NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 211 of 5883

BRAKE BOOSTER

BR-19

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

BRAKE BOOSTER

On Board InspectionINFOID:0000000001716999

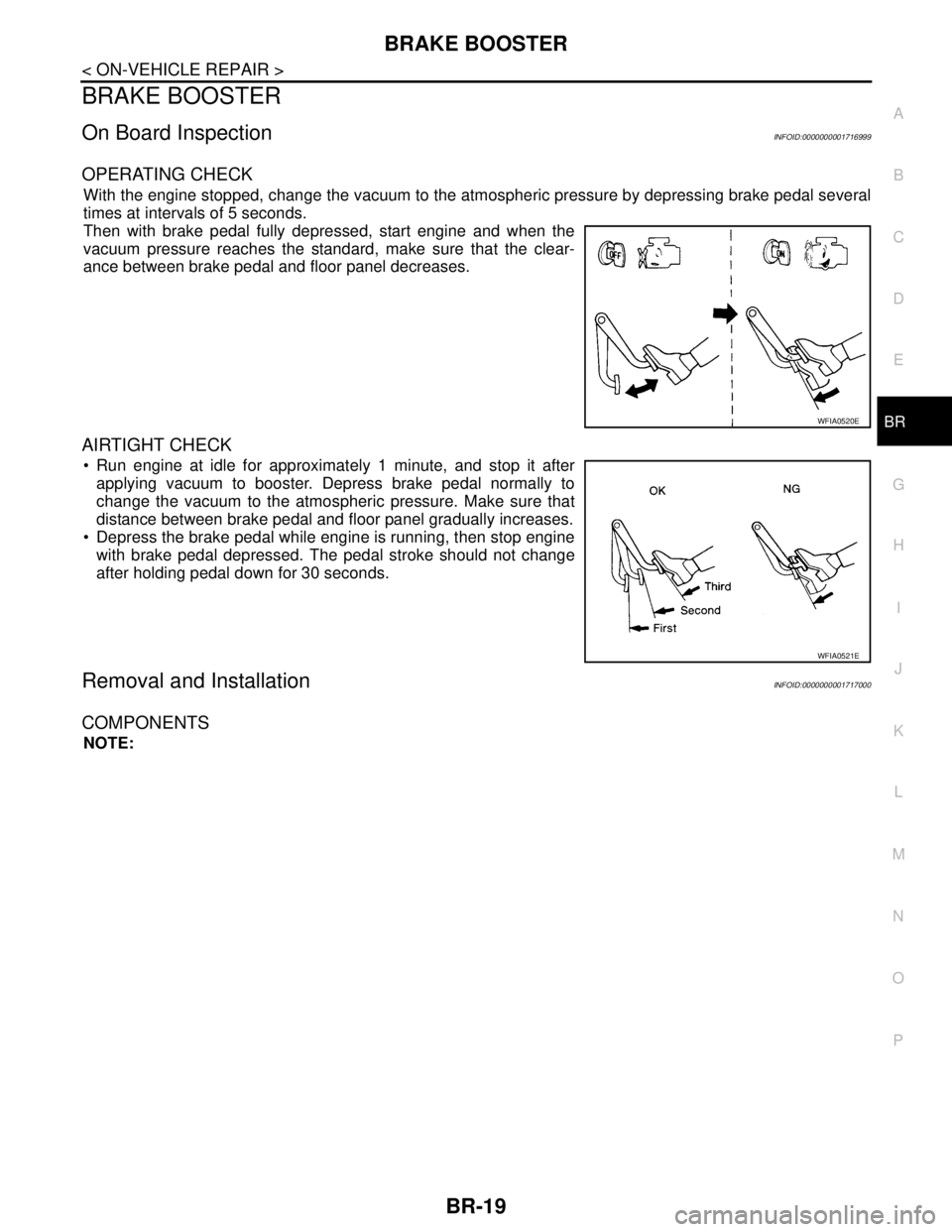

OPERATING CHECK

With the engine stopped, change the vacuum to the atmospheric pressure by depressing brake pedal several

times at intervals of 5 seconds.

Then with brake pedal fully depressed, start engine and when the

vacuum pressure reaches the standard, make sure that the clear-

ance between brake pedal and floor panel decreases.

AIRTIGHT CHECK

Run engine at idle for approximately 1 minute, and stop it after

applying vacuum to booster. Depress brake pedal normally to

change the vacuum to the atmospheric pressure. Make sure that

distance between brake pedal and floor panel gradually increases.

Depress the brake pedal while engine is running, then stop engine

with brake pedal depressed. The pedal stroke should not change

after holding pedal down for 30 seconds.

Removal and InstallationINFOID:0000000001717000

COMPONENTS

NOTE:

WFIA0520E

WFIA0521E

Page 212 of 5883

BR-20

< ON-VEHICLE REPAIR >

BRAKE BOOSTER

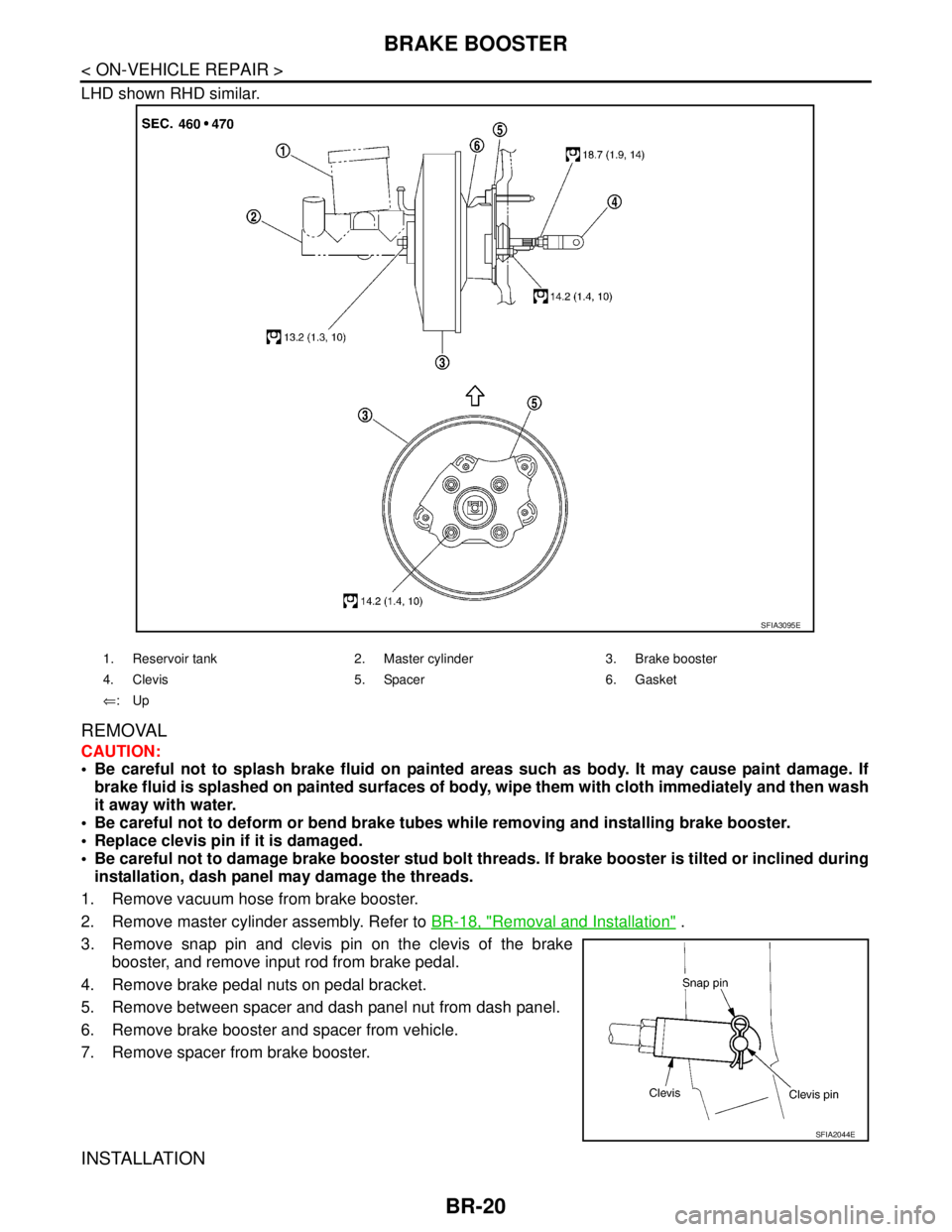

LHD shown RHD similar.

REMOVAL

CAUTION:

Be careful not to splash brake fluid on painted areas such as body. It may cause paint damage. If

brake fluid is splashed on painted surfaces of body, wipe them with cloth immediately and then wash

it away with water.

Be careful not to deform or bend brake tubes while removing and installing brake booster.

Replace clevis pin if it is damaged.

Be careful not to damage brake booster stud bolt threads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

1. Remove vacuum hose from brake booster.

2. Remove master cylinder assembly. Refer to BR-18, "

Removal and Installation" .

3. Remove snap pin and clevis pin on the clevis of the brake

booster, and remove input rod from brake pedal.

4. Remove brake pedal nuts on pedal bracket.

5. Remove between spacer and dash panel nut from dash panel.

6. Remove brake booster and spacer from vehicle.

7. Remove spacer from brake booster.

INSTALLATION

1. Reservoir tank 2. Master cylinder 3. Brake booster

4. Clevis 5. Spacer 6. Gasket

⇐:Up

SFIA3095E

SFIA2044E

Page 213 of 5883

BRAKE BOOSTER

BR-21

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

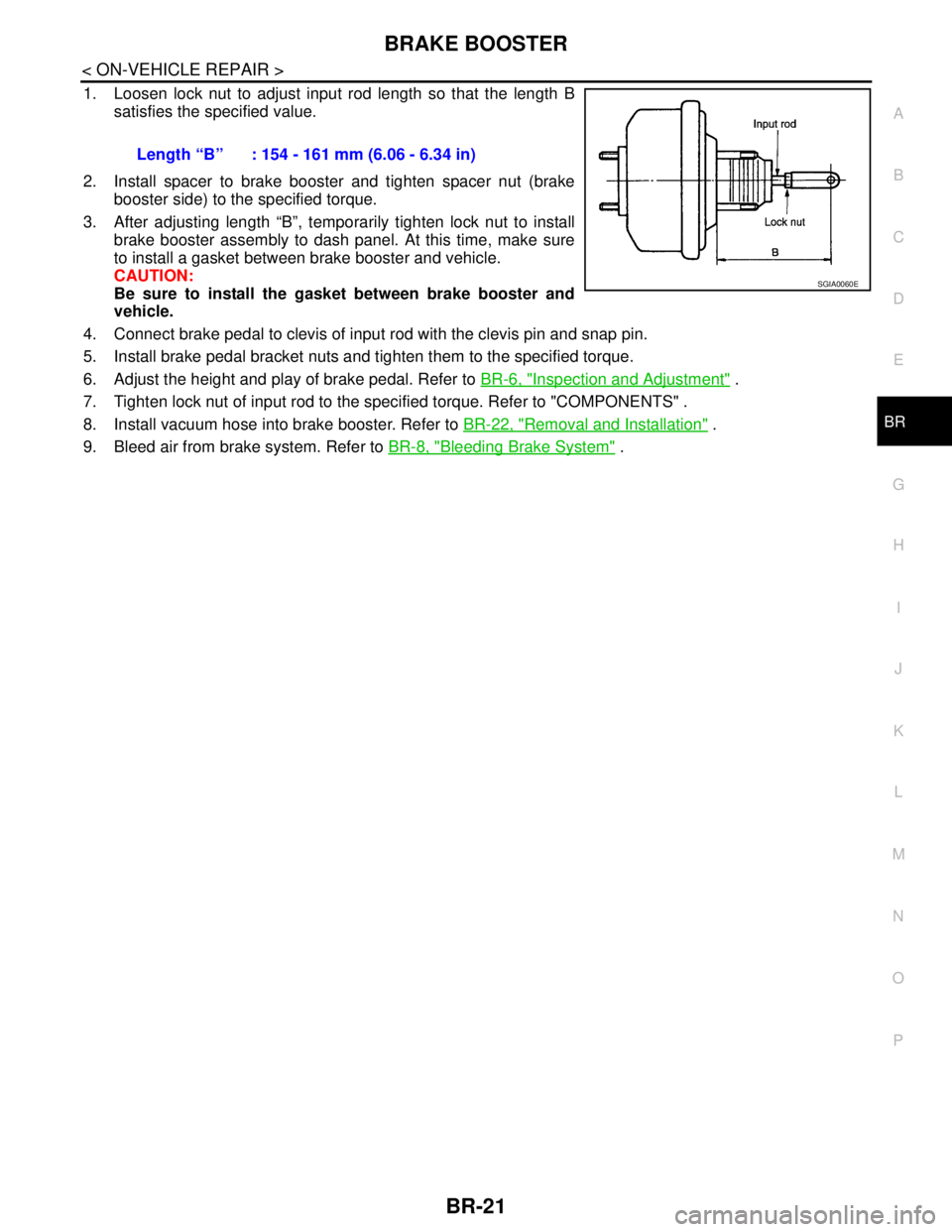

1. Loosen lock nut to adjust input rod length so that the length B

satisfies the specified value.

2. Install spacer to brake booster and tighten spacer nut (brake

booster side) to the specified torque.

3. After adjusting length “B”, temporarily tighten lock nut to install

brake booster assembly to dash panel. At this time, make sure

to install a gasket between brake booster and vehicle.

CAUTION:

Be sure to install the gasket between brake booster and

vehicle.

4. Connect brake pedal to clevis of input rod with the clevis pin and snap pin.

5. Install brake pedal bracket nuts and tighten them to the specified torque.

6. Adjust the height and play of brake pedal. Refer to BR-6, "

Inspection and Adjustment" .

7. Tighten lock nut of input rod to the specified torque. Refer to "COMPONENTS" .

8. Install vacuum hose into brake booster. Refer to BR-22, "

Removal and Installation" .

9. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" . Length “B” : 154 - 161 mm (6.06 - 6.34 in)

SGIA0060E

Page 214 of 5883

BR-22

< ON-VEHICLE REPAIR >

VACUUM LINES

VACUUM LINES

ComponentINFOID:0000000001717001

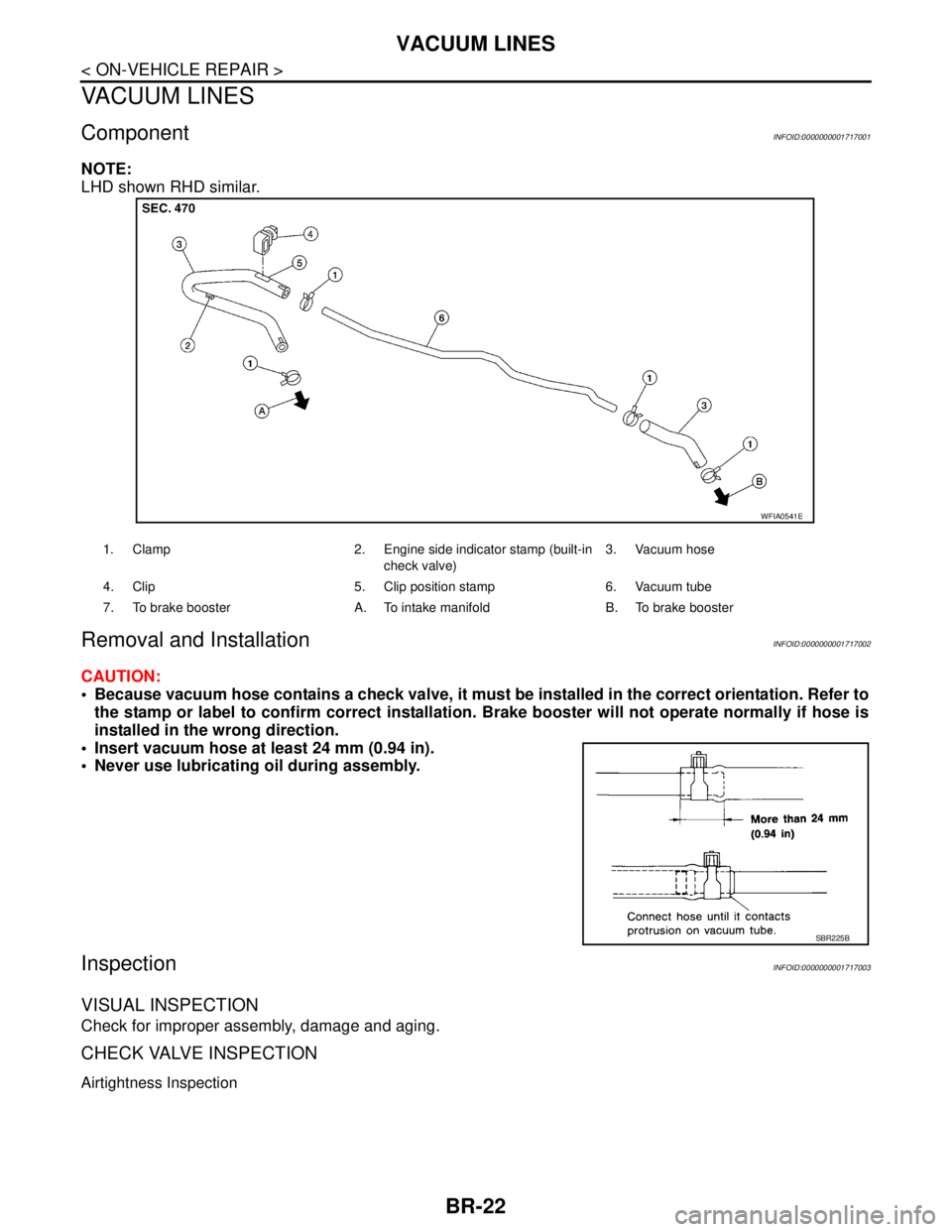

NOTE:

LHD shown RHD similar.

Removal and InstallationINFOID:0000000001717002

CAUTION:

Because vacuum hose contains a check valve, it must be installed in the correct orientation. Refer to

the stamp or label to confirm correct installation. Brake booster will not operate normally if hose is

installed in the wrong direction.

Insert vacuum hose at least 24 mm (0.94 in).

Never use lubricating oil during assembly.

InspectionINFOID:0000000001717003

VISUAL INSPECTION

Check for improper assembly, damage and aging.

CHECK VALVE INSPECTION

Airtightness Inspection

1. Clamp 2. Engine side indicator stamp (built-in

check valve)3. Vacuum hose

4. Clip 5. Clip position stamp 6. Vacuum tube

7. To brake booster A. To intake manifold B. To brake booster

WFIA0541E

SBR225B

Page 215 of 5883

VACUUM LINES

BR-23

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

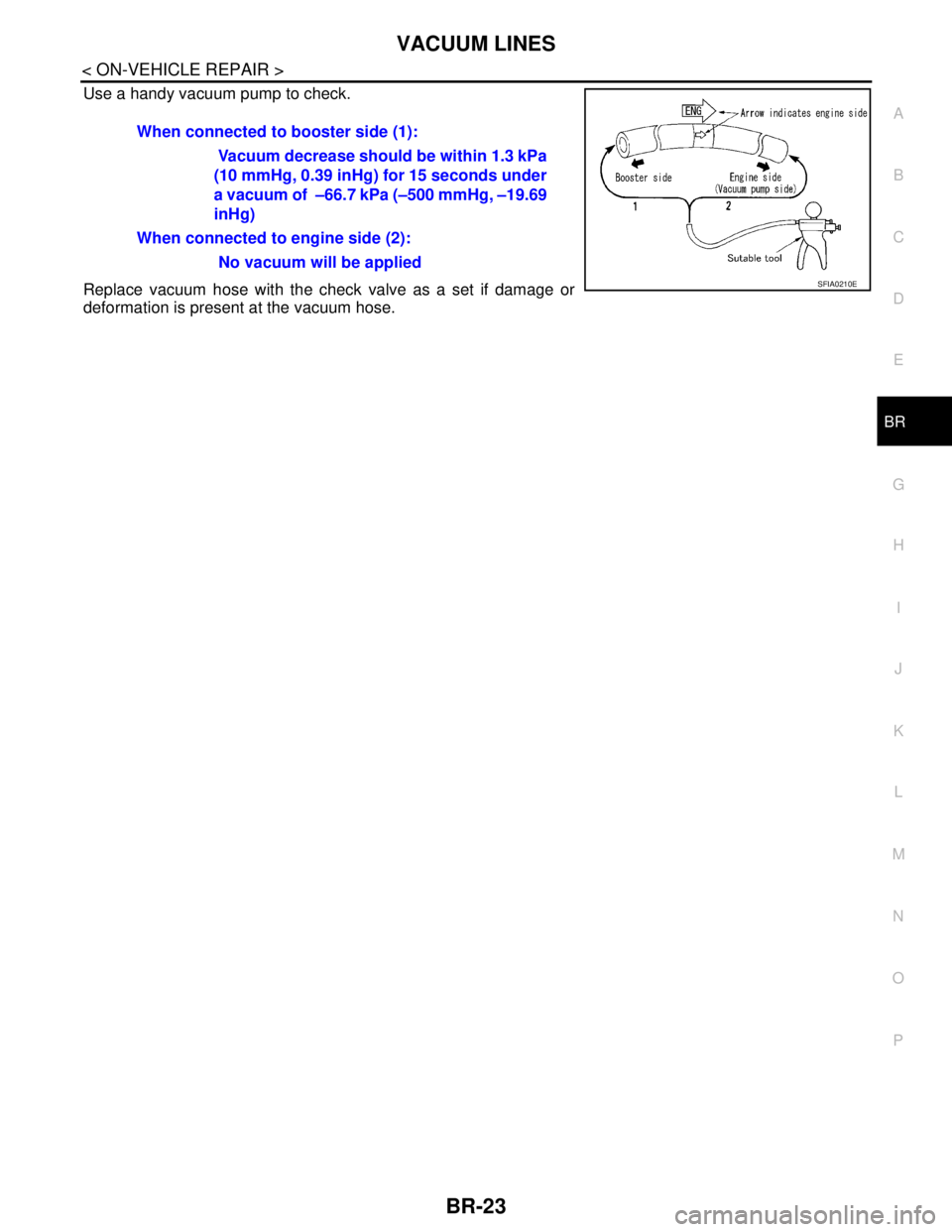

Use a handy vacuum pump to check.

Replace vacuum hose with the check valve as a set if damage or

deformation is present at the vacuum hose.When connected to booster side (1):

Vacuum decrease should be within 1.3 kPa

(10 mmHg, 0.39 inHg) for 15 seconds under

a vacuum of –66.7 kPa (–500 mmHg, –19.69

inHg)

When connected to engine side (2):

No vacuum will be applied

SFIA0210E

Page 216 of 5883

BR-24

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

FRONT DISC BRAKE

ComponentINFOID:0000000001717005

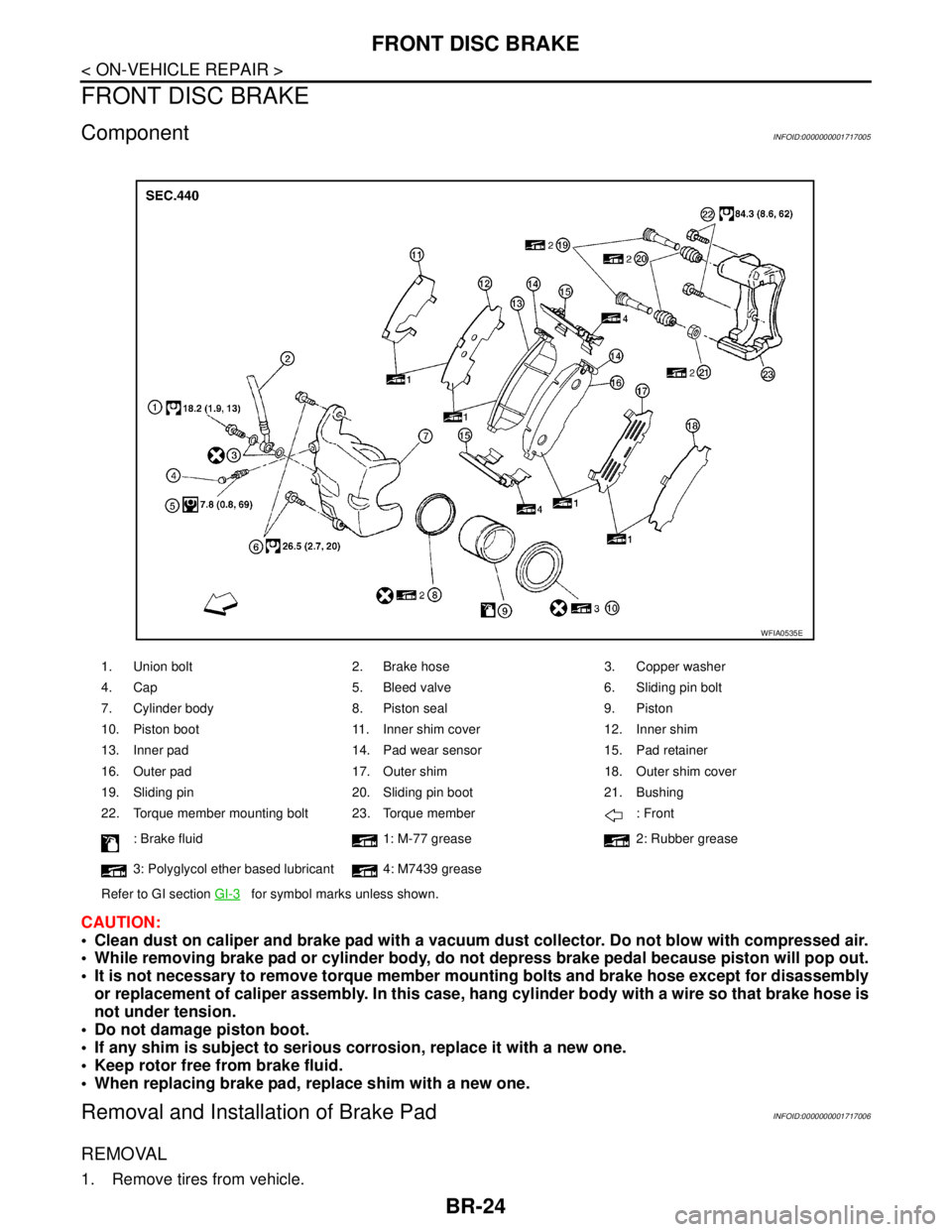

CAUTION:

Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

While removing brake pad or cylinder body, do not depress brake pedal because piston will pop out.

It is not necessary to remove torque member mounting bolts and brake hose except for disassembly

or replacement of caliper assembly. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

Do not damage piston boot.

If any shim is subject to serious corrosion, replace it with a new one.

Keep rotor free from brake fluid.

When replacing brake pad, replace shim with a new one.

Removal and Installation of Brake PadINFOID:0000000001717006

REMOVAL

1. Remove tires from vehicle.

1. Union bolt 2. Brake hose 3. Copper washer

4. Cap 5. Bleed valve 6. Sliding pin bolt

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Inner shim cover 12. Inner shim

13. Inner pad 14. Pad wear sensor 15. Pad retainer

16. Outer pad 17. Outer shim 18. Outer shim cover

19. Sliding pin 20. Sliding pin boot 21. Bushing

22. Torque member mounting bolt 23. Torque member : Front

: Brake fluid 1: M-77 grease 2: Rubber grease

3: Polyglycol ether based lubricant 4: M7439 grease

Refer to GI section GI-3

for symbol marks unless shown.

WFIA0535E

Page 217 of 5883

FRONT DISC BRAKE

BR-25

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

2. Remove sliding pin bolt (lower side).

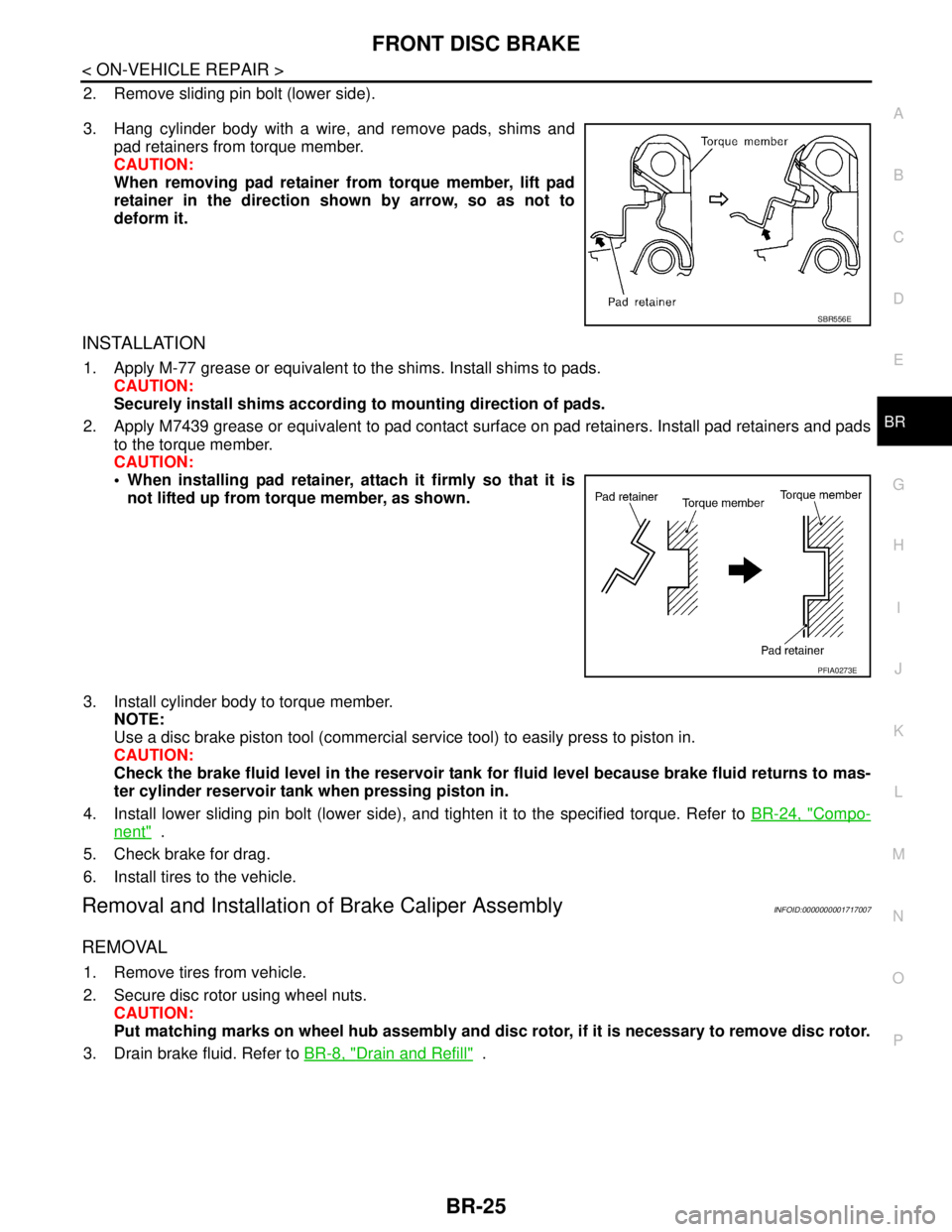

3. Hang cylinder body with a wire, and remove pads, shims and

pad retainers from torque member.

CAUTION:

When removing pad retainer from torque member, lift pad

retainer in the direction shown by arrow, so as not to

deform it.

INSTALLATION

1. Apply M-77 grease or equivalent to the shims. Install shims to pads.

CAUTION:

Securely install shims according to mounting direction of pads.

2. Apply M7439 grease or equivalent to pad contact surface on pad retainers. Install pad retainers and pads

to the torque member.

CAUTION:

When installing pad retainer, attach it firmly so that it is

not lifted up from torque member, as shown.

3. Install cylinder body to torque member.

NOTE:

Use a disc brake piston tool (commercial service tool) to easily press to piston in.

CAUTION:

Check the brake fluid level in the reservoir tank for fluid level because brake fluid returns to mas-

ter cylinder reservoir tank when pressing piston in.

4. Install lower sliding pin bolt (lower side), and tighten it to the specified torque. Refer to BR-24, "

Compo-

nent" .

5. Check brake for drag.

6. Install tires to the vehicle.

Removal and Installation of Brake Caliper AssemblyINFOID:0000000001717007

REMOVAL

1. Remove tires from vehicle.

2. Secure disc rotor using wheel nuts.

CAUTION:

Put matching marks on wheel hub assembly and disc rotor, if it is necessary to remove disc rotor.

3. Drain brake fluid. Refer to BR-8, "

Drain and Refill" .

SBR556E

PFIA0273E

Page 218 of 5883

BR-26

< ON-VEHICLE REPAIR >

FRONT DISC BRAKE

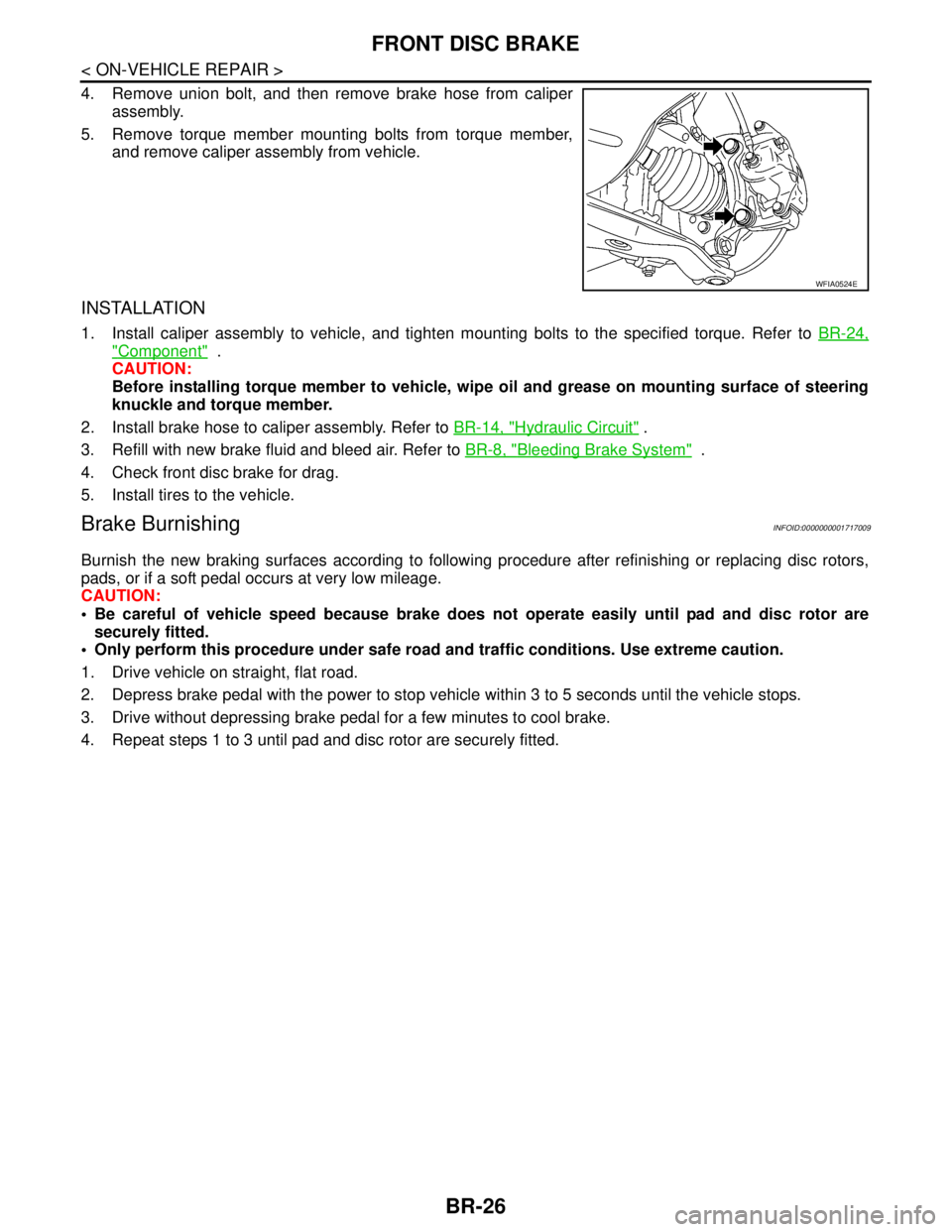

4. Remove union bolt, and then remove brake hose from caliper

assembly.

5. Remove torque member mounting bolts from torque member,

and remove caliper assembly from vehicle.

INSTALLATION

1. Install caliper assembly to vehicle, and tighten mounting bolts to the specified torque. Refer to BR-24,

"Component" .

CAUTION:

Before installing torque member to vehicle, wipe oil and grease on mounting surface of steering

knuckle and torque member.

2. Install brake hose to caliper assembly. Refer to BR-14, "

Hydraulic Circuit" .

3. Refill with new brake fluid and bleed air. Refer to BR-8, "

Bleeding Brake System" .

4. Check front disc brake for drag.

5. Install tires to the vehicle.

Brake BurnishingINFOID:0000000001717009

Burnish the new braking surfaces according to following procedure after refinishing or replacing disc rotors,

pads, or if a soft pedal occurs at very low mileage.

CAUTION:

Be careful of vehicle speed because brake does not operate easily until pad and disc rotor are

securely fitted.

Only perform this procedure under safe road and traffic conditions. Use extreme caution.

1. Drive vehicle on straight, flat road.

2. Depress brake pedal with the power to stop vehicle within 3 to 5 seconds until the vehicle stops.

3. Drive without depressing brake pedal for a few minutes to cool brake.

4. Repeat steps 1 to 3 until pad and disc rotor are securely fitted.

WFIA0524E

Page 219 of 5883

REAR DISC BRAKE

BR-27

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

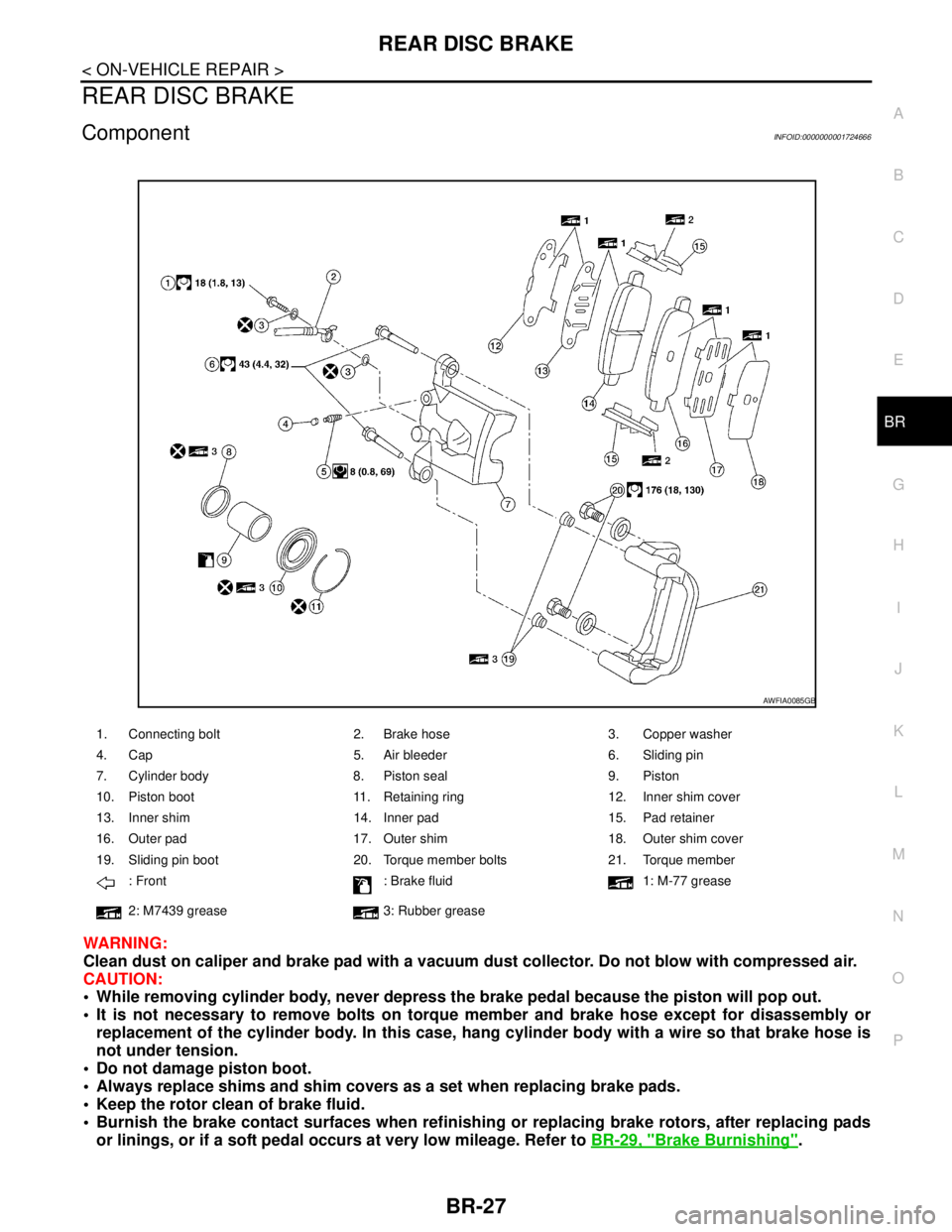

REAR DISC BRAKE

ComponentINFOID:0000000001724666

WARNING:

Clean dust on caliper and brake pad with a vacuum dust collector. Do not blow with compressed air.

CAUTION:

While removing cylinder body, never depress the brake pedal because the piston will pop out.

It is not necessary to remove bolts on torque member and brake hose except for disassembly or

replacement of the cylinder body. In this case, hang cylinder body with a wire so that brake hose is

not under tension.

Do not damage piston boot.

Always replace shims and shim covers as a set when replacing brake pads.

Keep the rotor clean of brake fluid.

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing pads

or linings, or if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

1. Connecting bolt 2. Brake hose 3. Copper washer

4. Cap 5. Air bleeder 6. Sliding pin

7. Cylinder body 8. Piston seal 9. Piston

10. Piston boot 11. Retaining ring 12. Inner shim cover

13. Inner shim 14. Inner pad 15. Pad retainer

16. Outer pad 17. Outer shim 18. Outer shim cover

19. Sliding pin boot 20. Torque member bolts 21. Torque member

: Front : Brake fluid 1: M-77 grease

2: M7439 grease 3: Rubber grease

AWFIA0085GB

Page 220 of 5883

BR-28

< ON-VEHICLE REPAIR >

REAR DISC BRAKE

Removal and Installation of Brake Pad

INFOID:0000000001724667

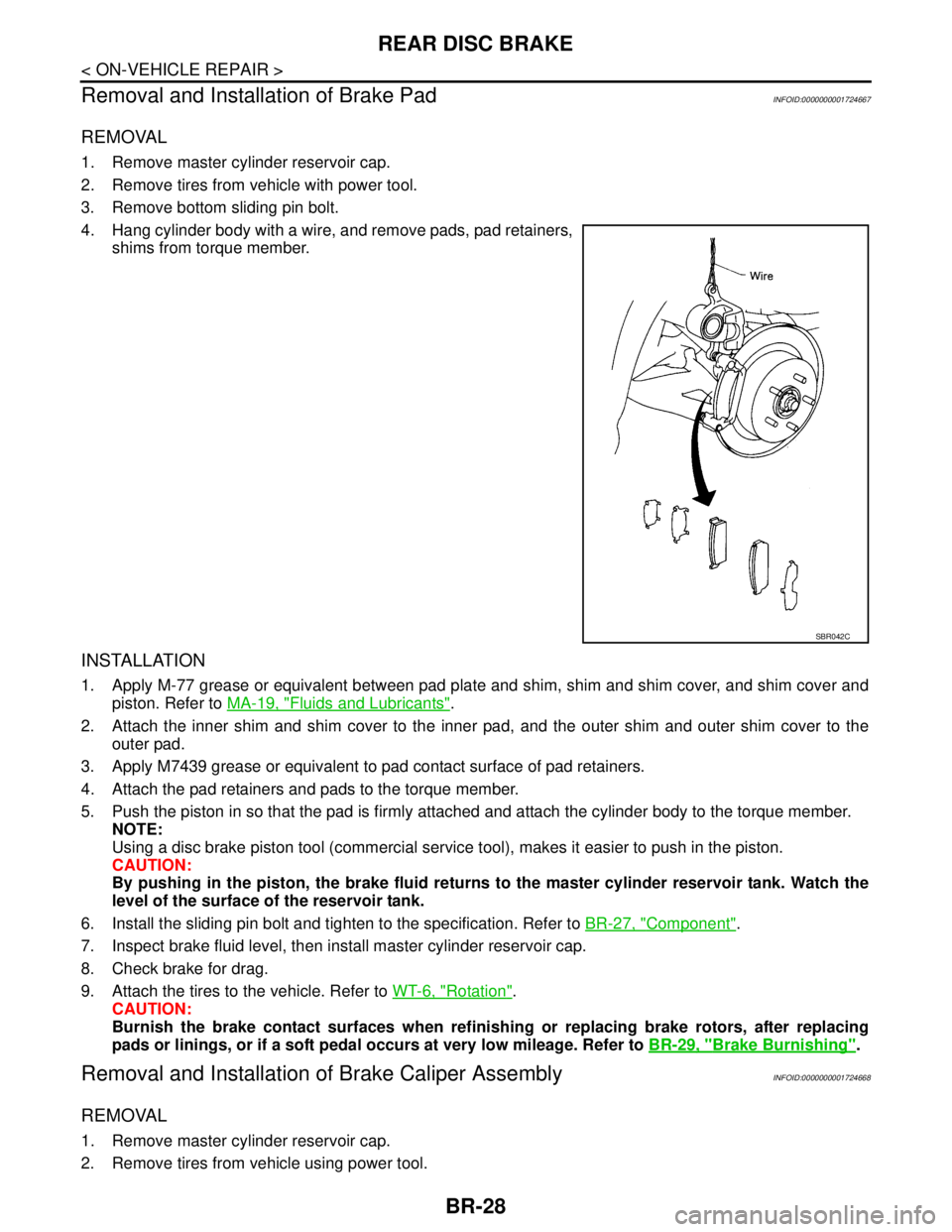

REMOVAL

1. Remove master cylinder reservoir cap.

2. Remove tires from vehicle with power tool.

3. Remove bottom sliding pin bolt.

4. Hang cylinder body with a wire, and remove pads, pad retainers,

shims from torque member.

INSTALLATION

1. Apply M-77 grease or equivalent between pad plate and shim, shim and shim cover, and shim cover and

piston. Refer to MA-19, "

Fluids and Lubricants".

2. Attach the inner shim and shim cover to the inner pad, and the outer shim and outer shim cover to the

outer pad.

3. Apply M7439 grease or equivalent to pad contact surface of pad retainers.

4. Attach the pad retainers and pads to the torque member.

5. Push the piston in so that the pad is firmly attached and attach the cylinder body to the torque member.

NOTE:

Using a disc brake piston tool (commercial service tool), makes it easier to push in the piston.

CAUTION:

By pushing in the piston, the brake fluid returns to the master cylinder reservoir tank. Watch the

level of the surface of the reservoir tank.

6. Install the sliding pin bolt and tighten to the specification. Refer to BR-27, "

Component".

7. Inspect brake fluid level, then install master cylinder reservoir cap.

8. Check brake for drag.

9. Attach the tires to the vehicle. Refer to WT-6, "

Rotation".

CAUTION:

Burnish the brake contact surfaces when refinishing or replacing brake rotors, after replacing

pads or linings, or if a soft pedal occurs at very low mileage. Refer to BR-29, "

Brake Burnishing".

Removal and Installation of Brake Caliper AssemblyINFOID:0000000001724668

REMOVAL

1. Remove master cylinder reservoir cap.

2. Remove tires from vehicle using power tool.

SBR042C