ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 5211 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-273

TROUBLESHOOTING

WINDSHIELD WIPER

1. Wiper dose not operate at any switch position

Checkpoint Trouble Cause Countermeasure

Reinstall or replace the fuse

No. C9 (20A)

Poor fuse contact or blown

NG

Repair open circuit or

connector contact

1. W iper motor function when

connecting the motor

connector 3

C4 to the

battery (+) terminal, and 1

C4 to the (-) terminal

(Should the wiper motor

rotate at a low speed)

2. W iper motor function when connecting the motor

connector 2

C4 to the

battery (+) terminal, 1

C4 to the (-) terminal

(Should the wiper motor

rotate at a high speed)

Voltage between 3 B59 and

the ground (Should be battery

v oltage present)

Open circuit or poor connector

contact

Replace the wiper & washer

SW .

Continuity in the wiper &

washer SW .

SW . malfunction

NG

NG

OK

OK

Fuse No. C9 (20A)

Repair grounding point

contact

Grounding point

C2 (LHD),

C

C36 (RHD)

Poor grounding point contact

NG

OK

OK

Replace the wiper motor

W iper motor malfunction

NG

Repair open circuit or

connector contact

Continuity between 1

C4

and

C36 (RHD), C2 (LHD)

Open circuit or poor connector

contact

NG

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5212 of 6020

8A-274 ELECTRICAL-BODY AND CHASSIS

2. Wiper dose not operate at “ INT “ position

Checkpoint Trouble Cause Countermeasure

Replace the wiper & washer

SW .

SW . malfunction

NG

Repair grounding point contact

Grounding point

C36 (RHD),

C2 (LHD)

Poor grounding point contact

Repair open circuit or

connector contact

Voltage between the

intermittent relay harness side

connector terminal 4

C3

and the ground at the “INT”

position (Should be battery

voltage present)

Open circuit or poor connector

contact

NG

NG

OK

OK

Continuity between the wiper

& washer SW connector

terminals 4

B59 and 2 B59

at the “ INT “ position

Replace the intermittent relay

Intermittent relay function

Relay malfunction

NG

OK

3. Wiper does not operate at “LO” position

Replace the wiper motor

W iper motor function

1. Disconnect the wiper & washer SW . connector

2. Turn the starter SW . on

3. Short-circuit between the wiper & washer SW .

harness side connector terminal 3

B59 and

5

B59 .

4. Check to see if the wiper

motor rotates at a low

speed

W iper motor malfunction

NG

Replace the wiper & washer

SW .

W iper & washer SW . function

SW . malfunction

NG

OK

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5213 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-275

4. Wiper does not operate at “HI” position

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

Replace the wiper motor

W iper motor function when

connecting the motor

connector 2

C4 to the

battery (+) terminal, and 1

C4 to the (-) terminal

(Should the wiper motor rotate

at a high speed)

W iper motor malfunction

NG

OK

Continuity between the wiper

& washer SW . connector

terminals 4

B59 at the “HI”

position

Repair open circuit or

connector contact

Continuity between 4

B59

and 2

C4

Open circuit or poor connector

contact

NG

OK

5. Rotation of the wiper motor does not stop

Replace the wiper & washer

SW .

SW . malfunction

NG

OK

Continuity in the wiper &

washer SW .

Replace the wiper motor

W iper motor function

W iper motor malfunction

NG

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5214 of 6020

8A-276 ELECTRICAL-BODY AND CHASSIS

6. Auto-stop function of the wiper motor does not operate

Checkpoint Trouble Cause Countermeasure

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG Continuity between the

intermittent relay harness side

connector 6

C3 and the

wiper motor harness side

connector 6

C4

Replace the intermittent relay

Relay malfunction

NG

Intermittent relay function

W iper motor function

1. Disconnect the wiper motor connector

2. Connect the motor connector 5

B59 to the

battery (+) terminal and

1

C4 to the (-) terminal,

and then change the

connection of the battery (+)

terminal to the connector

4

C4 while the motor

rotating at a low speed

3. Check to see if the wiper motor stops at the auto stop

position when connecting

the connector terminals

3

C4 and 1 C4 in this

condition

Continuity between the wiper

& washer SW . connector

terminals 5

B59 and 6 B59

at the “OFF” position

OK

Replace the wiper motor

W iper motor malfunction

NG

Repair an open circuit or a

poor connection of the

connectors between the fuse

No. C9 (20A) and 4

C4

Voltage between the wiper

motor harness side connector

terminal 4

C4 and the

ground (Should be battery

v oltage present)

Open circuit or poor connector

contact

NG

OK

OK

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5215 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-277

WASHER

1. Washer motor does not operate

Checkpoint Trouble Cause Countermeasure

Reinstall or replace the fuse

No. C9 (20A)

Poor fuse contact or blown

NG

Repair or an open circuit or a

poor connection of the

connectors between 2

C17

and 1

B59

Open circuit or poor connector

contact

NG Voltage between the washer

motor harness side connector

terminal 2

C17 and the

ground when the washer

button is depressed (Should

be battery v oltage present)

Repair grounding point

C36

contact

Poor grounding point contact

NG

Grounding point

C36

Replace the washer motor

Motor malfunction

NG

W asher motor function when

connecting the motor side

connector 2

C17 to the

battery (+) terminal, and the

connector 1

C17 to the (-)

terminal (Should the washer

motor rotate) OK

Repair open circuit or

connector contact

Open circuit or poor connector

contact

NG

Continuity between 1

C17

and

C36

OK

Continuity between the wiper

& washer SW . side connector

terminals 1

B59 and 7 B59

when the washer button is

depressed

Fuse No. C9 (20A)

OK

Replace the wiper & washer

SW .

SW . malfunction

NG

Repair or an open circuit or a

poor connection of the

connectors between the fuse

No. C-9 (20A) and 7

B59

Voltage between the wiper &

washer SW . harness side

connector terminal 7

B59

and the ground (Should be

battery v oltage preset)

Open circuit or poor connector

contact

NG

OK

OK

OK

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007

Page 5216 of 6020

8A-278 ELECTRICAL-BODY AND CHASSIS

REMOVAL AND INSTALLATION

WIPER AND WASHER SWITCH

Removal

Refer to the removal steps of the LIGHTING SW ITCH

(COMBINATION SW ITCH) in “ LIGHTING “ of this section.

Installation

Follow the removal procedure in the reverse order to install the

wiper and washer switch.

RTW 780SH001601

This illustration is based on RHD model

Pay close attention to the important points mentioned in the

following paragraphs.

Connector

Be absolutely sure that the wiper and washer switch connector

is securely connected.

This will prevent a poor contact and an open circuit.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5217 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-279

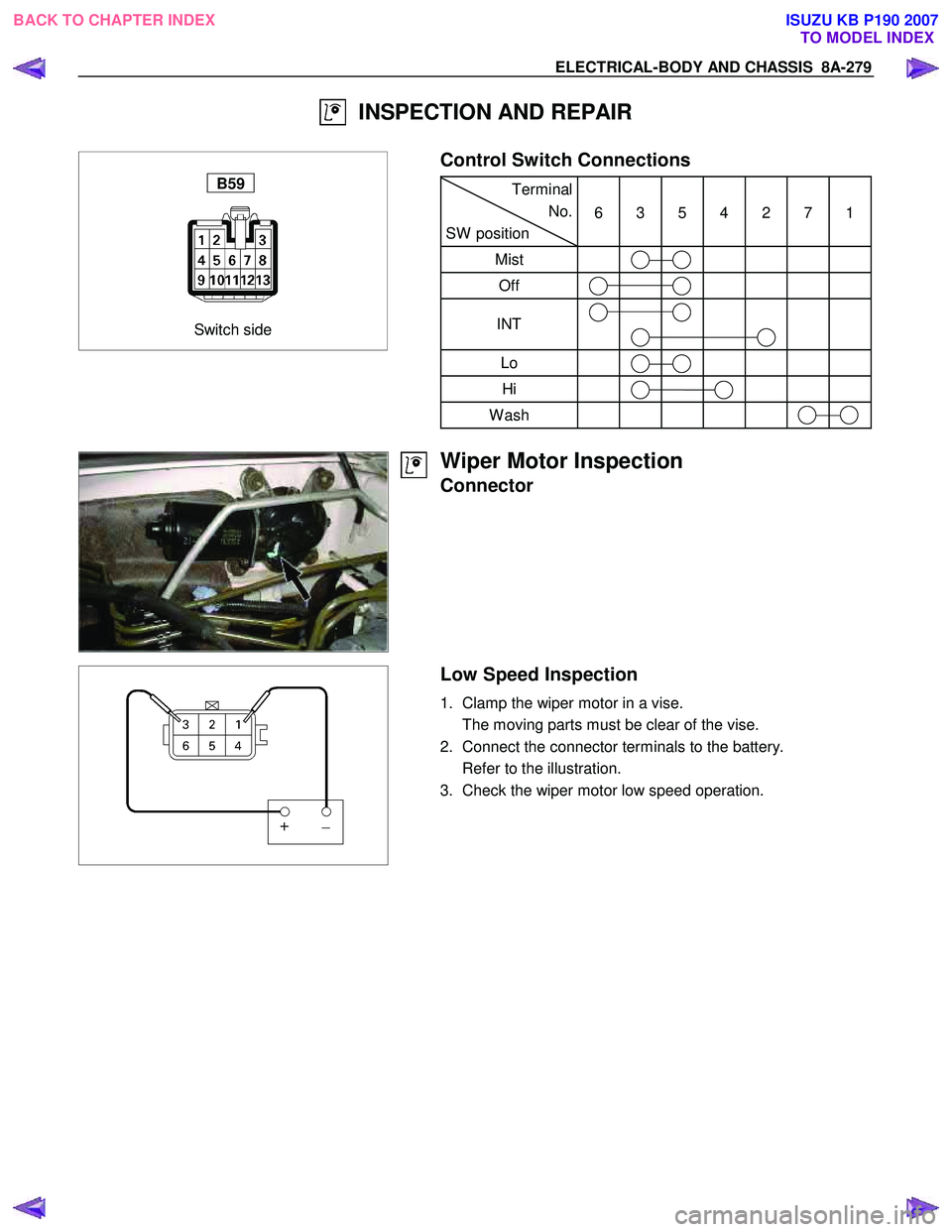

INSPECTION AND REPAIR

Switch side

B59

Control Switch Connections

Terminal

No.

SW position 6 3 5 4 2 7 1

Mist

Off

INT

Lo

Hi

Wash

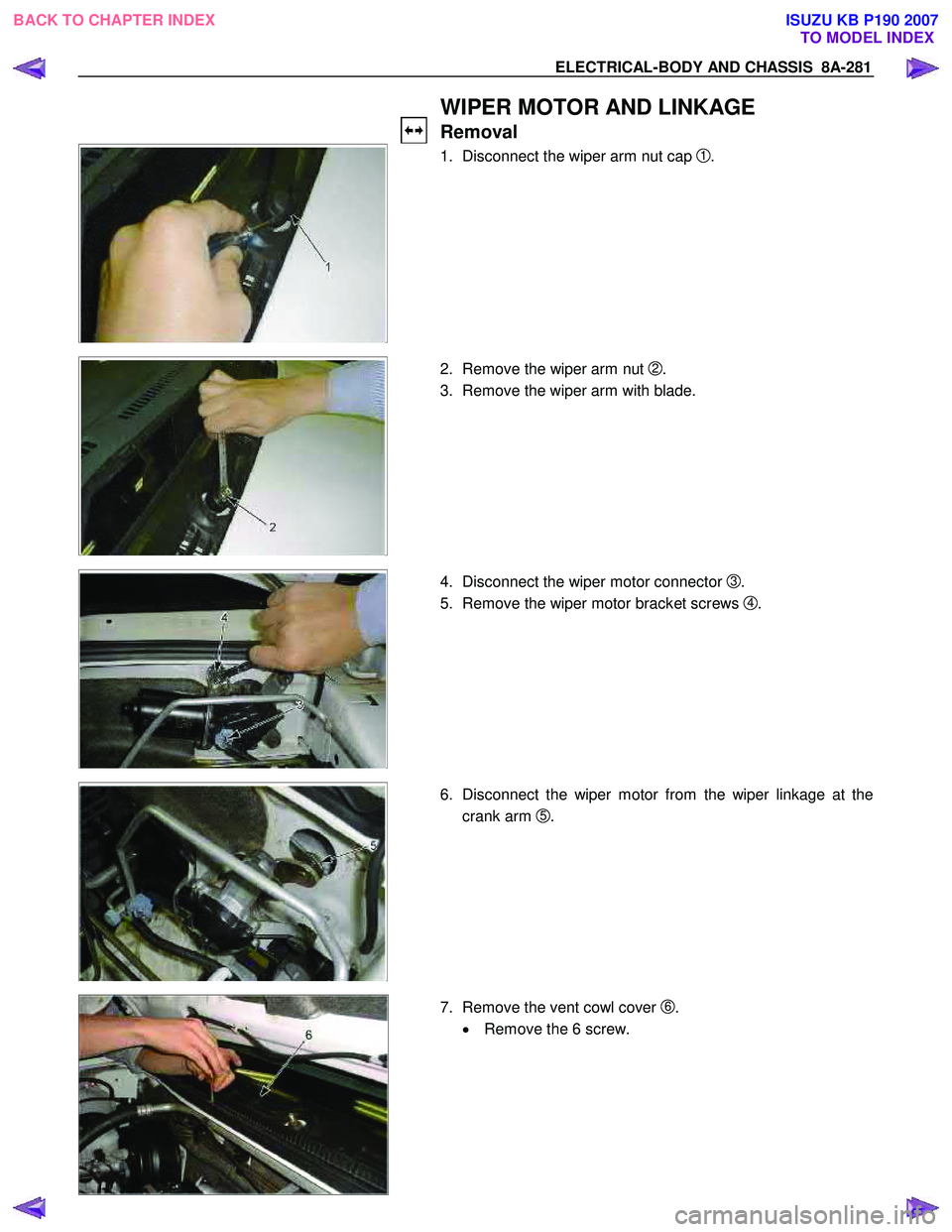

Wiper Motor Inspection

Connector

Low Speed Inspection

1. Clamp the wiper motor in a vise.

The moving parts must be clear of the vise.

2. Connect the connector terminals to the battery.

Refer to the illustration.

3. Check the wiper motor low speed operation.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5218 of 6020

8A-280 ELECTRICAL-BODY AND CHASSIS

High Speed Inspection

1. Clamp the wiper motor in a vise.

The moving parts must be clear of the vise.

2. Connect the connector terminals to the battery.

Refer to the illustration.

3. Check the wiper motor high speed operation.

Auto-Stop Inspection

1. Clamp the wiper motor in a vise.

The moving parts must be clear of the vise.

2. Connect the connector terminals to the battery.

Refer to the illustration.

3. Check the wiper motor low speed operation.

4. Disconnect the positive battery terminal.

This will stop the motor.

5. Connect the connector terminals No. 3 and No. 6 with a

lead wire.

Refer to the illustration.

6. Reconnect the positive battery terminal to connecto

r

terminal No. 4.

This will restart the motor.

Refer to the illustration.

7. Check the auto-stop operation.

Washer Motor Inspection

1. Fill the washer tank with washing solution.

2. Disconnect the motor connector.

3. Apply battery voltage to the washer motor connector.

4. Check the washer motor operation.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5219 of 6020

ELECTRICAL-BODY AND CHASSIS 8A-281

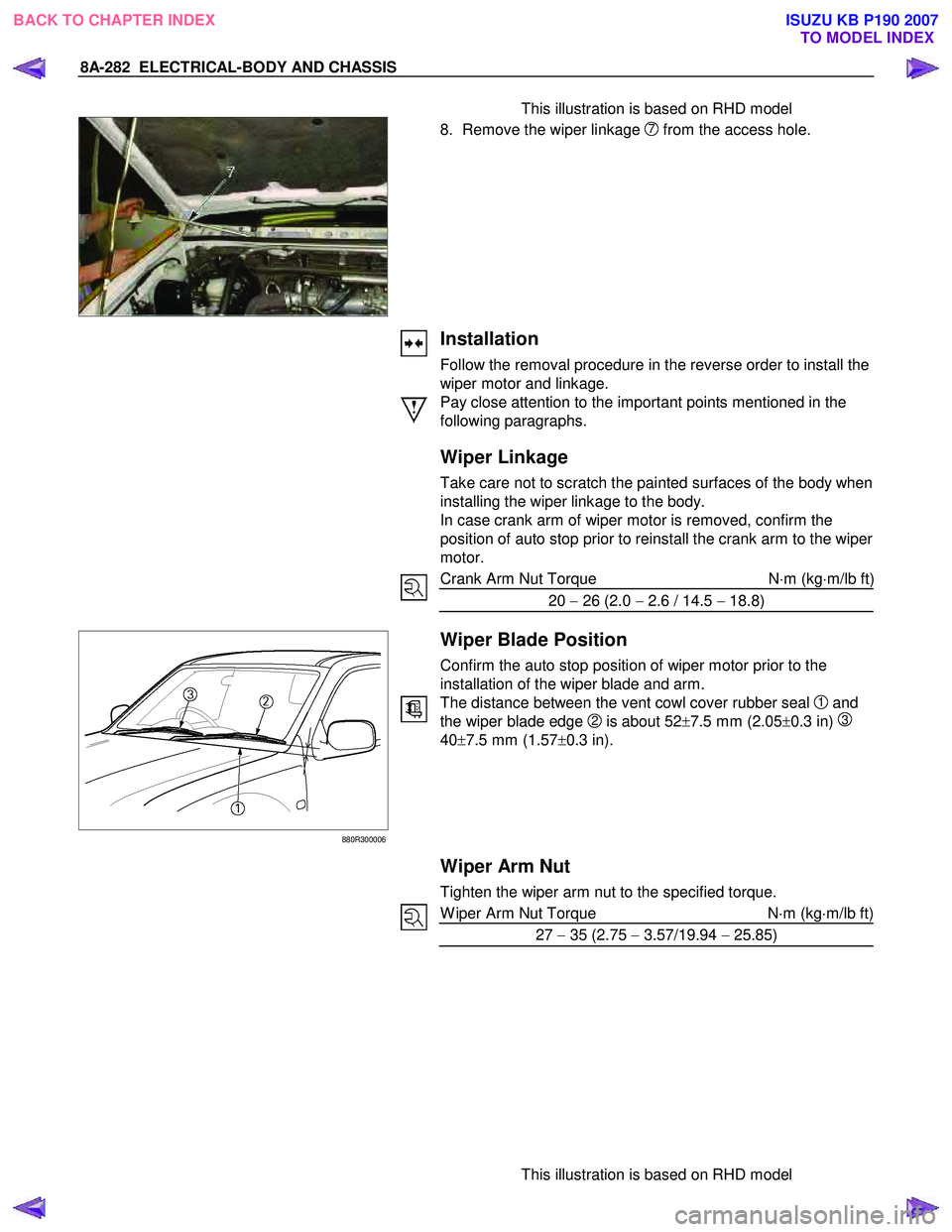

WIPER MOTOR AND LINKAGE

Removal

1. Disconnect the wiper arm nut cap

1 .

2. Remove the wiper arm nut

2.

3. Remove the wiper arm with blade.

4. Disconnect the wiper motor connector 3 .

5. Remove the wiper motor bracket screws

4 .

6. Disconnect the wiper motor from the wiper linkage at the

crank arm

5.

7. Remove the vent cowl cover

6.

• Remove the 6 screw.

BACK TO CHAPTER INDEX TO MODEL INDEXISUZU KB P190 2007

Page 5220 of 6020

8A-282 ELECTRICAL-BODY AND CHASSIS

This illustration is based on RHD model

8. Remove the wiper linkage

7 from the access hole.

Installation

Follow the removal procedure in the reverse order to install the

wiper motor and linkage.

Pay close attention to the important points mentioned in the

following paragraphs.

Wiper Linkage

Take care not to scratch the painted surfaces of the body when

installing the wiper linkage to the body.

In case crank arm of wiper motor is removed, confirm the

position of auto stop prior to reinstall the crank arm to the wiper

motor.

Crank Arm Nut Torque N⋅m (kg ⋅m/lb ft

)

20 − 26 (2.0 − 2.6 / 14.5 − 18.8)

880R300006

Wiper Blade Position

Confirm the auto stop position of wiper motor prior to the

installation of the wiper blade and arm.

The distance between the vent cowl cover rubber seal

1 and

the wiper blade edge

2 is about 52±7.5 mm (2.05 ±0.3 in) 3

40 ±7.5 mm (1.57 ±0.3 in).

Wiper Arm Nut

Tighten the wiper arm nut to the specified torque.

W iper Arm Nut Torque N ⋅m (kg ⋅m/lb ft)

27 − 35 (2.75 − 3.57/19.94 − 25.85)

This illustration is based on RHD model

BACK TO CHAPTER INDEX

TO MODEL INDEXISUZU KB P190 2007