LAND ROVER DISCOVERY 2002 Workshop Manual

Manufacturer: LAND ROVER, Model Year: 2002, Model line: DISCOVERY, Model: LAND ROVER DISCOVERY 2002Pages: 1672, PDF Size: 46.1 MB

Page 391 of 1672

EMISSION CONTROL - V8

17-2-54 REPAIRS

Pump - Fuel Leak Detection - up to 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from fuel leak detection

pump.

3.Release leak detection air filter hose from top of

pump.

4.Remove 3 Torx screws securing pump to

mounting bracket.

5.Remove clip securing EVAP canister hose to

pump.

6.Release EVAP canister hose from pump.

7.Remove pump.

Refit

1.Connect EVAP canister hose to pump and

secure with clip.

2.Position pump to mounting bracket and secure

with Torx screws.

3.Connect leak detection air filter hose to top of

leak detection pump.

4.Connect multiplug to pump.

5.Lower vehicle.

Pump - fuel leak detection - from 03MY

$% 17.45.41

Remove

1.Raise the vehicle on lift.

2.Disconnect multiplug from the fuel leak

detection pump.

3.Remove 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

4.Position absorbent cloth around fuel hoses to

collect any fuel spillage.

5.Disconnect the fuel leak detection filter pipe

from the fuel leak detection pump.

CAUTION: Always fit plugs to open

connections to prevent contamination.

6.Remove and discard clip securing EVAP pipe

to the fuel leak detection pump and disconnect

the pipe.

7.Remove the fuel leak detection pump.

Refit

1.Connect the EVAP pipe to the fuel leak

detection pump and secure with a new clip.

2.Connect the fuel leak detection filter pipe to the

fuel leak detection pump.

3.Remove absorbent cloth.

4.Fit and tighten 3 screws securing the fuel leak

detection pump to the chassis mounting

bracket.

5.Connect multiplug to the fuel leak detection

pump.

6.Lower the vehicle lift.

M17 0235

2

3

4

57

Page 392 of 1672

EMISSION CONTROL - V8

REPAIRS 17-2-55

Filter - fuel leak detection pump - up to

03MY

$% 17.45.42

Remove

1.Remove bolt securing air filter to mounting

bracket and collect nut.

2.Remove clip securing hose to air filter.

3.Release hose from air filter.

4.Remove air filter.

Refit

1.Connect hose to air filter and secure with clip.

2.Position air filter to mounting bracket and

secure with nut and bolt.

Filter - fuel leak detection pump - from

03MY

$% 17.45.42

Remove

1.Remove Allen bolt securing fuel leak detection

pump filter to the mounting bracket.

2.Remove and discard clip securing fuel pipe to

the fuel leak detection pump filter and

disconnect the pipe.

CAUTION: Always fit plugs to open

connections to prevent contamination.

3.Remove the fuel leak detection pump filter.

Refit

1.Connect fuel pipe to the fuel leak detection

pump and secure with a new clip.

2.Position fuel leak detection pump filter to

mounting bracket, fit Allen bolt and tighten to 3

Nm (2.2 lbf.ft).

17M 0224

Page 393 of 1672

EMISSION CONTROL - V8

17-2-56 REPAIRS

Page 394 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-1

Deze pagina werd opzettelijk niet gebruikt

Cette page est intentionnellement vierge

Questa pagina è stata lasciata in bianco di proposito Diese Seite ist leer

Esta página foi deixada intencionalmente em branco

Esta página fue dejada en blanco intencionalmente This page is intentionally left blank

ENGIN E MANAGEMENT SY STEM - Td5 DESCRIPTION AND OPERAT ION

Page 395 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-2 DESCRIPTION AND OPERATION

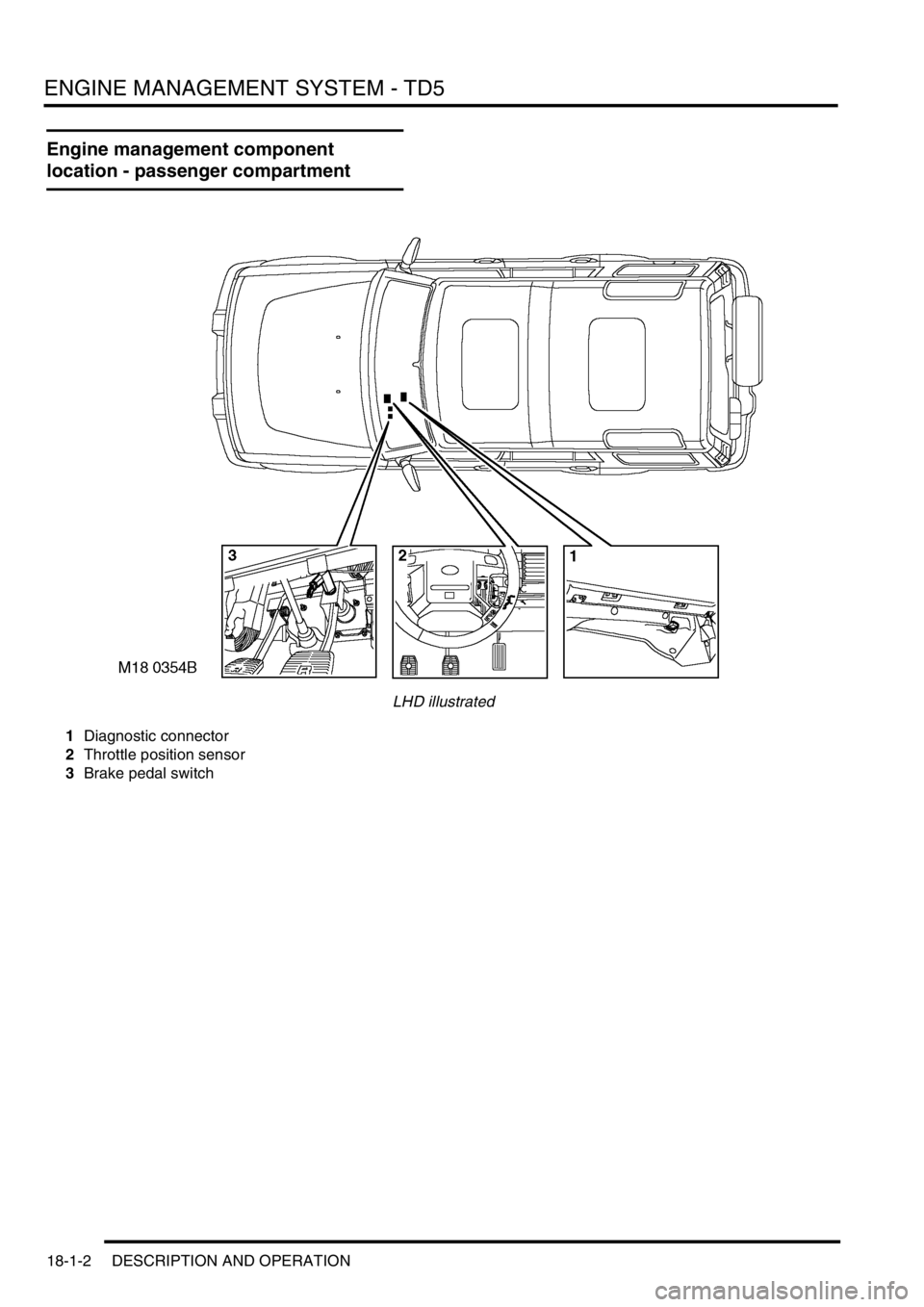

Engine management component

location - passenger compartment

LHD illustrated

1Diagnostic connector

2Throttle position sensor

3Brake pedal switch

Page 396 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-3

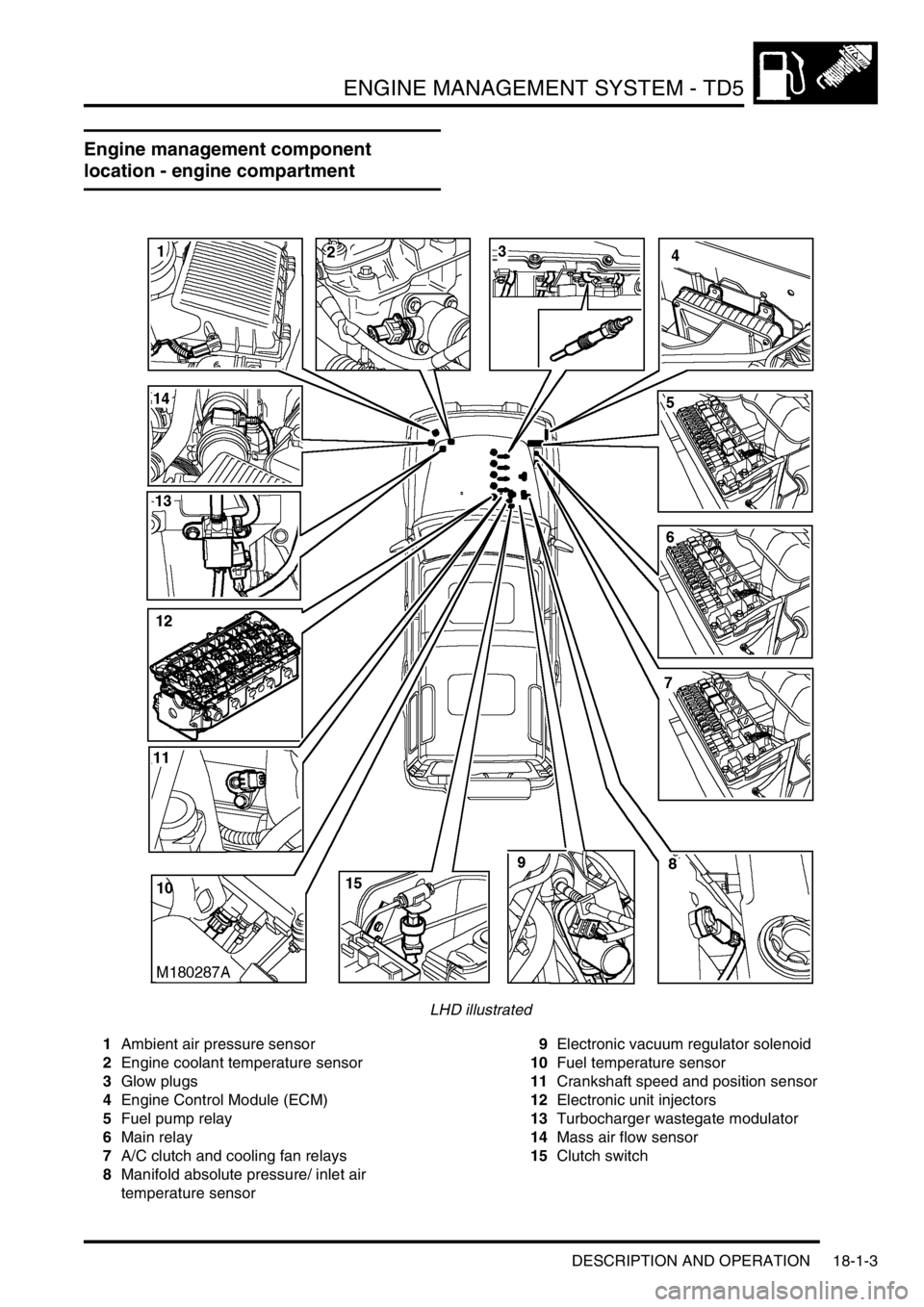

Engine management component

location - engine compartment

LHD illustrated

1Ambient air pressure sensor

2Engine coolant temperature sensor

3Glow plugs

4Engine Control Module (ECM)

5Fuel pump relay

6Main relay

7A/C clutch and cooling fan relays

8Manifold absolute pressure/ inlet air

temperature sensor9Electronic vacuum regulator solenoid

10Fuel temperature sensor

11Crankshaft speed and position sensor

12Electronic unit injectors

13Turbocharger wastegate modulator

14Mass air flow sensor

15Clutch switch

Page 397 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-4 DESCRIPTION AND OPERATION

Engine management block diagram

Page 398 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-5

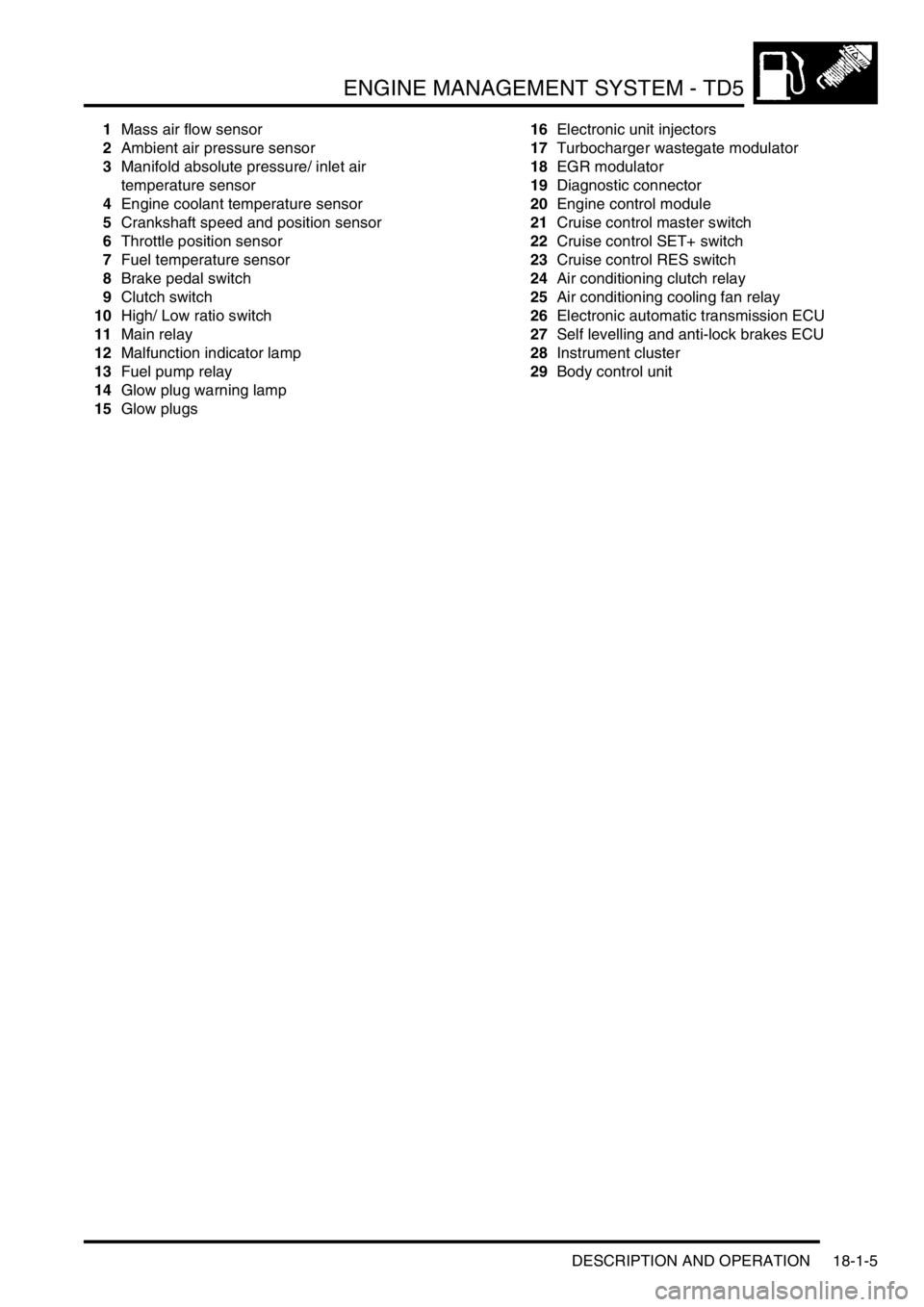

1Mass air flow sensor

2Ambient air pressure sensor

3Manifold absolute pressure/ inlet air

temperature sensor

4Engine coolant temperature sensor

5Crankshaft speed and position sensor

6Throttle position sensor

7Fuel temperature sensor

8Brake pedal switch

9Clutch switch

10High/ Low ratio switch

11Main relay

12Malfunction indicator lamp

13Fuel pump relay

14Glow plug warning lamp

15Glow plugs16Electronic unit injectors

17Turbocharger wastegate modulator

18EGR modulator

19Diagnostic connector

20Engine control module

21Cruise control master switch

22Cruise control SET+ switch

23Cruise control RES switch

24Air conditioning clutch relay

25Air conditioning cooling fan relay

26Electronic automatic transmission ECU

27Self levelling and anti-lock brakes ECU

28Instrument cluster

29Body control unit

Page 399 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

18-1-6 DESCRIPTION AND OPERATION

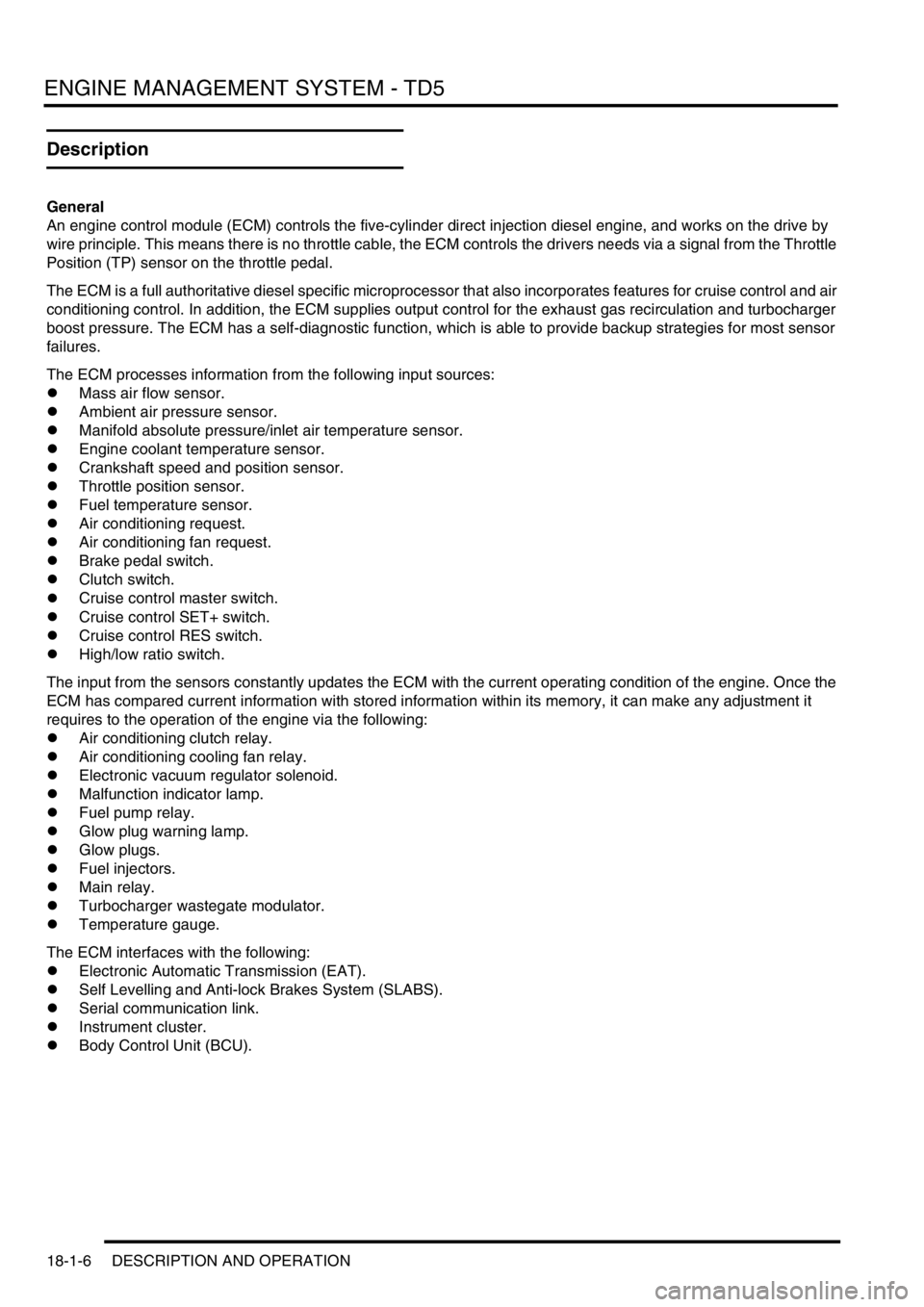

Description

General

An engine control module (ECM) controls the five-cylinder direct injection diesel engine, and works on the drive by

wire principle. This means there is no throttle cable, the ECM controls the drivers needs via a signal from the Throttle

Position (TP) sensor on the throttle pedal.

The ECM is a full authoritative diesel specific microprocessor that also incorporates features for cruise control and air

conditioning control. In addition, the ECM supplies output control for the exhaust gas recirculation and turbocharger

boost pressure. The ECM has a self-diagnostic function, which is able to provide backup strategies for most sensor

failures.

The ECM processes information from the following input sources:

lMass air flow sensor.

lAmbient air pressure sensor.

lManifold absolute pressure/inlet air temperature sensor.

lEngine coolant temperature sensor.

lCrankshaft speed and position sensor.

lThrottle position sensor.

lFuel temperature sensor.

lAir conditioning request.

lAir conditioning fan request.

lBrake pedal switch.

lClutch switch.

lCruise control master switch.

lCruise control SET+ switch.

lCruise control RES switch.

lHigh/low ratio switch.

The input from the sensors constantly updates the ECM with the current operating condition of the engine. Once the

ECM has compared current information with stored information within its memory, it can make any adjustment it

requires to the operation of the engine via the following:

lAir conditioning clutch relay.

lAir conditioning cooling fan relay.

lElectronic vacuum regulator solenoid.

lMalfunction indicator lamp.

lFuel pump relay.

lGlow plug warning lamp.

lGlow plugs.

lFuel injectors.

lMain relay.

lTurbocharger wastegate modulator.

lTemperature gauge.

The ECM interfaces with the following:

lElectronic Automatic Transmission (EAT).

lSelf Levelling and Anti-lock Brakes System (SLABS).

lSerial communication link.

lInstrument cluster.

lBody Control Unit (BCU).

Page 400 of 1672

ENGINE MANAGEMENT SYSTEM - TD5

DESCRIPTION AND OPERATION 18-1-7

Engine Control Module (ECM)

The ECM is made from aluminium alloy and is located in the engine compartment on the RH side inner wing. The

ECM has an interface of 72 pins via two connectors providing both input information and output control. The ECM

receives information from the sensors to inform it of the current state of the engine. The ECM then refers this

information to stored values in its memory and makes any changes to the operation of the engine as necessary via

the actuators. This is a rolling process and is called adaptive strategy. By using this adaptive strategy the ECM is

able to control the engine to give optimum driveability throughout all operating conditions. There is no ECM self test,

although the ECM saves driveability data from the last journey. Power down of the ECM can take between 10 seconds

and 10 minutes dependent on coolant temperature.