NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 1081 of 1659

Assembly.............................................................. 43

ADJUSTMENT......................................................... 45

Side Bearing Preload ........................................... 45

Drive Pinion Height .............................................. 47

Tooth Contact ...................................................... 49

ASSEMBLY.............................................................. 50

Differential Case .................................................. 50

Differential Carrier ................................................ 51

H233B

REAR FINAL DRIVE............................................... 55

DISASSEMBLY........................................................ 56

Pre-inspection ...................................................... 56

Differential Carrier ................................................ 57

Differential Case .................................................. 59

INSPECTION............................................................ 60

Ring Gear and Drive Pinion................................. 60

Differential Case Assembly.................................. 60Bearing ................................................................. 60

LIMITED SLIP DIFFERENTIAL............................... 61

Preparation for Disassembly................................ 61

Disassembly ......................................................... 61

Inspection ............................................................. 62

Adjustment ........................................................... 63

Assembly.............................................................. 64

ADJUSTMENT......................................................... 67

Drive Pinion Height .............................................. 67

Tooth Contact ...................................................... 70

ASSEMBLY.............................................................. 71

Differential Case .................................................. 71

Differential Carrier ................................................ 72

SERVICE DATA AND SPECIFICATIONS (SDS)... 75

Propeller Shaft ..................................................... 75

Final Drive ............................................................ 77

Page 1082 of 1659

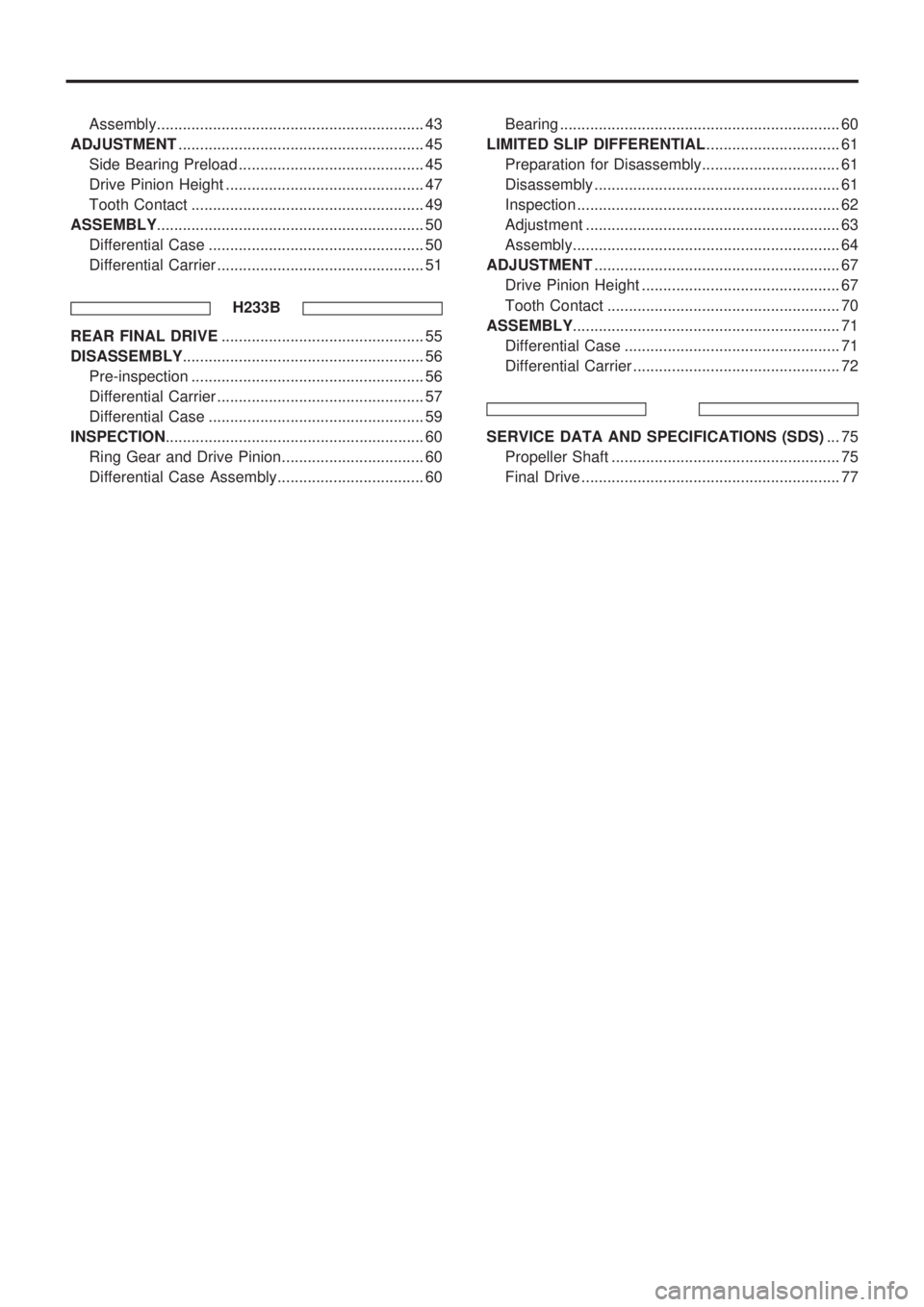

Special Service Tools

Tool number

Tool nameDescriptionUnit application

R180A C200 H233B

ST3127S000

Preload gauge

V1GG91030000

Torque wrench

V2HT62940000

Socket adapter

V3HT62900000

Socket adapter

NT124

Measuring pinion bearing

preload and total preload

XXX

KV38100800

Differential attachment

NT119

Mounting final drive

(To use, make a new hole.)

XÐÐ

a: 152 mm (5.98 in)

ST06340000

Differential attachment

NT140

Mounting final drive

ÐÐ X

ST32580000

Differential side bearing

adjusting nut wrench

NT141

Adjusting side bearing pre-

load and backlash (ring gear-

drive pinion)

ÐÐ X

ST33290001

Side bearing outer race

puller

NT076

Removing side bearing outer

race and side oil seal

XÐÐ

ST38060002

Drive pinion flange

wrench

NT113

Removing and installing

propeller shaft lock nut and

drive pinion lock nut

XXÐ

KV38104700

Drive pinion flange

wrench

NT113

Removing and installing pro-

peller shaft lock nut, and

drive pinion lock nut

ÐÐ X

PREPARATION

PD-1

Page 1083 of 1659

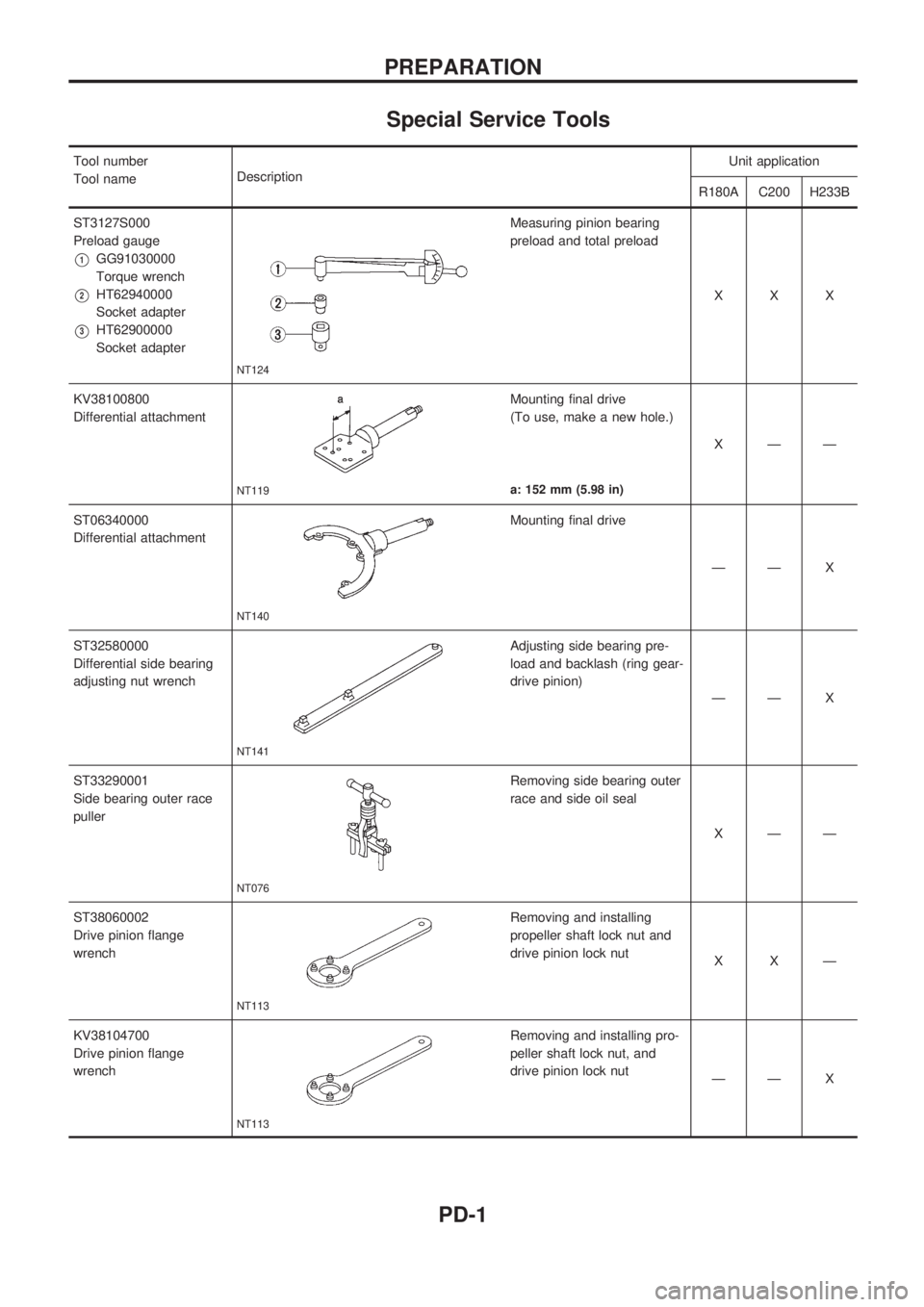

Tool number

Tool nameDescriptionUnit application

R180A C200 H233B

ST3090S000

Drive pinion rear inner

race puller set

V1ST30031000

Puller

V2ST30901000

Base

NT527

Removing and installing drive

pinion rear inner cone (All)

Removing rear wheel sensor

rotor (C200)

XXX

a: 79 mm (3.11 in) dia.

b: 45 mm (1.77 in) dia.

c: 35 mm (1.38 in) dia.

ST3306S001

Differential side bearing

puller set

V1ST33051001

Body

V2ST33061000

Adapter

NT072

Removing and installing dif-

ferential side bearing inner

cone (All)

Removing rear wheel sensor

rotor (C200)

XXX

a: 28.5 mm (1.122 in) dia.

b: 38 mm (1.50 in) dia.

ST33230000

Differential side bearing

drift

NT085

Installing side bearing inner

cone

XXÐ

a: 51 mm (2.01 in) dia.

b: 41 mm (1.61 in) dia.

c: 28.5 mm (1.122 in) dia.

ST33190000

Differential side bearing

drift

NT085

Installing side bearing inner

cone

ÐÐ X

a: 52 mm (2.05 in) dia.

b: 45.5 mm (1.791 in) dia.

c: 34 mm (1.34 in) dia.

ST33081000

Side bearing puller

adapter

NT431

Installing side bearing inner

cone

ÐX X

a: 43 mm (1.69 in) dia.

b: 33.5 mm (1.319 in) dia.

PREPARATION

Special Service Tools (Cont'd)

PD-2

Page 1084 of 1659

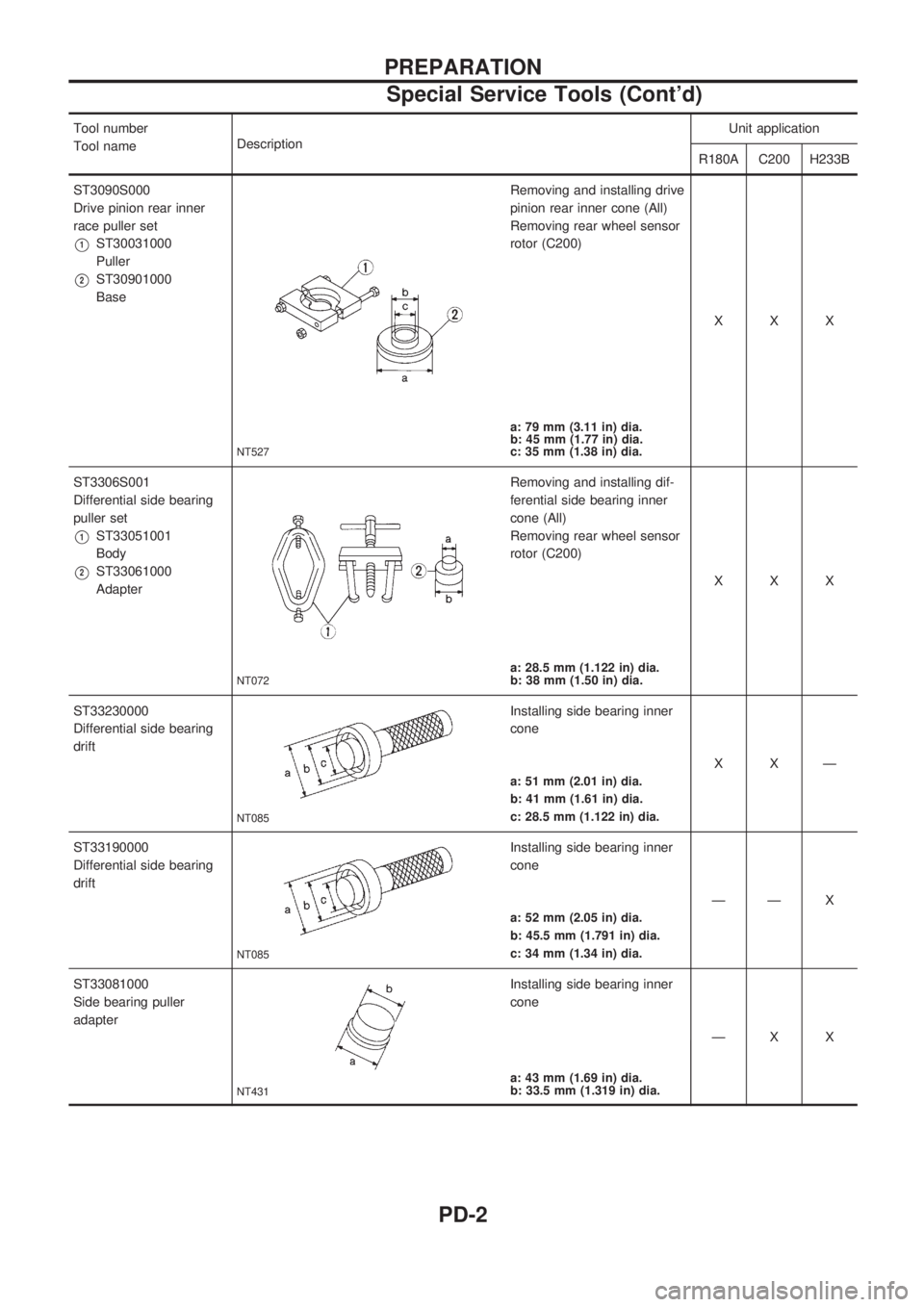

Tool number

Tool nameDescriptionUnit application

R180A C200 H233B

KV38100600

Side bearing spacer drift

NT528

Installing side bearing spacer

ÐXÐ

a: 8 mm (0.31 in)

b: R42.5 mm (1.673 in)

ST30611000

Drift

NT090

Installing pinion rear

bearing outer race

XXX

ST30621000

Drift

NT073

Installing pinion rear bearing

outer race

XXX

a: 79 mm (3.11 in) dia.

b: 59 mm (2.32 in) dia.

ST30701000

Drift

NT073

Installing pinion front bearing

outer race

XÐÐ

a: 61.5 mm (2.421 in) dia.

b: 41 mm (1.61 in) dia.

ST30613000

Drift

NT073

Installing pinion front bearing

outer race

ÐX X

a: 72 mm (2.83 in) dia.

b: 48 mm (1.89 in) dia.

KV381025S0

Oil seal fitting tool

V1ST30720000

Drift bar

V2KV38102510

Drift

NT525

Installing front oil seal

(R180A, H233B)

Installing rear wheel sensor

rotor (C200)

XXX

a: 77 mm (3.03 in) dia.

b: 55 mm (2.17 in) dia.

c: 71 mm (2.80 in) dia.

d: 65 mm (2.56 in) dia.

KV38100500

Gear carrier oil seal drift

NT115

Installing front oil seal

XXÐ

a: 85 mm (3.35 in) dia.

b: 60 mm (2.36 in) dia.

PREPARATION

Special Service Tools (Cont'd)

PD-3

Page 1085 of 1659

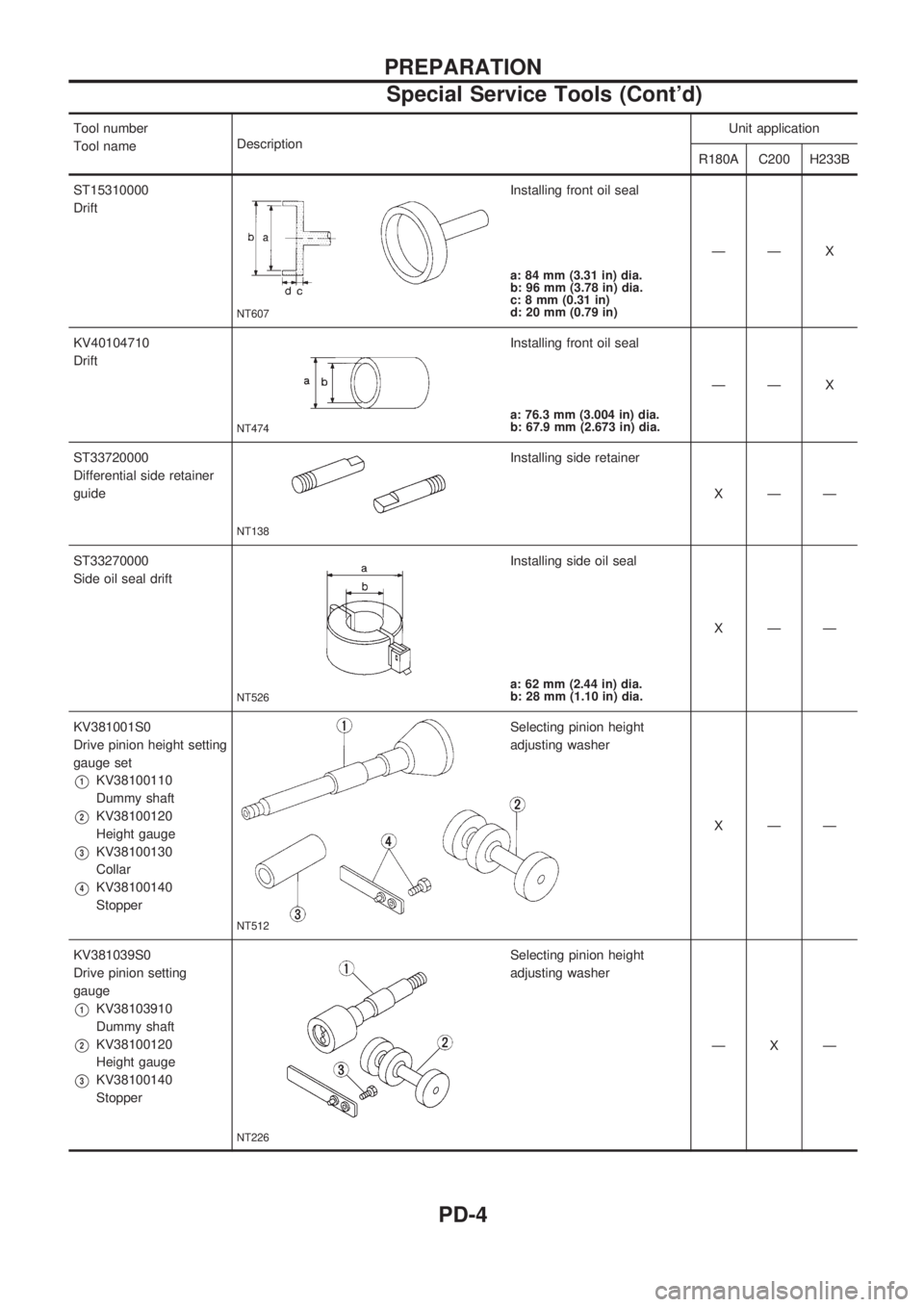

Tool number

Tool nameDescriptionUnit application

R180A C200 H233B

ST15310000

Drift

NT607

Installing front oil seal

ÐÐ X

a: 84 mm (3.31 in) dia.

b: 96 mm (3.78 in) dia.

c: 8 mm (0.31 in)

d: 20 mm (0.79 in)

KV40104710

Drift

NT474

Installing front oil seal

ÐÐ X

a: 76.3 mm (3.004 in) dia.

b: 67.9 mm (2.673 in) dia.

ST33720000

Differential side retainer

guide

NT138

Installing side retainer

XÐÐ

ST33270000

Side oil seal drift

NT526

Installing side oil seal

XÐÐ

a: 62 mm (2.44 in) dia.

b: 28 mm (1.10 in) dia.

KV381001S0

Drive pinion height setting

gauge set

V1KV38100110

Dummy shaft

V2KV38100120

Height gauge

V3KV38100130

Collar

V4KV38100140

Stopper

NT512

Selecting pinion height

adjusting washer

XÐÐ

KV381039S0

Drive pinion setting

gauge

V1KV38103910

Dummy shaft

V2KV38100120

Height gauge

V3KV38100140

Stopper

NT226

Selecting pinion height

adjusting washer

ÐXÐ

PREPARATION

Special Service Tools (Cont'd)

PD-4

Page 1086 of 1659

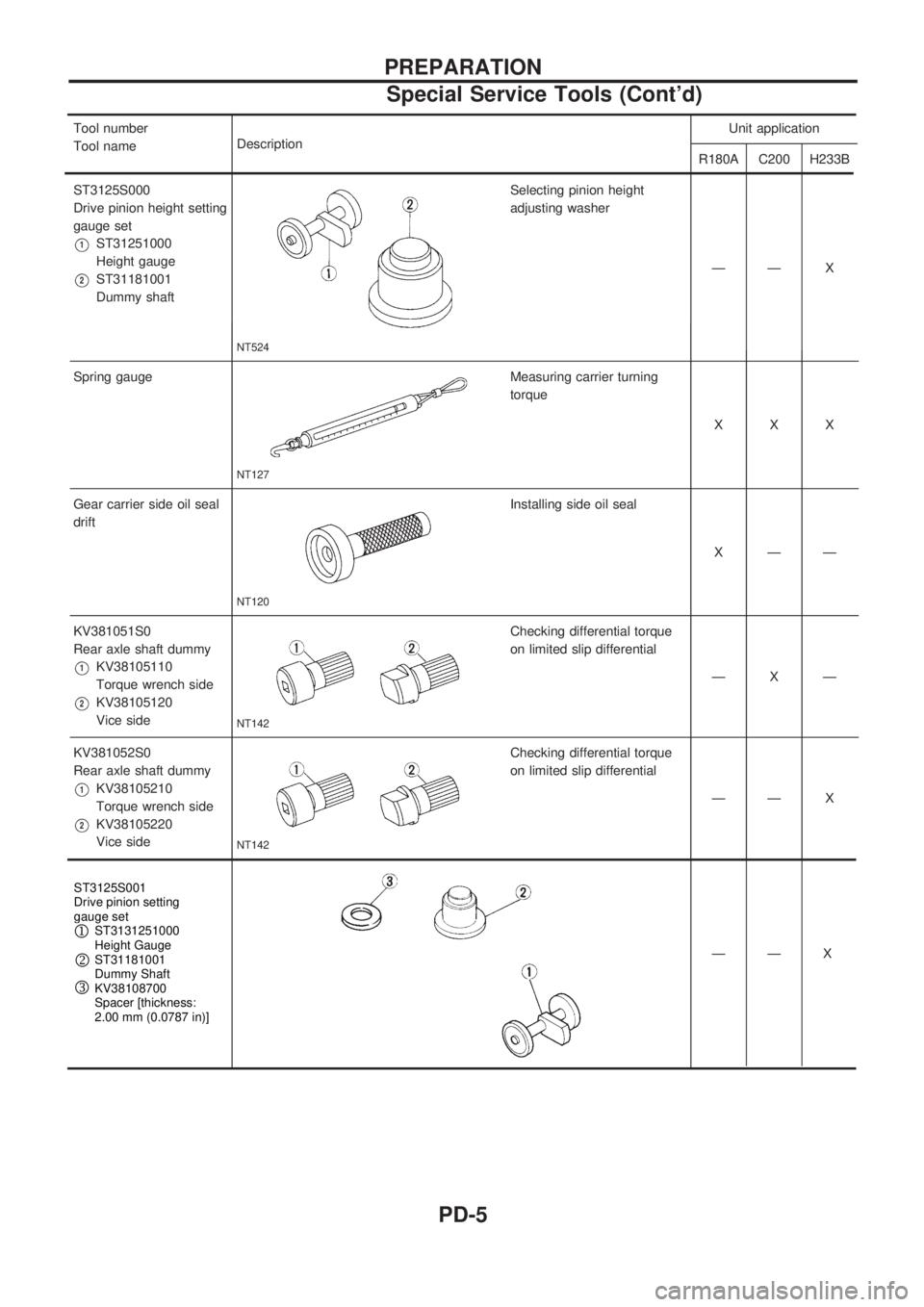

Tool number

Tool nameDescription Unit application

R180A C200 H233B

ST3125S000

Drive pinion height setting

gauge set

V1ST31251000

Height gauge

V2ST31181001

Dummy shaft

NT524

Selecting pinion height

adjusting washer

ÐÐ X

Spring gauge

NT127

Measuring carrier turning

torque XXX

Gear carrier side oil seal

drift

NT120

Installing side oil seal XÐÐ

KV381051S0

Rear axle shaft dummy

V1KV38105110

Torque wrench side

V2KV38105120

Vice side

NT142

Checking differential torque

on limited slip differential ÐXÐ

KV381052S0

Rearaxleshaftdummy

V1KV38105210

Torque wrench side

V2KV38105220

Vice side

NT142

Checking differential torque

on limited slip differential ÐÐX

——X

—X

PREPARATION

Special Service Tools (Cont'd)

PD-5

Page 1087 of 1659

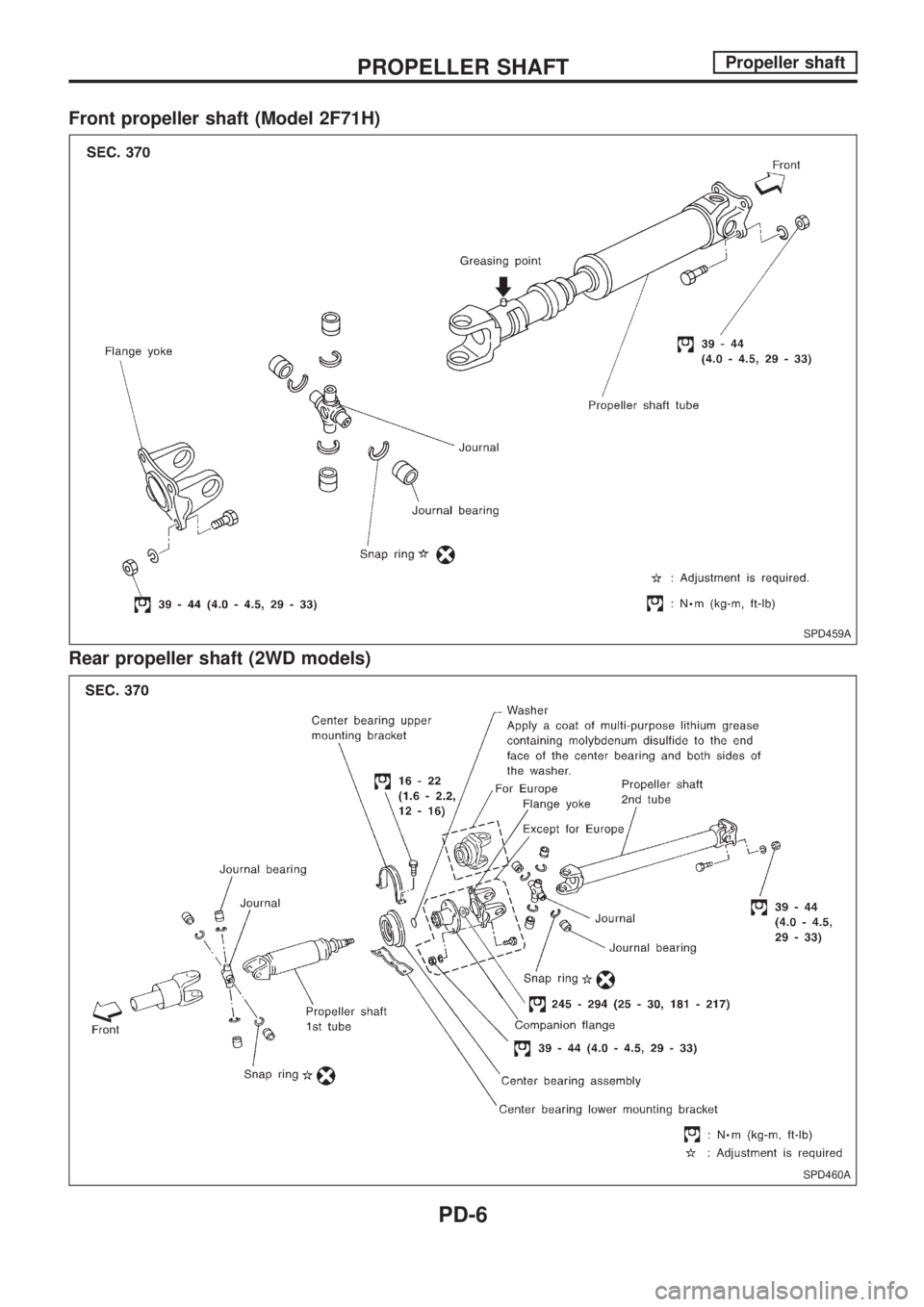

Front propeller shaft (Model 2F71H)

Rear propeller shaft (2WD models)

SPD459A

SPD460A

PROPELLER SHAFTPropeller shaft

PD-6

Page 1088 of 1659

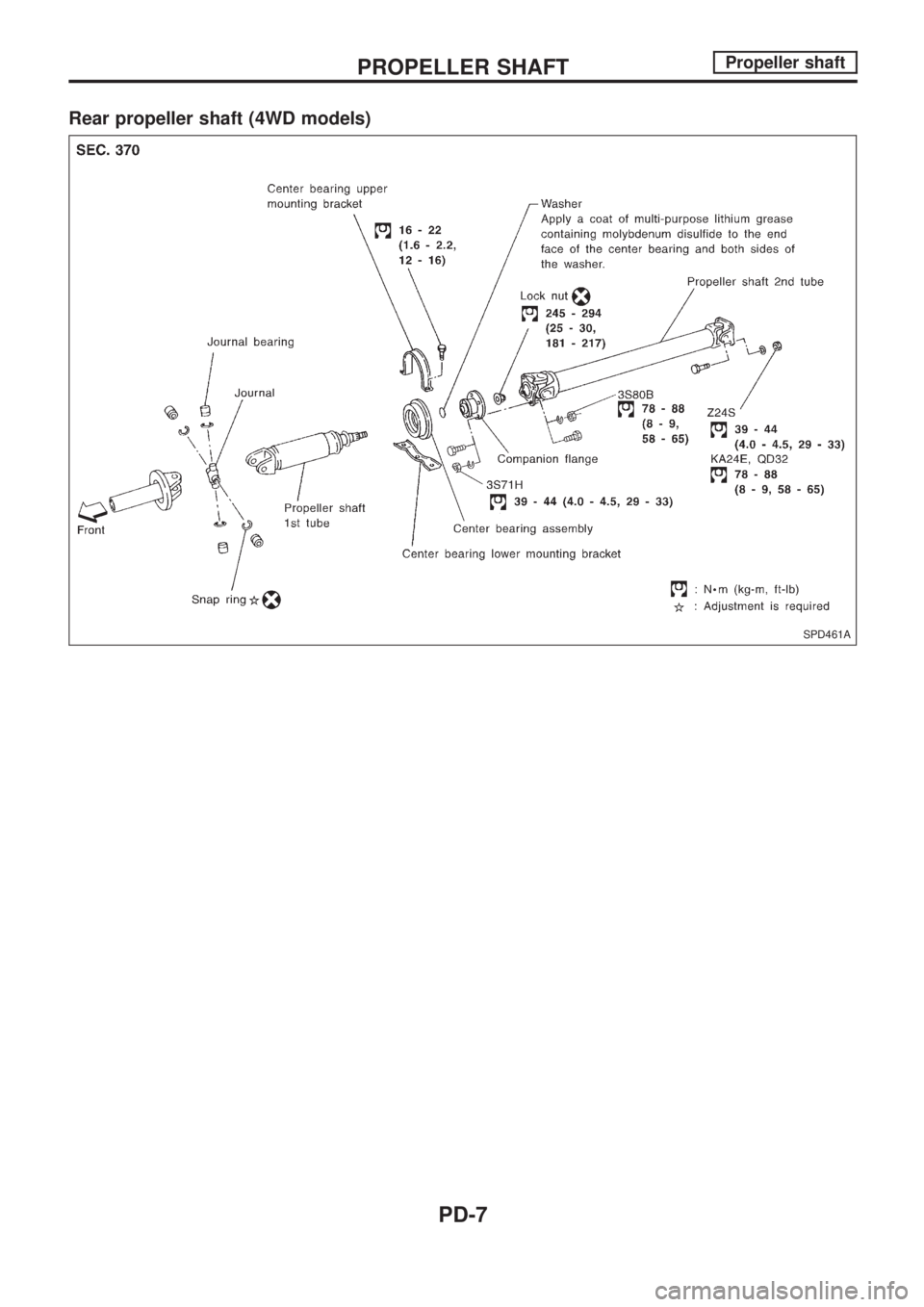

Rear propeller shaft (4WD models)

SPD461A

PROPELLER SHAFTPropeller shaft

PD-7

Page 1089 of 1659

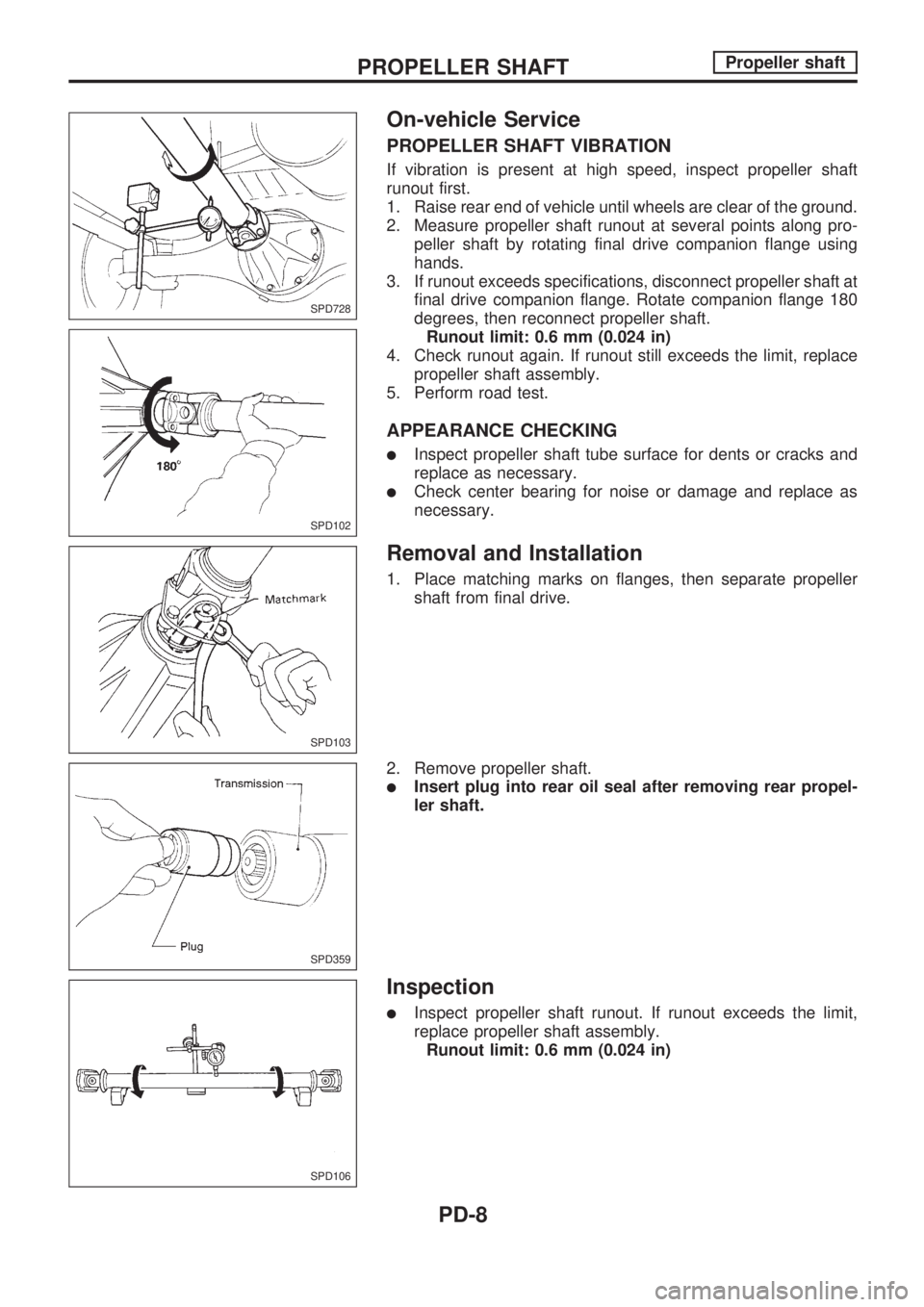

On-vehicle Service

PROPELLER SHAFT VIBRATION

If vibration is present at high speed, inspect propeller shaft

runout first.

1. Raise rear end of vehicle until wheels are clear of the ground.

2. Measure propeller shaft runout at several points along pro-

peller shaft by rotating final drive companion flange using

hands.

3. If runout exceeds specifications, disconnect propeller shaft at

final drive companion flange. Rotate companion flange 180

degrees, then reconnect propeller shaft.

Runout limit: 0.6 mm (0.024 in)

4. Check runout again. If runout still exceeds the limit, replace

propeller shaft assembly.

5. Perform road test.

APPEARANCE CHECKING

lInspect propeller shaft tube surface for dents or cracks and

replace as necessary.

lCheck center bearing for noise or damage and replace as

necessary.

Removal and Installation

1. Place matching marks on flanges, then separate propeller

shaft from final drive.

2. Remove propeller shaft.

lInsert plug into rear oil seal after removing rear propel-

ler shaft.

Inspection

lInspect propeller shaft runout. If runout exceeds the limit,

replace propeller shaft assembly.

Runout limit: 0.6 mm (0.024 in)

SPD728

SPD102

SPD103

SPD359

SPD106

PROPELLER SHAFTPropeller shaft

PD-8

Page 1090 of 1659

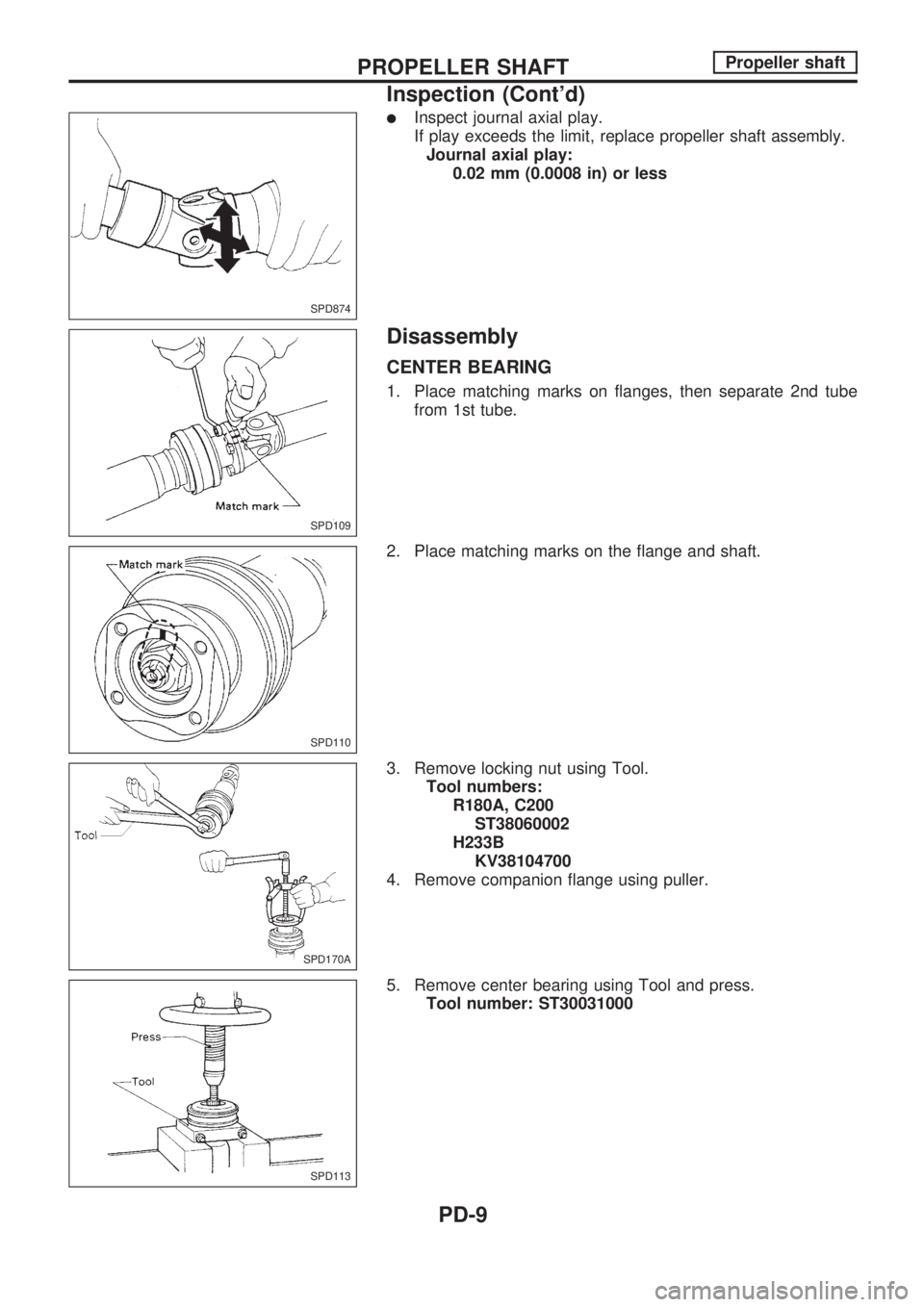

lInspect journal axial play.

If play exceeds the limit, replace propeller shaft assembly.

Journal axial play:

0.02 mm (0.0008 in) or less

Disassembly

CENTER BEARING

1. Place matching marks on flanges, then separate 2nd tube

from 1st tube.

2. Place matching marks on the flange and shaft.

3. Remove locking nut using Tool.

Tool numbers:

R180A, C200

ST38060002

H233B

KV38104700

4. Remove companion flange using puller.

5. Remove center bearing using Tool and press.

Tool number: ST30031000

SPD874

SPD109

SPD110

SPD170A

SPD113

PROPELLER SHAFTPropeller shaft

Inspection (Cont'd)

PD-9