NISSAN PICK-UP 1998 Repair Manual

PICK-UP 1998

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57374/w960_57374-0.png

NISSAN PICK-UP 1998 Repair Manual

Trending: oil reset, ESP, brake, spark plugs, brake pads replacement, audio, four wheel drive

Page 1061 of 1659

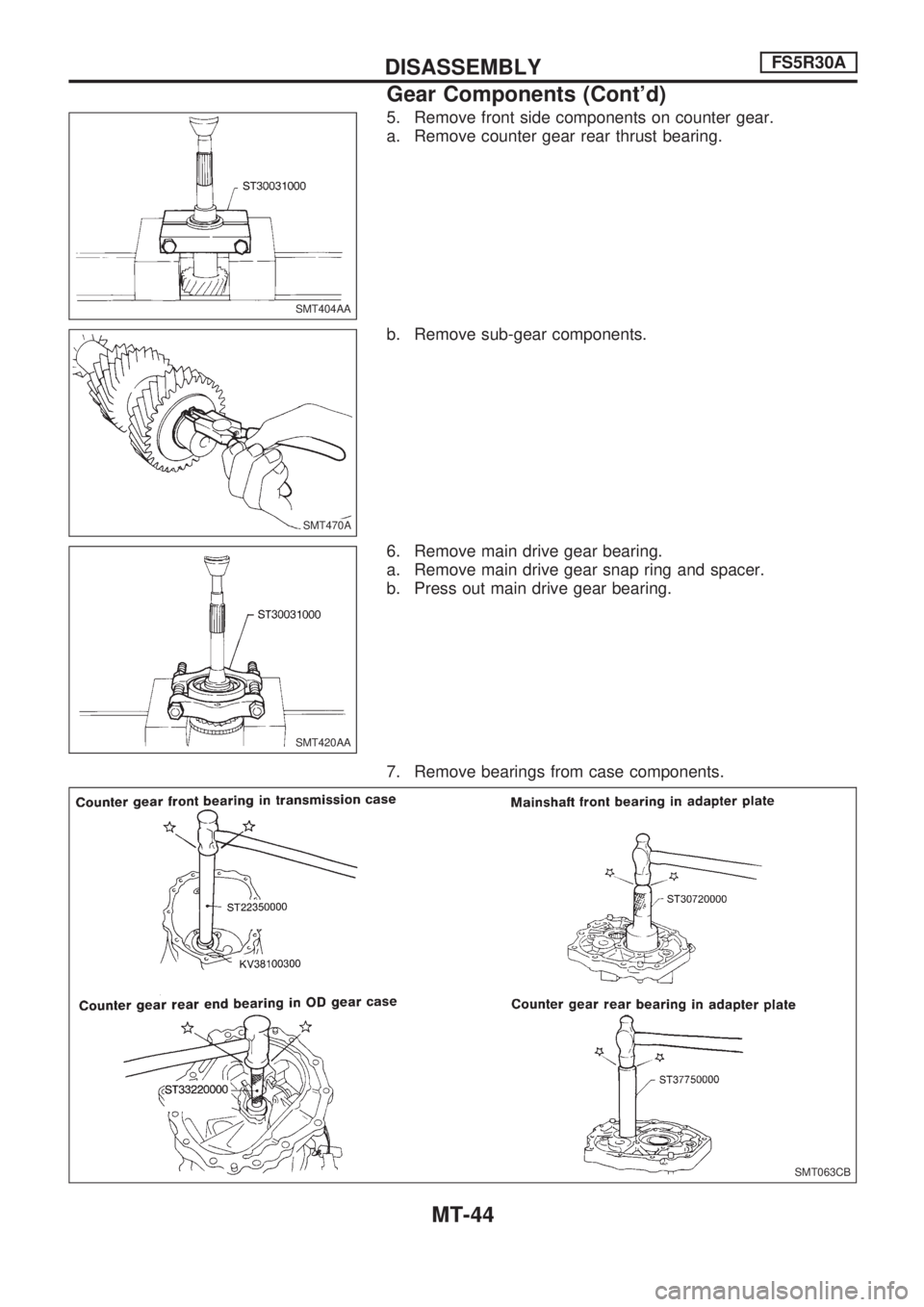

5. Remove front side components on counter gear.

a. Remove counter gear rear thrust bearing.

b. Remove sub-gear components.

6. Remove main drive gear bearing.

a. Remove main drive gear snap ring and spacer.

b. Press out main drive gear bearing.

7. Remove bearings from case components.

SMT404AA

SMT470A.SMT470A

SMT420AA

SMT063CB

DISASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-44

Page 1062 of 1659

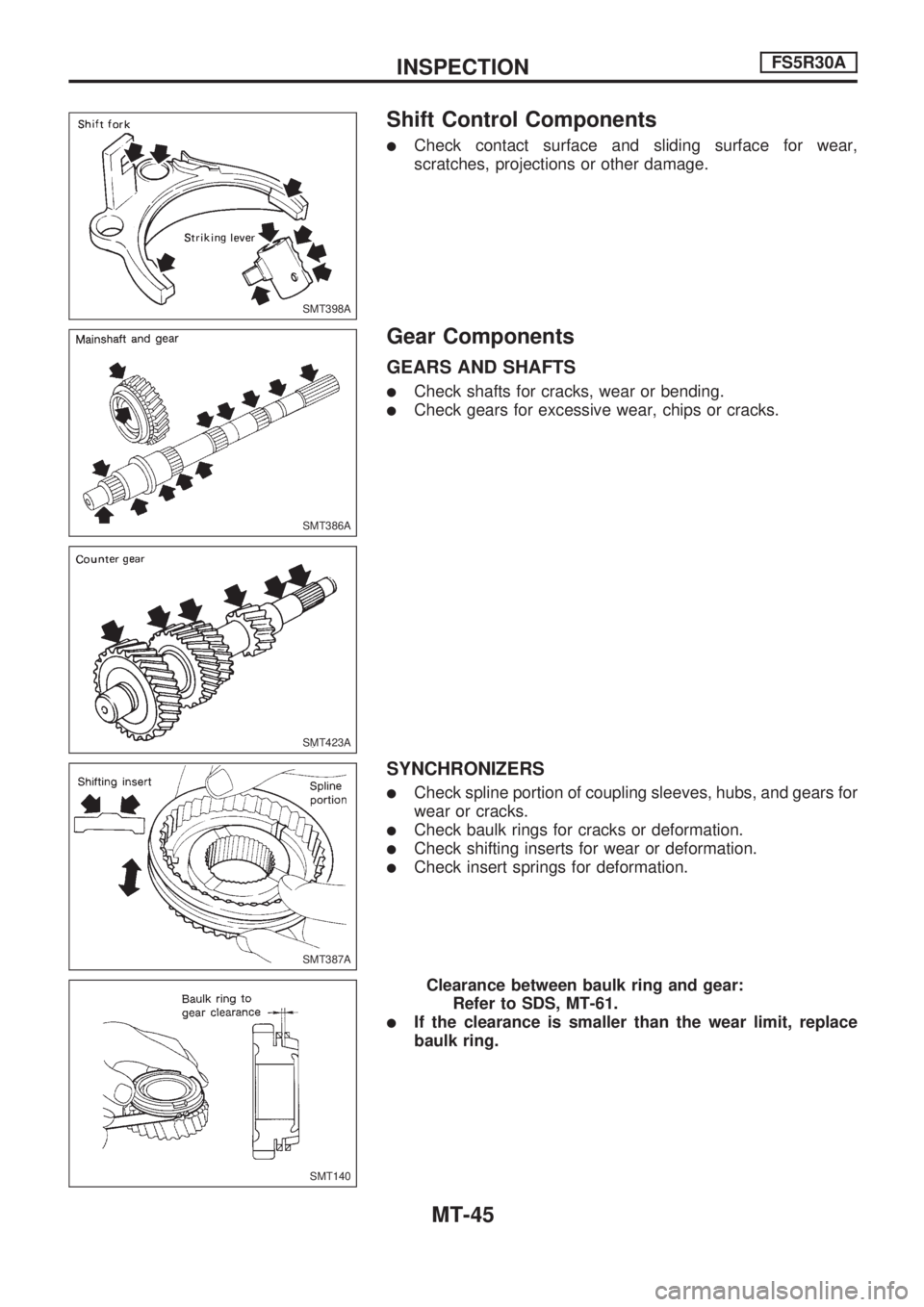

Shift Control Components

lCheck contact surface and sliding surface for wear,

scratches, projections or other damage.

Gear Components

GEARS AND SHAFTS

lCheck shafts for cracks, wear or bending.

lCheck gears for excessive wear, chips or cracks.

SYNCHRONIZERS

lCheck spline portion of coupling sleeves, hubs, and gears for

wear or cracks.

lCheck baulk rings for cracks or deformation.

lCheck shifting inserts for wear or deformation.

lCheck insert springs for deformation.

Clearance between baulk ring and gear:

Refer to SDS, MT-61.

lIf the clearance is smaller than the wear limit, replace

baulk ring.

SMT398A

SMT386A

SMT423A

SMT387A

SMT140

INSPECTIONFS5R30A

MT-45

Page 1063 of 1659

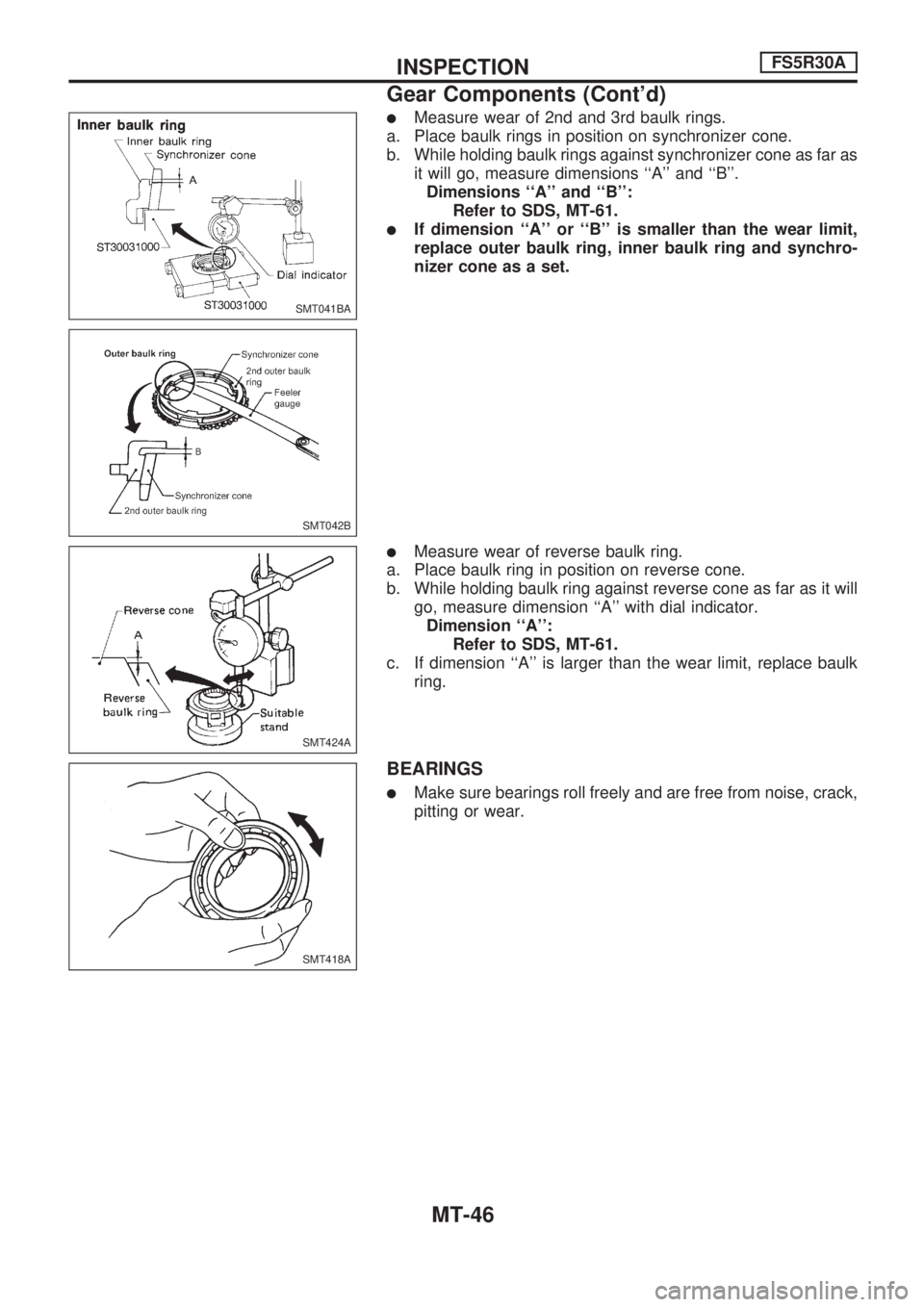

lMeasure wear of 2nd and 3rd baulk rings.

a. Place baulk rings in position on synchronizer cone.

b. While holding baulk rings against synchronizer cone as far as

it will go, measure dimensions ``A'' and ``B''.

Dimensions ``A'' and ``B'':

Refer to SDS, MT-61.

lIf dimension ``A'' or ``B'' is smaller than the wear limit,

replace outer baulk ring, inner baulk ring and synchro-

nizer cone as a set.

lMeasure wear of reverse baulk ring.

a. Place baulk ring in position on reverse cone.

b. While holding baulk ring against reverse cone as far as it will

go, measure dimension ``A'' with dial indicator.

Dimension ``A'':

Refer to SDS, MT-61.

c. If dimension ``A'' is larger than the wear limit, replace baulk

ring.

BEARINGS

lMake sure bearings roll freely and are free from noise, crack,

pitting or wear.

SMT041BA

SMT042B

SMT424A

SMT418A

INSPECTIONFS5R30A

Gear Components (Cont'd)

MT-46

Page 1064 of 1659

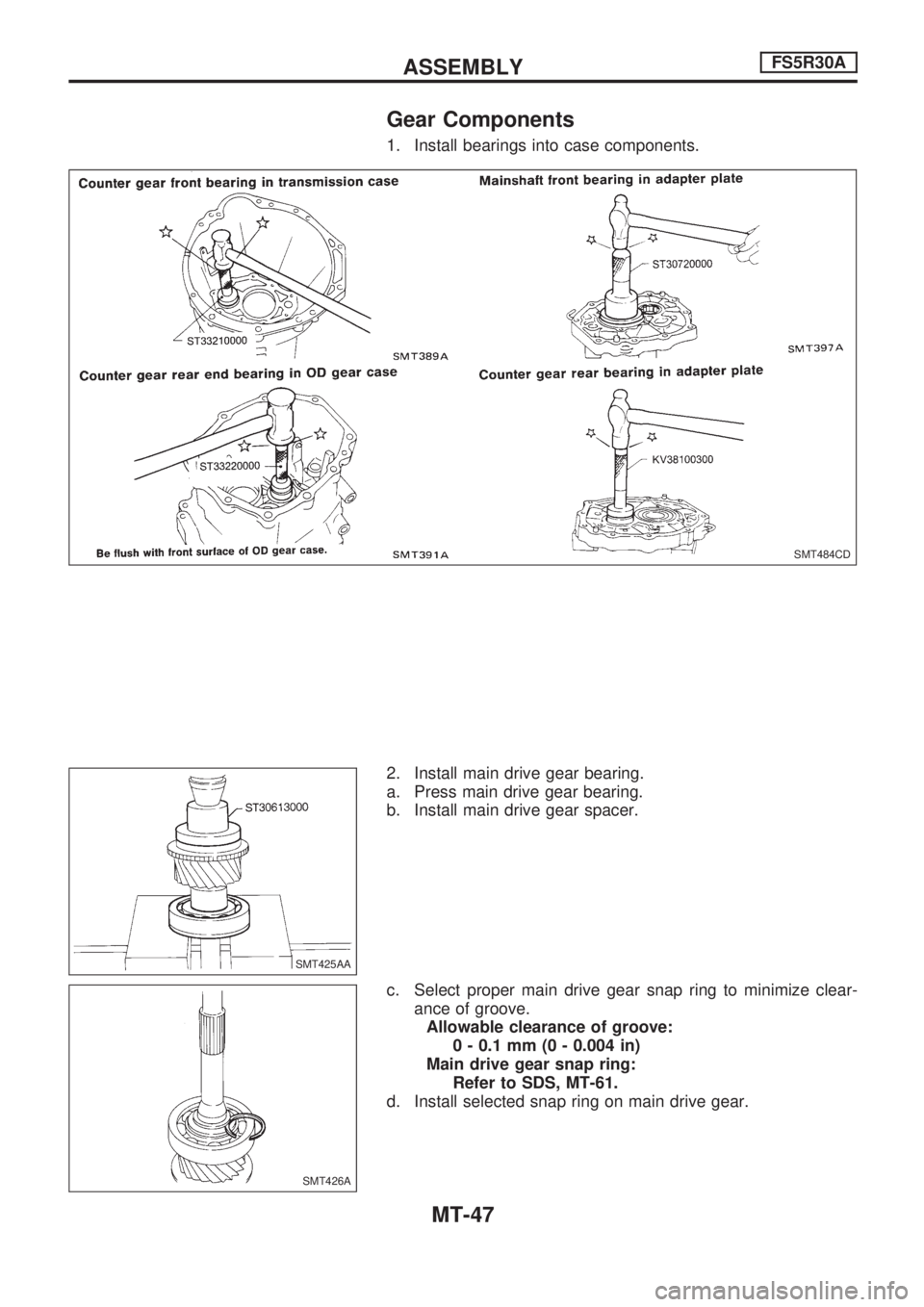

Gear Components

1. Install bearings into case components.

2. Install main drive gear bearing.

a. Press main drive gear bearing.

b. Install main drive gear spacer.

c. Select proper main drive gear snap ring to minimize clear-

ance of groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Main drive gear snap ring:

Refer to SDS, MT-61.

d. Install selected snap ring on main drive gear.

SMT484CD

SMT425AA

SMT426A

ASSEMBLYFS5R30A

MT-47

Page 1065 of 1659

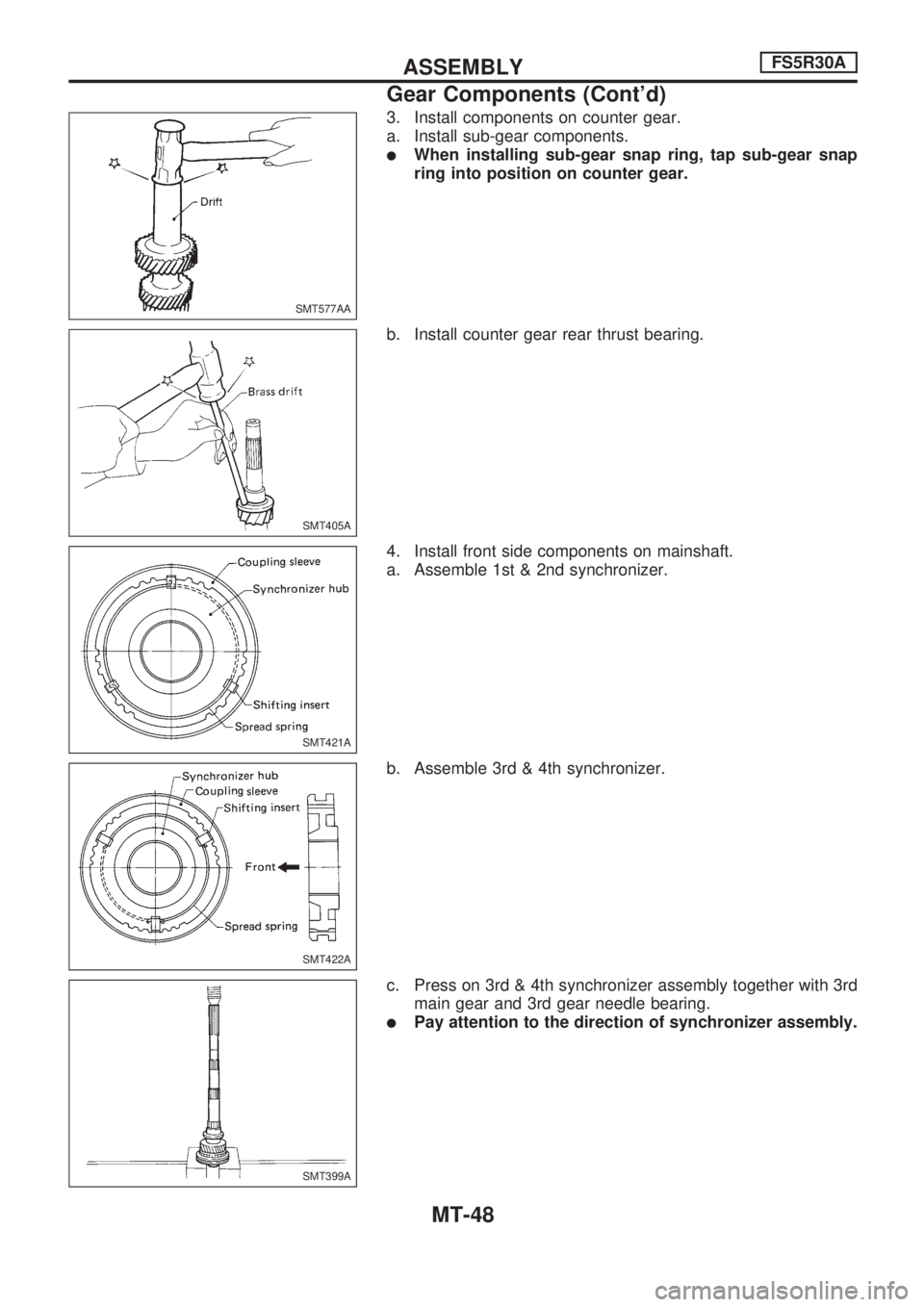

3. Install components on counter gear.

a. Install sub-gear components.

lWhen installing sub-gear snap ring, tap sub-gear snap

ring into position on counter gear.

b. Install counter gear rear thrust bearing.

4. Install front side components on mainshaft.

a. Assemble 1st & 2nd synchronizer.

b. Assemble 3rd & 4th synchronizer.

c. Press on 3rd & 4th synchronizer assembly together with 3rd

main gear and 3rd gear needle bearing.

lPay attention to the direction of synchronizer assembly.

SMT577AA

SMT405A

SMT421A

SMT422A

SMT399A

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-48

Page 1066 of 1659

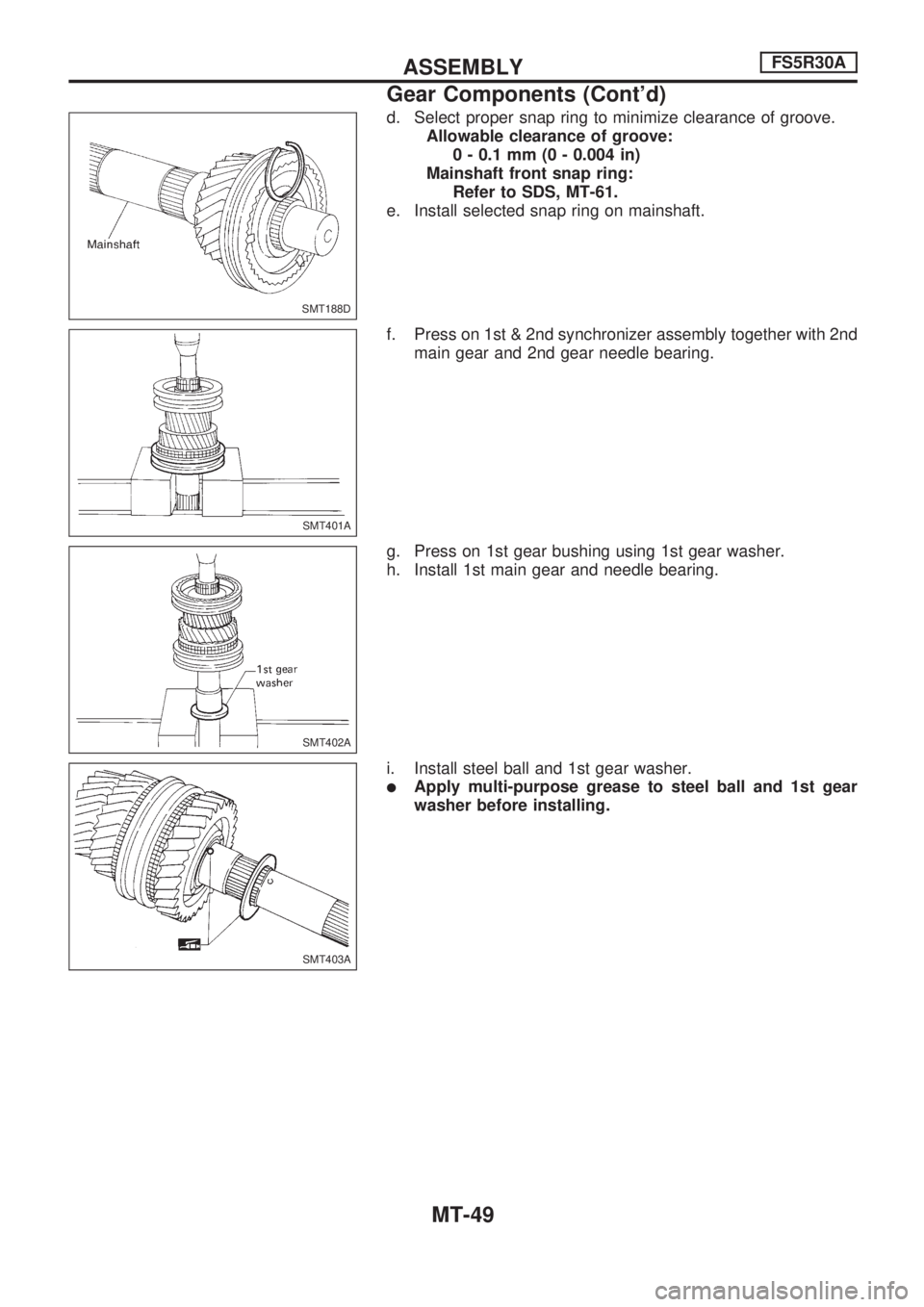

d. Select proper snap ring to minimize clearance of groove.

Allowable clearance of groove:

0 - 0.1 mm (0 - 0.004 in)

Mainshaft front snap ring:

Refer to SDS, MT-61.

e. Install selected snap ring on mainshaft.

f. Press on 1st & 2nd synchronizer assembly together with 2nd

main gear and 2nd gear needle bearing.

g. Press on 1st gear bushing using 1st gear washer.

h. Install 1st main gear and needle bearing.

i. Install steel ball and 1st gear washer.

lApply multi-purpose grease to steel ball and 1st gear

washer before installing.

SMT188D

SMT401A

SMT402A

SMT403A

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-49

Page 1067 of 1659

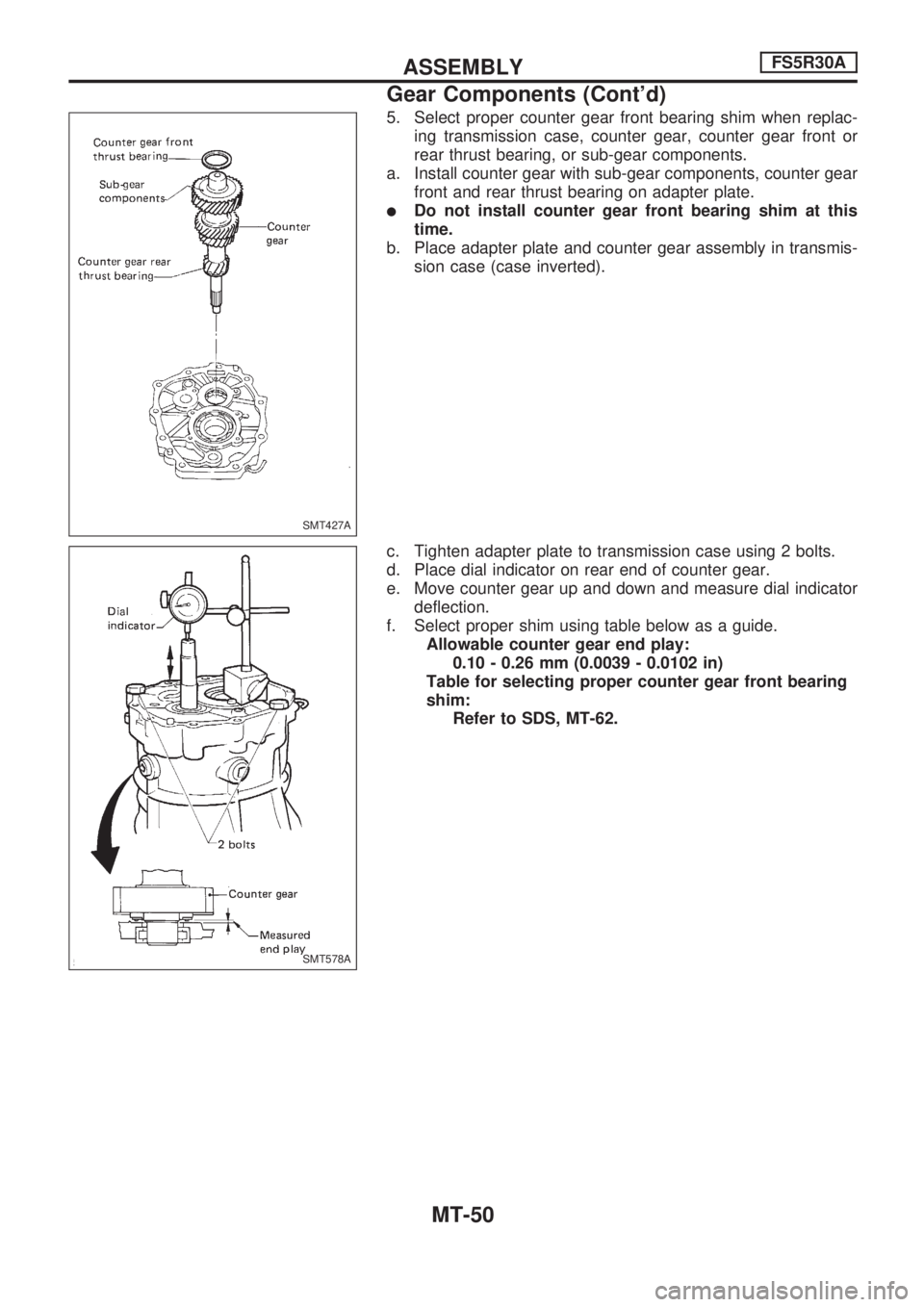

5. Select proper counter gear front bearing shim when replac-

ing transmission case, counter gear, counter gear front or

rear thrust bearing, or sub-gear components.

a. Install counter gear with sub-gear components, counter gear

front and rear thrust bearing on adapter plate.

lDo not install counter gear front bearing shim at this

time.

b. Place adapter plate and counter gear assembly in transmis-

sion case (case inverted).

c. Tighten adapter plate to transmission case using 2 bolts.

d. Place dial indicator on rear end of counter gear.

e. Move counter gear up and down and measure dial indicator

deflection.

f. Select proper shim using table below as a guide.

Allowable counter gear end play:

0.10 - 0.26 mm (0.0039 - 0.0102 in)

Table for selecting proper counter gear front bearing

shim:

Refer to SDS, MT-62.

SMT427A

SMT578A

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-50

Page 1068 of 1659

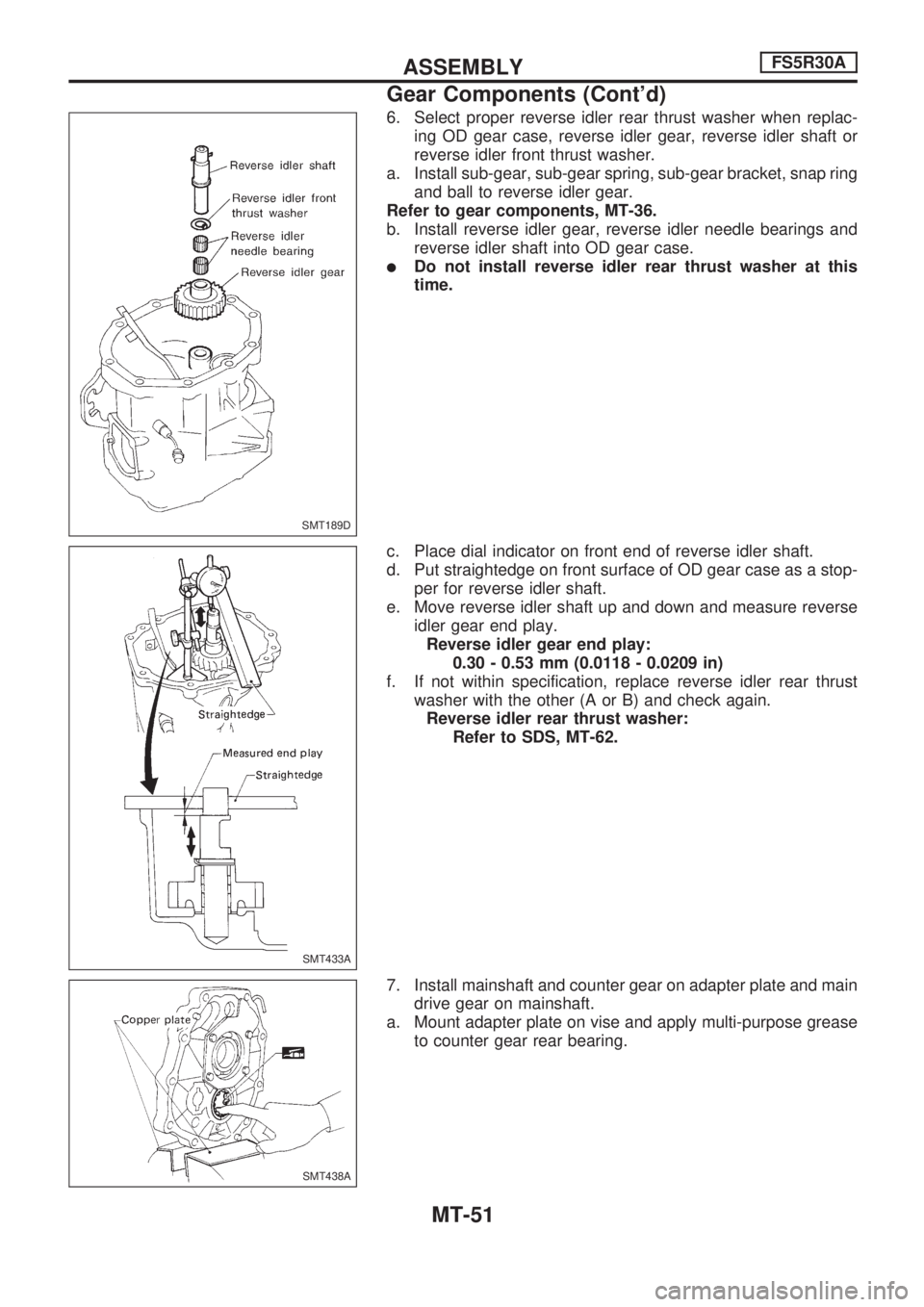

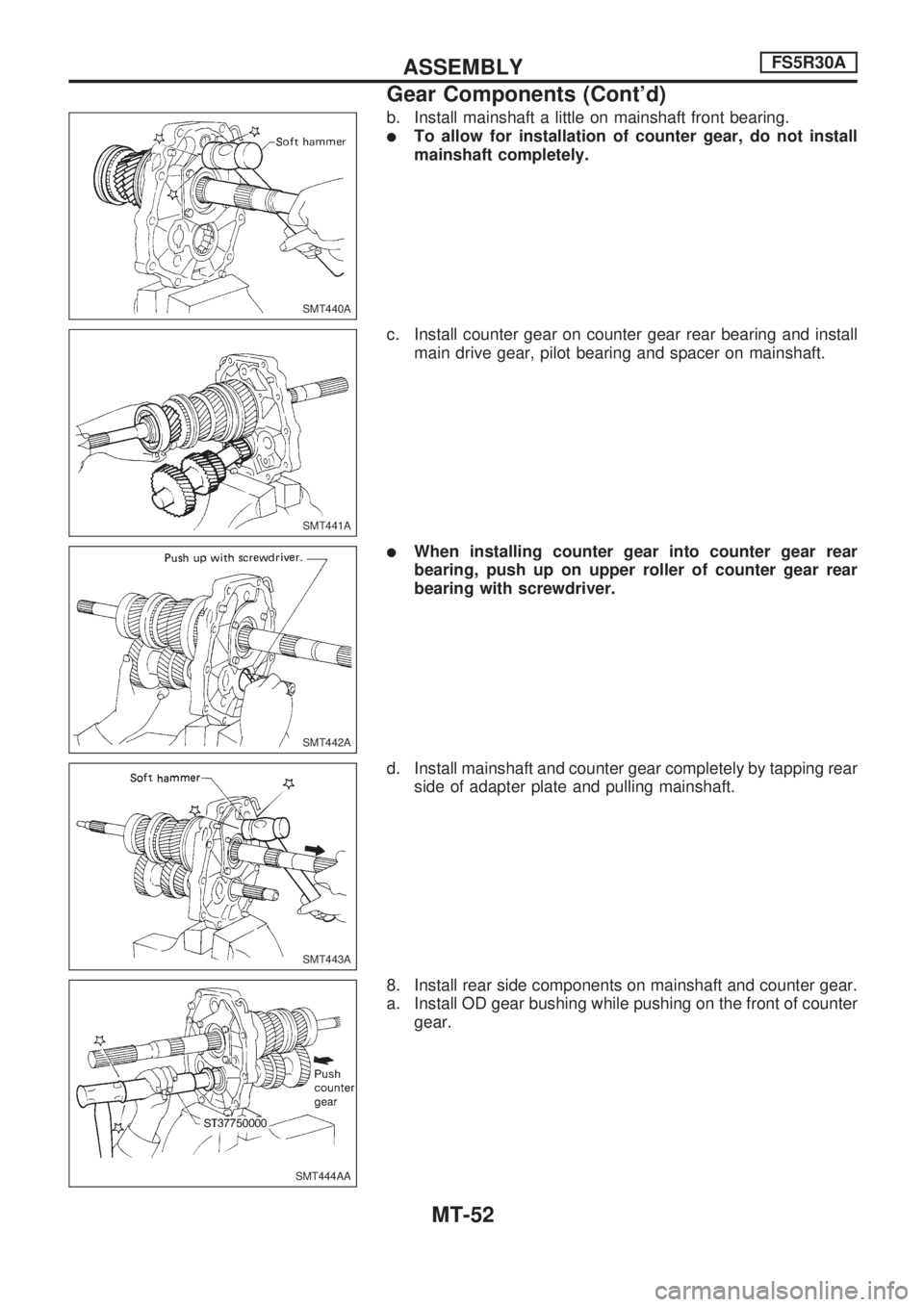

6. Select proper reverse idler rear thrust washer when replac-

ing OD gear case, reverse idler gear, reverse idler shaft or

reverse idler front thrust washer.

a. Install sub-gear, sub-gear spring, sub-gear bracket, snap ring

and ball to reverse idler gear.

Refer to gear components, MT-36.

b. Install reverse idler gear, reverse idler needle bearings and

reverse idler shaft into OD gear case.

lDo not install reverse idler rear thrust washer at this

time.

c. Place dial indicator on front end of reverse idler shaft.

d. Put straightedge on front surface of OD gear case as a stop-

per for reverse idler shaft.

e. Move reverse idler shaft up and down and measure reverse

idler gear end play.

Reverse idler gear end play:

0.30 - 0.53 mm (0.0118 - 0.0209 in)

f. If not within specification, replace reverse idler rear thrust

washer with the other (A or B) and check again.

Reverse idler rear thrust washer:

Refer to SDS, MT-62.

7. Install mainshaft and counter gear on adapter plate and main

drive gear on mainshaft.

a. Mount adapter plate on vise and apply multi-purpose grease

to counter gear rear bearing.

SMT189D

SMT433A

SMT438A

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-51

Page 1069 of 1659

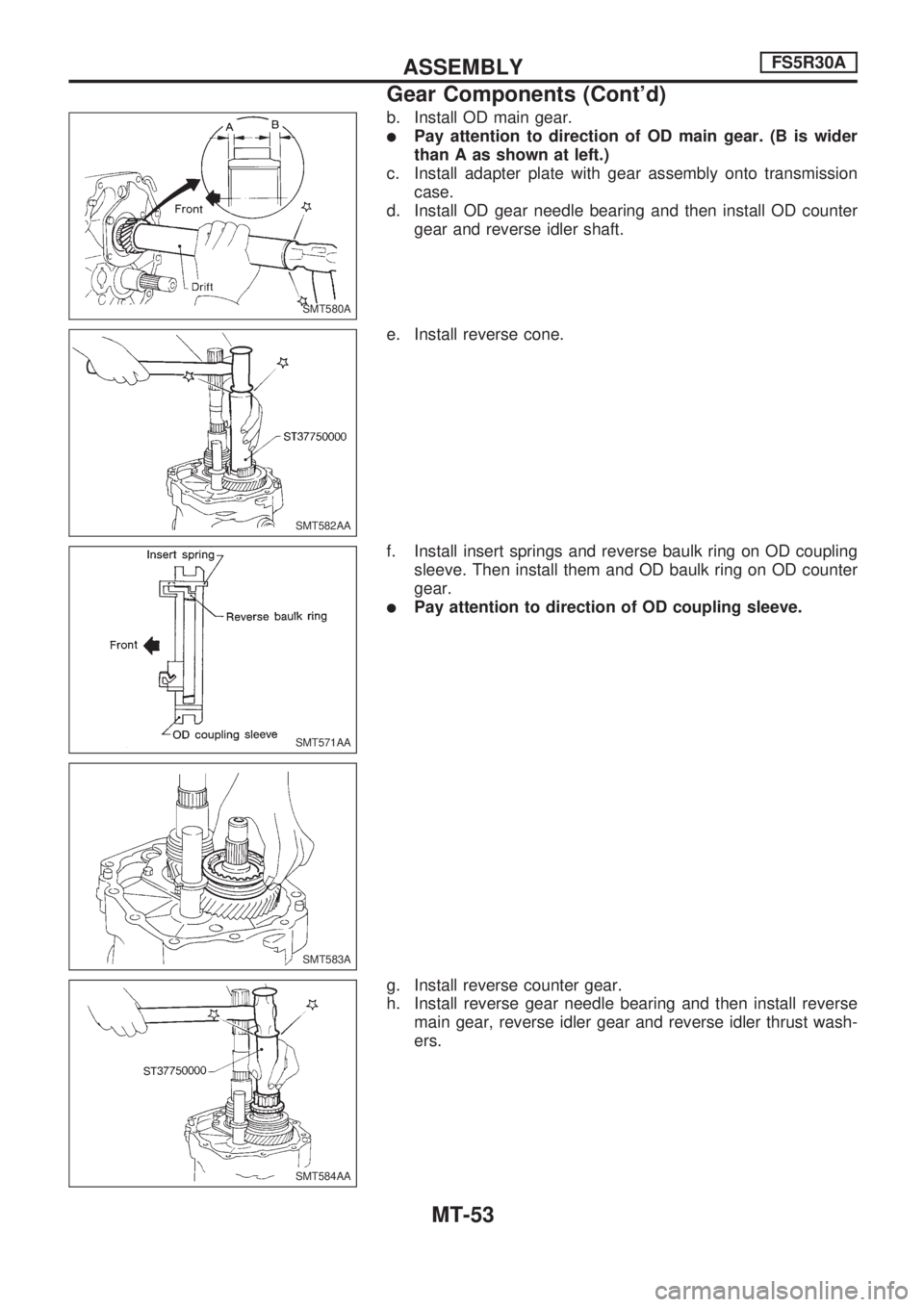

b. Install mainshaft a little on mainshaft front bearing.

lTo allow for installation of counter gear, do not install

mainshaft completely.

c. Install counter gear on counter gear rear bearing and install

main drive gear, pilot bearing and spacer on mainshaft.

lWhen installing counter gear into counter gear rear

bearing, push up on upper roller of counter gear rear

bearing with screwdriver.

d. Install mainshaft and counter gear completely by tapping rear

side of adapter plate and pulling mainshaft.

8. Install rear side components on mainshaft and counter gear.

a. Install OD gear bushing while pushing on the front of counter

gear.

SMT440A

SMT441A

SMT442A

SMT443A

SMT444AA

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-52

Page 1070 of 1659

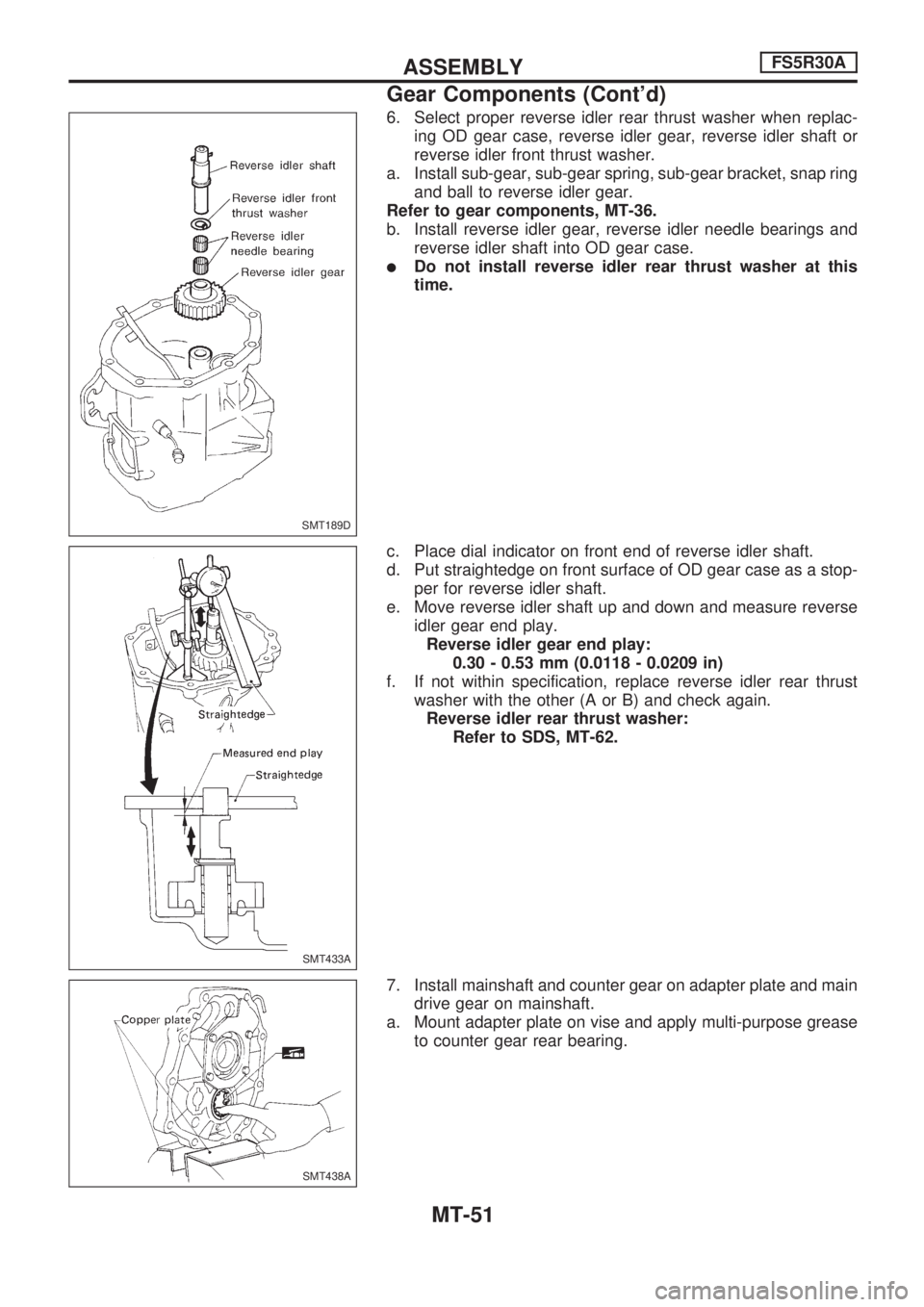

b. Install OD main gear.

lPay attention to direction of OD main gear. (B is wider

than A as shown at left.)

c. Install adapter plate with gear assembly onto transmission

case.

d. Install OD gear needle bearing and then install OD counter

gear and reverse idler shaft.

e. Install reverse cone.

f. Install insert springs and reverse baulk ring on OD coupling

sleeve. Then install them and OD baulk ring on OD counter

gear.

lPay attention to direction of OD coupling sleeve.

g. Install reverse counter gear.

h. Install reverse gear needle bearing and then install reverse

main gear, reverse idler gear and reverse idler thrust wash-

ers.

SMT580A

SMT582AA

SMT571AA

SMT583A

SMT584AA

ASSEMBLYFS5R30A

Gear Components (Cont'd)

MT-53

Trending: door lock, wheelbase, open gas tank, relay, fuse chart, adding oil, oil type