LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: tire size, camshaft service, charging, tire pressure, engine coolant, Rear, odometer

Page 4131 of 4500

b. Remove the 2 bolts.

c. Remove the fuel delivery pipe No. 2 by pulling it straight upward holding both the ends.

15.REMOVE FUEL INJECTOR ASSY

a. Remove the injector from the intake manifold.

b. Remove the O-ring, grommet and vibration insulator from the injector.

Fig. 32: Installing O

-Ring, Grommet And Vibration Insulator From Injector

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

16.INSTALL FUEL INJECTOR ASSY

a. Install a new grommet and vibration insulator to the injector.

b. Check the injector's grooves (where O-rings are installed) for foreign matter or damage. Apply

Page 4132 of 4500

gasoline to 2 new O-rings and install them to the injector's grooves.

c. To install the fuel injector into the fuel delivery pipe, push the fuel injector while twisting it back

and forth. Install the 4 injectors.

d. Check that the injector can rotate smoothly.

17.INSTALL FUEL DELIVERY PIPE SUB-ASSY NO.2

a. Install the injector (with delivery pipe) to the intake manifold.

b. Under the above condition, turn the injector both ways by approximately 45 degrees.

c. Inserting a spacer in between, install the delivery pipe (with injector) with the 2 nuts.

Torque: 21 N.m (214 kgf.cm, 15 ft.lbf)

18.INSTALL FUEL DELIVERY PIPE SUB-ASSY

a. Install the injector (with delivery pipe) to the intake manifold.

b. Under the above condition, turn the injector both ways by approximately 45 degrees.

c. Inserting a spacer in between, install the delivery pipe (with injector) with the 2 nuts.

Torque: 21 N.m (214 kgf.cm, 15 ft.lbf)

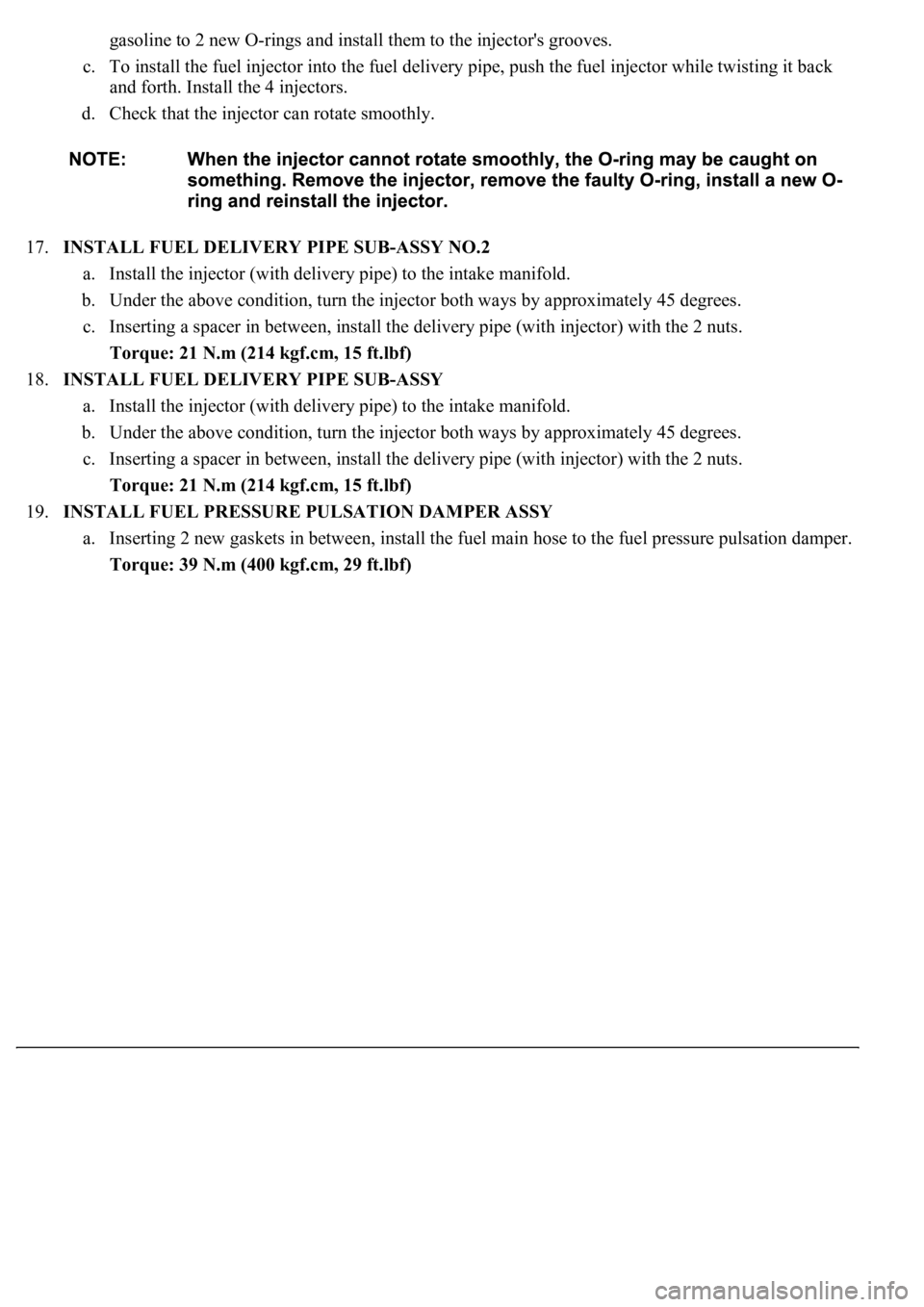

19.INSTALL FUEL PRESSURE PULSATION DAMPER ASSY

a. Inserting 2 new gaskets in between, install the fuel main hose to the fuel pressure pulsation damper.

Torque: 39 N.m (400 kgf.cm, 29 ft.lbf)

Page 4133 of 4500

Fig. 33: Installing Gaskets

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

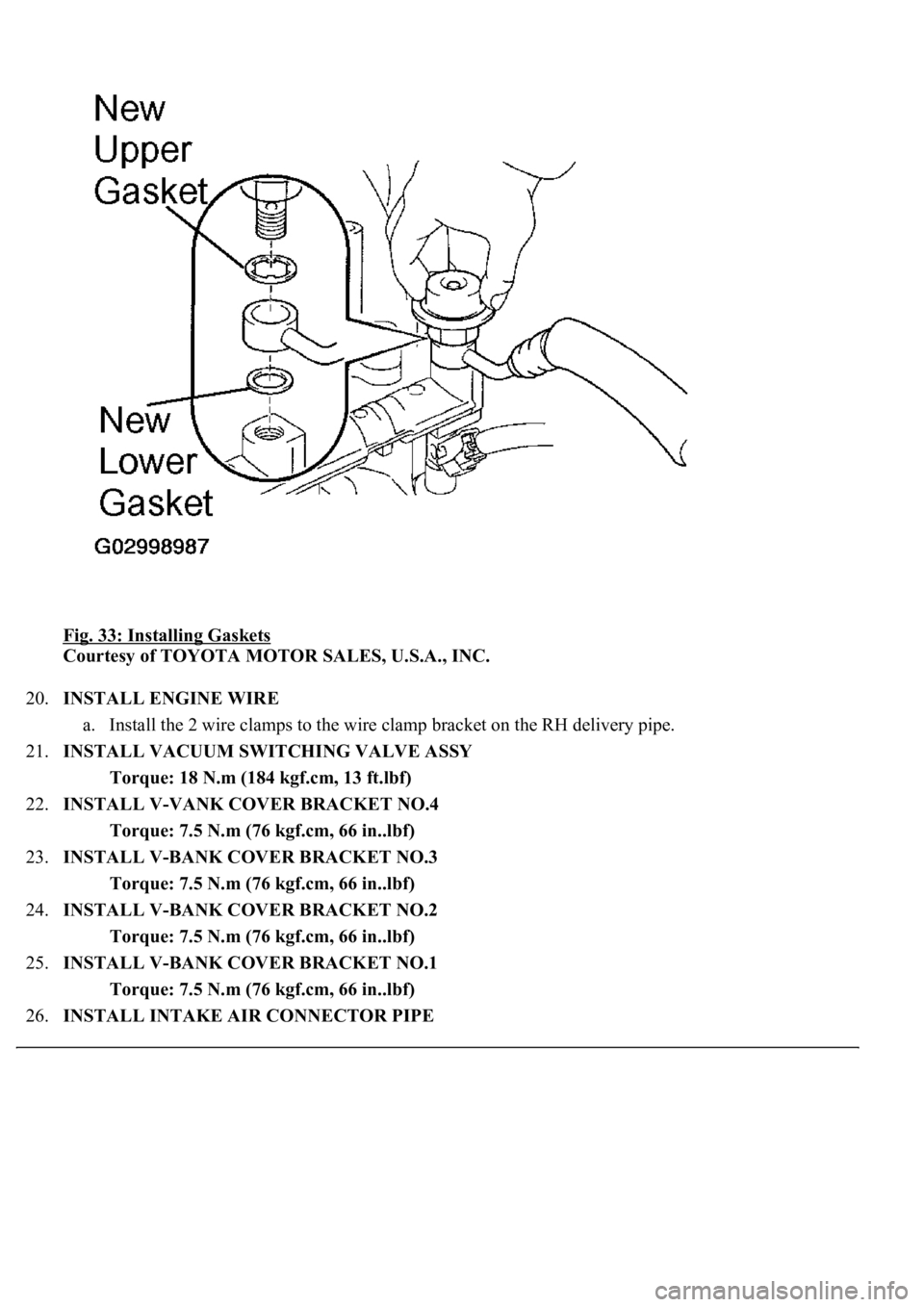

20.INSTALL ENGINE WIRE

a. Install the 2 wire clamps to the wire clamp bracket on the RH delivery pipe.

21.INSTALL VACUUM SWITCHING VALVE ASSY

Torque: 18 N.m (184 kgf.cm, 13 ft.lbf)

22.INSTALL V-VANK COVER BRACKET NO.4

Torque: 7.5 N.m (76 kgf.cm, 66 in..lbf)

23.INSTALL V-BANK COVER BRACKET NO.3

Torque: 7.5 N.m (76 kgf.cm, 66 in..lbf)

24.INSTALL V-BANK COVER BRACKET NO.2

Torque: 7.5 N.m (76 kgf.cm, 66 in..lbf)

25.INSTALL V-BANK COVER BRACKET NO.1

Torque: 7.5 N.m (76 kgf.cm, 66 in..lbf)

26.INSTALL INTAKE AIR CONNECTOR PIPE

Page 4134 of 4500

a. Install the intake air connector pipe with the bolt and hose clamp.

Torque:

4.0 N.m (40 kgf.cm, 35 in..lbf) for hose clamp

5.0 N.m (50 kgf.cm, 44 in..lbf) for bolt

b. Connect the air hose and ventilation hose No. 1 together.

27.INSTALL AIR CLEANER INLET NO.1

28.INSPECT FOR FUEL LEAKS (See ON

-VEHICLE INSPECTION )

29.INSTALL V-BANK COVER

Torque: 5.0 N.m (51 kgf.cm, 44 in..lbf)

30.CONNECT BATTERY NEGATIVE TERMINAL

Fig. 34: Identifying Wire Clamp Bracket

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 4135 of 4500

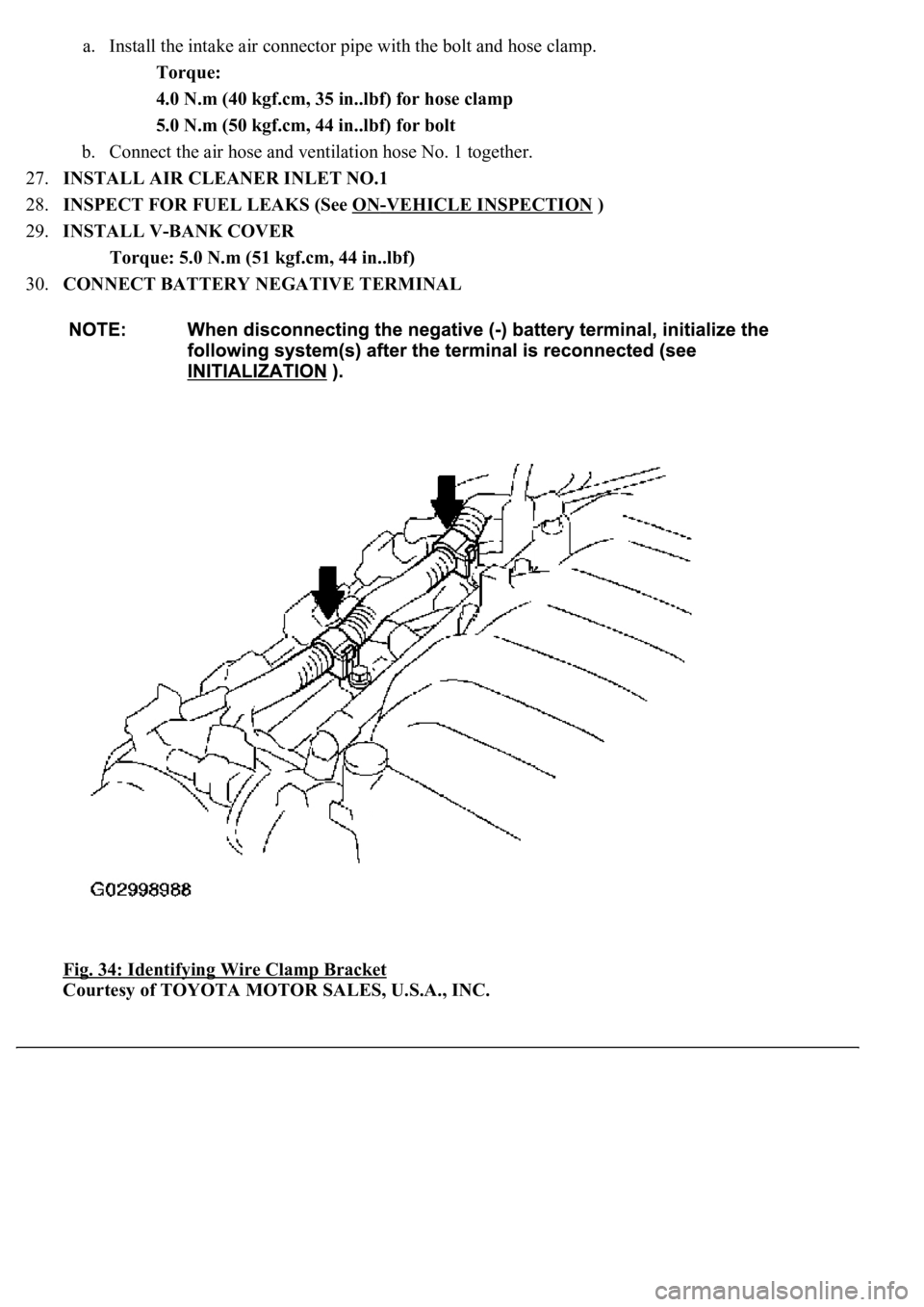

COMPONENTS

Fig. 35: Exploded View Of Fuel Pump Assy Components (1 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 4136 of 4500

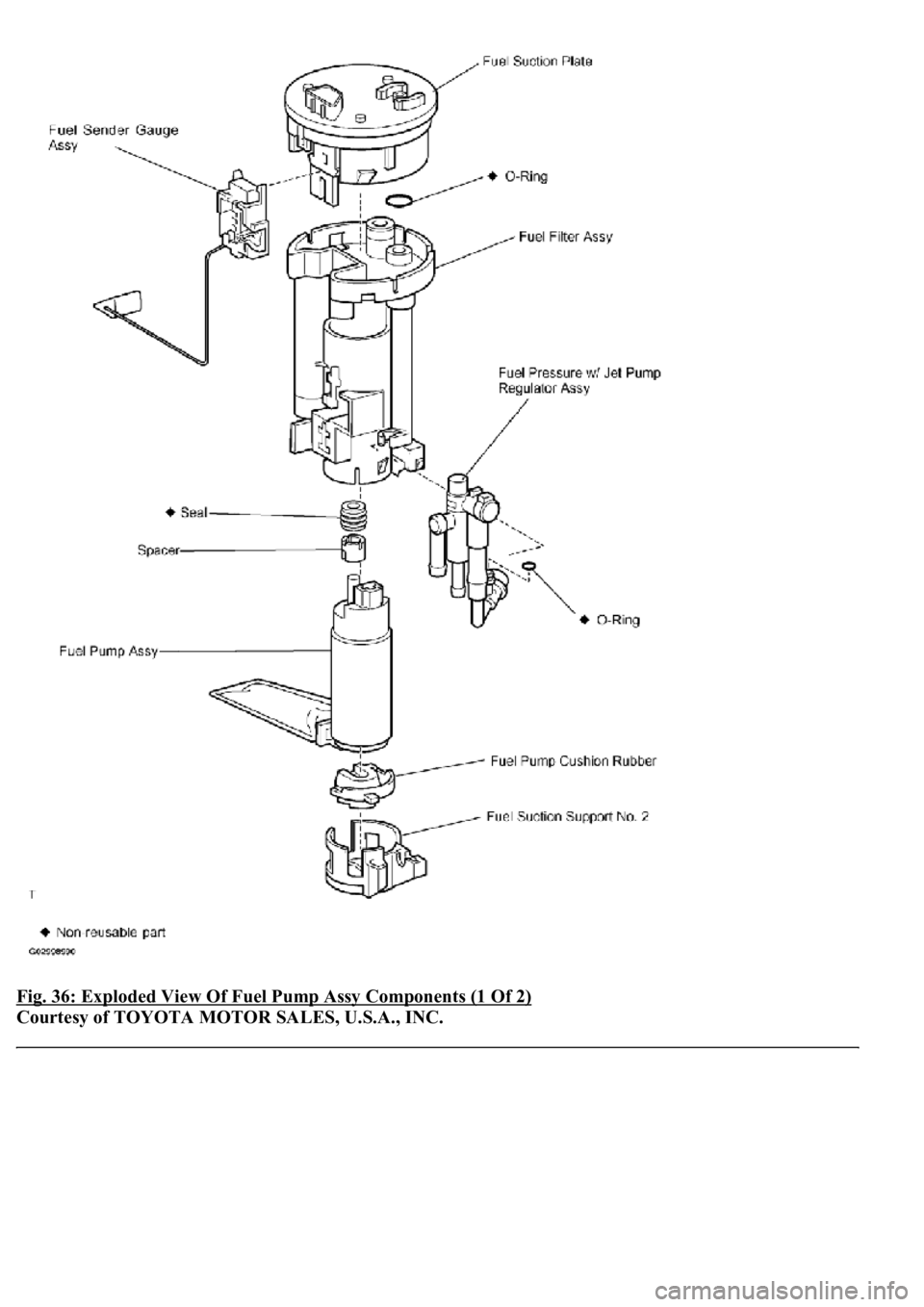

Fig. 36: Exploded View Of Fuel Pump Assy Components (1 Of 2)

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

Page 4137 of 4500

REPLACEMENT

1.WORK FOR PREVENTING GASOLINE FROM SPILLING OUT (See PRECAUTION

)

2.DISCONNECT BATTERY NEGATIVE TERMINAL

3.DRAIN FUEL (See PRECAUTION

)

4.REMOVE SEPARATE TYPE REAR SEAT CUSHION ASSY LH (SEPARATED TYPE REAR

SEAT) (See OVERHAUL

)

5.REMOVE BENCH TYPE REAR SEAT CUSHION ASSY (FIXED TYPE REAR SEAT) (See

OVERHAUL

)

6.REMOVE REAR FLOOR SERVICE HOLE COVER NO.2

a. Remove the 3 cap nuts and service hole cover.

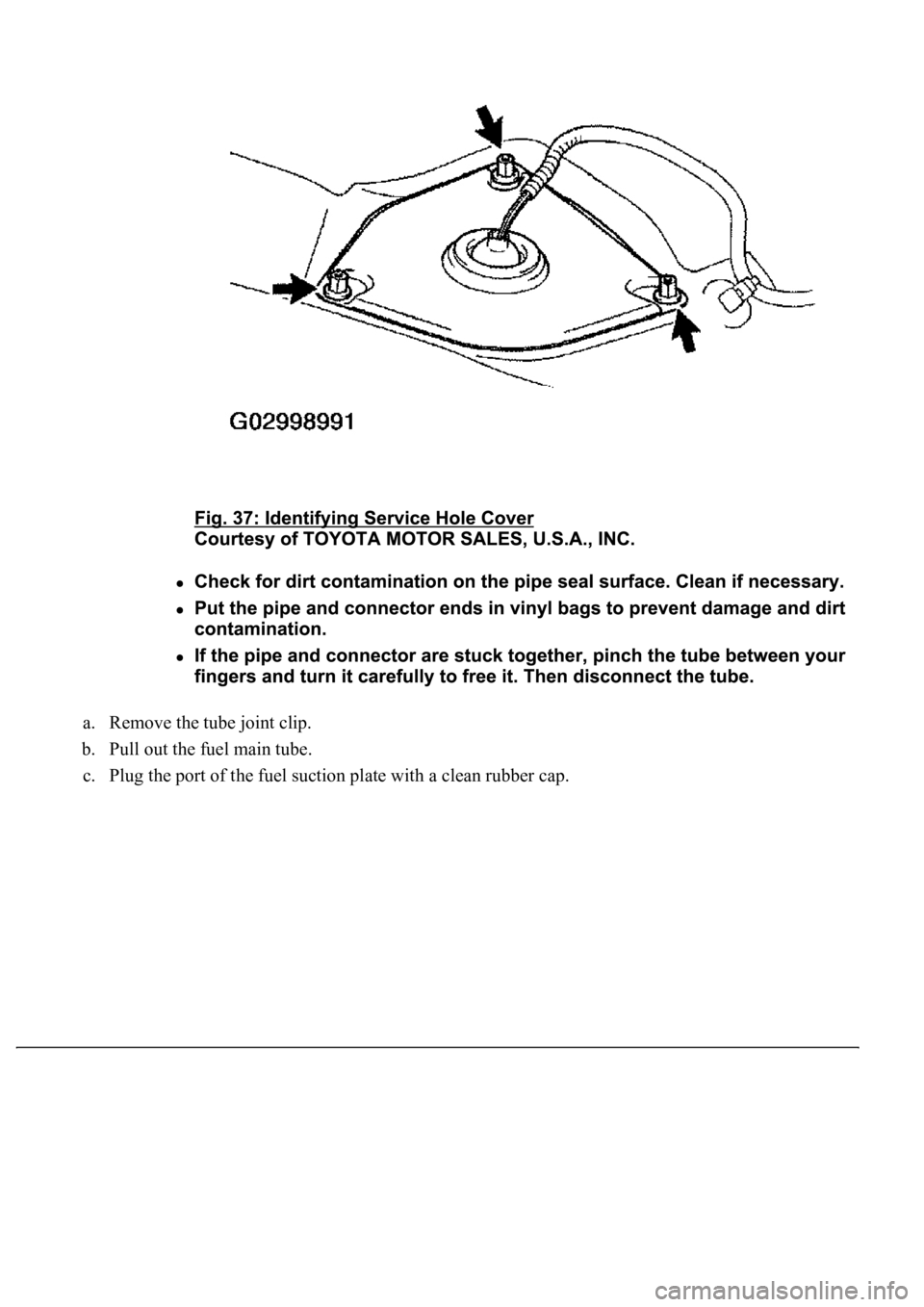

7.REMOVE FUEL TANK MAIN TUBE SUB-ASSY

Page 4138 of 4500

a. Remove the tube joint clip.

b. Pull out the fuel main tube.

c. Plu

g the port of the fuel suction plate with a clean rubber cap.

Page 4139 of 4500

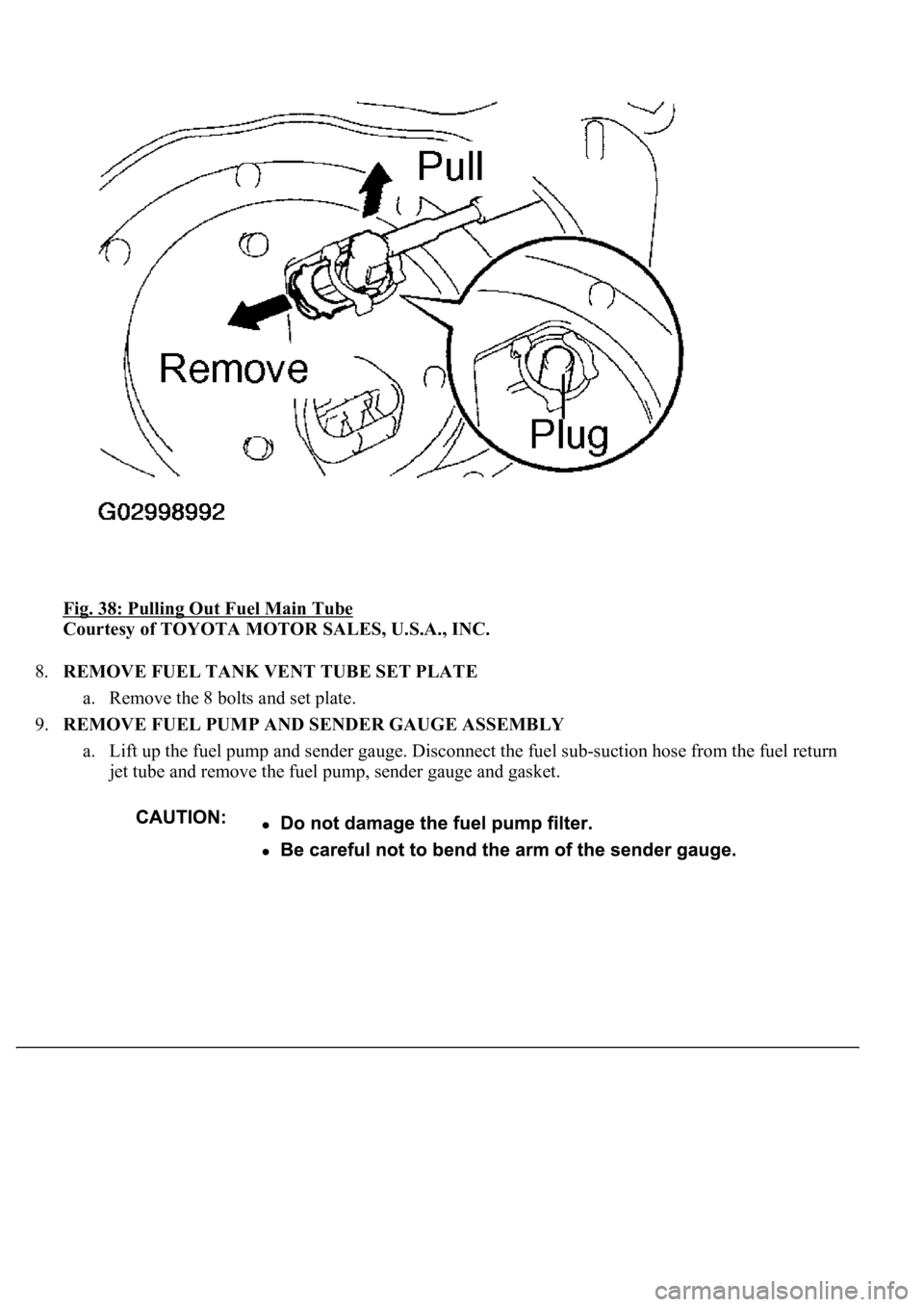

Fig. 38: Pulling Out Fuel Main Tube

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

8.REMOVE FUEL TANK VENT TUBE SET PLATE

a. Remove the 8 bolts and set plate.

9.REMOVE FUEL PUMP AND SENDER GAUGE ASSEMBLY

a. Lift up the fuel pump and sender gauge. Disconnect the fuel sub-suction hose from the fuel return

<004d00480057000300570058004500480003004400510047000300550048005000520059004800030057004b00480003004900580048004f00030053005800500053000f00030056004800510047004800550003004a00440058004a004800030044005100

470003004a00440056004e00480057001100030003[

Page 4140 of 4500

Fig. 39: Disconnecting Fuel Sub-Suction Hose

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

10.REMOVE FUEL SUCTION SUPPORT NO.2

a. Using 2 screwdrivers, disconnect the 3 snap claws from the claw holes and remove the fuel suction

support.

11.REMOVE FUEL PUMP CUSHION RUBBER

Trending: inter lock cable, zero point calibration, weight, transmission, steering, oil level, buttons