LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: alternator, high beam, spare tire, replacement, tire type, power steering fluid, CD changer

Page 3701 of 4500

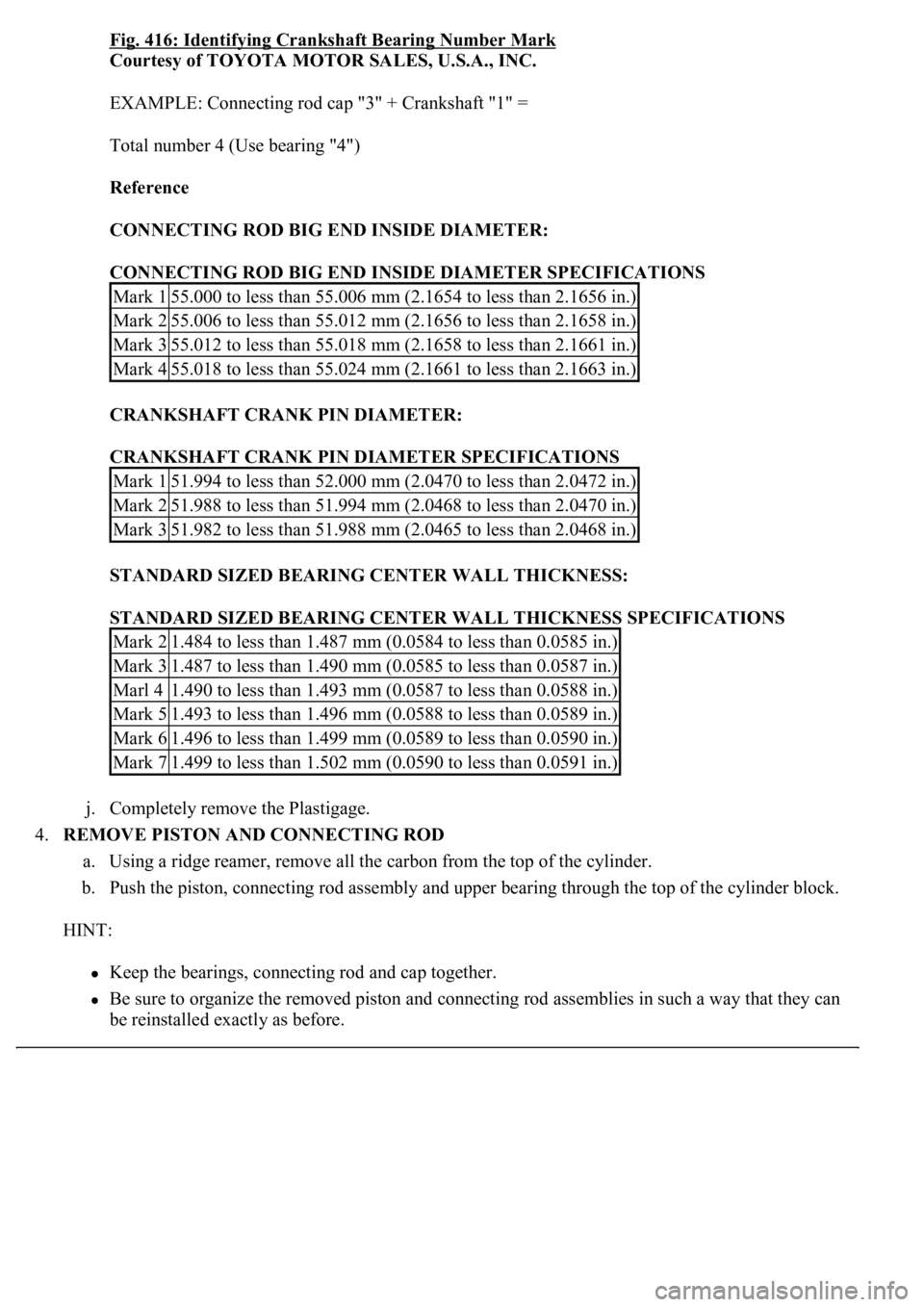

Fig. 416: Identifying Crankshaft Bearing Number Mark

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

EXAMPLE: Connecting rod cap "3" + Crankshaft "1" =

Total number 4 (Use bearing "4")

Reference

CONNECTING ROD BIG END INSIDE DIAMETER:

CONNECTING ROD BIG END INSIDE DIAMETER SPECIFICATIONS

CRANKSHAFT CRANK PIN DIAMETER:

CRANKSHAFT CRANK PIN DIAMETER SPECIFICATIONS

STANDARD SIZED BEARING CENTER WALL THICKNESS:

STANDARD SIZED BEARING CENTER WALL THICKNESS SPECIFICATIONS

j. Completely remove the Plastigage.

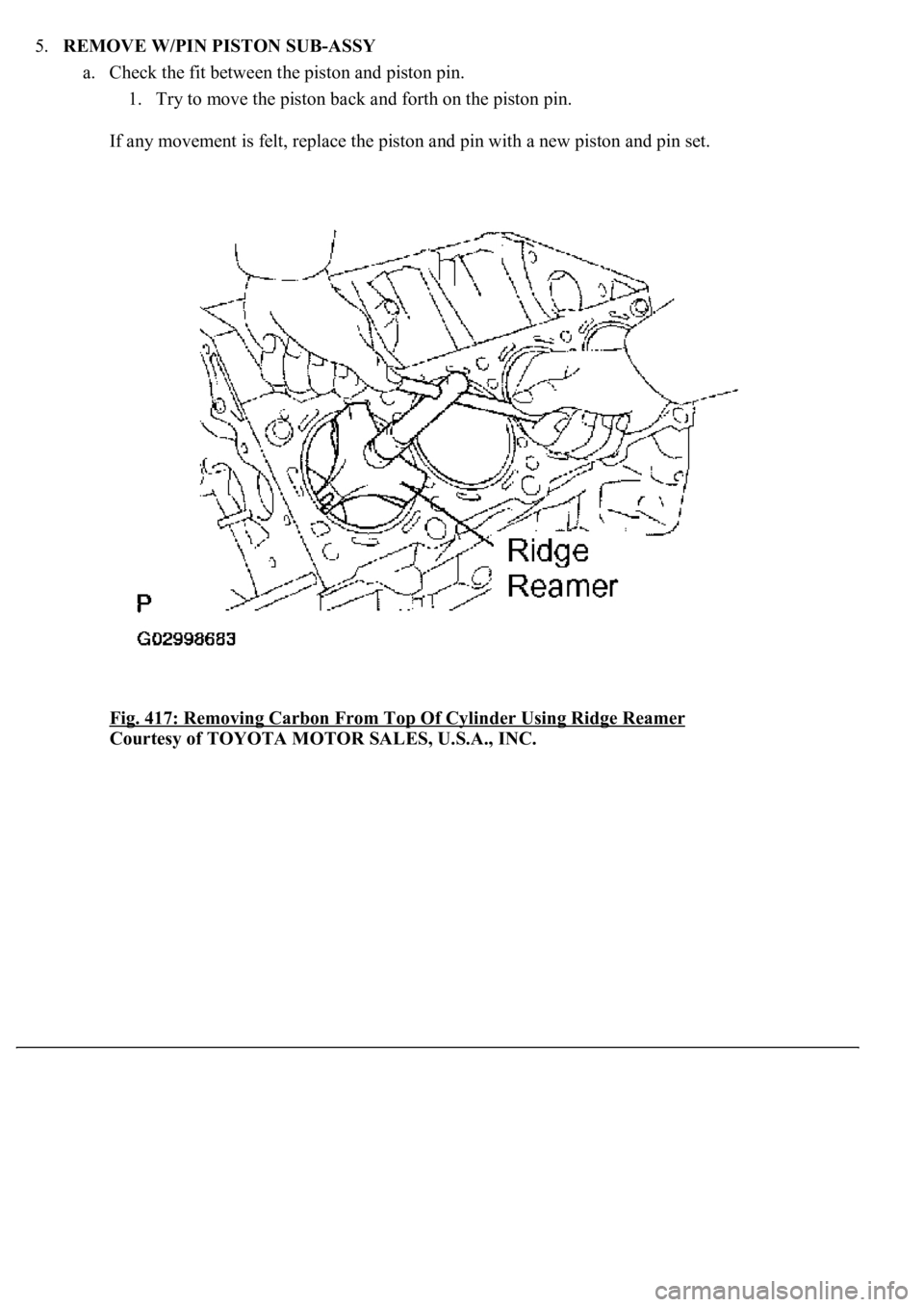

4.REMOVE PISTON AND CONNECTING ROD

a. Using a ridge reamer, remove all the carbon from the top of the cylinder.

b. Push the piston, connecting rod assembly and upper bearing through the top of the cylinder block.

HINT:

<002e00480048005300030057004b004800030045004800440055004c0051004a0056000f00030046005200510051004800460057004c0051004a000300550052004700030044005100470003004600440053000300570052004a00480057004b0048005500

1100030003[

Be sure to organize the removed piston and connecting rod assemblies in such a way that they can

be reinstalled exactly as before.

Mark 155.000 to less than 55.006 mm (2.1654 to less than 2.1656 in.)

Mark 255.006 to less than 55.012 mm (2.1656 to less than 2.1658 in.)

Mark 355.012 to less than 55.018 mm (2.1658 to less than 2.1661 in.)

Mark 455.018 to less than 55.024 mm (2.1661 to less than 2.1663 in.)

Mark 151.994 to less than 52.000 mm (2.0470 to less than 2.0472 in.)

Mark 251.988 to less than 51.994 mm (2.0468 to less than 2.0470 in.)

Mark 351.982 to less than 51.988 mm (2.0465 to less than 2.0468 in.)

Mark 21.484 to less than 1.487 mm (0.0584 to less than 0.0585 in.)

Mark 31.487 to less than 1.490 mm (0.0585 to less than 0.0587 in.)

Marl 41.490 to less than 1.493 mm (0.0587 to less than 0.0588 in.)

Mark 51.493 to less than 1.496 mm (0.0588 to less than 0.0589 in.)

Mark 61.496 to less than 1.499 mm (0.0589 to less than 0.0590 in.)

Mark 71.499 to less than 1.502 mm (0.0590 to less than 0.0591 in.)

Page 3702 of 4500

5.REMOVE W/PIN PISTON SUB-ASSY

a. Check the fit between the piston and piston pin.

1. Try to move the piston back and forth on the piston pin.

If any movement is felt, replace the piston and pin with a new piston and pin set.

Fig. 417: Removing Carbon From Top Of Cylinder Using Ridge Reamer

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3703 of 4500

<0029004c004a0011000300170014001b001d000300290048004f0057004c0051004a00030033004c0056005700520051000300240051004700030033004c00510003003a004c0057004b00030033004c005600570052005100030024005100470003003300

4c0051[

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

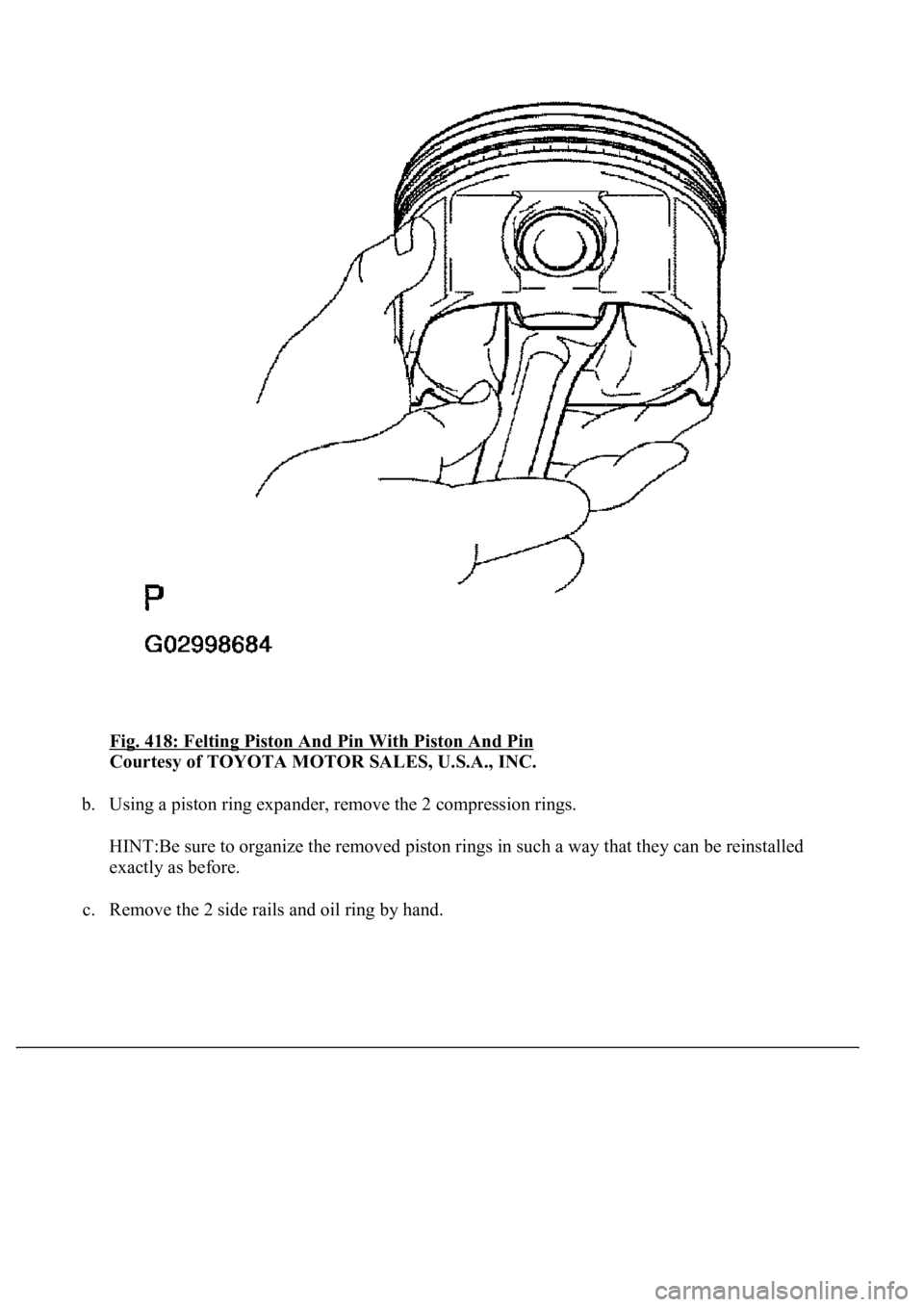

b. Using a piston ring expander, remove the 2 compression rings.

HINT:Be sure to organize the removed piston rings in such a way that they can be reinstalled

exactly as before.

c. Remove the 2 side rails and oil rin

g by hand.

Page 3704 of 4500

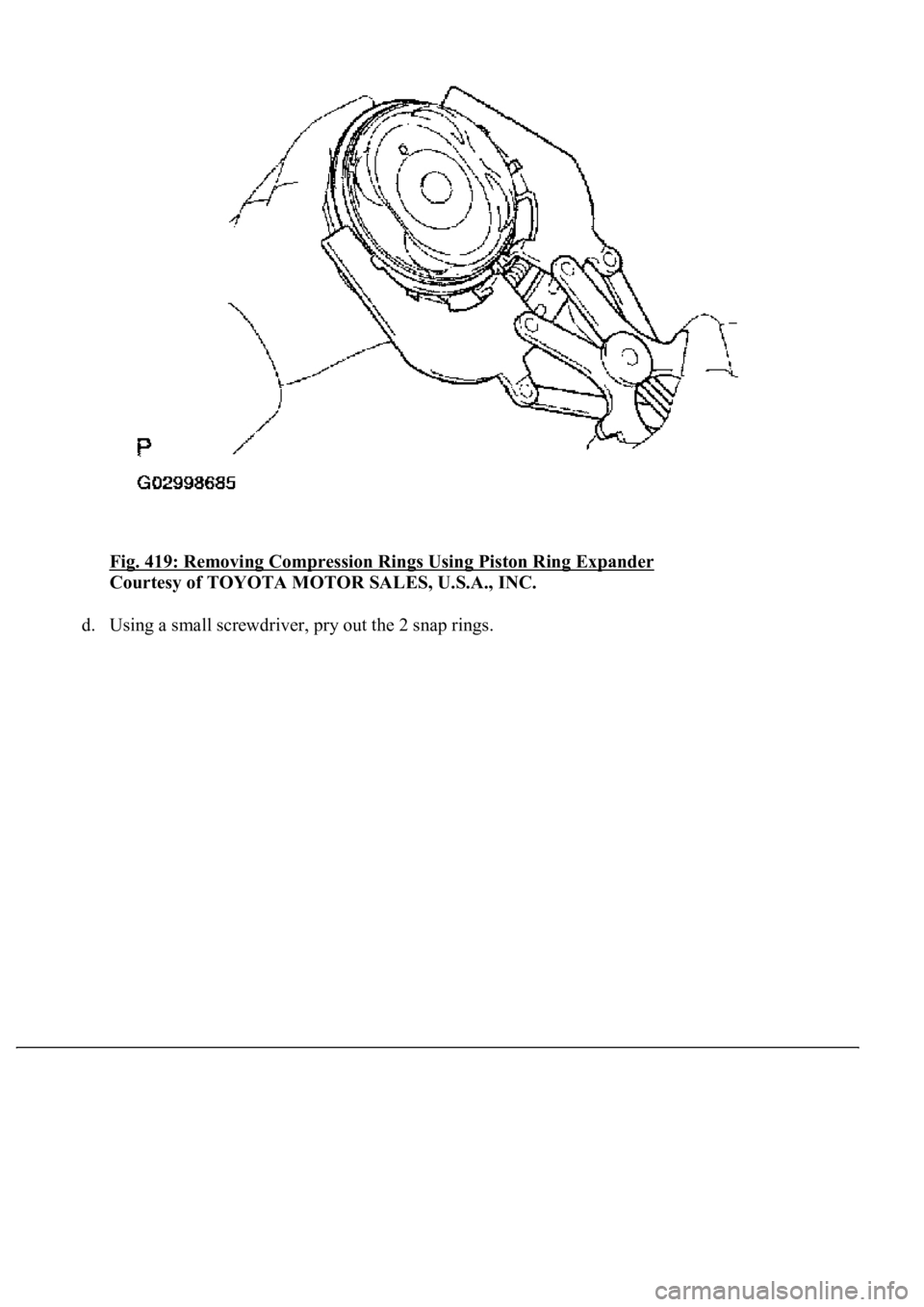

Fig. 419: Removing Compression Rings Using Piston Ring Expander

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

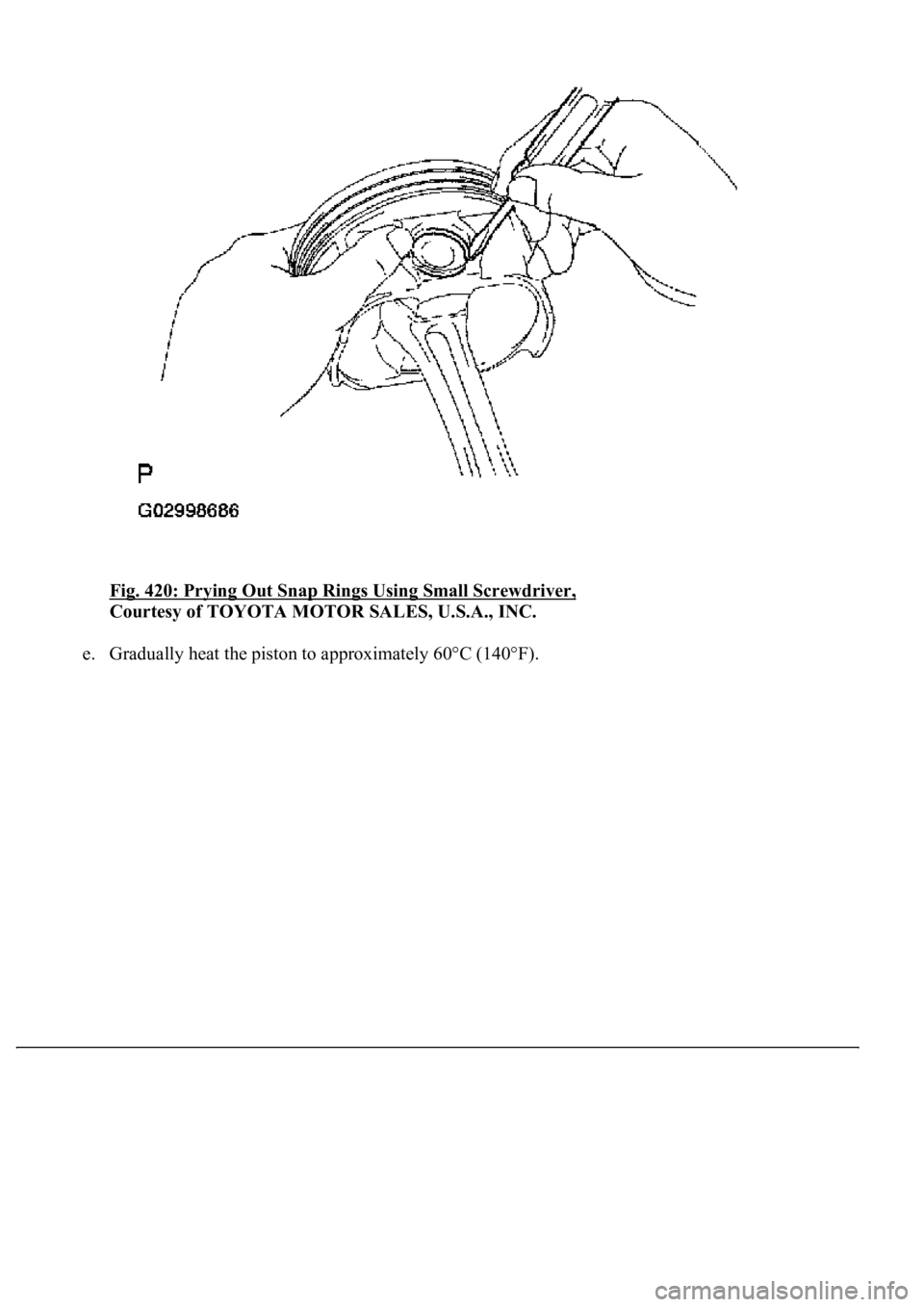

d. Usin

g a small screwdriver, pry out the 2 snap rings.

Page 3705 of 4500

Fig. 420: Prying Out Snap Rings Using Small Screwdriver,

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

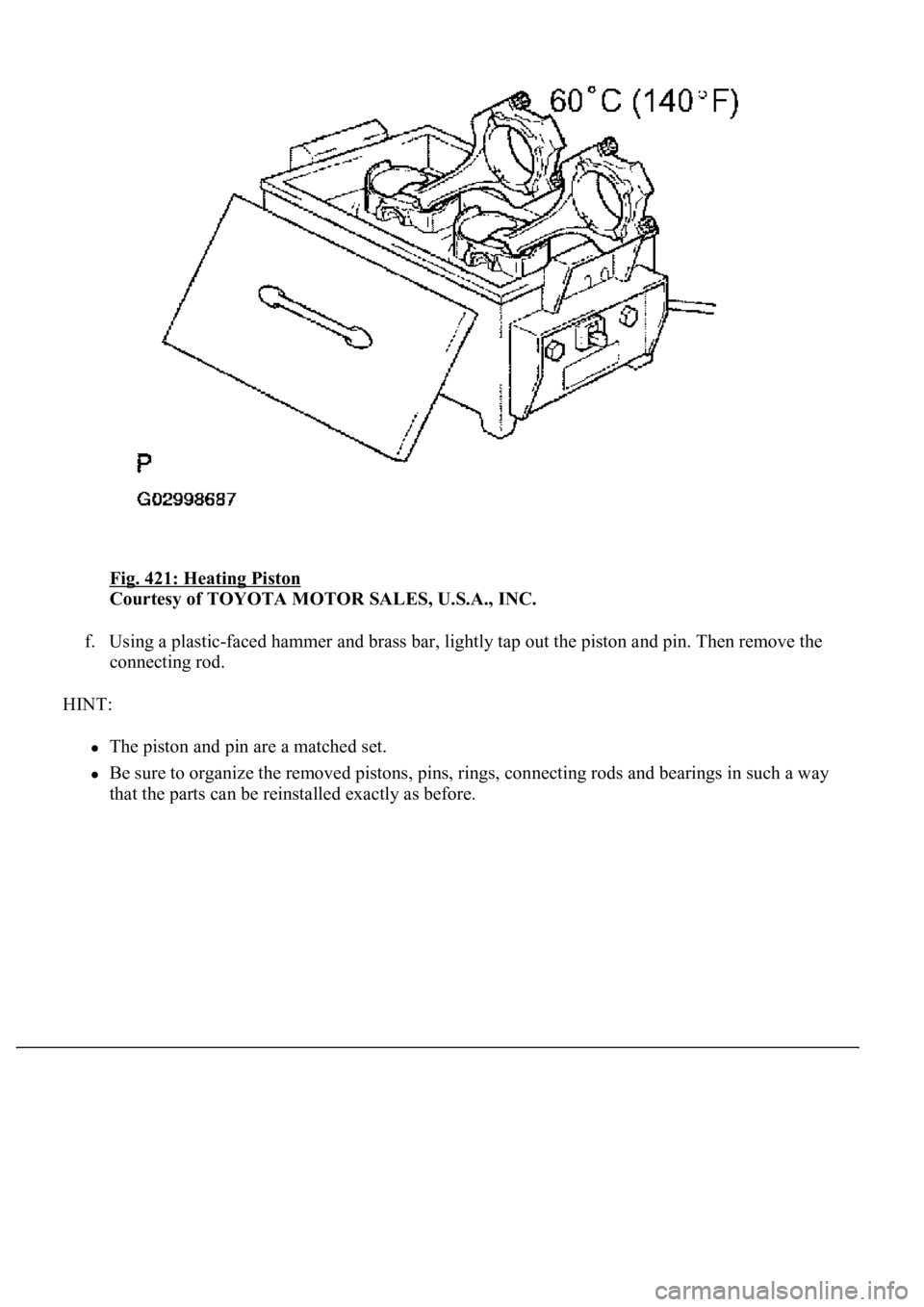

e. Gradually heat the piston to approximately 60°C (140°F).

Page 3706 of 4500

Fig. 421: Heating Piston

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

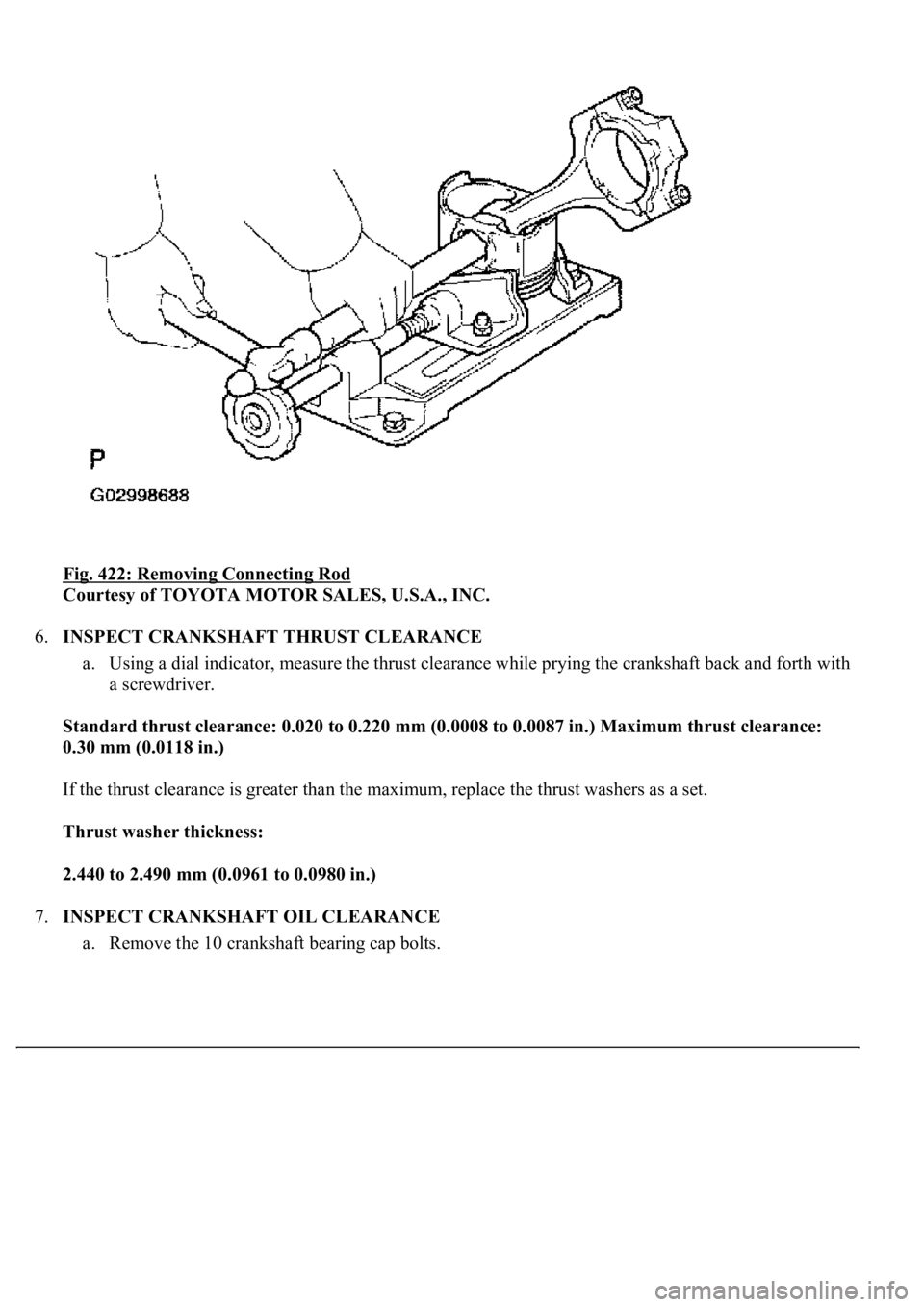

f. Using a plastic-faced hammer and brass bar, lightly tap out the piston and pin. Then remove the

connecting rod.

HINT:

The piston and pin are a matched set.

Be sure to organize the removed pistons, pins, rings, connecting rods and bearings in such a way

that the parts can be reinstalled exactl

y as before.

Page 3707 of 4500

Fig. 422: Removing Connecting Rod

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

6.INSPECT CRANKSHAFT THRUST CLEARANCE

a. Using a dial indicator, measure the thrust clearance while prying the crankshaft back and forth with

a screwdriver.

<0036005700440051004700440055004700030057004b005500580056005700030046004f0048004400550044005100460048001d0003001300110013001500130003005700520003001300110015001500130003005000500003000b001300110013001300

13001b00030057005200030013001100130013001b001a0003[in.) Maximum thrust clearance:

0.30 mm (0.0118 in.)

If the thrust clearance is greater than the maximum, replace the thrust washers as a set.

Thrust washer thickness:

2.440 to 2.490 mm (0.0961 to 0.0980 in.)

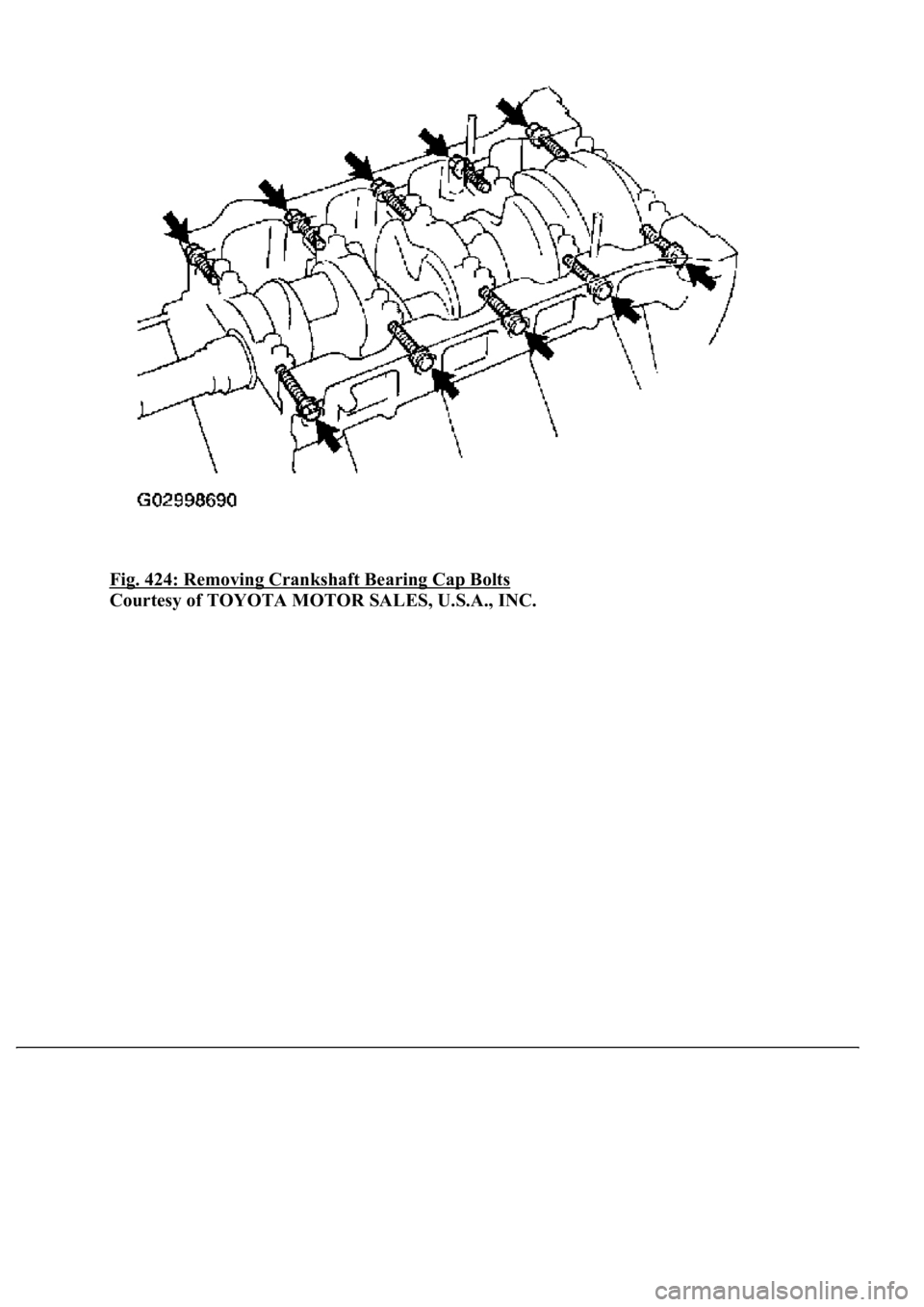

7.INSPECT CRANKSHAFT OIL CLEARANCE

a. Remove the 10 crankshaft bearin

g cap bolts.

Page 3708 of 4500

Fig. 423: Measuring Thrust Clearance Using Dial Indicator

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3709 of 4500

Fig. 424: Removing Crankshaft Bearing Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 3710 of 4500

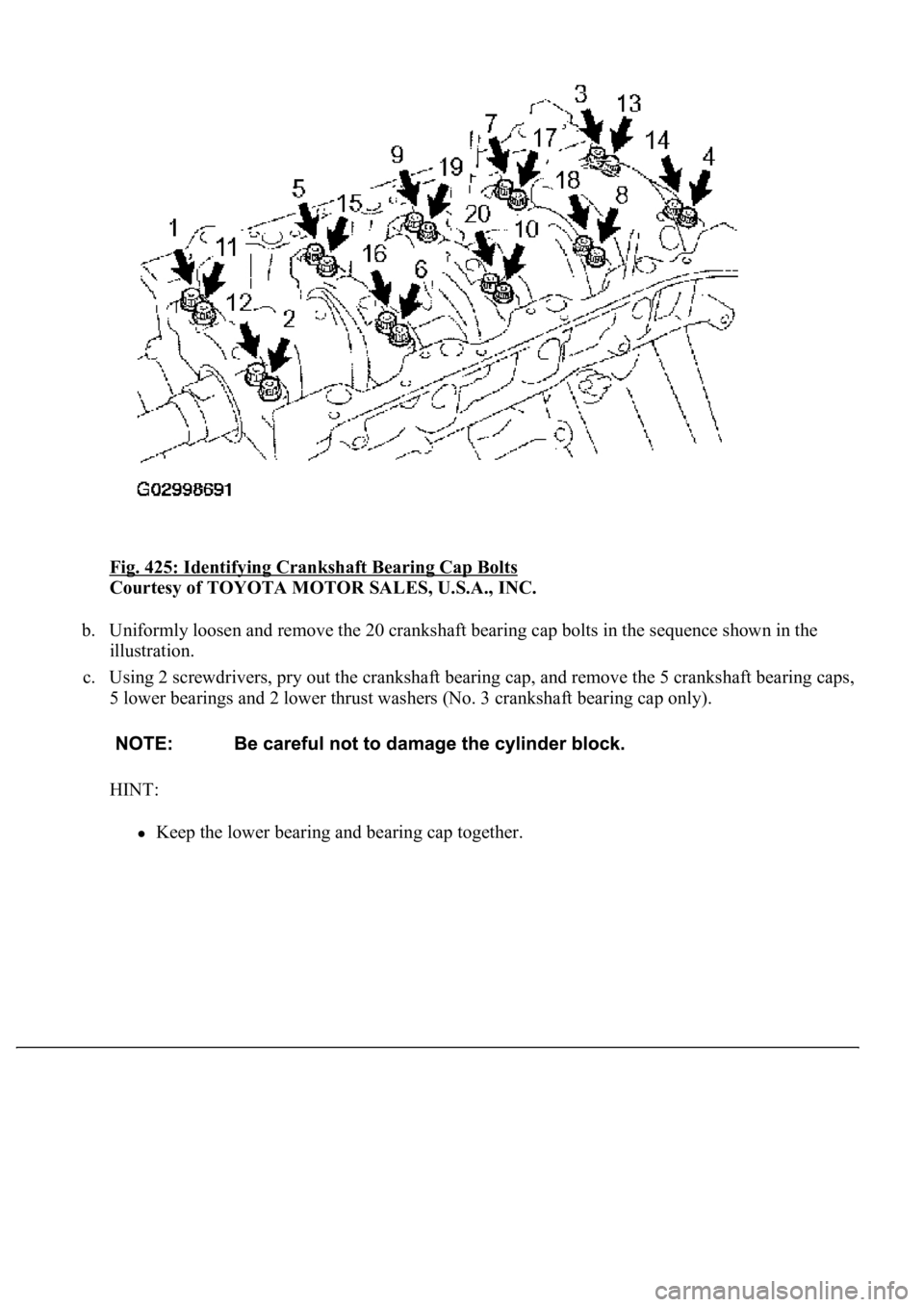

Fig. 425: Identifying Crankshaft Bearing Cap Bolts

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Uniformly loosen and remove the 20 crankshaft bearing cap bolts in the sequence shown in the

illustration.

c. Using 2 screwdrivers, pry out the crankshaft bearing cap, and remove the 5 crankshaft bearing caps,

5 lower bearings and 2 lower thrust washers (No. 3 crankshaft bearing cap only).

HINT:

Keep the lower bearing and bearing cap together.

Trending: camshaft service, steering, oxygen sensor, mirror, adding oil, fuel cap, differential