FORD MUSTANG 1969 Volume One Chassis

Manufacturer: FORD, Model Year: 1969, Model line: MUSTANG, Model: FORD MUSTANG 1969Pages: 413, PDF Size: 75.81 MB

Page 211 of 413

04-02-14

Rear Axle

—

Removable Carrier Type

04-02-14

DIFFERENTIAL

BEARING

Tool—

7

571-4220-A

T66P°4220-P

E1015-B

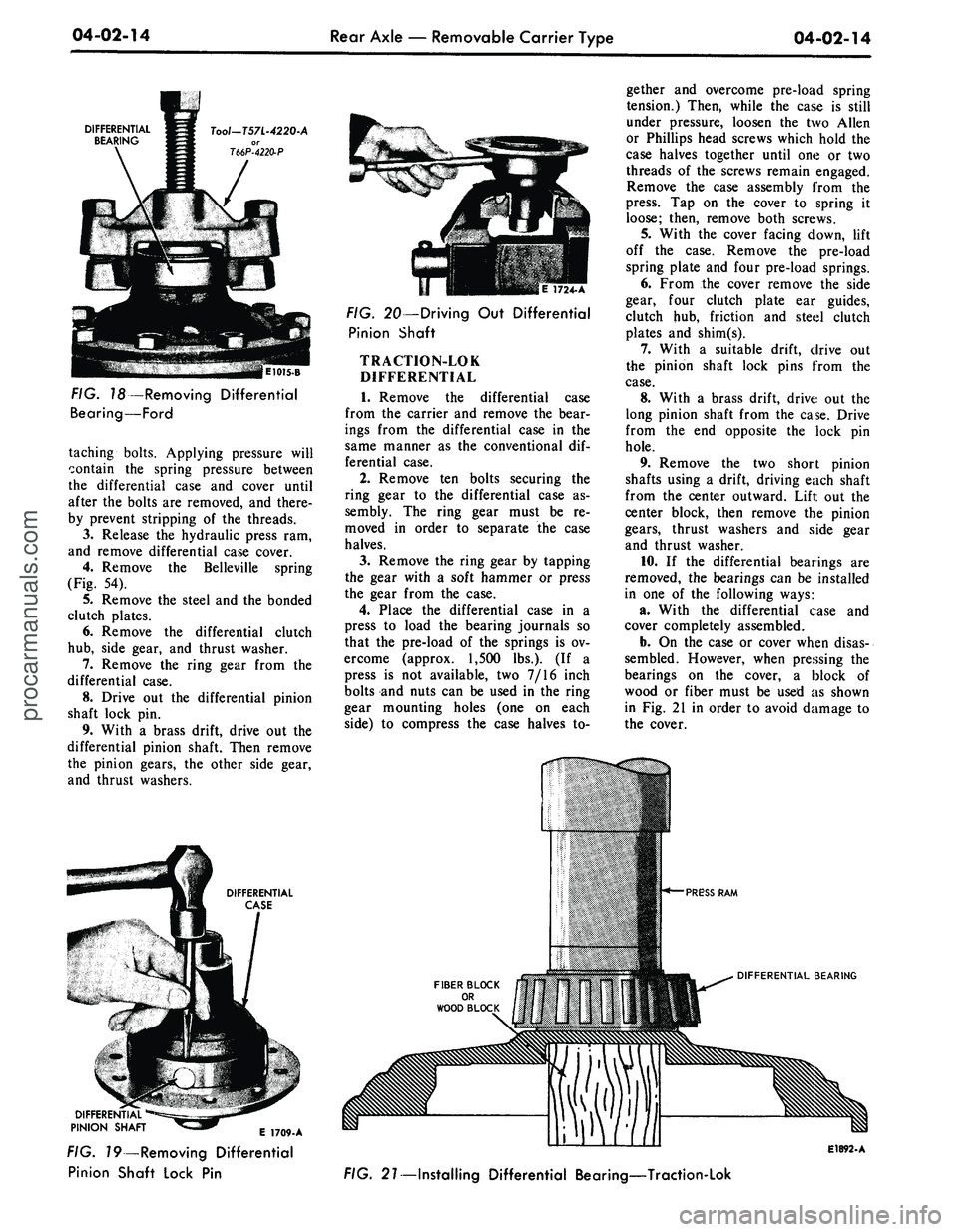

FIG. 18—Removing Differential

Bearing—Ford

taching bolts. Applying pressure will

contain

the

spring pressure between

the differential case

and

cover until

after

the

bolts

are

removed,

and

there-

by prevent stripping

of the

threads.

3.

Release

the

hydraulic press

ram,

and remove differential case cover.

4.

Remove

the

Belleville spring

(Fig.

54).

5.

Remove

the

steel

and the

bonded

clutch plates.

6. Remove

the

differential clutch

hub,

side gear,

and

thrust washer.

7.

Remove

the

ring gear from

the

differential case.

8. Drive

out the

differential pinion

shaft lock

pin.

9. With

a

brass drift, drive

out the

differential pinion shaft. Then remove

the pinion gears,

the

other side gear,

and thrust washers.

E 1724-A

FIG. 20—Driving

Out

Differential

Pinion Shaft

TRACTION-LOK

DIFFERENTIAL

1.

Remove

the

differential case

from

the

carrier

and

remove

the

bear-

ings from

the

differential case

in the

same manner

as the

conventional

dif-

ferential case.

2.

Remove

ten

bolts securing

the

ring gear

to the

differential case

as-

sembly.

The

ring gear must

be re-

moved

in

order

to

separate

the

case

halves.

3.

Remove

the

ring gear

by

tapping

the gear with

a

soft hammer

or

press

the gear from

the

case.

4.

Place

the

differential case

in a

press

to

load

the

bearing journals

so

that

the

pre-load

of the

springs

is ov-

ercome (approx.

1,500

lbs.).

(If a

press

is not

available,

two 7/16

inch

bolts

and

nuts

can be

used

in the

ring

gear mounting holes

(one on

each

side)

to

compress

the

case halves

to-

gether

and

overcome pre-load spring

tension.) Then, while

the

case

is

still

under pressure, loosen

the two

Allen

or Phillips head screws which hold

the

case halves together until

one or two

threads

of the

screws remain engaged.

Remove

the

case assembly from

the

press.

Tap on the

cover

to

spring

it

loose; then, remove both screws.

5.

With

the

cover facing down, lift

off

the

case. Remove

the

pre-load

spring plate

and

four pre-load springs.

6. From

the

cover remove

the

side

gear, four clutch plate

ear

guides,

clutch

hub,

friction

and

steel clutch

plates

and

shim(s).

7.

With

a

suitable drift, drive

out

the pinion shaft lock pins from

the

case.

8. With

a

brass drift, drive

out the

long pinion shaft from

the

case. Drive

from

the end

opposite

the

lock

pin

hole.

9. Remove

the two

short pinion

shafts using

a

drift, driving each shaft

from

the

center outward. Lift

out the

center block, then remove

the

pinion

gears,

thrust washers

and

side gear

and thrust washer.

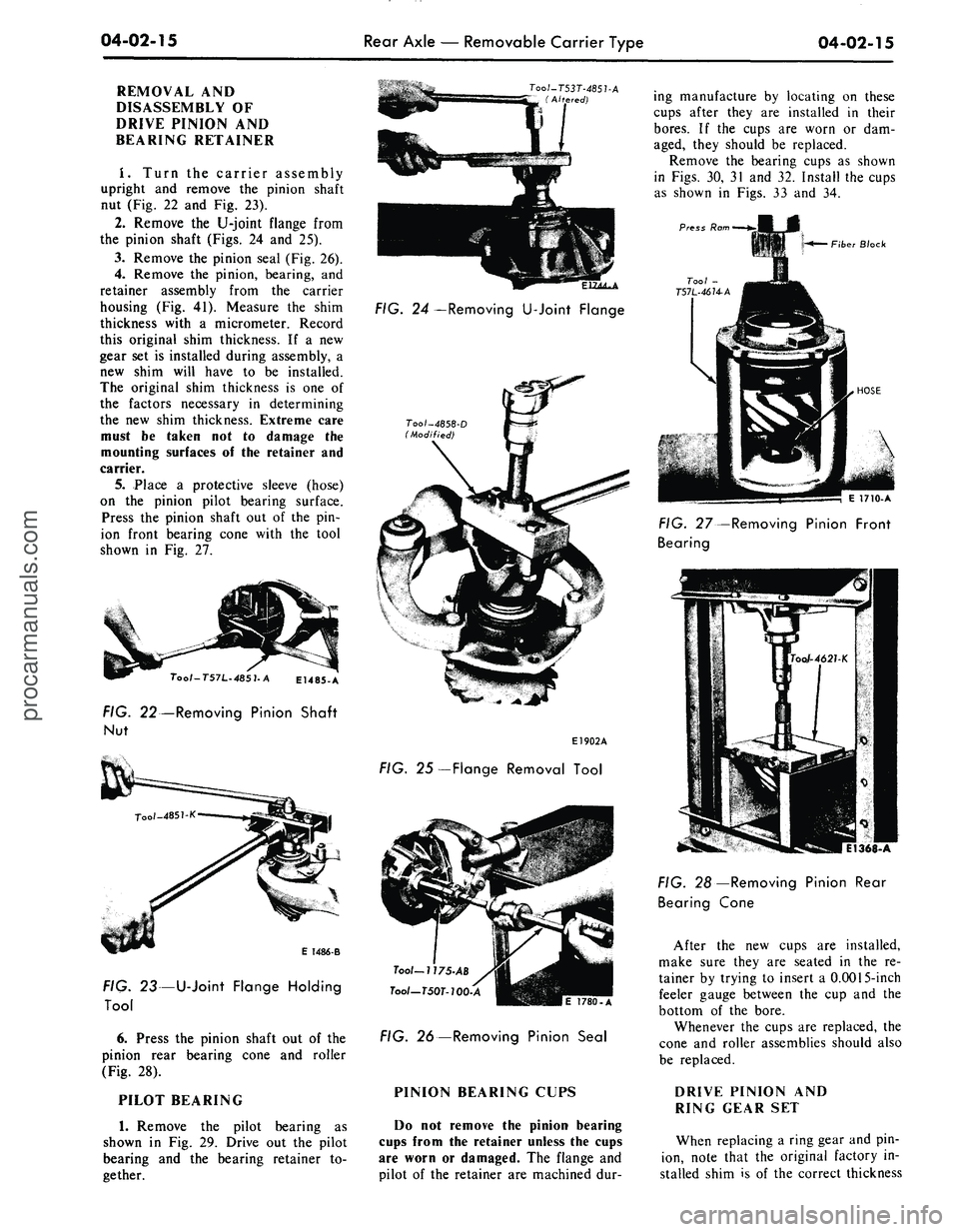

10.

If the

differential bearings

are

removed,

the

bearings

can be

installed

in

one of the

following ways:

a. With

the

differential case

and

cover completely assembled.

b.

On the

case

or

cover when disas-

sembled. However, when pressing

the

bearings

on the

cover,

a

block

of

wood

or

fiber must

be

used

as

shown

in Fig.

21 in

order

to

avoid damage

to

the cover.

E 1709-A

FIG. 79—Removing Differential

Pinion Shaft Lock

Pin

DIFFERENTIAL BEARING

E1892-A

FIG. 21—Installing Differential Bearing—Traction-Lokprocarmanuals.com

Page 212 of 413

04-02-15

Rear

Axle — Removable Carrier Type

04-02-15

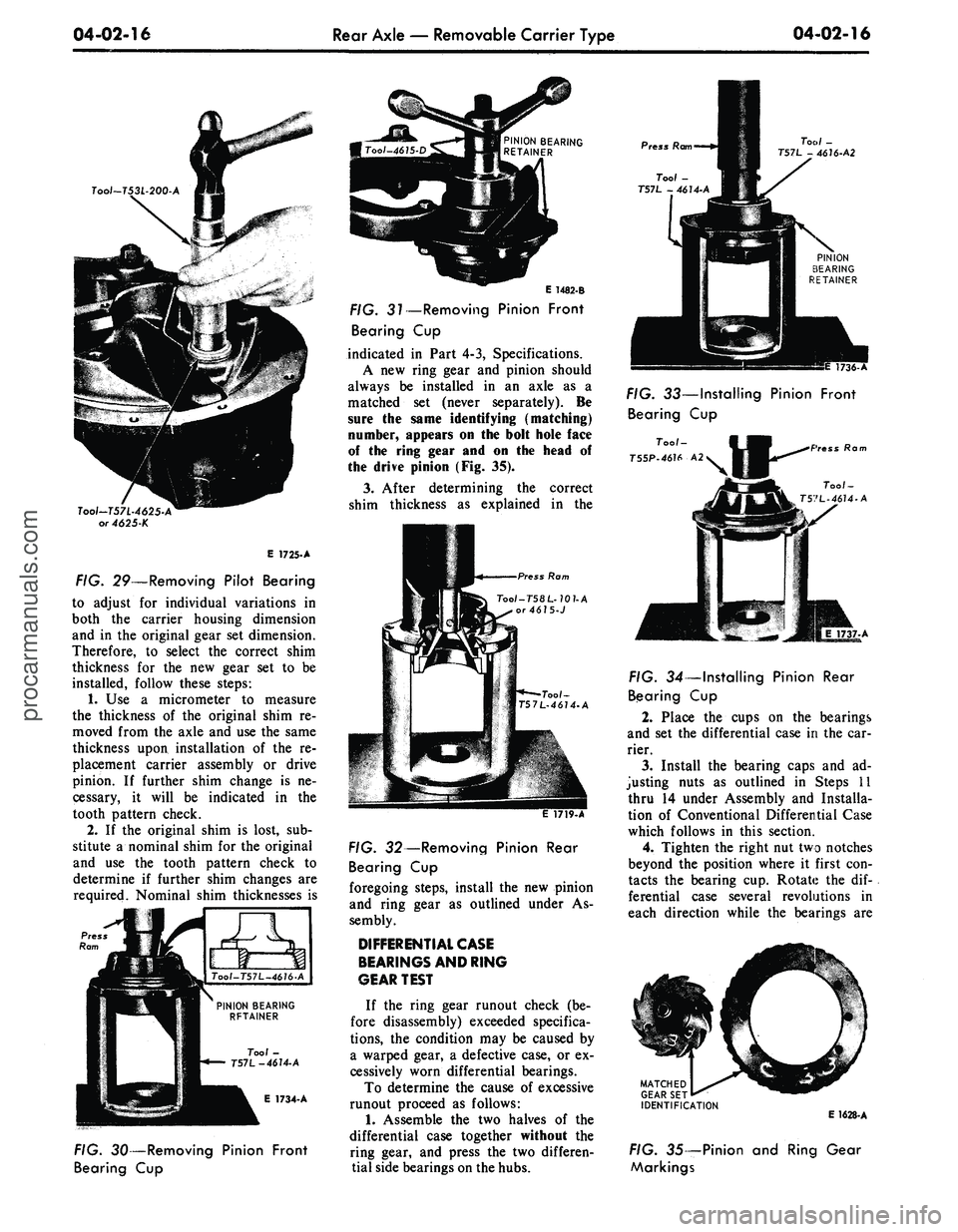

REMOVAL AND

DISASSEMBLY OF

DRIVE PINION AND

BEARING RETAINER

I. Turn the carrier assembly

upright and remove the pinion shaft

nut (Fig. 22 and Fig. 23).

2.

Remove the U-joint flange from

the pinion shaft (Figs. 24 and 25).

3.

Remove the pinion seal (Fig. 26).

4.

Remove the pinion, bearing, and

retainer assembly from the carrier

housing (Fig. 41). Measure the shim

thickness with a micrometer. Record

this original shim thickness. If a new

gear set is installed during assembly, a

new shim will have to be installed.

The original shim thickness is one of

the factors necessary in determining

the new shim thickness. Extreme care

must be taken not to damage the

mounting surfaces of the retainer and

carrier.

5. Place a protective sleeve (hose)

on the pinion pilot bearing surface.

Press the pinion shaft out of the pin-

ion front bearing cone with the tool

shown in Fig. 27.

O/-T57L-485

7-A

E1485-A

FIG.

22—Removing Pinion Shaft

Nut

E 1486-B

FIG. 23—

U-Joint Flange Holding

Tool

6. Press the pinion shaft out of the

pinion rear bearing cone and roller

(Fig. 28).

PILOT BEARING

1.

Remove the pilot bearing as

shown in Fig. 29. Drive out the pilot

bearing and the bearing retainer to-

gether.

FIG.

24 —

Removing

U-Joint Flange

E1902A

FIG.

25 —Flange Removal Tool

Tool-

7 7

75-AB

Tool—T50T-100-A

|E

1780.

A

FIG.

26—Removing Pinion Seal

PINION BEARING CUPS

Do not remove the pinion bearing

cups from the retainer unless the cups

are worn or damaged. The flange and

pilot of the retainer are machined dur-

ing manufacture by locating on these

cups after they are installed in their

bores.

If the cups are worn or dam-

aged, they should be replaced.

Remove the bearing cups as shown

in Figs. 30, 31 and 32. Install the cups

as shown in Figs. 33 and 34.

Press

Ram

Tool

-

757L-4674-A

Fiber Block

HOSE

\

1710-A

FIG.

27

Bearing

-Removing

Pinion Front

FIG.

28 —Removing Pinion Rear

Bearing

Cone

After the new cups are installed,

make sure they are seated in the re-

tainer by trying to insert a 0.0015-inch

feeler gauge between the cup and the

bottom of the bore.

Whenever the cups are replaced, the

cone and roller assemblies should also

be replaced.

DRIVE PINION AND

RING GEAR SET

When replacing a ring gear and pin-

ion, note that the original factory in-

stalled shim is of the correct thicknessprocarmanuals.com

Page 213 of 413

04-02-16

Rear Axle — Removable Carrier Type

04-02-16

Tool~T53L-200-A

Tool-T57L-4625-A

or 4625-K

E 1725-A

FIG. 29—Removing Pilot Bearing

to adjust for individual variations in

both the carrier housing dimension

and in the original gear set dimension.

Therefore, to select the correct shim

thickness for the new gear set to be

installed, follow these steps:

1.

Use a micrometer to measure

the thickness of the original shim re-

moved from the axle and use the same

thickness upon installation of the re-

placement carrier assembly or drive

pinion. If further shim change is ne-

cessary, it will be indicated in the

tooth pattern check.

2.

If the original shim is lost, sub-

stitute a nominal shim for the original

and use the tooth pattern check to

determine if further shim changes are

required. Nominal shim thicknesses is

E 1734-A

PINION BEARING

RETAINER

E 1482-B

FIG. 31—Removing Pinion Front

Bearing Cup

indicated in Part 4-3, Specifications.

A new ring gear and pinion should

always be installed in an axle as a

matched set (never separately). Be

sure the same identifying (matching)

number, appears on the bolt hole face

of the ring gear and on the head of

the drive pinion (Fig. 35).

3.

After determining the correct

shim thickness as explained in the

ss

Rom

Too/-T58L-70?-A

or4675-J

FIG. 30—Removing Pinion Front

Bearing Cup

FIG. 32—Removing Pinion Rear

Bearing Cup

foregoing steps, install the new pinion

and ring gear as outlined under As-

sembly.

DIFFERENTIAL

CASE

BEARINGS

AND

RING

GEAR

TEST

If the ring gear runout check (be-

fore disassembly) exceeded specifica-

tions,

the condition may be caused by

a warped gear, a defective case, or ex-

cessively worn differential bearings.

To determine the cause of excessive

runout proceed as follows:

1.

Assemble the two halves of the

differential case together without the

ring gear, and press the two differen-

tial side bearings on the hubs.

Press Ram

Tool -

T57L - 4614-A

Tool -

T57L - 4676-A2

1736-/

FIG. 33—Installing Pinion Front

Bearing Cup

too;-

IB .

T55P-46U

A2V •H"^^

\

Press Ram

Tool-

T57L-46U-A

FIG. 34—Installing Pinion Rear

Bearing Cup

2.

Place the cups on the bearings

and set the differential case in the car-

rier.

3.

Install the bearing caps and ad-

justing nuts as outlined in Steps 11

thru 14 under Assembly and Installa-

tion of Conventional Differential Case

which follows in this section.

4.

Tighten the right nut two notches

beyond the position where it first con-

tacts the bearing cup. Rotate the dif-

ferential case several revolutions in

each direction while the bearings are

MATCHED

GEAR SET

IDENTIFICATION

E 1628-A

FIG. 35— Pinion and Ring Gear

Markingsprocarmanuals.com

Page 214 of 413

04-02-17

Rear Axle

—

Removable Carrier Type

04-02-17

Too/-T53L-200-A

L-462S-A

4625-K

or

4625-KA

>:

M

E 1726-A

FIG. 36—Installing Pilot Bearing

loaded

to

seat

the

bearings

in

their

cups.

This step

is

important.

5. Again loosen the- right

nut to re-

lease

the

preload. Check

to see

that

the left

nut

contacts

the

bearing

cup.

Using

the

dial indicator set-up shown

in Fig.

10,

Part 4-1, adjust the preload

to 0.008

to

0.012 case spread

for new

bearings

or

0.005

to

0.008

for the ori-

ginal bearings,

if

re-used.

6. Check

the

runout

of

the differen-

tial case flange with

a

dial indicator.

If

the

runout does

not now

exceed

specifications, install

a new

ring gear.

If

the

runout still exceeds specifica-

tions,

the

ring gear

is

true

and the

trouble

is due to

either

a

defective

case

or

worn bearings.

7. Remove

the

differential case

from

the

carrier

and

remove

the

side

bearings from

the

case.

8. Install

new

bearings

on the

case

hubs,

and

again install

the

differential

assembly

in the

carrier without

the

ring gear.

9. Check the case runout again with

the new bearings.

If the

runout

is

now

within limits,

the old

bearings were

excessively worn.

Use the new

bear-

ings

for

assembly.

If the

runout

is

still

excessive,

the

case

is

defective

and

should

be

replaced.

Press,

Ram

REAR BEARING

CONE

AND

ROLLER

Too/-

T57L-46U-A

Fiber B/oc.

DRIVE

PINION

Too/-

T57L-4621-B

1701-A

FIG. 37—Installing Pinion Rear

Bearing Cone

PRESS RAM

Tool - 4621

L

E1903A

FIG. 38—Installing Pinion Rear

Bearing Cone

ASSEMBLY

OF

DIFFERENTIAL

CARRIER

PILOT BEARING

INSTALLATION

1.

Drive

the new

pilot bearing

in-

ward until

it

bottoms,

as

shown

in

Fig.

36.

2.

Using

the

same tool indicated

in

Fig.

36,

install

the new

pilot bearing

retainer with

the

concave side

up.

COLLAPSIBLE PINION

BEARING SPACER

INSTALLATION

1.

Install

the

drive pinion rear bear-

ing cone and roller

on the

pinion shaft

(Figs.

37

m 38).

Place

a new

spacer

on the

pinion

shaft (Fig.

39).

2.

Place

the

bearing retainer

on the

pinion shaft,

and

install

the

front

bearing cone

and

roller. Press

the

front bearing cone and roller into posi-

tion

as

shown

in Fig. 40. Be

careful

not

to

crush

the

bearing spacer.

3.

Lubricate

the

O-ring with axle

lubricant and install

it in its

groove

in

the pinion retainer.

Be

careful

not to

twist

it.

Snap

the

O-ring into position.

4.

Place

the

proper shim

on the

carrier housing

and

install

the

pinion

and retainer assembly, being careful

not

to

pinch

the

O-ring (Fig.

41).

5. Install

the

pinion attaching bolts.

Torque

the

bolts

to

specification.

6. Place

the

slinger over

the

pinion

shaft

and

against

the

front bearing.

7.

Install

a new

seal

in the

bearing

retainer (Fig.

47).

8. Install

the

U-joint flange

(Fig.

49).

9. Start

a new

integral

nut and

washer

on the

pinion shaft.

Press

Ram

L*

Fiber Block

Tool-

T57L-4621

E 1712-A

FIG. 40—Installing Pinion Front

Bearing

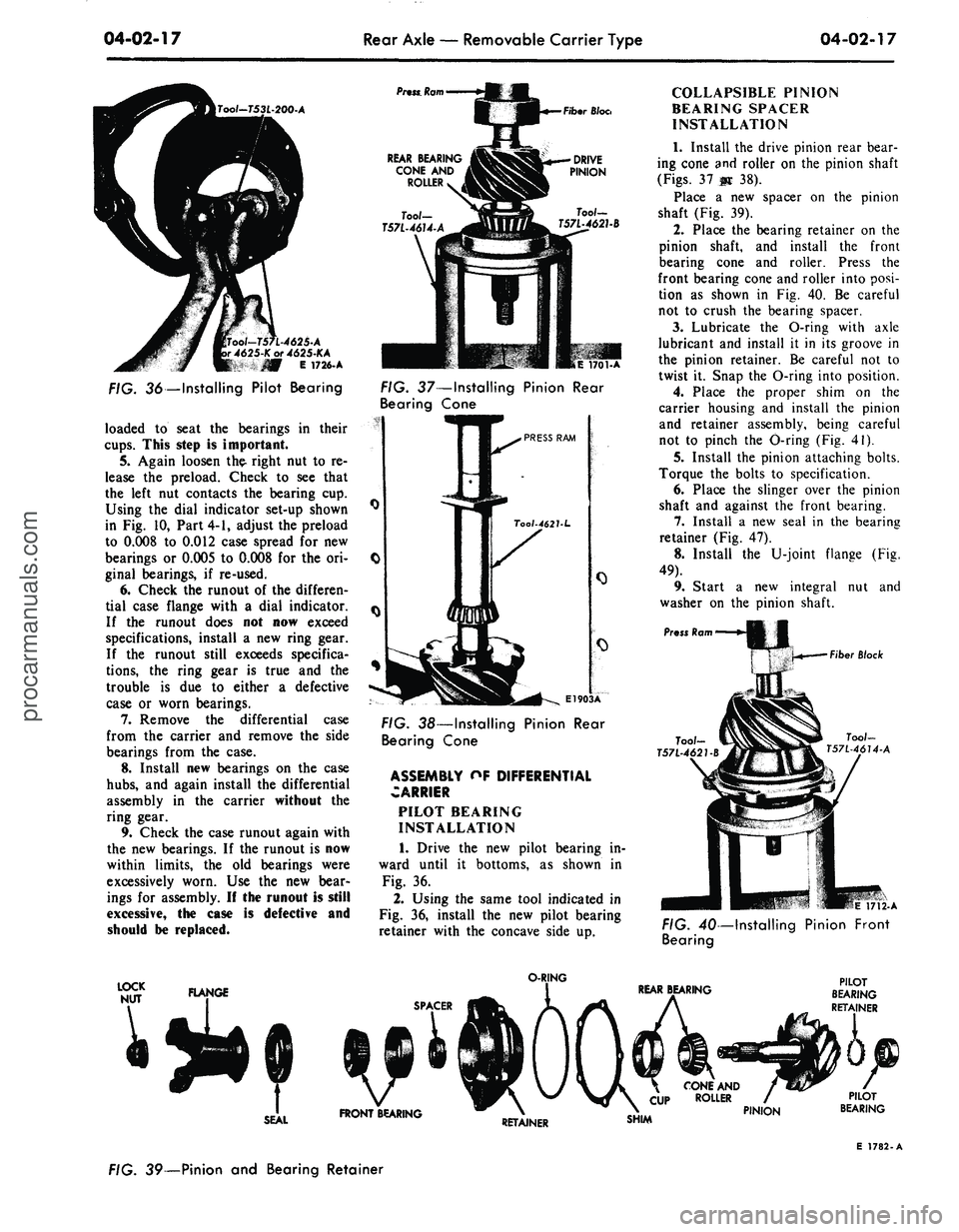

FLANGE

O-RING

REAR BEARING

SPACER

SEAL

FRONT BEARING

RETAINER

SHIM

PINION

FIG. 39—Pinion

and

Bearing Retainer

PILOT

BEARING

RETAINER

PILOT

BEARING

E 1782-Aprocarmanuals.com

Page 215 of 413

04-02-18

Rear Axle — Removable Carrier Type

04-02-18

E 1195-C

FIG. 41—Removing

or

Installing

Pinion

and

Retainer Assembly

10.

Hold

the

flange with

the

tool

shown

in Fig. 22

(Ford)

or Fig. 23

(Mercury),

and

torque

the

pinion shaft

nut

to 175

ft-lbs.

Do not

exceed

175

ft-Ibs

at

this time.

11.

Check

the

pinion bearing

pre-

load

as

shown

in Fig. 42.

Correct

pre-load will

be

obtained when

the

torque required

to

rotate

the

pinion

in

the retainer

is as

specified

in

Part

4-3.

If

the

torque required

to

rotate

the pin-

ion

is

less than specified, tighten

the

pinion shaft

nut a

little

at a

time until

Inch-Pound

Torque Wrench

E1899A

FIG. 42—Checking Pinion Bearing

Preload

the proper preload

is

established.

Do

not overtighten

the nut. If

excessive

preload

is

obtained

as a

result

of

over-

tightening, replace

the

collapsible

bearing spacer.

Do

not

back

off the

pinion shaft

nut

to establish pinion bearing preload.

If

the torque

on the

pinion shaft

nut is

less than

175

ft-lbs after bearing

pre-

load

is

established,

a new

collapsible

spacer must

be

used.

SOLID PINION BEARING

SPACER INSTALLATION

The spacer

is

serviced

in 20

sizes

listed

in

Part

4-5. The

manner

of sel-

ecting

the

size spacer required

for ob-

taining correct preload

is

included

in

the following assembly procedure.

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

pinion shaft

as

shown

in

Figs.

38 or

39.

2.

Select

a new

solid spacer

of a

larger size (0.485 inch thick),

and

slide

it over

the

pinion shaft against

the

rear bearing.

The pinion bearing preload

can be

accurately measured only when

the

pinion shaft

nut is

torqued

to 180-

220 ft-lbs.

If a

spacer smaller than

re-

quired

was

used,

the

specified

180-

220 ft-lbs torque would damage

the

bearings.

For

this reason,

the

largest

spacer should

be

tried first. Then,

if

the bearings

are too

loose,

the

size

of

the spacer

can be

decreased until

the

correct preload

is

obtained.

3.

Position

the

bearing retainer

and

cup assembly

on the

pinion shaft

and

install

the

front bearing cone

and rol-

ler. Press

the

front bearing cone

and

roller assembly into position,

as

shown

in Fig. 38.

4.

Mount

the

retainer

in a

holding

fixture

as

shown

in Fig. 23, and

place

the slinger over

the

pinion shaft

and

against

the

front bearing.

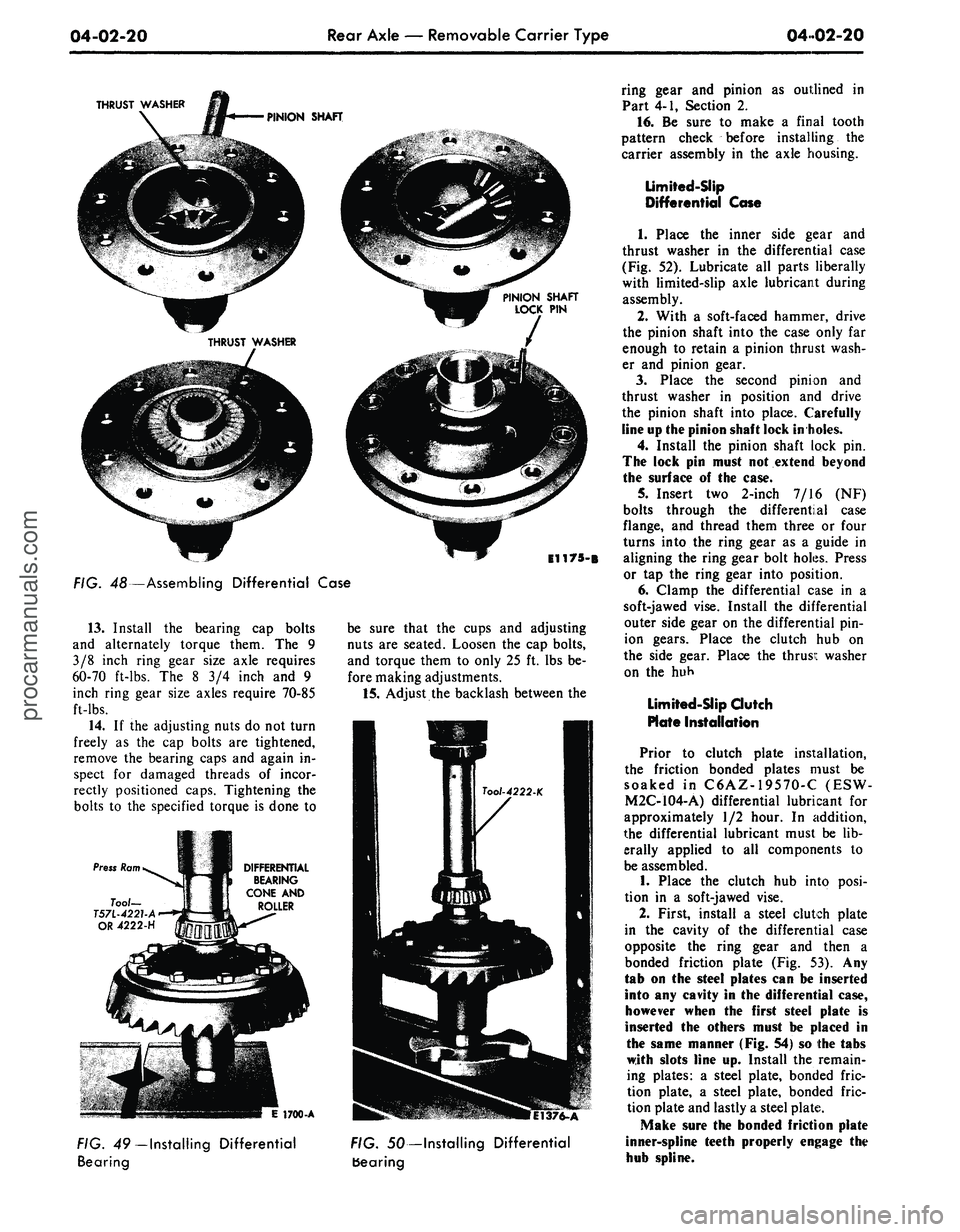

5.

Install

the

U-joint flange with

the tool shown

in Fig. 46.

6. Hold

the

flange with

the

tool

shown

in Fig. 23 or 24, and

install

the

old pinion shaft

nut.

Using

a

ft-lb

tor-

que wrench, torque

the nut to

180-220

ft-lbs.

While tightening

the nut,

rotate

the bearing retainer

to

determine

the

existance

of any

bearing preload

which will

be

indicated

by a

slight

drag

in the

rotation

of the

retainer.

DETERMINING SPACER

SIZE FROM

PRELOAD READING

1.

If

bearing drag indicates

a pre-

load condition exists, apply

an

in-lb

torque wrench

to the

pinion

nut as

shown

in Fig. 42 and

read

the

torque

required

to

turn

the

shaft. Effort

should

be

12-1/2

to

32-1/2 in-lbs.

2.

If

preload

is the

correct valve,

proceed with assembly procedure

given

in

Final Assembly

of

Pinion

and

Retainer, which follows.

2.

If

preload exists,

but is

below

specification, select

the

correct spacer

from

Fig. 43 and

install, completing

assembly

as

shown

in

Final Assembly

of Pinion

and

Retainer.

DETERMINING SPACER

SIZE FROM

END

PLAY READING

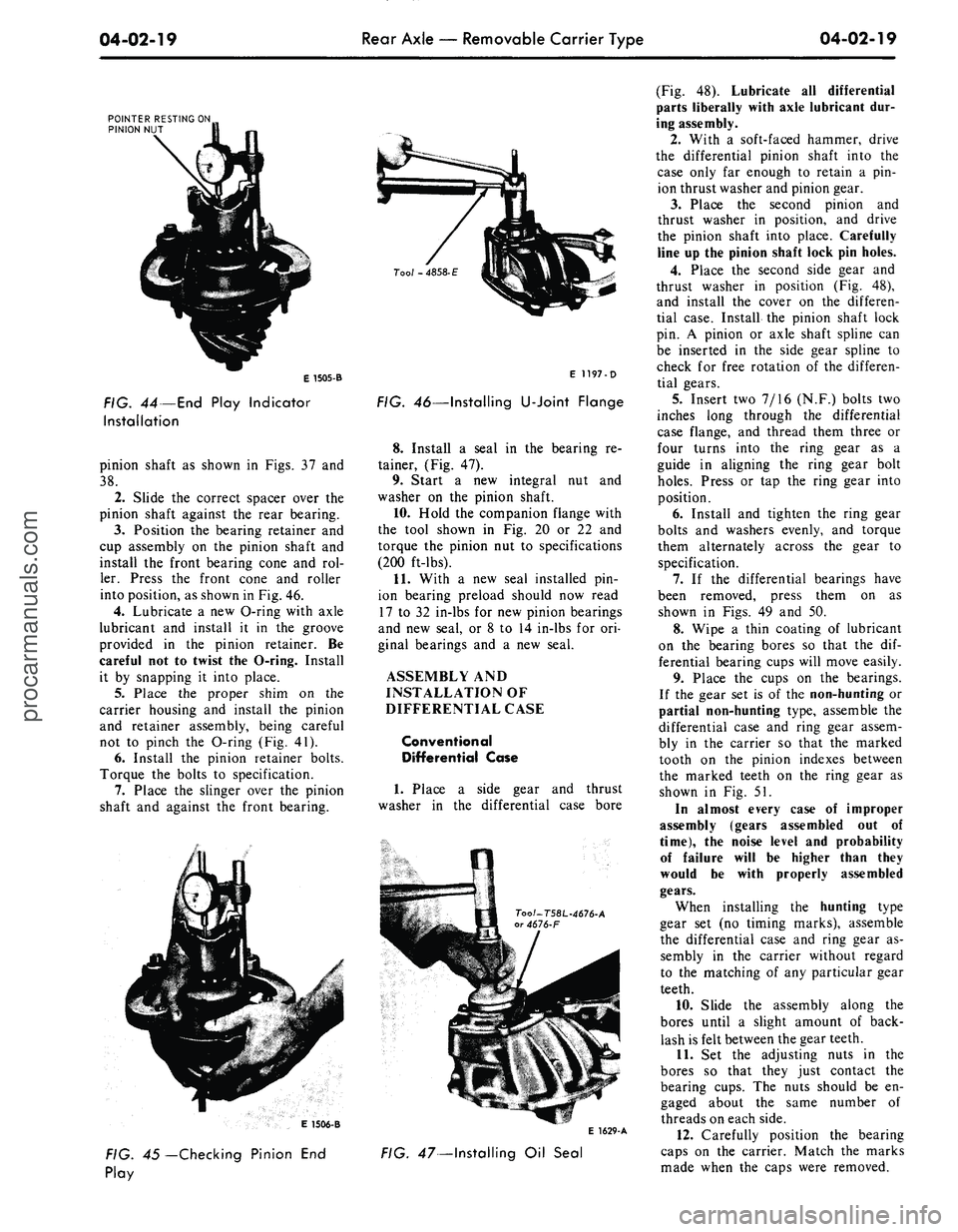

1.

If no

perceptible preload

is

felt

when rotating

the

pinion shaft, install

a dial indicator

as

shown

in Fig. 44,

so that

the

indicator point

is

resting

on

the end of the

pinion gear shaft

(companion flange

end).

2.

Use

both hands

to

squeeze

the

pinion shaft

and the

bearing retainer

together

(Fig. 45).

Record

the

endplay

reading shown

on the

dial indicator.

3.

Disassemble

the

pinion shaft

and

retainer

and

install

the

correct spacer

as shown

in Fig. 43.

4.

Proceed with assembly

of the pin-

ion shaft

and

retainer

as

directed

in

Final Assembly

of

Pinion

and

Retain-

er.

FINAL ASSEMBLY

OF

PINION

AND

RETAINER

1.

Install

the

drive pinion rear bear-

ing cone

and

roller assembly

on the

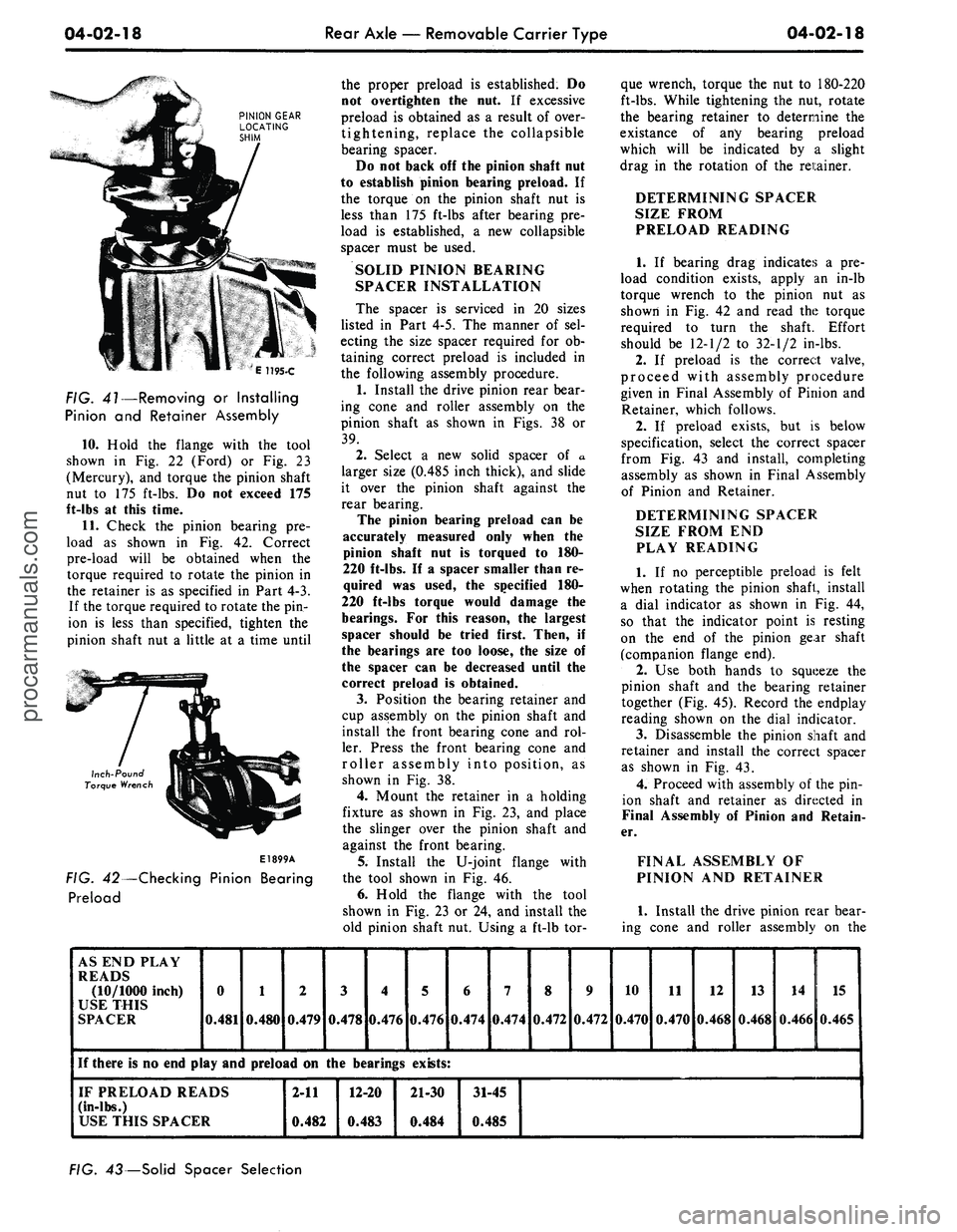

AS

END

PLAY

READS

(10/1000 inch)

USE THIS

SPACER

0

0.481

1

0.480

2

0.479

3

0.478

4

0.476

If there

is no end

play

and

preload

on the

bearings

IF PRELOAD READS

(in-lbs.)

USE THIS SPACER

2-11

0.482

12-20

0.483

5

0.476

6

0.474

7

0.474

8

0.472

9

0.472

10

0.470

11

0.470

12

0.468

13

0.468

14

0.466

15

0.465

exists:

21-30

0.484

31-45

0.485

FIG. 43— Solid Spacer Selectionprocarmanuals.com

Page 216 of 413

04-02-19

Rear Axle — Removable Carrier Type

04-02-19

POINTER RESTING ON

PINION NUT

E 1505-B

FIG.

44

— End Play Indicator

Installation

pinion shaft as shown in Figs. 37 and

38.

2.

Slide the correct spacer over the

pinion shaft against the rear bearing.

3.

Position the bearing retainer and

cup assembly on the pinion shaft and

install the front bearing cone and rol-

ler. Press the front cone and roller

into position, as shown in Fig. 46.

4.

Lubricate a new O-ring with axle

lubricant and install it in the groove

provided in the pinion retainer. Be

careful not to twist the O-ring. Install

it by snapping it into place.

5.

Place the proper shim on the

carrier housing and install the pinion

and retainer assembly, being careful

not to pinch the O-ring (Fig. 41).

6. Install the pinion retainer bolts.

Torque the bolts to specification.

7.

Place the slinger over the pinion

shaft and against the front bearing.

Tool - 4858-

E

E 1197-D

FIG. 46—Installing

U-Joint

Flange

8. Install a seal in the bearing re-

tainer, (Fig. 47).

9. Start a new integral nut and

washer on the pinion shaft.

10.

Hold the companion flange with

the tool shown in Fig. 20 or 22 and

torque the pinion nut to specifications

(200 ft-lbs).

11.

With a new seal installed pin-

ion bearing preload should now read

17 to 32 in-lbs for new pinion bearings

and new seal, or 8 to 14 in-lbs for ori-

ginal bearings and a new seal.

ASSEMBLY AND

INSTALLATION OF

DIFFERENTIAL CASE

Conventional

Differential Case

1.

Place a side gear and thrust

washer in the differential case bore

E 1506-B

E 1629-A

FIG. 45— Checking Pinion End

Play

FIG. 47—Installing Oil Seal

(Fig. 48). Lubricate all differential

parts liberally with axle lubricant dur-

ing assembly.

2.

With a soft-faced hammer, drive

the differential pinion shaft into the

case only far enough to retain a pin-

ion thrust washer and pinion gear.

3.

Place the second pinion and

thrust washer in position, and drive

the pinion shaft into place. Carefully

line up the pinion shaft lock pin holes.

4.

Place the second side gear and

thrust washer in position (Fig. 48),

and install the cover on the differen-

tial case. Install the pinion shaft lock

pin. A pinion or axle shaft spline can

be inserted in the side gear spline to

check for free rotation of the differen-

tial gears.

5.

Insert two 7/16 (N.F.) bolts two

inches long through the differential

case flange, and thread them three or

four turns into the ring gear as a

guide in aligning the ring gear bolt

holes.

Press or tap the ring gear into

position.

6. Install and tighten the ring gear

bolts and washers evenly, and torque

them alternately across the gear to

specification.

7.

If the differential bearings have

been removed, press them on as

shown in Figs. 49 and 50.

8. Wipe a thin coating of lubricant

on the bearing bores so that the dif-

ferential bearing cups will move easily.

9. Place the cups on the bearings.

If the gear set is of the non-hunting or

partial non-hunting type, assemble the

differential case and ring gear assem-

bly in the carrier so that the marked

tooth on the pinion indexes between

the marked teeth on the ring gear as

shown in Fig. 51.

In almost every case of improper

assembly (gears assembled out of

time),

the noise level and probability

of failure will be higher than they

would be with properly assembled

gears.

When installing the hunting type

gear set (no timing marks), assemble

the differential case and ring gear as-

sembly in the carrier without regard

to the matching of any particular gear

teeth.

10.

Slide the assembly along the

bores until a slight amount of back-

lash is felt between the gear teeth.

11.

Set the adjusting nuts in the

bores so that they just contact the

bearing cups. The nuts should be en-

gaged about the same number of

threads on each side.

12.

Carefully position the bearing

caps on the carrier. Match the marks

made when the caps were removed.procarmanuals.com

Page 217 of 413

04-02-20

Rear Axle — Removable Carrier Type

0402-20

THRUST WASHER

E1175-B

FIG. 48—Assembling Differential Case

13.

Install the bearing cap bolts

and alternately torque them. The 9

3/8 inch ring gear size axle requires

60-70 ft-lbs. The 8 3/4 inch and 9

inch ring gear size axles require 70-85

ft-lbs.

14.

If the adjusting nuts do not turn

freely as the cap bolts are tightened,

remove the bearing caps and again in-

spect for damaged threads of incor-

rectly positioned caps. Tightening the

bolts to the specified torque is done to

be sure that the cups and adjusting

nuts are seated. Loosen the cap bolts,

and torque them to only 25 ft. lbs be-

fore making adjustments.

15.

Adjust the backlash between the

DIFFERENTIAL

BEARING

CONE AND

ROLLER

E 1700-A

FIG. 49—

Installing

Differential

Bearing

1376-A

FIG. 50—Installing Differential

bearing

ring gear and pinion as outlined in

Part 4-1, Section 2.

16.

Be sure to make a final tooth

pattern check before installing the

carrier assembly in the axle housing.

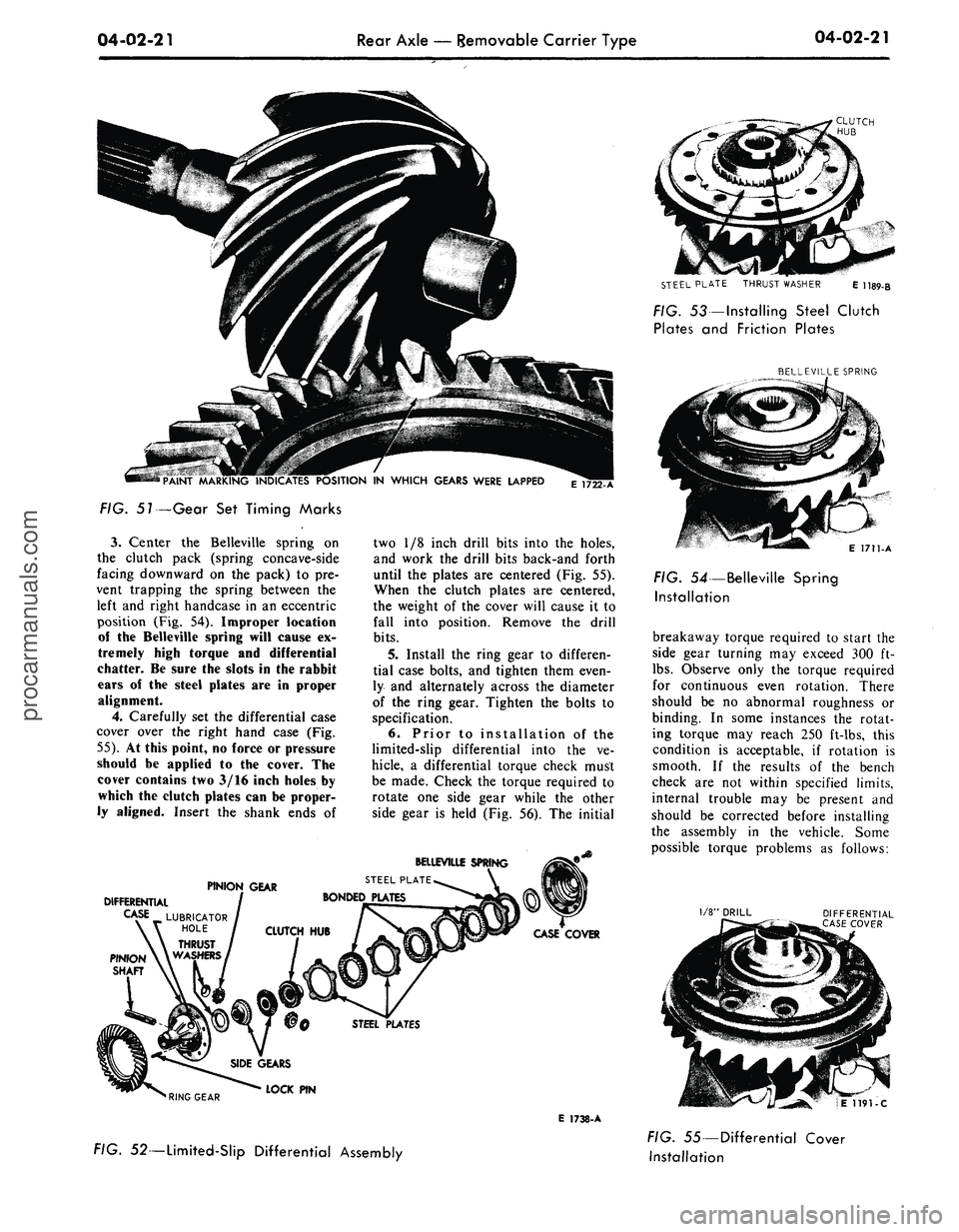

Limited-Slip

Differential Case

1.

Place the inner side gear and

thrust washer in the differential case

(Fig. 52). Lubricate all parts liberally

with limited-slip axle lubricant during

assembly.

2.

With a soft-faced hammer, drive

the pinion shaft into the case only far

enough to retain a pinion thrust wash-

er and pinion gear.

3.

Place the second pinion and

thrust washer in position and drive

the pinion shaft into place. Carefully

line up the pinion shaft lock in holes.

4.

Install the pinion shaft lock pin.

The lock pin must not extend beyond

the surface of the case.

5. Insert two 2-inch 7/16 (NF)

bolts through the differential case

flange, and thread them three or four

turns into the ring gear as a guide in

aligning the ring gear bolt holes. Press

or tap the ring gear into position.

6. Clamp the differential case in a

soft-jawed vise. Install the differential

outer side gear on the differential pin-

ion gears. Place the clutch hub on

the side gear. Place the thrusi: washer

on the huh

Limited-Slip dutch

Plate Installation

Prior to clutch plate installation,

the friction bonded plates must be

soaked in C6AZ-19570-C (ESW-

M2C-104-A) differential lubricant for

approximately 1/2 hour. In addition,

the differential lubricant must be lib-

erally applied to all components to

be assembled.

1.

Place the clutch hub into posi-

tion in a soft-jawed vise.

2.

First, install a steel clutch plate

in the cavity of the differential case

opposite the ring gear and then a

bonded friction plate (Fig. 53). Any

tab on the steel plates can be inserted

into any cavity in the differential case,

however when the first steel plate is

inserted the others must be placed in

the same manner (Fig. 54) so the tabs

with slots line up. Install the remain-

ing plates: a steel plate, bonded fric-

tion plate, a steel plate, bonded fric-

tion plate and lastly a steel plate.

Make sure the bonded friction plate

inner-spline teeth properly engage the

hub spline.procarmanuals.com

Page 218 of 413

04-02-21

Rear Axle

—

Removable Carrier Type

04-02-21

SITION IN WHICH GEARS WERE LAPPED

FIG. 51—Gear

Set

Timing Marks

3.

Center

the

Belleville spring

on

the clutch pack (spring concave-side

facing downward

on the

pack)

to pre-

vent trapping

the

spring between

the

left

and

right handcase

in an

eccentric

position

(Fig. 54).

Improper location

of

the

Belleville spring will cause

ex-

tremely high torque

and

differential

chatter.

Be

sure

the

slots

in the

rabbit

ears

of the

steel plates

are in

proper

alignment.

4.

Carefully

set the

differential case

cover over

the

right hand case

(Fig.

55).

At

this point,

no

force

or

pressure

should

be

applied

to the

cover.

The

cover contains

two 3/16

inch holes

by

which

the

clutch plates

can be

proper-

ly aligned. Insert

the

shank ends

of

two

1/8

inch drill bits into

the

holes,

and work

the

drill bits back-and forth

until

the

plates

are

centered

(Fig. 55).

When

the

clutch plates

are

centered,

the weight

of the

cover will cause

it to

fall into position. Remove

the

drill

bits.

5.

Install

the

ring gear

to

differen-

tial case bolts,

and

tighten them even-

ly

and

alternately across

the

diameter

of

the

ring gear. Tighten

the

bolts

to

specification.

6. Prior

to

installation

of the

limited-slip differential into

the ve-

hicle,

a

differential torque check must

be made. Check

the

torque required

to

rotate

one

side gear while

the

other

side gear

is

held

(Fig. 56). The

initial

PINION GEAR

DIFFERENTIAL

CASE

_

LUBRICATOR

HOLE / CLUTCH HUB

THRUST /

PINION \\WASHERS/

SHAFT

BELLEVILLE SPRING

STEEL

PLATE.

BONDED PLATES

CASE COVER

STEEL PLATES

RING GEAR

SIDE GEARS

LOCK

PIN

E 1738-A

STEEL PLATE THRUST WASHER

E 1189-

FIG. 53—Installing Steel Clutch

Plates

and

Friction Plates

BELLEVILLE SPRING

E 1711-A

FIG.

54

— Belleville

Spring

Installation

breakaway torque required

to

start

the

side gear turning

may

exceed

300 ft-

lbs.

Observe only

the

torque required

for continuous even rotation. There

should

be no

abnormal roughness

or

binding.

In

some instances

the

rotat-

ing torque

may

reach

250

ft-lbs, this

condition

is

acceptable,

if

rotation

is

smooth.

If the

results

of the

bench

check

are not

within specified limits,

internal trouble

may be

present

and

should

be

corrected before installing

the assembly

in the

vehicle. Some

possible torque problems

as

follows:

1/8" DRILL

DIFFERENTIAL

CASE COVER

E 1191-C

FIG. 52—Limited-Slip Differential Assembly

FIG.

55—

Differential Cover

Installationprocarmanuals.com

Page 219 of 413

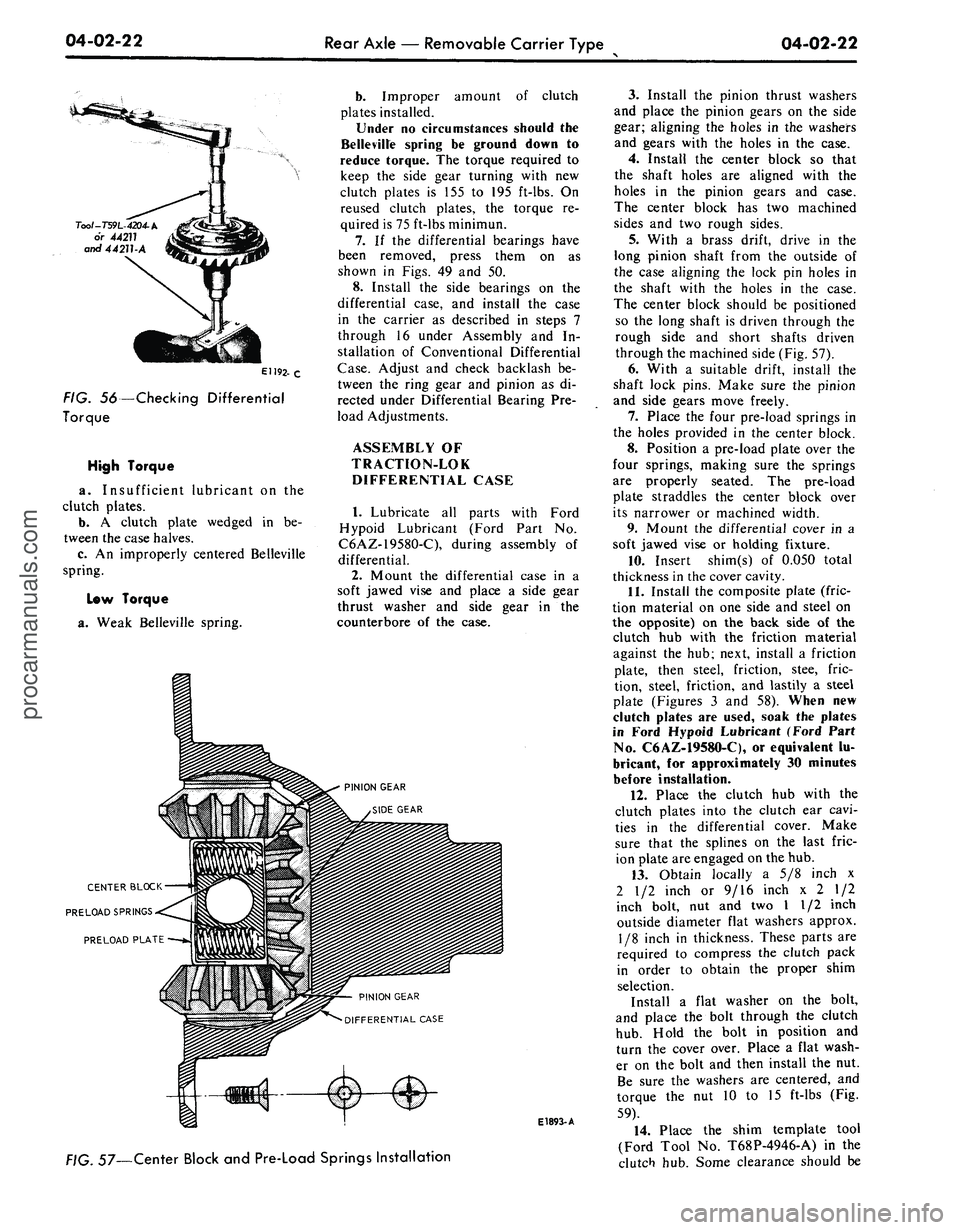

04-02-22

Rear Axle — Removable Carrier Type

04-02-22

Too/-T59L-4204-A

or

44211

and

44211-A

EH92-C

FIG. 56—Checking Differential

Torque

High Torque

a. Insufficient lubricant on the

clutch plates.

b.

A clutch plate wedged in be-

tween the case halves.

c. An improperly centered Belleville

spring.

Low Torque

a. Weak Belleville spring.

b.

Improper amount of clutch

plates installed.

Under no circumstances should the

Belleville spring be ground down to

reduce torque. The torque required to

keep the side gear turning with new

clutch plates is 155 to 195 ft-lbs. On

reused clutch plates, the torque re-

quired is 75 ft-lbs minimun.

7.

If the differential bearings have

been removed, press them on as

shown in Figs. 49 and 50.

8. Install the side bearings on the

differential case, and install the case

in the carrier as described in steps 7

through 16 under Assembly and In-

stallation of Conventional Differential

Case. Adjust and check backlash be-

tween the ring gear and pinion as di-

rected under Differential Bearing Pre-

load Adjustments.

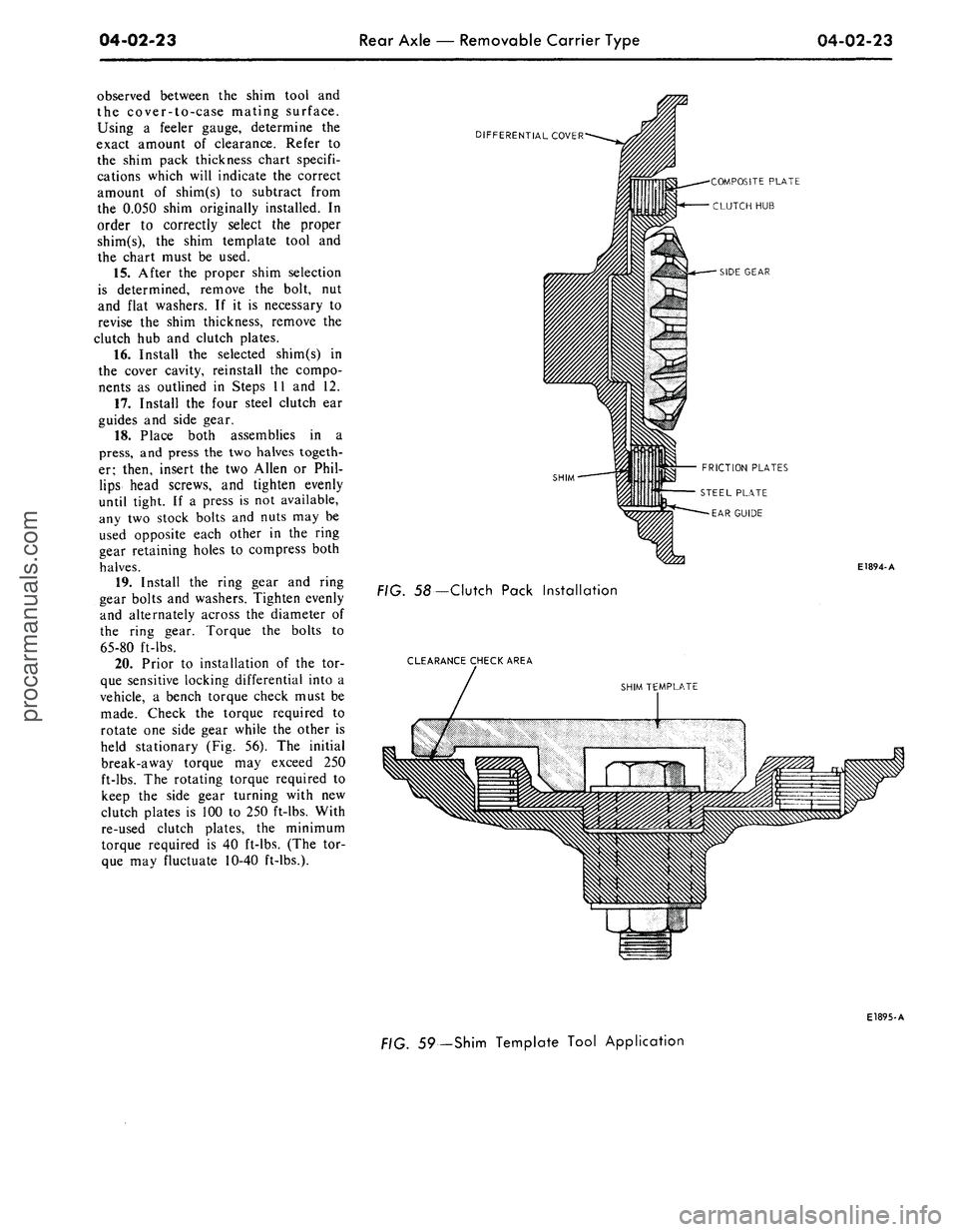

ASSEMBLY OF

TRACTION-LOK

DIFFERENTIAL CASE

1.

Lubricate all parts with Ford

Hypoid Lubricant (Ford Part No.

C6AZ-19580-C), during assembly of

differential.

2.

Mount the differential case in a

soft jawed vise and place a side gear

thrust washer and side gear in the

counterbore of the case.

CENTER BLOCK

PRELOAD SPRINGS

PRELOAD PLATE

PINION GEAR

DIFFERENTIAL CASE

E1893-

A

. 57—Center Block and Pre-Load Springs Installation

3.

Install the pinion thrust washers

and place the pinion gears on the side

gear; aligning the holes in the washers

and gears with the holes in the case.

4.

Install the center block so that

the shaft holes are aligned with the

holes in the pinion gears and case.

The center block has two machined

sides and two rough sides.

5.

With a brass drift, drive in the

long pinion shaft from the outside of

the case aligning the lock pin holes in

the shaft with the holes in the case.

The center block should be positioned

so the long shaft is driven through the

rough side and short shafts driven

through the machined side (Fig. 57).

6. With a suitable drift, install the

shaft lock pins. Make sure the pinion

and side gears move freely.

7.

Place the four pre-load springs in

the holes provided in the center block.

8. Position a pre-load plate over the

four springs, making sure the springs

are properly seated. The pre-load

plate straddles the center block over

its narrower or machined width.

9. Mount the differential cover in a

soft jawed vise or holding fixture.

10.

Insert shim(s) of 0.050 total

thickness in the cover cavity.

11.

Install the composite plate (fric-

tion material on one side and steel on

the opposite) on the back side of the

clutch hub with the friction material

against the hub; next, install a friction

plate, then steel, friction, stee, fric-

tion, steel, friction, and lastily a steel

plate (Figures 3 and 58). When new

clutch plates are used, soak the plates

in Ford Hypoid Lubricant (Ford Part

No.

C6AZ-19580-C), or equivalent lu-

bricant, for approximately 30 minutes

before installation.

12.

Place the clutch hub with the

clutch plates into the clutch ear cavi-

ties in the differential cover. Make

sure that the splines on the last fric-

ion plate are engaged on the hub.

13.

Obtain locally a 5/8 inch x

2 1/2 inch or 9/16 inch x 2 1/2

inch bolt, nut and two I 1/2 inch

outside diameter flat washers approx.

1/8 inch in thickness. These parts are

required to compress the clutch pack

in order to obtain the proper shim

selection.

Install a flat washer on the bolt,

and place the bolt through the clutch

hub.

Hold the bolt in position and

turn the cover over. Place a flat wash-

er on the bolt and then install the nut.

Be sure the washers are centered, and

torque the nut 10 to 15 ft-lbs (Fig.

59).

14.

Place the shim template tool

(Ford Tool No. T68P-4946-A) in the

clutch hub. Some clearance should beprocarmanuals.com

Page 220 of 413

04-02-23

Rear Axle — Removable Carrier Type

04-02-23

observed between the shim tool and

the cover-to-case mating surface.

Using a feeler gauge, determine the

exact amount of clearance. Refer to

the shim pack thickness chart specifi-

cations which will indicate the correct

amount of shim(s) to subtract from

the 0.050 shim originally installed. In

order to correctly select the proper

shim(s), the shim template tool and

the chart must be used.

15.

After the proper shim selection

is determined, remove the bolt, nut

and flat washers. If it is necessary to

revise the shim thickness, remove the

clutch hub and clutch plates.

16.

Install the selected shim(s) in

the cover cavity, reinstall the compo-

nents as outlined in Steps 11 and 12.

17.

Install the four steel clutch ear

guides and side gear.

18.

Place both assemblies in a

press,

and press the two halves togeth-

er; then, insert the two Allen or Phil-

lips head screws, and tighten evenly

until tight. If a press is not available,

any two stock bolts and nuts may be

used opposite each other in the ring

gear retaining holes to compress both

halves.

19.

Install the ring gear and ring

gear bolts and washers. Tighten evenly

and alternately across the diameter of

the ring gear. Torque the bolts to

65-80 ft-lbs.

20.

Prior to installation of the tor-

que sensitive locking differential into a

vehicle, a bench torque check must be

made. Check the torque required to

rotate one side gear while the other is

held stationary (Fig. 56). The initial

break-away torque may exceed 250

ft-lbs.

The rotating torque required to

keep the side gear turning with new

clutch plates is 100 to 250 ft-lbs. With

re-used clutch plates, the minimum

torque required is 40 ft-lbs. (The tor-

que may fluctuate 10-40 ft-lbs.).

DIFFERENTIAL COVER

SHIM

-COMPOSITE PLATE

CLUTCH HUB

SIDE GEAR

FRICTION PLATES

E1894-A

FIG. 58— Clutch Pack Installation

CLEARANCE CHECK AREA

SHIM TEMPLATE

E1895-A

59—Shim Template Tool Applicationprocarmanuals.com