NISSAN PICK-UP 1998 Repair Manual

Manufacturer: NISSAN, Model Year: 1998, Model line: PICK-UP, Model: NISSAN PICK-UP 1998Pages: 1659, PDF Size: 53.39 MB

Page 381 of 1659

When installing, use a new O-ring.

WARNING:

Do not touch the cooled fuel temperature switch with your

bare hand.

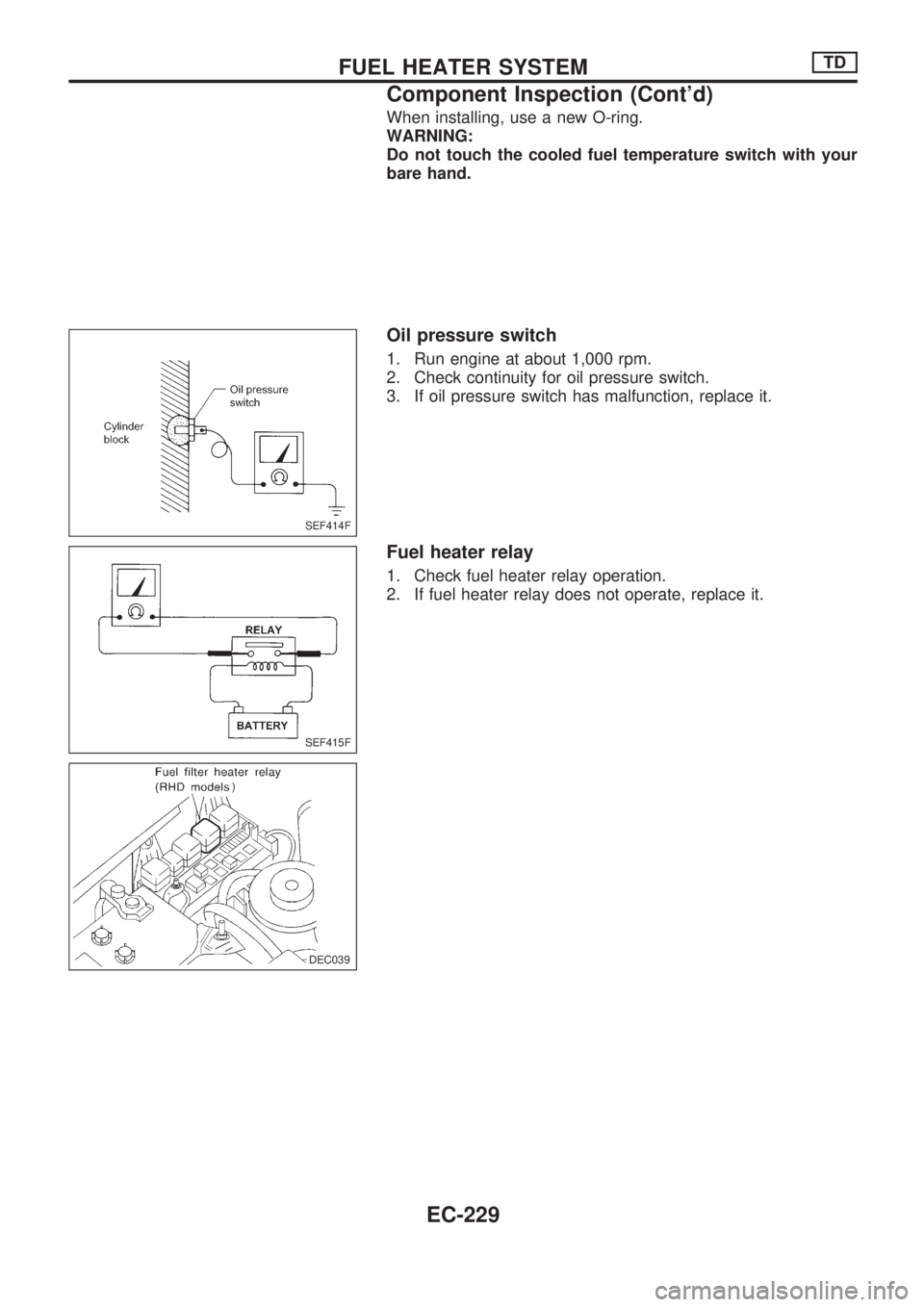

Oil pressure switch

1. Run engine at about 1,000 rpm.

2. Check continuity for oil pressure switch.

3. If oil pressure switch has malfunction, replace it.

Fuel heater relay

1. Check fuel heater relay operation.

2. If fuel heater relay does not operate, replace it.

SEF414F

SEF415F

DEC039

.)

.DEC039

FUEL HEATER SYSTEMTD

Component Inspection (Cont'd)

EC-229

Page 382 of 1659

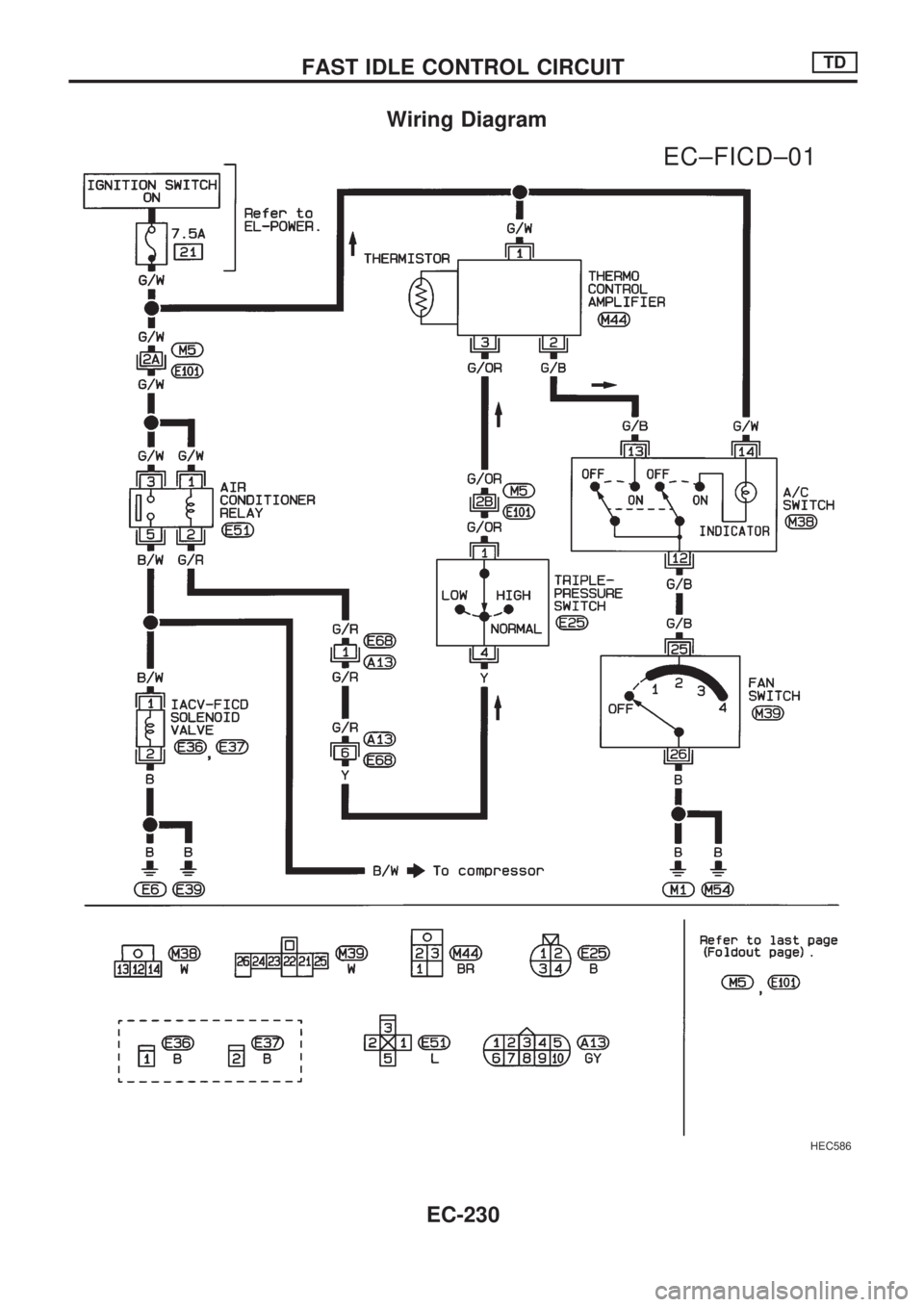

Wiring Diagram

HEC586

.

EC±FICD±01

FAST IDLE CONTROL CIRCUITTD

EC-230

Page 383 of 1659

Electrical Components Inspection

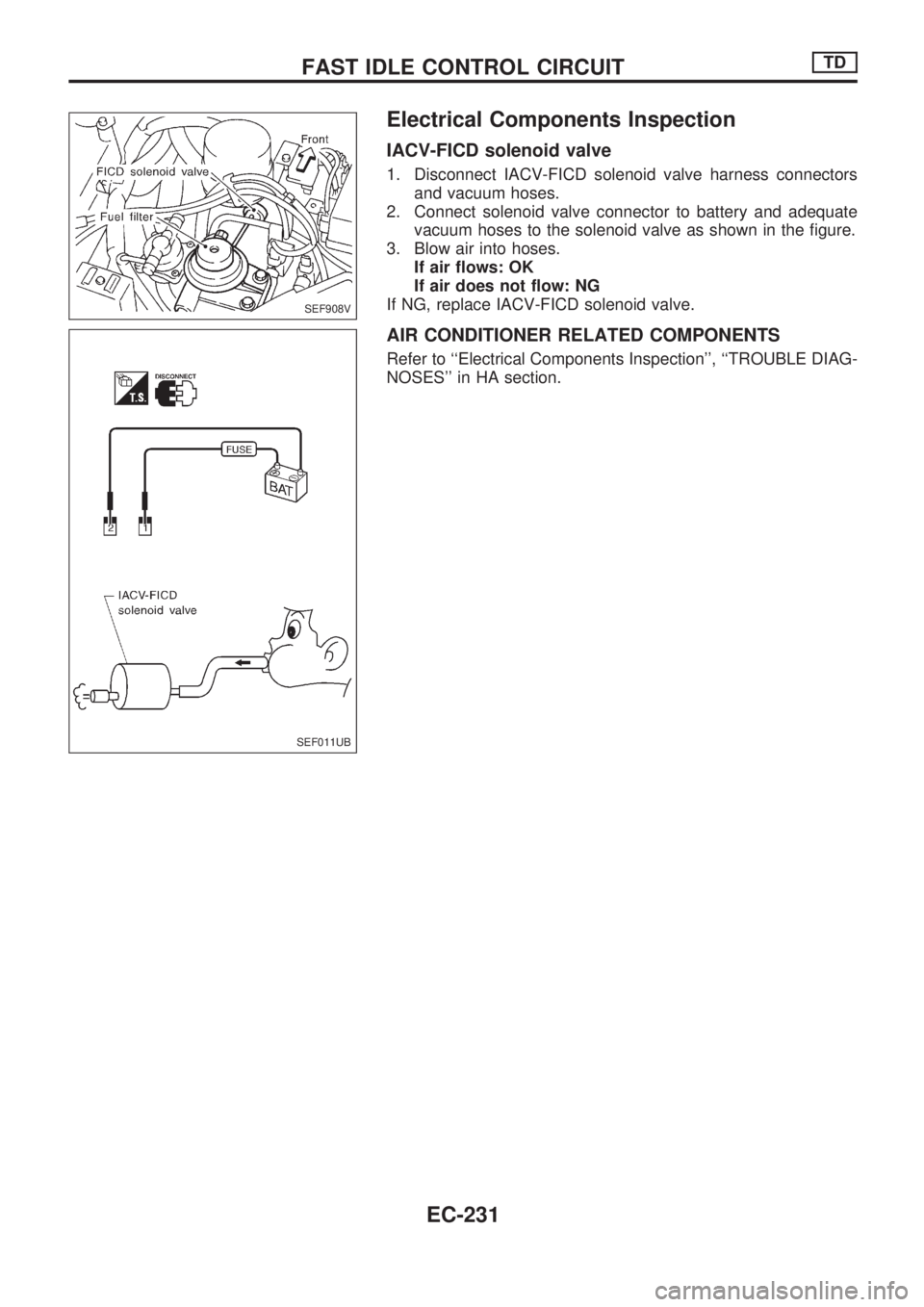

IACV-FICD solenoid valve

1. Disconnect IACV-FICD solenoid valve harness connectors

and vacuum hoses.

2. Connect solenoid valve connector to battery and adequate

vacuum hoses to the solenoid valve as shown in the figure.

3. Blow air into hoses.

If air flows: OK

If air does not flow: NG

If NG, replace IACV-FICD solenoid valve.

AIR CONDITIONER RELATED COMPONENTS

Refer to ``Electrical Components Inspection'', ``TROUBLE DIAG-

NOSES'' in HA section.

SEF908V

SEF011UB

FAST IDLE CONTROL CIRCUITTD

EC-231

Page 384 of 1659

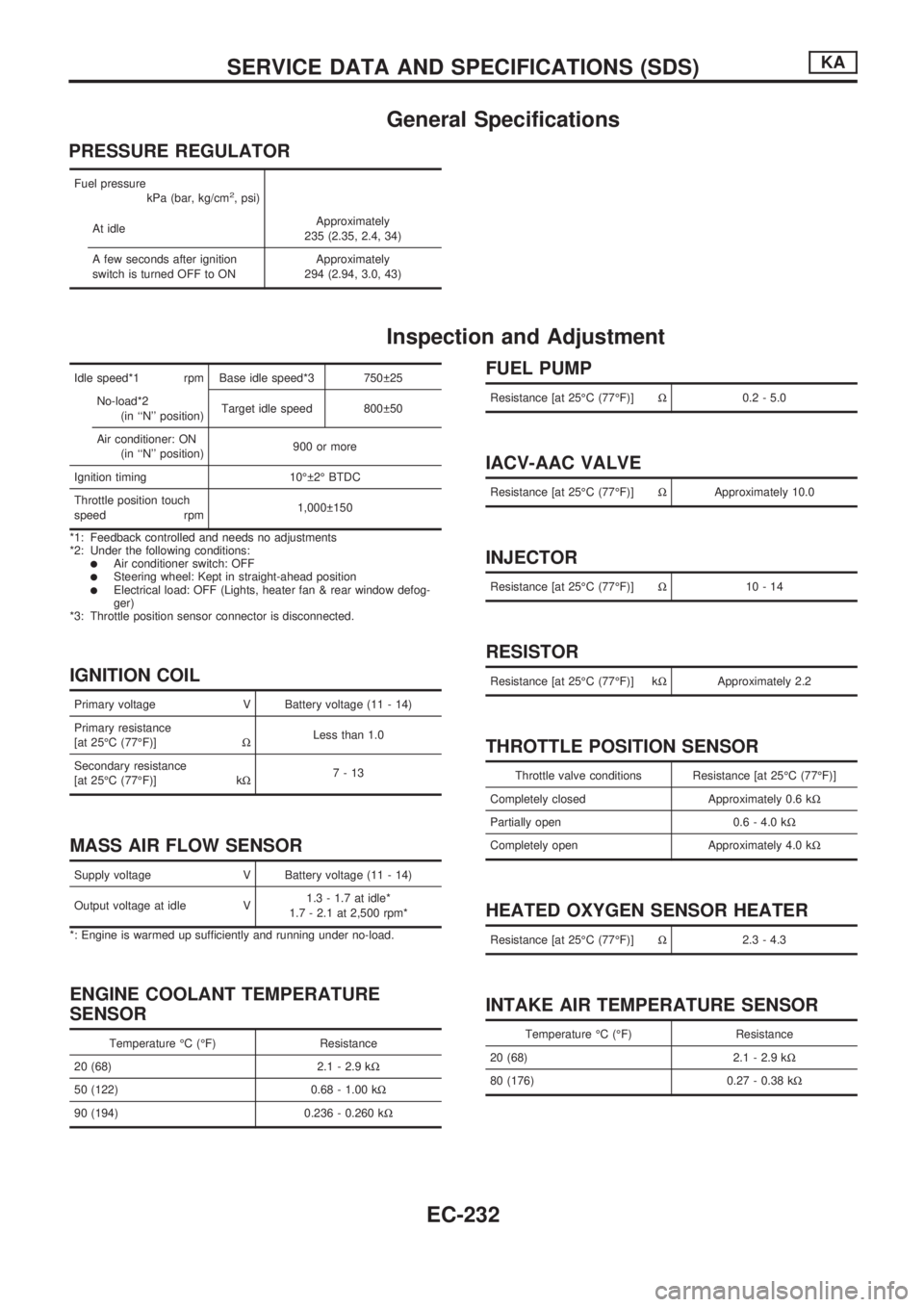

General Specifications

PRESSURE REGULATOR

Fuel pressure

kPa (bar, kg/cm2, psi)

At idleApproximately

235 (2.35, 2.4, 34)

A few seconds after ignition

switch is turned OFF to ONApproximately

294 (2.94, 3.0, 43)

Inspection and Adjustment

Idle speed*1 rpm Base idle speed*3 750 25

No-load*2

(in ``N'' position)Target idle speed 800 50

Air conditioner: ON

(in ``N'' position)900 or more

Ignition timing 10É 2É BTDC

Throttle position touch

speed rpm1,000 150

*1: Feedback controlled and needs no adjustments

*2: Under the following conditions:

lAir conditioner switch: OFFlSteering wheel: Kept in straight-ahead positionlElectrical load: OFF (Lights, heater fan & rear window defog-

ger)

*3: Throttle position sensor connector is disconnected.

IGNITION COIL

Primary voltage V Battery voltage (11 - 14)

Primary resistance

[at 25ÉC (77ÉF)]WLess than 1.0

Secondary resistance

[at 25ÉC (77ÉF)] kW7-13

MASS AIR FLOW SENSOR

Supply voltage V Battery voltage (11 - 14)

Output voltage at idle V1.3 - 1.7 at idle*

1.7 - 2.1 at 2,500 rpm*

*: Engine is warmed up sufficiently and running under no-load.

ENGINE COOLANT TEMPERATURE

SENSOR

Temperature ÉC (ÉF) Resistance

20 (68) 2.1 - 2.9 kW

50 (122) 0.68 - 1.00 kW

90 (194) 0.236 - 0.260 kW

FUEL PUMP

Resistance [at 25ÉC (77ÉF)]W0.2 - 5.0

IACV-AAC VALVE

Resistance [at 25ÉC (77ÉF)]WApproximately 10.0

INJECTOR

Resistance [at 25ÉC (77ÉF)]W10-14

RESISTOR

Resistance [at 25ÉC (77ÉF)] kWApproximately 2.2

THROTTLE POSITION SENSOR

Throttle valve conditions Resistance [at 25ÉC (77ÉF)]

Completely closed Approximately 0.6 kW

Partially open 0.6 - 4.0 kW

Completely open Approximately 4.0 kW

HEATED OXYGEN SENSOR HEATER

Resistance [at 25ÉC (77ÉF)]W2.3 - 4.3

INTAKE AIR TEMPERATURE SENSOR

Temperature ÉC (ÉF) Resistance

20 (68) 2.1 - 2.9 kW

80 (176) 0.27 - 0.38 kW

SERVICE DATA AND SPECIFICATIONS (SDS)KA

EC-232

Page 385 of 1659

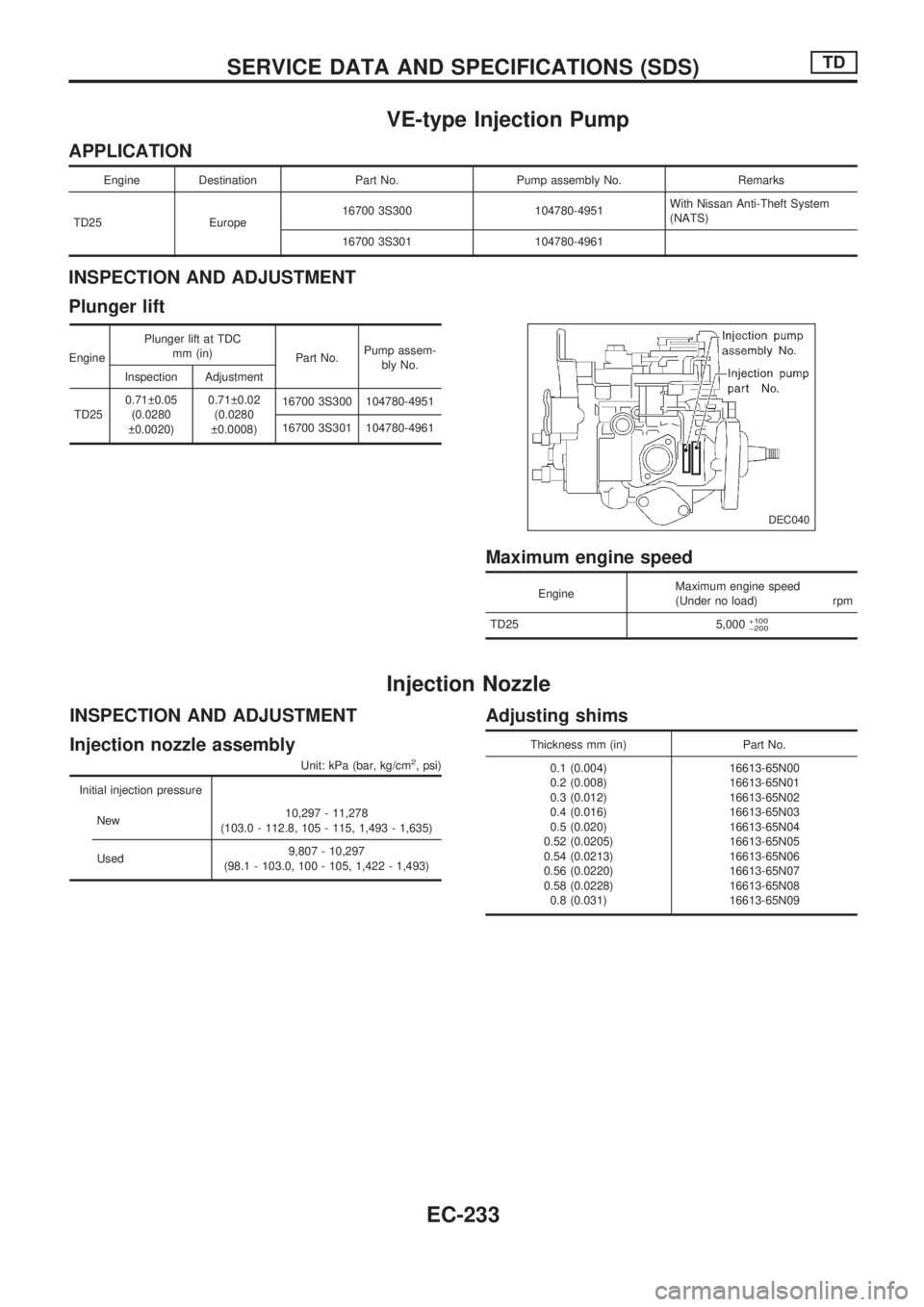

VE-type Injection Pump

APPLICATION

Engine Destination Part No. Pump assembly No. Remarks

TD25 Europe16700 3S300 104780-4951With Nissan Anti-Theft System

(NATS)

16700 3S301 104780-4961

INSPECTION AND ADJUSTMENT

Plunger lift

EnginePlunger lift at TDC

mm (in)

Part No.Pump assem-

bly No.

Inspection Adjustment

TD250.71 0.05

(0.0280

0.0020)0.71 0.02

(0.0280

0.0008)16700 3S300 104780-4951

16700 3S301 104780-4961

Maximum engine speed

EngineMaximum engine speed

(Under no load) rpm

TD25 5,000

+100

þ200

Injection Nozzle

INSPECTION AND ADJUSTMENT

Injection nozzle assembly

Unit: kPa (bar, kg/cm2, psi)

Initial injection pressure

New10,297 - 11,278

(103.0 - 112.8, 105 - 115, 1,493 - 1,635)

Used9,807 - 10,297

(98.1 - 103.0, 100 - 105, 1,422 - 1,493)

Adjusting shims

Thickness mm (in) Part No.

0.1 (0.004)

0.2 (0.008)

0.3 (0.012)

0.4 (0.016)

0.5 (0.020)

0.52 (0.0205)

0.54 (0.0213)

0.56 (0.0220)

0.58 (0.0228)

0.8 (0.031)16613-65N00

16613-65N01

16613-65N02

16613-65N03

16613-65N04

16613-65N05

16613-65N06

16613-65N07

16613-65N08

16613-65N09

DEC040

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EC-233

Page 386 of 1659

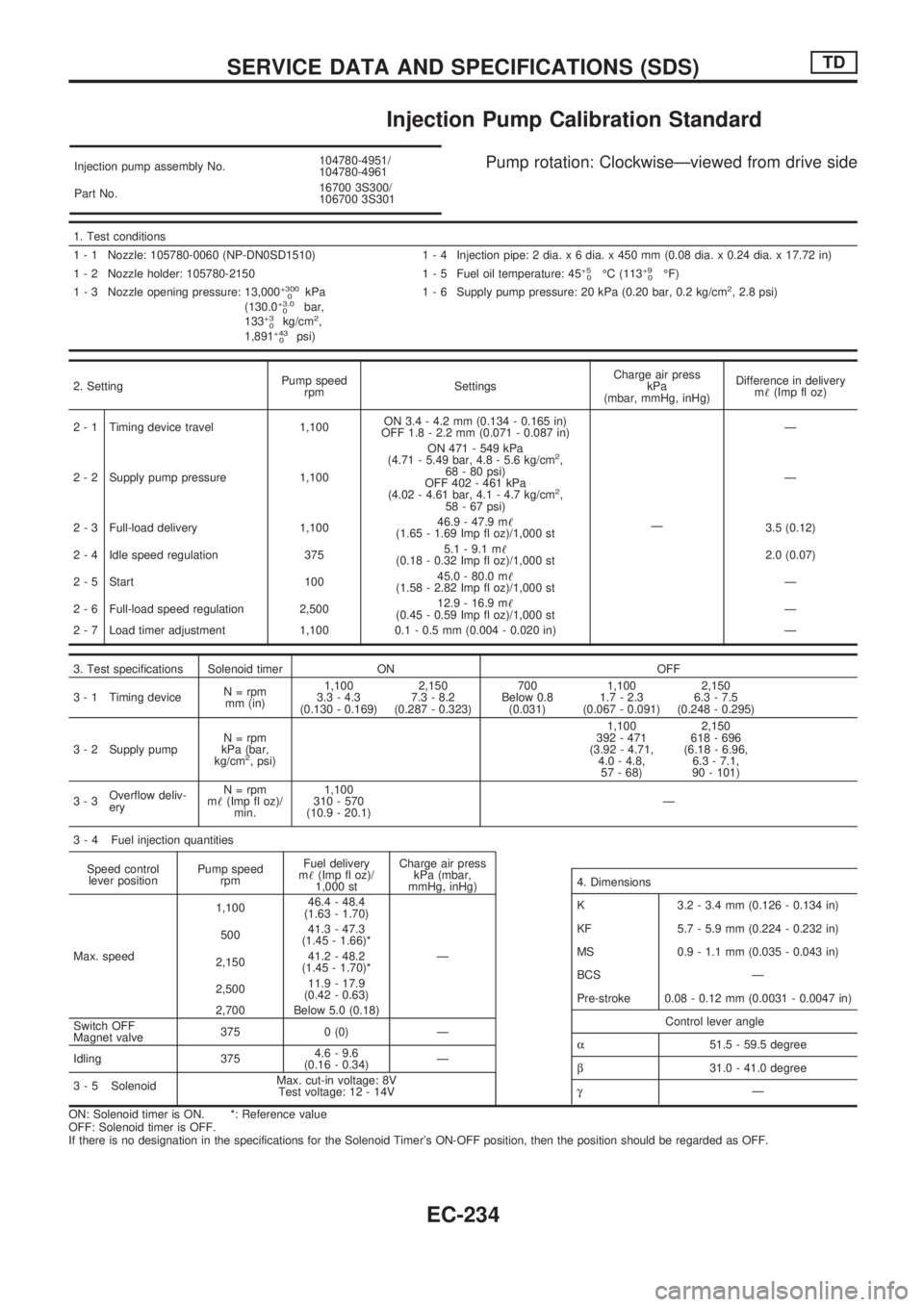

Injection Pump Calibration Standard

Injection pump assembly No.104780-4951/

104780-4961

Part No.16700 3S300/

106700 3S301Pump rotation: ClockwiseÐviewed from drive side

1. Test conditions

1 - 1 Nozzle: 105780-0060 (NP-DN0SD1510) 1 - 4 Injection pipe: 2 dia. x 6 dia. x 450 mm (0.08 dia. x 0.24 dia. x 17.72 in)

1 - 2 Nozzle holder: 105780-2150 1 - 5 Fuel oil temperature: 45

+5

0ÉC (113+9

0ÉF)

1 - 3 Nozzle opening pressure: 13,000+300

0kPa

(130.0+3.0

0bar,

133+3

0kg/cm2,

1,891+43

0psi)1 - 6 Supply pump pressure: 20 kPa (0.20 bar, 0.2 kg/cm

2, 2.8 psi)

2. SettingPump speed

rpmSettingsCharge air press

kPa

(mbar, mmHg, inHg)Difference in delivery

m!(Imp fl oz)

2 - 1 Timing device travel 1,100ON 3.4 - 4.2 mm (0.134 - 0.165 in)

OFF 1.8 - 2.2 mm (0.071 - 0.087 in)

ÐÐ

2 - 2 Supply pump pressure 1,100ON 471 - 549 kPa

(4.71 - 5.49 bar, 4.8 - 5.6 kg/cm

2,

68 - 80 psi)

OFF 402 - 461 kPa

(4.02 - 4.61 bar, 4.1 - 4.7 kg/cm

2,

58 - 67 psi)Ð

2 - 3 Full-load delivery 1,10046.9 - 47.9 m!

(1.65 - 1.69 Imp fl oz)/1,000 st3.5 (0.12)

2 - 4 Idle speed regulation 3755.1 - 9.1 m!

(0.18 - 0.32 Imp fl oz)/1,000 st2.0 (0.07)

2 - 5 Start 10045.0 - 80.0 m!

(1.58 - 2.82 Imp fl oz)/1,000 stÐ

2 - 6 Full-load speed regulation 2,50012.9 - 16.9 m!

(0.45 - 0.59 Imp fl oz)/1,000 stÐ

2 - 7 Load timer adjustment 1,100 0.1 - 0.5 mm (0.004 - 0.020 in) Ð

3. Test specifications Solenoid timer ON OFF

3 - 1 Timing deviceN = rpm

mm (in)1,100

3.3 - 4.3

(0.130 - 0.169)2,150

7.3 - 8.2

(0.287 - 0.323)700

Below 0.8

(0.031)1,100

1.7 - 2.3

(0.067 - 0.091)2,150

6.3 - 7.5

(0.248 - 0.295)

3 - 2 Supply pumpN = rpm

kPa (bar,

kg/cm

2, psi)1,100

392 - 471

(3.92 - 4.71,

4.0 - 4.8,

57 - 68)2,150

618 - 696

(6.18 - 6.96,

6.3 - 7.1,

90 - 101)

3-3Overflow deliv-

eryN = rpm

m!(Imp fl oz)/

min.1,100

310 - 570

(10.9 - 20.1)Ð

3 - 4 Fuel injection quantities

Speed control

lever positionPump speed

rpmFuel delivery

m!(Imp fl oz)/

1,000 stCharge air press

kPa (mbar,

mmHg, inHg)

Max. speed1,10046.4 - 48.4

(1.63 - 1.70)

Ð 50041.3 - 47.3

(1.45 - 1.66)*

2,15041.2 - 48.2

(1.45 - 1.70)*

2,50011.9 - 17.9

(0.42 - 0.63)

2,700 Below 5.0 (0.18)

Switch OFF

Magnet valve375 0 (0) Ð

Idling 3754.6 - 9.6

(0.16 - 0.34)Ð

3 - 5 SolenoidMax. cut-in voltage: 8V

Test voltage: 12 - 14V

ON: Solenoid timer is ON. *: Reference value

OFF: Solenoid timer is OFF.

If there is no designation in the specifications for the Solenoid Timer's ON-OFF position, then the position should be regarded as OFF.

4. Dimensions

K 3.2 - 3.4 mm (0.126 - 0.134 in)

KF 5.7 - 5.9 mm (0.224 - 0.232 in)

MS 0.9 - 1.1 mm (0.035 - 0.043 in)

BCS Ð

Pre-stroke 0.08 - 0.12 mm (0.0031 - 0.0047 in)

Control lever angle

a51.5 - 59.5 degree

b31.0 - 41.0 degree

gÐ

SERVICE DATA AND SPECIFICATIONS (SDS)TD

EC-234

Page 387 of 1659

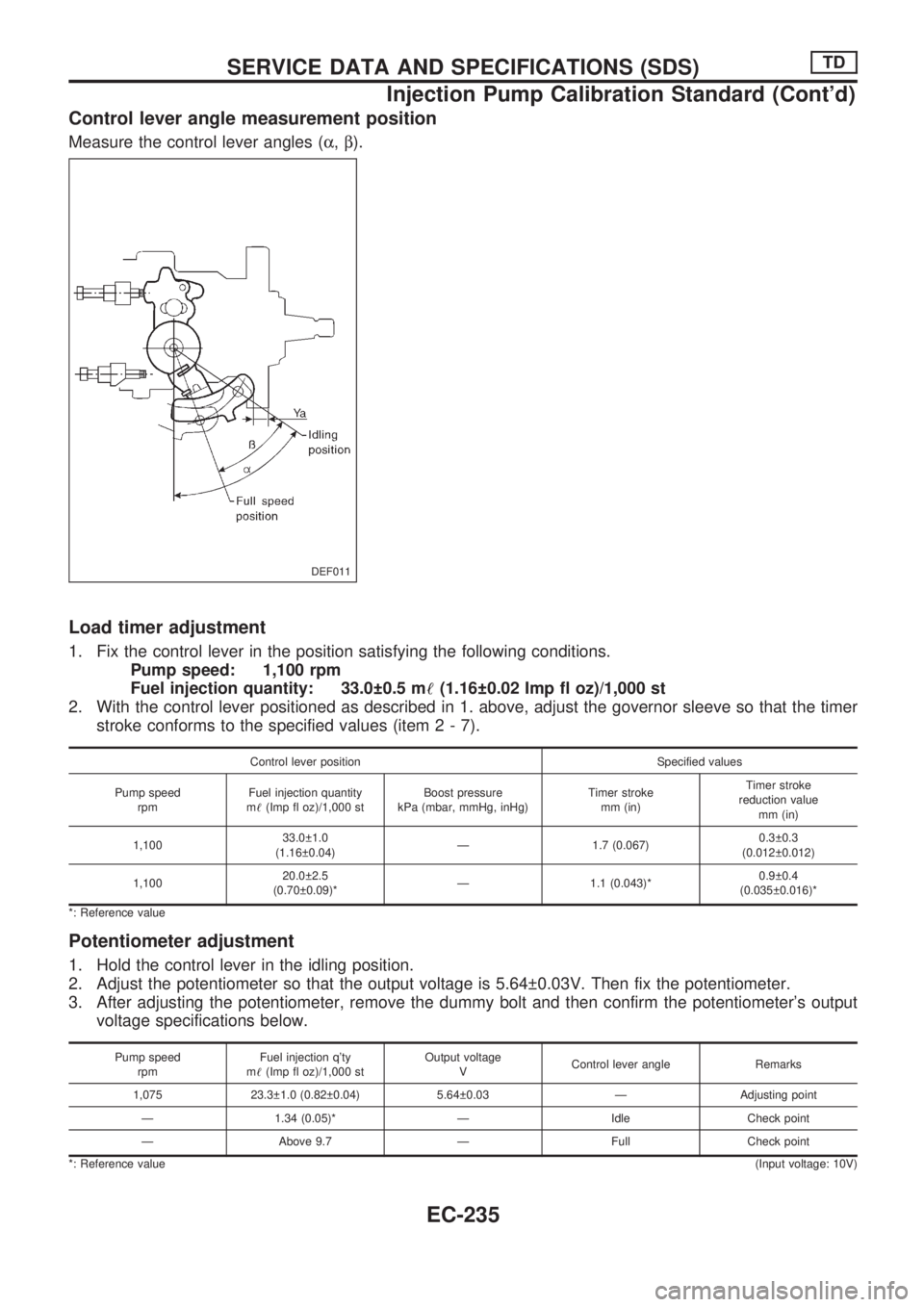

Control lever angle measurement position

Measure the control lever angles (a,b).

Load timer adjustment

1. Fix the control lever in the position satisfying the following conditions.

Pump speed: 1,100 rpm

Fuel injection quantity: 33.0 0.5 m!(1.16 0.02 Imp fl oz)/1,000 st

2. With the control lever positioned as described in 1. above, adjust the governor sleeve so that the timer

stroke conforms to the specified values (item2-7).

Control lever position Specified values

Pump speed

rpmFuel injection quantity

m!(Imp fl oz)/1,000 stBoost pressure

kPa (mbar, mmHg, inHg)Timer stroke

mm (in)Timer stroke

reduction value

mm (in)

1,10033.0 1.0

(1.16 0.04)Ð 1.7 (0.067)0.3 0.3

(0.012 0.012)

1,10020.0 2.5

(0.70 0.09)*Ð 1.1 (0.043)*0.9 0.4

(0.035 0.016)*

*: Reference value

Potentiometer adjustment

1. Hold the control lever in the idling position.

2. Adjust the potentiometer so that the output voltage is 5.64 0.03V. Then fix the potentiometer.

3. After adjusting the potentiometer, remove the dummy bolt and then confirm the potentiometer's output

voltage specifications below.

Pump speed

rpmFuel injection q'ty

m!(Imp fl oz)/1,000 stOutput voltage

VControl lever angle Remarks

1,075 23.3 1.0 (0.82 0.04) 5.64 0.03 Ð Adjusting point

Ð 1.34 (0.05)* Ð Idle Check point

Ð Above 9.7 Ð Full Check point

*: Reference value(Input voltage: 10V)

DEF011

SERVICE DATA AND SPECIFICATIONS (SDS)TD

Injection Pump Calibration Standard (Cont'd)

EC-235

Page 388 of 1659

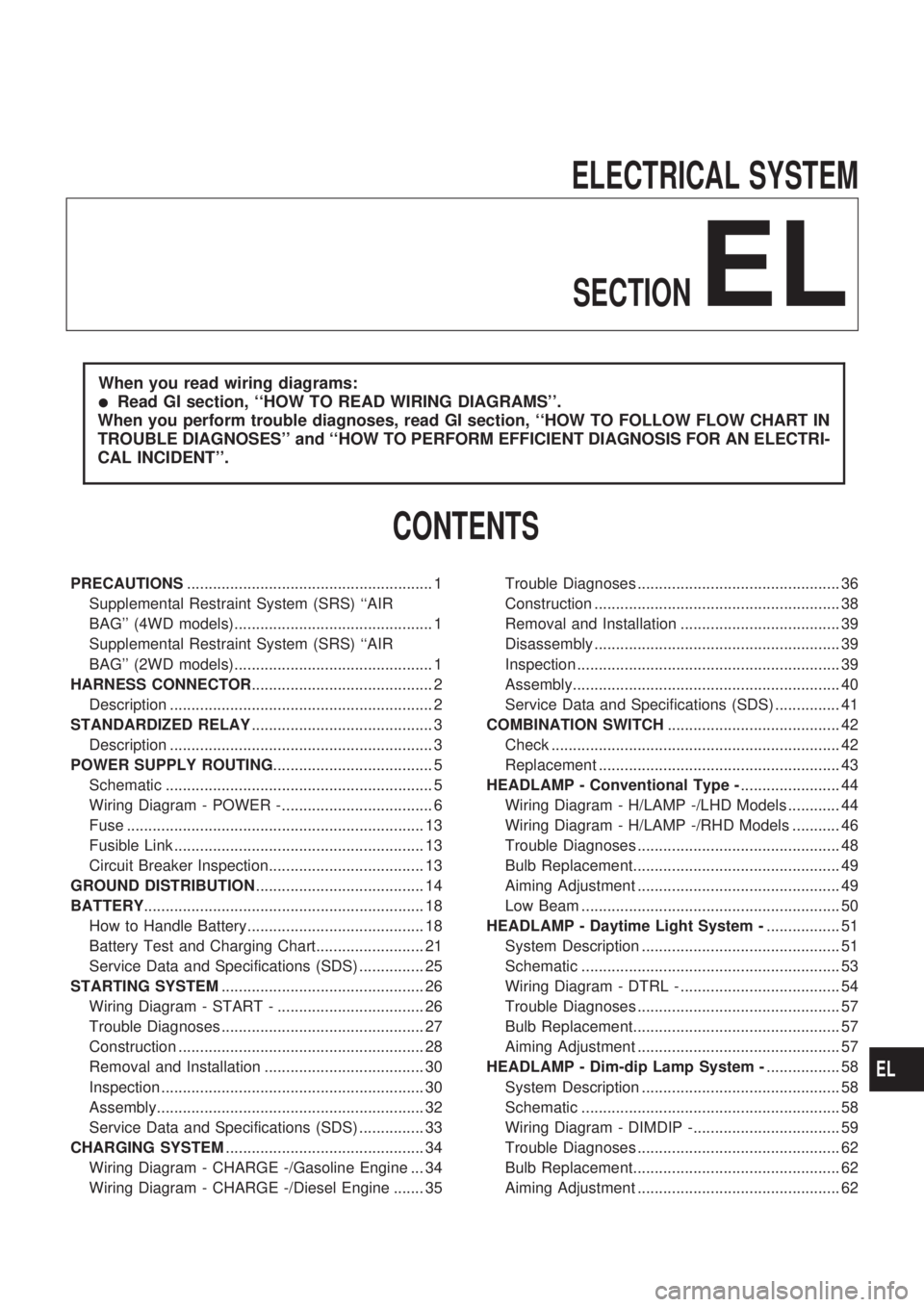

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

lRead GI section, ``HOW TO READ WIRING DIAGRAMS''.

When you perform trouble diagnoses, read GI section, ``HOW TO FOLLOW FLOW CHART IN

TROUBLE DIAGNOSES'' and ``HOW TO PERFORM EFFICIENT DIAGNOSIS FOR AN ELECTRI-

CAL INCIDENT''.

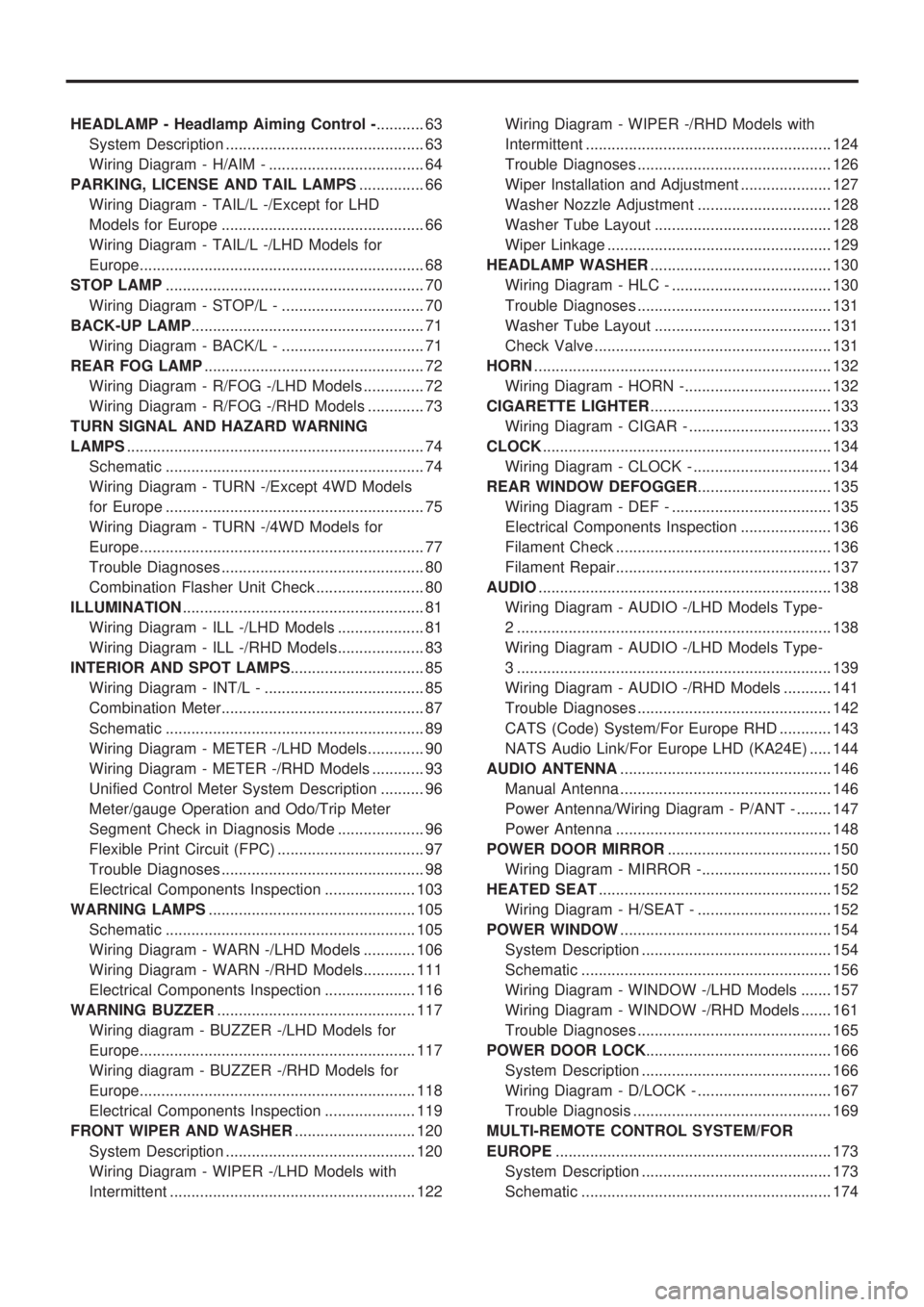

CONTENTS

PRECAUTIONS......................................................... 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (4WD models).............................................. 1

Supplemental Restraint System (SRS) ``AIR

BAG'' (2WD models).............................................. 1

HARNESS CONNECTOR.......................................... 2

Description ............................................................. 2

STANDARDIZED RELAY.......................................... 3

Description ............................................................. 3

POWER SUPPLY ROUTING..................................... 5

Schematic .............................................................. 5

Wiring Diagram - POWER -................................... 6

Fuse ..................................................................... 13

Fusible Link .......................................................... 13

Circuit Breaker Inspection.................................... 13

GROUND DISTRIBUTION....................................... 14

BATTERY................................................................. 18

How to Handle Battery......................................... 18

Battery Test and Charging Chart......................... 21

Service Data and Specifications (SDS) ............... 25

STARTING SYSTEM............................................... 26

Wiring Diagram - START - .................................. 26

Trouble Diagnoses ............................................... 27

Construction ......................................................... 28

Removal and Installation ..................................... 30

Inspection ............................................................. 30

Assembly.............................................................. 32

Service Data and Specifications (SDS) ............... 33

CHARGING SYSTEM.............................................. 34

Wiring Diagram - CHARGE -/Gasoline Engine ... 34

Wiring Diagram - CHARGE -/Diesel Engine ....... 35Trouble Diagnoses ............................................... 36

Construction ......................................................... 38

Removal and Installation ..................................... 39

Disassembly ......................................................... 39

Inspection ............................................................. 39

Assembly.............................................................. 40

Service Data and Specifications (SDS) ............... 41

COMBINATION SWITCH........................................ 42

Check ................................................................... 42

Replacement ........................................................ 43

HEADLAMP - Conventional Type -....................... 44

Wiring Diagram - H/LAMP -/LHD Models ............ 44

Wiring Diagram - H/LAMP -/RHD Models ........... 46

Trouble Diagnoses ............................................... 48

Bulb Replacement................................................ 49

Aiming Adjustment ............................................... 49

Low Beam ............................................................ 50

HEADLAMP - Daytime Light System -................. 51

System Description .............................................. 51

Schematic ............................................................ 53

Wiring Diagram - DTRL - ..................................... 54

Trouble Diagnoses ............................................... 57

Bulb Replacement................................................ 57

Aiming Adjustment ............................................... 57

HEADLAMP - Dim-dip Lamp System -................. 58

System Description .............................................. 58

Schematic ............................................................ 58

Wiring Diagram - DIMDIP -.................................. 59

Trouble Diagnoses ............................................... 62

Bulb Replacement................................................ 62

Aiming Adjustment ............................................... 62

EL

Page 389 of 1659

HEADLAMP - Headlamp Aiming Control -........... 63

System Description .............................................. 63

Wiring Diagram - H/AIM - .................................... 64

PARKING, LICENSE AND TAIL LAMPS............... 66

Wiring Diagram - TAIL/L -/Except for LHD

Models for Europe ............................................... 66

Wiring Diagram - TAIL/L -/LHD Models for

Europe.................................................................. 68

STOP LAMP............................................................ 70

Wiring Diagram - STOP/L - ................................. 70

BACK-UP LAMP...................................................... 71

Wiring Diagram - BACK/L - ................................. 71

REAR FOG LAMP................................................... 72

Wiring Diagram - R/FOG -/LHD Models .............. 72

Wiring Diagram - R/FOG -/RHD Models ............. 73

TURN SIGNAL AND HAZARD WARNING

LAMPS..................................................................... 74

Schematic ............................................................ 74

Wiring Diagram - TURN -/Except 4WD Models

for Europe ............................................................ 75

Wiring Diagram - TURN -/4WD Models for

Europe.................................................................. 77

Trouble Diagnoses ............................................... 80

Combination Flasher Unit Check ......................... 80

ILLUMINATION........................................................ 81

Wiring Diagram - ILL -/LHD Models .................... 81

Wiring Diagram - ILL -/RHD Models.................... 83

INTERIOR AND SPOT LAMPS............................... 85

Wiring Diagram - INT/L - ..................................... 85

Combination Meter............................................... 87

Schematic ............................................................ 89

Wiring Diagram - METER -/LHD Models............. 90

Wiring Diagram - METER -/RHD Models ............ 93

Unified Control Meter System Description .......... 96

Meter/gauge Operation and Odo/Trip Meter

Segment Check in Diagnosis Mode .................... 96

Flexible Print Circuit (FPC) .................................. 97

Trouble Diagnoses ............................................... 98

Electrical Components Inspection ..................... 103

WARNING LAMPS................................................ 105

Schematic .......................................................... 105

Wiring Diagram - WARN -/LHD Models ............ 106

Wiring Diagram - WARN -/RHD Models............ 111

Electrical Components Inspection ..................... 116

WARNING BUZZER.............................................. 117

Wiring diagram - BUZZER -/LHD Models for

Europe................................................................ 117

Wiring diagram - BUZZER -/RHD Models for

Europe................................................................ 118

Electrical Components Inspection ..................... 119

FRONT WIPER AND WASHER............................ 120

System Description ............................................ 120

Wiring Diagram - WIPER -/LHD Models with

Intermittent ......................................................... 122Wiring Diagram - WIPER -/RHD Models with

Intermittent ......................................................... 124

Trouble Diagnoses ............................................. 126

Wiper Installation and Adjustment ..................... 127

Washer Nozzle Adjustment ............................... 128

Washer Tube Layout ......................................... 128

Wiper Linkage .................................................... 129

HEADLAMP WASHER.......................................... 130

Wiring Diagram - HLC - ..................................... 130

Trouble Diagnoses ............................................. 131

Washer Tube Layout ......................................... 131

Check Valve ....................................................... 131

HORN..................................................................... 132

Wiring Diagram - HORN -.................................. 132

CIGARETTE LIGHTER.......................................... 133

Wiring Diagram - CIGAR - ................................. 133

CLOCK................................................................... 134

Wiring Diagram - CLOCK - ................................ 134

REAR WINDOW DEFOGGER............................... 135

Wiring Diagram - DEF - ..................................... 135

Electrical Components Inspection ..................... 136

Filament Check .................................................. 136

Filament Repair.................................................. 137

AUDIO.................................................................... 138

Wiring Diagram - AUDIO -/LHD Models Type-

2 ......................................................................... 138

Wiring Diagram - AUDIO -/LHD Models Type-

3 ......................................................................... 139

Wiring Diagram - AUDIO -/RHD Models ........... 141

Trouble Diagnoses ............................................. 142

CATS (Code) System/For Europe RHD ............ 143

NATS Audio Link/For Europe LHD (KA24E) ..... 144

AUDIO ANTENNA................................................. 146

Manual Antenna ................................................. 146

Power Antenna/Wiring Diagram - P/ANT - ........ 147

Power Antenna .................................................. 148

POWER DOOR MIRROR...................................... 150

Wiring Diagram - MIRROR -.............................. 150

HEATED SEAT...................................................... 152

Wiring Diagram - H/SEAT - ............................... 152

POWER WINDOW................................................. 154

System Description ............................................ 154

Schematic .......................................................... 156

Wiring Diagram - WINDOW -/LHD Models ....... 157

Wiring Diagram - WINDOW -/RHD Models ....... 161

Trouble Diagnoses ............................................. 165

POWER DOOR LOCK........................................... 166

System Description ............................................ 166

Wiring Diagram - D/LOCK - ............................... 167

Trouble Diagnosis .............................................. 169

MULTI-REMOTE CONTROL SYSTEM/FOR

EUROPE................................................................ 173

System Description ............................................ 173

Schematic .......................................................... 174

Page 390 of 1659

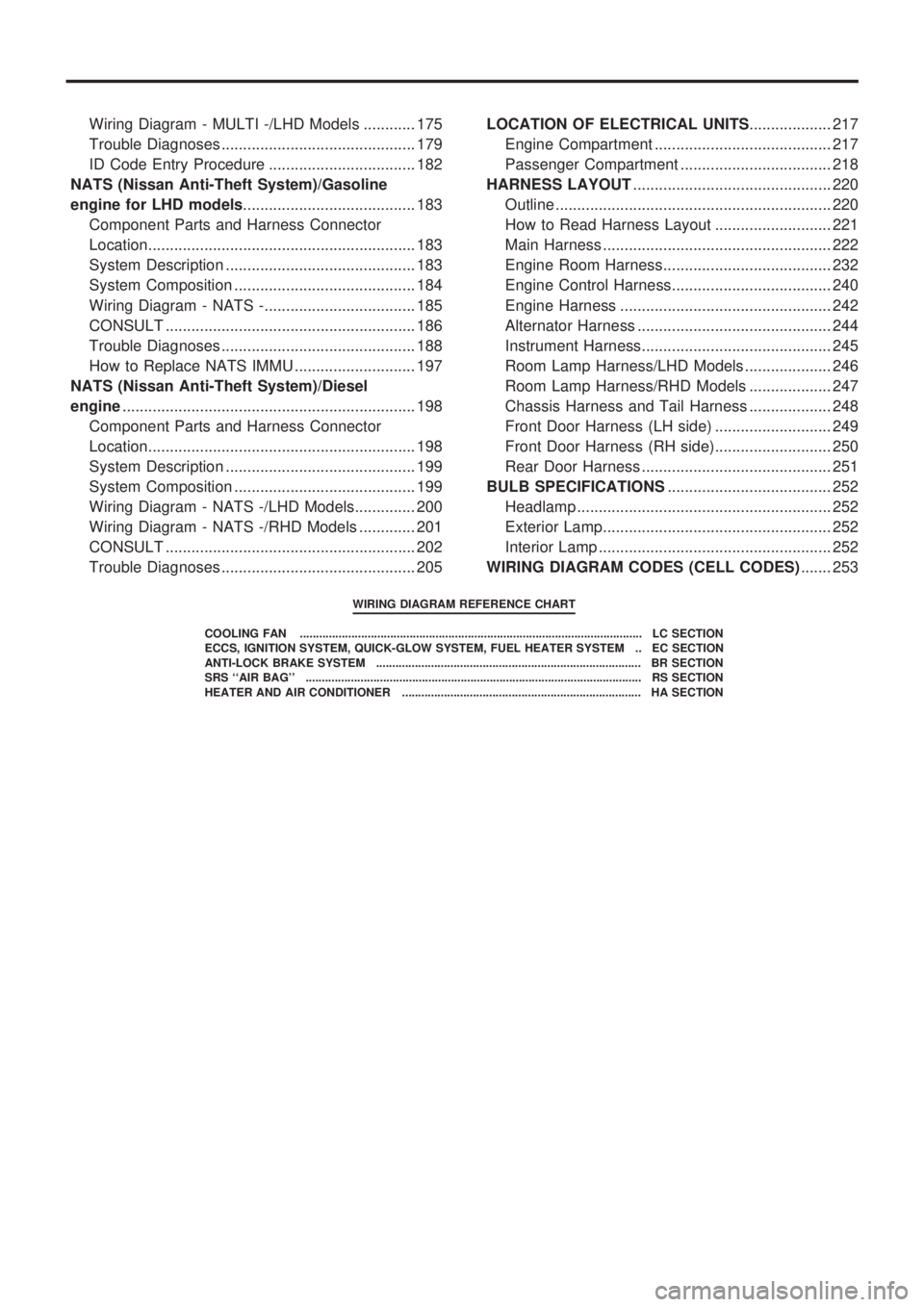

Wiring Diagram - MULTI -/LHD Models ............ 175

Trouble Diagnoses ............................................. 179

ID Code Entry Procedure .................................. 182

NATS (Nissan Anti-Theft System)/Gasoline

engine for LHD models........................................ 183

Component Parts and Harness Connector

Location.............................................................. 183

System Description ............................................ 183

System Composition .......................................... 184

Wiring Diagram - NATS -................................... 185

CONSULT .......................................................... 186

Trouble Diagnoses ............................................. 188

How to Replace NATS IMMU ............................ 197

NATS (Nissan Anti-Theft System)/Diesel

engine.................................................................... 198

Component Parts and Harness Connector

Location.............................................................. 198

System Description ............................................ 199

System Composition .......................................... 199

Wiring Diagram - NATS -/LHD Models.............. 200

Wiring Diagram - NATS -/RHD Models ............. 201

CONSULT .......................................................... 202

Trouble Diagnoses ............................................. 205LOCATION OF ELECTRICAL UNITS................... 217

Engine Compartment ......................................... 217

Passenger Compartment ................................... 218

HARNESS LAYOUT.............................................. 220

Outline ................................................................ 220

How to Read Harness Layout ........................... 221

Main Harness ..................................................... 222

Engine Room Harness....................................... 232

Engine Control Harness..................................... 240

Engine Harness ................................................. 242

Alternator Harness ............................................. 244

Instrument Harness............................................ 245

Room Lamp Harness/LHD Models .................... 246

Room Lamp Harness/RHD Models ................... 247

Chassis Harness and Tail Harness ................... 248

Front Door Harness (LH side) ........................... 249

Front Door Harness (RH side)........................... 250

Rear Door Harness ............................................ 251

BULB SPECIFICATIONS...................................... 252

Headlamp ........................................................... 252

Exterior Lamp..................................................... 252

Interior Lamp ...................................................... 252

WIRING DIAGRAM CODES (CELL CODES)....... 253

WIRING DIAGRAM REFERENCE CHART

COOLING FAN .......................................................................................................... LC SECTION

ECCS, IGNITION SYSTEM, QUICK-GLOW SYSTEM, FUEL HEATER SYSTEM .. EC SECTION

ANTI-LOCK BRAKE SYSTEM .................................................................................. BR SECTION

SRS ``AIR BAG'' ........................................................................................................ RS SECTION

HEATER AND AIR CONDITIONER .......................................................................... HA SECTION