ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3131 of 6020

Engine Mechanical – V6 Page 6A1–354

Page 6A1–354

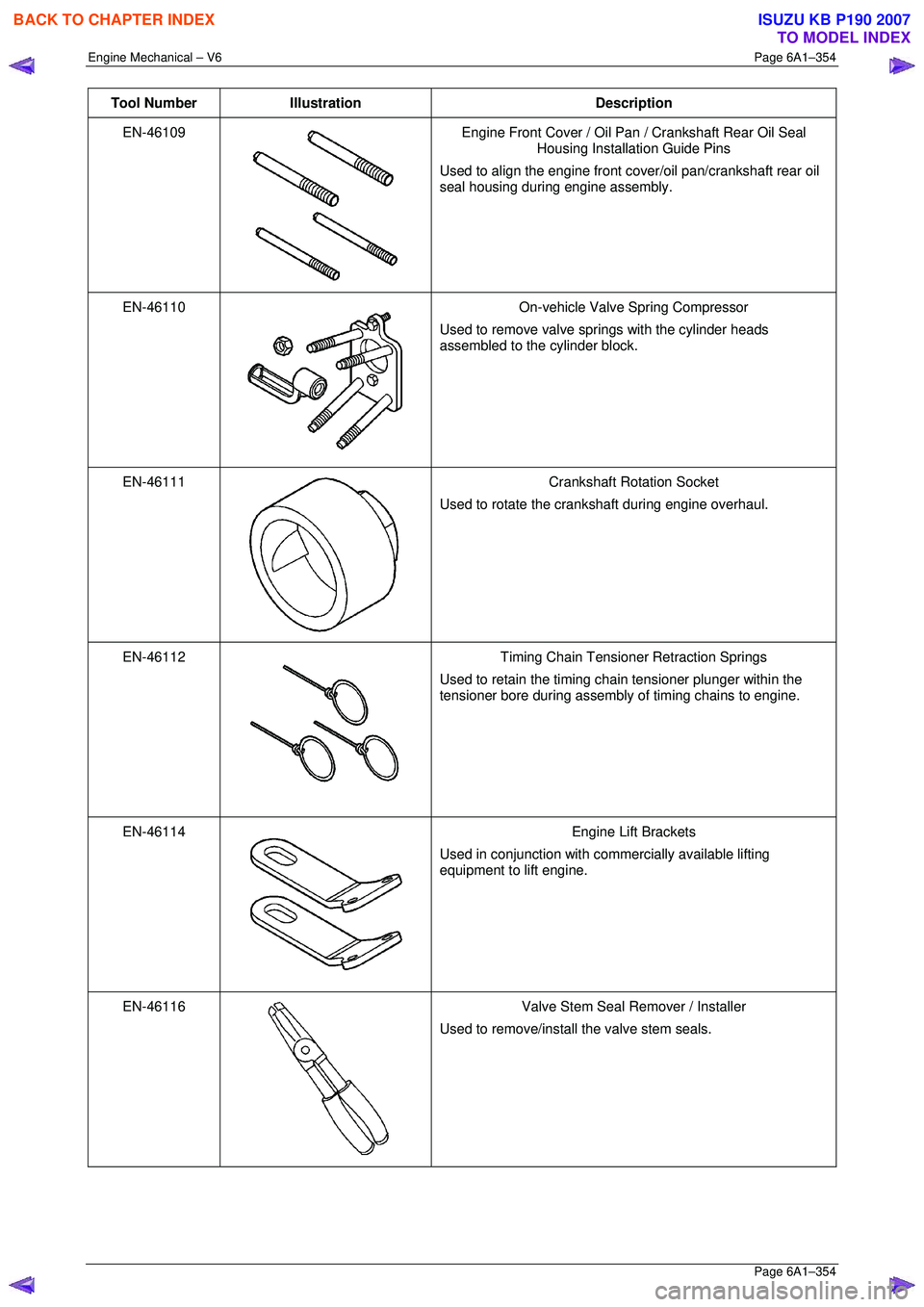

Tool Number Illustration Description

EN-46109

Engine Front Cover / Oil Pan / Crankshaft Rear Oil Seal

Housing Installation Guide Pins

Used to align the engine front co ver/oil pan/crankshaft rear oil

seal housing during engine assembly.

EN-46110

On-vehicle Valve Spring Compressor

Used to remove valve springs with the cylinder heads

assembled to the cylinder block.

EN-46111

Crankshaft Rotation Socket

Used to rotate the crankshaft during engine overhaul.

EN-46112

Timing Chain Tensioner Retraction Springs

Used to retain the timing chain tensioner plunger within the

tensioner bore during assembly of timing chains to engine.

EN-46114

Engine Lift Brackets

Used in conjunction with commercially available lifting

equipment to lift engine.

EN-46116

Valve Stem Seal Remover / Installer

Used to remove/install the valve stem seals.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3132 of 6020

Engine Mechanical – V6 Page 6A1–355

Page 6A1–355

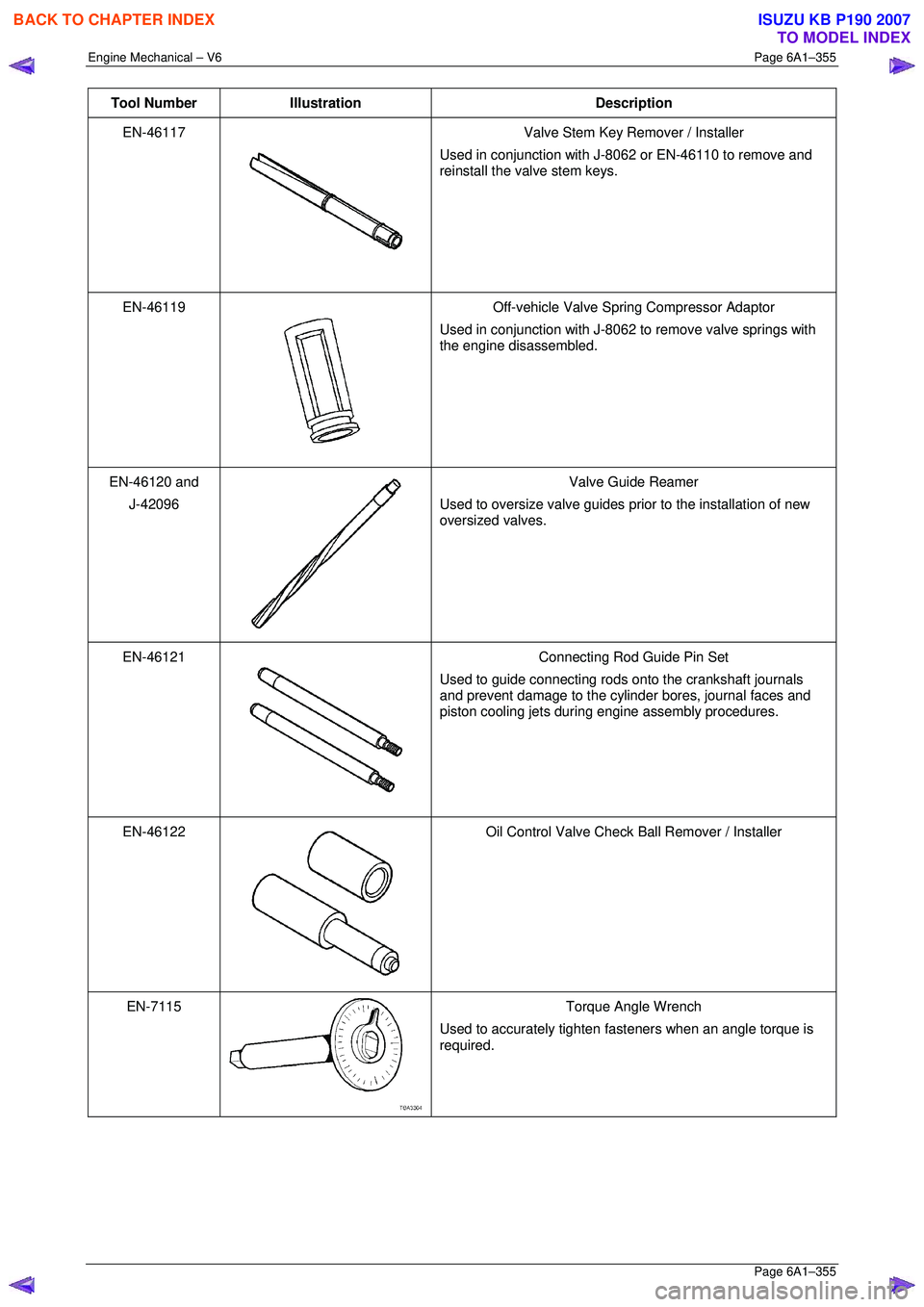

Tool Number Illustration Description

EN-46117

Valve Stem Key Remover / Installer

Used in conjunction with J-8062 or EN-46110 to remove and

reinstall the valve stem keys.

EN-46119

Off-vehicle Valve Spring Compressor Adaptor

Used in conjunction with J-8062 to remove valve springs with

the engine disassembled.

EN-46120 and

J-42096

Valve Guide Reamer

Used to oversize valve guides prior to the installation of new

oversized valves.

EN-46121

Connecting Rod Guide Pin Set

Used to guide connecting rods onto the crankshaft journals

and prevent damage to the cylinder bores, journal faces and

piston cooling jets during engine assembly procedures.

EN-46122

Oil Control Valve Check Ball Remover / Installer

EN-7115

Torque Angle Wrench

Used to accurately tighten fasteners when an angle torque is

required.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3133 of 6020

Engine Mechanical – V6 Page 6A1–356

Page 6A1–356

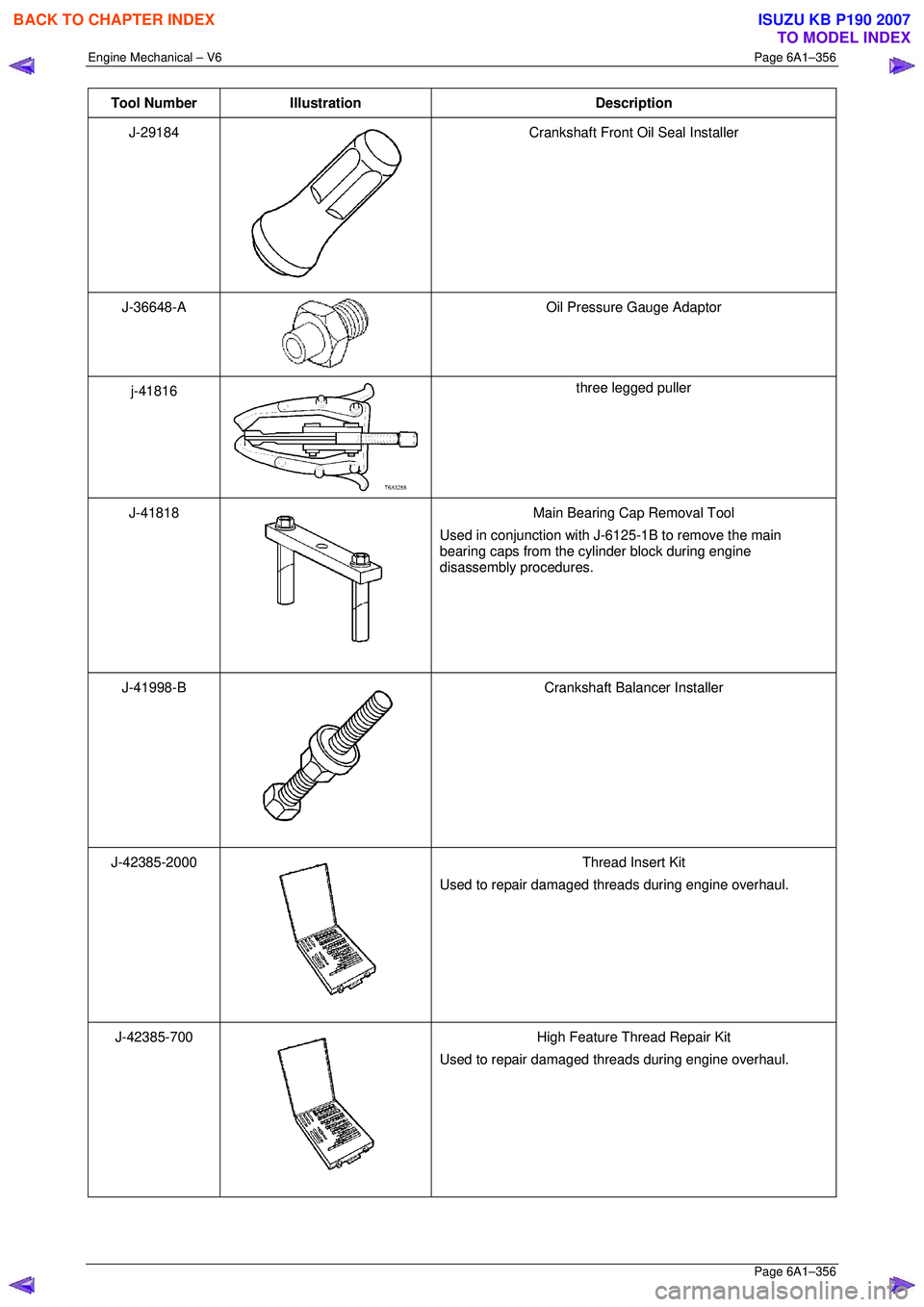

Tool Number Illustration Description

J-29184

Crankshaft Front Oil Seal Installer

J-36648-A

Oil Pressure Gauge Adaptor

j-41816

three legged puller

J-41818

Main Bearing Cap Removal Tool

Used in conjunction with J-6125-1B to remove the main

bearing caps from the cylinder block during engine

disassembly procedures.

J-41998-B

Crankshaft Balancer Installer

J-42385-2000

Thread Insert Kit

Used to repair damaged threads during engine overhaul.

J-42385-700

High Feature Thread Repair Kit

Used to repair damaged threads during engine overhaul.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3134 of 6020

Engine Mechanical – V6 Page 6A1–357

Page 6A1–357

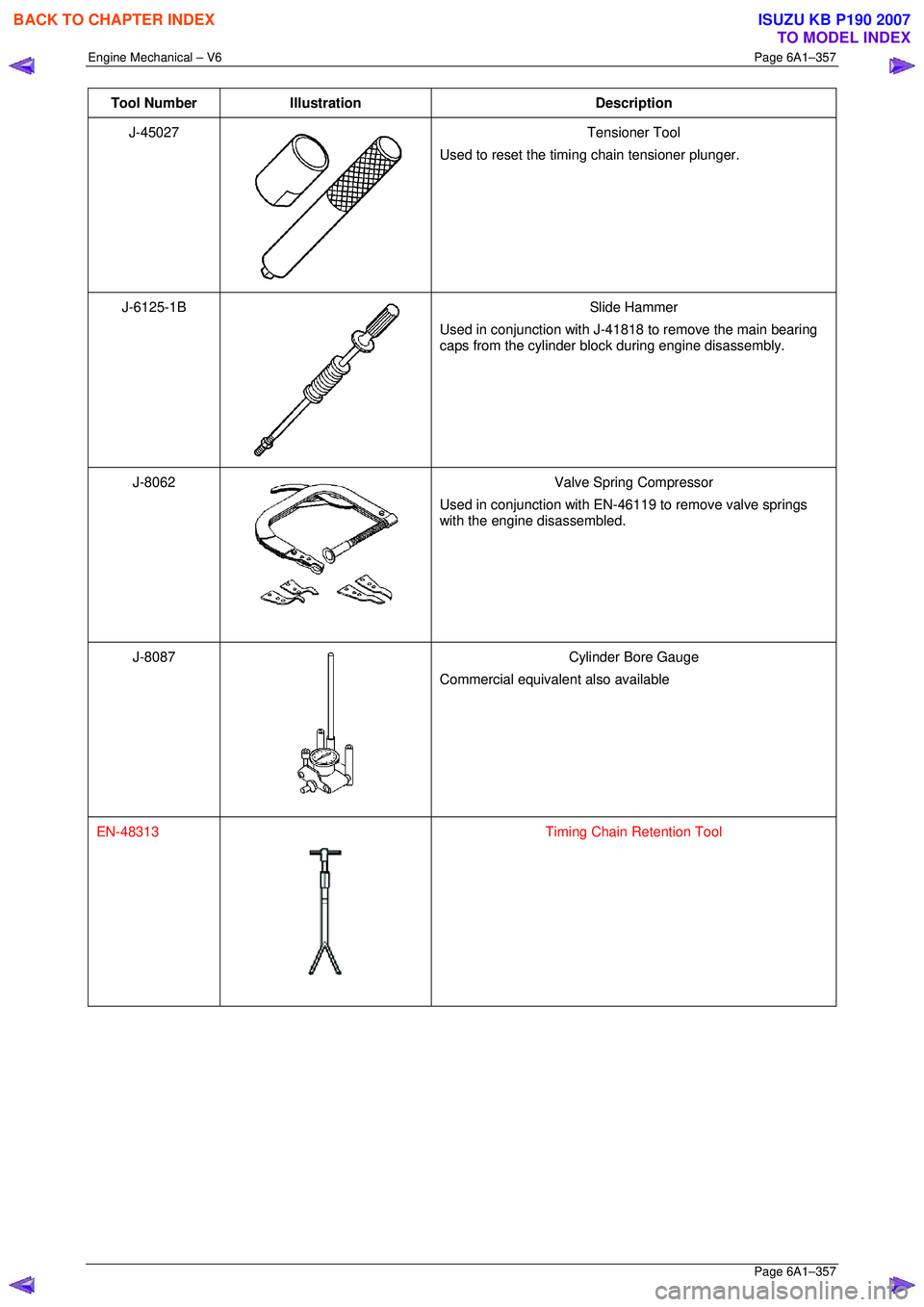

Tool Number Illustration Description

J-45027

Tensioner Tool

Used to reset the timing chain tensioner plunger.

J-6125-1B

Slide Hammer

Used in conjunction with J-41818 to remove the main bearing

caps from the cylinder block during engine disassembly.

J-8062

Valve Spring Compressor

Used in conjunction with EN-46119 to remove valve springs

with the engine disassembled.

J-8087

Cylinder Bore Gauge

Commercial equivalent also available

EN-48313

Timing Chain Retention Tool

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3135 of 6020

Engine Mechanical – V6 Page 6A1–358

Page 6A1–358

MY2005 VZ

6A1

Engine Mechanical – V6

Update Number

Date Section / Subsection Affected Brief Change Description

22 MAY 2007 Complete Document

THE FOLLOWING CHANGES WERE

MADE:

Page 4 & 5

Page 8, 13, 110-115, 117, 119, 122, 124,

130, 132-134, 139-151, 156-166, 171-179,

186, 187, 190, 193-201, 203, 351, 355.

Figure 6A1 – 100, 102, 151, 152, 171-197,

219-239, 263-285, 299, 302, 303, 306, 312-

327

EN-48313 This C1-file replaces the previous (Holden Rodeo)

C-file

Content page change

Text changes

Graphic changes

New special tool (Timing Chain Retention Tool)

TEXT COLOURS TO INDICATE SPECIFIC APPLICATION

......................................... Text in th is colour indicates that the original text has been updated and is to repla ce

the existing, regardless of model.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3136 of 6020

Engine Cooling – V6 Engine Page 6B1–1

Section 6B1

Engine Cooling – V6

ATTENTION

Before performing any Service Operation or other procedure described in this Section, refer to 1.1 WARNING,

CAUTION and NOTES for correct workshop practices with regard to safety and/or property damage.

1 General Information ............................................................................................................ ...................3

1.1 WARNING, CAUTION and NOTES ..................................................................................................... ................... 4

1.2 Definition of WARNING, CAUTION and NOTE Statements ......................................................................... .. 4

WARNING defined ............................................................................................................................................. 4

CAUTION defined .............................................................................................................................................. 4

NOTE defined..................................................................................................................................................... 4

2 General Description ............................................................................................................ ...................5

2.1 Radiator Assembly .............................................................................................................. .................................. 5

2.2 Cooling Fan – Standard Specification.................................................................................................................. 7

Overview ................................................................................................................................................................. 7

Cooling Fan and Shroud Assembly ................................................................................................ .................... 8

Fan Motor ........................................................................................................................................................... 8

Fan Operation .................................................................................................................. .................................. 8

V6 Cooling Fan Wiring Diagram .................................................................................................. ....................... 9

Fan Assembly connector .................................................................................................................................. 10

2.3 Coolant Pump....................................................................................................................................................... 10

2.4 Coolant Outlet Housing ......................................................................................................... .............................. 11

2.5 Thermostat ........................................................................................................................................................... 11

2.6 Coolant Filler Cap ............................................................................................................. ................................... 13

2.7 Coolant Recovery Reservoir ..................................................................................................... .......................... 14

2.8 Engine Coolant Temperature Sensor .............................................................................................. ................... 15

3 Service Operations ...............................................................................................................................16

3.1 Service Notes ....................................................................................................................................................... 16

Safety .................................................................................................................................................................... 16

Periodic Servicing............................................................................................................. ................................... 16

Environmental Issues ........................................................................................................... ............................... 16

3.2 Coolant Maintenance ........................................................................................................................................... 17

Topping Up the Cooling System.................................................................................................. ....................... 18

Testing Coolant Concentration........................................................................................................................... 18

Method 1 – Refractometer................................................................................................................................ 18

Method 2 – Hydrometer.................................................................................................................................... 21

3.3 Draining and Filling Cooling System ............................................................................................ ..................... 22

Draining ................................................................................................................................................................ 22

Filling .................................................................................................................................................................... 22

3.4 Cleaning Cooling System ........................................................................................................ ............................ 25

Cooling System Reverse Flush ................................................................................................... ....................... 25

Radiator............................................................................................................................................................ 25

Engine .............................................................................................................................................................. 26

Heater Hoses and Core.......................................................................................................... .......................... 27

3.5 Drive Belt Tension ............................................................................................................................................... 28

Inspect .................................................................................................................................................................. 29

3.6 Coolant Hoses ...................................................................................................................................................... 30

3.7 Pressure Testing ............................................................................................................... ................................... 31

Coolant Filler Cap Pressure Testing ............................................................................................ ...................... 31

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3137 of 6020

Engine Cooling – V6 Engine Page 6B1–2

Cooling System Pressure Testing ................................................................................................ ...................... 32

3.8 Thermostat ........................................................................................................................................................... 34

Remove ................................................................................................................................................................. 34

Test ....................................................................................................................................................................... 37

Dismantle ...................................................................................................................... ........................................ 37

Reassembly .......................................................................................................................................................... 37

Install .................................................................................................................................................................... 38

3.9 Coolant Recovery Reservoir ..................................................................................................... .......................... 39

Remove ................................................................................................................................................................. 39

Inspect .................................................................................................................................................................. 39

Install .................................................................................................................................................................... 39

3.10 Coolant Pump................................................................................................................... .................................... 40

Remove ................................................................................................................................................................. 40

Inspect .................................................................................................................................................................. 43

Reinstall ................................................................................................................................................................ 43

3.11 Coolant Outlet Housing ......................................................................................................... .............................. 45

Remove ................................................................................................................................................................. 45

Reinstall ................................................................................................................................................................ 46

3.12 Coolant Inlet Pipe............................................................................................................. .................................... 46

Remove ................................................................................................................................................................. 46

Install .................................................................................................................................................................... 48

3.13 Cooling Fan and Shroud Assembly ................................................................................................ ................... 48

Remove ................................................................................................................................................................. 48

Install .................................................................................................................................................................... 50

Disassemble ......................................................................................................................................................... 51

Reassemble .......................................................................................................................................................... 51

3.14 Flexible Transmission Cooler Hose .............................................................................................. ..................... 51

Replace ................................................................................................................................................................. 51

Reinstall ................................................................................................................................................................ 53

3.15 Radiator ....................................................................................................................... ......................................... 54

Remove ......................................................................................................................... ........................................ 54

Reinstall ................................................................................................................................................................ 56

Radiator Repair Procedure...................................................................................................... ............................ 57

Repairable Leaks ............................................................................................................................................. 57

Repair Method.................................................................................................................................................. 58

Tube Blocking................................................................................................................................................... 58

Header Repair .................................................................................................................. ................................ 58

General Core Repair ............................................................................................................ ............................ 59

Transmission Oil Cooler Leak Test .............................................................................................. .................... 60

Transmission Oil Cooler Seal Replacement. ...................................................................................... .............. 60

4 Engine Cooling System Diagnosis .....................................................................................................61

4.1 Poor Heater Operation......................................................................................................................................... 61

4.2 Leaking Cylinder Head Gasket ................................................................................................... ........................ 61

4.3 Question the Customer ....................................................................................................................................... 61

4.4 Diagnostic Chart .................................................................................................................................................. 61

4.5 Problems Not Requiring Disassembly of Cooling System ........................................................................... .... 63

4.6 Problems Requiring Disassembly of Cooling System ...................................................................................... 63

4.7 Black Light and Dye Leak Diagnosis Method .................................................................................................... 63

5 Specifications .......................................................................................................................................64

6 Torque Wrench Specifications................................................................................................... .........66

7 Special Tools ........................................................................................................................................67

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3138 of 6020

Engine Cooling – V6 Engine Page 6B1–3

1 General Information

The cooling system for the HFV6 engine has been re-designed to accommodate this engine’s unique configuration and

engine cooling performance requirements. The following list is a summary of new and modified components:

• Revised radiator assembly.

• New plumbing including radiator hoses, inlet pipe, heater pipes, heater hoses and heater water valve.

• New rear mount thermostat assembly and thermostat housing.

• New coolant outlet with pressure cap.

• New coolant specification.

• New side chutes and radiator shroud.

• Modified cooling fan operating strategy.

• A four stage cooling fan operating system is used.

The cooling fan motor is controlled by duty signal from the ECM which results in the fan operating from low speed Stage

1), up to high speed (Stage 4).

Operation of the cooling fan is dependant on the engine temperature, vehicle speed, A/C request (where fitted) and A/C

system pressure. Refer to 6C1 – 1 Engine management general information.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3139 of 6020

Engine Cooling – V6 Engine Page 6B1–4

1.1 WARNING, CAUTION and NOTES

This Section contains various W ARNINGS, CAUTIONS and NOTE statements that you must observe carefully to reduce

the risk of death or injury during service, repair procedures or vehicle operation. Incorrect service or repair procedures

may damage the vehicle or cause operational faults. W ARNINGS, CAUTION and NOTE statements are not exhaustive.

HOLDEN LTD can not possibly warn of all the potentially hazardous consequences of failure to follow these instructions.

1.2 Definition of WARNING, CAUTION and NOTE Statements

Diagnosis and repair procedures in this Section contain both general and specific W ARNING, CAUTION and NOTE

statements. HOLDEN LTD is dedicated to the presentation of service information that helps the technician to diagnose

and repair the systems necessary for proper operation of the vehicle. Certain procedures may present a hazard to the

technician if they are not followed in the recommended manner. W ARNING, CAUTION and NOTE statements are

designed to help prevent these hazards from occurring, but not all hazards can be foreseen.

WARNING defined

A W ARNING statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in death or injury. A W ARNING statement alerts you to take necessary action or not to take a

prohibited action. If a W ARNING statement is ignored, the following consequences may occur:

• Death or injury to the technician or other personnel working on the vehicle,

• Death or injury to other people in or near the workplace area, and / or

• Death or injury to the driver / or passenger(s) of the vehicle or other people, if the vehicle has been improperly

repaired.

CAUTION defined

A CAUTION statement immediately precedes an operating procedure or maintenance practice which, if not correctly

followed, could result in damage to or destruction of equipment, or corruption of data. If a CAUTION statement is ignored,

the following consequences may occur:

• Damage to the vehicle,

• Unnecessary vehicle repairs or component replacement,

• Faulty operation or performance of any system or component being repaired,

• Damage to any system or components which depend on the proper operation of the system or component being

repaired,

• Faulty operation or performance of any systems or components which depend on the proper operation or

performance of the system or component under repair,

• Damage to fasteners, basic tools or special tools and / or

• Leakage of coolant, lubricant or other vital fluids.

NOTE defined

A NOTE statement immediately precedes or follows an operating procedure, maintenance practice or condition that

requires highlighting. A NOTE statement also emphasises necessary characteristics of a diagnostic or repair procedure.

A NOTE statement is designed to:

• Clarify a procedure,

• Present additional information for accomplishing a procedure,

• Give insight into the reasons for performing a procedure in the recommended manner, and / or

Present information that gives the technician the benefit of past experience in accomplishing a procedure with greater

ease.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3140 of 6020

Engine Cooling – V6 Engine Page 6B1–5

2 General Description

2.1 Radiator Assembly

The radiator has an aluminium core and is of the cross-flow design. Plastic side tanks are attached to the core by clinch

tabs. The clinch tabs are formed as part of the core assembly.

The lower frame of the radiator assembly is attached to the vehicle frame by two bolts supported in rubber mounts, pegs

are attached to the upper area of each side tank. These pegs are used to support the radiator with two rubber insert

mounting brackets.

A high temperature rubber seal is used to seal the mating surface between the core and each side tank. The seal(s)

must be replaced any time the side tank is removed from the core.

NOTE

The radiator core side tanks or transmission oil

cooler cannot be replaced separately. If there is a

fault with any of these components, the radiator

assembly must be replaced. Small core repairs

may be made using an aluminised silicon based

liquid repair agent. Refer to 3.15 Radiator in

this Section.

For vehicles with automatic transmission, a transmission oil cooler is located in the right-hand side radiator tank. The

cooler pipes from and to the transmission are connected to the oil cooler flexible hoses by means of quick connect

fittings.

The cooling fan motor is attached by three screws to the one-piece plastic fan shroud. In turn, the fan shroud is mounted

to the rear of the radiator and is located and supported by two bolts and two locating tabs. The upper clips lock the fan

shroud in place and can be released by hand to facilitate fan shroud removal. The shroud must be removed to allow fan

motor and blade assembly removal.

One harness connector is mounted to the upper section of the fan shroud allowing the fan motor and blade assemblies

to be removed individually from the shroud. The fan motor and blade is balanced as an assembly. These two

components are serviced only as a unit and are not to be separated.

The shroud, fan assembly and transmission cooler hoses can be removed and installed individually from the vehicle. For

removal and installation procedures, refer to 3.13Cooling Fan and Shroud Assembly, 3.14 Flexible Transmission

Cooler Hose and 3.15 Radiator in this Section.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007