lock INFINITI QX4 2001 Factory Workshop Manual

[x] Cancel search | Manufacturer: INFINITI, Model Year: 2001, Model line: QX4, Model: INFINITI QX4 2001Pages: 2395, PDF Size: 43.2 MB

Page 270 of 2395

DescriptionNBAT0093IThe mechanical key interlock mechanism also operates as a

shift lock:

With the key switch turned to ªONº, the selector lever cannot

be shifted from ªPº (parking) to any other position unless the

brake pedal is depressed.

With the key removed, the selector lever cannot be shifted

from ªPº to any other position.

The key cannot be removed unless the selector lever is placed

in ªPº.

IThe shift lock and key interlock mechanisms are controlled by

the ON-OFF operation of the shift lock solenoid and by the

operation of the rotator and slider located inside the key

cylinder, respectively.

SAT145K

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

A/T SHIFT LOCK SYSTEM

Description

AT-265

Page 271 of 2395

Wiring Diagram Ð SHIFT ÐNBAT0094

MAT921A

A/T SHIFT LOCK SYSTEM

Wiring Diagram Ð SHIFT Ð

AT-266

Page 272 of 2395

Diagnostic ProcedureNBAT0095SYMPTOM 1:

ISelector lever cannot be moved from ªPº position with key

in ªONº position and brake pedal applied.

ISelector lever can be moved from ªPº position with key in

ªONº position and brake pedal released.

ISelector lever can be moved from ªPº position when key

is removed from key cylinder.

SYMPTOM 2:

Ignition key cannot be removed when selector lever is set to

ªPº position. It can be removed when selector lever is set to

any position except ªPº.

1 CHECK KEY INTERLOCK CABLE

Check key interlock cable for damage.

OK or NG

OK©GO TO 2.

NG©Repair key interlock cable. Refer to ªKey Interlock Cableº, AT-271.

2 CHECK SELECTOR LEVER POSITION

Check selector lever position for damage.

OK or NG

OK©GO TO 3.

NG©Check selector lever. Refer to ªON-VEHICLE SERVICE Ð PNP Switch and Manual Con-

trol Linkage Adjustmentº, AT-276 and AT-276.

3 CHECK POWER SOURCE

1. Turn ignition switch to ON position. (Do not start engine.)

2. Check voltage between A/T device harness terminal 5 and ground.

SAT758JA

OK or NG

OK©GO TO 5.

NG©GO TO 4.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure

AT-267

Page 273 of 2395

![INFINITI QX4 2001 Factory Workshop Manual 4 DETECT MALFUNCTIONING ITEM

Check the following items:

1. Harness for short or open between ignition switch and A/T device harness terminal 5

2. 7.5A fuse [No. 11, located in the fuse block (J/B)]

3. INFINITI QX4 2001 Factory Workshop Manual 4 DETECT MALFUNCTIONING ITEM

Check the following items:

1. Harness for short or open between ignition switch and A/T device harness terminal 5

2. 7.5A fuse [No. 11, located in the fuse block (J/B)]

3.](/img/42/57027/w960_57027-272.png)

4 DETECT MALFUNCTIONING ITEM

Check the following items:

1. Harness for short or open between ignition switch and A/T device harness terminal 5

2. 7.5A fuse [No. 11, located in the fuse block (J/B)]

3. Ignition switch (Refer to EL-9, ªSchematicº.)

OK or NG

OK©GO TO 5.

NG©Repair or replace damaged parts.

5 CHECK INPUT SIGNAL A/T DEVICE

Turn ignition switch to OFF position.

ICheck voltage between A/T device harness terminal 7 and ground.

SAT179K

OK or NG

OK©GO TO 7.

NG©GO TO 6.

6 DETECT MALFUNCTIONING ITEM

Check the following items:

1. Harness for short or open between battery and stop lamp switch harness connector 1

2. Harness for short or open between stop lamp switch harness connector 2 and A/T device harness connector 7

3. Diode

4. 10A fuse [No. 14, located in the fuse block (J/B)]

5. Stop lamp switch

a. Check continuity between terminals 1 and 2.

SAT146K

Check stop lamp switch after adjusting brake pedal Ð refer to BR-14, ªAdjustmentº.

OK or NG

OK©GO TO 7.

NG©Repair or replace damaged parts.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-268

Page 274 of 2395

7 CHECK GROUND CIRCUIT

1. Turn ignition switch to OFF position.

2. Disconnect A/T device harness connector.

3. Check continuity between A/T device harness terminal 6 and ground. Refer to wiring diagram Ð SHIFT Ð.

Continuity should exist.

If OK, check harness for short to ground and short to power.

OK or NG

OK©GO TO 8.

NG©Repair open circuit or short to ground or short to power in harness or connectors.

8 CHECK RELAY CIRCUIT

1. Turn ignition switch to ON and OFF position.

ICheck continuity between terminals 1, 2, 3 and 5.

SAT775J

YesorNo

Ye s©GO TO 9.

No©Replace relay.

9 CHECK PARK POSITION SWITCH

ICheck continuity between A/T device harness terminal 6 and relay (park position switch) harness terminal 1.

SAT180K

OK or NG

OK©GO TO 10.

NG©Replace park position switch.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-269

Page 275 of 2395

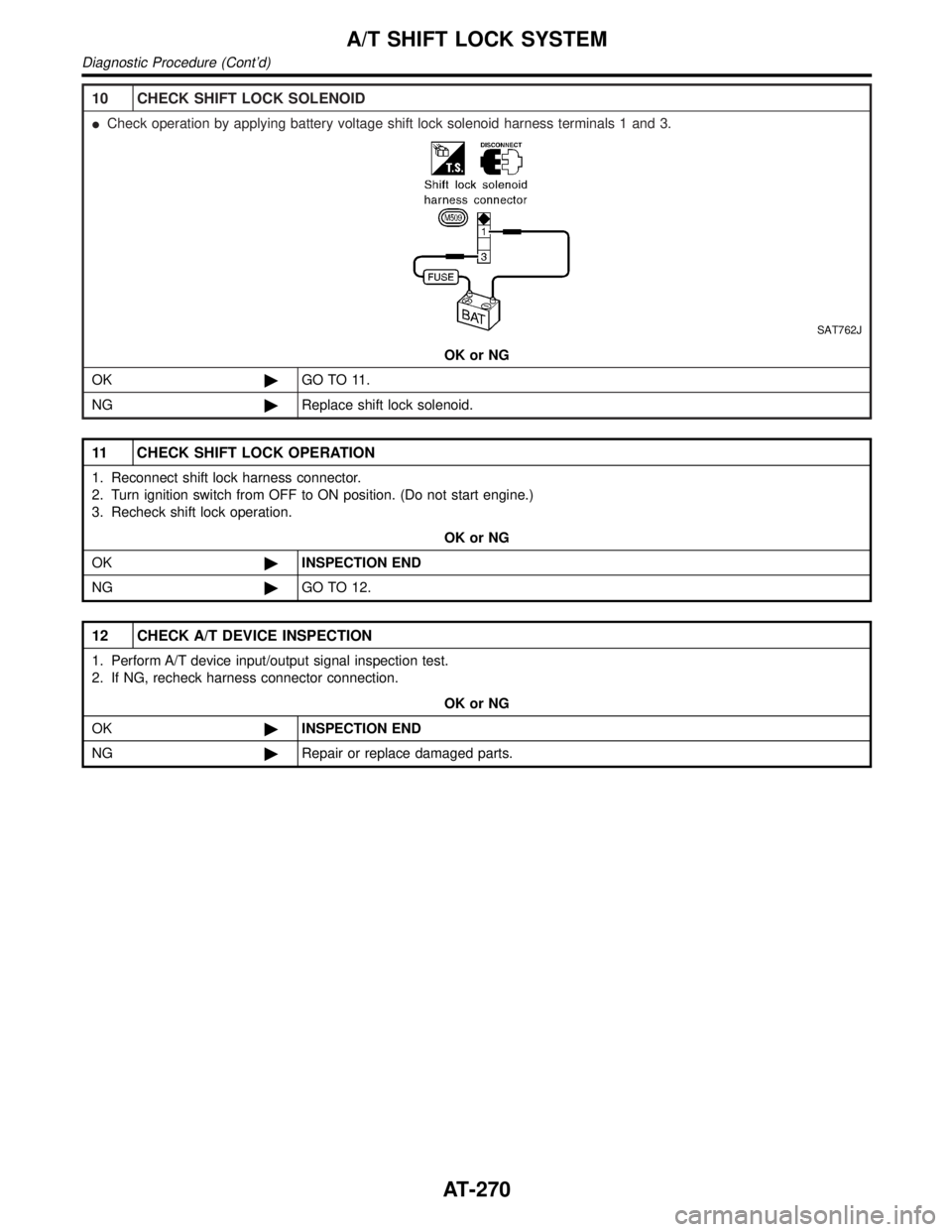

10 CHECK SHIFT LOCK SOLENOID

ICheck operation by applying battery voltage shift lock solenoid harness terminals 1 and 3.

SAT762J

OK or NG

OK©GO TO 11.

NG©Replace shift lock solenoid.

11 CHECK SHIFT LOCK OPERATION

1. Reconnect shift lock harness connector.

2. Turn ignition switch from OFF to ON position. (Do not start engine.)

3. Recheck shift lock operation.

OK or NG

OK©INSPECTION END

NG©GO TO 12.

12 CHECK A/T DEVICE INSPECTION

1. Perform A/T device input/output signal inspection test.

2. If NG, recheck harness connector connection.

OK or NG

OK©INSPECTION END

NG©Repair or replace damaged parts.

A/T SHIFT LOCK SYSTEM

Diagnostic Procedure (Cont'd)

AT-270

Page 276 of 2395

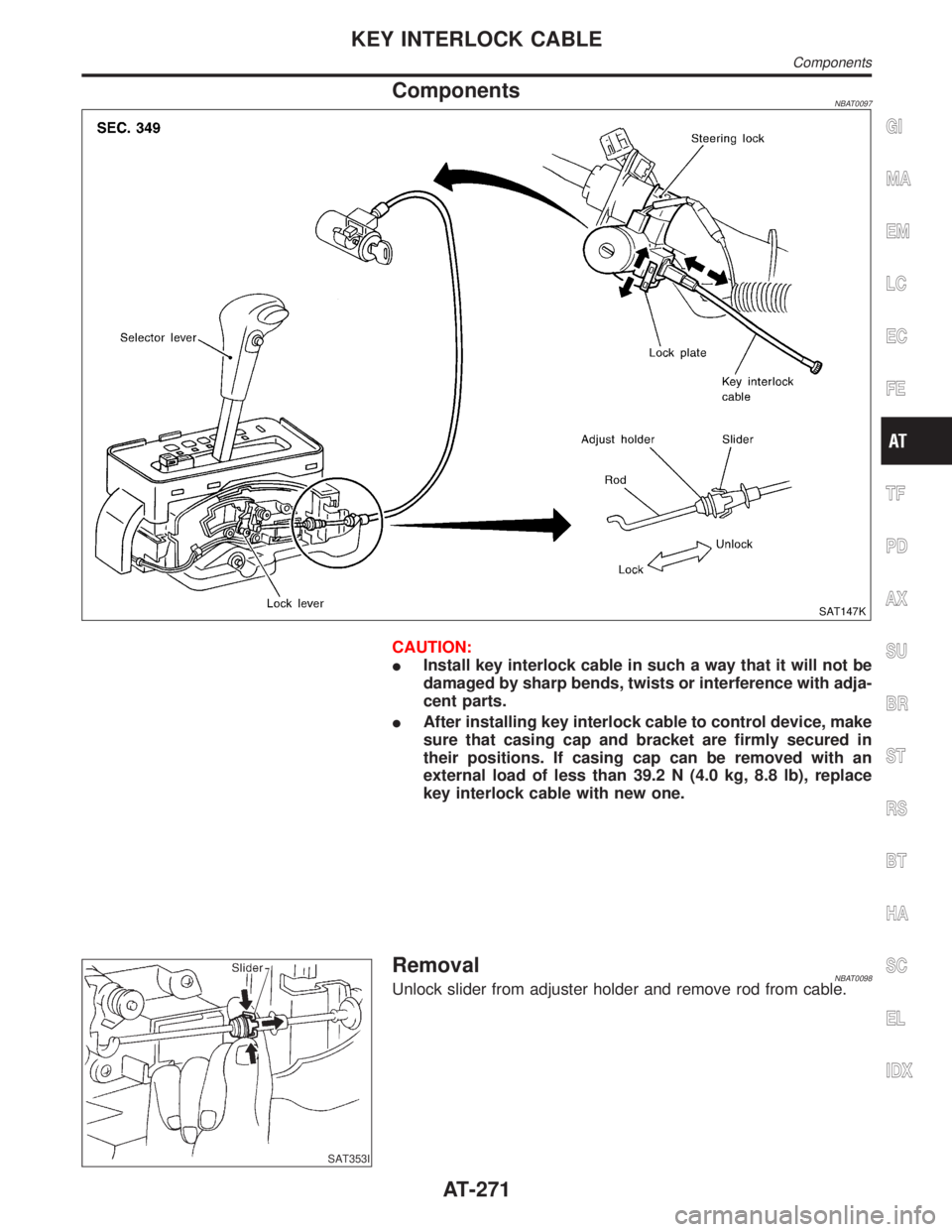

ComponentsNBAT0097

SAT147K

CAUTION:

IInstall key interlock cable in such a way that it will not be

damaged by sharp bends, twists or interference with adja-

cent parts.

IAfter installing key interlock cable to control device, make

sure that casing cap and bracket are firmly secured in

their positions. If casing cap can be removed with an

external load of less than 39.2 N (4.0 kg, 8.8 lb), replace

key interlock cable with new one.

SAT353I

RemovalNBAT0098Unlock slider from adjuster holder and remove rod from cable.

GI

MA

EM

LC

EC

FE

TF

PD

AX

SU

BR

ST

RS

BT

HA

SC

EL

IDX

KEY INTERLOCK CABLE

Components

AT-271

Page 277 of 2395

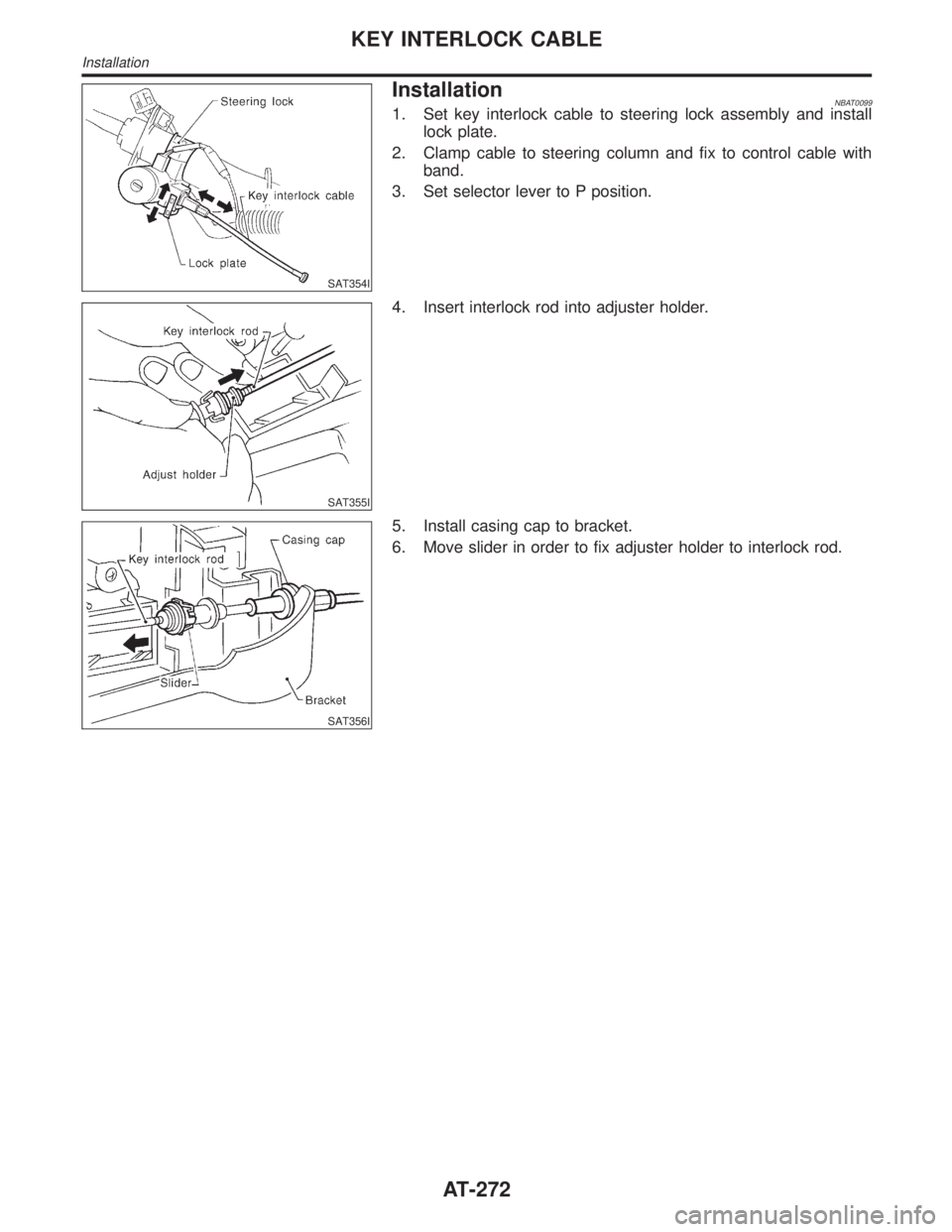

SAT354I

InstallationNBAT00991. Set key interlock cable to steering lock assembly and install

lock plate.

2. Clamp cable to steering column and fix to control cable with

band.

3. Set selector lever to P position.

SAT355I

4. Insert interlock rod into adjuster holder.

SAT356I

5. Install casing cap to bracket.

6. Move slider in order to fix adjuster holder to interlock rod.

KEY INTERLOCK CABLE

Installation

AT-272

Page 281 of 2395

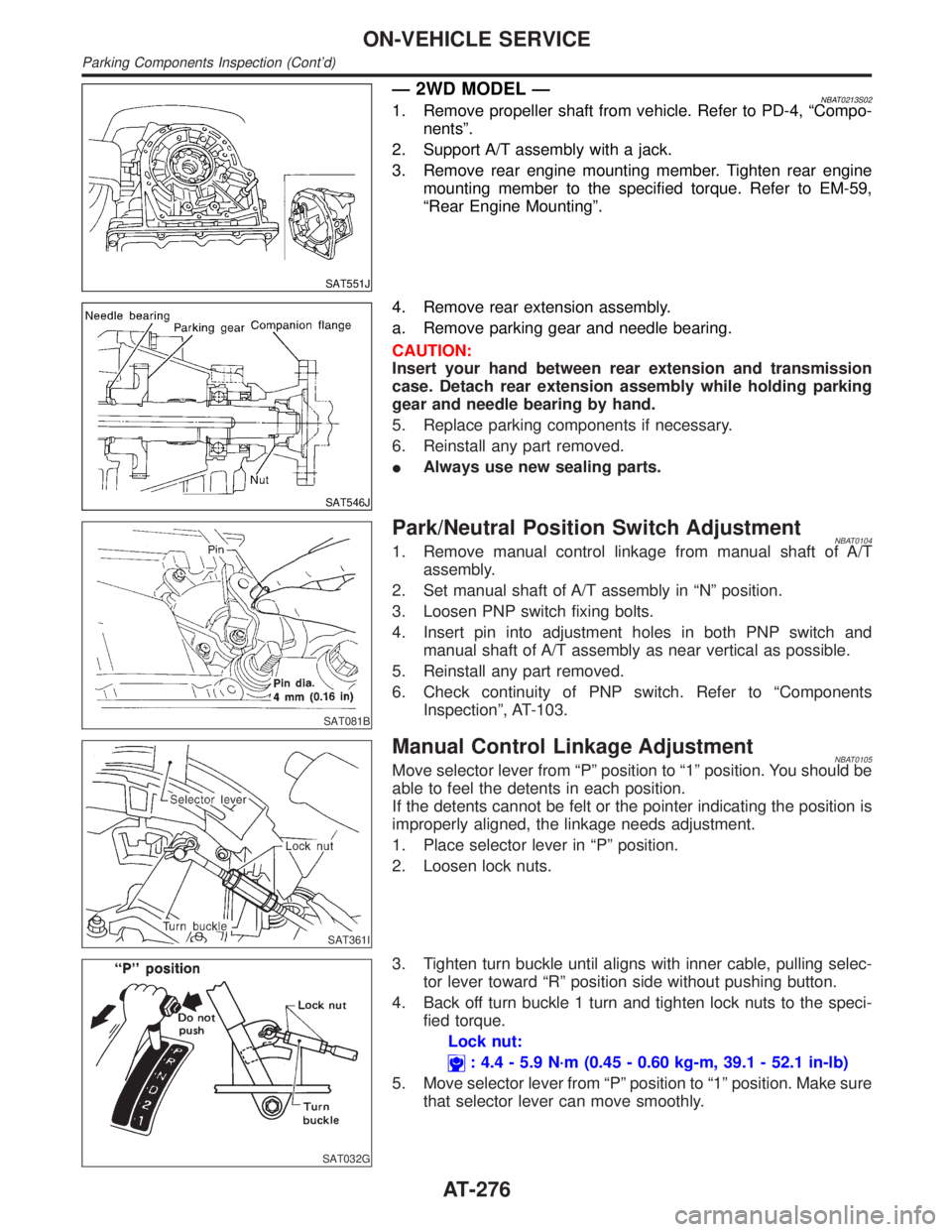

SAT551J

Ð 2WD MODEL ÐNBAT0213S021. Remove propeller shaft from vehicle. Refer to PD-4, ªCompo-

nentsº.

2. Support A/T assembly with a jack.

3. Remove rear engine mounting member. Tighten rear engine

mounting member to the specified torque. Refer to EM-59,

ªRear Engine Mountingº.

SAT546J

4. Remove rear extension assembly.

a. Remove parking gear and needle bearing.

CAUTION:

Insert your hand between rear extension and transmission

case. Detach rear extension assembly while holding parking

gear and needle bearing by hand.

5. Replace parking components if necessary.

6. Reinstall any part removed.

IAlways use new sealing parts.

SAT081B

Park/Neutral Position Switch AdjustmentNBAT01041. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to ªComponents

Inspectionº, AT-103.

SAT361I

Manual Control Linkage AdjustmentNBAT0105Move selector lever from ªPº position to ª1º position. You should be

able to feel the detents in each position.

If the detents cannot be felt or the pointer indicating the position is

improperly aligned, the linkage needs adjustment.

1. Place selector lever in ªPº position.

2. Loosen lock nuts.

SAT032G

3. Tighten turn buckle until aligns with inner cable, pulling selec-

tor lever toward ªRº position side without pushing button.

4. Back off turn buckle 1 turn and tighten lock nuts to the speci-

fied torque.

Lock nut:

: 4.4 - 5.9 N´m (0.45 - 0.60 kg-m, 39.1 - 52.1 in-lb)

5. Move selector lever from ªPº position to ª1º position. Make sure

that selector lever can move smoothly.

ON-VEHICLE SERVICE

Parking Components Inspection (Cont'd)

AT-276

Page 291 of 2395

NBAT0111

SAT018B

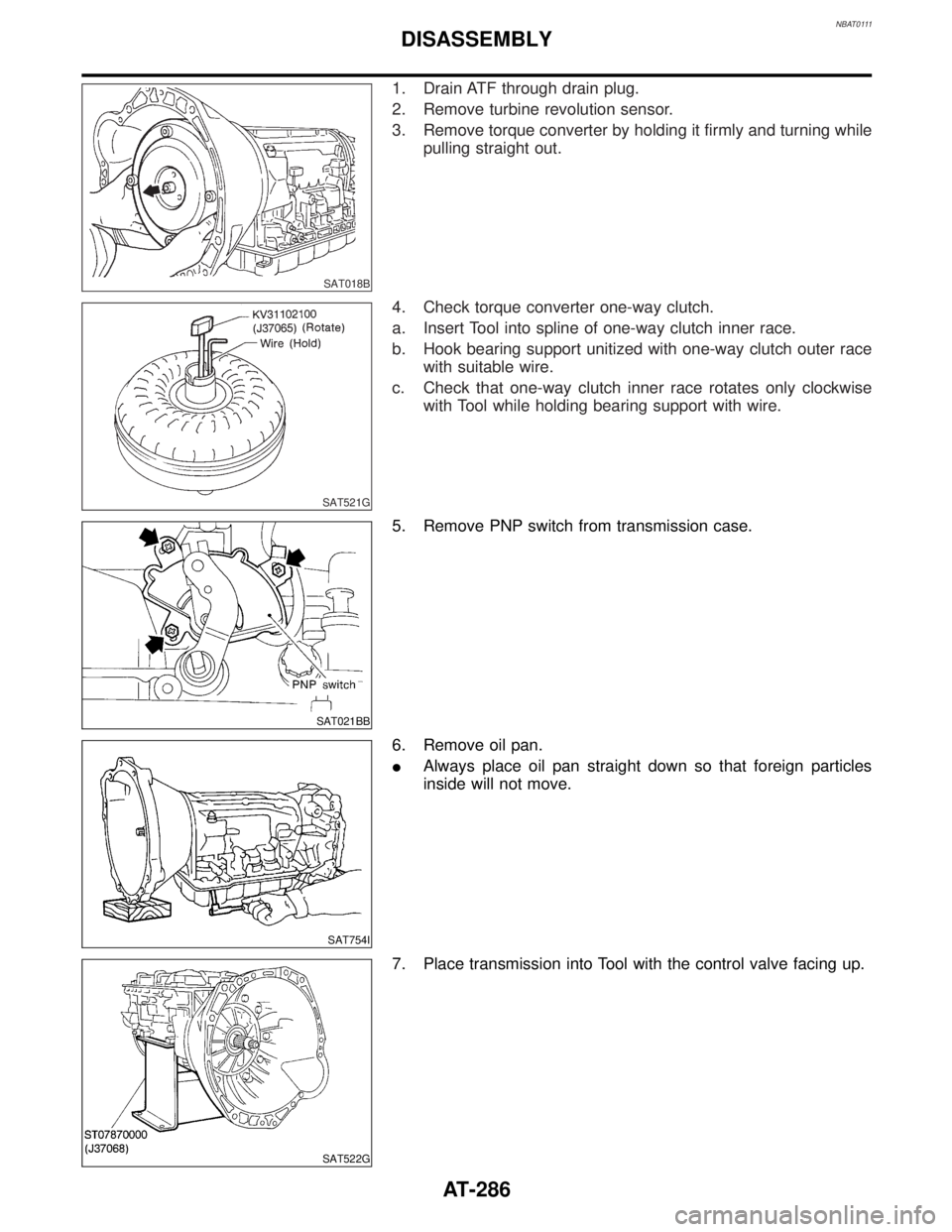

1. Drain ATF through drain plug.

2. Remove turbine revolution sensor.

3. Remove torque converter by holding it firmly and turning while

pulling straight out.

SAT521G

4. Check torque converter one-way clutch.

a. Insert Tool into spline of one-way clutch inner race.

b. Hook bearing support unitized with one-way clutch outer race

with suitable wire.

c. Check that one-way clutch inner race rotates only clockwise

with Tool while holding bearing support with wire.

SAT021BB

5. Remove PNP switch from transmission case.

SAT754I

6. Remove oil pan.

IAlways place oil pan straight down so that foreign particles

inside will not move.

SAT522G

7. Place transmission into Tool with the control valve facing up.

DISASSEMBLY

AT-286