NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 221 of 5883

REAR DISC BRAKE

BR-29

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. Drain brake fluid. Refer to BR-8, "Bleeding Brake System".

4. Remove connecting bolt and torque member bolts using power tool, and remove cylinder body.

5. Remove caliper and disc rotor. If the disc rotor cannot be removed, remove as follows:

Make sure parking brake lever is completely disengaged.

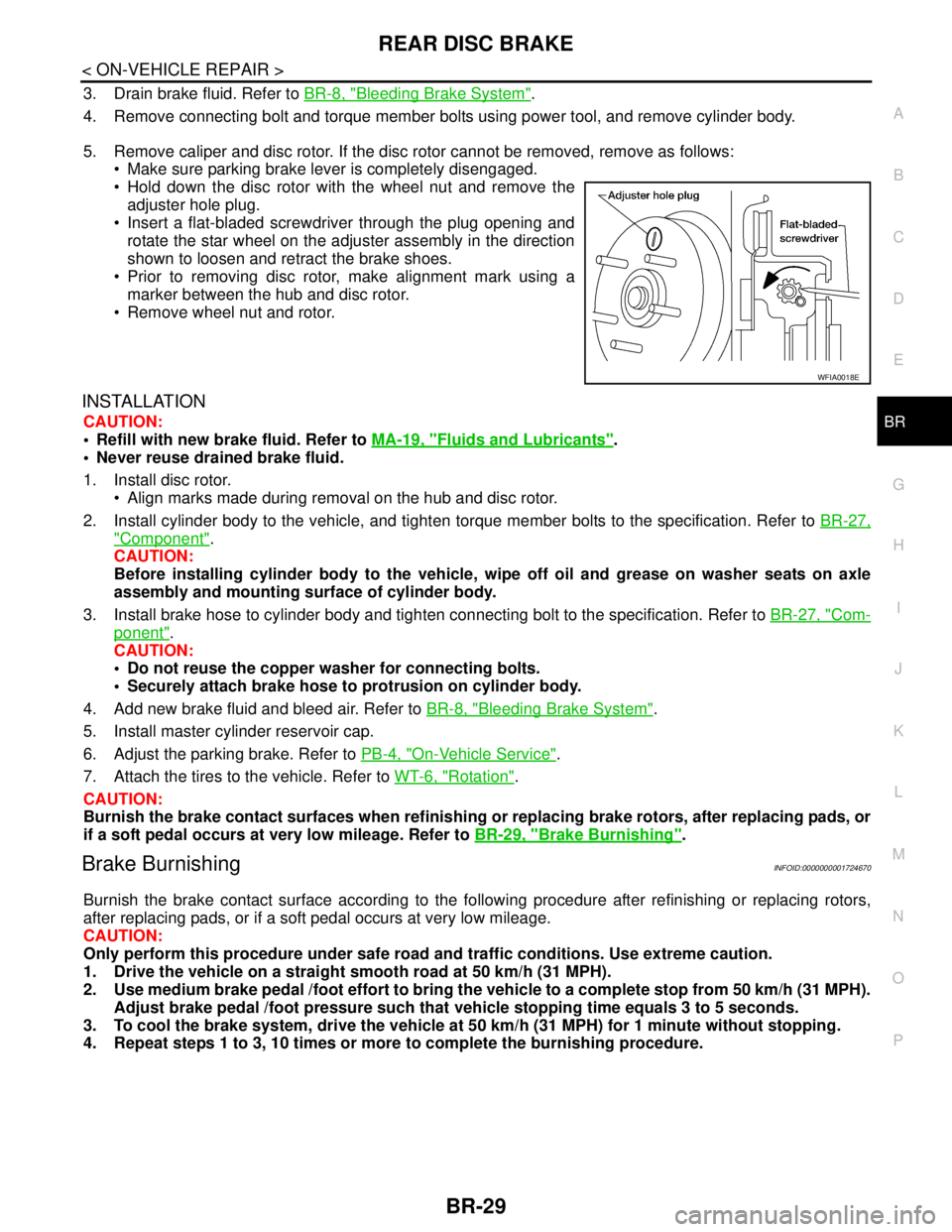

Hold down the disc rotor with the wheel nut and remove the

adjuster hole plug.

Insert a flat-bladed screwdriver through the plug opening and

rotate the star wheel on the adjuster assembly in the direction

shown to loosen and retract the brake shoes.

Prior to removing disc rotor, make alignment mark using a

marker between the hub and disc rotor.

Remove wheel nut and rotor.

INSTALLATION

CAUTION:

Refill with new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

1. Install disc rotor.

Align marks made during removal on the hub and disc rotor.

2. Install cylinder body to the vehicle, and tighten torque member bolts to the specification. Refer to BR-27,

"Component".

CAUTION:

Before installing cylinder body to the vehicle, wipe off oil and grease on washer seats on axle

assembly and mounting surface of cylinder body.

3. Install brake hose to cylinder body and tighten connecting bolt to the specification. Refer to BR-27, "

Com-

ponent".

CAUTION:

Do not reuse the copper washer for connecting bolts.

Securely attach brake hose to protrusion on cylinder body.

4. Add new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System".

5. Install master cylinder reservoir cap.

6. Adjust the parking brake. Refer to PB-4, "

On-Vehicle Service".

7. Attach the tires to the vehicle. Refer to WT-6, "

Rotation".

CAUTION:

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads, or

if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

Brake BurnishingINFOID:0000000001724670

Burnish the brake contact surface according to the following procedure after refinishing or replacing rotors,

after replacing pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive the vehicle on a straight smooth road at 50 km/h (31 MPH).

2. Use medium brake pedal /foot effort to bring the vehicle to a complete stop from 50 km/h (31 MPH).

Adjust brake pedal /foot pressure such that vehicle stopping time equals 3 to 5 seconds.

3. To cool the brake system, drive the vehicle at 50 km/h (31 MPH) for 1 minute without stopping.

4. Repeat steps 1 to 3, 10 times or more to complete the burnishing procedure.

WFIA0018E

Page 222 of 5883

BR-30

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

DISASSEMBLY AND ASSEMBLY

BRAKE MASTER CYLINDER

Disassembly and AssemblyINFOID:0000000001717016

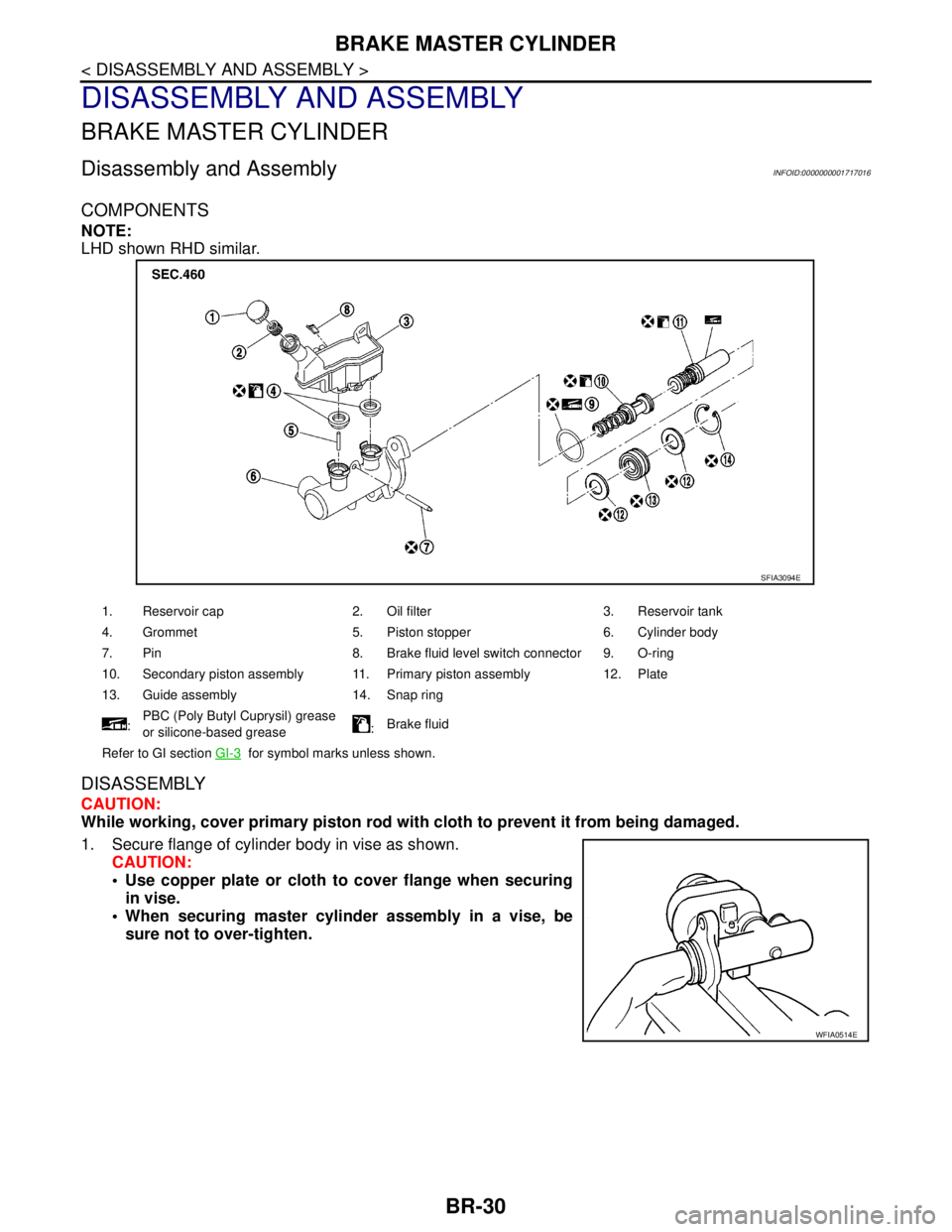

COMPONENTS

NOTE:

LHD shown RHD similar.

DISASSEMBLY

CAUTION:

While working, cover primary piston rod with cloth to prevent it from being damaged.

1. Secure flange of cylinder body in vise as shown.

CAUTION:

Use copper plate or cloth to cover flange when securing

in vise.

When securing master cylinder assembly in a vise, be

sure not to over-tighten.

1. Reservoir cap 2. Oil filter 3. Reservoir tank

4. Grommet 5. Piston stopper 6. Cylinder body

7. Pin 8. Brake fluid level switch connector 9. O-ring

10. Secondary piston assembly 11. Primary piston assembly 12. Plate

13. Guide assembly 14. Snap ring

:PBC (Poly Butyl Cuprysil) grease

or silicone-based grease:Brake fluid

Refer to GI section GI-3

for symbol marks unless shown.

SFIA3094E

WFIA0514E

Page 223 of 5883

![NISSAN TIIDA 2007 Service Repair Manual BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank NISSAN TIIDA 2007 Service Repair Manual BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank](/img/5/57395/w960_57395-222.png)

BRAKE MASTER CYLINDER

BR-31

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Using a pin-punch [commercial service tool: diameter approx. 4

mm (0.16 in)], remove pin from reservoir tank.

3. Remove master cylinder assembly from vise.

4. Remove reservoir tank and grommet from cylinder body.

5. While pushing primary piston, remove piston stopper through

secondary tank boss hole in the cylinder body.

6. Remove snap ring with pushing primary piston.

CAUTION:

Be careful not to pop out piston.

7. Holding rod of primary piston, remove primary piston assembly,

plate and guide assembly by pulling straight to prevent piston

cup from being caught by the inner wall of cylinder.

8. Remove plate and guide assembly from primary piston.

CAUTION:

Be careful not to damage rod from the inner wall of plate.

9. Tap flange using a soft block such as wood, and carefully pull

secondary piston assembly straight out to prevent cylinder inner

wall from being damaged.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for damage, wear, corrosion, and pin holes. Replace cylinder body if neces-

sary.

ASSEMBLY

CAUTION:

Never use mineral oils such as kerosene or gasoline during the cleaning and assembly processes.

Make sure that there is no foreign material such as dirt and dust on the inner wall of cylinder, piston,

and piston cup. Be careful not to damage parts with a service tool when assembling.

Do not drop parts. If a part is dropped, do not use it.

WFIA0515E

WFIA0516E

BRA0561DWFIA0517E

WFIA0518E

Page 224 of 5883

BR-32

< DISASSEMBLY AND ASSEMBLY >

BRAKE MASTER CYLINDER

1. Apply brake fluid to the inner wall of cylinder body, primary pis-

ton assembly and secondary piston assembly.

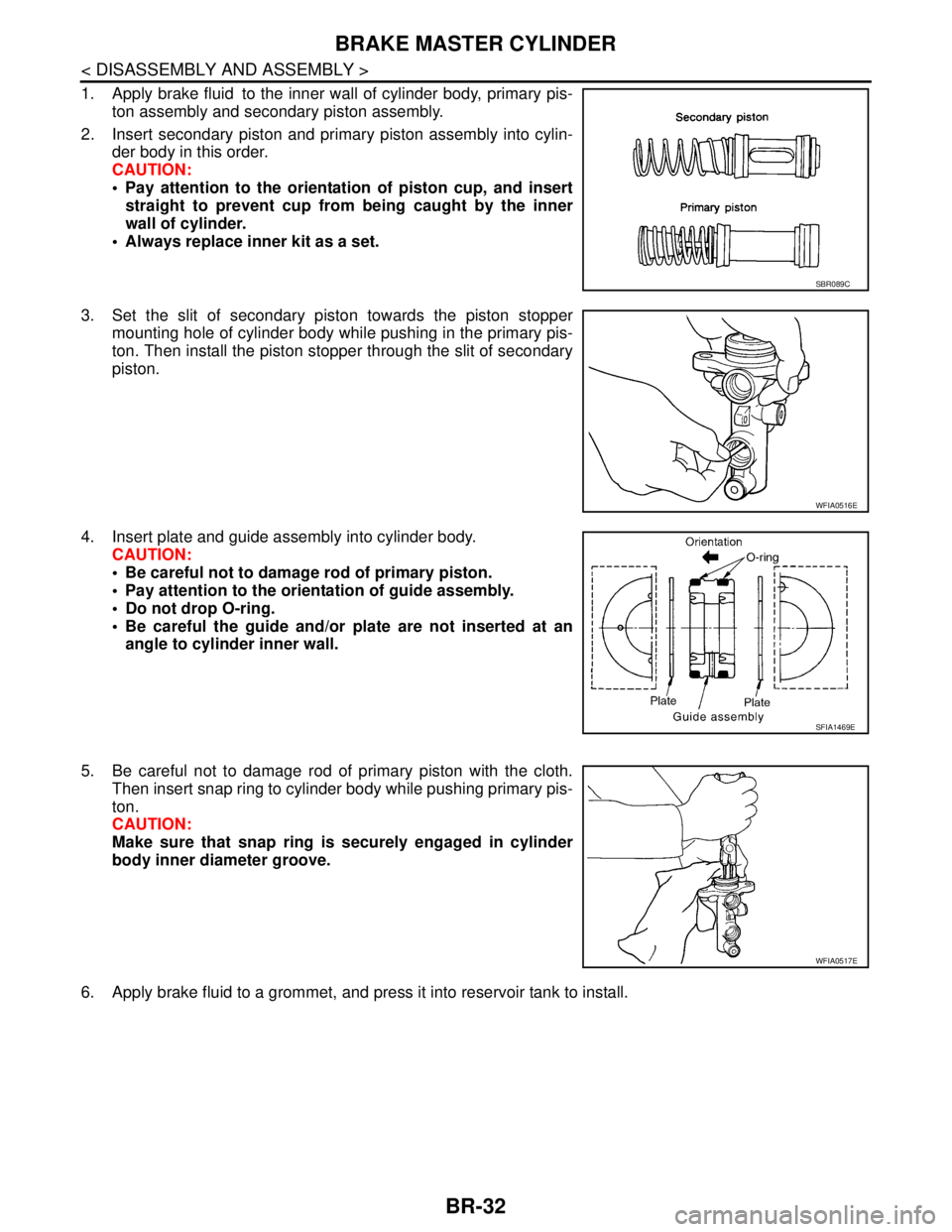

2. Insert secondary piston and primary piston assembly into cylin-

der body in this order.

CAUTION:

Pay attention to the orientation of piston cup, and insert

straight to prevent cup from being caught by the inner

wall of cylinder.

Always replace inner kit as a set.

3. Set the slit of secondary piston towards the piston stopper

mounting hole of cylinder body while pushing in the primary pis-

ton. Then install the piston stopper through the slit of secondary

piston.

4. Insert plate and guide assembly into cylinder body.

CAUTION:

Be careful not to damage rod of primary piston.

Pay attention to the orientation of guide assembly.

Do not drop O-ring.

Be careful the guide and/or plate are not inserted at an

angle to cylinder inner wall.

5. Be careful not to damage rod of primary piston with the cloth.

Then insert snap ring to cylinder body while pushing primary pis-

ton.

CAUTION:

Make sure that snap ring is securely engaged in cylinder

body inner diameter groove.

6. Apply brake fluid to a grommet, and press it into reservoir tank to install.

SBR089C

WFIA0516E

SFIA1469E

WFIA0517E

Page 225 of 5883

BRAKE MASTER CYLINDER

BR-33

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

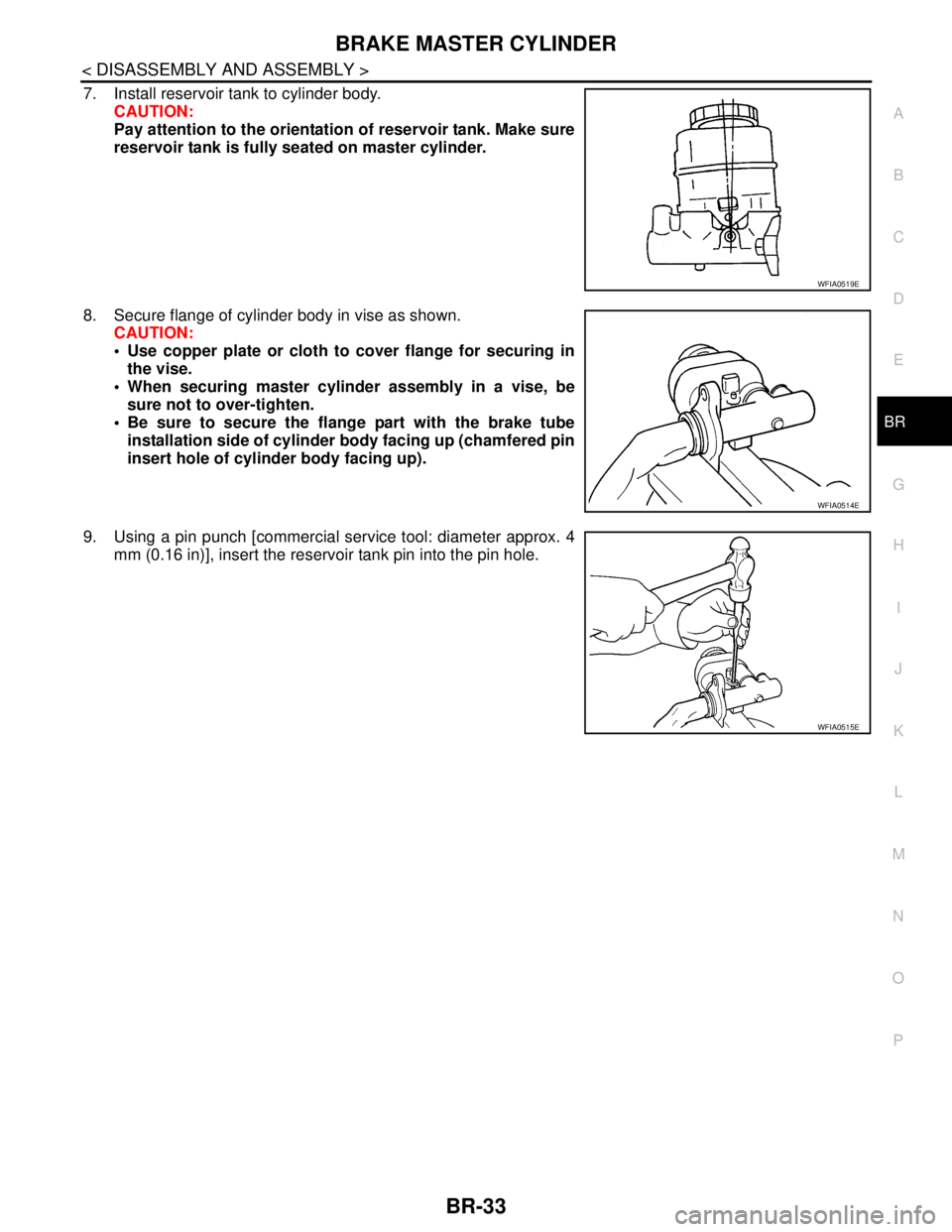

7. Install reservoir tank to cylinder body.

CAUTION:

Pay attention to the orientation of reservoir tank. Make sure

reservoir tank is fully seated on master cylinder.

8. Secure flange of cylinder body in vise as shown.

CAUTION:

Use copper plate or cloth to cover flange for securing in

the vise.

When securing master cylinder assembly in a vise, be

sure not to over-tighten.

Be sure to secure the flange part with the brake tube

installation side of cylinder body facing up (chamfered pin

insert hole of cylinder body facing up).

9. Using a pin punch [commercial service tool: diameter approx. 4

mm (0.16 in)], insert the reservoir tank pin into the pin hole.

WFIA0519E

WFIA0514E

WFIA0515E

Page 226 of 5883

BR-34

< DISASSEMBLY AND ASSEMBLY >

FRONT DISC BRAKE

FRONT DISC BRAKE

Disassembly and Assembly of Brake Caliper AssemblyINFOID:0000000001717023

NOTE:

Do not remove torque member, brake pads, shims and pad retainers, when disassembling or assembling cyl-

inder body.

DISASSEMBLY

1. Remove caliper assembly from vehicle. Refer to BR-25,

"Removal and Installation of Brake Caliper Assembly" .

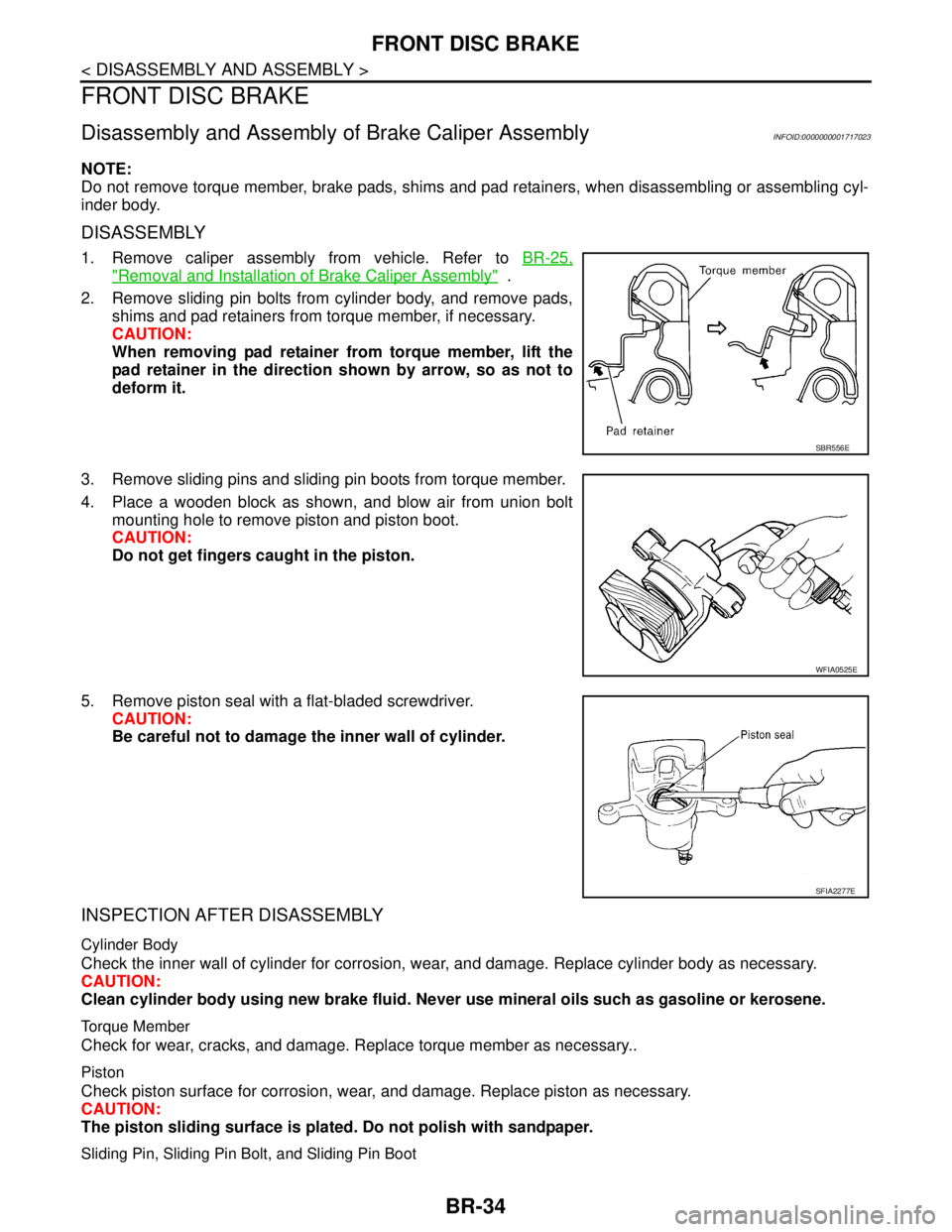

2. Remove sliding pin bolts from cylinder body, and remove pads,

shims and pad retainers from torque member, if necessary.

CAUTION:

When removing pad retainer from torque member, lift the

pad retainer in the direction shown by arrow, so as not to

deform it.

3. Remove sliding pins and sliding pin boots from torque member.

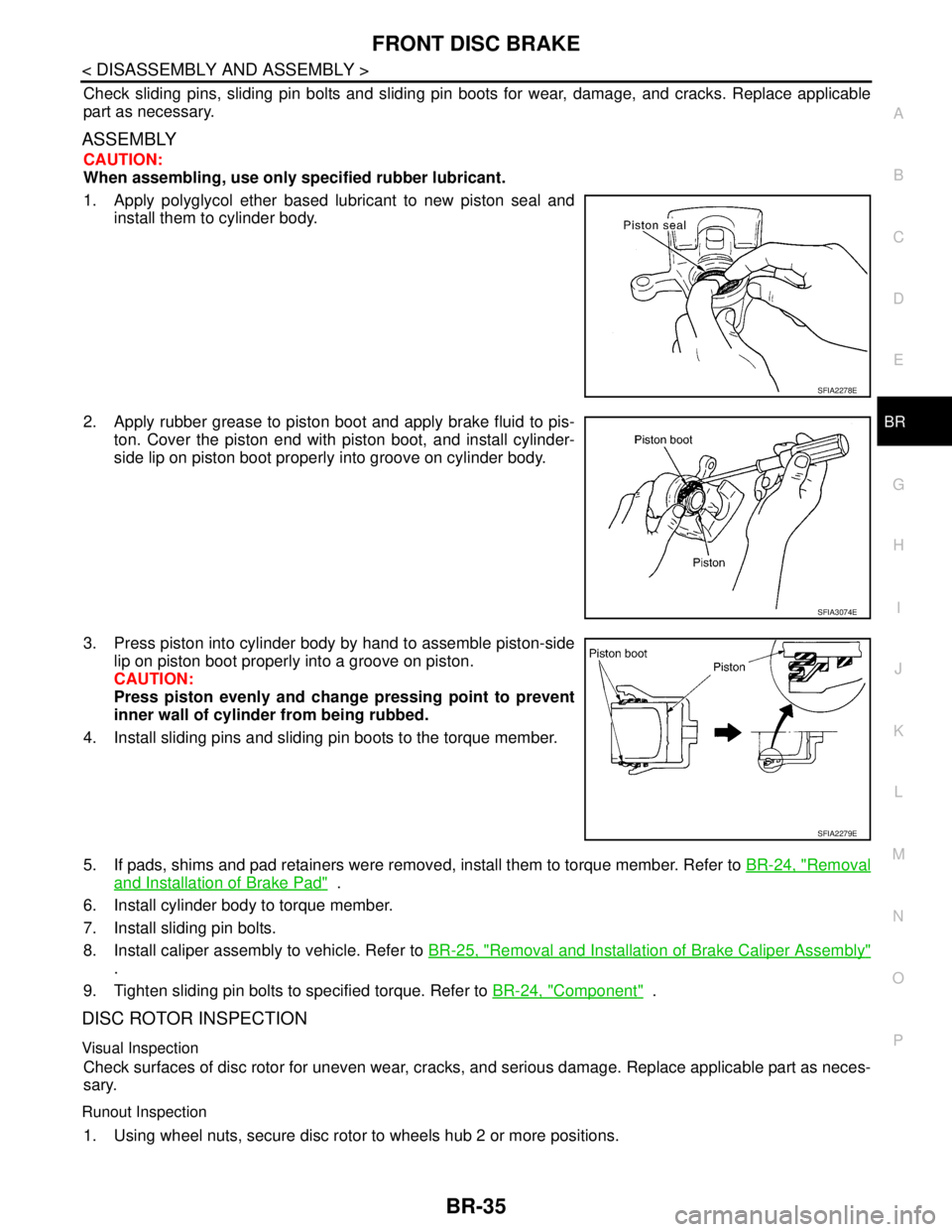

4. Place a wooden block as shown, and blow air from union bolt

mounting hole to remove piston and piston boot.

CAUTION:

Do not get fingers caught in the piston.

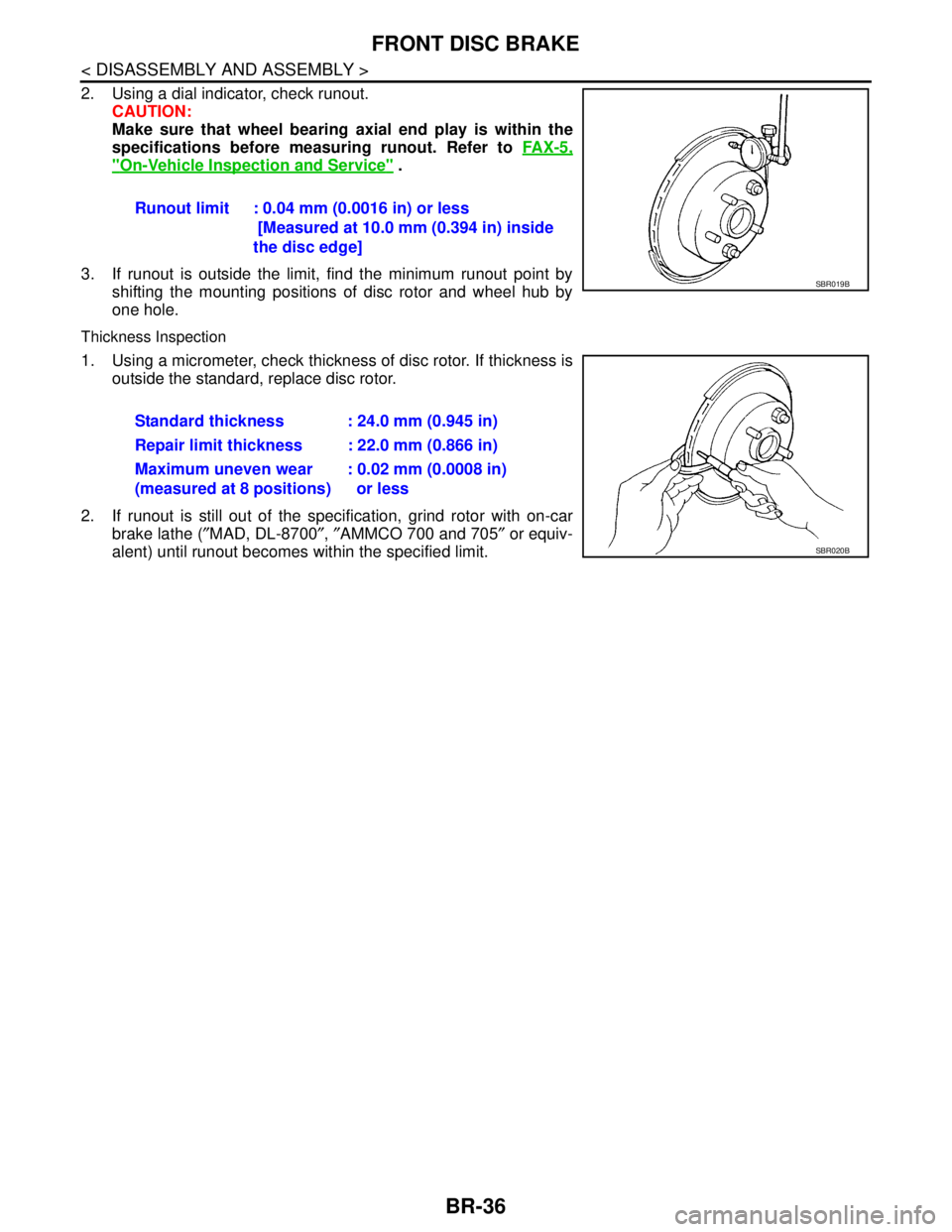

5. Remove piston seal with a flat-bladed screwdriver.

CAUTION:

Be careful not to damage the inner wall of cylinder.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

Check the inner wall of cylinder for corrosion, wear, and damage. Replace cylinder body as necessary.

CAUTION:

Clean cylinder body using new brake fluid. Never use mineral oils such as gasoline or kerosene.

Torque Member

Check for wear, cracks, and damage. Replace torque member as necessary..

Piston

Check piston surface for corrosion, wear, and damage. Replace piston as necessary.

CAUTION:

The piston sliding surface is plated. Do not polish with sandpaper.

Sliding Pin, Sliding Pin Bolt, and Sliding Pin Boot

SBR556E

WFIA0525E

SFIA2277E

Page 227 of 5883

FRONT DISC BRAKE

BR-35

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

Check sliding pins, sliding pin bolts and sliding pin boots for wear, damage, and cracks. Replace applicable

part as necessary.

ASSEMBLY

CAUTION:

When assembling, use only specified rubber lubricant.

1. Apply polyglycol ether based lubricant to new piston seal and

install them to cylinder body.

2. Apply rubber grease to piston boot and apply brake fluid to pis-

ton. Cover the piston end with piston boot, and install cylinder-

side lip on piston boot properly into groove on cylinder body.

3. Press piston into cylinder body by hand to assemble piston-side

lip on piston boot properly into a groove on piston.

CAUTION:

Press piston evenly and change pressing point to prevent

inner wall of cylinder from being rubbed.

4. Install sliding pins and sliding pin boots to the torque member.

5. If pads, shims and pad retainers were removed, install them to torque member. Refer to BR-24, "

Removal

and Installation of Brake Pad" .

6. Install cylinder body to torque member.

7. Install sliding pin bolts.

8. Install caliper assembly to vehicle. Refer to BR-25, "

Removal and Installation of Brake Caliper Assembly"

.

9. Tighten sliding pin bolts to specified torque. Refer to BR-24, "

Component" .

DISC ROTOR INSPECTION

Visual Inspection

Check surfaces of disc rotor for uneven wear, cracks, and serious damage. Replace applicable part as neces-

sary.

Runout Inspection

1. Using wheel nuts, secure disc rotor to wheels hub 2 or more positions.

SFIA2278E

SFIA3074E

SFIA2279E

Page 228 of 5883

BR-36

< DISASSEMBLY AND ASSEMBLY >

FRONT DISC BRAKE

2. Using a dial indicator, check runout.

CAUTION:

Make sure that wheel bearing axial end play is within the

specifications before measuring runout. Refer to FA X - 5 ,

"On-Vehicle Inspection and Service" .

3. If runout is outside the limit, find the minimum runout point by

shifting the mounting positions of disc rotor and wheel hub by

one hole.

Thickness Inspection

1. Using a micrometer, check thickness of disc rotor. If thickness is

outside the standard, replace disc rotor.

2. If runout is still out of the specification, grind rotor with on-car

brake lathe (″MAD, DL-8700″, ″AMMCO 700 and 705″ or equiv-

alent) until runout becomes within the specified limit.Runout limit : 0.04 mm (0.0016 in) or less

[Measured at 10.0 mm (0.394 in) inside

the disc edge]

SBR019B

Standard thickness : 24.0 mm (0.945 in)

Repair limit thickness : 22.0 mm (0.866 in)

Maximum uneven wear

(measured at 8 positions): 0.02 mm (0.0008 in)

or less

SBR020B

Page 229 of 5883

REAR DISC BRAKE

BR-37

< DISASSEMBLY AND ASSEMBLY >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

Disassembly and AssemblyINFOID:0000000001724669

DISASSEMBLY

1. Remove the sliding pin bolt, and then remove the pad, shim, shim cover, and pad retainer from the torque

member and cylinder.

2. Remove sliding pin boot from torque member.

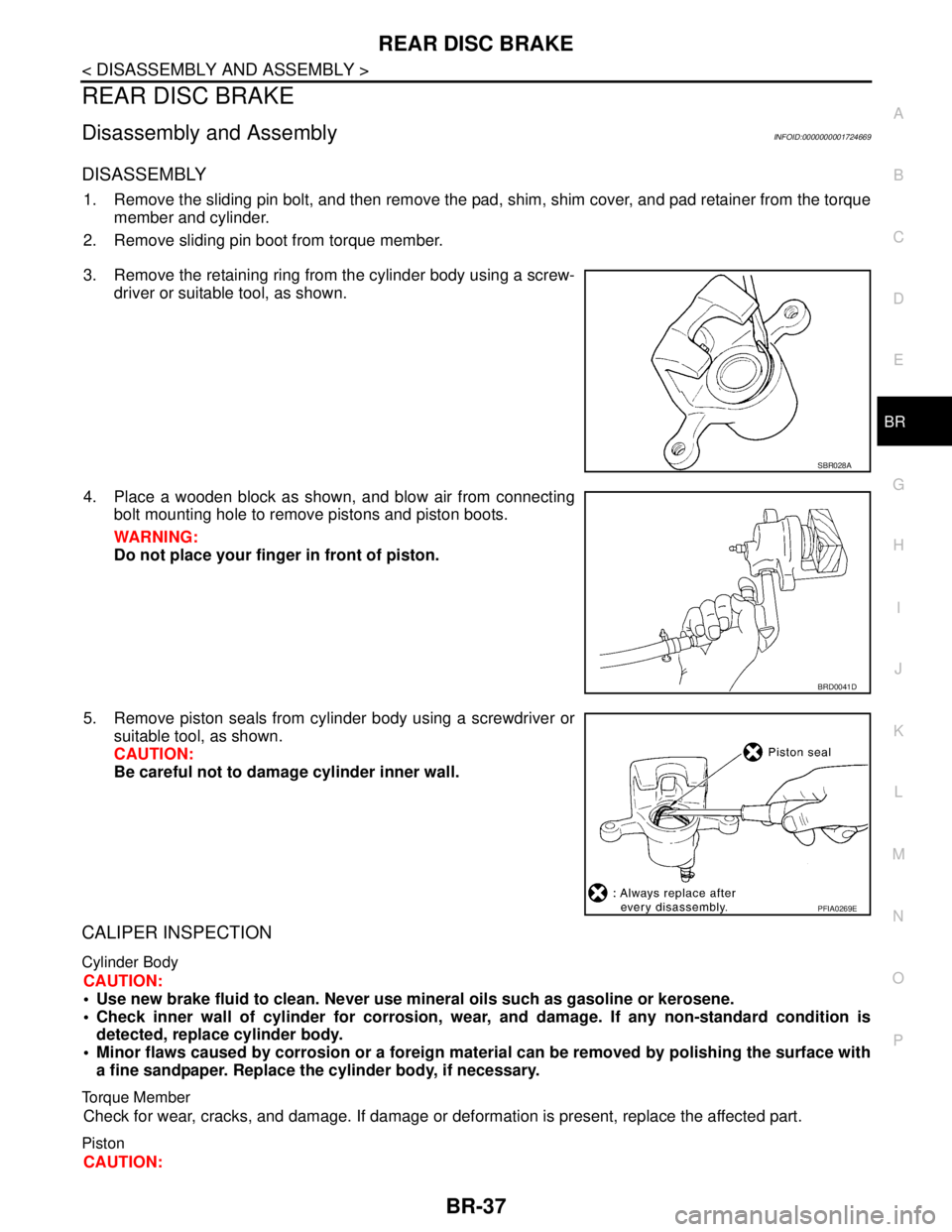

3. Remove the retaining ring from the cylinder body using a screw-

driver or suitable tool, as shown.

4. Place a wooden block as shown, and blow air from connecting

bolt mounting hole to remove pistons and piston boots.

WARNING:

Do not place your finger in front of piston.

5. Remove piston seals from cylinder body using a screwdriver or

suitable tool, as shown.

CAUTION:

Be careful not to damage cylinder inner wall.

CALIPER INSPECTION

Cylinder Body

CAUTION:

Use new brake fluid to clean. Never use mineral oils such as gasoline or kerosene.

Check inner wall of cylinder for corrosion, wear, and damage. If any non-standard condition is

detected, replace cylinder body.

Minor flaws caused by corrosion or a foreign material can be removed by polishing the surface with

a fine sandpaper. Replace the cylinder body, if necessary.

Torque Member

Check for wear, cracks, and damage. If damage or deformation is present, replace the affected part.

Piston

CAUTION:

SBR028A

BRD0041D

PFIA0269E

Page 230 of 5883

BR-38

< DISASSEMBLY AND ASSEMBLY >

REAR DISC BRAKE

Since the piston surface is plated, do not repair using sandpaper.

Check piston surface for corrosion, wear, and damage. If any non-standard condition is detected, replace

applicable part.

Sliding Pin Bolts and Sliding Pin Boots

Check that there is no wear, damage, or cracks in the sliding pin bolts and sliding pin boots, and if there are,

replace them.

ASSEMBLY

CAUTION:

Do not use Nissan Rubber Grease (KRE00 00010 or KRE00 00010 01) when assembling.

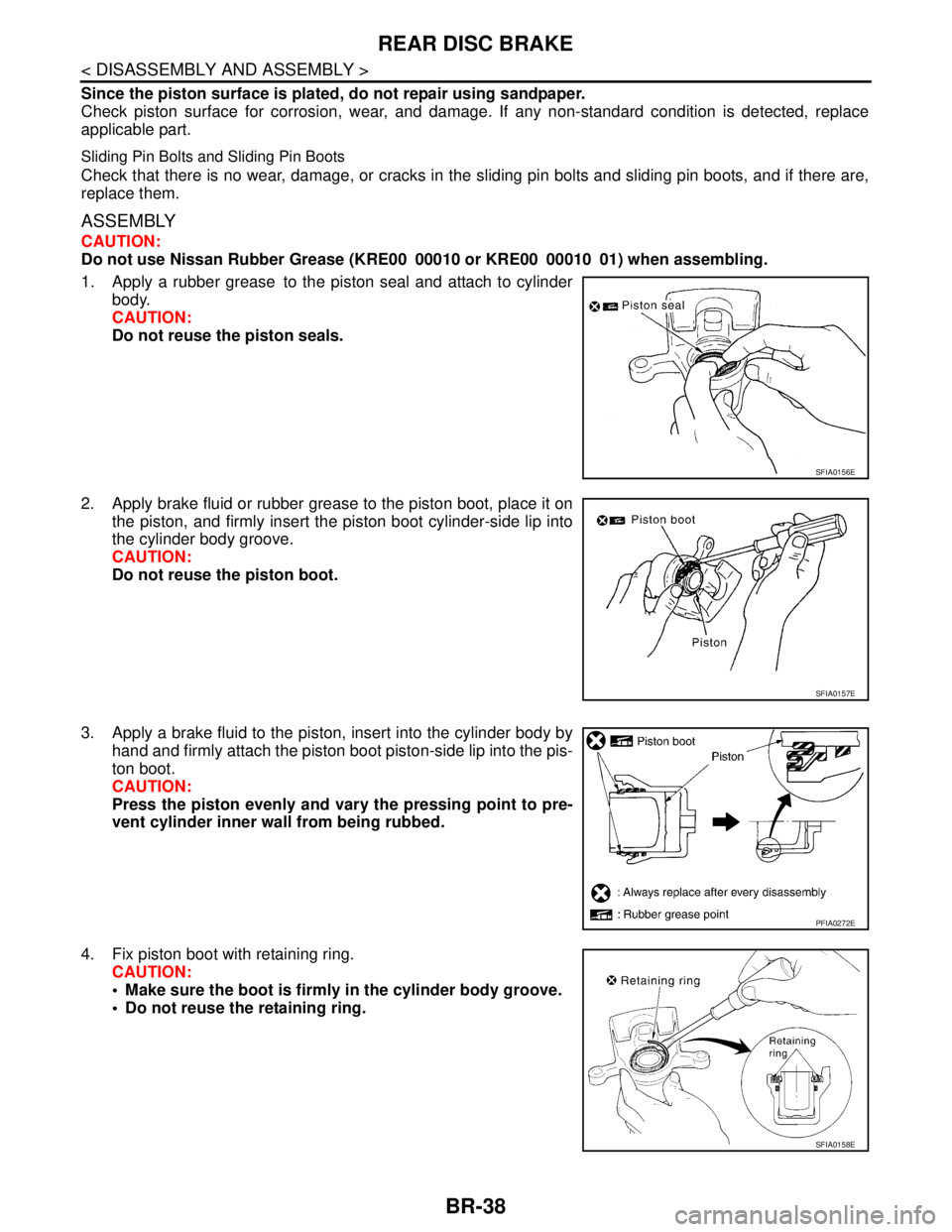

1. Apply a rubber grease to the piston seal and attach to cylinder

body.

CAUTION:

Do not reuse the piston seals.

2. Apply brake fluid or rubber grease to the piston boot, place it on

the piston, and firmly insert the piston boot cylinder-side lip into

the cylinder body groove.

CAUTION:

Do not reuse the piston boot.

3. Apply a brake fluid to the piston, insert into the cylinder body by

hand and firmly attach the piston boot piston-side lip into the pis-

ton boot.

CAUTION:

Press the piston evenly and vary the pressing point to pre-

vent cylinder inner wall from being rubbed.

4. Fix piston boot with retaining ring.

CAUTION:

Make sure the boot is firmly in the cylinder body groove.

Do not reuse the retaining ring.

SFIA0156E

SFIA0157E

PFIA0272E

SFIA0158E