MAZDA 6 2002 Workshop Manual Suplement

Manufacturer: MAZDA, Model Year: 2002, Model line: 6, Model: MAZDA 6 2002Pages: 909, PDF Size: 17.16 MB

Page 831 of 909

T–20

EXTERIOR LIGHTING SYSTEM

REAR AUTO LEVELING SENSOR REMOVAL/INSTALLATIONA6E8112510302011. Disconnect the negative battery cable.

2. Jack up the vehicle.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

5. Adjust the headlight zeroset.

End Of SieHIGH-MOUNT BRAKE LIGHT REMOVAL/INSTALLATIONA6E811251580201In-vehicle-type

1. Disconnect the negative battery cable.

2. Remove the liftgate upper trim.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

EXTERIOR LIGHTING SYSTEM

1 Connector

2Bolt

3Bracket

4 Rear auto leveling sensor

2

1

3

4

4

6.9—9.8 N·m {70—99 kgf·cm, 61—85 in·lbf}

REAR STABILIZER

3

A6E81121158

1 Connector

2Socket

3 High-mount brake light bulb

4 High-mount brake light

12

3HOOK

LIFTGATE

4

A6A8112W113

Page 832 of 909

EXTERIOR LIGHTING SYSTEM, INTERIOR LIGHTING SYSTEM

T–21

T

Rear spoiler type

1. Disconnect the negative battery cable.

2. Remove the rear spoiler.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

End Of Sie

CARGO COMPARTMENT LIGHT REMOVAL/INSTALLATIONA6E8114514412011. Disconnect the negative battery cable.

2. Remove in the order indicated in the table.

3. Install in the reverse order of removal.

Lens Removal Note

1. Insert a tape-wrapped flathead screwdriver into

the service hole.

2. Twist the flathead screwdriver as indicated by the

arrow to remove the lens.

End Of Sie

1Bolt

2 Cover

3 Connector

4 High-mount brake light

4

12

3

A6J81121004

INTERIOR LIGHTING SYSTEM

1Lens

(See T–21 Lens Removal Note)

2 Cargo compartment light bulb

3 Screw (if equipped)

4 Cargo compartment light

5 Connector

12

33

4

5

A6J81141102

SERVICE HOLE

A6A8114W104

Page 833 of 909

T–22

INTERIOR LIGHTING SYSTEM, WIPER AND WASHER

CARGO COMPARTMENT LIGHT INSPECTIONA6E8114514412021. Remove the cargo compartment light. (See T–21 CARGO COMPARTMENT LIGHT REMOVAL/

INSTALLATION)

2. Inspect for continuity between the cargo

compartment light terminals using an ohmmeter.

•If not as specified, replace the cargo

compartment light.

End Of Sie

REAR WIPER MOTOR REMOVAL/INSTALLATIONA6E8116674502011. Disconnect the negative battery cable.

2. Remove the rear wiper arm and blade. (See T–23 REAR WIPER ARM AND BLADE REMOVAL/

INSTALLATION.)

3. Remove the liftgate lower trim. (See S–24 LIFTGATE LOWER TRIM REMOVAL/INSTALLATION)

4. Remove in the order indicated in the table.

5. Install in the reverse order of removal.

6. Adjust the rear wiper arm and blade. (See T–24

REAR WIPER ARM AND BLADE

ADJUSTMENT.)

End Of SieREAR WIPER MOTOR INSPECTIONA6E8116674502021. Disconnect the negative battery cable.

2. Remove the liftgate lower trim. (See S–24 LIFTGATE LOWER TRIM REMOVAL/INSTALLATION)

3. Disconnect the rear wiper motor connector.

4. Connect battery positive voltage to the rear wiper motor terminal A, and ground the rear wiper motor terminal B

to a bare metal part of the vehicle.

A

B OFF

DOORAB

**

A6J81141112

: Bulb

Switch position

DOOR

OFFTerminal

B A

A6A81141119

WIPER AND WASHER

1 Connector

2Bolt

3 Rear wiper motor

4 Outer bushing

N·m {kgf·cm, in·lbf}

4

31

2

3.92—6.86

{40.0—69.9,

34.8—60.6}

A6E81161110

Page 834 of 909

WIPER AND WASHER

T–23

T

5. Verify that the rear wiper motor operates.

6. Disconnect the ground to the terminal B while the

rear wiper is operating.

7. Verify that the rear wiper stops in the park

position.

•If not as specified, replace the rear wiper

motor.

End Of SieREAR WIPER ARM AND BLADE REMOVAL/INSTALLATIONA6E8116674202011. Remove in the order indicated in the table.

2. Install in the reverse order of removal.

3. Adjust the rear wiper arm and blade. (See T–24

REAR WIPER ARM AND BLADE

ADJUSTMENT)

AUTOSTOP

SWITCH

BAA B M

A6E81161119

AUTOSTOP

SWITCH

BA M

A B

A6E81161120

1Cap

2Nut

3 Rear wiper arm (See T–24 Rear Wiper Arm

Installation Note)

4 Rear wiper blade

5 Rubber brush

N·m {kgf·cm, in·lbf}

53

1

25.89—9.81

{60.0—100, 52.1—86.7}

4

A6E81161112

Page 835 of 909

T–24

WIPER AND WASHER

Rear Wiper Arm Installation Note

1. Clean the rear wiper arm connector shaft using a

wire brush before installing the rear wiper arm.

End Of SieREAR WIPER ARM AND BLADE ADJUSTMENTA6E8116674202021. Operate the rear wiper motor to set the wiper in the park position.

2. Set the rear wiper arm onto the ceramic end line.

End Of SieREAR WASHER NOZZLE REMOVAL/INSTALLATIONA6E8116675112011. Disconnect the negative battery cable.

2. Remove the liftgate upper trim. (See S–23 LIFTGATE UPPER TRIM REMOVAL/INSTALLATION)

3. Remove the high-mount brake light (In-vehicle-type).

4. Remove the rear washer hose from the rear washer nozzle.

5. Squeeze the tabs of the rear washer nozzle.

6. Pull the rear washer nozzle out to remove it.

7. Install in the reverse order of removal.

8. Adjust the rear washer nozzle. (See T–25 REAR

WASHER NOZZLE ADJUSTMENT.)

End Of Sie

REAR WIPER ARM

CONNECTOR

SHAFT

A6E81161103

20—23

CERAMIC

END LINE GLASS

END LINE

CERAMIC

END

LINE

GLASS

END LINE {0.8—0.9}

mm {in}

A6E81161129

TA B

A6E81161105

Page 836 of 909

WIPER AND WASHER

T–25

T

REAR WASHER NOZZLE ADJUSTMENTA6E8116675112021. Insert a needle or an equivalent tool into the spray

hole of the rear washer nozzle and adjust the

nozzle direction as shown.

End Of SieREAR WASHER HOSE REMOVAL/INSTALLATIONA6E8116674702011. Disconnect the negative battery cable.

2. Remove the washer tank.

3. Partially peel off the right side mud guard.

4. Remove rear washer hose No.1 from the clips.

5. Remove rear washer hose No.1 and joint pipe A.

6. Remove joint pipe C from the body.

7. Remove the A-pillar trim.

8. Remove rear washer hose No.2 from clip A.

9. Remove clips B from the body.

10. Remove rear washer hose No.2 and joint pipes B.

11. Remove the D-pillar trim.

12. Remove the liftgate upper trim. (See S–23

LIFTGATE UPPER TRIM REMOVAL/

INSTALLATION)

mm {in}

GLASS

END LINE

13 {0.5}

7 {0.3}

28 {1.1} GLASS

END LINE

A6E81161118

aJOINT

PIPE AREAR

WASHER

HOSE

NO.1

CLIPCLIP

A6E81161148

a

JOINT

PIPE BREAR

WASHER

HOSE

NO.2CLIP BCLIP A

JOINT PIPEJOINT PIPE C

A6E81161149

Page 837 of 909

T–26

WIPER AND WASHER

13. Remove rear washer hose No.3 from clip C.

14. Remove rear washer hose No.3 and joint pipe D.

15. Remove the headliner. (See S–26 HEADLINER

REMOVAL/INSTALLATION)

16. Remove the tape from rear washer hose No.4.

17. Install in the reverse order of removal.

End Of SieINTERMITTENT REAR WIPER RELAY REMOVAL/INSTALLATIONA6E8116668102011. Disconnect the negative battery cable.

2. Remove the trunk side trim. (See S–21 TRUNK SIDE TRIM REMOVAL/INSTALLATION)

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

End Of Sie

JOINT

PIPE D

REAR WASHER

HOSE NO.3CLIP C

a

A6E81161150

a

REAR WASHER

HOSE NO.4 TAPE

TAPE

A6E81161151

1Bolt

2 Intermittent rear wiper relay

3 Connector

1

23

A6J81161015

Page 838 of 909

WARNING AND INDICATOR SYSTEM

T–27

T

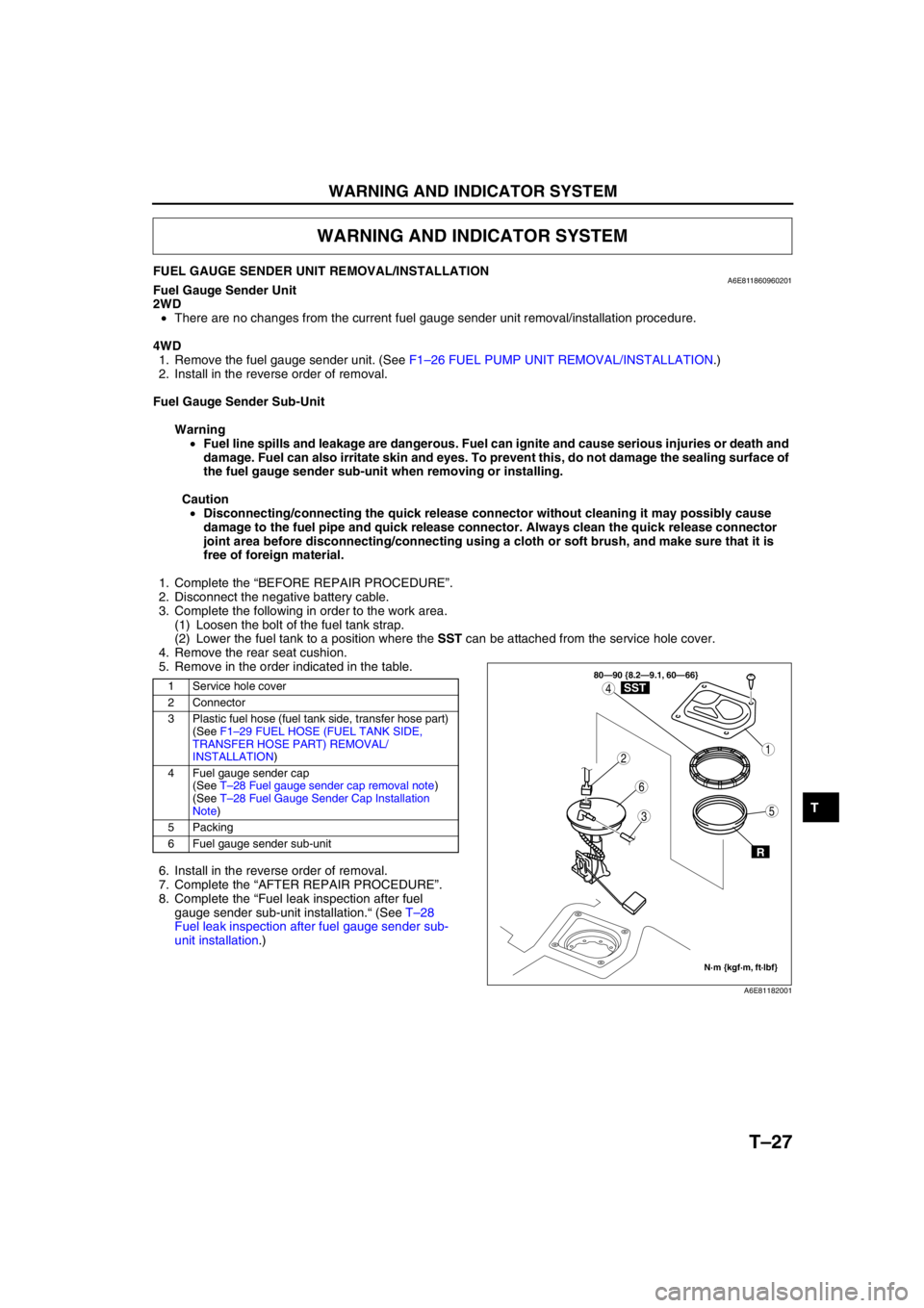

FUEL GAUGE SENDER UNIT REMOVAL/INSTALLATIONA6E811860960201Fuel Gauge Sender Unit

2WD

•There are no changes from the current fuel gauge sender unit removal/installation procedure.

4WD

1. Remove the fuel gauge sender unit. (See F1–26 FUEL PUMP UNIT REMOVAL/INSTALLATION.)

2. Install in the reverse order of removal.

Fuel Gauge Sender Sub-Unit

Warning

•Fuel line spills and leakage are dangerous. Fuel can ignite and cause serious injuries or death and

damage. Fuel can also irritate skin and eyes. To prevent this, do not damage the sealing surface of

the fuel gauge sender sub-unit when removing or installing.

Caution

•Disconnecting/connecting the quick release connector without cleaning it may possibly cause

damage to the fuel pipe and quick release connector. Always clean the quick release connector

joint area before disconnecting/connecting using a cloth or soft brush, and make sure that it is

free of foreign material.

1. Complete the “BEFORE REPAIR PROCEDURE”.

2. Disconnect the negative battery cable.

3. Complete the following in order to the work area.

(1) Loosen the bolt of the fuel tank strap.

(2) Lower the fuel tank to a position where the SST can be attached from the service hole cover.

4. Remove the rear seat cushion.

5. Remove in the order indicated in the table.

6. Install in the reverse order of removal.

7. Complete the “AFTER REPAIR PROCEDURE”.

8. Complete the “Fuel leak inspection after fuel

gauge sender sub-unit installation.“ (See T–28

Fuel leak inspection after fuel gauge sender sub-

unit installation.)

WARNING AND INDICATOR SYSTEM

1 Service hole cover

2 Connector

3 Plastic fuel hose (fuel tank side, transfer hose part)

(See F1–29 FUEL HOSE (FUEL TANK SIDE,

TRANSFER HOSE PART) REMOVAL/

INSTALLATION)

4 Fuel gauge sender cap

(See T–28 Fuel gauge sender cap removal note)

(See T–28 Fuel Gauge Sender Cap Installation

Note)

5 Packing

6 Fuel gauge sender sub-unit

3

1

4

5

6

2

80—90 {8.2—9.1, 60—66}

N·m {kgf·m, ft·lbf}

R

SST

A6E81182001

Page 839 of 909

T–28

WARNING AND INDICATOR SYSTEM

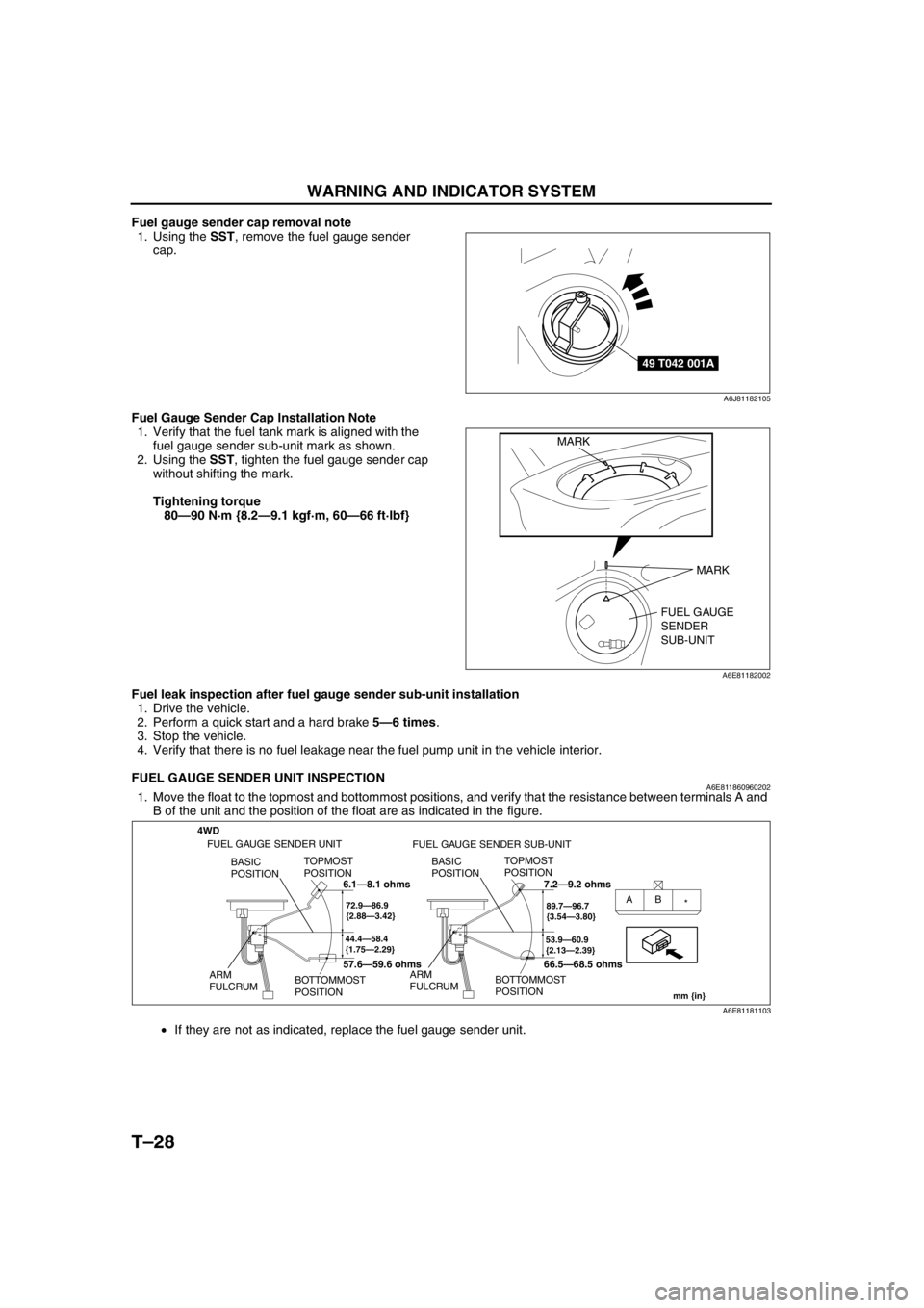

Fuel gauge sender cap removal note

1. Using the SST, remove the fuel gauge sender

cap.

Fuel Gauge Sender Cap Installation Note

1. Verify that the fuel tank mark is aligned with the

fuel gauge sender sub-unit mark as shown.

2. Using the SST, tighten the fuel gauge sender cap

without shifting the mark.

Tightening torque

80—90 N·m {8.2—9.1 kgf·m, 60—66 ft·lbf}

Fuel leak inspection after fuel gauge sender sub-unit installation

1. Drive the vehicle.

2. Perform a quick start and a hard brake 5—6 times.

3. Stop the vehicle.

4. Verify that there is no fuel leakage near the fuel pump unit in the vehicle interior.

End Of Sie

FUEL GAUGE SENDER UNIT INSPECTIONA6E8118609602021. Move the float to the topmost and bottommost positions, and verify that the resistance between terminals A and

B of the unit and the position of the float are as indicated in the figure.

•If they are not as indicated, replace the fuel gauge sender unit.

End Of Sie

49 T042 001A

A6J81182105

FUEL GAUGE

SENDER

SUB-UNIT MARK

MARK

A6E81182002

4WD

44.4—58.4

{1.75—2.29}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

72.9—86.9

{2.88—3.42}AB

*

53.9—60.9

{2.13—2.39}

TOPMOST

POSITION

BOTTOMMOST

POSITION BASIC

POSITION

ARM

FULCRUM

89.7—96.7

{3.54—3.80}

mm {in}

FUEL GAUGE SENDER UNIT

FUEL GAUGE SENDER SUB-UNIT

6.1—8.1 ohms

57.6—59.6 ohms7.2—9.2 ohms

66.5—68.5 ohms

A6E81181103

Page 840 of 909

THEFT-DETERRENT SYSTEM

T–29

T

INTRUDER SENSOR REMOVAL/INSTALLATIONA6E812000172201Front Intruder Sensor (With Sliding Sunroof)

•There are no changes from the current front intruder sensor removal/installation procedure.

Center Intruder Sensor (Without Sliding Sunroof)

•There are no changes from the current center intruder sensor removal/installation procedure.

Rear Intruder Sensor (WGN)

1. Disconnect the negative battery cable.

2. Remove the headliner.

3. Remove in the order indicated in the table.

4. Install in the reverse order of removal.

End Of Sie

THEFT-DETERRENT SYSTEM

1 Connector

2Screw

3 Rear intruder sensor

1

2

3

A6E81201105