LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: CD changer, wheel size, warning lights, Sp1, catalytic converter, service interval, window

Page 3691 of 4500

Fig. 407: Exploded View Of Cylinder Block Assy Components

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

OVERHAUL

HINT:

Page 3692 of 4500

Thoroughly clean all parts to be assembled.

Before installing the parts, apply new engine oil to all sliding and rotating surfaces.

Replace all gaskets, O-rings and oil seals with new parts.

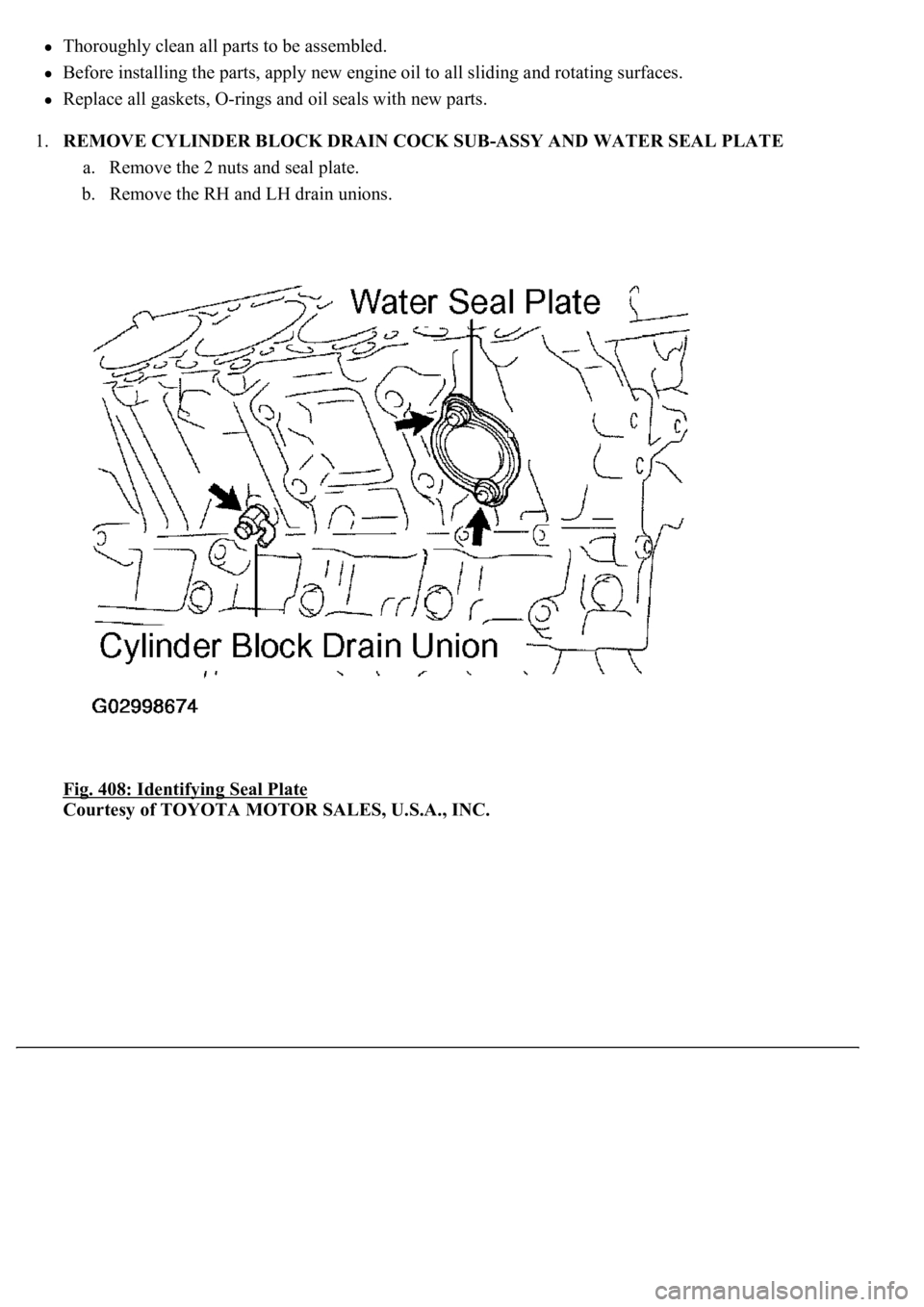

1.REMOVE CYLINDER BLOCK DRAIN COCK SUB-ASSY AND WATER SEAL PLATE

a. Remove the 2 nuts and seal plate.

b. Remove the RH and LH drain unions.

Fig. 408: Identifying Seal Plate

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3693 of 4500

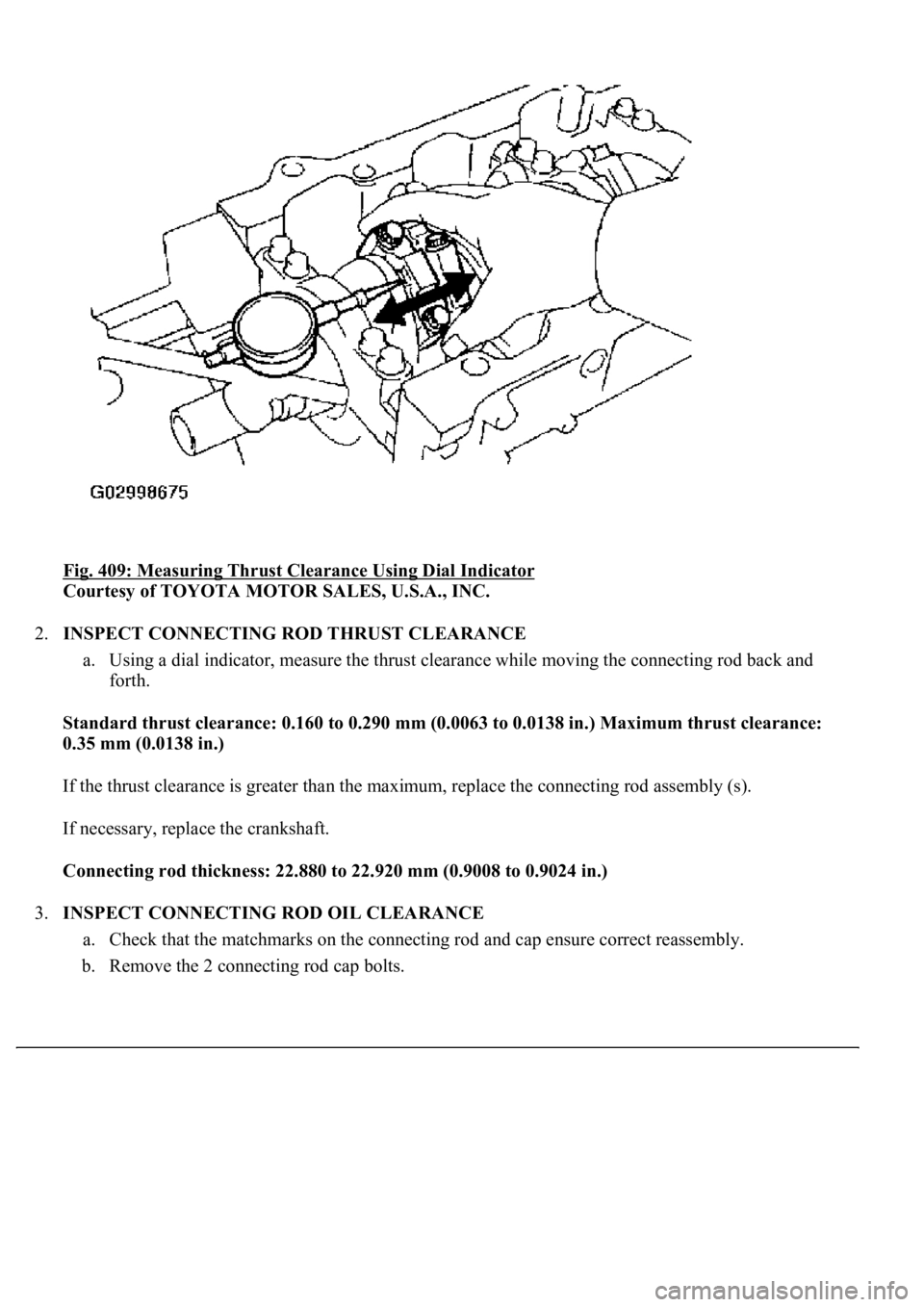

Fig. 409: Measuring Thrust Clearance Using Dial Indicator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2.INSPECT CONNECTING ROD THRUST CLEARANCE

a. Using a dial indicator, measure the thrust clearance while moving the connecting rod back and

forth.

<0036005700440051004700440055004700030057004b005500580056005700030046004f0048004400550044005100460048001d0003001300110014001900130003005700520003001300110015001c00130003005000500003000b001300110013001300

190016000300570052000300130011001300140016001b0003[in.) Maximum thrust clearance:

0.35 mm (0.0138 in.)

If the thrust clearance is greater than the maximum, replace the connecting rod assembly (s).

If necessary, replace the crankshaft.

Connecting rod thickness: 22.880 to 22.920 mm (0.9008 to 0.9024 in.)

3.INSPECT CONNECTING ROD OIL CLEARANCE

a. Check that the matchmarks on the connecting rod and cap ensure correct reassembly.

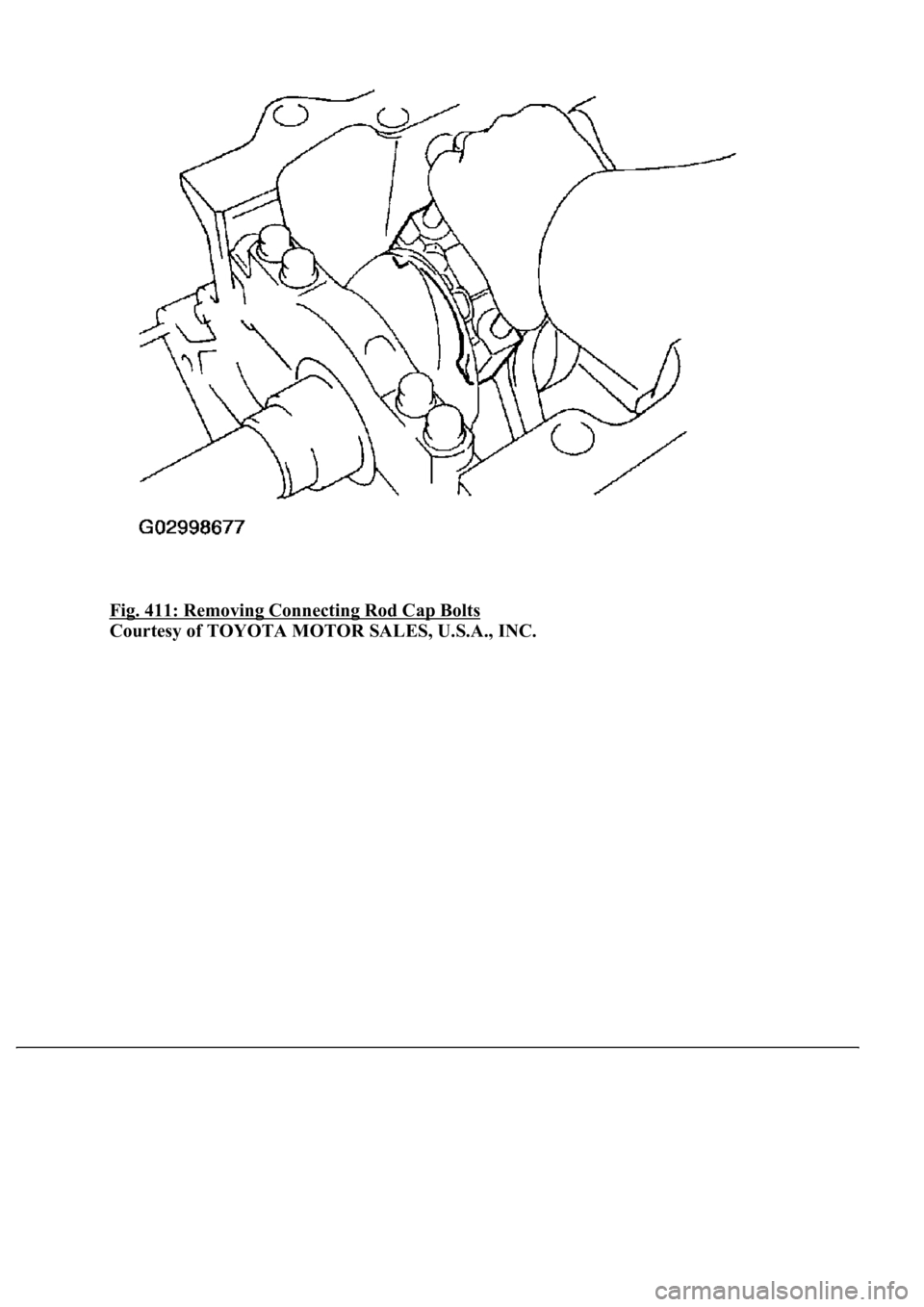

b. Remove the 2 connecting rod cap bolts.

Page 3694 of 4500

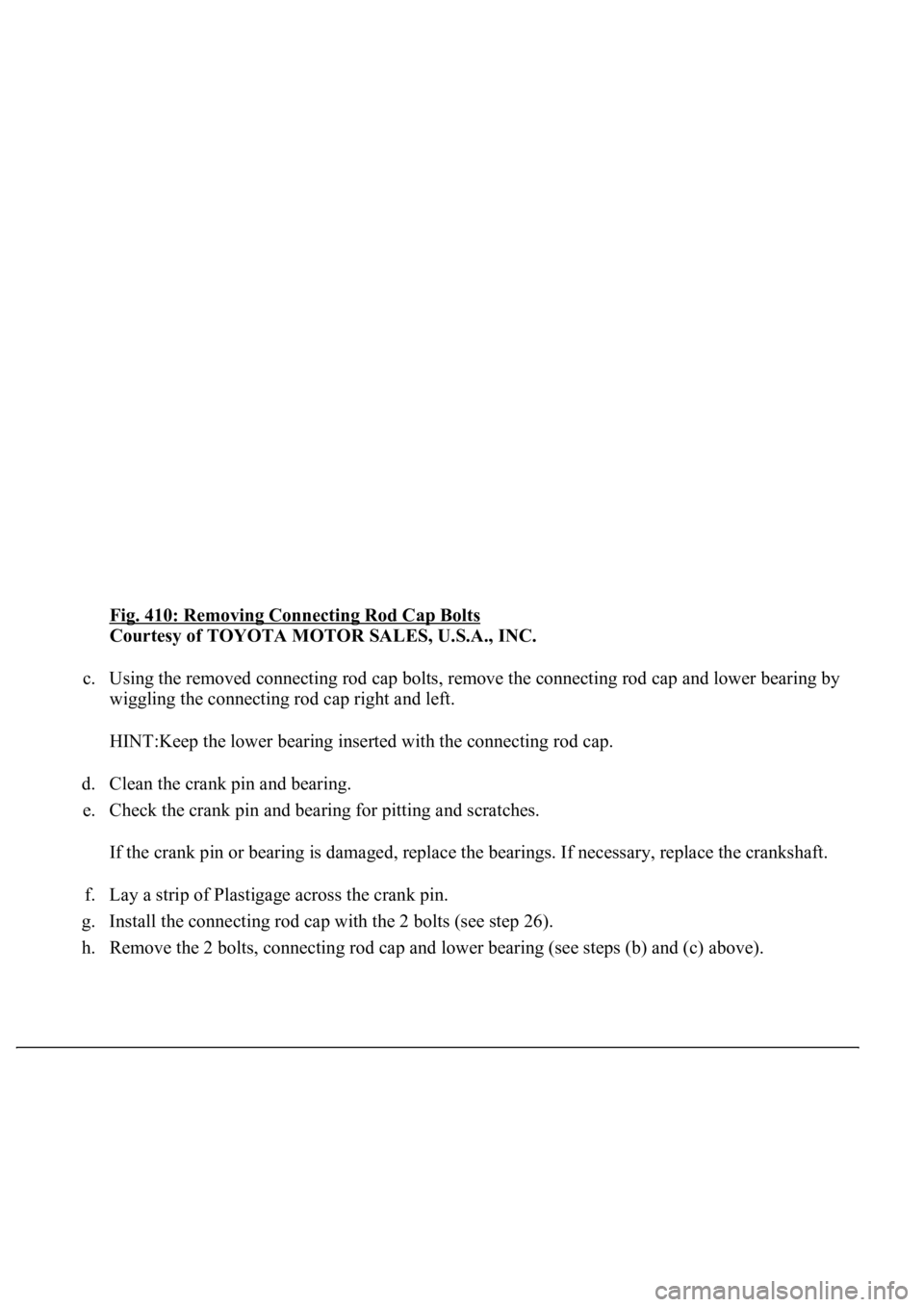

Fig. 410: Removing Connecting Rod Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

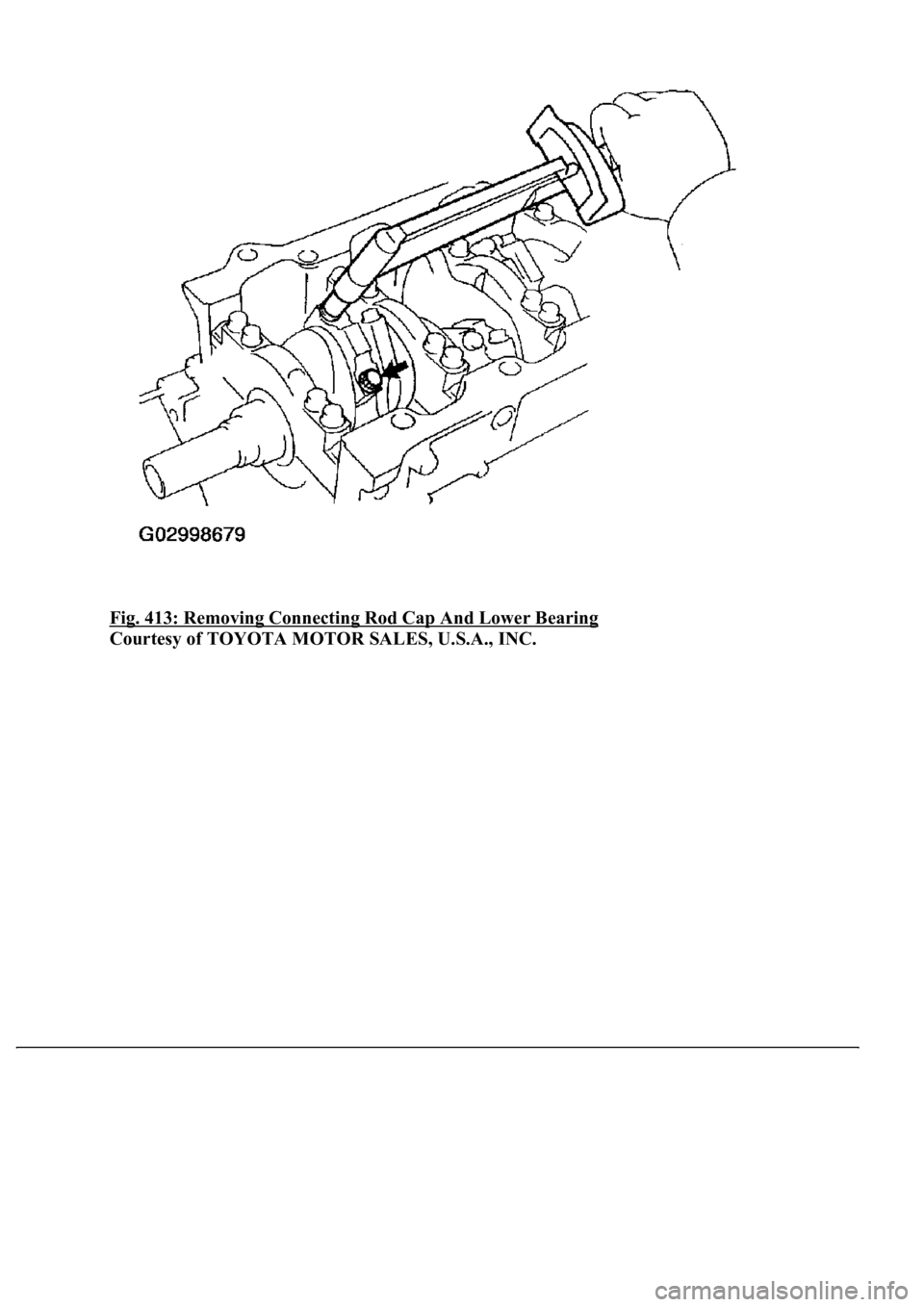

c. Using the removed connecting rod cap bolts, remove the connecting rod cap and lower bearing by

wiggling the connecting rod cap right and left.

HINT:Keep the lower bearing inserted with the connecting rod cap.

d. Clean the crank pin and bearing.

e. Check the crank pin and bearing for pitting and scratches.

If the crank pin or bearing is damaged, replace the bearings. If necessary, replace the crankshaft.

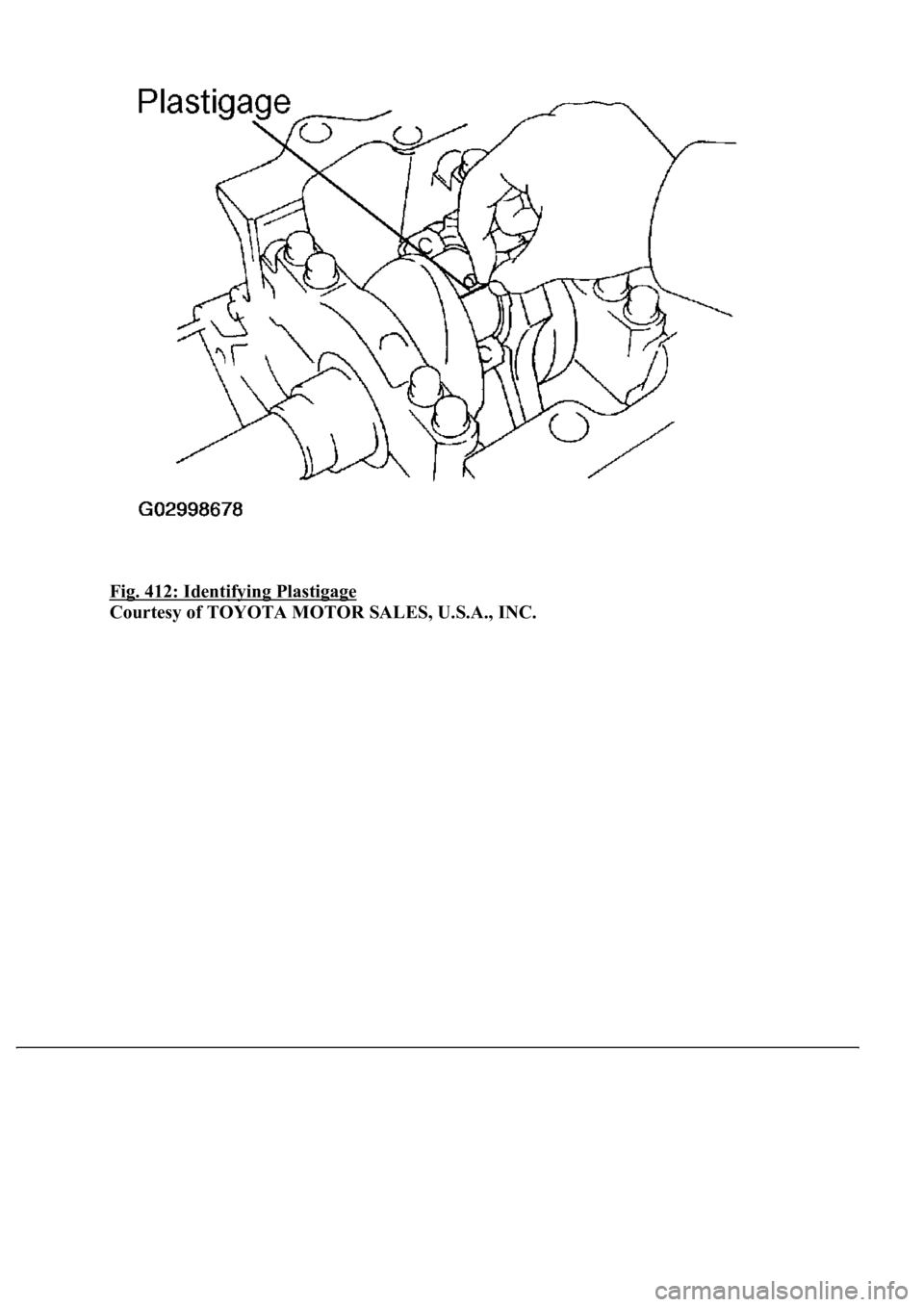

f. Lay a strip of Plastigage across the crank pin.

g. Install the connecting rod cap with the 2 bolts (see step 26).

h. Remove the 2 bolts, connectin

g rod cap and lower bearing (see steps (b) and (c) above).

Page 3695 of 4500

Fig. 411: Removing Connecting Rod Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3696 of 4500

Fig. 412: Identifying Plastigage

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3697 of 4500

Fig. 413: Removing Connecting Rod Cap And Lower Bearing

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3698 of 4500

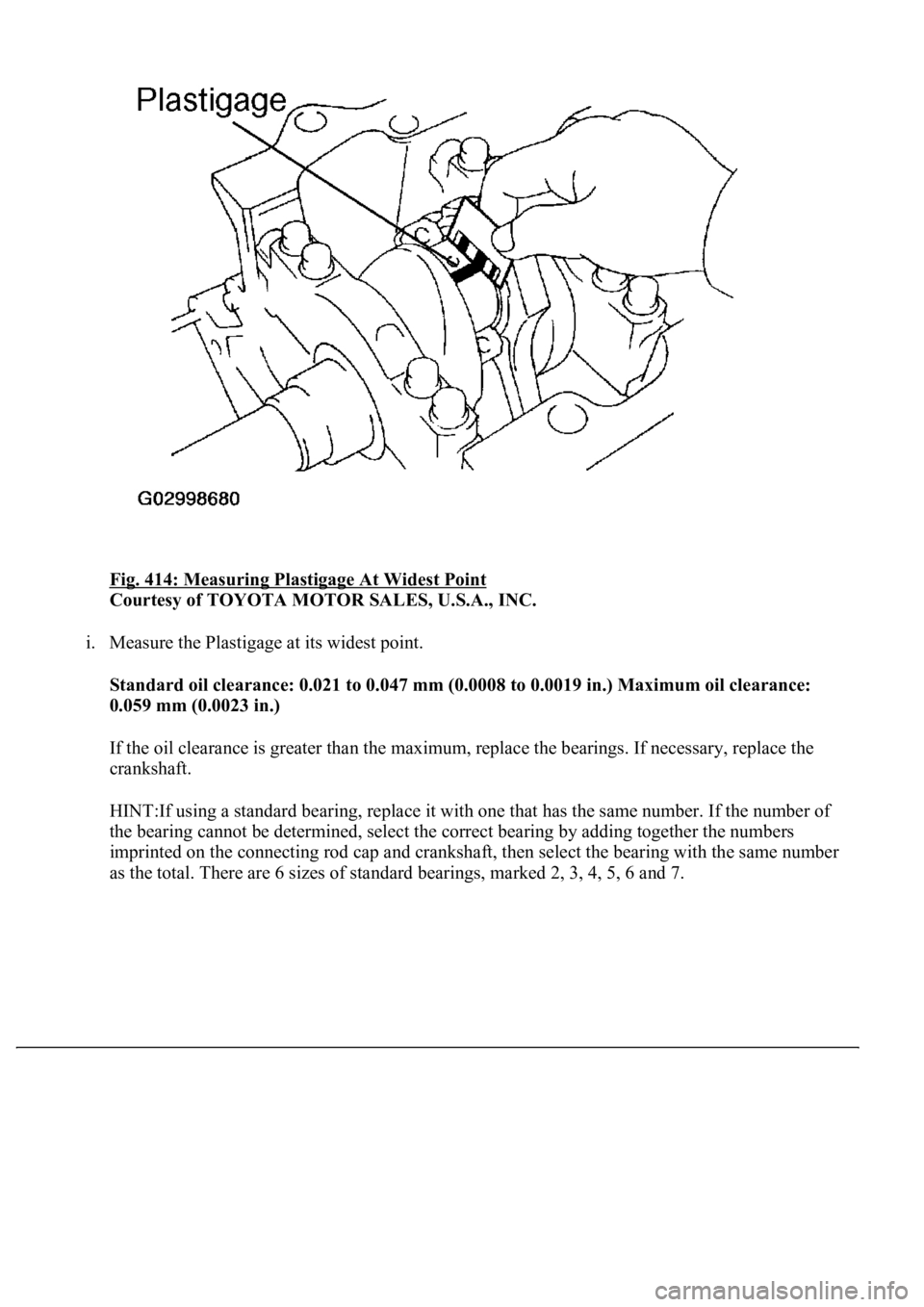

Fig. 414: Measuring Plastigage At Widest Point

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

i. Measure the Plastigage at its widest point.

Standard oil clearance: 0.021 to 0.047 mm (0.0008 to 0.0019 in.) Maximum oil clearance:

0.059 mm (0.0023 in.)

If the oil clearance is greater than the maximum, replace the bearings. If necessary, replace the

crankshaft.

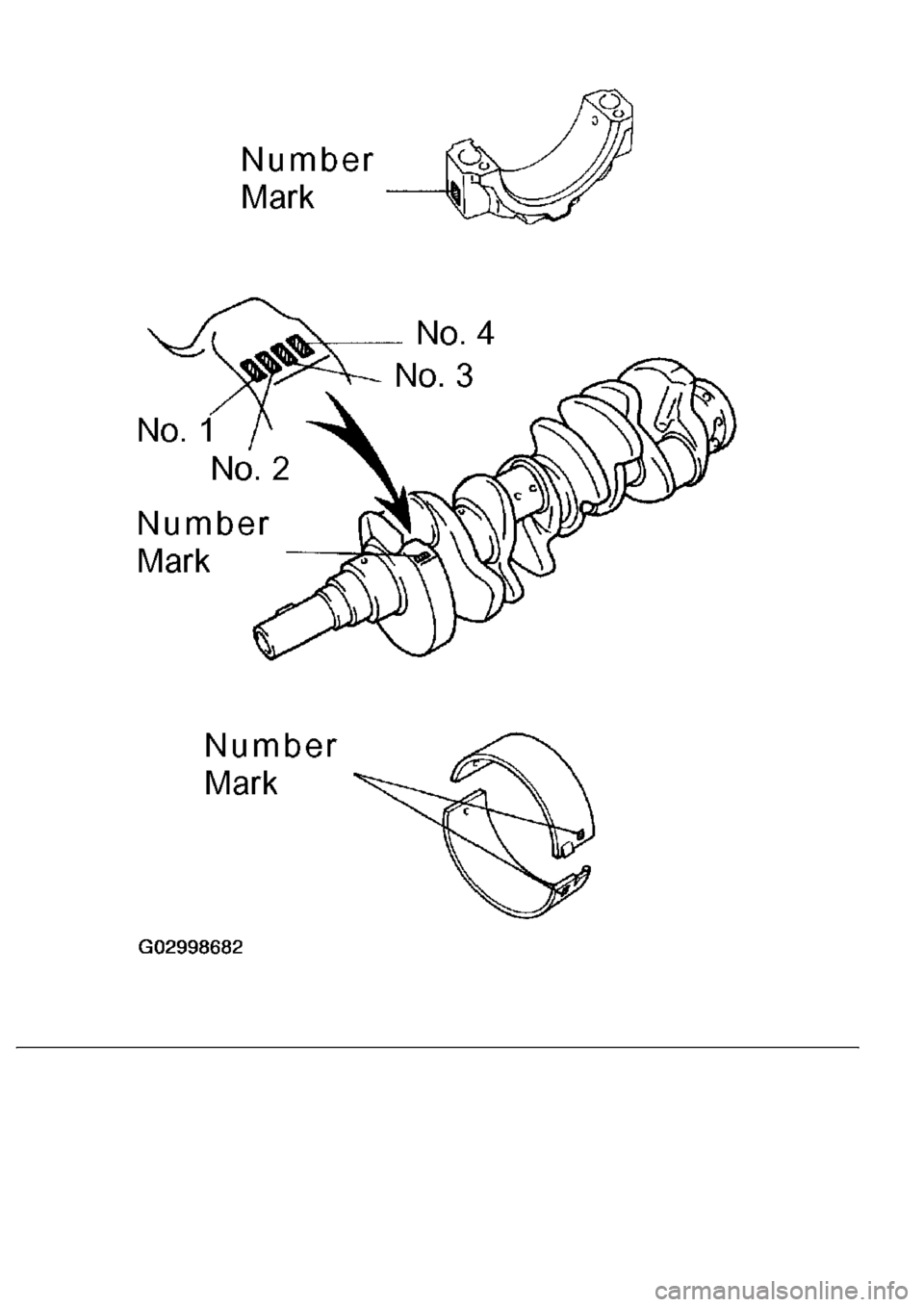

HINT:If using a standard bearing, replace it with one that has the same number. If the number of

the bearing cannot be determined, select the correct bearing by adding together the numbers

imprinted on the connecting rod cap and crankshaft, then select the bearing with the same number

as the total. There are 6 sizes of standard bearin

gs, marked 2, 3, 4, 5, 6 and 7.

Page 3699 of 4500

Fig. 415: Crankshaft Bearing Number Mark Table

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3700 of 4500

Trending: AC Expansion Valve, display, seats, alternator, rear view mirror, spare tire, Suspension control