INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 2701 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-139

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

OPISTON PIN

Unit: mm (in)

CONNECTING ROD

Unit: mm (in)

*: After installing in connecting rod

CRANKSHAFT

End gap

Top 0.23 - 0.28 (0.0091 - 0.0110) 0.50 (0.0197)

2nd 0.50 - 0.65 (0.0197 - 0.0256) 0.84 (0.0331)

Oil (rail ring) 0.20 - 0.60 (0.0079 - 0.0236) 0.95 (0.0374)

Items Standard Limit

Piston pin outer diameter 21.989 - 21.995 (0.8657 - 0.8659) —

Piston to piston pin oil clearance 0.002 - 0.006 (0.0001 - 0.0002) —

Connecting rod bushing oil clearance 0.005 - 0.017 (0.0002 - 0.0007) 0.030 (0.0012)

Items Standard Limit

Center distance 154.45 - 154.55 (6.08 - 6.08) —

Bend [per 100 (3.94)] — 0.15 (0.0059)

Torsion [per 100 (3.94)] — 0.30 (0.0118)

Connecting rod bushing inner diameter* 22.000 - 22.006 (0.8661 - 0.8664) —

Connecting rod big end diameter (Without bearing) Grade No. A 57.000 - 57.001 (2.2441 - 2.2441)

Grade No. B 57.001 - 57.002 (2.2441 - 2.2442)

Grade No. C 57.002 - 57.003 (2.2442 - 2.2442)

Grade No. D 57.003 - 57.004 (2.2442 - 2.2442)

Grade No. E 57.004 - 57.005 (2.2442 - 2.2443)

Grade No. F 57.005 - 57.006 (2.2443 - 2.2443)

Grade No. G 57.006 - 57.007 (2.2443 - 2.2444)

Grade No. H 57.007 - 57.008 (2.2444 - 2.2444)

Grade No. J 57.008 - 57.009 (2.2444 - 2.2444)

Grade No. K 57.009 - 57.010 (2.2444 - 2.2445)

Grade No. L 57.010 - 57.011 (2.2445 - 2.2445)

Grade No. M 57.011 - 57.012 (2.2445 - 2.2446)

Grade No. N 57.012 - 57.013 (2.2446 - 2.2446)

Side clearance 0.20 - 0.40 (0.0079 - 0.0158) 0.40 (0.0157)

Revision: 2010 May2011 QX56

Page 2702 of 5598

EM-140

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

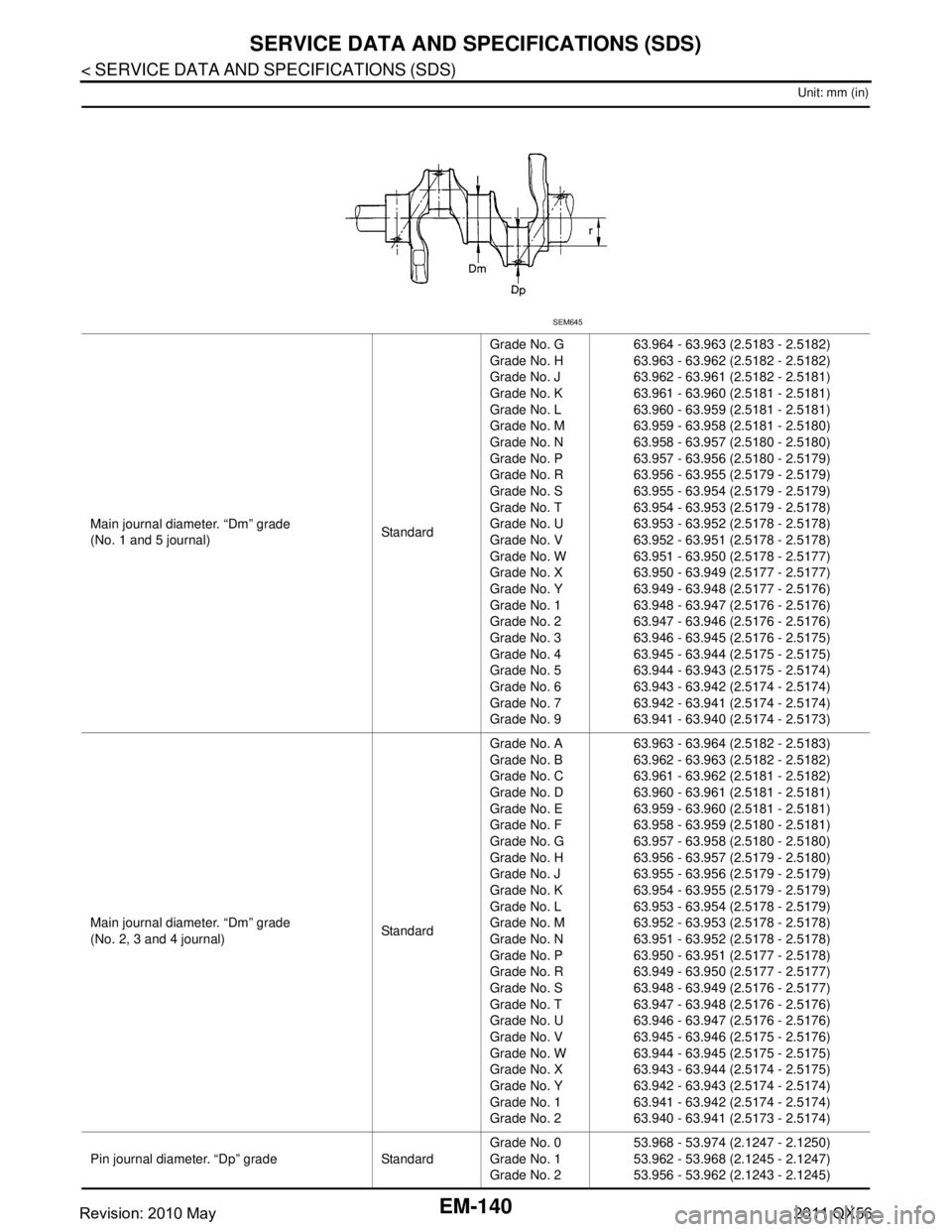

Unit: mm (in)

Main journal diameter. “Dm” grade

(No. 1 and 5 journal)StandardGrade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2

Grade No. 3

Grade No. 4

Grade No. 5

Grade No. 6

Grade No. 7

Grade No. 9 63.964 - 63.963 (2.5183 - 2.5182)

63.963 - 63.962 (2.5182 - 2.5182)

63.962 - 63.961 (2.5182 - 2.5181)

63.961 - 63.960 (2.5181 - 2.5181)

63.960 - 63.959 (2.5181 - 2.5181)

63.959 - 63.958 (2.5181 - 2.5180)

63.958 - 63.957 (2.5180 - 2.5180)

63.957 - 63.956 (2.5180 - 2.5179)

63.956 - 63.955 (2.5179 - 2.5179)

63.955 - 63.954 (2.5179 - 2.5179)

63.954 - 63.953 (2.5179 - 2.5178)

63.953 - 63.952 (2.5178 - 2.5178)

63.952 - 63.951 (2.5178 - 2.5178)

63.951 - 63.950 (2.5178 - 2.5177)

63.950 - 63.949 (2.5177 - 2.5177)

63.949 - 63.948 (2.5177 - 2.5176)

63.948 - 63.947 (2.5176 - 2.5176)

63.947 - 63.946 (2.5176 - 2.5176)

63.946 - 63.945 (2.5176 - 2.5175)

63.945 - 63.944 (2.5175 - 2.5175)

63.944 - 63.943 (2.5175 - 2.5174)

63.943 - 63.942 (2.5174 - 2.5174)

63.942 - 63.941 (2.5174 - 2.5174)

63.941 - 63.940 (2.5174 - 2.5173)

Main journal diameter. “Dm” grade

(No. 2, 3 and 4 journal) StandardGrade No. A

Grade No. B

Grade No. C

Grade No. D

Grade No. E

Grade No. F

Grade No. G

Grade No. H

Grade No. J

Grade No. K

Grade No. L

Grade No. M

Grade No. N

Grade No. P

Grade No. R

Grade No. S

Grade No. T

Grade No. U

Grade No. V

Grade No. W

Grade No. X

Grade No. Y

Grade No. 1

Grade No. 2 63.963 - 63.964 (2.5182 - 2.5183)

63.962 - 63.963 (2.5182 - 2.5182)

63.961 - 63.962 (2.5181 - 2.5182)

63.960 - 63.961 (2.5181 - 2.5181)

63.959 - 63.960 (2.5181 - 2.5181)

63.958 - 63.959 (2.5180 - 2.5181)

63.957 - 63.958 (2.5180 - 2.5180)

63.956 - 63.957 (2.5179 - 2.5180)

63.955 - 63.956 (2.5179 - 2.5179)

63.954 - 63.955 (2.5179 - 2.5179)

63.953 - 63.954 (2.5178 - 2.5179)

63.952 - 63.953 (2.5178 - 2.5178)

63.951 - 63.952 (2.5178 - 2.5178)

63.950 - 63.951 (2.5177 - 2.5178)

63.949 - 63.950 (2.5177 - 2.5177)

63.948 - 63.949 (2.5176 - 2.5177)

63.947 - 63.948 (2.5176 - 2.5176)

63.946 - 63.947 (2.5176 - 2.5176)

63.945 - 63.946 (2.5175 - 2.5176)

63.944 - 63.945 (2.5175 - 2.5175)

63.943 - 63.944 (2.5174 - 2.5175)

63.942 - 63.943 (2.5174 - 2.5174)

63.941 - 63.942 (2.5174 - 2.5174)

63.940 - 63.941 (2.5173 - 2.5174)

Pin journal diameter. “Dp” grade Standard Grade No. 0

Grade No. 1

Grade No. 253.968 - 53.974 (2.1247 - 2.1250)

53.962 - 53.968 (2.1245 - 2.1247)

53.956 - 53.962 (2.1243 - 2.1245)

SEM645

Revision: 2010 May2011 QX56

Page 2703 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

EM-141

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D E

F

G H

I

J

K L

M A

EM

NP

O

*: Total indicator reading

Main BearingINFOID:0000000006289596

MAIN BEARING

UNDERSIZE

Unit: mm (in)

MAIN BEARING OIL CLEARANCE

Center distance “r”

45.96 - 46.04 (1.8095 - 1.8126)

Ta p e r Limit 0.0025 (0.0001)

Out-of-round 0.0025 (0.0001)

Crankshaft runout [TIR*] Standard Less than 0.05 (0.002)

Limit 0.10 (0.0039)

Crankshaft end play Standard 0.10 - 0.26 (0.0039 - 0.0102)

Limit 0.30 (0.012)

Grade number Thickness mm (in) Width mm (in) Identification color Remarks

0 2.483 - 2.486 (0.0978 - 0.0979)

19.9 - 20.1

(0.783 - 0.791) Black

Grade is the same

for upper and lower

bearings.

1 2.486 - 2.489 (0.0979 - 0.0980) Brown

2 2.489 - 2.492 (0.0980 - 0.0981) Green

3 2.492 - 2.495 (0.0981 - 0.0982) Yellow

4 2.495 - 2.498 (0.0982 - 0.0983) Blue

5 2.498 - 2.501 (0.0983 - 0.0985) Pink

6 2.501 - 2.504 (0.0985 - 0.0986) Purple

7 2.504 - 2.507 (0.0986 - 0.0987) White

8 2.507 - 2.510 (0.0987 - 0.0988) Red

01 UPR 2.483 - 2.486 (0.0978 - 0.0979) Black

Grade and color are

different for upper

and lower bearings.

LWR 2.486 - 2.489 (0.0979 - 0.0980) Brown

12 UPR 2.486 - 2.489 (0.0979 - 0.0980) Brown

LWR 2.489 - 2.492 (0.0980 - 0.0981) Green

23 UPR 2.489 - 2.492 (0.0980 - 0.0981) Green

LWR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

34 UPR 2.492 - 2.495 (0.0981 - 0.0982) Yellow

LWR 2.495 - 2.498 (0.0982 - 0.0983) Blue

45 UPR 2.495 - 2.498 (0.0982 - 0.0983) Blue

LWR 2.498 - 2.501 (0.0983 - 0.0985) Pink

56 UPR 2.498 - 2.501 (0.0983 - 0.0985) Pink

LWR 2.501 - 2.504 (0.0985 - 0.0986) Purple

67 UPR 2.501 - 2.504 (0.0985 - 0.0986) Purple

LWR 2.504 - 2.507 (0.0986 - 0.0987) White

78 UPR 2.504 - 2.507 (0.0986 - 0.0987) White

LWR 2.507 - 2.510 (0.0987 - 0.0988) Red

Items Thickness Main journal diameter

0.25 (0.0098) 2.618 - 2.626 (0.1031 - 0.1034) Grind so that bearing clearance is the specified value.

Revision: 2010 May2011 QX56

Page 2704 of 5598

EM-142

< SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

Unit: mm (in)

*: Actual clearance

Connecting Rod BearingINFOID:0000000006289597

CONNECTING ROD BEARING

UNDERSIZE

Unit: mm (in)

CONNECTING ROD BEARING OIL CLEARANCE

Unit: mm (in)

*: Actual clearanceItems Standard Limit

Main bearing oil clearance No.1 and 5 0.001 - 0.011 (0.00004 - 0.00043)*

0.065 (0.0026)

No.2, 3 and 4 0.007 - 0.017 (0.0003 - 0.0007)*

Grade number Thickness mm (in) Width mm (in) Identification color (mark)

1 1.500 - 1.503 (0.0591 - 0.0592)

18.1 - 18.3

(0.713 - 0.720) Black

2 1.503 - 1.506 (0.0592 - 0.0593) Brown

3 1.506 - 1.509 (0.0593 - 0.0594) Green

4 1.509 - 1.512 (0.0594 - 0.0595) Yellow

Items Thickness Pin journal diameter

0.25 (0.0098) 1.627 - 1.635 (0.0641 - 0.0644) Grind so that bearing clearance is the specified value.

Items Standard Limit

Connecting rod bearing oil clearance 0.020 - 0.039 (0.0008 - 0.0015)* 0.070 (0.0028)

Revision: 2010 May2011 QX56

Page 2705 of 5598

EX-1

ENGINE

C

DE

F

G H

I

J

K L

M

SECTION EX

A

EX

N

O P

CONTENTS

EXHAUST SYSTEM

PRECAUTION ................ ...............................2

PRECAUTIONS .............................................. .....2

Removal and Installation ..................................... ......2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tool ..........................................3

PERIODIC MAINTENANCE .........................4

EXHAUST SYSTEM ...........................................4

Inspection ............................................................ .....4

REMOVAL AND INSTALLATION ................5

EXHAUST SYSTEM ...........................................5

Exploded View ..................................................... .....5

Removal and Installation ..........................................5

Inspection .................................................................6

Revision: 2010 May2011 QX56

Page 2706 of 5598

EX-2

< PRECAUTION >

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Removal and InstallationINFOID:0000000006289691

CAUTION:

• Be sure to use genuine exhaust system parts or equivalents which are specially designed for heat

resistance, corrosion resistance, and shape.

Perform the operation with the exhaust system fully cooled down because the system will be hot

just after engine stops.

Be careful not to cut your hand on the heat insulator edge.

Revision: 2010 May2011 QX56

Page 2707 of 5598

PREPARATIONEX-3

< PREPARATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

PREPARATION

PREPARATION

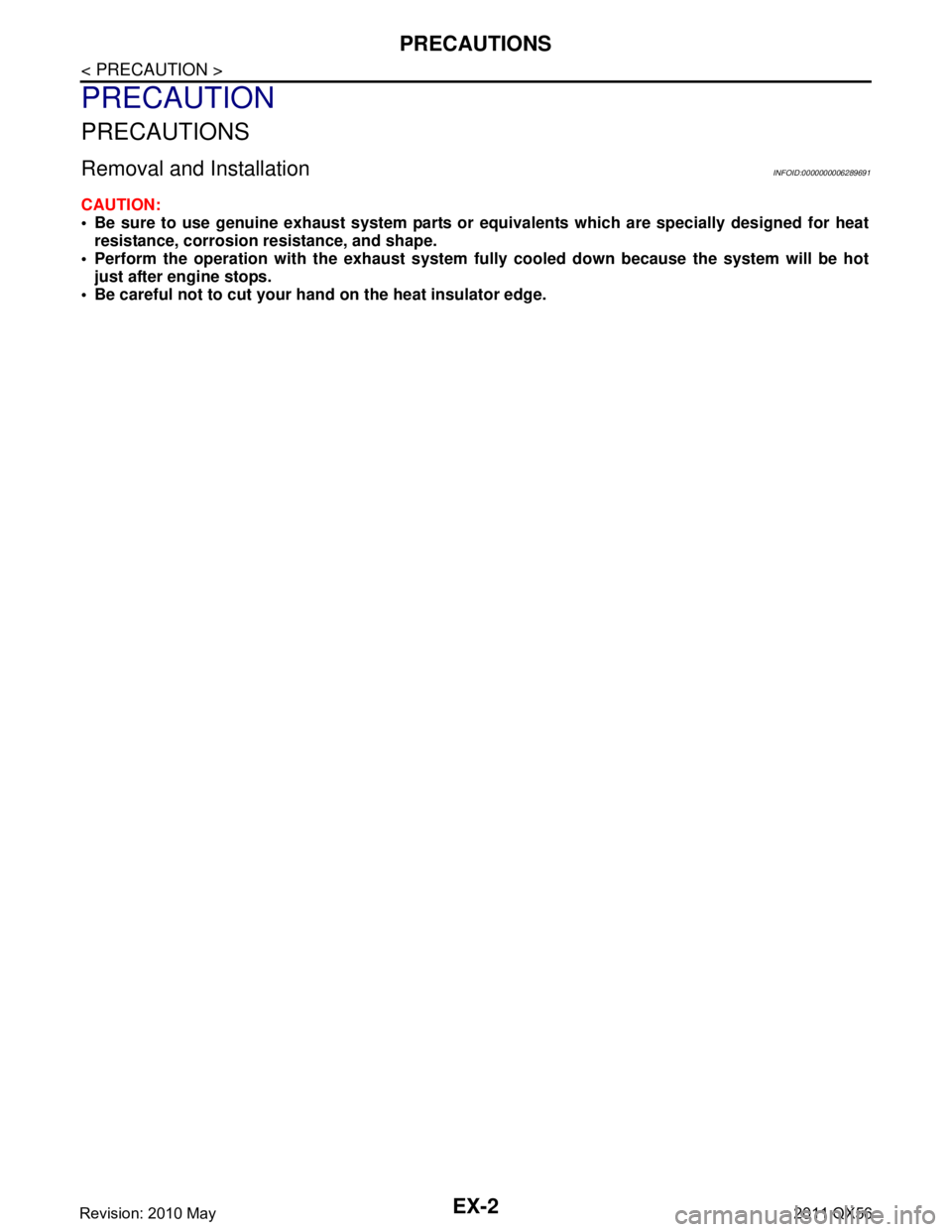

Special Service ToolINFOID:0000000006289692

Commercial Service ToolINFOID:0000000006289693

Tool number

(Kent-Moore No.)

Tool name

Description

KV10114400

(J-38365)

Heated oxygen sensor wrench Loosening or tightening heated oxygen sen-

sor 2

For 22 mm (0.87 in) (a) width hexagon nut

S-NT636

Tool name

Description

Power tool Loosening bolts and nuts

PBIC0190E

Revision: 2010 May2011 QX56

Page 2708 of 5598

EX-4

< PERIODIC MAINTENANCE >

EXHAUST SYSTEM

PERIODIC MAINTENANCE

EXHAUST SYSTEM

InspectionINFOID:0000000006289694

Check exhaust pipes, muffler and mounting for improper attachment,

leakage, cracks, damage or deterioration.

• If damage is found, repair or replace damaged parts.

SMA211A

Revision: 2010 May2011 QX56

Page 2709 of 5598

EXHAUST SYSTEMEX-5

< REMOVAL AND INSTALLATION >

C

DE

F

G H

I

J

K L

M A

EX

NP

O

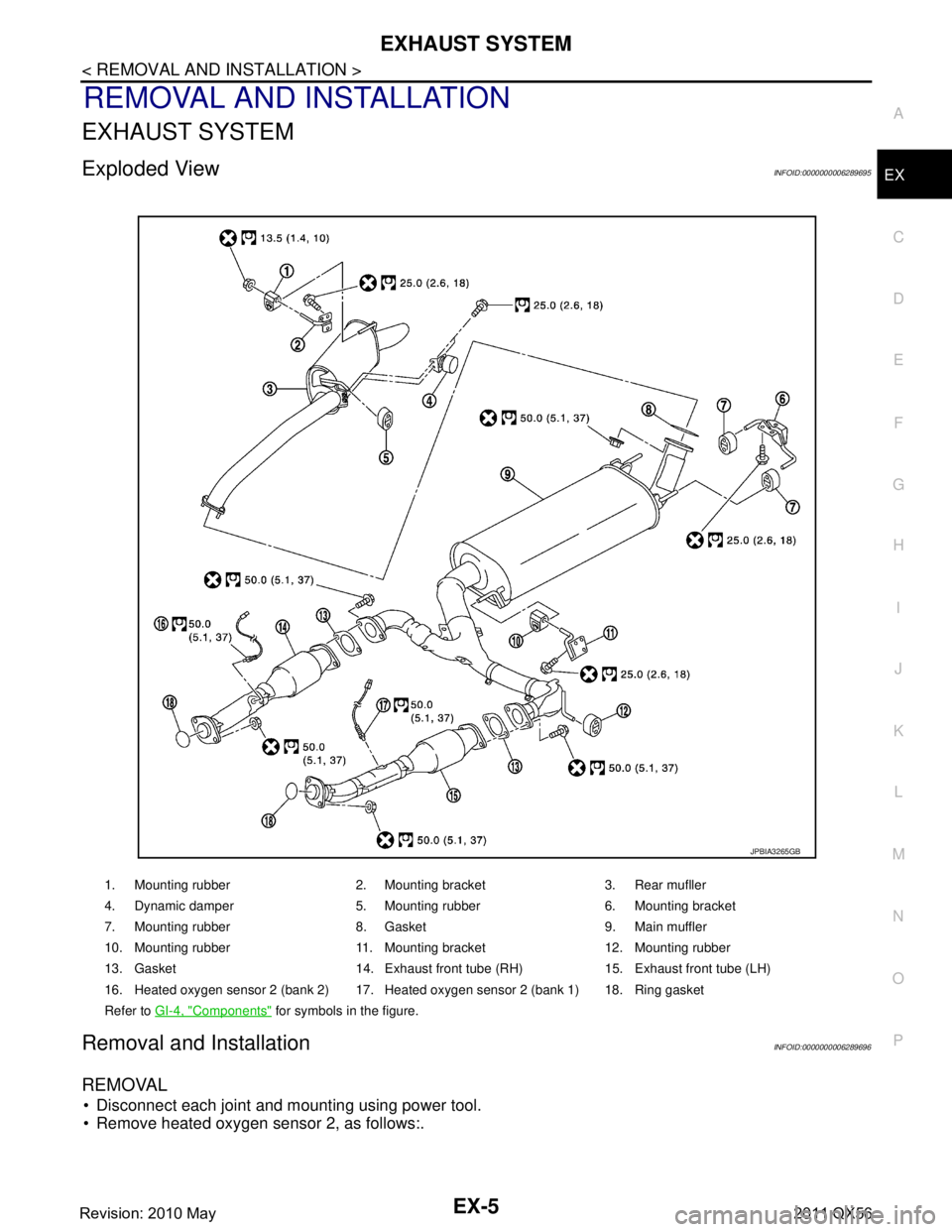

REMOVAL AND INSTALLATION

EXHAUST SYSTEM

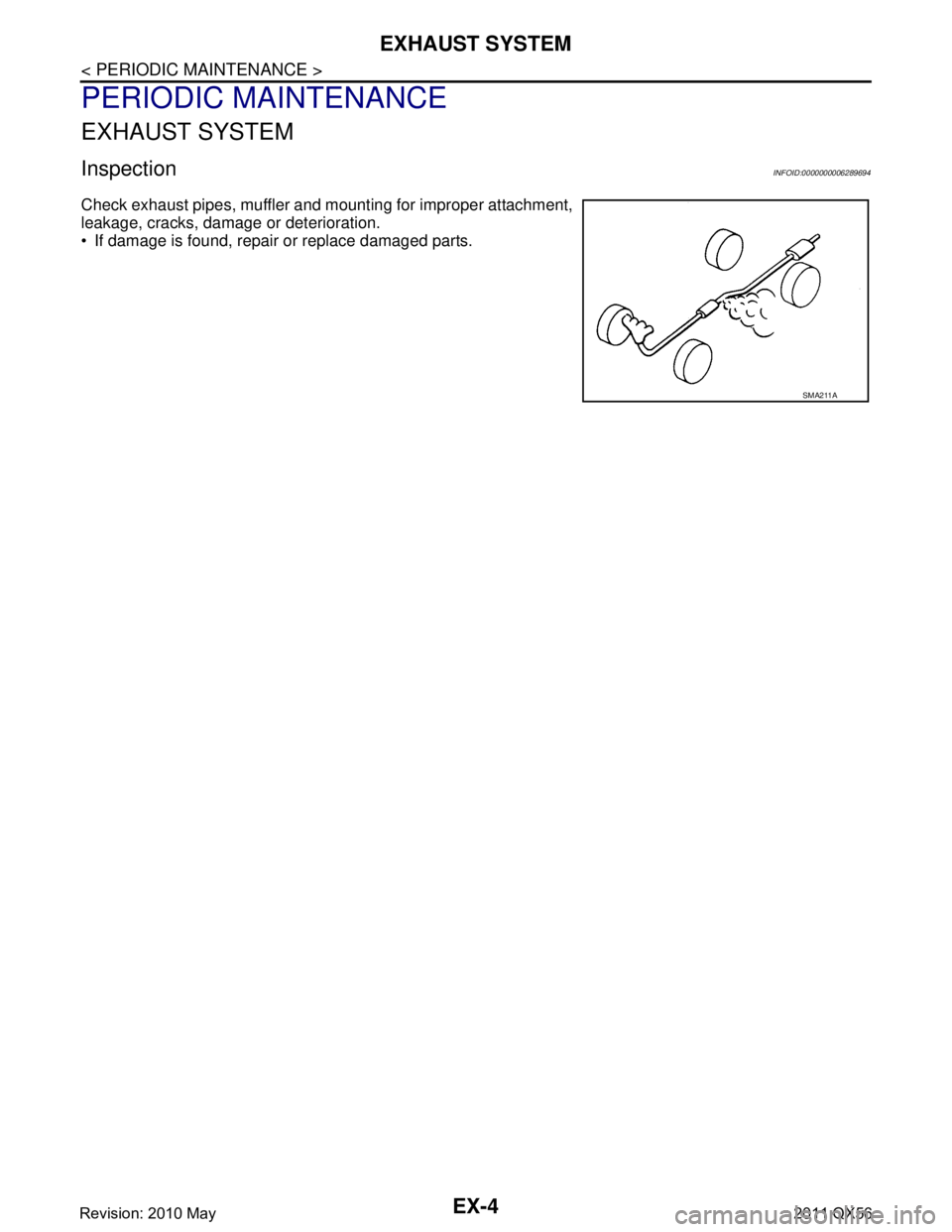

Exploded ViewINFOID:0000000006289695

Removal and InstallationINFOID:0000000006289696

REMOVAL

Disconnect each joint and mounting using power tool.

Remove heated oxygen sens

or 2, as follows:.

1. Mounting rubber 2. Mounting bracket 3. Rear mufller

4. Dynamic damper 5. Mounting rubber 6. Mounting bracket

7. Mounting rubber 8. Gasket 9. Main muffler

10. Mounting rubber 11. Mounting bracket 12. Mounting rubber

13. Gasket 14. Exhaust front tube (RH) 15. Exhaust front tube (LH)

16. Heated oxygen sensor 2 (bank 2) 17. Heated oxygen sensor 2 (bank 1) 18. Ring gasket

Refer to GI-4, "

Components" for symbols in the figure.

JPBIA3265GB

Revision: 2010 May2011 QX56

Page 2710 of 5598

![INFINITI QX56 2011 Factory Service Manual

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the re INFINITI QX56 2011 Factory Service Manual

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the re](/img/42/57033/w960_57033-2709.png)

EX-6

< REMOVAL AND INSTALLATION >

EXHAUST SYSTEM

- Using heated oxygen sensor wrench [SST: KV10114400] (C),removal heated oxygen sensor 2.

INSTALLATION

Note the following items, and install in the reverse order of removal.

Temporarily tighten bolts and nuts when installing exhaust pipe assembly. Tighten them to the specifiedtorque when connecting the vehicle rear to the vehicle front.

CAUTION:

Always replace exhaust tube gasket s with new ones when reassembling.

If heat insulator is badly deformed, repair or re place it. If deposits such as mud pile up on the heat

insulator, remove them.

When installing heat insulator avoid large gaps or interference between heat insulator and each

exhaust pipe.

Remove deposits from the sealing surface of each connection. Connect them securely to avoid

gases leakage.

Check each part for unusual interference, and then tighten them to the specified torque.

When installing each moun ting rubber, avoid twisting or unusua l extension in up/down and right/left

directions.

InspectionINFOID:0000000006289697

INSPECTION AFTER INSTALLATION

Check clearance between tail tube and rear bumper is even.

With engine running, check exhaust tube joints for gas leakage and unusual noises.

Check to ensure that mounting brackets and mounting rubbers are installed properly and free from undue stress. Improper installation could result in excessive noise and vibration.

A: Bank 1

B: Bank 2

: Vehicle front

JPBIA3395ZZ

Revision: 2010 May2011 QX56