ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 4851 of 6020

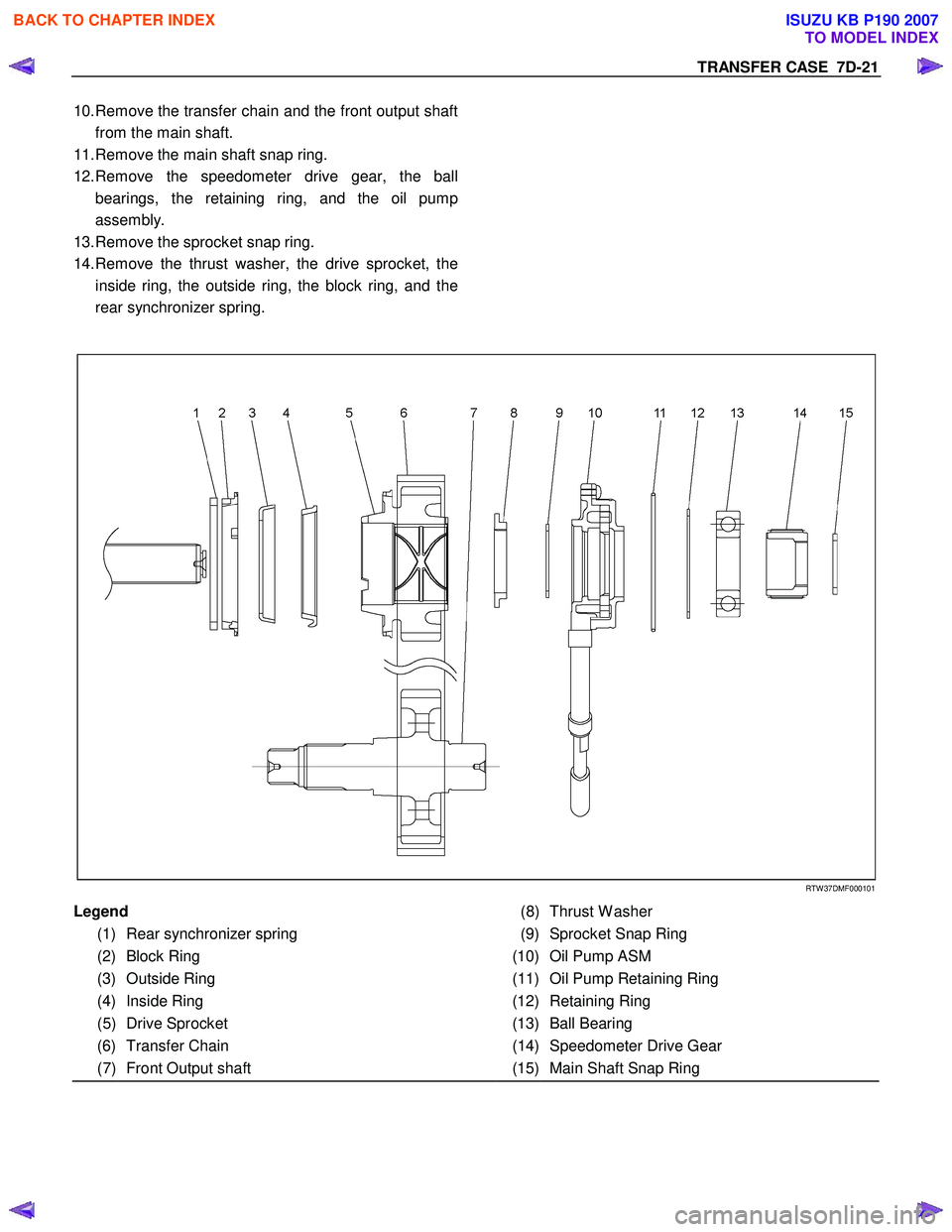

TRANSFER CASE 7D-21

10. Remove the transfer chain and the front output shaft

from the main shaft.

11. Remove the main shaft snap ring.

12. Remove the speedometer drive gear, the ball

bearings, the retaining ring, and the oil pump

assembly.

13. Remove the sprocket snap ring.

14. Remove the thrust washer, the drive sprocket, the

inside ring, the outside ring, the block ring, and the

rear synchronizer spring.

RTW 37DMF000101

Legend

(8) Thrust W asher

(1) Rear synchronizer spring

(9) Sprocket Snap Ring

(2) Block Ring

(10) Oil Pump ASM

(3) Outside Ring

(11) Oil Pump Retaining Ring

(4) Inside Ring

(12) Retaining Ring

(5) Drive Sprocket

(13) Ball Bearing

(6) Transfer Chain (14) Speedometer Drive Gear

(7) Front Output shaft (15) Main Shaft Snap Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4852 of 6020

7D-22 TRANSFER CASE

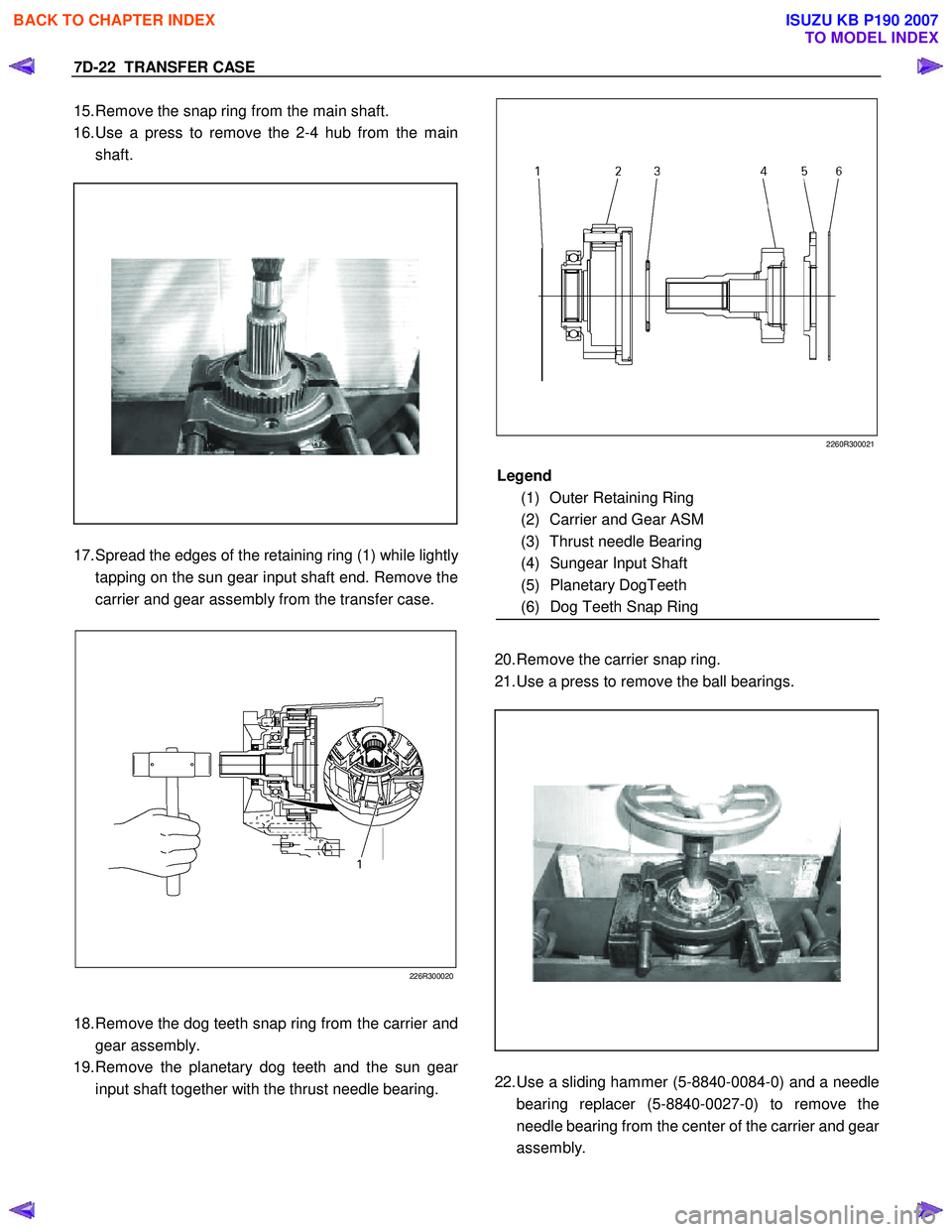

15. Remove the snap ring from the main shaft.

16. Use a press to remove the 2-4 hub from the main

shaft.

17. Spread the edges of the retaining ring (1) while lightl

y

tapping on the sun gear input shaft end. Remove the

carrier and gear assembly from the transfer case.

226R300020

18. Remove the dog teeth snap ring from the carrier and

gear assembly.

19. Remove the planetary dog teeth and the sun gear

input shaft together with the thrust needle bearing.

2260R300021

20. Remove the carrier snap ring.

21. Use a press to remove the ball bearings.

22. Use a sliding hammer (5-8840-0084-0) and a needle

bearing replacer (5-8840-0027-0) to remove the

needle bearing from the center of the carrier and gea

r

assembly.

Legend

(1) Outer Retaining Ring

(2) Carrier and Gear ASM

(3) Thrust needle Bearing

(4) Sungear Input Shaft

(5) Planetary DogTeeth

(6) Dog Teeth Snap Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4853 of 6020

TRANSFER CASE 7D-23

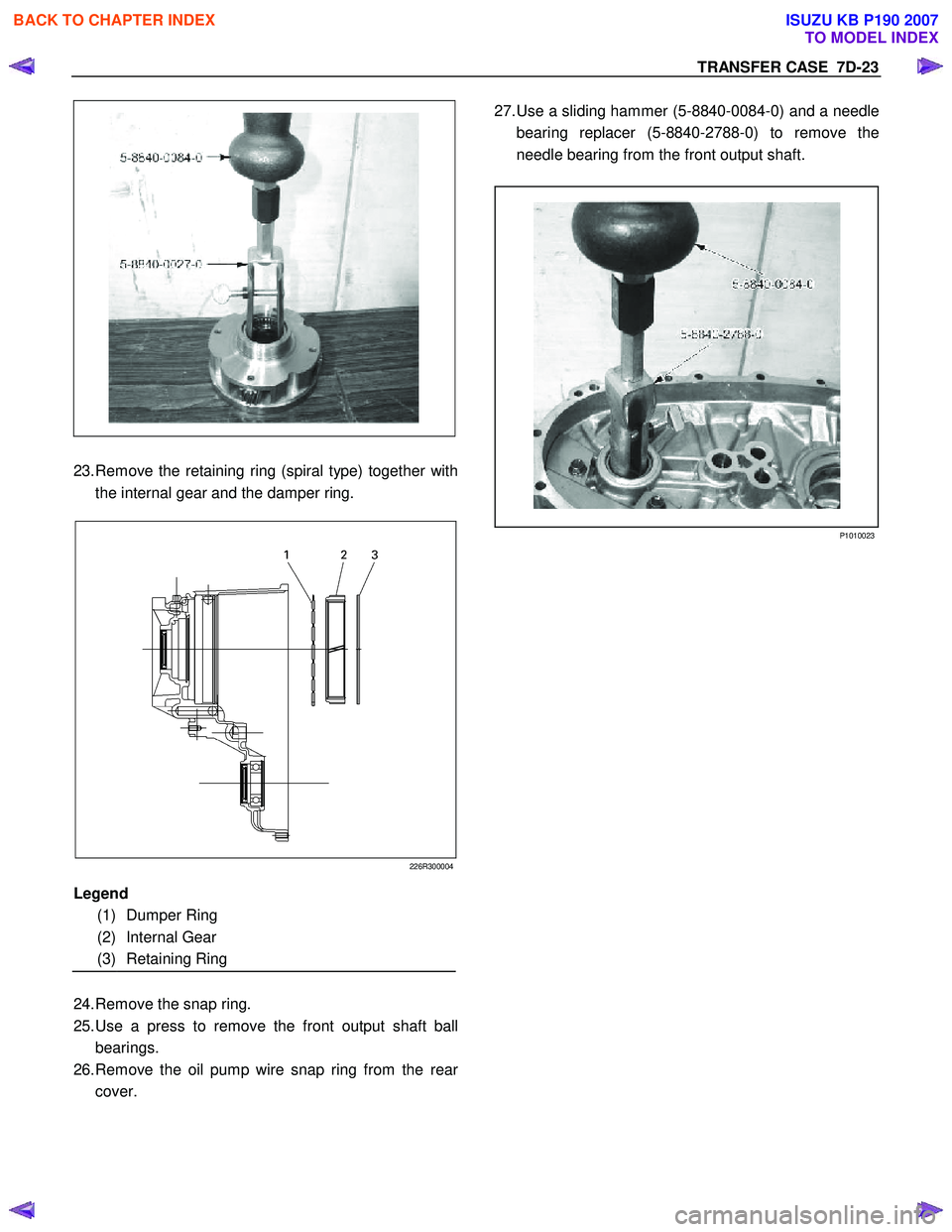

23. Remove the retaining ring (spiral type) together with

the internal gear and the damper ring.

226R300004

24. Remove the snap ring.

25. Use a press to remove the front output shaft ball

bearings.

26. Remove the oil pump wire snap ring from the rear

cover.

27. Use a sliding hammer (5-8840-0084-0) and a needle

bearing replacer (5-8840-2788-0) to remove the

needle bearing from the front output shaft.

P1010023

Legend

(1) Dumper Ring

(2) Internal Gear

(3) Retaining Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4854 of 6020

7D-24 TRANSFER CASE

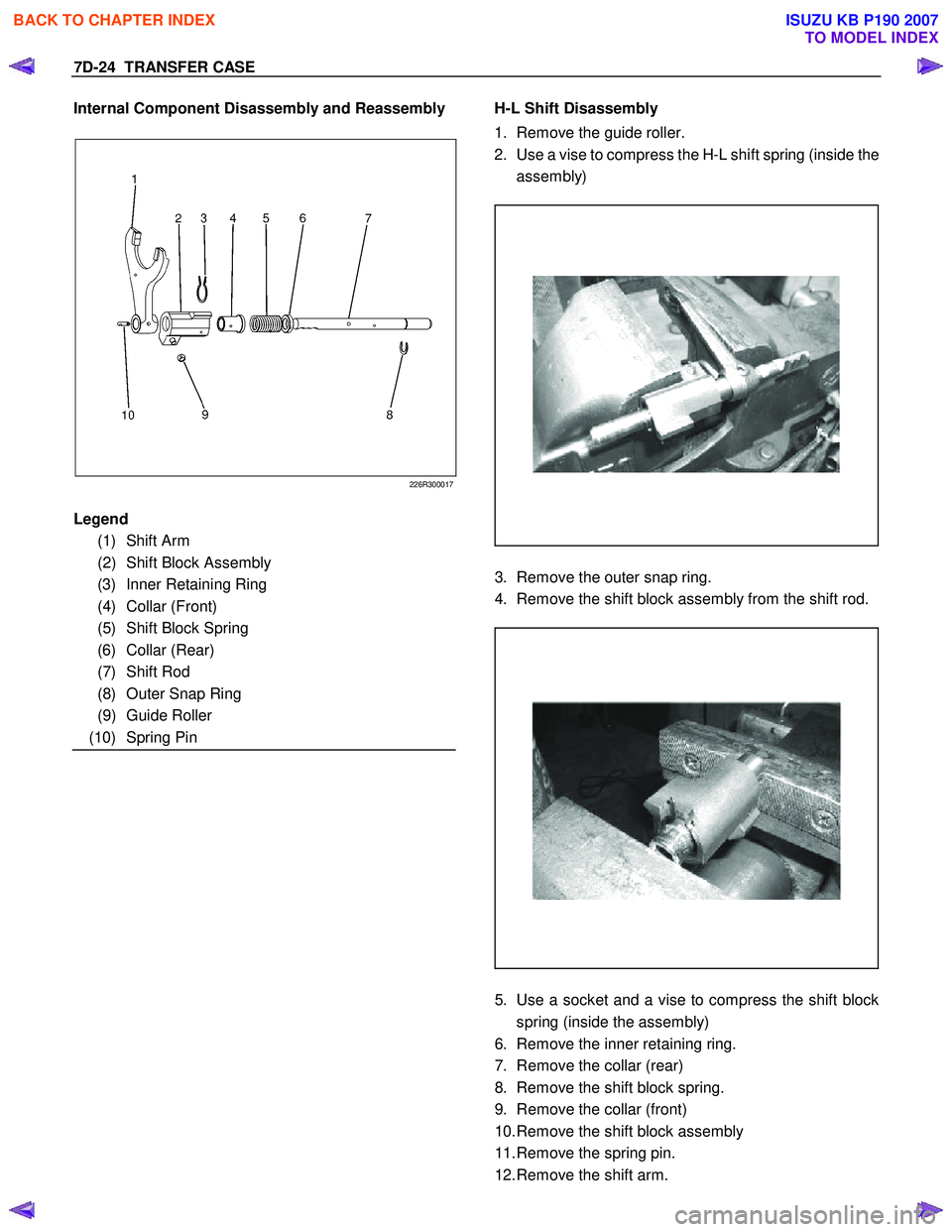

Internal Component Disassembly and Reassembly

226R300017

H-L Shift Disassembly

1. Remove the guide roller.

2. Use a vise to compress the H-L shift spring (inside the

assembly)

3. Remove the outer snap ring.

4. Remove the shift block assembly from the shift rod.

5. Use a socket and a vise to compress the shift block

spring (inside the assembly)

6. Remove the inner retaining ring.

7. Remove the collar (rear)

8. Remove the shift block spring.

9. Remove the collar (front)

10. Remove the shift block assembly

11. Remove the spring pin.

12. Remove the shift arm.

Legend

(1) Shift Arm

(2) Shift Block Assembly

(3) Inner Retaining Ring

(4) Collar (Front)

(5) Shift Block Spring

(6) Collar (Rear)

(7) Shift Rod

(8) Outer Snap Ring

(9) Guide Roller

(10) Spring Pin

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4855 of 6020

TRANSFER CASE 7D-25

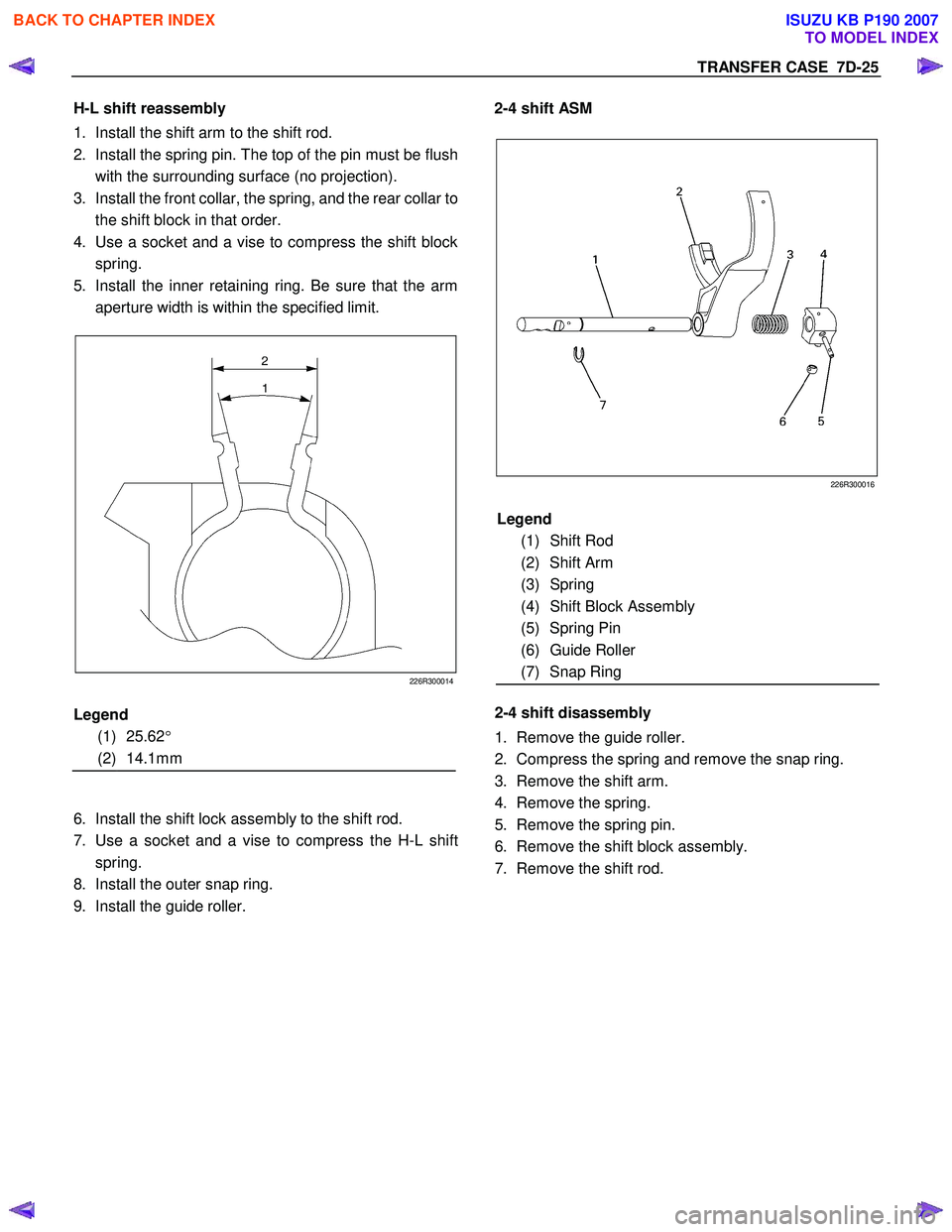

H-L shift reassembly

1. Install the shift arm to the shift rod.

2. Install the spring pin. The top of the pin must be flush

with the surrounding surface (no projection).

3. Install the front collar, the spring, and the rear collar to

the shift block in that order.

4. Use a socket and a vise to compress the shift block

spring.

5. Install the inner retaining ring. Be sure that the arm

aperture width is within the specified limit.

226R300014

6. Install the shift lock assembly to the shift rod.

7. Use a socket and a vise to compress the H-L shift

spring.

8. Install the outer snap ring.

9. Install the guide roller.

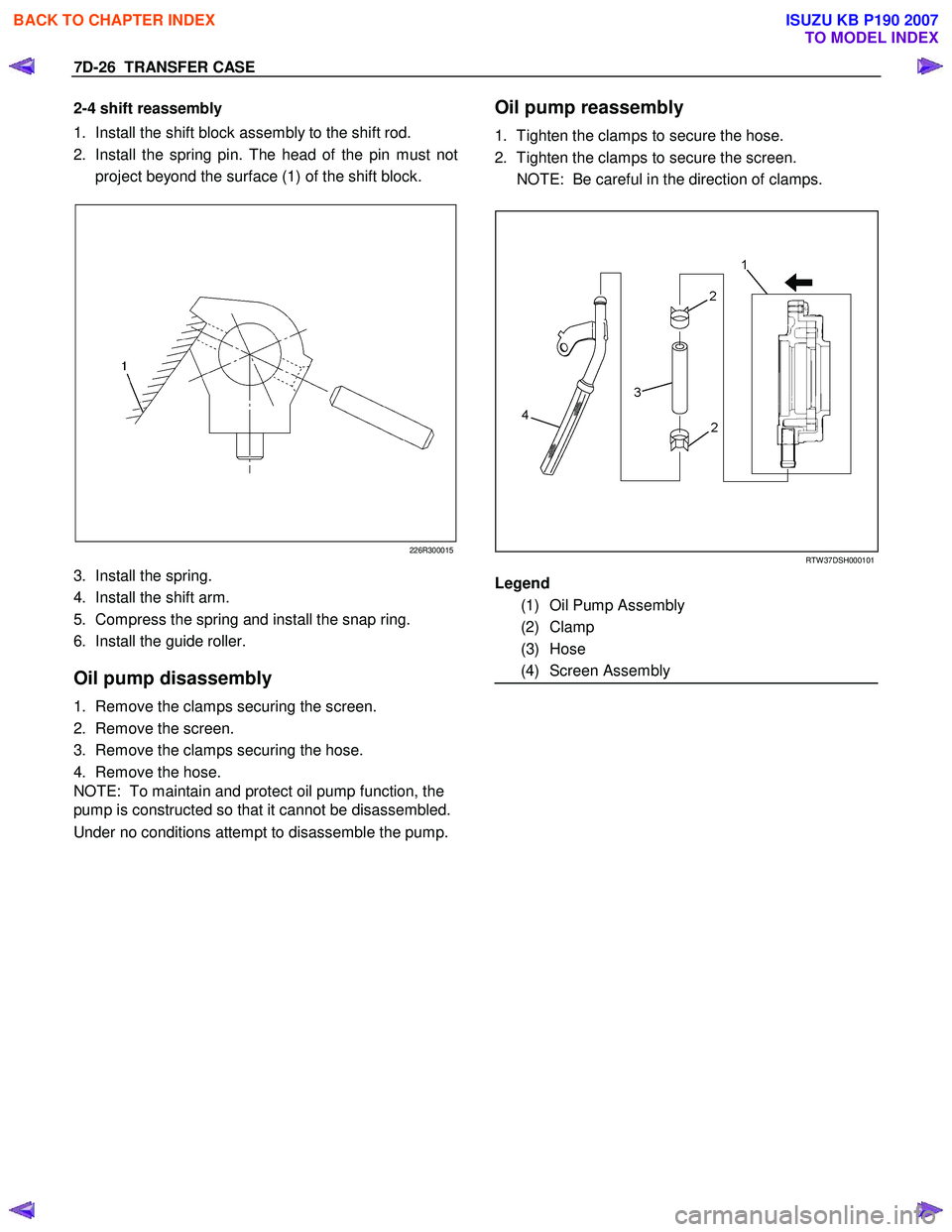

2-4 shift ASM

226R300016

2-4 shift disassembly

1. Remove the guide roller.

2. Compress the spring and remove the snap ring.

3. Remove the shift arm.

4. Remove the spring.

5. Remove the spring pin.

6. Remove the shift block assembly.

7. Remove the shift rod.

Legend

(1) 25.62 °

(2) 14.1mm Legend

(1) Shift Rod

(2) Shift Arm

(3) Spring

(4) Shift Block Assembly

(5) Spring Pin

(6) Guide Roller

(7) Snap Ring

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4856 of 6020

7D-26 TRANSFER CASE

2-4 shift reassembly

1. Install the shift block assembly to the shift rod.

2. Install the spring pin. The head of the pin must not

project beyond the surface (1) of the shift block.

226R300015

3. Install the spring.

4. Install the shift arm.

5. Compress the spring and install the snap ring.

6. Install the guide roller.

Oil pump disassembly

1. Remove the clamps securing the screen.

2. Remove the screen.

3. Remove the clamps securing the hose.

4. Remove the hose.

NOTE: To maintain and protect oil pump function, the

pump is constructed so that it cannot be disassembled.

Under no conditions attempt to disassemble the pump.

Oil pump reassembly

1. Tighten the clamps to secure the hose.

2. Tighten the clamps to secure the screen.

NOTE: Be careful in the direction of clamps.

RTW 37DSH000101

Legend

(1) Oil Pump Assembly

(2) Clamp

(3) Hose

(4) Screen Assembly

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4857 of 6020

TRANSFER CASE 7D-27

Inspection and Repair

1. Make the necessary repair or parts replacement if

wear, damage or any other abnormal conditions are

found during inspection.

2. W ash all parts thoroughly in clean solvent. Be sure all

old lubricant, metallic particles, dirt, or foreign material

are removed from the surfaces of every part. Appl

y

compressed air to each oil feed port and channel in

each case half to remove any obstructions or cleaning

solvent residue.

Inspection and Repair (Transfer Case

Assembly)

W hen wear, damage, or any other defects are observed

during the inspection, the part or parts must be repaired

or replaced. W ash all the parts with clean detergent, and

check that old oil, metallic particles, dirt, or foreign

materials are completely removed. Blow the air into oil

holes and grooves to remove foreign materials or

residual detergent.

Chain

• Check whether the face that contacts the sprocket is

free from excessive wear or damage. If defects are

observed, replace the part.

• If the chain interference mark is found on the inside

wall of the transfer cover or the chain is so slack that a

skipped engagement occurs between the chain and

sprocket, replace the chain.

Sprocket

• Check whether the sprocket tooth surface is

excessively worn or damaged, and there is evidence

of burrs, chipping, wear, or damage on the gear

spline. Remove minor flaws or scratches with oil

stone. If excessive wear or damage is observed,

replace the part.

• If excessive wear or damage is observed on the

sprocket inside sliding surface, replace the part.

Gear

• Check whether the gear tooth surface is excessively

worn or damaged, and there is evidence of burrs,

chipping, wear, or damage on the gear spline.

• Remove minor flaws or scratches with oil stone. I

f

excessive wear or damage is observed, replace the

part.

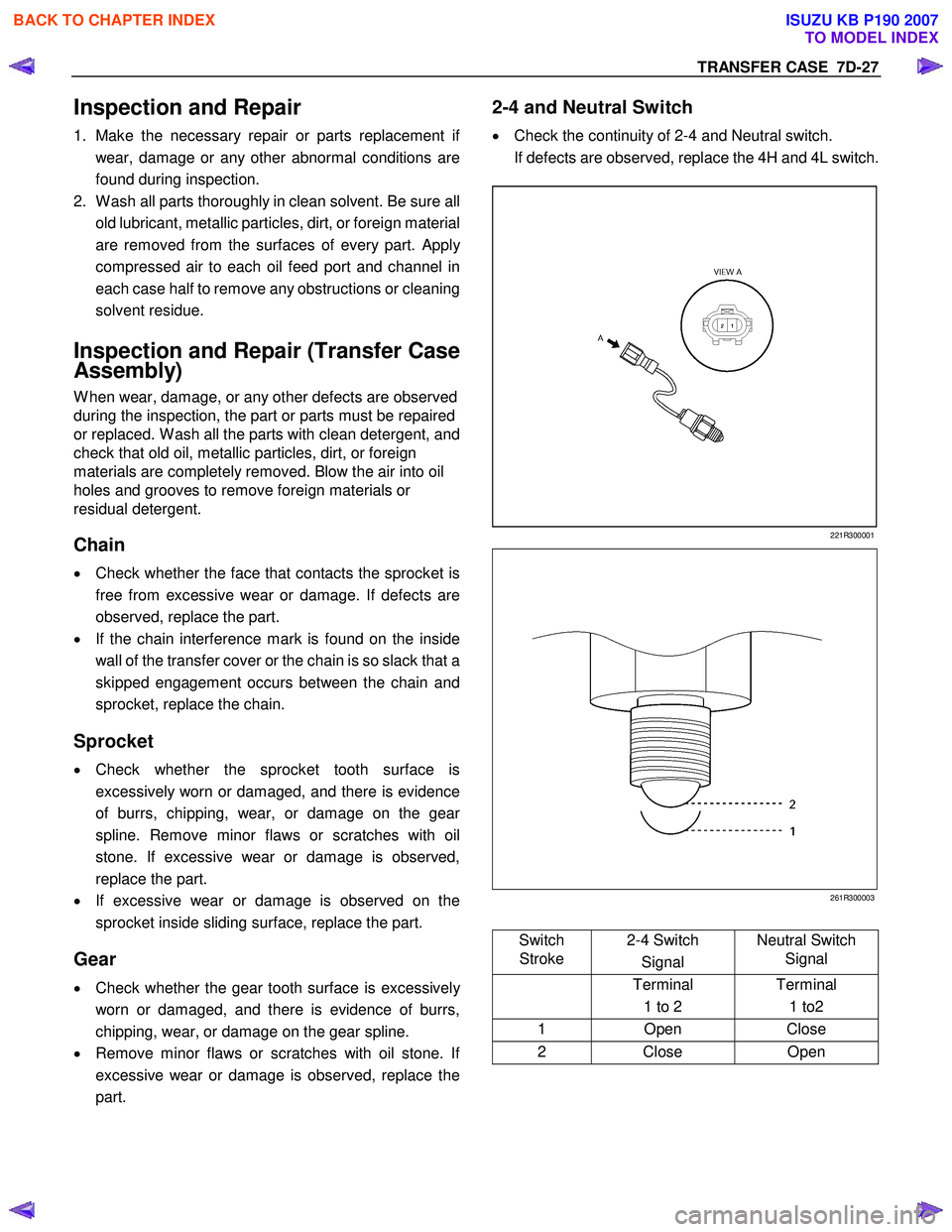

2-4 and Neutral Switch

• Check the continuity of 2-4 and Neutral switch.

If defects are observed, replace the 4H and 4L switch.

221R300001

261R300003

Switch

Stroke 2-4 Switch

Signal Neutral Switch

Signal

Terminal

1 to 2 Terminal

1 to2

1 Open Close

2 Close Open

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4858 of 6020

7D-28 TRANSFER CASE

Oil Pump

• Remove foreign materials from the strainer. If the

strainer is damaged, replace it.

If the area into which the shaft is inserted is excessively

worn or damaged, replace the oil pump assembly.

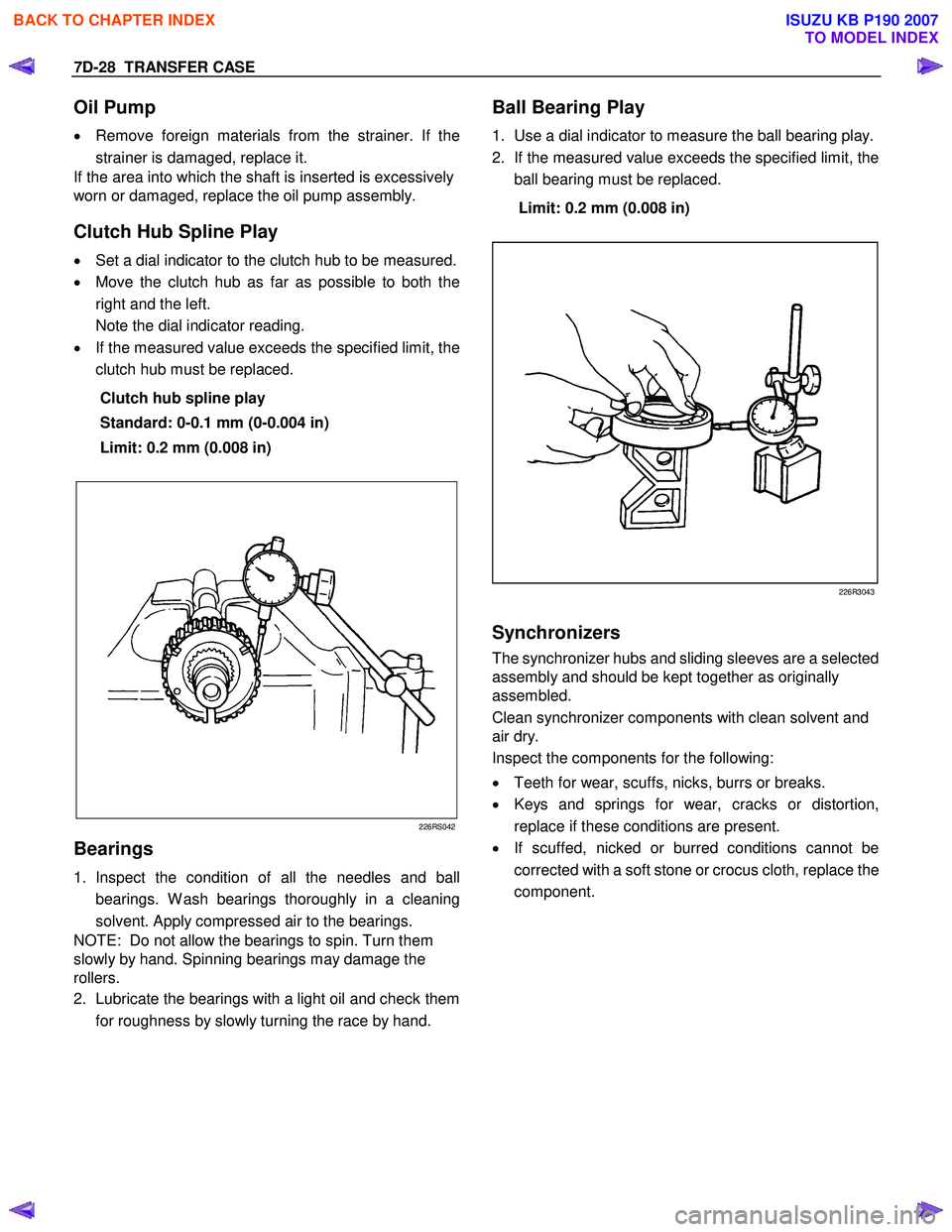

Clutch Hub Spline Play

• Set a dial indicator to the clutch hub to be measured.

• Move the clutch hub as far as possible to both the

right and the left.

Note the dial indicator reading.

• If the measured value exceeds the specified limit, the

clutch hub must be replaced.

Clutch hub spline play

Standard: 0-0.1 mm (0-0.004 in)

Limit: 0.2 mm (0.008 in)

226RS042

Bearings

1. Inspect the condition of all the needles and ball

bearings. W ash bearings thoroughly in a cleaning

solvent. Apply compressed air to the bearings.

NOTE: Do not allow the bearings to spin. Turn them

slowly by hand. Spinning bearings may damage the

rollers.

2. Lubricate the bearings with a light oil and check them

for roughness by slowly turning the race by hand.

Ball Bearing Play

1. Use a dial indicator to measure the ball bearing play.

2. If the measured value exceeds the specified limit, the

ball bearing must be replaced.

Limit: 0.2 mm (0.008 in)

226R3043

Synchronizers

The synchronizer hubs and sliding sleeves are a selected

assembly and should be kept together as originally

assembled.

Clean synchronizer components with clean solvent and

air dry.

Inspect the components for the following:

• Teeth for wear, scuffs, nicks, burrs or breaks.

• Keys and springs for wear, cracks or distortion,

replace if these conditions are present.

• If scuffed, nicked or burred conditions cannot be

corrected with a soft stone or crocus cloth, replace the

component.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4859 of 6020

TRANSFER CASE 7D-29

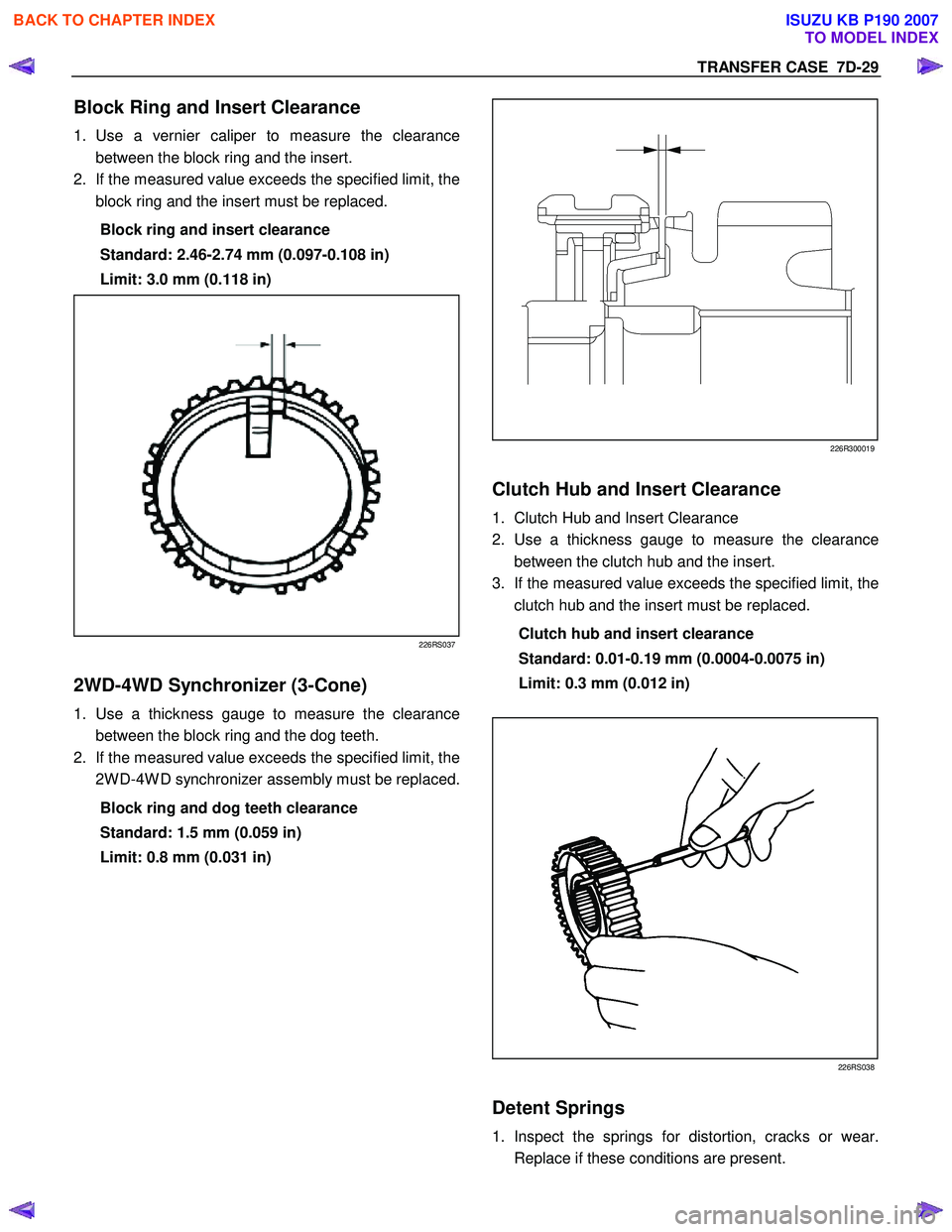

Block Ring and Insert Clearance

1. Use a vernier caliper to measure the clearance

between the block ring and the insert.

2. If the measured value exceeds the specified limit, the

block ring and the insert must be replaced.

Block ring and insert clearance

Standard: 2.46-2.74 mm (0.097-0.108 in)

Limit: 3.0 mm (0.118 in)

226RS037

2WD-4WD Synchronizer (3-Cone)

1. Use a thickness gauge to measure the clearance

between the block ring and the dog teeth.

2. If the measured value exceeds the specified limit, the

2W D-4W D synchronizer assembly must be replaced.

Block ring and dog teeth clearance

Standard: 1.5 mm (0.059 in)

Limit: 0.8 mm (0.031 in)

226R300019

Clutch Hub and Insert Clearance

1. Clutch Hub and Insert Clearance

2. Use a thickness gauge to measure the clearance

between the clutch hub and the insert.

3. If the measured value exceeds the specified limit, the

clutch hub and the insert must be replaced.

Clutch hub and insert clearance

Standard: 0.01-0.19 mm (0.0004-0.0075 in)

Limit: 0.3 mm (0.012 in)

226RS038

Detent Springs

1. Inspect the springs for distortion, cracks or wear.

Replace if these conditions are present.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 4860 of 6020

7D-30 TRANSFER CASE

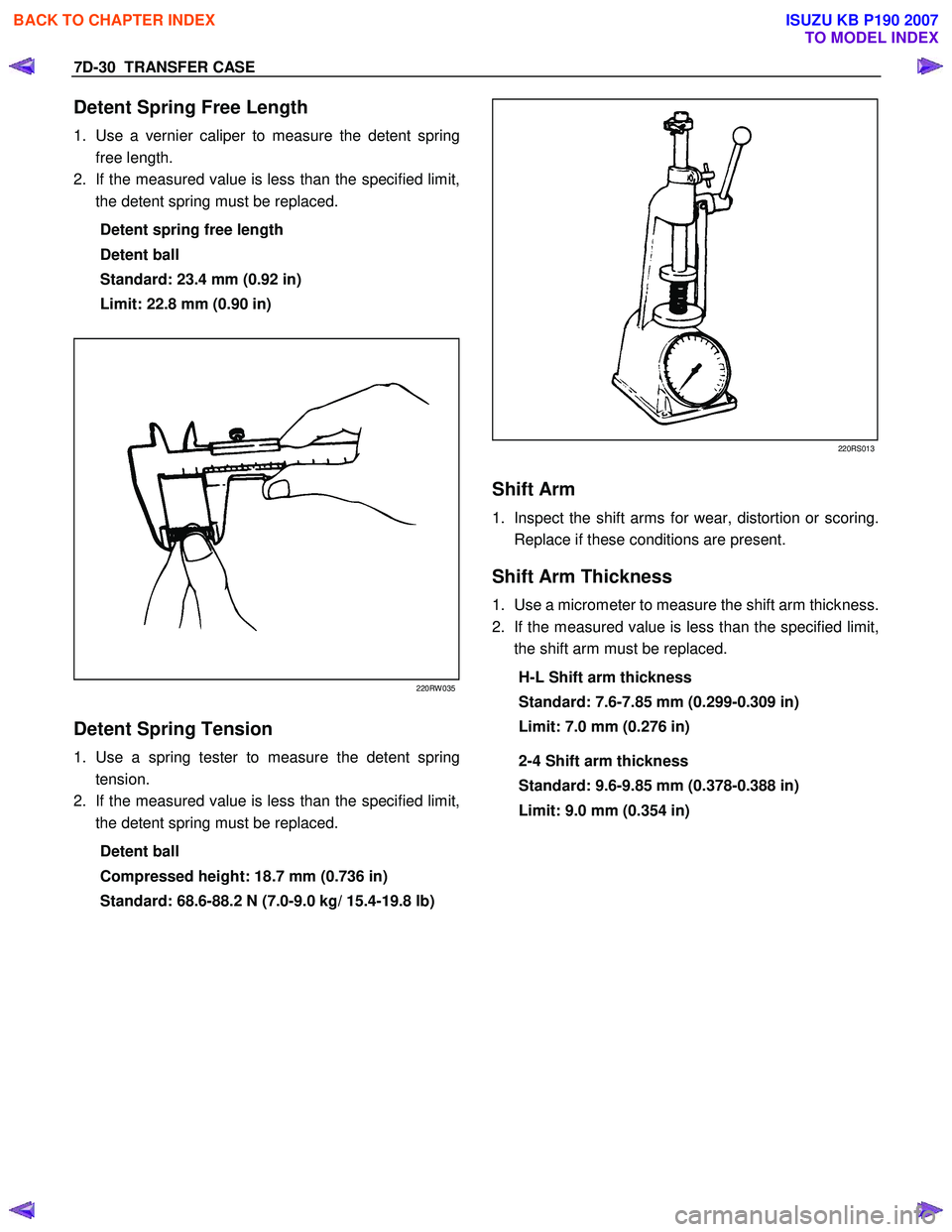

Detent Spring Free Length

1. Use a vernier caliper to measure the detent spring

free length.

2. If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent spring free length

Detent ball

Standard: 23.4 mm (0.92 in)

Limit: 22.8 mm (0.90 in)

220RW 035

Detent Spring Tension

1. Use a spring tester to measure the detent spring

tension.

2. If the measured value is less than the specified limit,

the detent spring must be replaced.

Detent ball

Compressed height: 18.7 mm (0.736 in)

Standard: 68.6-88.2 N (7.0-9.0 kg/ 15.4-19.8 lb)

220RS013

Shift Arm

1. Inspect the shift arms for wear, distortion or scoring.

Replace if these conditions are present.

Shift Arm Thickness

1. Use a micrometer to measure the shift arm thickness.

2. If the measured value is less than the specified limit,

the shift arm must be replaced.

H-L Shift arm thickness

Standard: 7.6-7.85 mm (0.299-0.309 in)

Limit: 7.0 mm (0.276 in)

2-4 Shift arm thickness

Standard: 9.6-9.85 mm (0.378-0.388 in)

Limit: 9.0 mm (0.354 in)

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007