ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 3561 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–37

Test

Under no circumstances should battery

voltage be applied to the heated oxygen

sensor (HO2S) heater.

To prevent component damage use connector

test adaptor kit J 35616-A.

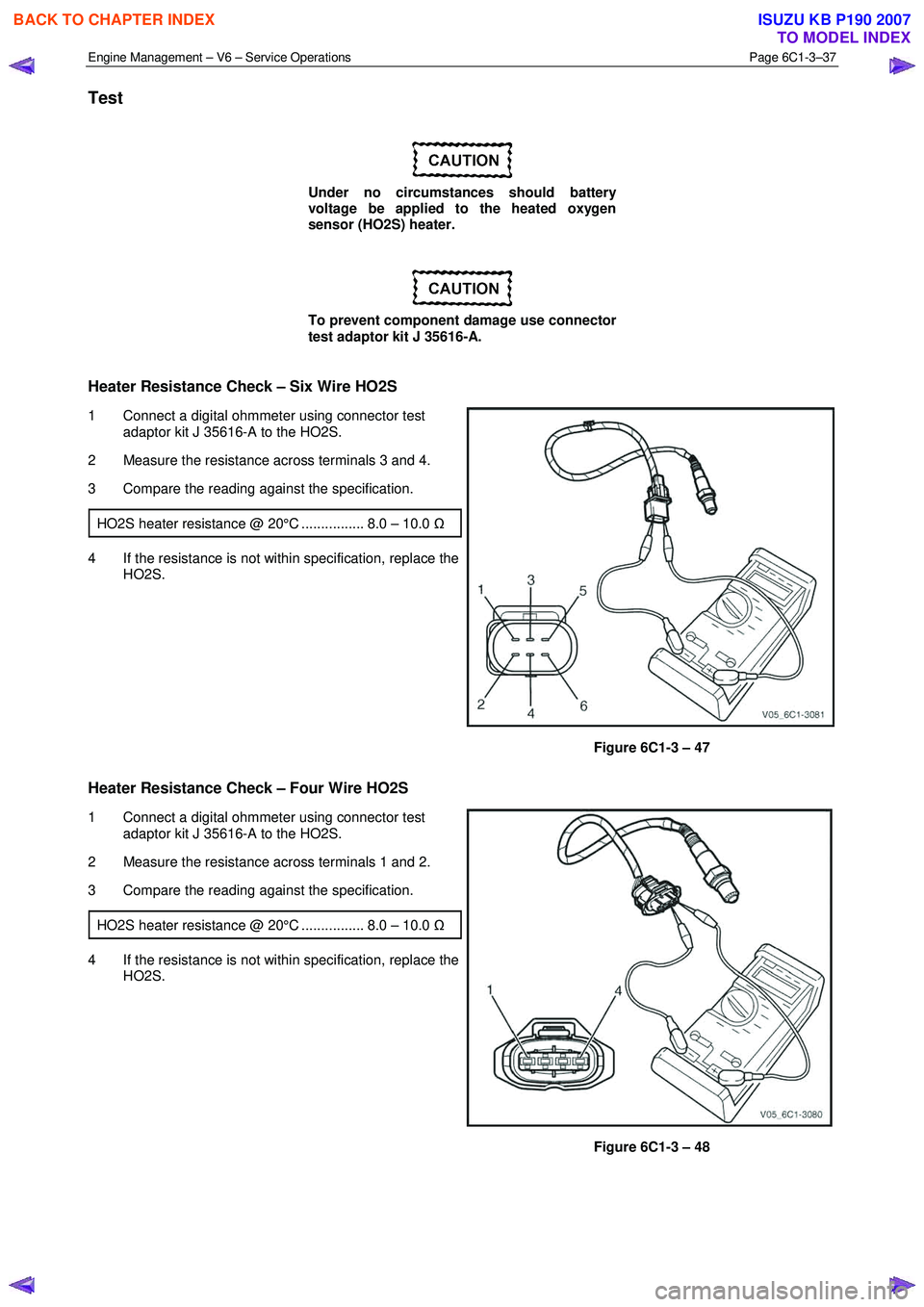

Heater Resistance Check – Six Wire HO2S

1 Connect a digital ohmmeter using connector test adaptor kit J 35616-A to the HO2S.

2 Measure the resistance across terminals 3 and 4.

3 Compare the reading against the specification.

HO2S heater resistance @ 20°C ................ 8.0 – 10.0 Ω

4 If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 47

Heater Resistance Check – Four Wire HO2S

1 Connect a digital ohmmeter using connector test

adaptor kit J 35616-A to the HO2S.

2 Measure the resistance across terminals 1 and 2.

3 Compare the reading against the specification.

HO2S heater resistance @ 20°C ................ 8.0 – 10.0 Ω

4 If the resistance is not within specification, replace the

HO2S.

Figure 6C1-3 – 48

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3562 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–38

2.15 Ignition Coil

Ignition Coils

The replacement procedure for all ignition coils is the same except for the removal of the ignition coil on cylinder No's 1,

3 and 4, it is necessary to remove the upper intake manifold assembly.

Remove

1 Turn the ignition switch off.

NOTE

If the upper intake manifold has been removed,

plug the lower manifold openings to prevent dirt

and other contaminants from entering.

2 If required, remove the upper intake manifold assembly, refer to 6A1 Engine Mechanical – V6.

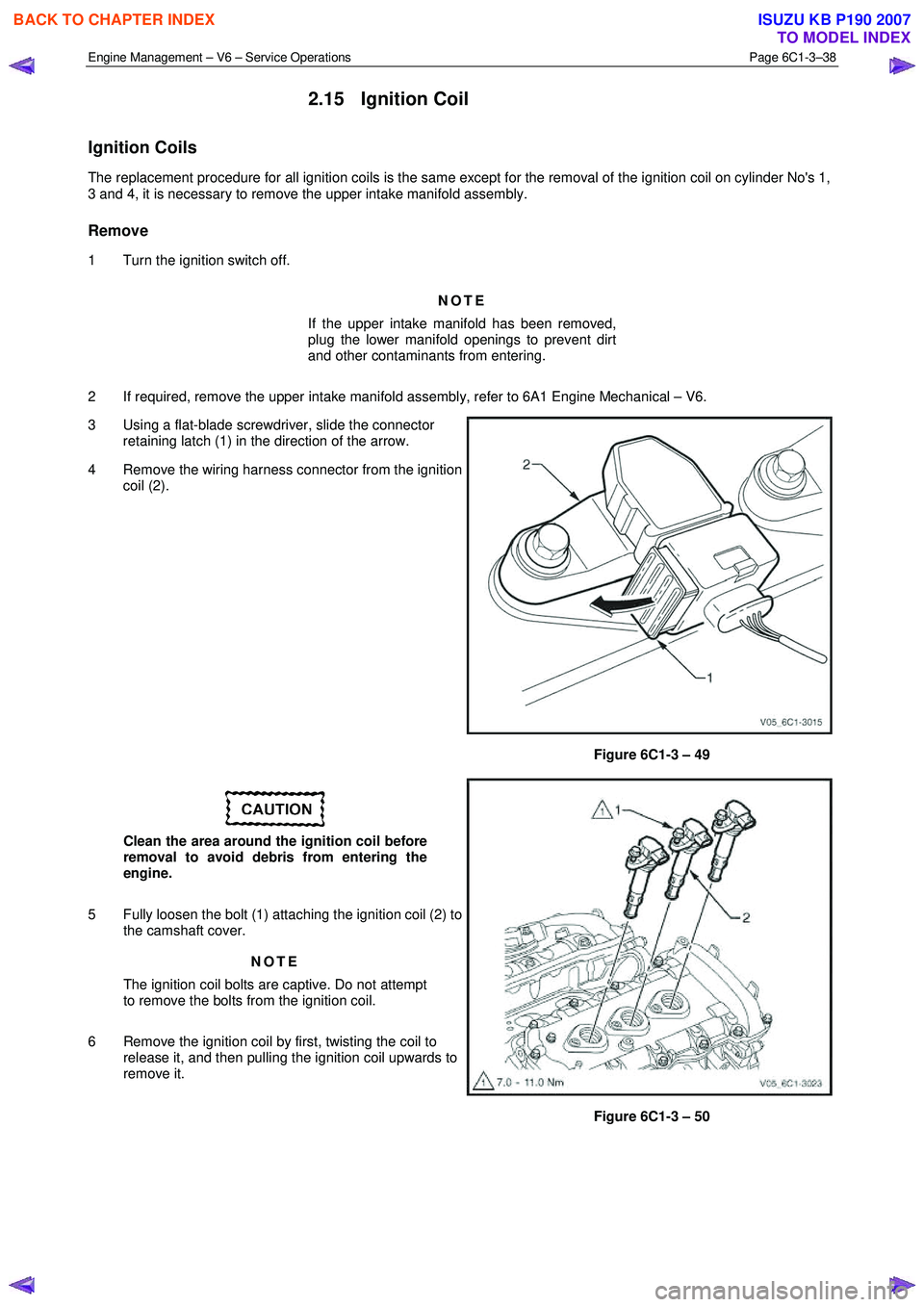

3 Using a flat-blade screwdriver, slide the connector retaining latch (1) in the direction of the arrow.

4 Remove the wiring harness connector from the ignition coil (2).

Figure 6C1-3 – 49

Clean the area around the ignition coil before

removal to avoid debris from entering the

engine.

5 Fully loosen the bolt (1) attaching the ignition coil (2) to the camshaft cover.

NOTE

The ignition coil bolts are captive. Do not attempt

to remove the bolts from the ignition coil.

6 Remove the ignition coil by first, twisting the coil to release it, and then pulling the ignition coil upwards to

remove it.

Figure 6C1-3 – 50

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3563 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–39

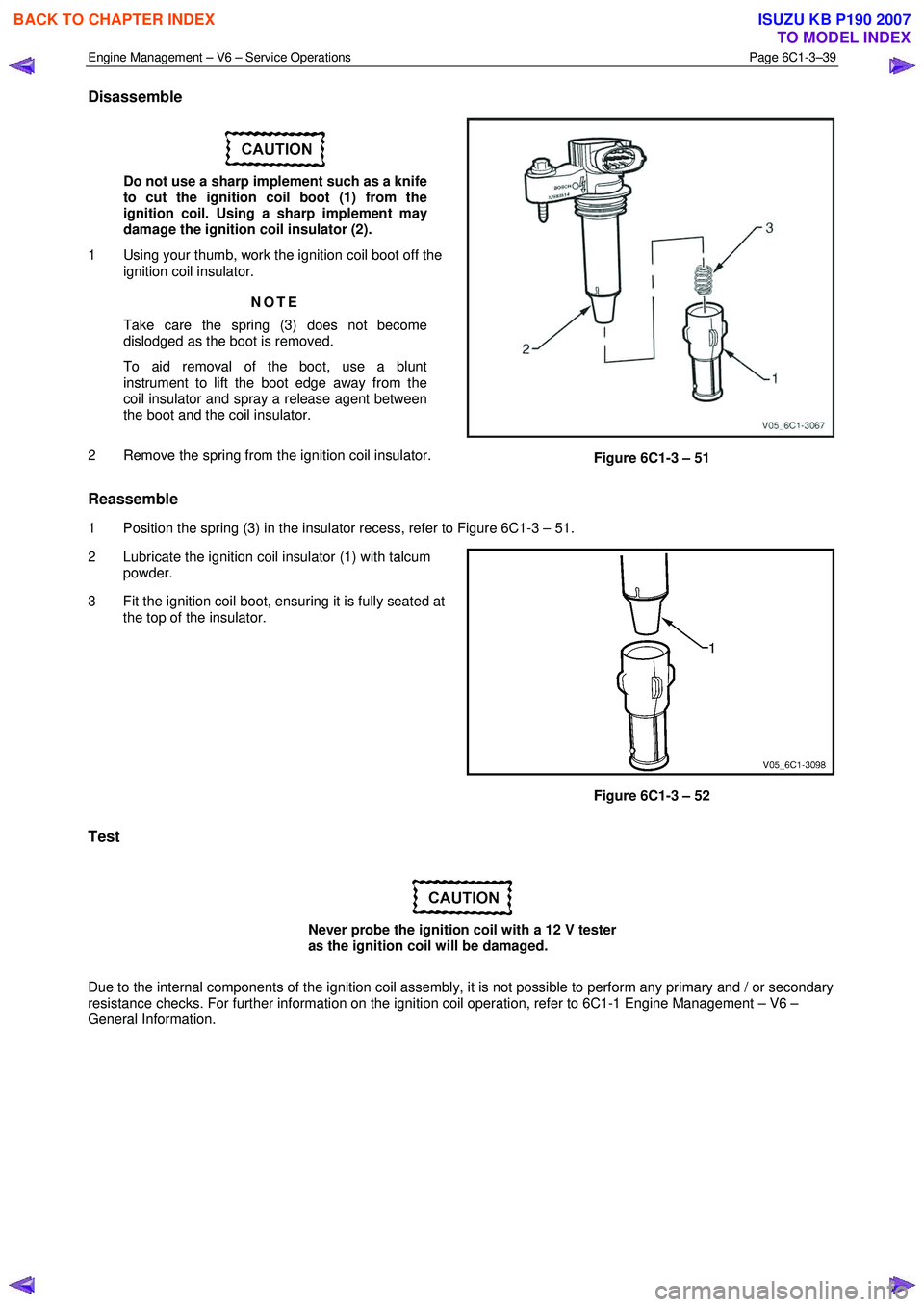

Disassemble

Do not use a sharp implement such as a knife

to cut the ignition coil boot (1) from the

ignition coil. Using a sharp implement may

damage the ignition coil insulator (2).

1 Using your thumb, work the ignition coil boot off the ignition coil insulator.

NOTE

Take care the spring (3) does not become

dislodged as the boot is removed.

To aid removal of the boot, use a blunt

instrument to lift the boot edge away from the

coil insulator and spray a release agent between

the boot and the coil insulator.

2 Remove the spring from the ignition coil insulator.

Figure 6C1-3 – 51

Reassemble

1 Position the spring (3) in the insulator recess, refer to Figure 6C1-3 – 51.

2 Lubricate the ignition coil insulator (1) with talcum powder.

3 Fit the ignition coil boot, ensuring it is fully seated at the top of the insulator.

Figure 6C1-3 – 52

Test

Never probe the ignition coil with a 12 V tester

as the ignition coil will be damaged.

Due to the internal components of the ignition coil assembly, it is not possible to perform any primary and / or secondary

resistance checks. For further information on the ignition coil operation, refer to 6C1-1 Engine Management – V6 –

General Information.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3564 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–40

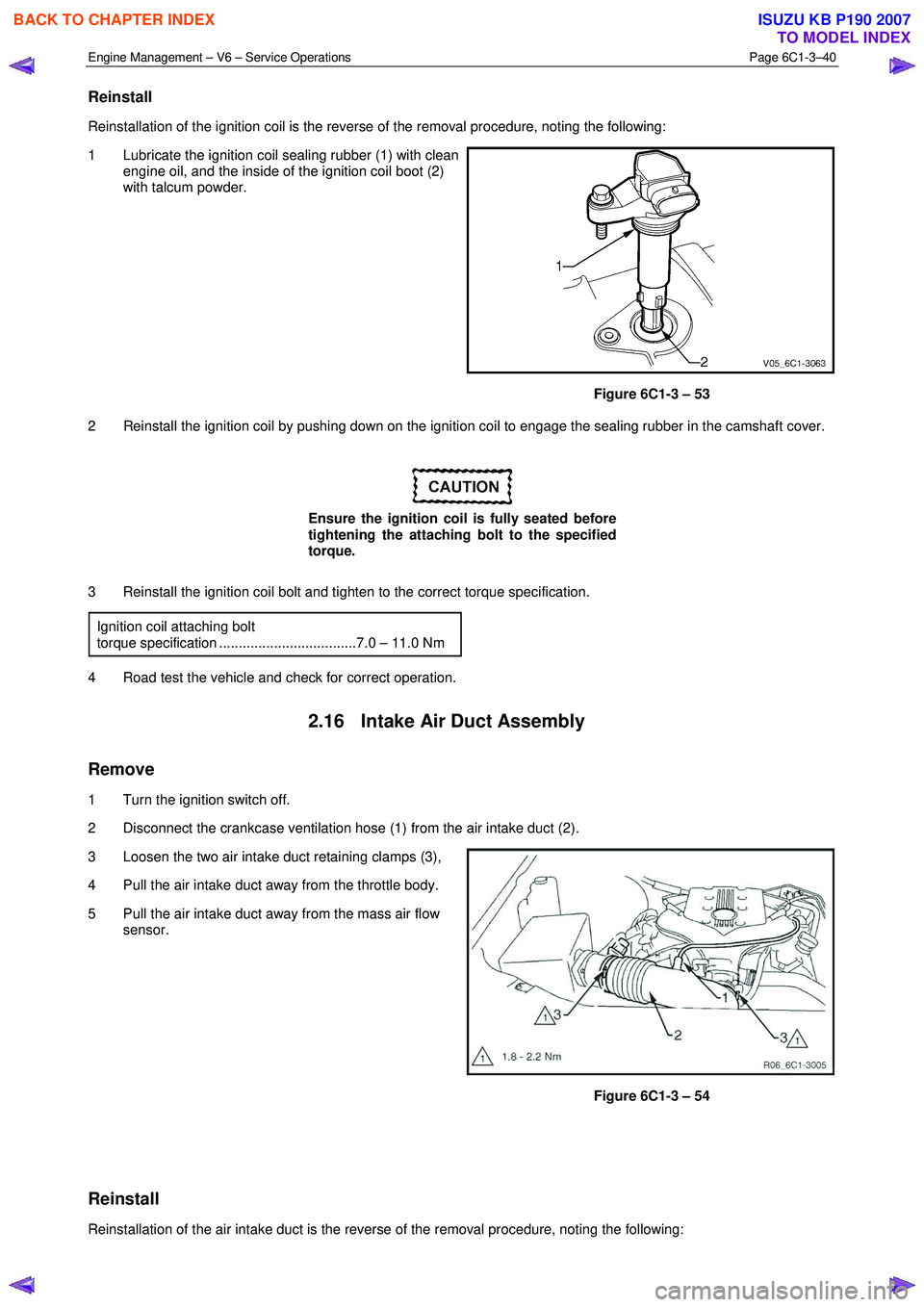

Reinstall

Reinstallation of the ignition coil is the reverse of the removal procedure, noting the following:

1 Lubricate the ignition coil sealing rubber (1) with clean engine oil, and the inside of the ignition coil boot (2)

with talcum powder.

Figure 6C1-3 – 53

2 Reinstall the ignition coil by pushing down on the ignition coil to engage the sealing rubber in the camshaft cover.

Ensure the ignition coil is fully seated before

tightening the attaching bolt to the specified

torque.

3 Reinstall the ignition coil bolt and tighten to the correct torque specification. Ignition coil attaching bolt

torque specification ...................................7.0 – 11.0 Nm

4 Road test the vehicle and check for correct operation.

2.16 Intake Air Duct Assembly

Remove

1 Turn the ignition switch off.

2 Disconnect the crankcase ventilation hose (1) from the air intake duct (2).

3 Loosen the two air intake duct retaining clamps (3),

4 Pull the air intake duct away from the throttle body.

5 Pull the air intake duct away from the mass air flow sensor.

Figure 6C1-3 – 54

Reinstall

Reinstallation of the air intake duct is the reverse of the removal procedure, noting the following:

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3565 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–41

Ensure the air intake duct sealing rubber is

correctly positioned on the throttle body.

Failure to do this may result in engine

damage due to unfiltered air entering the

engine intake system.

1 Reinstall the air intake duct and tighten the retaining clamps to the correct torque specification. Air intake duct retaining clamp

torque specification .....................................1.8 – 2.2 Nm

2 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

2.17 Intake Air Temperature Sensor

The intake air temperature (IAT) sensor is part of the mass air flow (MAF) sensor assembly, refer to 2.20 Mass Air

Flow Sensor for the replacement procedure.

Test

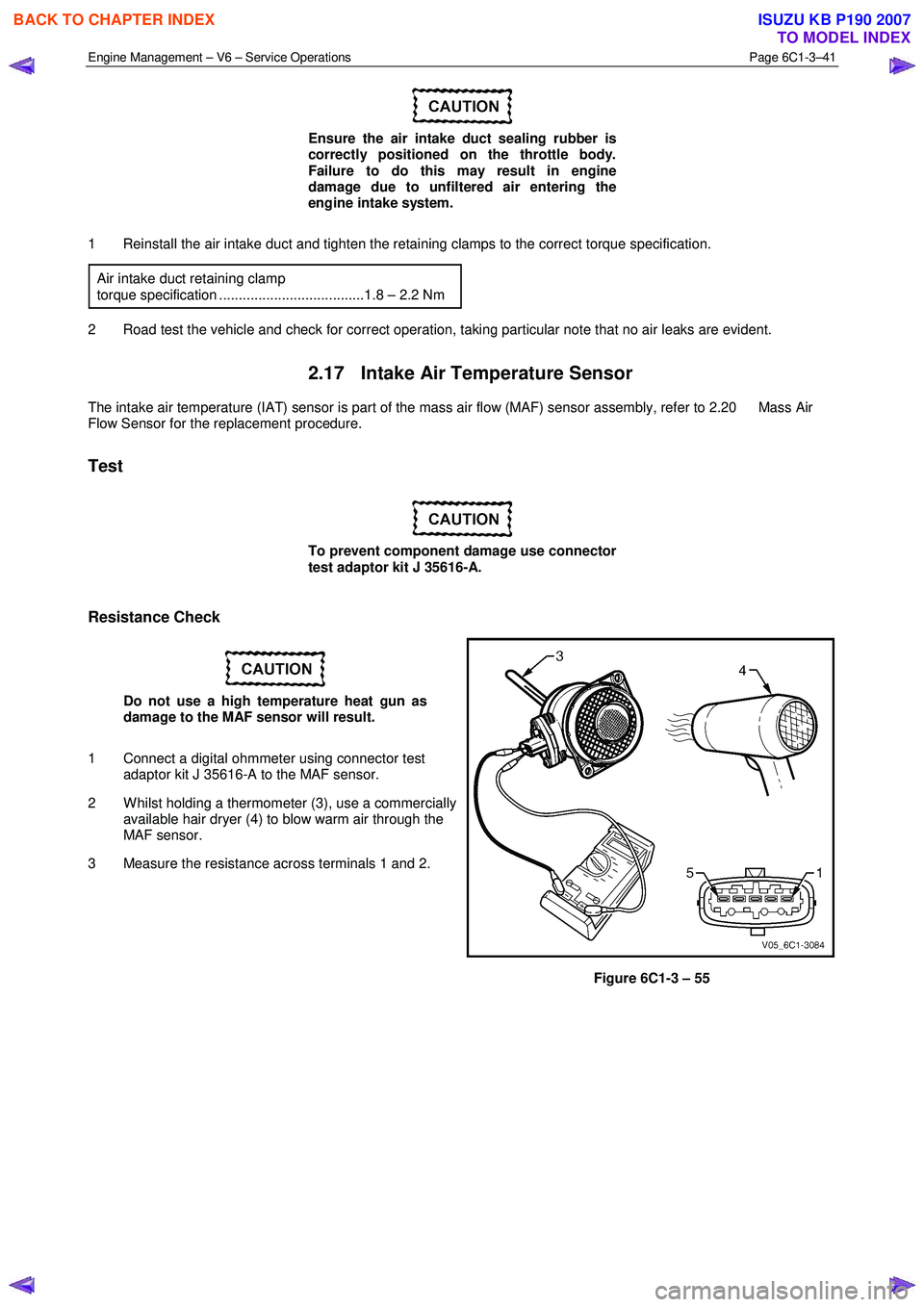

To prevent component damage use connector

test adaptor kit J 35616-A.

Resistance Check

Do not use a high temperature heat gun as

damage to the MAF sensor will result.

1 Connect a digital ohmmeter using connector test adaptor kit J 35616-A to the MAF sensor.

2 W hilst holding a thermometer (3), use a commercially available hair dryer (4) to blow warm air through the

MAF sensor.

3 Measure the resistance across terminals 1 and 2.

Figure 6C1-3 – 55

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3566 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–42

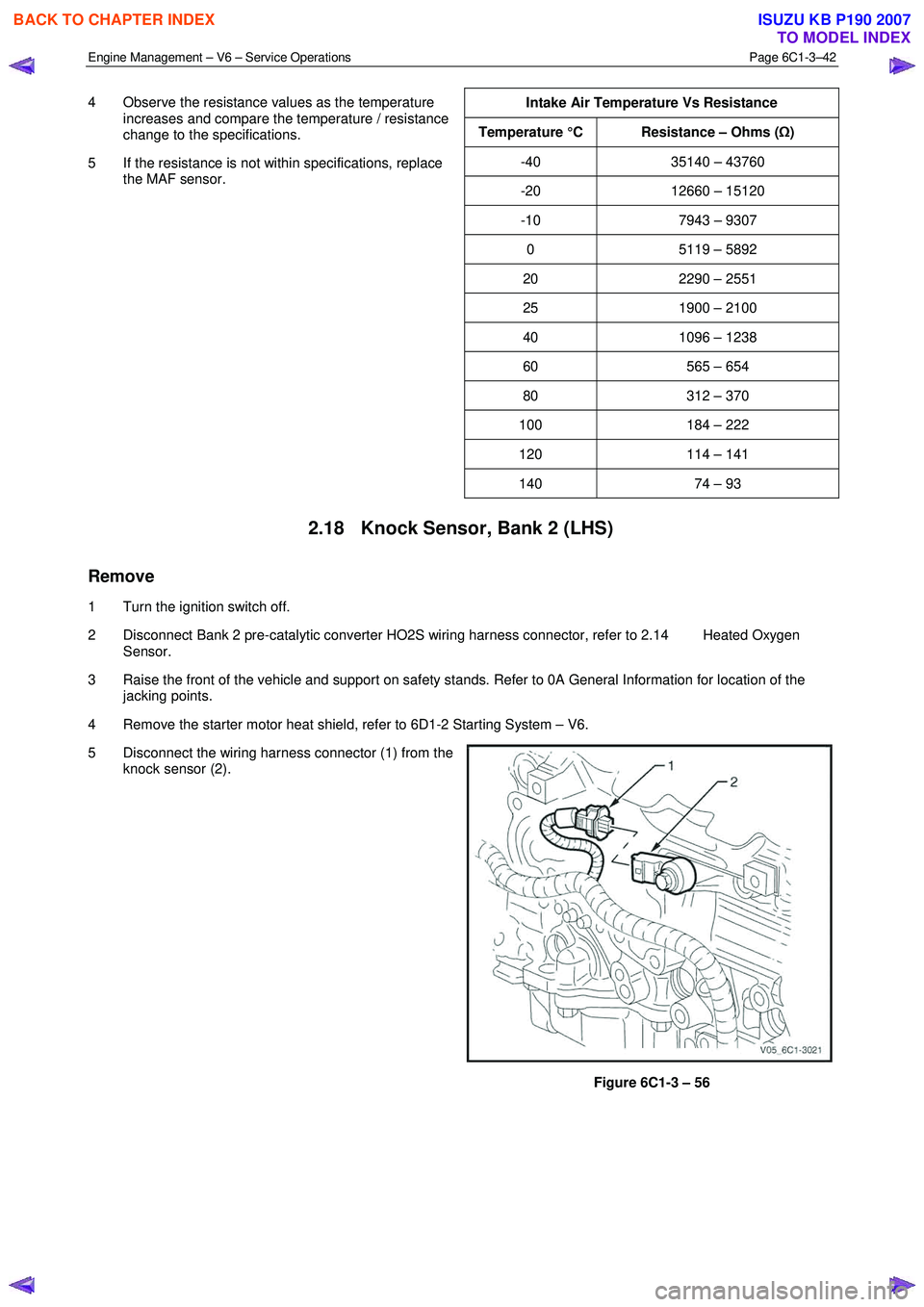

4 Observe the resistance values as the temperature

increases and compare the temperature / resistance

change to the specifications.

5 If the resistance is not within specifications, replace the MAF sensor.

Intake Air Temperature Vs Resistance

Temperature °C Resistance – Ohms (

Ω)

-40 35140 – 43760

-20 12660 – 15120

-10 7943 – 9307

0 5119 – 5892

20 2290 – 2551

25 1900 – 2100

40 1096 – 1238

60 565 – 654

80 312 – 370

100 184 – 222

120 114 – 141

140 74 – 93

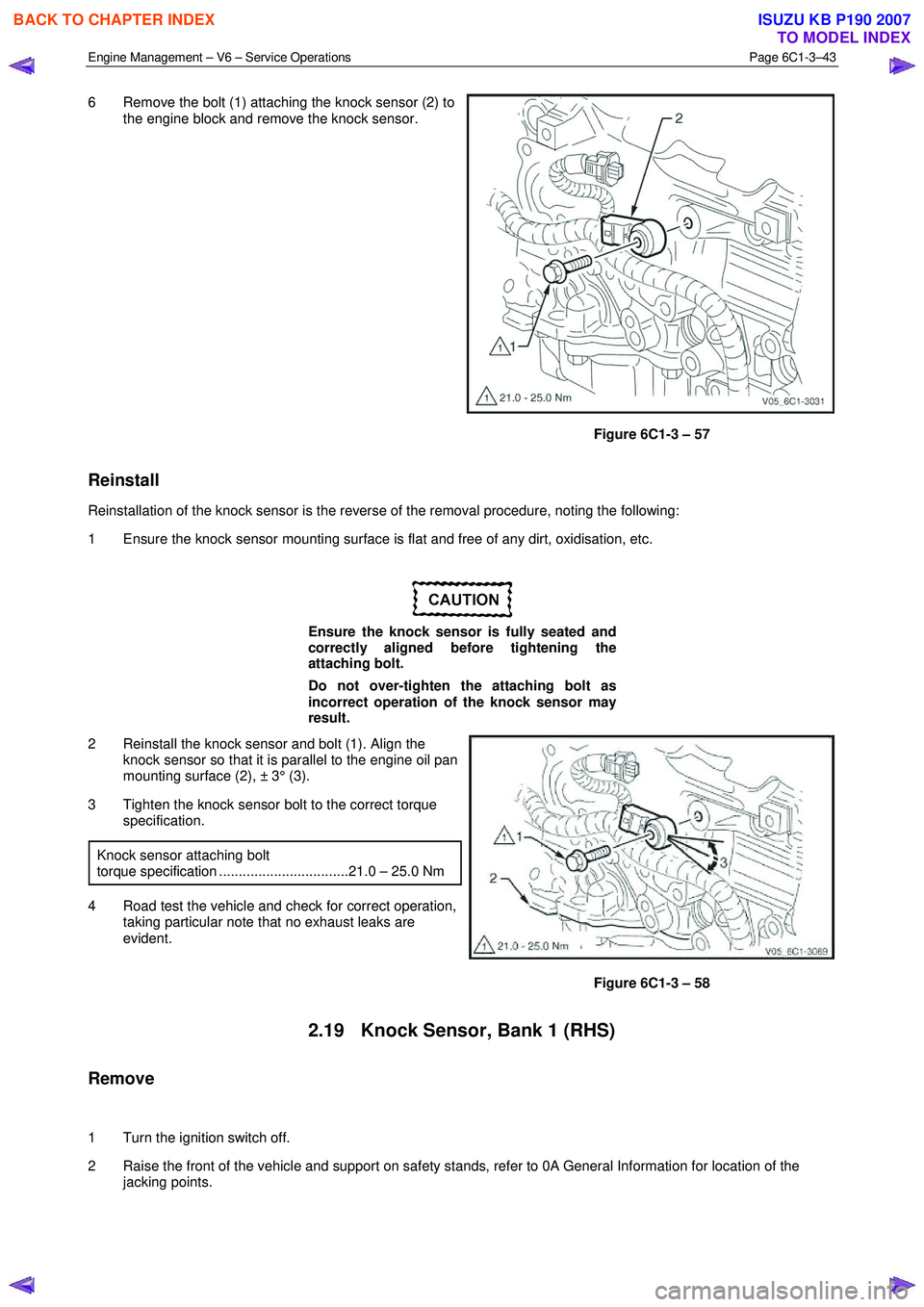

2.18 Knock Sensor, Bank 2 (LHS)

Remove

1 Turn the ignition switch off.

2 Disconnect Bank 2 pre-catalytic converter HO2S wiring harness connector, refer to 2.14 Heated Oxygen Sensor.

3 Raise the front of the vehicle and support on safety stands. Refer to 0A General Information for location of the jacking points.

4 Remove the starter motor heat shield, refer to 6D1-2 Starting System – V6.

5 Disconnect the wiring harness connector (1) from the knock sensor (2).

Figure 6C1-3 – 56

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3567 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–43

6 Remove the bolt (1) attaching the knock sensor (2) to

the engine block and remove the knock sensor.

Figure 6C1-3 – 57

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1 Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

Ensure the knock sensor is fully seated and

correctly aligned before tightening the

attaching bolt.

Do not over-tighten the attaching bolt as

incorrect operation of the knock sensor may

result.

2 Reinstall the knock sensor and bolt (1). Align the knock sensor so that it is parallel to the engine oil pan

mounting surface (2), ± 3° (3).

3 Tighten the knock sensor bolt to the correct torque specification.

Knock sensor attaching bolt

torque specification .................................21.0 – 25.0 Nm

4 Road test the vehicle and check for correct operation, taking particular note that no exhaust leaks are

evident.

Figure 6C1-3 – 58

2.19 Knock Sensor, Bank 1 (RHS)

Remove

1 Turn the ignition switch off.

2 Raise the front of the vehicle and support on safety stands, refer to 0A General Information for location of the jacking points.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3568 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–44

3 Disconnect the wiring harness connector (1) from the

knock sensor (2).

Figure 6C1-3 – 59

4 Remove the bolt (1) attaching the knock sensor (2) to the engine block, and remove the knock sensor.

Figure 6C1-3 – 60

Reinstall

Reinstallation of the knock sensor is the reverse of the removal procedure, noting the following:

1 Ensure the knock sensor mounting surface is flat and free of any dirt, oxidisation, etc.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3569 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–45

Ensure the knock sensor is fully seated

before tightening the attaching bolt.

Do not over-tighten the attaching bolt as

incorrect operation of the knock sensor may

result.

2 Reinstall the knock sensor and bolt (1). Align the knock sensor so that it is parallel to the engine oil pan

mounting surface (2), ± 3° (3).

3 Tighten the knock sensor bolt to the correct torque specification.

Knock sensor attaching bolt

torque specification .................................21.0 – 25.0 Nm

4 Road test the vehicle and check for correct operation.

Figure 6C1-3 – 61

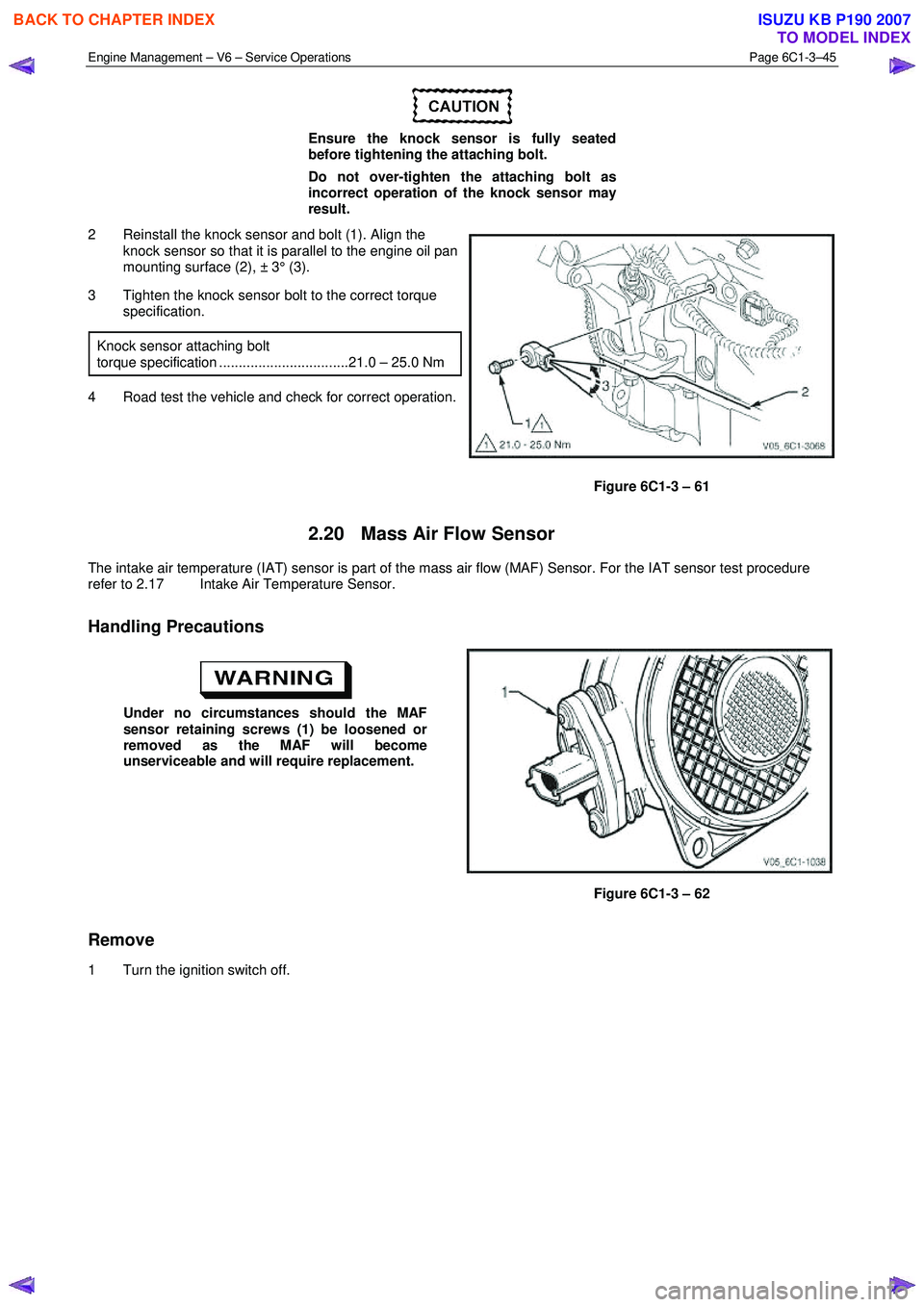

2.20 Mass Air Flow Sensor

The intake air temperature (IAT) sensor is part of the mass air flow (MAF) Sensor. For the IAT sensor test procedure

refer to 2.17 Intake Air Temperature Sensor.

Handling Precautions

Under no circumstances should the MAF

sensor retaining screws (1) be loosened or

removed as the MAF will become

unserviceable and will require replacement.

Figure 6C1-3 – 62

Remove

1 Turn the ignition switch off.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 3570 of 6020

Engine Management – V6 – Service Operations Page 6C1-3–46

2 Disconnect the wiring harness connector (1) from the

MAF sensor.

3 Remove the air intake duct, refer to 2.16 Intake Air Duct Assembly.

Figure 6C1-3 – 63

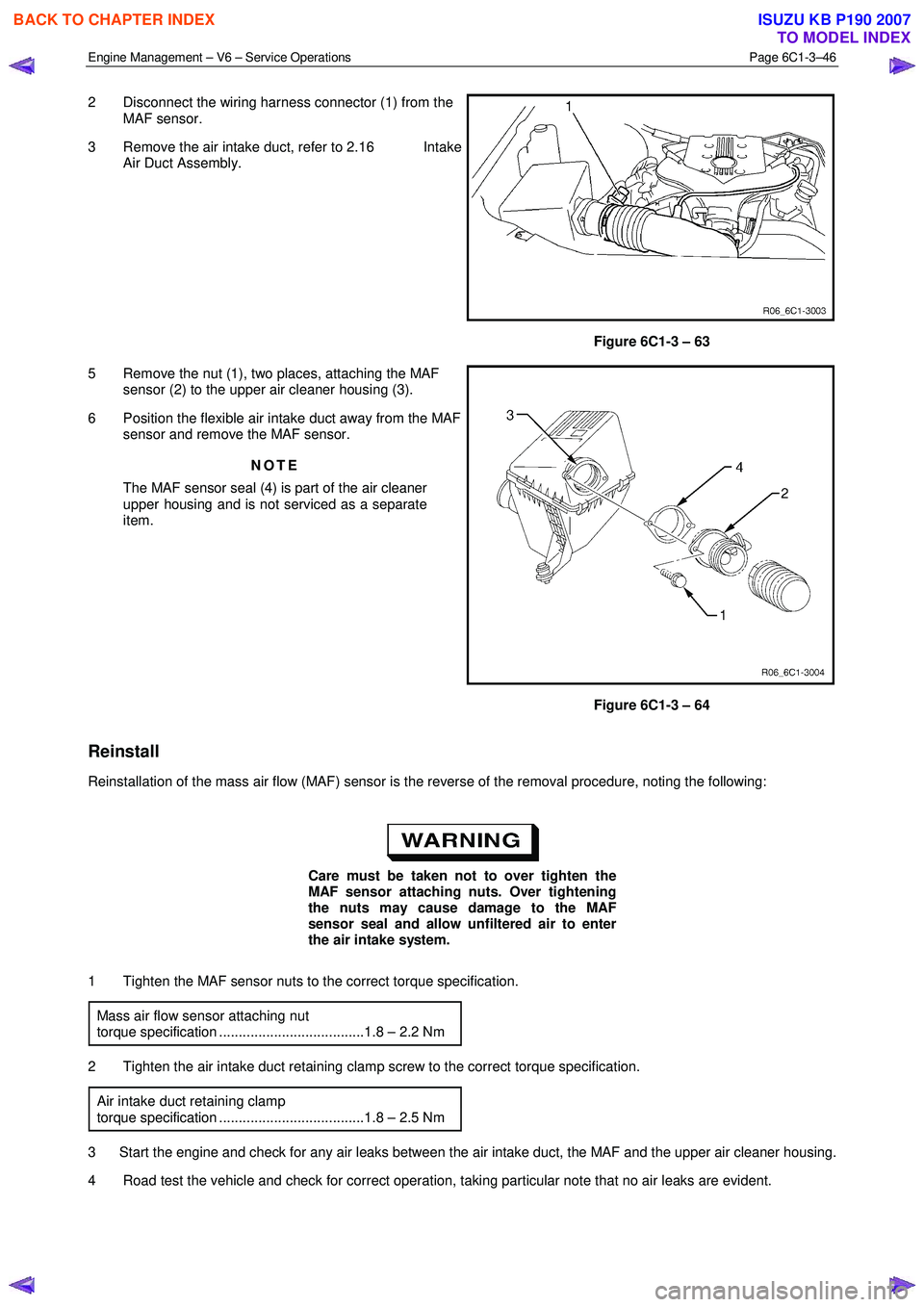

5 Remove the nut (1), two places, attaching the MAF sensor (2) to the upper air cleaner housing (3).

6 Position the flexible air intake duct away from the MAF sensor and remove the MAF sensor.

NOTE

The MAF sensor seal (4) is part of the air cleaner

upper housing and is not serviced as a separate

item.

Figure 6C1-3 – 64

Reinstall

Reinstallation of the mass air flow (MAF) sensor is the reverse of the removal procedure, noting the following:

Care must be taken not to over tighten the

MAF sensor attaching nuts. Over tightening

the nuts may cause damage to the MAF

sensor seal and allow unfiltered air to enter

the air intake system.

1 Tighten the MAF sensor nuts to the correct torque specification. Mass air flow sensor attaching nut

torque specification .....................................1.8 – 2.2 Nm

2 Tighten the air intake duct retaining clamp screw to the correct torque specification. Air intake duct retaining clamp

torque specification .....................................1.8 – 2.5 Nm

3 Start the engine and check for any air leaks between the air intake duct, the MAF and the upper air cleaner housing.

4 Road test the vehicle and check for correct operation, taking particular note that no air leaks are evident.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007