MITSUBISHI 3000GT 1991 Service Manual

3000GT 1991

MITSUBISHI

MITSUBISHI

https://www.carmanualsonline.info/img/19/57085/w960_57085-0.png

MITSUBISHI 3000GT 1991 Service Manual

Trending: jump cable, oil filter, seats, clock reset, lock, window, brakes

Page 791 of 1146

SERVICE BRAKES - Master Cylinder and Brake Booster35-69light

scale14AO471

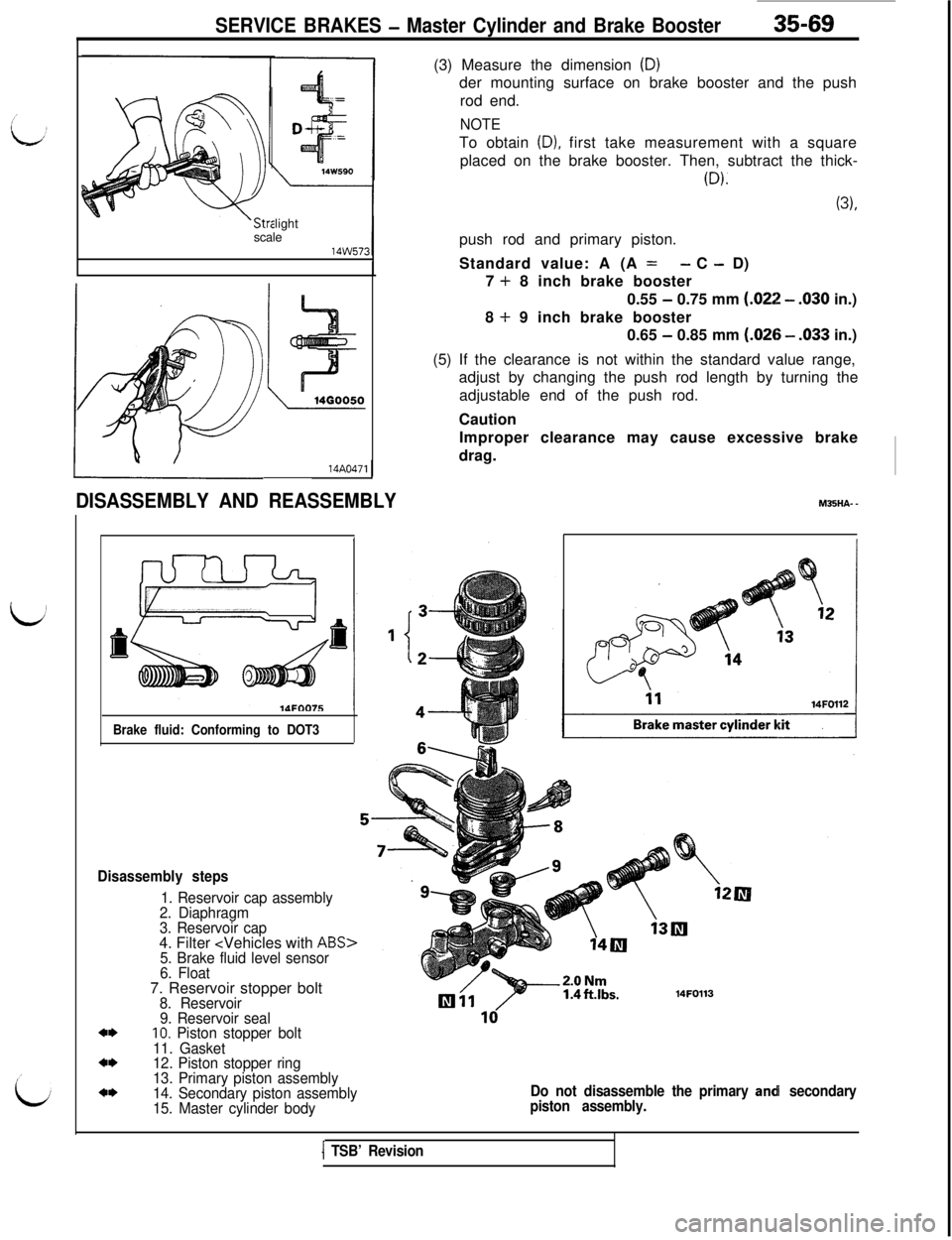

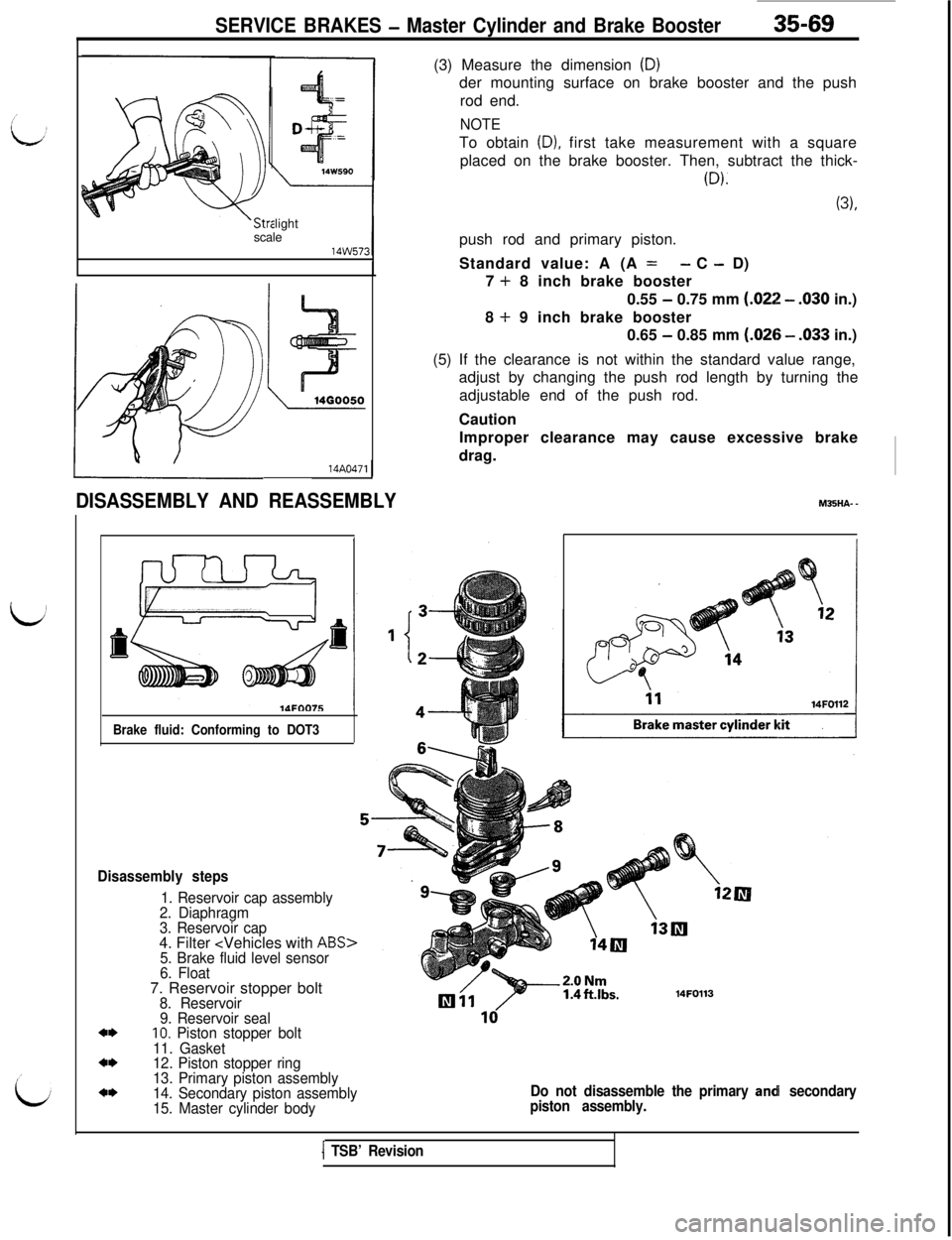

DISASSEMBLY AND REASSEMBLY

Brake fluid: Conforming to DOT3

Disassembly steps

1. Reservoir cap assembly

2. Diaphragm

3. Reservoir cap4. Filter

5. Brake fluid level sensor

6. Float7. Reservoir stopper bolt

8. Reservoir

9. Reservoir seal

*I)IO. Piston stopper bolt

11. Gasket

a*12. Piston stopper ring

13. Primary piston assembly

a*14. Secondary piston assembly

15. Master cylinder body(3) Measure the dimension

(D)der mounting surface on brake booster and the push

rod end.

NOTETo obtain

(D), first take measurement with a square

placed on the brake booster. Then, subtract the thick-

(D).

(3),push rod and primary piston.

Standard value: A (A

=- C - D)

7

+ 8 inch brake booster

0.55

- 0.75 mm (.022 - .030 in.)

8

+ 9 inch brake booster

0.65

- 0.85 mm (.026 - .033 in.)

(5) If the clearance is not within the standard value range,

adjust by changing the push rod length by turning the

adjustable end of the push rod.

Caution

Improper clearance may cause excessive brake

drag.M35HA-

-

14FOll3

Do not disassemble the primary ancH secondary

piston assembly.

1 TSB’ Revision

Page 792 of 1146

35-70SERVICE BRAKES - Master Cylinder and Brake Booster

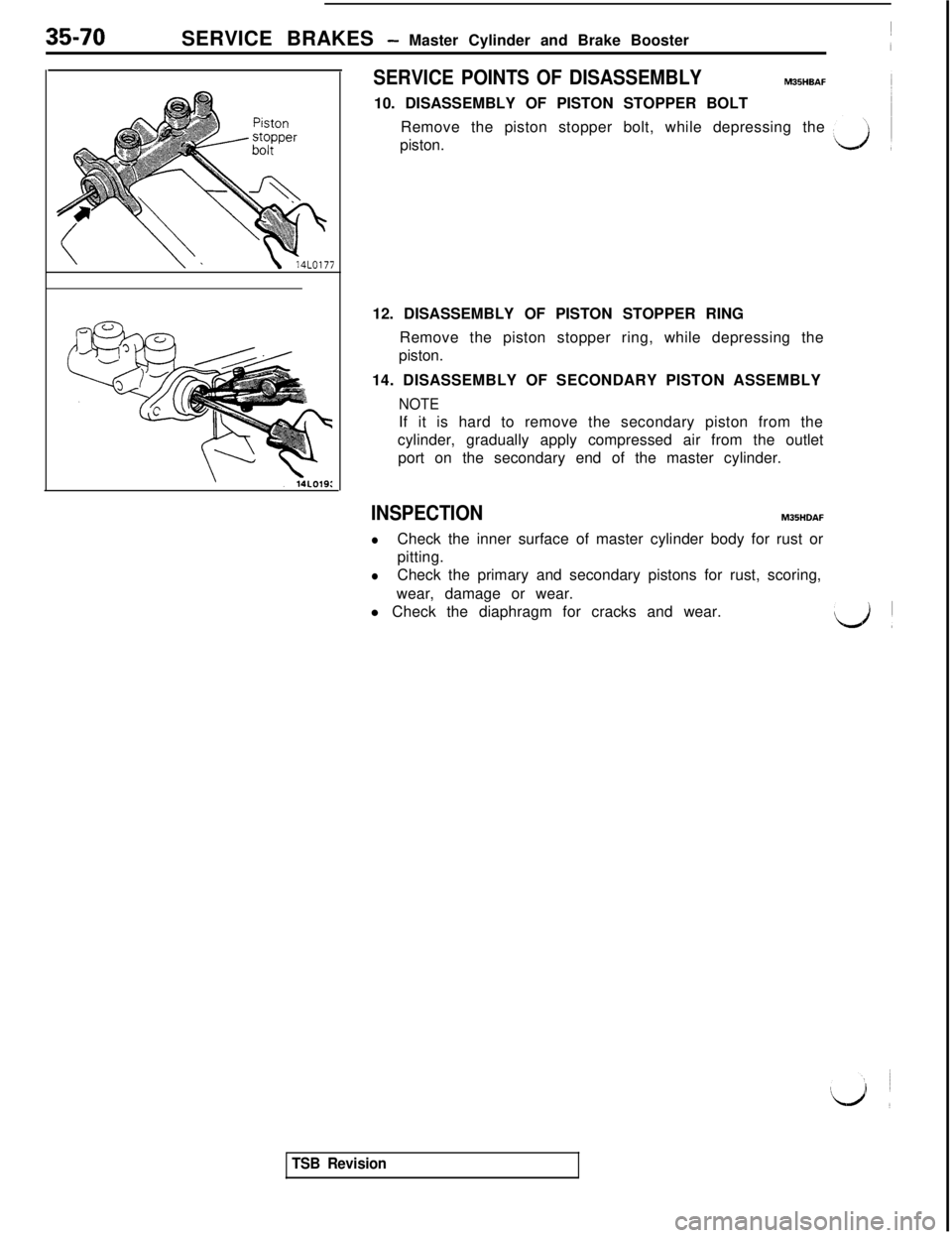

SERVICE POINTS OF DISASSEMBLYMBSHBAF10. DISASSEMBLY OF PISTON STOPPER BOLT

Remove the piston stopper bolt, while depressing the

piston.

12. DISASSEMBLY OF PISTON STOPPER RING

Remove the piston stopper ring, while depressing the

piston.

14. DISASSEMBLY OF SECONDARY PISTON ASSEMBLY

NOTEIf it is hard to remove the secondary piston from the

cylinder, gradually apply compressed air from the outlet

port on the secondary end of the master cylinder.

INSPECTIONM35HDAF

lCheck the inner surface of master cylinder body for rust or

pitting.

lCheck the primary and secondary pistons for rust, scoring,

wear, damage or wear.

l Check the diaphragm for cracks and wear.

‘.‘d I

TSB Revision

Page 793 of 1146

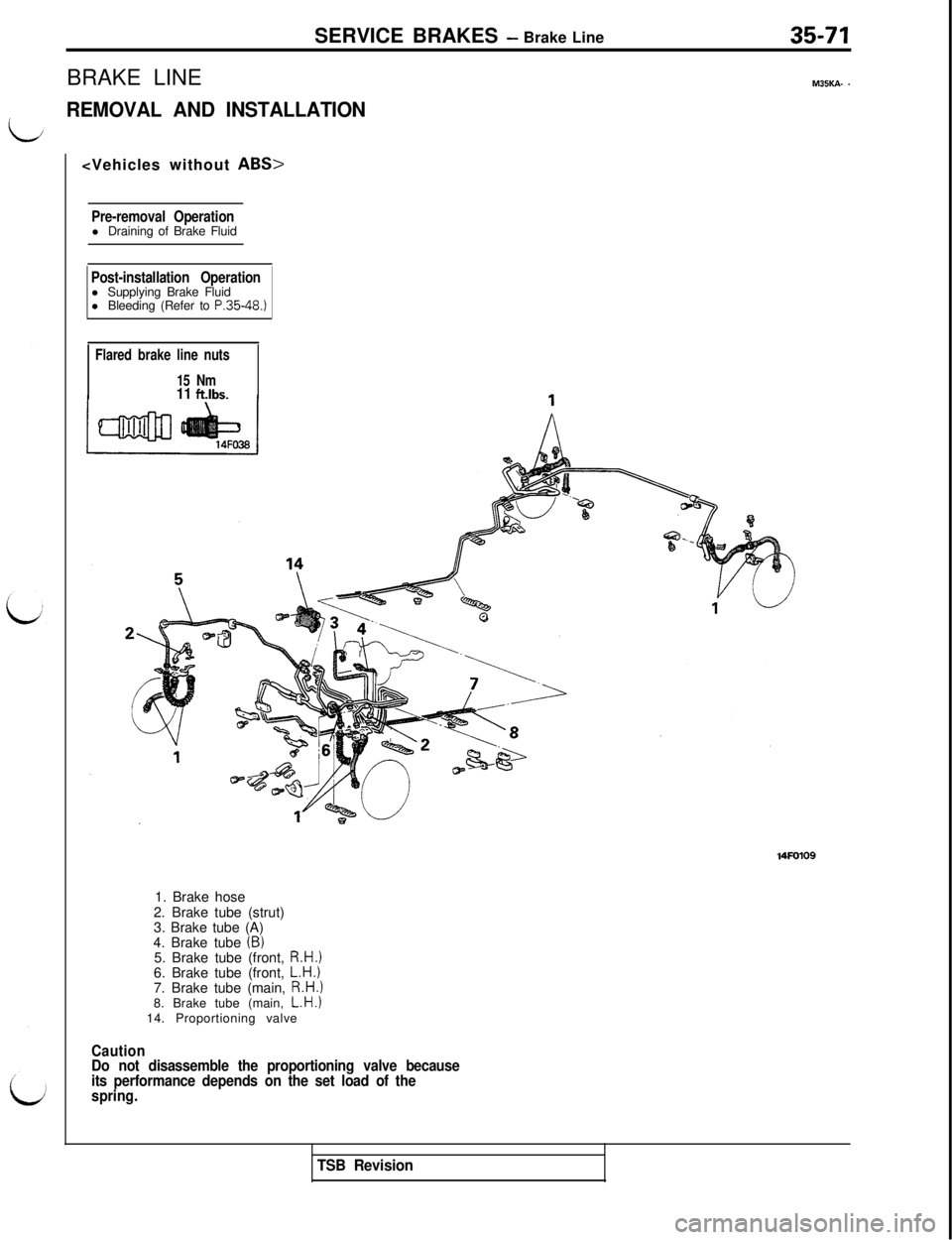

SERVICE BRAKES - Brake Line

BRAKE LINE

REMOVAL AND INSTALLATION35-71

M35uA. -

ABS>

Pre-removal Operationl Draining of Brake Fluid

Post-installation Operationl Supplying Brake Fluid

l Bleeding (Refer to P.35-48.)

Flared brake line nuts

15 Nm

11 ft.lbs.1. Brake hose

2. Brake tube (strut)

3. Brake tube (A)

4. Brake tube

(B)5. Brake tube (front, R.H.)6. Brake tube (front, L.H.)7. Brake tube (main, R.H.)8. Brake tube (main, L.H.)14. Proportioning valve

Caution

Do not disassemble the proportioning valve because

its performance depends on the set load of the

spring.

TSB Revision

Page 794 of 1146

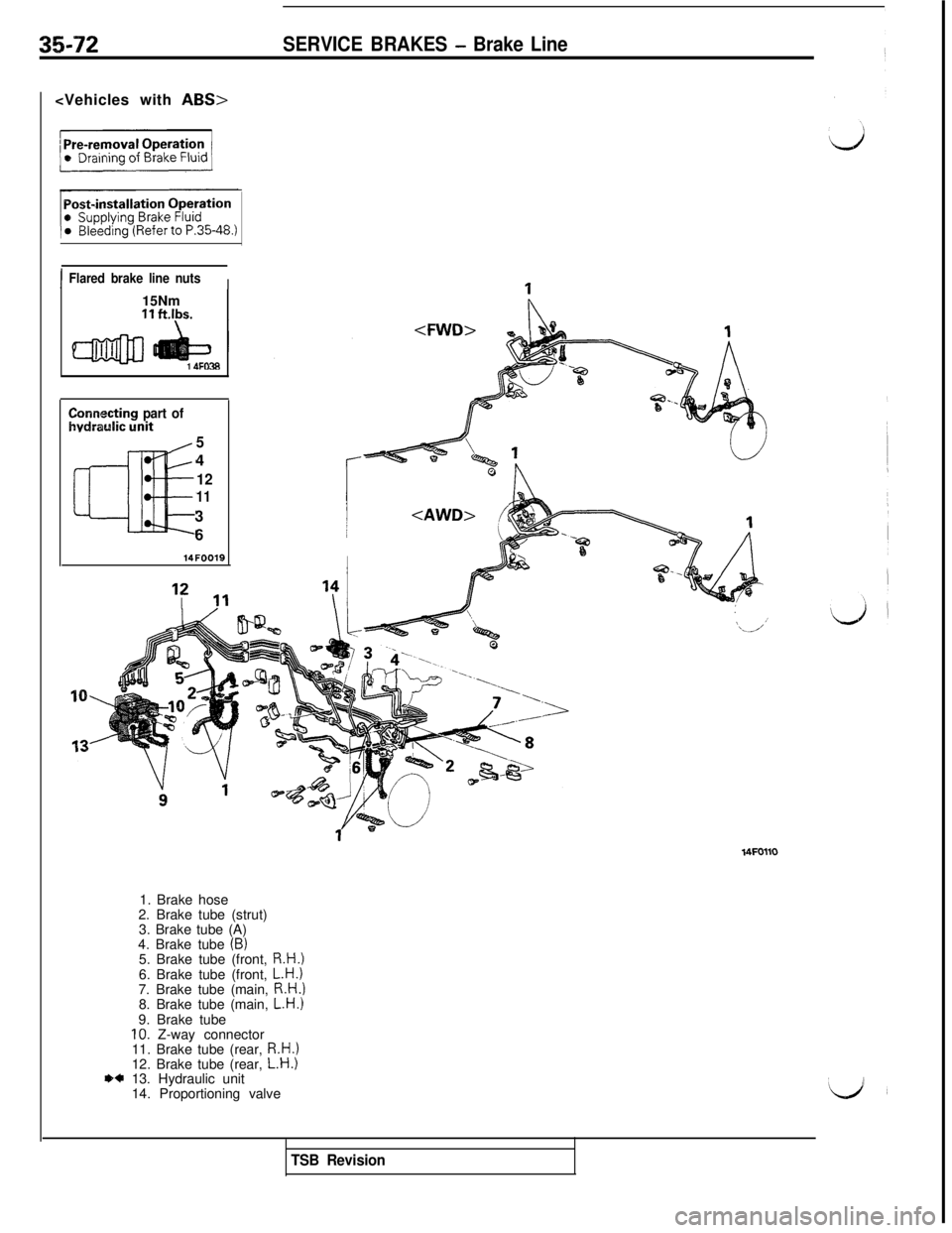

35-72SERVICE BRAKES - Brake Line

ABS>

IFlared brake line nutsI15Nm

11 ft.lbs.

1 AFO38

Cormecting part ofhvdraulic wnit

54

12

113

614FOOlS

,1. Brake hose

2. Brake tube (strut)

3. Brake tube (A)

4. Brake tube

(B)5. Brake tube (front, R.H.)6. Brake tube (front, L.H.)7. Brake tube (main, R.H.)8. Brake tube (main, L.H.)9. Brake tube

10. Z-way connector

11. Brake tube (rear, R.H.)12. Brake tube (rear, L.H.)O+ 13. Hydraulic unit

14. Proportioning valve

TSB Revision

Page 795 of 1146

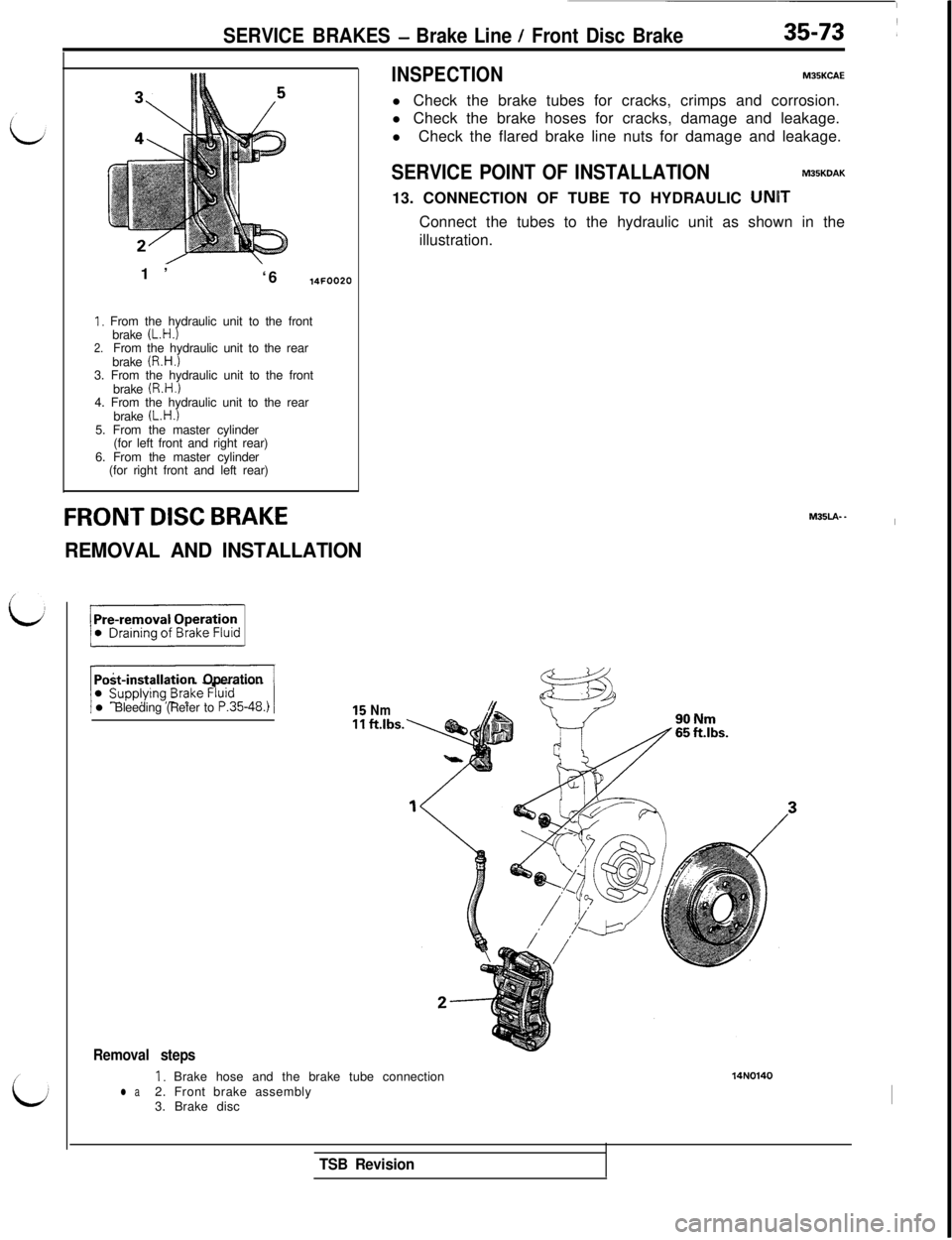

SERVICE BRAKES - Brake Line / Front Disc Brake35-73 (1’

‘6

14FOO20

1. From the hydraulic unit to the front

brake (L.H.)2.From the hydraulic unit to the rear

brake (R.H.)3. From the hydraulic unit to the front

brake

(R.H.)4. From the hydraulic unit to the rear

brake

(L.H.)5. From the master cylinder

(for left front and right rear)

6. From the master cylinder

(for right front and left rear)

INSPECTIONMPBKCAEl Check the brake tubes for cracks, crimps and corrosion.

l Check the brake hoses for cracks, damage and leakage.

lCheck the flared brake line nuts for damage and leakage.

SERVICE POINT OF INSTALLATIONMOBKDAK13. CONNECTION OF TUBE TO HYDRAULIC

UNIITConnect the tubes to the hydraulic unit as shown in the

illustration.

FRONT DISC BRAKE

REMOVAL AND INSTALLATIONM35LA-.

I

Pod-installation Operationl Bleeding (Refer to

P.35-48.)

::Nmft.lbs.

Removal steps

I, Brake hose and the brake tube connection14N0140

l a2. Front brake assembly

3. Brake discI

TSB Revision

Page 796 of 1146

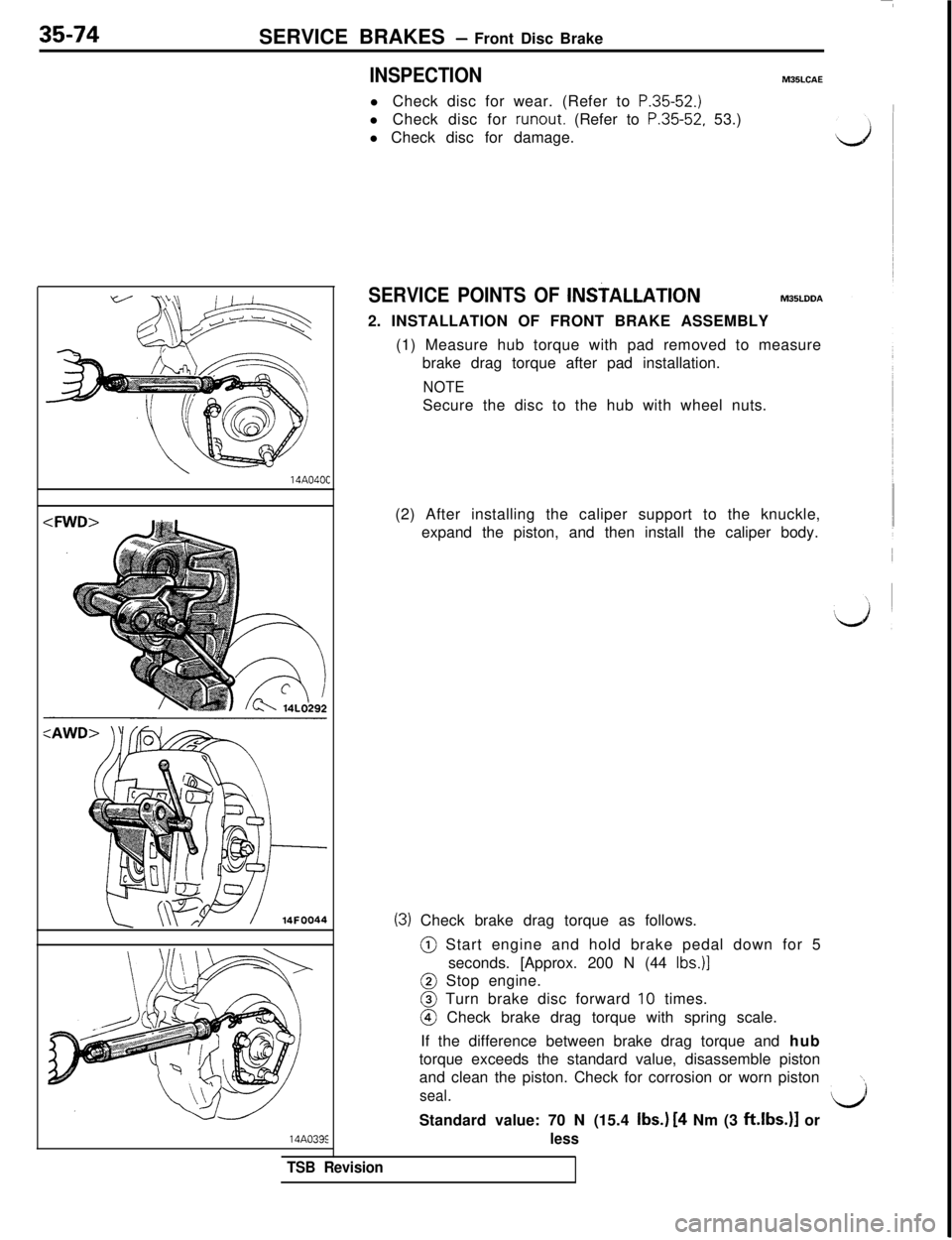

35-74

SERVICE BRAKES - Front Disc Brake

INSPECTIONM35LCAEl Check disc for wear. (Refer to

P.35-52.)l Check disc for runout. (Refer to

P.35-52, 53.)Il Check disc for damage.14A040C

(2) After installing the caliper support to the knuckle,

expand the piston, and then install the caliper body.

(3) Check brake drag torque as follows.@ Start engine and hold brake pedal down for 5

seconds. [Approx. 200 N (44

Ibs.)]@ Stop engine.@ Turn brake disc forward

10 times.@ Check brake drag torque with spring scale.

If the difference between brake drag torque and hub

torque exceeds the standard value, disassemble piston

and clean the piston. Check for corrosion or worn piston

\\

seal.l/iStandard value: 70 N (15.4 Ibs.)

[4 Nm (3 ft.lbs.)l or14A033E

less

SERVICE POINTS OF lNS?ALLATlONM35LDDA2. INSTALLATION OF FRONT BRAKE ASSEMBLY

(1) Measure hub torque with pad removed to measure

brake drag torque after pad installation.

NOTESecure the disc to the hub with wheel nuts.

TSB Revision

Page 797 of 1146

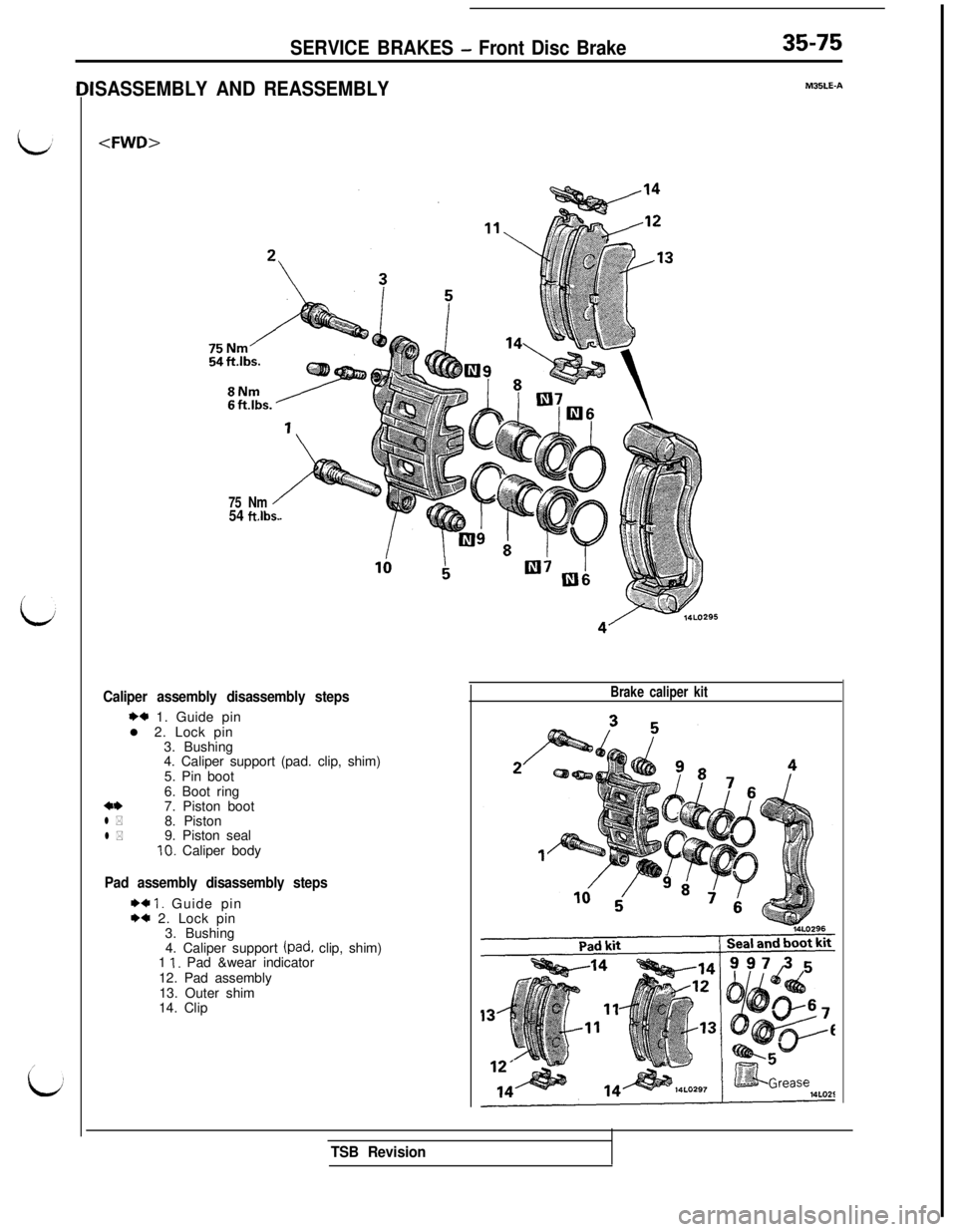

SERVICE BRAKES - Front Disc Brake35-75

SASSEMBLY AND REASSEMBLYM35LE-A

Caliper assembly disassembly steps

1)* 1. Guide pin

l 2. Lock pin

3. Bushing

4. Caliper support (pad. clip, shim)

5. Pin boot

6. Boot ring

7. Piston boot

8. Piston

9. Piston sealIO. Caliper body

a*l *

l *

Pad assembly disassembly steps

I)+ I. Guide pinw 2. Lock pin

3. Bushing

4. Caliper support

(pad, clip, shim)

1 I. Pad &wear indicator

12. Pad assembly

13. Outer shim

14. Clip

75 Nm54 ftlbs.

Brake caliper kit

TSB Revision

Page 798 of 1146

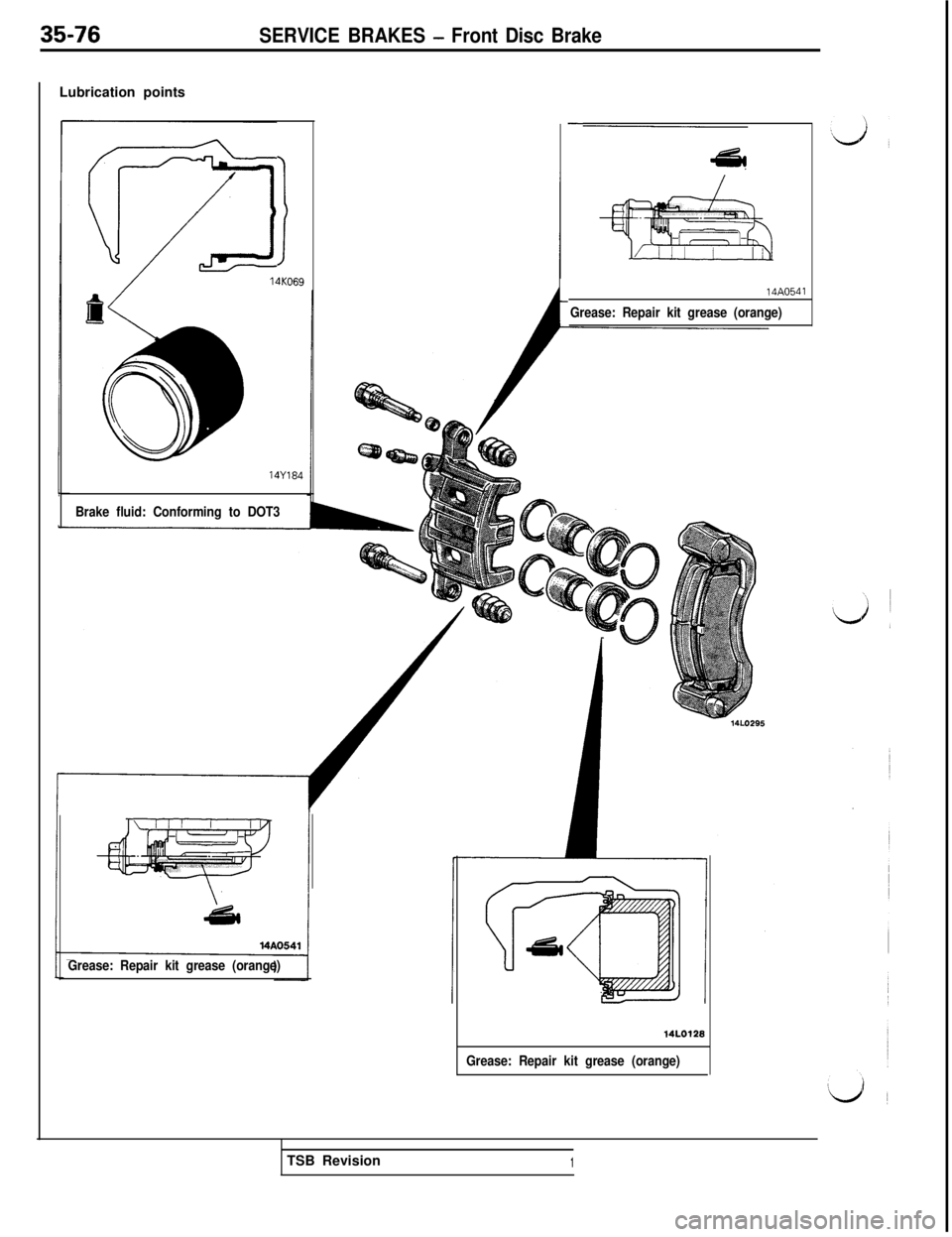

35-76SERVICE BRAKES - Front Disc BrakeLubrication points

!14KO6914Y184

-

ai

Brake fluid: Conforming to DOT3

Grease: Repair kit grease (orange)14A0541

Grease: Repair kit grease (orange)

14LO128

Grease: Repair kit grease (orange)TSB Revision

1

Page 799 of 1146

SERVICE BRAKES - Front Disc Brake35-77

14AO553

14AO55114uoo7i

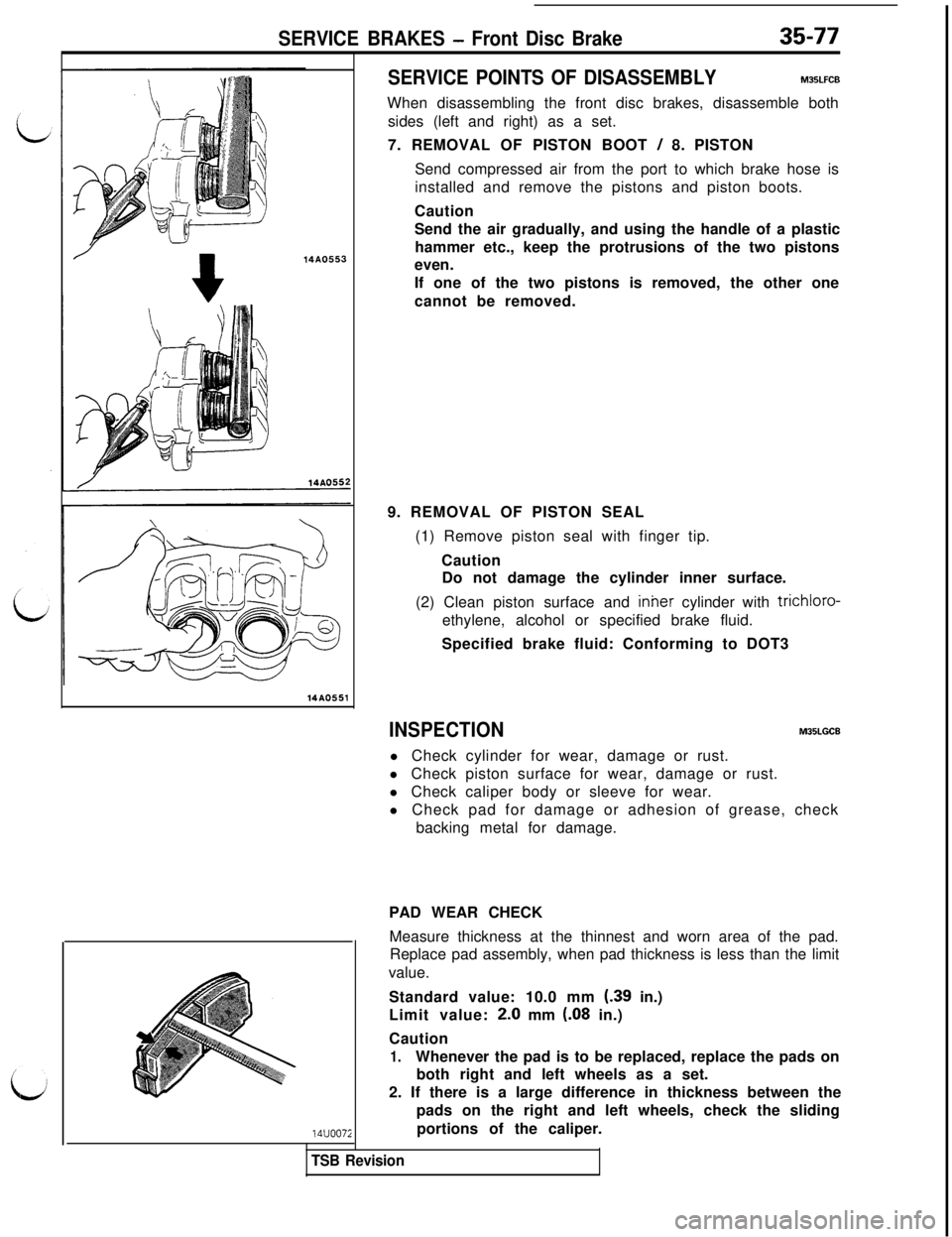

SERVICE POINTS OF DISASSEMBLYM35LFCB

When disassembling the front disc brakes, disassemble both

sides (left and right) as a set.

7. REMOVAL OF PISTON BOOT

/ 8. PISTON

Send compressed air from the port to which brake hose is

installed and remove the pistons and piston boots.

Caution

Send the air gradually, and using the handle of a plastic

hammer etc., keep the protrusions of the two pistons

even.

If one of the two pistons is removed, the other one

cannot be removed.

9. REMOVAL OF PISTON SEAL

(1) Remove piston seal with finger tip.

Caution

Do not damage the cylinder inner surface.

(2) Clean piston surface and inher cylinder with trichloro-

ethylene, alcohol or specified brake fluid.

Specified brake fluid: Conforming to DOT3

INSPECTIONMOBLGCBl Check cylinder for wear, damage or rust.

l Check piston surface for wear, damage or rust.

l Check caliper body or sleeve for wear.

l Check pad for damage or adhesion of grease, check

backing metal for damage.

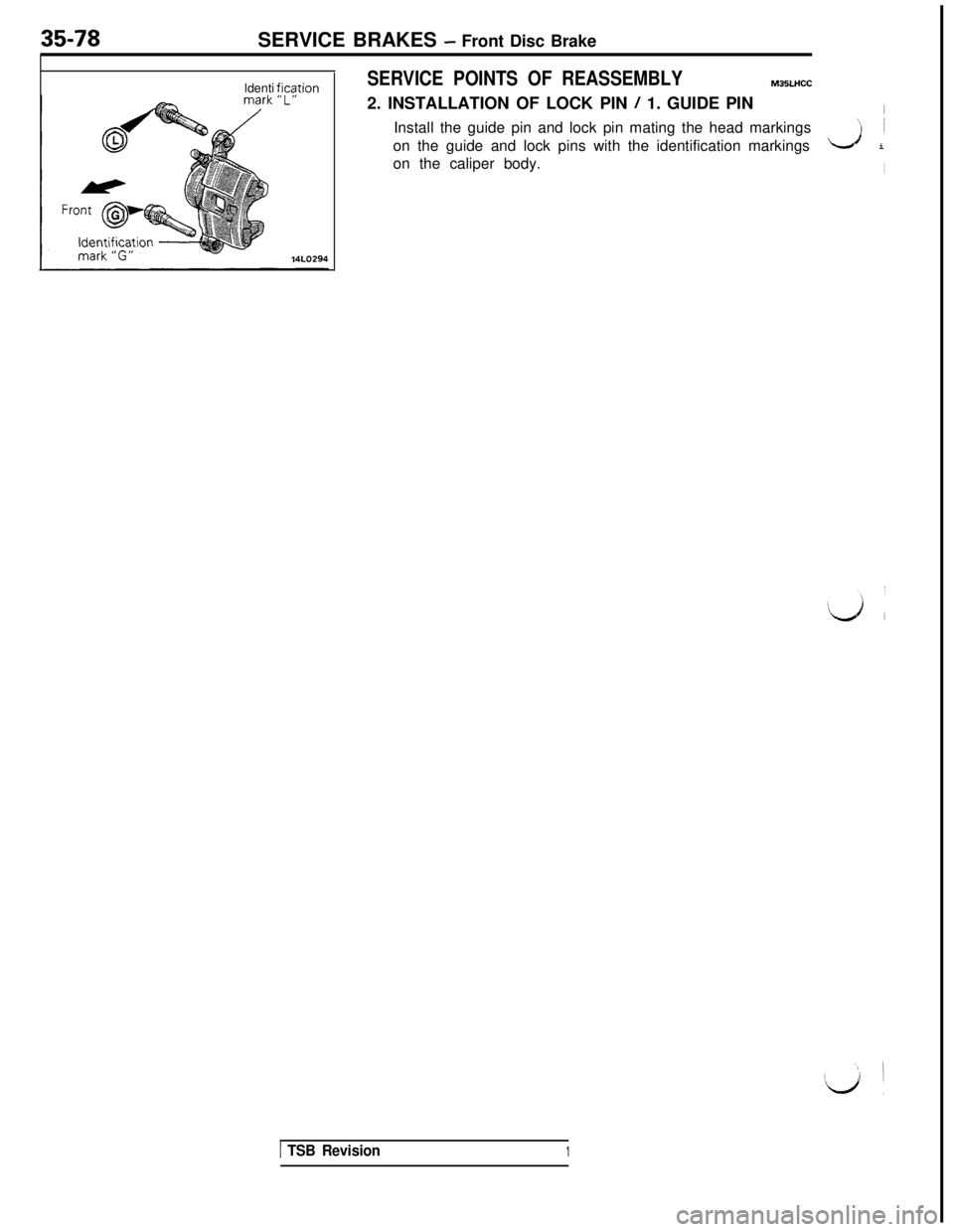

PAD WEAR CHECK

Measure thickness at the thinnest and worn area of the pad.

Replace pad assembly, when pad thickness is less than the limit

value.

Standard value: 10.0 mm (.39 in.)

Limit value: 2.0 mm

(08 in.)

Caution

1.Whenever the pad is to be replaced, replace the pads on

both right and left wheels as a set.

2. If there is a large difference in thickness between the

pads on the right and left wheels, check the sliding

portions of the caliper.

TSB Revision

Page 800 of 1146

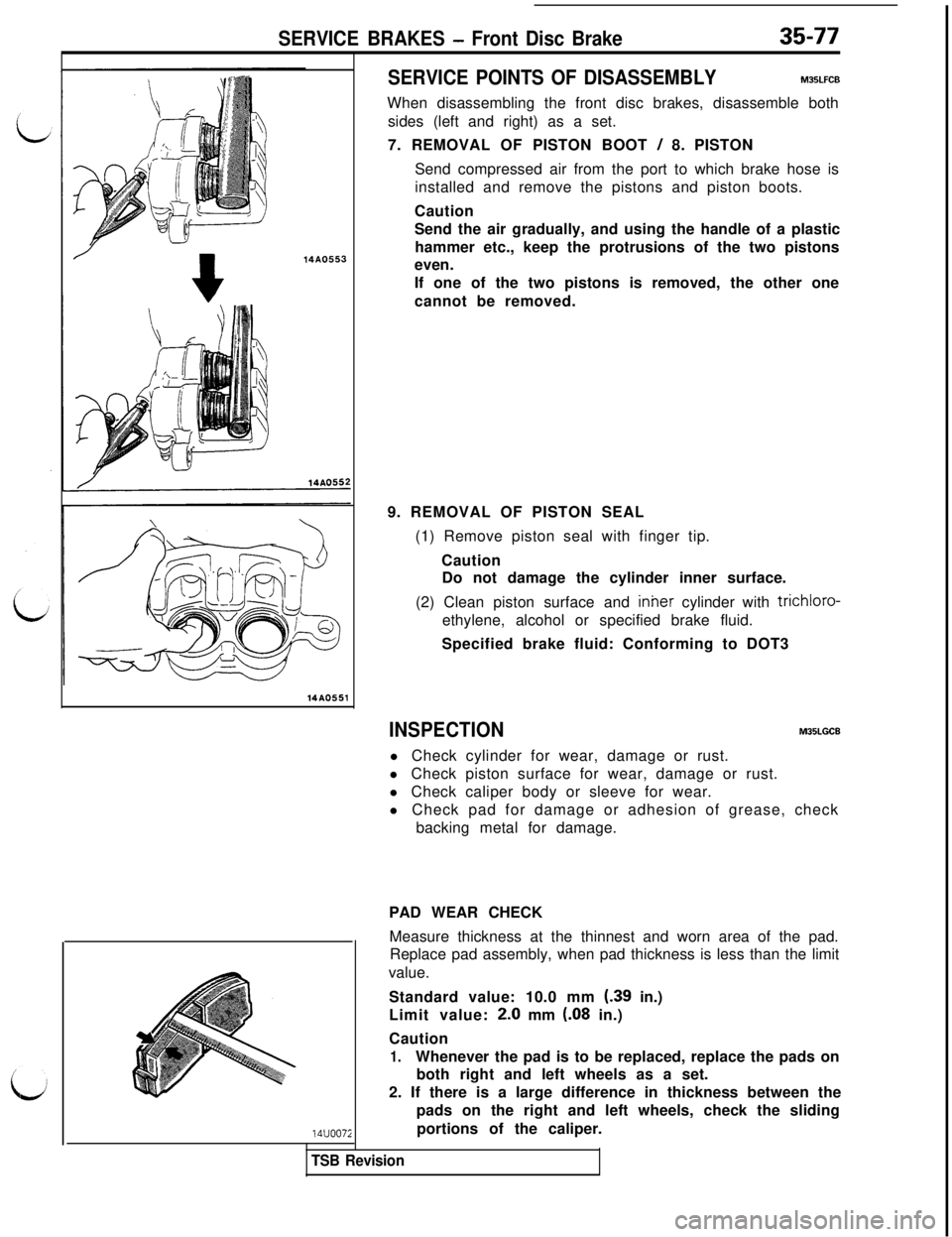

SERVICE BRAKES - Front Disc Brake

ldenti

ficationSERVICE POINTS OF REASSEMBLYM35LHCC2. INSTALLATION OF LOCK PIN

/ 1. GUIDE PINIInstall the guide pin and lock pin mating the head markings

‘I ~

on the guide and lock pins with the identification markings

LJ i

on the caliper body.

I

1 TSB Revision1

Trending: coolant reservoir, wheel bolt torque, air bleeding, gas mileage, automatic transmission fluid, transmission fluid, length