPEED SENSOR PINION GEAR..... 64

DISASSEMBLY AND ASSEMBLY

ACCUMULATOR-RECONDITION............ 83

DIFFERENTIAL REPAIR................... 95

FRONT CLUTCH-RECONDITION............ 78

FRONT PLANETARY AND ANNULUS GEAR-

RECONDITION........................ 81

KICKDOWN SERVO (CONTROLLED LOAD)-

RECONDITION........................ 83

LOW/REVERSE (REAR)

SERVO-RECONDITION.................. 82

OIL PUMP-RECONDITION................. 78

OUTPUT SHAFT REPAIR.................. 89

PARKING PAWL......................... 89

REAR CLUTCH-RECONDITION............. 79

TRANSAXLE........................... 67

TRANSFER SHAFT REPAIR................ 83

VALVE BODY RECONDITION............... 74

CLEANING AND INSPECTION

VALVE BODY........................... 99

ADJUSTMENTS

BAND ADJUSTMENT.................... 101

BEARING ADJUSTMENT PROCEDURES..... 101

DIFFERENTIAL BEARING................. 102

GEARSHIFT CABLE...................... 99

HYDRAULIC CONTROL PRESSURE

ADJUSTMENTS....................... 101

OUTPUT SHAFT BEARING................ 102

SHIFTER/IGNITION INTERLOCK SYSTEM.... 100

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE........................ 100

TRANSFER SHAFT BEARING............. 103

SCHEMATICS AND DIAGRAMS

31TH TRANSAXLE HYDRAULIC SCHEMATIC . 105

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE............ 113

31TH TRANSAXLE TORQUE

SPECIFICATIONS..................... 113

SPECIAL TOOLS

31TH AUTOMATIC TRANSAXLE............ 114

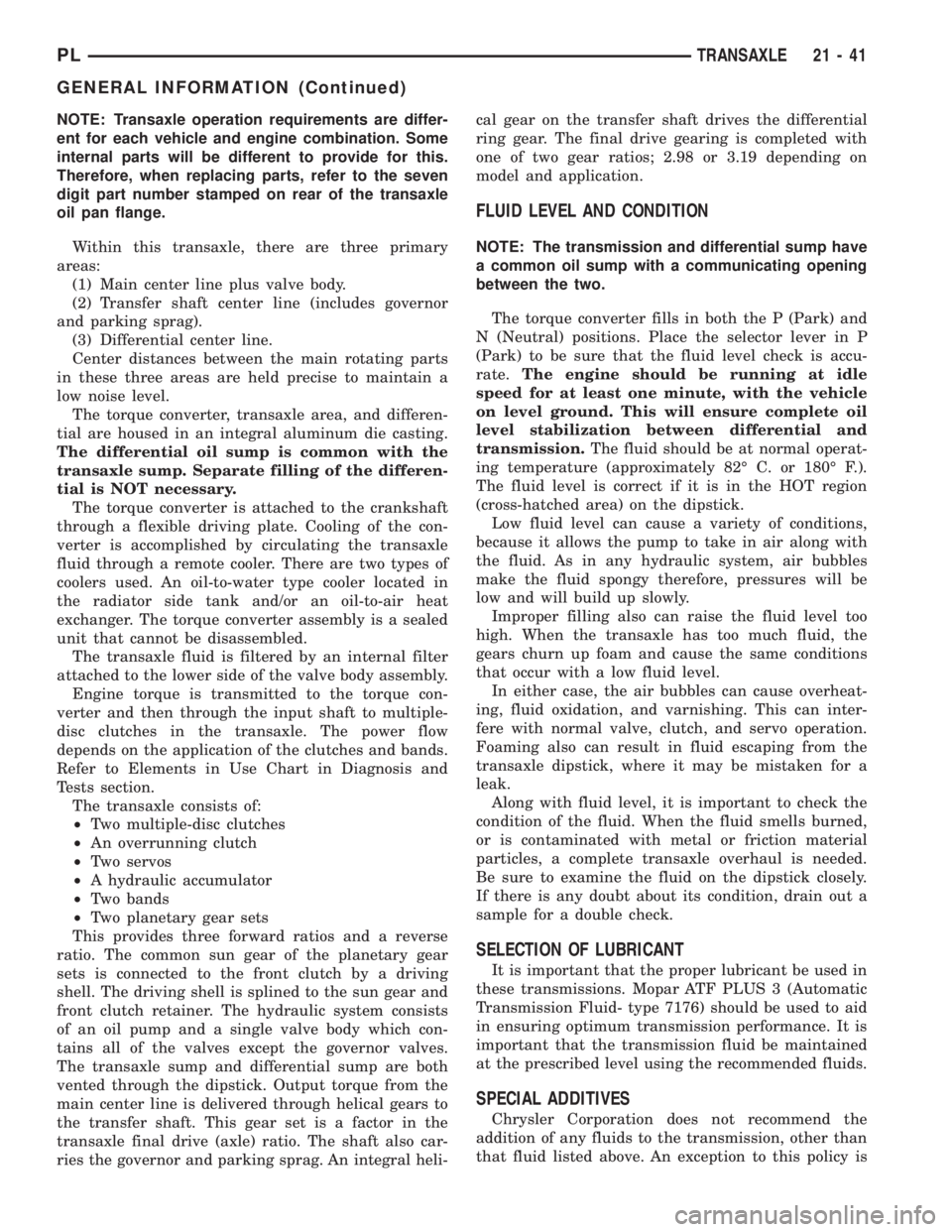

GENERAL INFORMATION

GENERAL INFORMATION

NOTE: Safety goggles should be worn at all times

when working on these transaxles.This transaxle combines torque converter, three

speed transmission, final drive gearing, and differen-

tial into a front wheel drive system. The identifica-

tion markings and usage of the transaxle are charted

in Diagnosis and Tests.

21 - 40 TRANSAXLEPL

Page 984 of 1200

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.

Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heat

exchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

ries the governor and parking sprag. An integral heli-cal gear on the transfer shaft drives the differential

ring gear. The final drive gearing is completed with

one of two gear ratios; 2.98 or 3.19 depending on

model and application.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

The torque converter fills in both the P (Park) and

N (Neutral) positions. Place the selector lever in P

(Park) to be sure that the fluid level check is accu-

rate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground. This will ensure complete oil

level stabilization between differential and

transmission.The fluid should be at normal operat-

ing temperature (approximately 82É C. or 180É F.).

The fluid level is correct if it is in the HOT region

(cross-hatched area) on the dipstick.

Low fluid level can cause a variety of conditions,

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy therefore, pressures will be

low and will build up slowly.

Improper filling also can raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

that occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming also can result in fluid escaping from the

transaxle dipstick, where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

or is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

If there is any doubt about its condition, drain out a

sample for a double check.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. Mopar ATF PLUS 3 (Automatic

Transmission Fluid- type 7176) should be used to aid

in ensuring optimum transmission performance. It is

important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the

addition of any fluids to the transmission, other than

that fluid listed above. An exception to this policy is

PLTRANSAXLE 21 - 41

GENERAL INFORMATION (Continued)

Page 985 of 1200

the use of special dyes to aid in detecting fluid leaks.

The use of transmission sealers should be avoided,

since they may adversely affect seals.

DESCRIPTION AND OPERATION

TORQUE CONVERTER CLUTCH

A torque converter clutch is standard on all vehi-

cles. The torque converter clutch is activated only in

direct drive and is controlled by the engine electron-

ics. A solenoid on the valve body, is powered by the

powertrain control module to activate the torque con-

verter clutch.

HYDRAULIC CONTROL SYSTEM

The hydraulic control system makes the transaxle

fully automatic, and has four important functions to

perform. The components of any automatic control

system may be grouped into the following basic

groups:

²Pressure supply system

²Pressure regulating valves

²Flow control valves

²Clutches

²Band servos

Taking each of these basic groups or systems in

turn, the control system may be described as follows:

PRESSURE SUPPLY SYSTEM

The pressure supply system consists of an oil pump

driven by the engine through the torque converter.

The single pump furnishes pressure for all hydraulic

and lubrication requirements.Oil pump housing

assemblies are available with preselected pump

gears.

PRESSURE REGULATING VALVES

The pressure regulating valve controls line pres-

sure dependent on throttle opening. The governor

valve transmits regulated pressure to the valve body

(in conjunction with vehicle speed) to control upshift

and downshift.

The throttle valve transmits regulated pressure to

the transaxle (dependent on throttle position) to con-

trol upshift and downshift.

FLOW CONTROL VALVES

The manual valve provides the different transaxle

drive ranges selected by the vehicle operator.

The 1-2 shift valve automatically shifts the tran-

saxle from first to second or from second to first,

depending on the vehicle operation.

The 2-3 shift valve automatically shifts the tran-

saxle from second to third or from third to second

depending on the vehicle operation.The kickdown valve makes possible a forced down-

shift from third to second, second to first, or third to

first (depending on vehicle speed). This can be done

by depressing the accelerator pedal past the detent

feel near wide open throttle.

The shuttle valve has two separate functions and

performs each independently of the other. The first is

providing fast release of the kickdown band, and

smooth front clutch engagement when a lift-foot

upshift from second to third is made. The second

function is to regulate the application of the kick-

down servo and band when making third±to±second

kickdown.

The bypass valve provides for smooth application

of the kickdown band on 1-2 upshifts.

The torque converter clutch solenoid allows for the

electronic control of the torque converter clutch. It

also disengages the torque converter at closed throt-

tle. This is done during engine warm-up and part-

throttle acceleration.

The switch valve directs oil to apply the torque

converter clutch in one position. The switch valve

releases the torque converter clutch in the other posi-

tion.

CLUTCHES, BAND SERVOS, AND ACCUMULATOR

The front and rear clutch pistons, and both servo

pistons, are moved hydraulically to engage the

clutches and apply the bands. The pistons are

released by spring tension when hydraulic pressure

is released. On the 2-3 upshift, the kickdown servo

piston is released by spring tension and hydraulic

pressure.

The accumulator controls the hydraulic pressure

on the apply±side of the kickdown servo during the

1-2 upshift; thereby cushioning the kickdown band

application at any throttle position.

AUTOMATIC TRANSMISSION SHIFTER/IGNITION

INTERLOCK

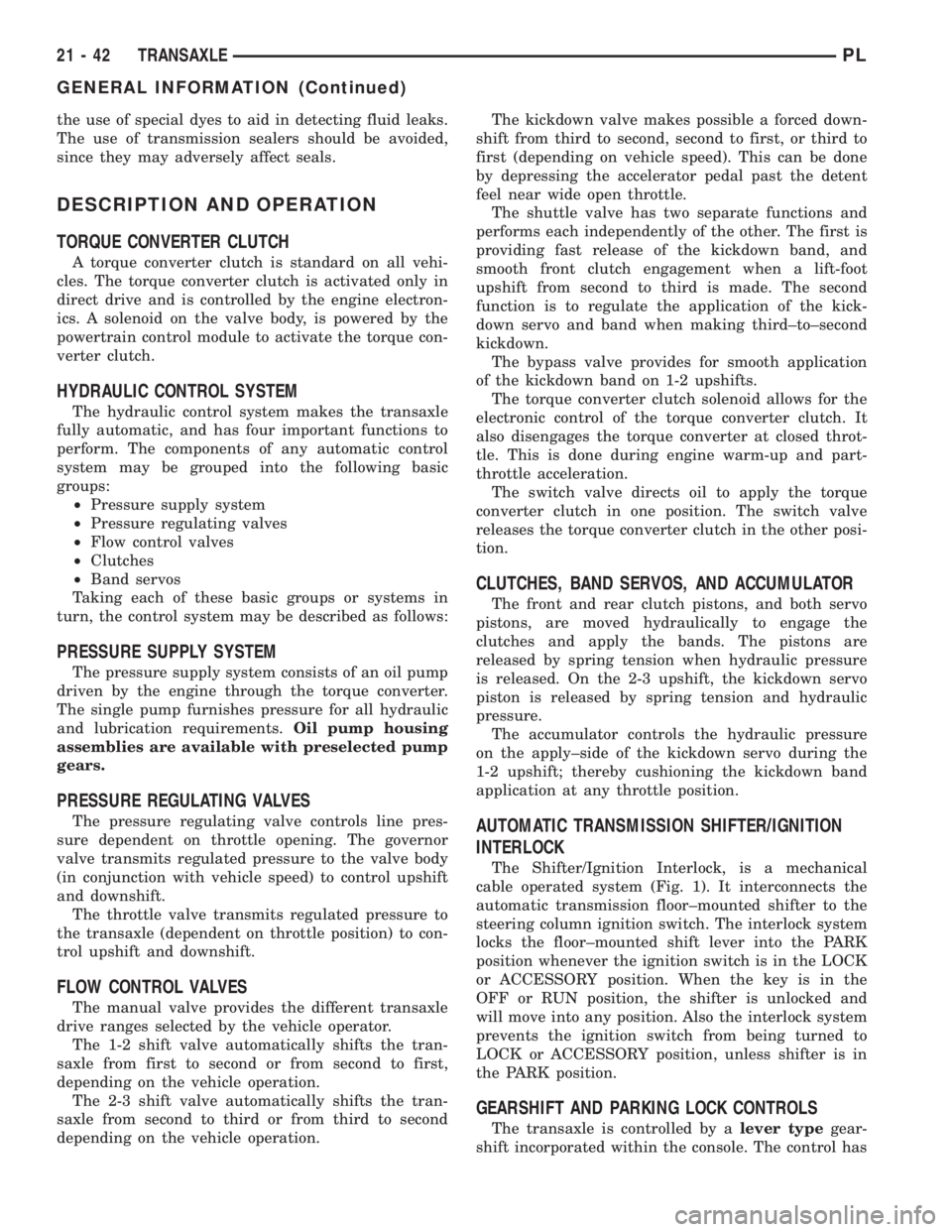

The Shifter/Ignition Interlock, is a mechanical

cable operated system (Fig. 1). It interconnects the

automatic transmission floor±mounted shifter to the

steering column ignition switch. The interlock system

locks the floor±mounted shift lever into the PARK

position whenever the ignition switch is in the LOCK

or ACCESSORY position. When the key is in the

OFF or RUN position, the shifter is unlocked and

will move into any position. Also the interlock system

prevents the ignition switch from being turned to

LOCK or ACCESSORY position, unless shifter is in

the PARK position.

GEARSHIFT AND PARKING LOCK CONTROLS

The transaxle is controlled by alever typegear-

shift incorporated within the console. The control has

21 - 42 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 986 of 1200

six selector lever positions: P (Park), R (Reverse), N

(Neutral), and D (Drive), 2 (Second), and 1 (First).

The parking lock is applied by moving the selector

lever past a gate to the (P) position.Do not apply

the parking lock until the vehicle has stopped;

otherwise, a severe banging noise will occur.

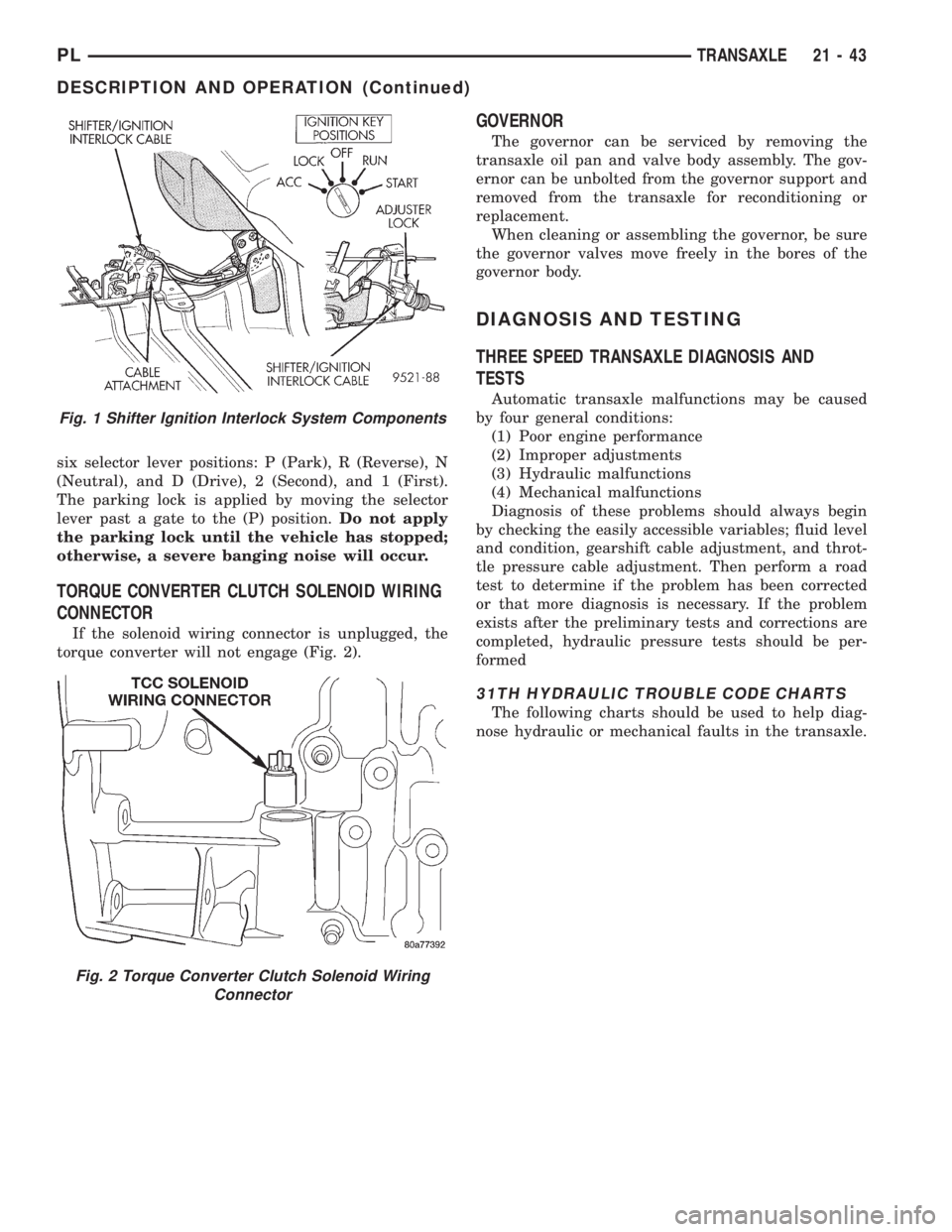

TORQUE CONVERTER CLUTCH SOLENOID WIRING

CONNECTOR

If the solenoid wiring connector is unplugged, the

torque converter will not engage (Fig. 2).

GOVERNOR

The governor can be serviced by removing the

transaxle oil pan and valve body assembly. The gov-

ernor can be unbolted from the governor support and

removed from the transaxle for reconditioning or

replacement.

When cleaning or assembling the governor, be sure

the governor valves move freely in the bores of the

governor body.

DIAGNOSIS AND TESTING

THREE SPEED TRANSAXLE DIAGNOSIS AND

TESTS

Automatic transaxle malfunctions may be caused

by four general conditions:

(1) Poor engine performance

(2) Improper adjustments

(3) Hydraulic malfunctions

(4) Mechanical malfunctions

Diagnosis of these problems should always begin

by checking the easily accessible variables; fluid level

and condition, gearshift cable adjustment, and throt-

tle pressure cable adjustment. Then perform a road

test to determine if the problem has been corrected

or that more diagnosis is necessary. If the problem

exists after the preliminary tests and corrections are

completed, hydraulic pressure tests should be per-

formed

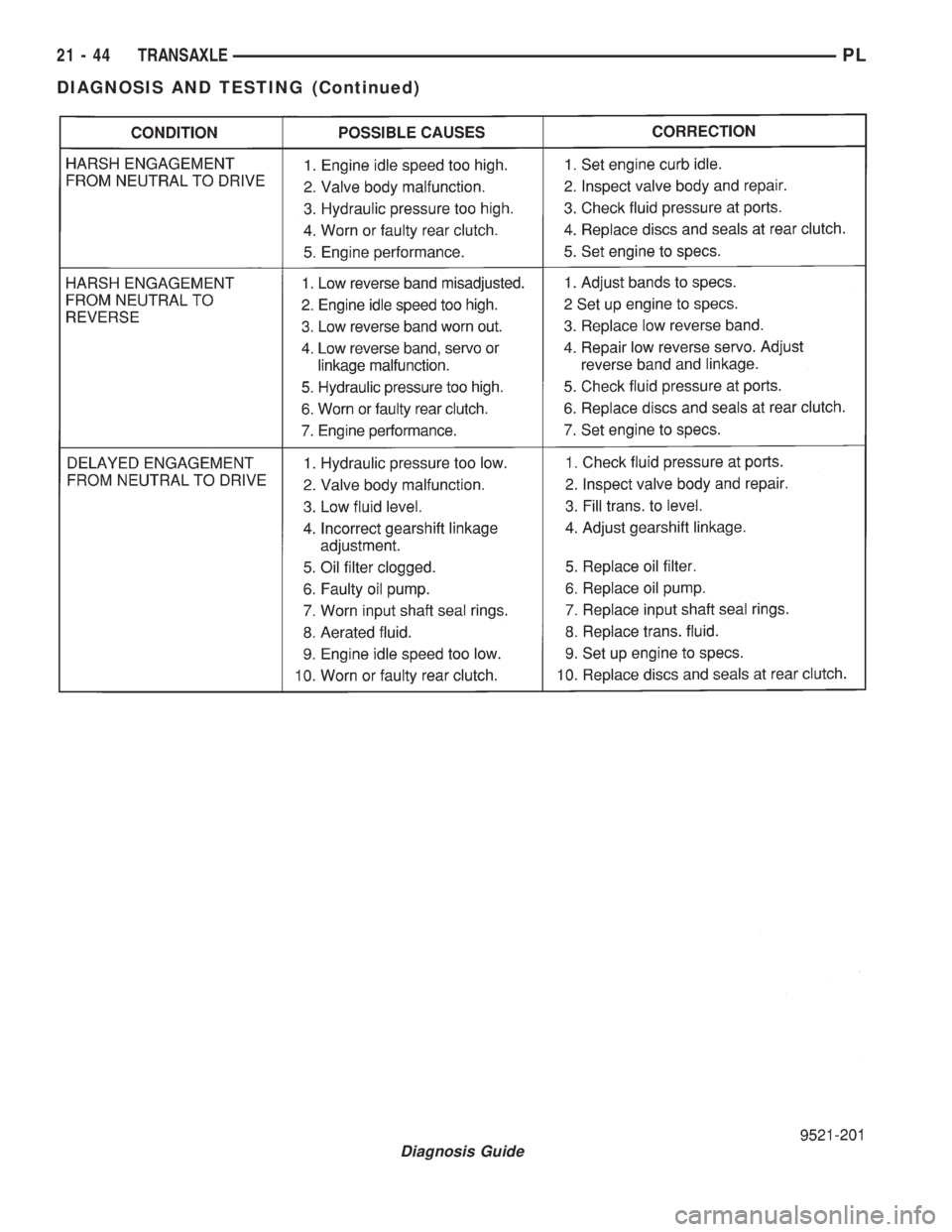

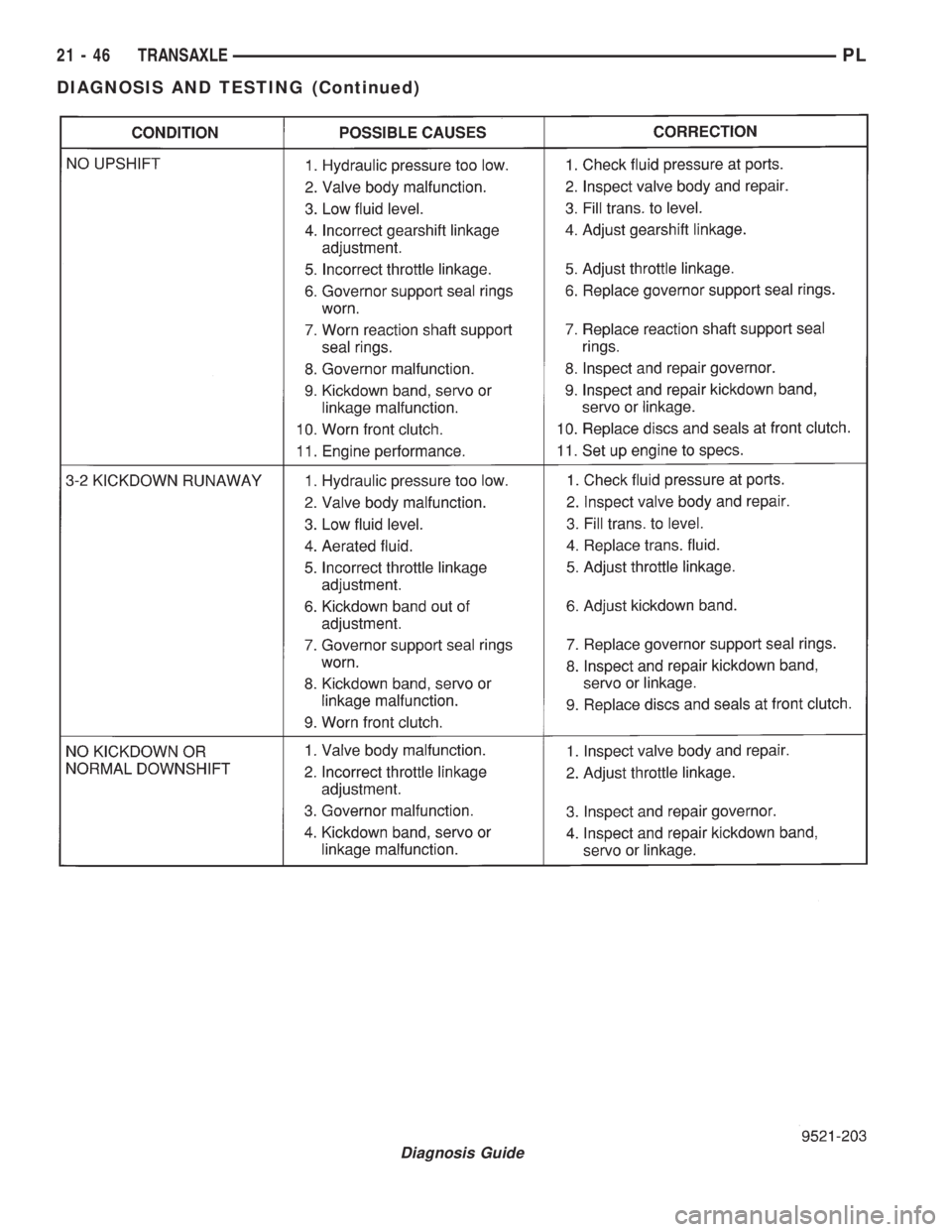

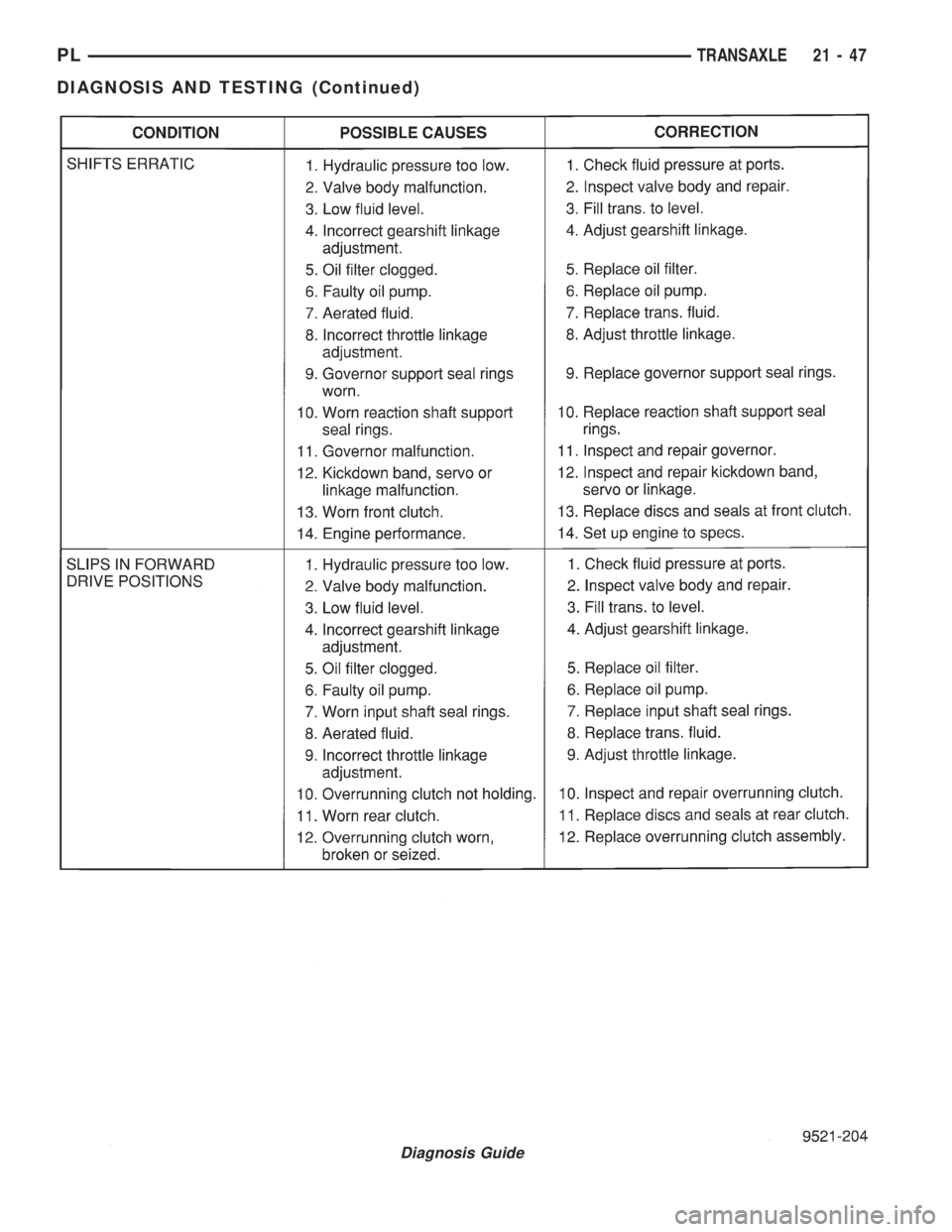

31TH HYDRAULIC TROUBLE CODE CHARTS

The following charts should be used to help diag-

nose hydraulic or mechanical faults in the transaxle.

Fig. 1 Shifter Ignition Interlock System Components

Fig. 2 Torque Converter Clutch Solenoid Wiring

Connector

PLTRANSAXLE 21 - 43

DESCRIPTION AND OPERATION (Continued)

Page 987 of 1200

Diagnosis Guide

21 - 44 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

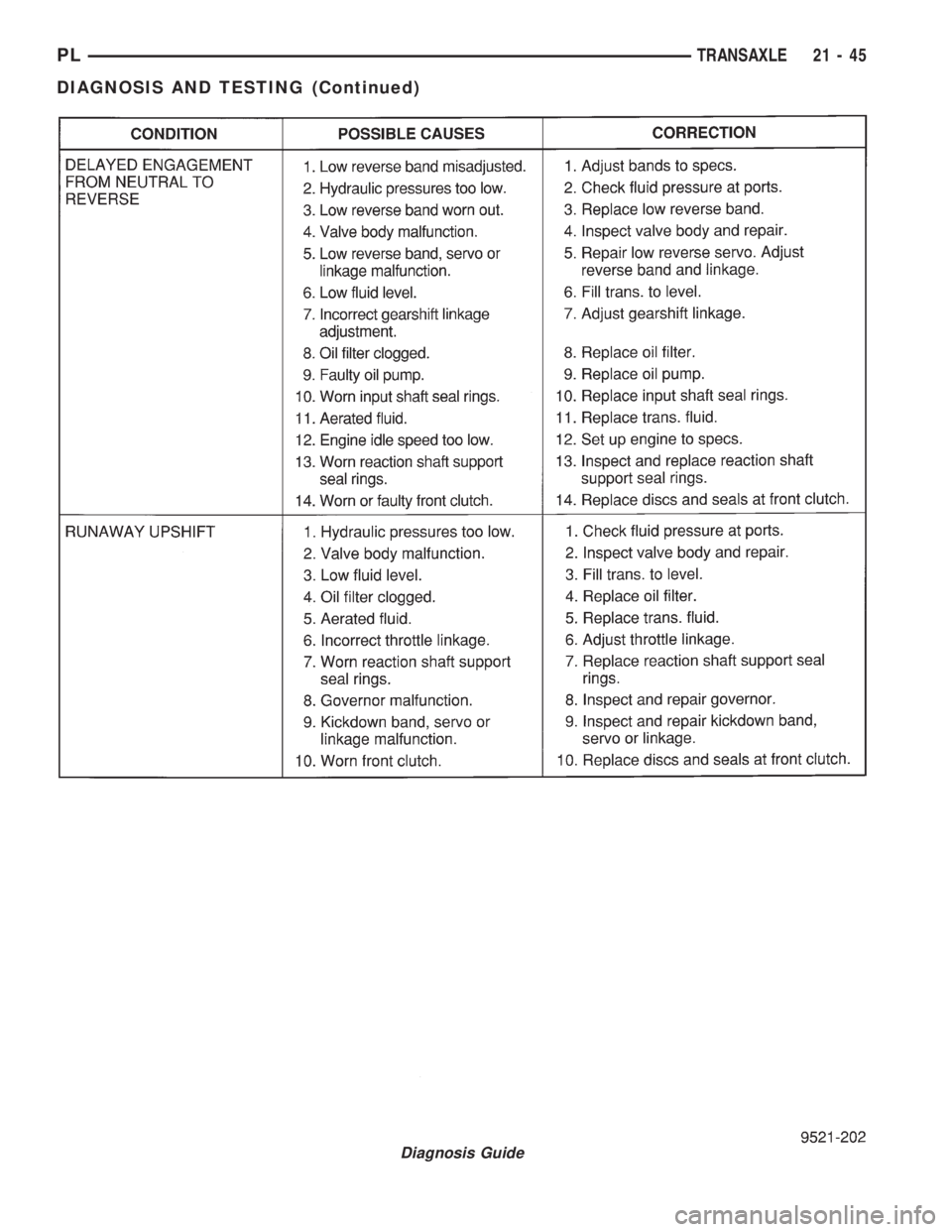

Page 988 of 1200

Diagnosis Guide

PLTRANSAXLE 21 - 45

DIAGNOSIS AND TESTING (Continued)

Page 989 of 1200

Diagnosis Guide

21 - 46 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 990 of 1200

Diagnosis Guide

PLTRANSAXLE 21 - 47

DIAGNOSIS AND TESTING (Continued)