INFINITI QX56 2011 Factory Service Manual

Manufacturer: INFINITI, Model Year: 2011, Model line: QX56, Model: INFINITI QX56 2011Pages: 5598, PDF Size: 94.53 MB

Page 5511 of 5598

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGWT-61

< SYMPTOM DIAGNOSIS >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000006225544

Use the chart below to find the cause of the symp tom. If necessary, repair or replace these parts.

×: ApplicableReference

WT-64, "

Exploded View

"

WT-64, "

Inspection

"

WT-62, "

Adjustment

"

WT-69, "

Tire Air Pressure

"

WT-64, "

Inspection

"

—

—

WT-69, "

Tire Air Pressure

"

NVH in DLN section.

NVH in DLN section.

NVH in FAX and FSU sections.

NVH in RAX and RSU sections.

Refer to TIRES in this chart.

Refer to ROAD WHEEL in this chart.

NVH in FAX, RAX section.

NVH in BR section.

NVH in ST section.

Possible cause and SUSPECTED PARTS

Improper installation, looseness

Out-of-round

Unbalance

Incorrect tire pressure

Uneven tire wear

Deformation or damage

Non-uniformity

Incorrect tire size

PROPELLER SHAFT

DIFFERENTIAL

FRONT AXLE AND FRONT SUSPENSION

REAR AXLE AND REAR SUSPENSION

TIRES

ROAD WHEELS

DRIVE SHAFT

BRAKE

STEERING

Symptom TIRESNoise

××××××× ×××× ××××

Shake ×××××× ×× ×× ××××

Vibration ×××××××

Shimmy ×××××××× ×× × ××

Judder ×

××××× × ×× × ××

Poor quality ride or

handling ×××××× × × ××

ROAD

WHEEL Noise

××× × ××××× ×××

Shake ××× × × ××× ×××

Shimmy, Judder ××× × ××× ××

Poor quality ride or

handling ××× × ×××

Revision: 2010 May2011 QX56

Page 5512 of 5598

WT-62

< PERIODIC MAINTENANCE >

ROAD WHEEL

PERIODIC MAINTENANCE

ROAD WHEEL

AdjustmentINFOID:0000000006225545

BALANCING WHEELS (BONDING WEIGHT TYPE)

Preparation Before Adjustment

Using releasing agent, remove double-faced adhesive tape from the road wheel.

CAUTION:

Be careful not to scratch the road wheel during removal.

After removing double-faced adhesive tape, wi pe clean traces of releasing agent from the road

wheel.

Wheel Balance Adjustment

If a tire balance machine has adhesion balance weight m ode settings and drive-in weight mode setting, select

and adjust a drive-in weight mode suitable for road wheels.

1. Set road wheel on tire balance machine using the center hole as a guide. Start the tire balance machine.

2. When inner and outer unbalance values are shown on the tire balance machine indicator, multiply outer unbalance value by 5/3 to determine balance weight t hat should be used. Select the outer balance weight

with a value closest to the calculated value above and in stall to the designated outer position of, or at the

designated angle in relation to the road wheel.

CAUTION:

Never install the inner balance weight be fore installing the outer balance weight.

Before installing the balance weight, always to clean the mating surface of the road wheel.

a. Indicated unbalance value × 5/3 = balance weight to be installed

Calculation example:

23 g (0.81 oz) × 5/3 = 38.33 g (1.35 oz) ⇒ 37.5 g (1.32 oz) bal-

ance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

36.2 ⇒ 35 g (1.23 oz)

36.3 ⇒ 37.5 g (1.32 oz)

b. Installed balance weight in the position.

SMA054D

Revision: 2010 May2011 QX56

Page 5513 of 5598

ROAD WHEELWT-63

< PERIODIC MAINTENANCE >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

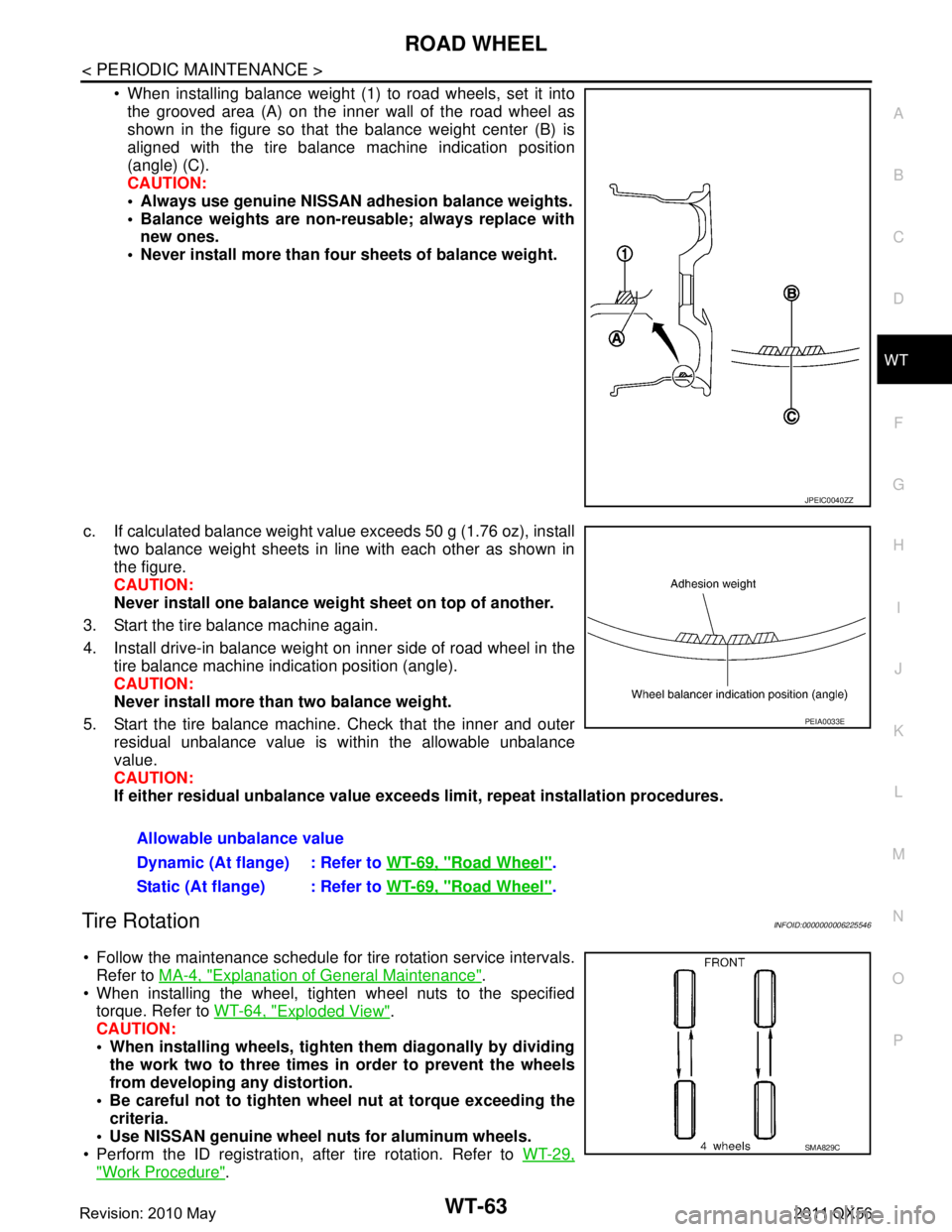

When installing balance weight (1) to road wheels, set it into the grooved area (A) on the inner wall of the road wheel as

shown in the figure so that the balance weight center (B) is

aligned with the tire balance machine indication position

(angle) (C).

CAUTION:

Always use genuine NISSAN ad hesion balance weights.

Balance weights are non-re usable; always replace with

new ones.

Never install more than four sheets of balance weight.

c. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown in

the figure.

CAUTION:

Never install one balance weight sheet on top of another.

3. Start the tire balance machine again.

4. Install drive-in balance weight on inner side of road wheel in the tire balance machine indication position (angle).

CAUTION:

Never install more than two balance weight.

5. Start the tire balance machine. Check that the inner and outer residual unbalance value is within the allowable unbalance

value.

CAUTION:

If either residual unbalan ce value exceeds limit, repeat installation procedures.

Tire RotationINFOID:0000000006225546

Follow the maintenance schedule for tire rotation service intervals.

Refer to MA-4, "

Explanation of General Maintenance".

When installing the wheel, tighten wheel nuts to the specified torque. Refer to WT-64, "

Exploded View".

CAUTION:

When installing wheels, tighte n them diagonally by dividing

the work two to three times in order to prevent the wheels

from developing any distortion.

Be careful not to tighten wh eel nut at torque exceeding the

criteria.

Use NISSAN genuine wheel nuts for aluminum wheels.

Perform the ID registration, after tire rotation. Refer to WT-29,

"Work Procedure".

JPEIC0040ZZ

Allowable unbalance value

Dynamic (At flange) : Refer to WT-69, "

Road Wheel".

Static (At flange) : Refer to WT-69, "

Road Wheel".

PEIA0033E

SMA829C

Revision: 2010 May2011 QX56

Page 5514 of 5598

WT-64

< REMOVAL AND INSTALLATION >

ROAD WHEEL TIRE ASSEMBLY

REMOVAL AND INSTALLATION

ROAD WHEEL TIRE ASSEMBLY

Exploded ViewINFOID:0000000006225547

Removal and InstallationINFOID:0000000006225548

REMOVAL

1. Remove wheel nuts.

2. Remove tire assembly.

INSTALLATION

Note the following, install in the reverse order of removal.

When replacing or rotating wheels, perform the ID registration. Refer to WT-29, "

Work Procedure".

InspectionINFOID:0000000006225549

ALUMINUM WHEEL

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other damage. If deformed, remove wheel and check wheel

runout.

a. Remove tire from aluminum wheel and mount on a tire balance machine.

b. Set dial indicator as shown in the figure.

c. Check radial runout, if the latera l deflection (A) or vertical deflec-

tion (B) for radial runout value exceeds the limit, replace alumi-

num wheel.

1. Tire assembly

Refer to GI-4, "

Components" for symbols in the figure.

JPEIC0088GB

Limit

Lateral deflection (A) : Refer to WT-69, "

Road Wheel".

Vertical deflection (B) : Refer to WT-69, "

Road Wheel".

SEIA0737E

Revision: 2010 May2011 QX56

Page 5515 of 5598

LOW TIRE PRESSURE WARNING CONTROL UNIT

WT-65

< REMOVAL AND INSTALLATION >

C

D F

G H

I

J

K L

M A

B

WT

N

O P

LOW TIRE PRESSURE WA RNING CONTROL UNIT

Exploded ViewINFOID:0000000006225550

Removal and InstallationINFOID:0000000006225551

REMOVAL

1. Remove the glove box assembly. Refer to IP-14, "Removal and Installation".

2. Remove the instrument lower panel RH. Refer to IP-14, "

Removal and Installation".

3. Disconnect low tire pressure warning control unit connector.

4. Remove the low tire pressure warning control unit control unit.

INSTALLATION

Note the following, install in the reverse order of removal.

Perform ID registration after replacing low tire pressure warning control unit. Refer to WT-29, "

Work Proce-

dure".

1. Low tire pressure warning control unit 2. Bracket

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JPEIC0072ZZ

Revision: 2010 May2011 QX56

Page 5516 of 5598

WT-66

< REMOVAL AND INSTALLATION >

TRANSMITTER

TRANSMITTER

Exploded ViewINFOID:0000000006225552

Removal and InstallationINFOID:0000000006225553

REMOVAL

1. Deflate tire. Unscrew transmitter retaining nut and allow transmitter to fall into tire.

2. Gently bounce tire so that trans mitter falls to bottom of tire.

Place on tire changing machine and break both tire beads

ensuring that the transmitter remains at the bottom of the tire.

3. Turn tire so that valve hole is at bottom and bounce so that transmitter (1) is near valve hole. Carefully lift tire onto turntable

and position valve hole (and transmitter) 270 degree from

mounting/dismounting head (2).

4. Lubricate tire well and remove first side of the tire. Reach inside the tire and remove the transmitter.

INSTALLATION

JPEIC0081GB

1. Transmitter 2. Grommet seal 3. Valve nut

4. Valve core 5. Cap

Refer to GI-4, "

Components" for symbols in figure.

SEIA0047E

JPEIC0014GB

Revision: 2010 May2011 QX56

Page 5517 of 5598

TRANSMITTERWT-67

< REMOVAL AND INSTALLATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

1. Put first side of tire onto rim.

2. Mount transmitter on rim and tighten nut. CAUTION:

Speed for tightening nut sh ould be less than 10 rpm.

3. Place wheel on turntable of tire machine. Ensure that transmitter (1) is 270 degree from mounting head (2) when second side of

tire is fitted.

NOTE:

Do not touch transmitter at mounting head.

4. Lubricate tire well and fit second side of tire as normal. Ensure that tire does not rotate relative to rim.

5. Inflate tire and fit to appropriate wheel position.

6. Perform the transmitter wake-up after replacing transmitter. Refer to WT-28, "

Work Procedure".

SEIA0049E

JPEIC0014GB

Revision: 2010 May2011 QX56

Page 5518 of 5598

WT-68

< REMOVAL AND INSTALLATION >

TIRE PRESSURE RECEIVER

TIRE PRESSURE RECEIVER

Exploded ViewINFOID:0000000006225554

FRONT TIRE PRESSURE RECEIVER

FRONT TIRE PRESSURE RECEIVER : Removal and InstallationINFOID:0000000006225555

REMOVAL

1. Remove fender protector (rear). Refer to EXT-23, "FENDER PROTECTOR : Removal and Installation".

2. Remove mounting bolt for the front tire pressure receiver.

3. Disconnect front tire pressure receiver harness connector.

4. Remove front tire pressure receiver.

INSTALLATION

Installation is the reverse order of removal.

REAR TIRE PRESSURE RECEIVER

REAR TIRE PRESSURE RECEIVER : Removal and InstallationINFOID:0000000006225556

REMOVAL

1. Remove rear wheel house protector. Refer to EXT-24, "REAR WHEEL HOUSE PROTECTOR : Removal

and Installation".

2. Remove mounting bolt for the rear tire pressure receiver.

3. Disconnect rear tire pressure receiver harness connector.

4. Remove rear tire pressure receiver.

INSTALLATION

Installation is the reverse order of removal.

1. Front tire pressure receiver 2. Rear tire pressure receiver

: Vehicle front

Refer to GI-4, "

Components" for symbols in the figure.

JSEIA0010GB

Revision: 2010 May2011 QX56

Page 5519 of 5598

SERVICE DATA AND SPECIFICATIONS (SDS)

WT-69

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

D F

G H

I

J

K L

M A

B

WT

N

O P

SERVICE DATA AND SPECIFICATIONS (SDS)

SERVICE DATA AND SPECIFICATIONS (SDS)

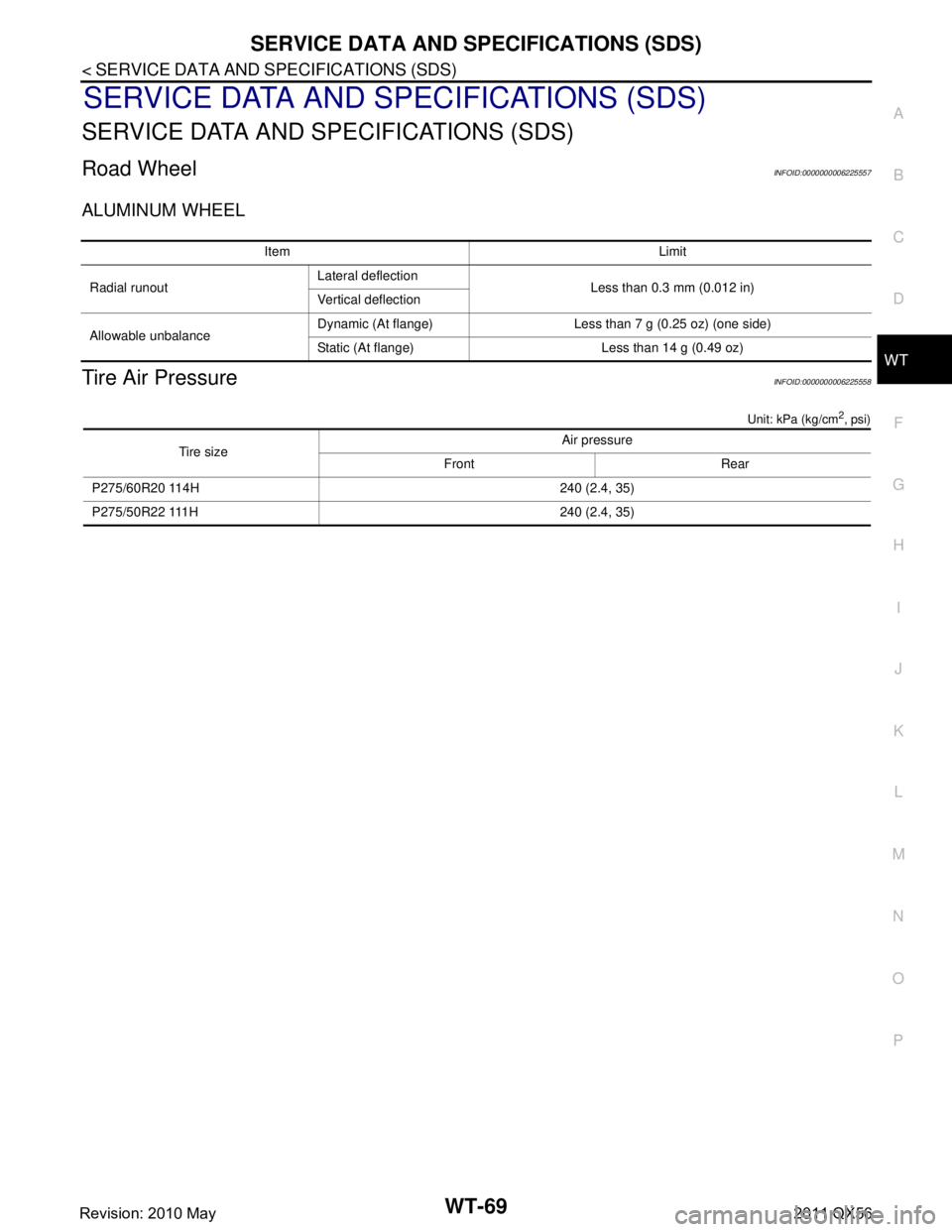

Road WheelINFOID:0000000006225557

ALUMINUM WHEEL

Tire Air PressureINFOID:0000000006225558

Unit: kPa (kg/cm2, psi)

Item Limit

Radial runout Lateral deflection

Less than 0.3 mm (0.012 in)

Vertical deflection

Allowable unbalance Dynamic (At flange) Less than 7 g (0.25 oz) (one side)

Static (At flange) Less than 14 g (0.49 oz)

Tire size Air pressure

Front Rear

P275/60R20 114H 240 (2.4, 35)

P275/50R22 111H 240 (2.4, 35)

Revision: 2010 May2011 QX56

Page 5520 of 5598

WW-1

DRIVER CONTROLS

C

DE

F

G H

I

J

K

M

SECTION WW

A

B

WW

N

O P

CONTENTS

WIPER & WASHER

PRECAUTION ................ ...............................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion after Battery Disconnect .....................................

3

Precaution for Procedure without Cowl Top Cover ......4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Component Description ............................................6

Washer Switch ..........................................................6

SYSTEM ..............................................................7

FRONT WIPER AND WASHER SYSTEM ............. ......7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Diagram ..............................................................

7

FRONT WIPER AND WASHER SYSTEM : Sys-

tem Description .........................................................

7

FRONT WIPER AND WASHER SYSTEM : Fail-

safe ...........................................................................

9

REAR WIPER AND WASHER SYSTEM ............... ....10

REAR WIPER AND WASHER SYSTEM : System

Diagram ...................................................................

10

REAR WIPER AND WASHER SYSTEM : System

Description ..............................................................

10

REAR WIPER AND WASHER SYSTEM :

Fail Safe .................................................................

12

HEADLAMP WASHER SYSTEM .......................... ....12

HEADLAMP WASHER SYSTEM : System Dia-

gram ........................................................................

13

HEADLAMP WASHER SYSTEM : System De-

scription ...................................................................

13

DIAGNOSIS SYSTEM (BCM) ............................14

COMMON ITEM ..................................................... ....14

COMMON ITEM : CONSULT-III Function (BCM -

COMMON ITEM) .....................................................

14

WIPER .................................................................... ....15

WIPER : CONSULT-III Function (BCM - WIPER) ....15

DIAGNOSIS SYSTEM (IPDM E/R) ...................18

Diagnosis Description ..............................................18

CONSULT-III Function (IPDM E/R) .........................20

ECU DIAGNOSIS INFORMATION ..............23

BCM, IPDM E/R .................................................23

List of ECU Reference ......................................... ....23

WIRING DIAGRAM ......................................24

WIPER AND WASHER SYSTEM .....................24

Wiring Diagram .................................................... ....24

BASIC INSPECTION ...................................33

DIAGNOSIS AND REPAIR WORKFLOW ........33

Work Flow ............................................................ ....33

DTC/CIRCUIT DIAGNOSIS .........................35

WIPER AND WASHER FUSE ...........................35

Diagnosis Procedure ........................................... ....35

FRONT WIPER MOTOR LO CIRCUIT ..............36

Component Function Check ....................................36

Diagnosis Procedure ...............................................36

FRONT WIPER MOTOR HI CIRCUIT ...............37

Component Function Check ....................................37

Diagnosis Procedure ...............................................37

FRONT WIPER AUTO STOP SIGNAL CIR-

CUIT ..................................................................

38

Component Function Check ....................................38

Diagnosis Procedure ...............................................38

Revision: 2010 May2011 QX56