NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1071 of 1659

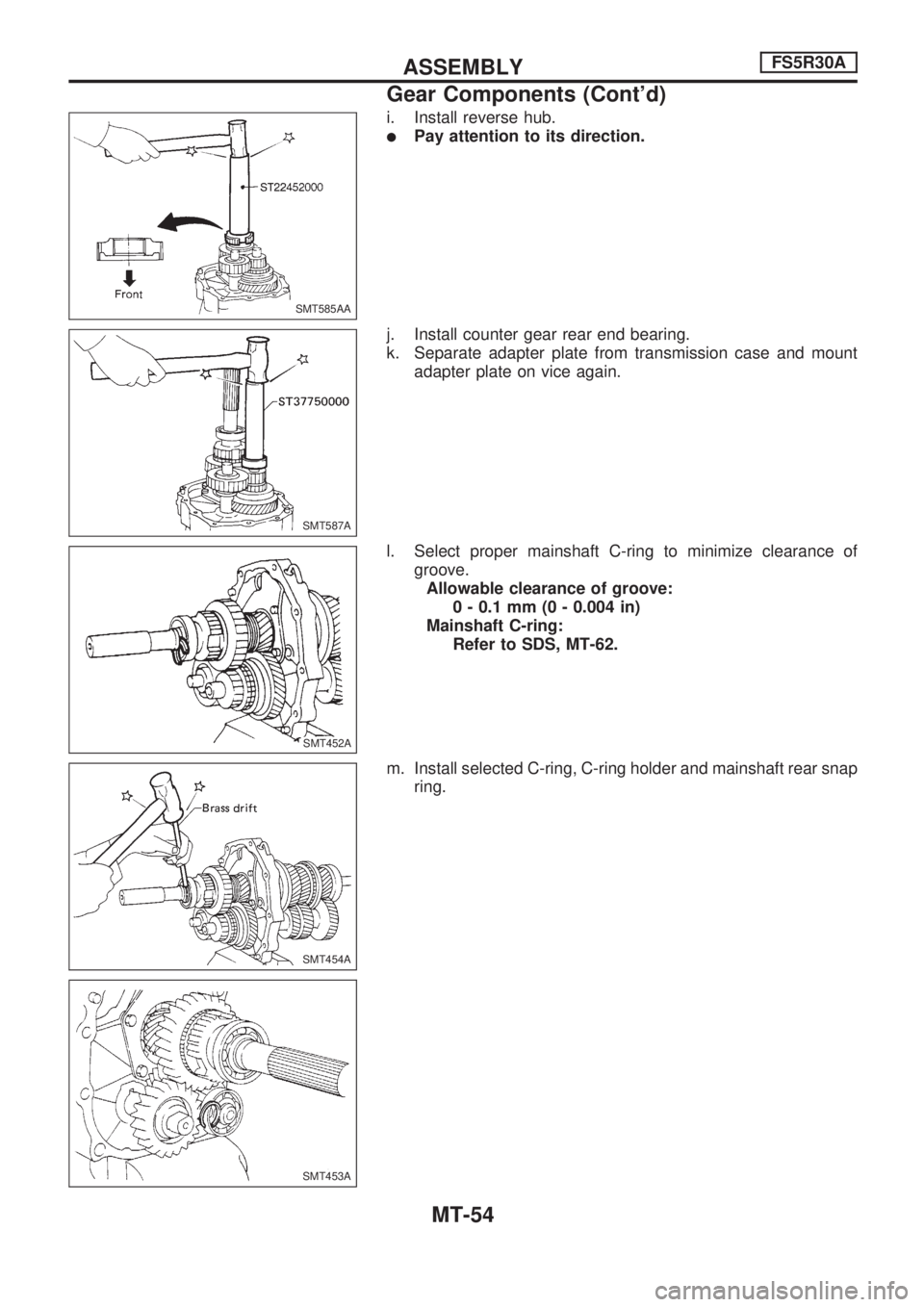

i. Install reverse hub.

lPay attention to its direction.

j. Install counter gear rear end bearing.

k. Separate adapter plate from transmission case and mount

adapter plate on vice again.

l. Select proper mainshaft C-ring to minimize clearance of

groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Mainshaft C-ring:

Refer to SDS, MT-62.

m. Install selected C-ring, C-ring holder and mainshaft rear snap

ring.

SMT585AA

SMT587A

SMT452A.SMT452A

SMT454A

SMT453A

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-54

Page 1072 of 1659

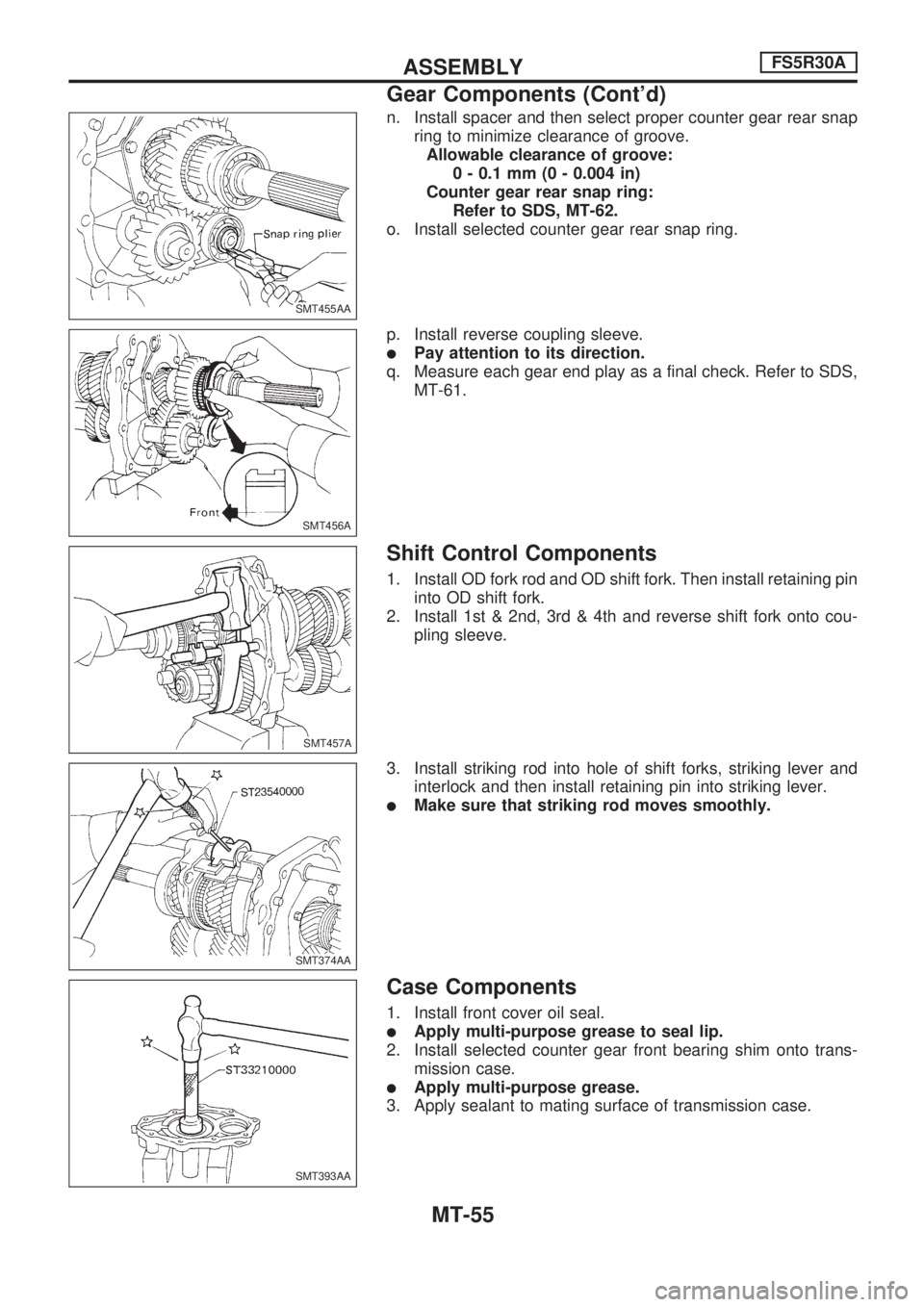

n. Install spacer and then select proper counter gear rear snap

ring to minimize clearance of groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Counter gear rear snap ring:

Refer to SDS, MT-62.

o. Install selected counter gear rear snap ring.

p. Install reverse coupling sleeve.

lPay attention to its direction.

q. Measure each gear end play as a final check. Refer to SDS,

MT-61.

Shift Control Components

1. Install OD fork rod and OD shift fork. Then install retaining pin

into OD shift fork.

2. Install 1st & 2nd, 3rd & 4th and reverse shift fork onto cou-

pling sleeve.

3. Install striking rod into hole of shift forks, striking lever and

interlock and then install retaining pin into striking lever.

lMake sure that striking rod moves smoothly.

Case Components

1. Install front cover oil seal.

lApply multi-purpose grease to seal lip.

2. Install selected counter gear front bearing shim onto trans-

mission case.

lApply multi-purpose grease.

3. Apply sealant to mating surface of transmission case.

SMT455AA.SMT455AA

SMT456A

SMT457A.SMT457A

SMT374AA.SMT374AA

SMT393AA

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-55

Page 1073 of 1659

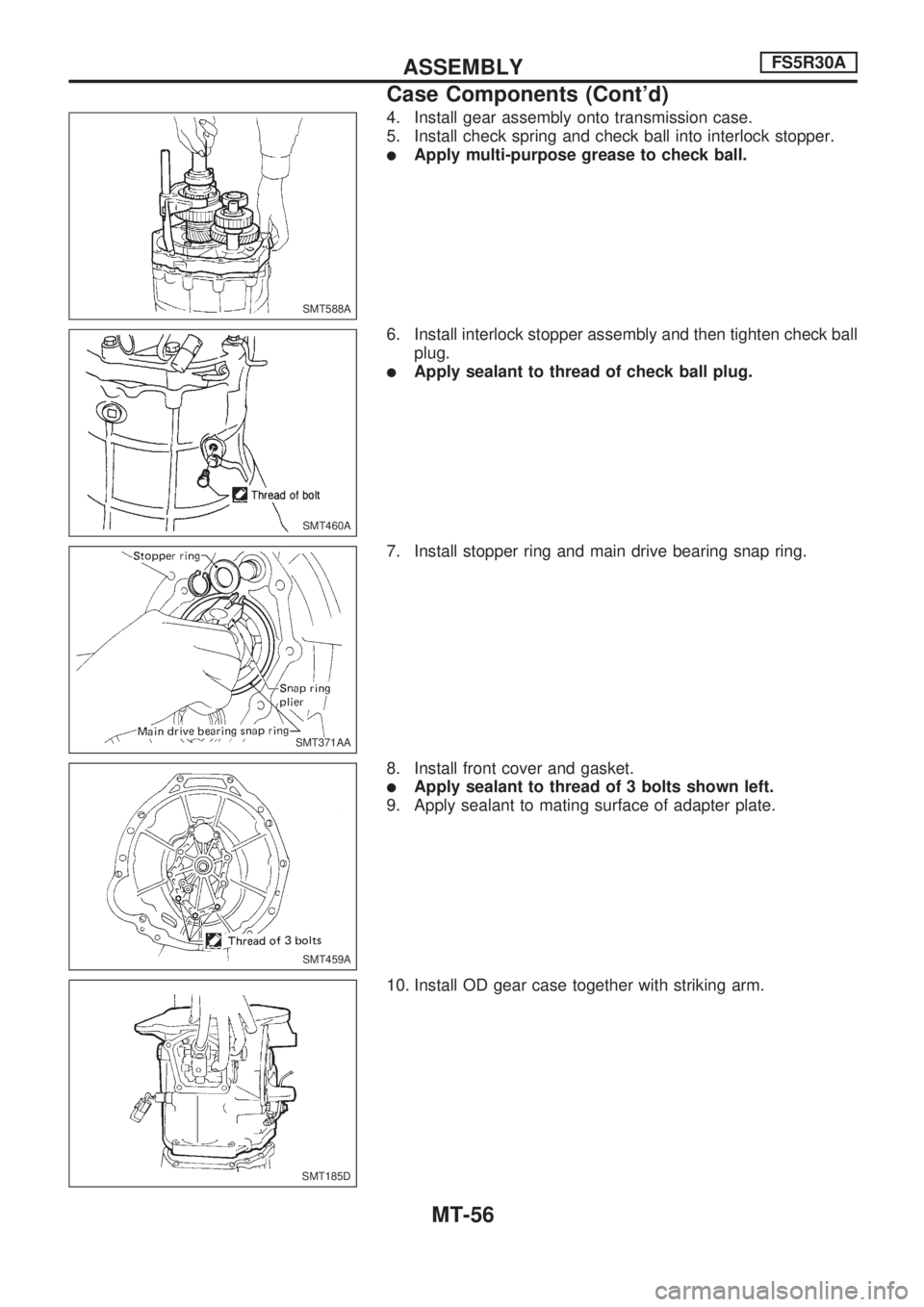

4. Install gear assembly onto transmission case.

5. Install check spring and check ball into interlock stopper.

lApply multi-purpose grease to check ball.

6. Install interlock stopper assembly and then tighten check ball

plug.

lApply sealant to thread of check ball plug.

7. Install stopper ring and main drive bearing snap ring.

8. Install front cover and gasket.

lApply sealant to thread of 3 bolts shown left.

9. Apply sealant to mating surface of adapter plate.

10. Install OD gear case together with striking arm.

SMT588A

SMT460A

SMT371AA

SMT459A

SMT185D

ASSEMBLYFS5R30A

Case Components (Cont'd)

MT-56

Page 1074 of 1659

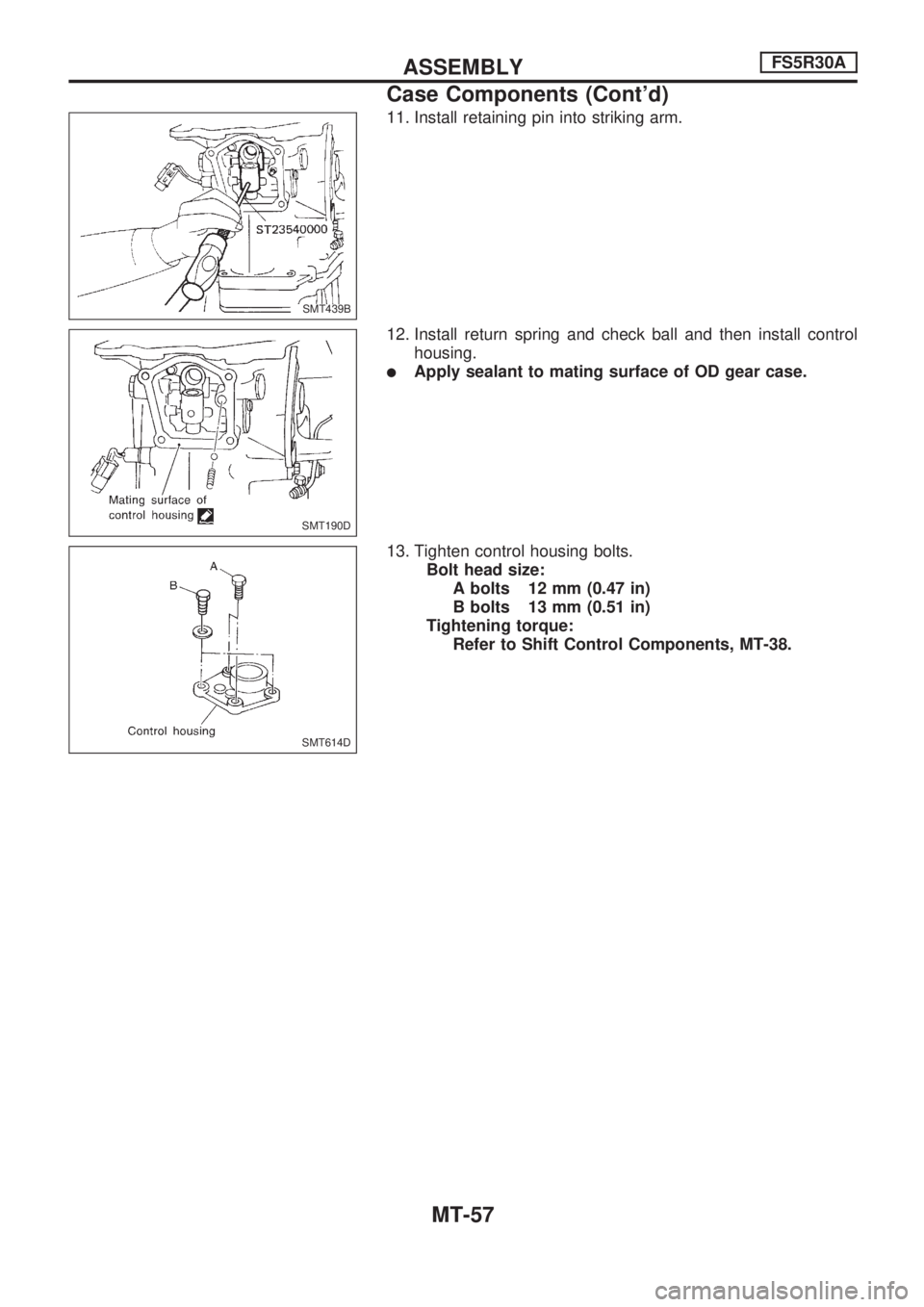

11. Install retaining pin into striking arm.

12. Install return spring and check ball and then install control

housing.

lApply sealant to mating surface of OD gear case.

13. Tighten control housing bolts.

Bolt head size:

A bolts 12 mm (0.47 in)

B bolts 13 mm (0.51 in)

Tightening torque:

Refer to Shift Control Components, MT-38.

SMT439B

SMT190D

SMT614D

ASSEMBLYFS5R30A

Case Components (Cont'd)

MT-57

Page 1075 of 1659

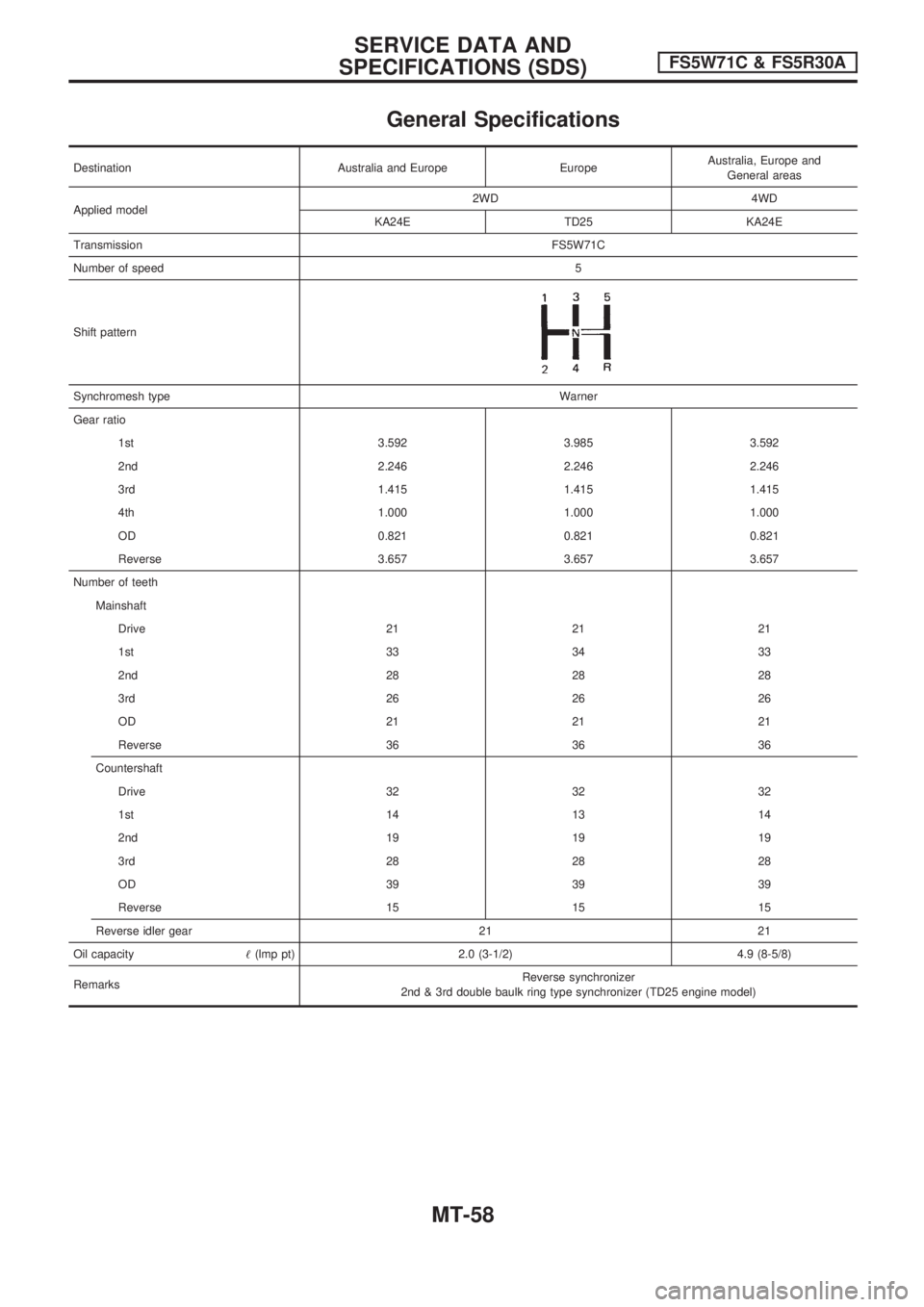

General Specifications

Destination Australia and Europe EuropeAustralia, Europe and

General areas

Applied model2WD 4WD

KA24E TD25 KA24E

TransmissionFS5W71C

Number of speed5

Shift pattern

Synchromesh typeWarner

Gear ratio

1st 3.592 3.985 3.592

2nd 2.246 2.246 2.246

3rd 1.415 1.415 1.415

4th 1.000 1.000 1.000

OD 0.821 0.821 0.821

Reverse 3.657 3.657 3.657

Number of teeth

Mainshaft

Drive 21 21 21

1st 33 34 33

2nd 28 28 28

3rd 26 26 26

OD 21 21 21

Reverse 36 36 36

Countershaft

Drive 32 32 32

1st 14 13 14

2nd 19 19 19

3rd 28 28 28

OD 39 39 39

Reverse 15 15 15

Reverse idler gear 21 21

Oil capacity!(lmp pt) 2.0 (3-1/2) 4.9 (8-5/8)

RemarksReverse synchronizer

2nd & 3rd double baulk ring type synchronizer (TD25 engine model)

SERVICE DATA AND

SPECIFICATIONS (SDS)FS5W71C & FS5R30A

MT-58

Page 1076 of 1659

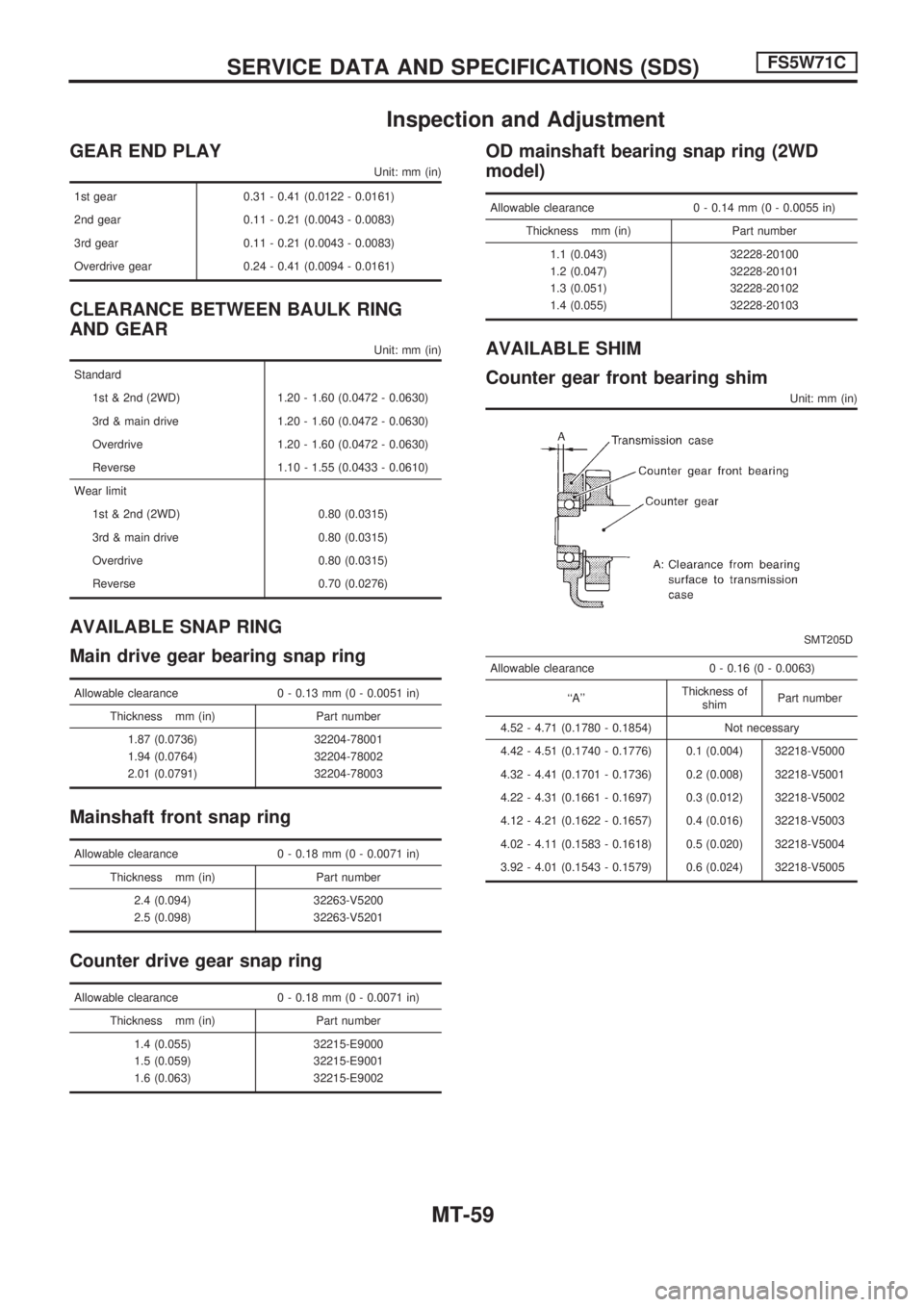

Inspection and Adjustment

GEAR END PLAY

Unit: mm (in)

1st gear 0.31 - 0.41 (0.0122 - 0.0161)

2nd gear 0.11 - 0.21 (0.0043 - 0.0083)

3rd gear 0.11 - 0.21 (0.0043 - 0.0083)

Overdrive gear 0.24 - 0.41 (0.0094 - 0.0161)

CLEARANCE BETWEEN BAULK RING

AND GEAR

Unit: mm (in)

Standard

1st & 2nd (2WD) 1.20 - 1.60 (0.0472 - 0.0630)

3rd & main drive 1.20 - 1.60 (0.0472 - 0.0630)

Overdrive 1.20 - 1.60 (0.0472 - 0.0630)

Reverse 1.10 - 1.55 (0.0433 - 0.0610)

Wear limit

1st & 2nd (2WD) 0.80 (0.0315)

3rd & main drive 0.80 (0.0315)

Overdrive 0.80 (0.0315)

Reverse 0.70 (0.0276)

AVAILABLE SNAP RING

Main drive gear bearing snap ring

Allowable clearance 0 - 0.13 mm (0 - 0.0051 in)

Thickness mm (in) Part number

1.87 (0.0736) 32204-78001

1.94 (0.0764) 32204-78002

2.01 (0.0791) 32204-78003

Mainshaft front snap ring

Allowable clearance 0 - 0.18 mm (0 - 0.0071 in)

Thickness mm (in) Part number

2.4 (0.094) 32263-V5200

2.5 (0.098) 32263-V5201

Counter drive gear snap ring

Allowable clearance 0 - 0.18 mm (0 - 0.0071 in)

Thickness mm (in) Part number

1.4 (0.055) 32215-E9000

1.5 (0.059) 32215-E9001

1.6 (0.063) 32215-E9002

OD mainshaft bearing snap ring (2WD

model)

Allowable clearance 0 - 0.14 mm (0 - 0.0055 in)

Thickness mm (in) Part number

1.1 (0.043) 32228-20100

1.2 (0.047) 32228-20101

1.3 (0.051) 32228-20102

1.4 (0.055) 32228-20103

AVAILABLE SHIM

Counter gear front bearing shim

Unit: mm (in)

SMT205D

Allowable clearance 0 - 0.16 (0 - 0.0063)

``A''Thickness of

shimPart number

4.52 - 4.71 (0.1780 - 0.1854) Not necessary

4.42 - 4.51 (0.1740 - 0.1776) 0.1 (0.004) 32218-V5000

4.32 - 4.41 (0.1701 - 0.1736) 0.2 (0.008) 32218-V5001

4.22 - 4.31 (0.1661 - 0.1697) 0.3 (0.012) 32218-V5002

4.12 - 4.21 (0.1622 - 0.1657) 0.4 (0.016) 32218-V5003

4.02 - 4.11 (0.1583 - 0.1618) 0.5 (0.020) 32218-V5004

3.92 - 4.01 (0.1543 - 0.1579) 0.6 (0.024) 32218-V5005

SERVICE DATA AND SPECIFICATIONS (SDS)FS5W71C

MT-59

Page 1077 of 1659

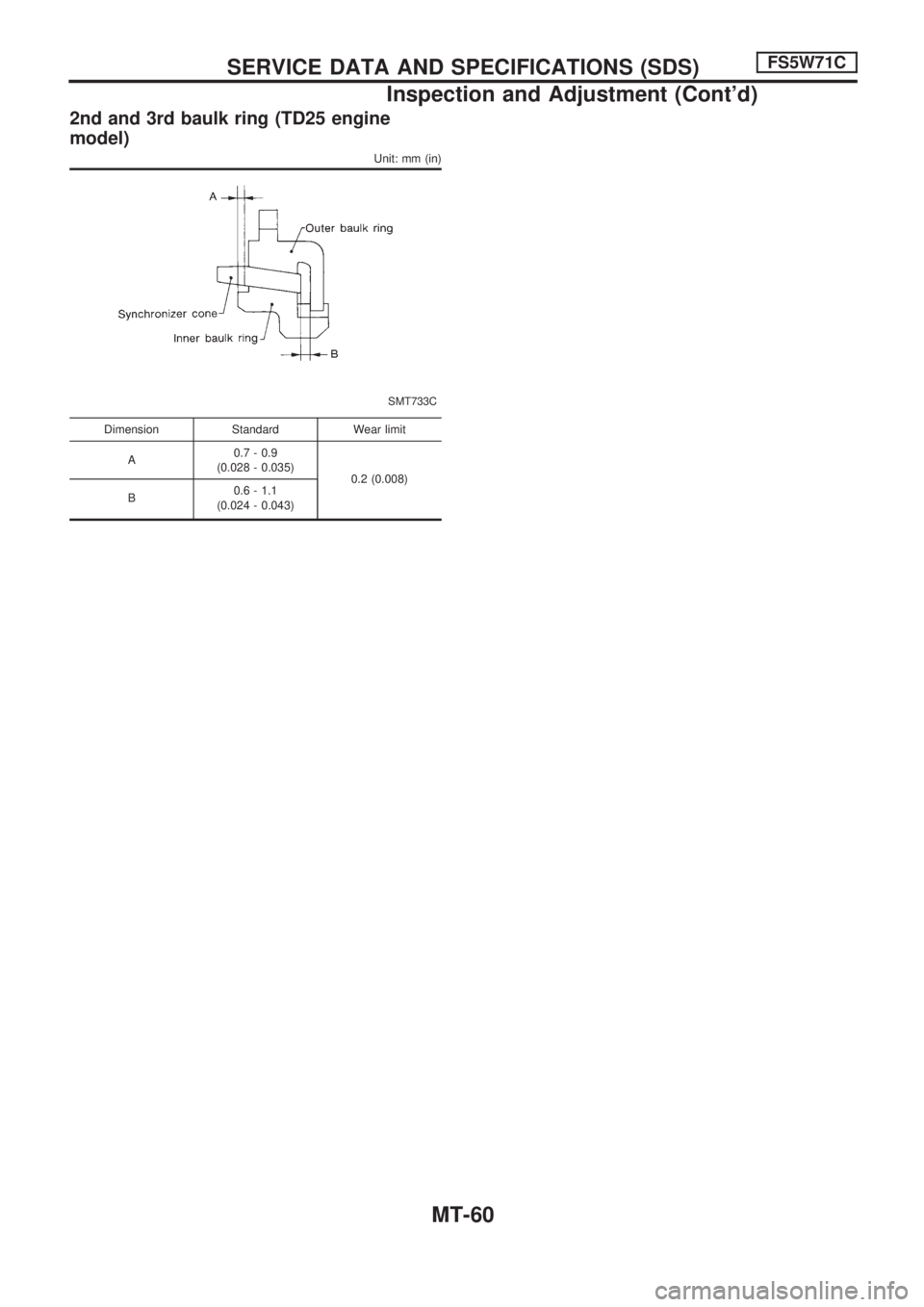

2nd and 3rd baulk ring (TD25 engine

model)

Unit: mm (in)

SMT733C

Dimension Standard Wear limit

A0.7 - 0.9

(0.028 - 0.035)

0.2 (0.008)

B0.6 - 1.1

(0.024 - 0.043)

SERVICE DATA AND SPECIFICATIONS (SDS)FS5W71C

Inspection and Adjustment (Cont'd)

MT-60

Page 1078 of 1659

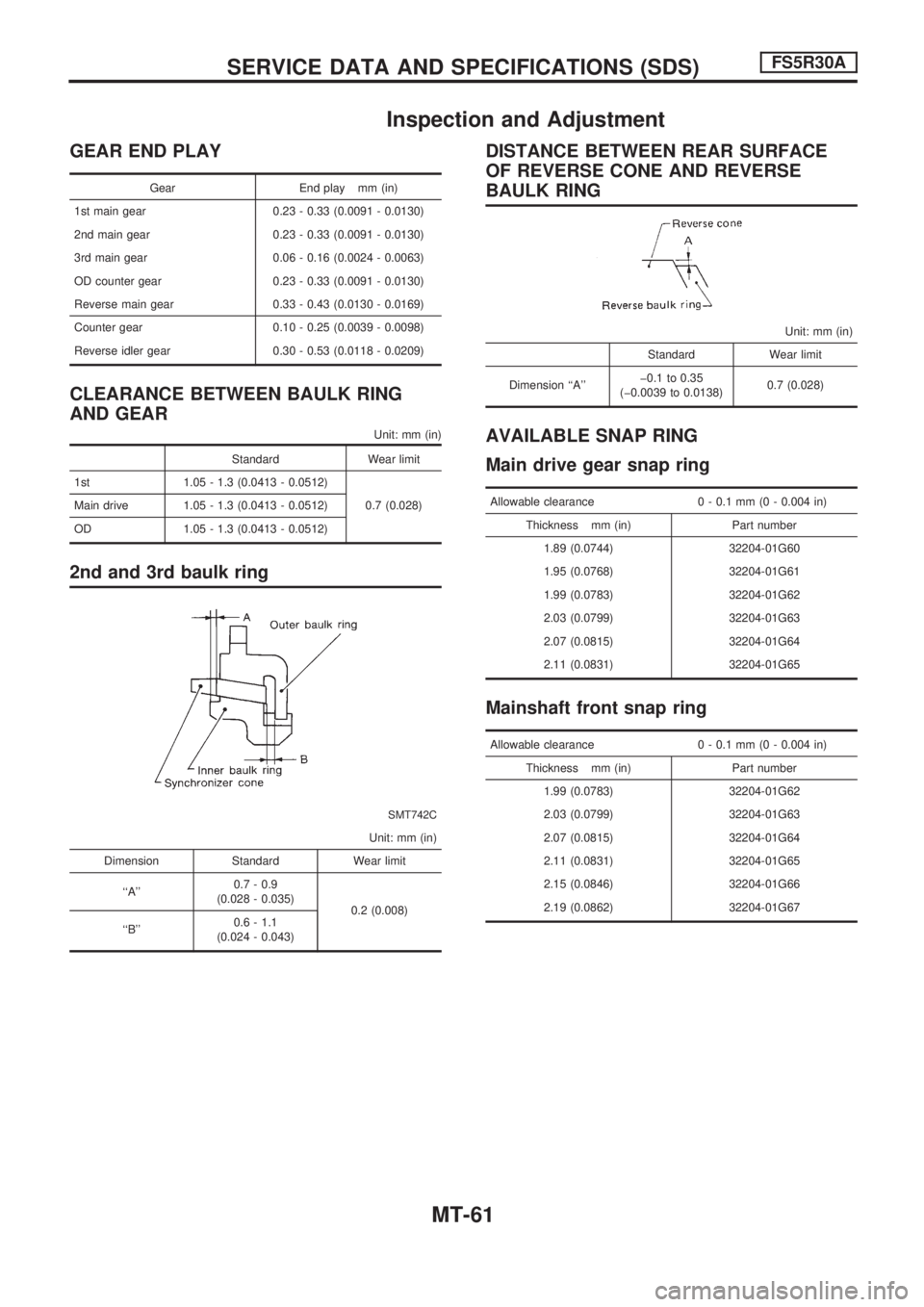

Inspection and Adjustment

GEAR END PLAY

Gear End play mm (in)

1st main gear 0.23 - 0.33 (0.0091 - 0.0130)

2nd main gear 0.23 - 0.33 (0.0091 - 0.0130)

3rd main gear 0.06 - 0.16 (0.0024 - 0.0063)

OD counter gear 0.23 - 0.33 (0.0091 - 0.0130)

Reverse main gear 0.33 - 0.43 (0.0130 - 0.0169)

Counter gear 0.10 - 0.25 (0.0039 - 0.0098)

Reverse idler gear 0.30 - 0.53 (0.0118 - 0.0209)

CLEARANCE BETWEEN BAULK RING

AND GEAR

Unit: mm (in)

Standard Wear limit

1st 1.05 - 1.3 (0.0413 - 0.0512)

0.7 (0.028) Main drive 1.05 - 1.3 (0.0413 - 0.0512)

OD 1.05 - 1.3 (0.0413 - 0.0512)

2nd and 3rd baulk ring

SMT742C

Unit: mm (in)

Dimension Standard Wear limit

``A''0.7 - 0.9

(0.028 - 0.035)

0.2 (0.008)

``B''0.6 - 1.1

(0.024 - 0.043)

DISTANCE BETWEEN REAR SURFACE

OF REVERSE CONE AND REVERSE

BAULK RING

Unit: mm (in)

Standard Wear limit

Dimension ``A''þ0.1 to 0.35

(þ0.0039 to 0.0138)0.7 (0.028)

AVAILABLE SNAP RING

Main drive gear snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.89 (0.0744) 32204-01G60

1.95 (0.0768) 32204-01G61

1.99 (0.0783) 32204-01G62

2.03 (0.0799) 32204-01G63

2.07 (0.0815) 32204-01G64

2.11 (0.0831) 32204-01G65

Mainshaft front snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.99 (0.0783) 32204-01G62

2.03 (0.0799) 32204-01G63

2.07 (0.0815) 32204-01G64

2.11 (0.0831) 32204-01G65

2.15 (0.0846) 32204-01G66

2.19 (0.0862) 32204-01G67

SERVICE DATA AND SPECIFICATIONS (SDS)FS5R30A

MT-61

Page 1079 of 1659

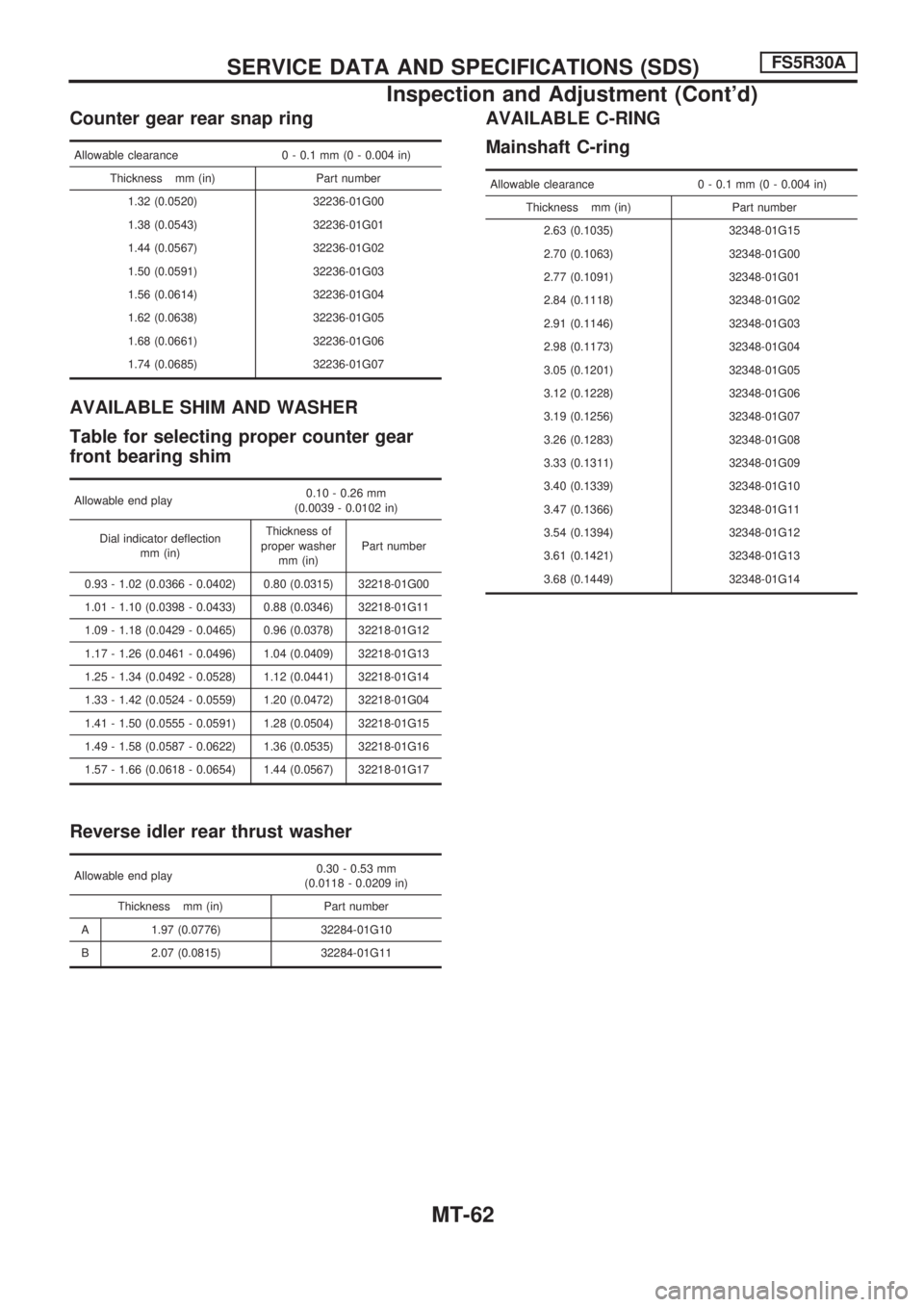

Counter gear rear snap ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

1.32 (0.0520) 32236-01G00

1.38 (0.0543) 32236-01G01

1.44 (0.0567) 32236-01G02

1.50 (0.0591) 32236-01G03

1.56 (0.0614) 32236-01G04

1.62 (0.0638) 32236-01G05

1.68 (0.0661) 32236-01G06

1.74 (0.0685) 32236-01G07

AVAILABLE SHIM AND WASHER

Table for selecting proper counter gear

front bearing shim

Allowable end play0.10 - 0.26 mm

(0.0039 - 0.0102 in)

Dial indicator deflection

mm (in)Thickness of

proper washer

mm (in)Part number

0.93 - 1.02 (0.0366 - 0.0402) 0.80 (0.0315) 32218-01G00

1.01 - 1.10 (0.0398 - 0.0433) 0.88 (0.0346) 32218-01G11

1.09 - 1.18 (0.0429 - 0.0465) 0.96 (0.0378) 32218-01G12

1.17 - 1.26 (0.0461 - 0.0496) 1.04 (0.0409) 32218-01G13

1.25 - 1.34 (0.0492 - 0.0528) 1.12 (0.0441) 32218-01G14

1.33 - 1.42 (0.0524 - 0.0559) 1.20 (0.0472) 32218-01G04

1.41 - 1.50 (0.0555 - 0.0591) 1.28 (0.0504) 32218-01G15

1.49 - 1.58 (0.0587 - 0.0622) 1.36 (0.0535) 32218-01G16

1.57 - 1.66 (0.0618 - 0.0654) 1.44 (0.0567) 32218-01G17

Reverse idler rear thrust washer

Allowable end play0.30 - 0.53 mm

(0.0118 - 0.0209 in)

Thickness mm (in) Part number

A 1.97 (0.0776) 32284-01G10

B 2.07 (0.0815) 32284-01G11

AVAILABLE C-RING

Mainshaft C-ring

Allowable clearance 0 - 0.1 mm (0 - 0.004 in)

Thickness mm (in) Part number

2.63 (0.1035) 32348-01G15

2.70 (0.1063) 32348-01G00

2.77 (0.1091) 32348-01G01

2.84 (0.1118) 32348-01G02

2.91 (0.1146) 32348-01G03

2.98 (0.1173) 32348-01G04

3.05 (0.1201) 32348-01G05

3.12 (0.1228) 32348-01G06

3.19 (0.1256) 32348-01G07

3.26 (0.1283) 32348-01G08

3.33 (0.1311) 32348-01G09

3.40 (0.1339) 32348-01G10

3.47 (0.1366) 32348-01G11

3.54 (0.1394) 32348-01G12

3.61 (0.1421) 32348-01G13

3.68 (0.1449) 32348-01G14

SERVICE DATA AND SPECIFICATIONS (SDS)FS5R30A

Inspection and Adjustment (Cont'd)

MT-62

Page 1080 of 1659

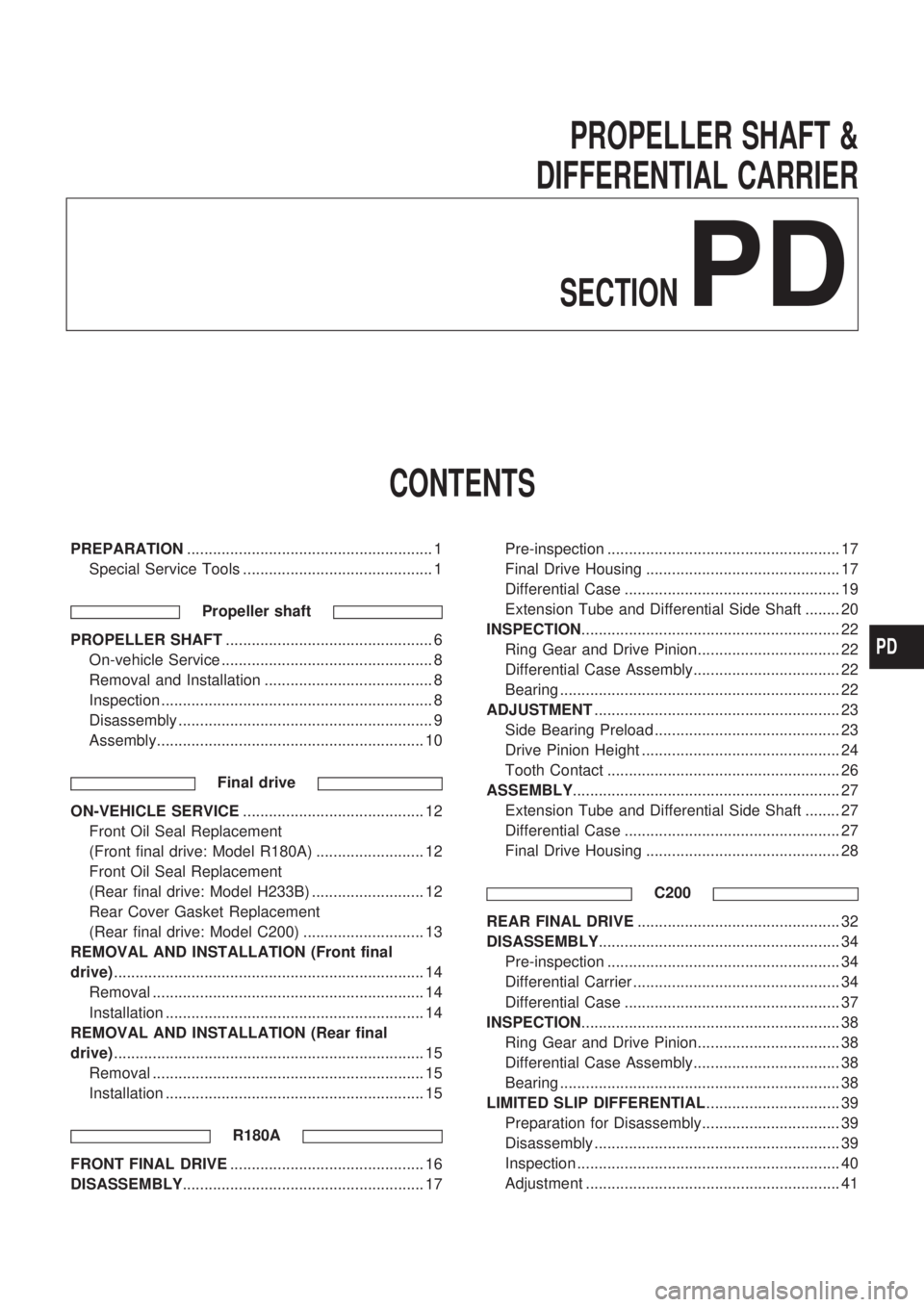

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

CONTENTS

PREPARATION......................................................... 1

Special Service Tools ............................................ 1

Propeller shaft

PROPELLER SHAFT................................................ 6

On-vehicle Service ................................................. 8

Removal and Installation ....................................... 8

Inspection ............................................................... 8

Disassembly ........................................................... 9

Assembly.............................................................. 10

Final drive

ON-VEHICLE SERVICE.......................................... 12

Front Oil Seal Replacement

(Front final drive: Model R180A) ......................... 12

Front Oil Seal Replacement

(Rear final drive: Model H233B) .......................... 12

Rear Cover Gasket Replacement

(Rear final drive: Model C200) ............................ 13

REMOVAL AND INSTALLATION (Front final

drive)........................................................................ 14

Removal ............................................................... 14

Installation ............................................................ 14

REMOVAL AND INSTALLATION (Rear final

drive)........................................................................ 15

Removal ............................................................... 15

Installation ............................................................ 15

R180A

FRONT FINAL DRIVE............................................. 16

DISASSEMBLY........................................................ 17Pre-inspection ...................................................... 17

Final Drive Housing ............................................. 17

Differential Case .................................................. 19

Extension Tube and Differential Side Shaft ........ 20

INSPECTION............................................................ 22

Ring Gear and Drive Pinion................................. 22

Differential Case Assembly.................................. 22

Bearing ................................................................. 22

ADJUSTMENT......................................................... 23

Side Bearing Preload ........................................... 23

Drive Pinion Height .............................................. 24

Tooth Contact ...................................................... 26

ASSEMBLY.............................................................. 27

Extension Tube and Differential Side Shaft ........ 27

Differential Case .................................................. 27

Final Drive Housing ............................................. 28

C200

REAR FINAL DRIVE............................................... 32

DISASSEMBLY........................................................ 34

Pre-inspection ...................................................... 34

Differential Carrier ................................................ 34

Differential Case .................................................. 37

INSPECTION............................................................ 38

Ring Gear and Drive Pinion................................. 38

Differential Case Assembly.................................. 38

Bearing ................................................................. 38

LIMITED SLIP DIFFERENTIAL............................... 39

Preparation for Disassembly................................ 39

Disassembly ......................................................... 39

Inspection ............................................................. 40

Adjustment ........................................................... 41

PD