NISSAN TIIDA 2007 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2007, Model line: TIIDA, Model: NISSAN TIIDA 2007Pages: 5883, PDF Size: 78.95 MB

Page 201 of 5883

BRAKE FLUID

BR-9

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

3. With brake pedal depressed, loosen bleed valve to let the air out, and then tighten it immediately.

4. Repeat steps 2, 3 until no more air comes out.

5. Tighten bleed valve to specified torque. Refer to BR-24, "

Component" (front disc brake), BR-27, "Compo-

nent" (rear drum brake).

6. Following the steps 1 to 5 above, with master cylinder reservoir tank filled at least half way, bleed air from

the rear right, front left, rear left, and front right brake, in that order.

Page 202 of 5883

BR-10

< ON-VEHICLE MAINTENANCE >

FRONT DISC BRAKE

FRONT DISC BRAKE

InspectionINFOID:0000000001717004

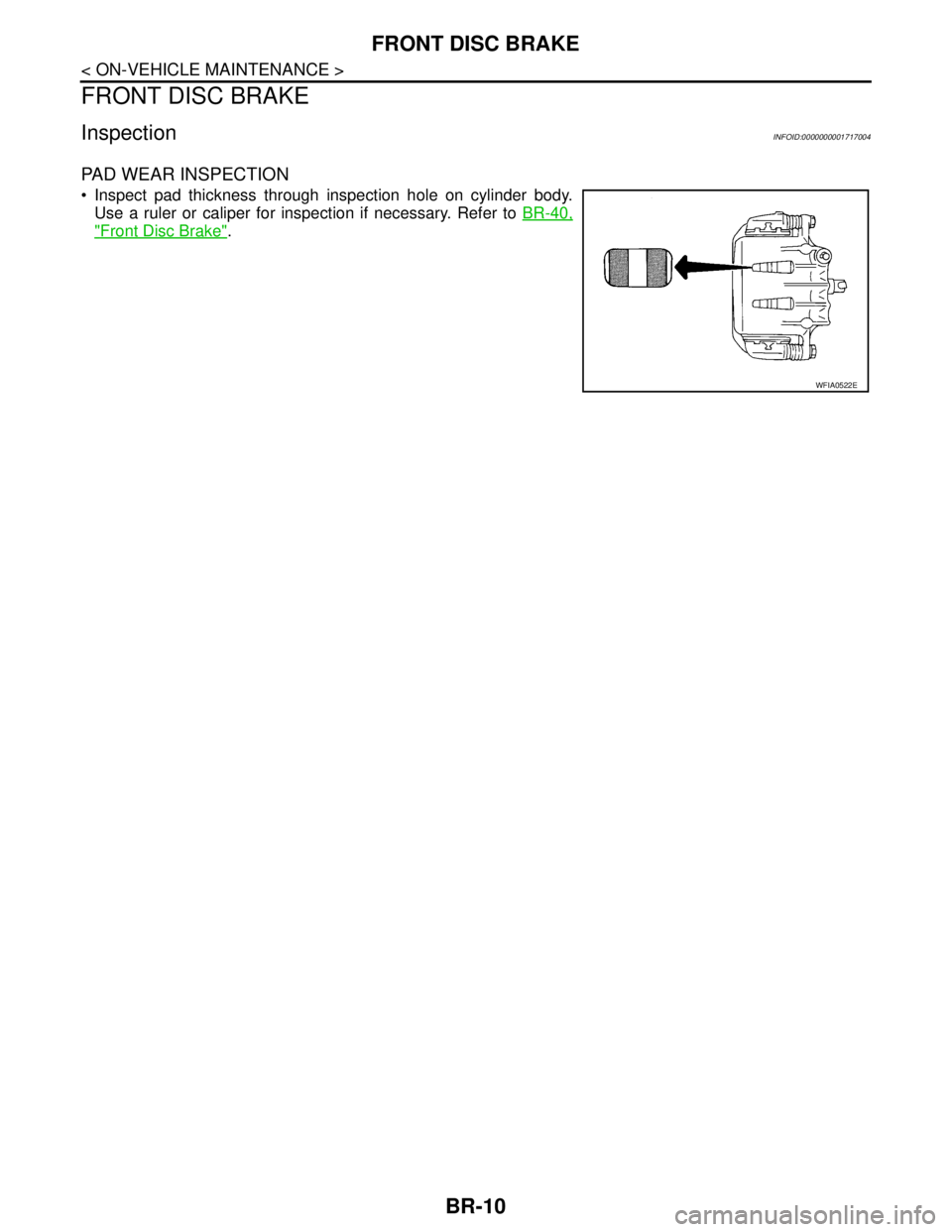

PAD WEAR INSPECTION

Inspect pad thickness through inspection hole on cylinder body.

Use a ruler or caliper for inspection if necessary. Refer to BR-40,

"Front Disc Brake".

WFIA0522E

Page 203 of 5883

REAR DISC BRAKE

BR-11

< ON-VEHICLE MAINTENANCE >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

REAR DISC BRAKE

InspectionINFOID:0000000001724674

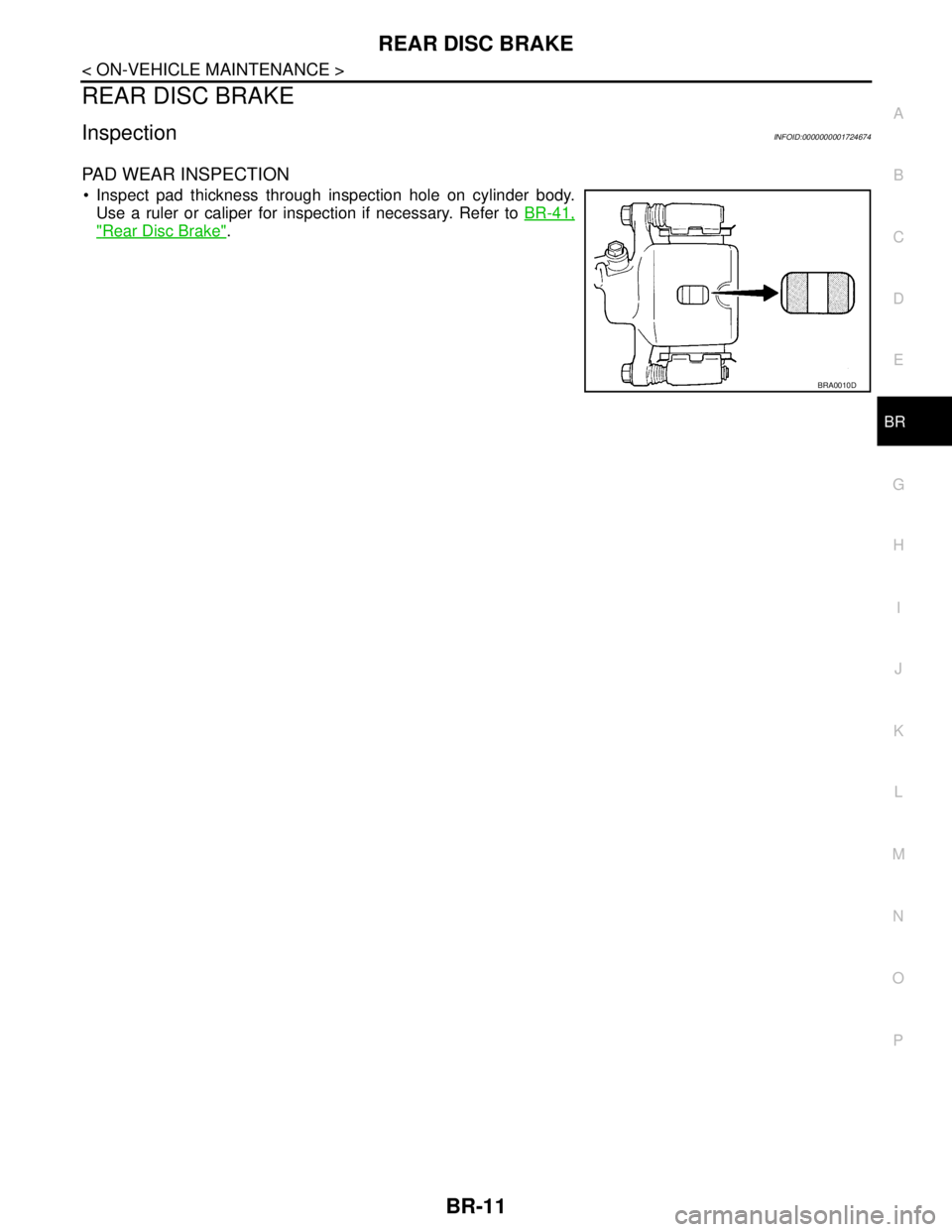

PAD WEAR INSPECTION

Inspect pad thickness through inspection hole on cylinder body.

Use a ruler or caliper for inspection if necessary. Refer to BR-41,

"Rear Disc Brake".

BRA0010D

Page 204 of 5883

BR-12

< ON-VEHICLE REPAIR >

BRAKE PEDAL

ON-VEHICLE REPAIR

BRAKE PEDAL

Removal and InstallationINFOID:0000000001716977

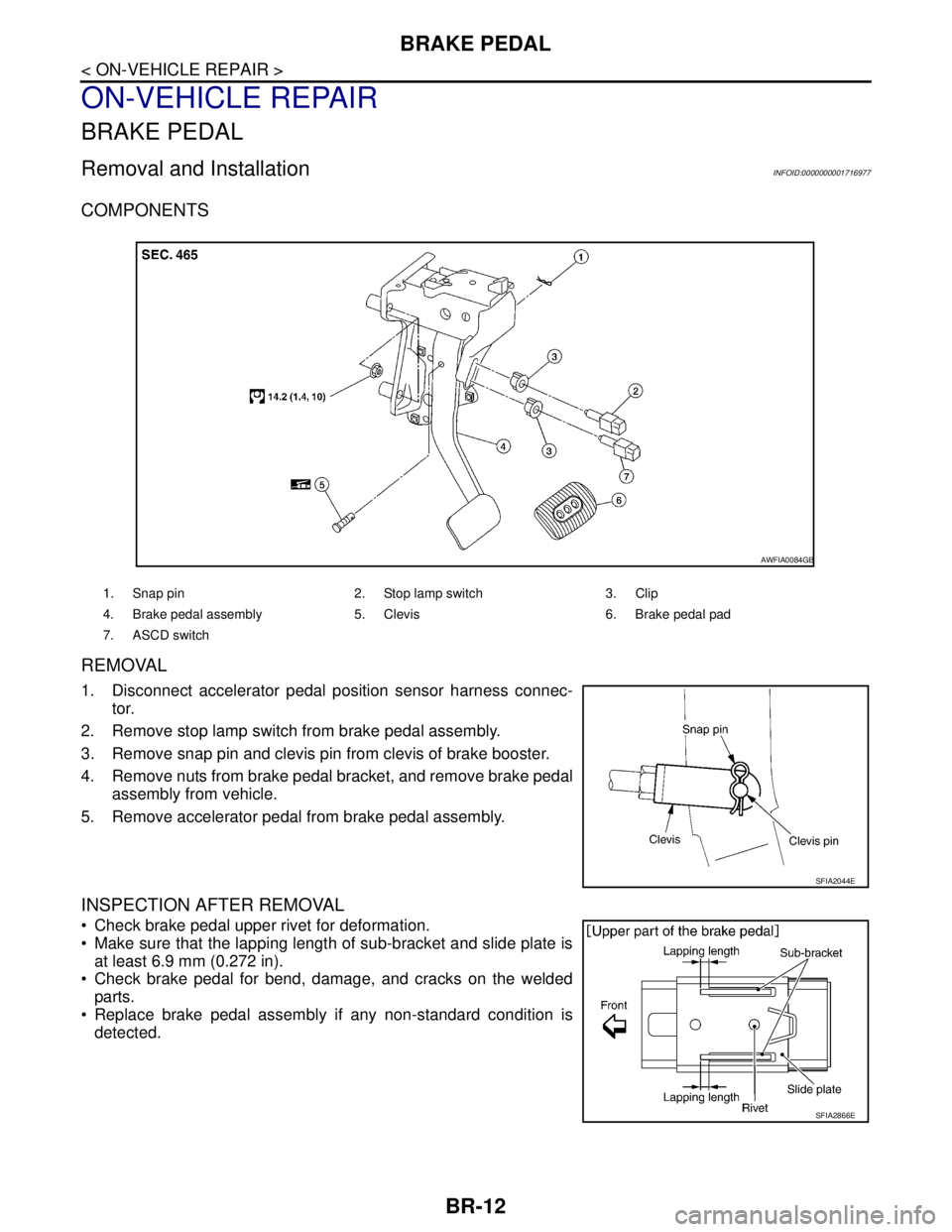

COMPONENTS

REMOVAL

1. Disconnect accelerator pedal position sensor harness connec-

tor.

2. Remove stop lamp switch from brake pedal assembly.

3. Remove snap pin and clevis pin from clevis of brake booster.

4. Remove nuts from brake pedal bracket, and remove brake pedal

assembly from vehicle.

5. Remove accelerator pedal from brake pedal assembly.

INSPECTION AFTER REMOVAL

Check brake pedal upper rivet for deformation.

Make sure that the lapping length of sub-bracket and slide plate is

at least 6.9 mm (0.272 in).

Check brake pedal for bend, damage, and cracks on the welded

parts.

Replace brake pedal assembly if any non-standard condition is

detected.

1. Snap pin 2. Stop lamp switch 3. Clip

4. Brake pedal assembly 5. Clevis 6. Brake pedal pad

7. ASCD switch

AWFIA0084GB

SFIA2044E

SFIA2866E

Page 205 of 5883

BRAKE PEDAL

BR-13

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

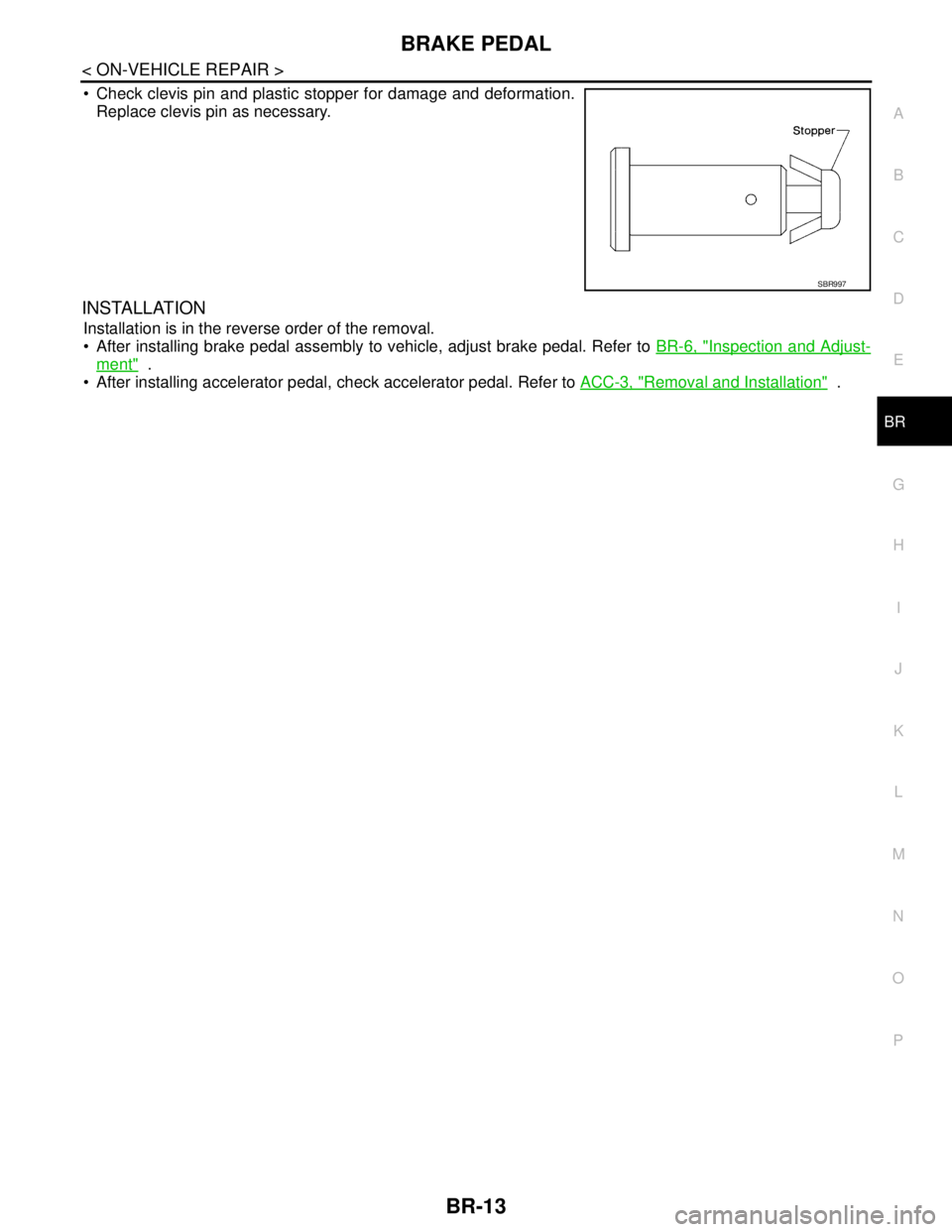

Check clevis pin and plastic stopper for damage and deformation.

Replace clevis pin as necessary.

INSTALLATION

Installation is in the reverse order of the removal.

After installing brake pedal assembly to vehicle, adjust brake pedal. Refer to BR-6, "

Inspection and Adjust-

ment" .

After installing accelerator pedal, check accelerator pedal. Refer to ACC-3, "

Removal and Installation" .

SBR997

Page 206 of 5883

BR-14

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

BRAKE TUBE AND HOSE

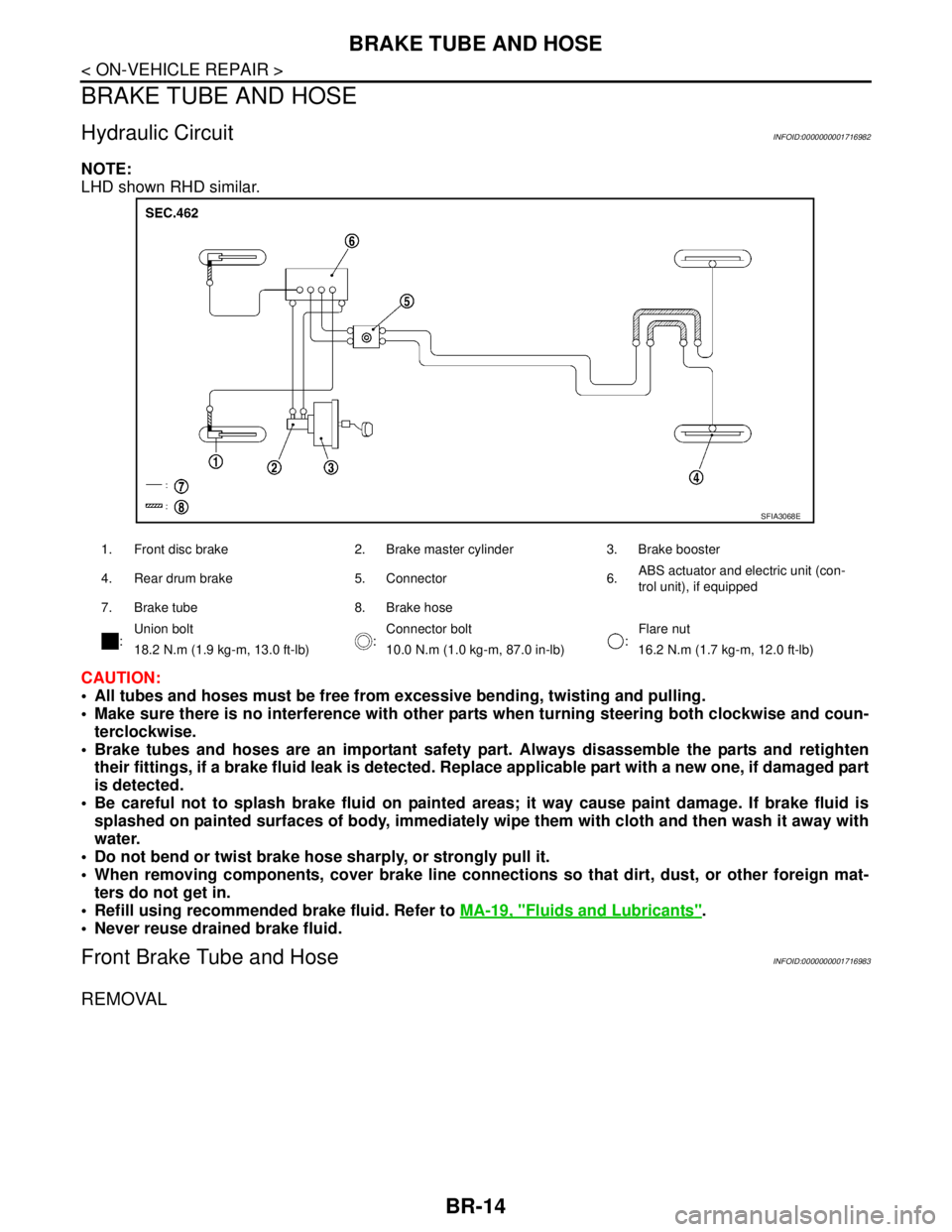

Hydraulic CircuitINFOID:0000000001716982

NOTE:

LHD shown RHD similar.

CAUTION:

All tubes and hoses must be free from excessive bending, twisting and pulling.

Make sure there is no interference with other parts when turning steering both clockwise and coun-

terclockwise.

Brake tubes and hoses are an important safety part. Always disassemble the parts and retighten

their fittings, if a brake fluid leak is detected. Replace applicable part with a new one, if damaged part

is detected.

Be careful not to splash brake fluid on painted areas; it way cause paint damage. If brake fluid is

splashed on painted surfaces of body, immediately wipe them with cloth and then wash it away with

water.

Do not bend or twist brake hose sharply, or strongly pull it.

When removing components, cover brake line connections so that dirt, dust, or other foreign mat-

ters do not get in.

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Front Brake Tube and HoseINFOID:0000000001716983

REMOVAL

1. Front disc brake 2. Brake master cylinder 3. Brake booster

4. Rear drum brake 5. Connector 6.ABS actuator and electric unit (con-

trol unit), if equipped

7. Brake tube 8. Brake hose

:Union bolt

:Connector bolt

:Flare nut

18.2 N.m (1.9 kg-m, 13.0 ft-lb) 10.0 N.m (1.0 kg-m, 87.0 in-lb) 16.2 N.m (1.7 kg-m, 12.0 ft-lb)

SFIA3068E

Page 207 of 5883

BRAKE TUBE AND HOSE

BR-15

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

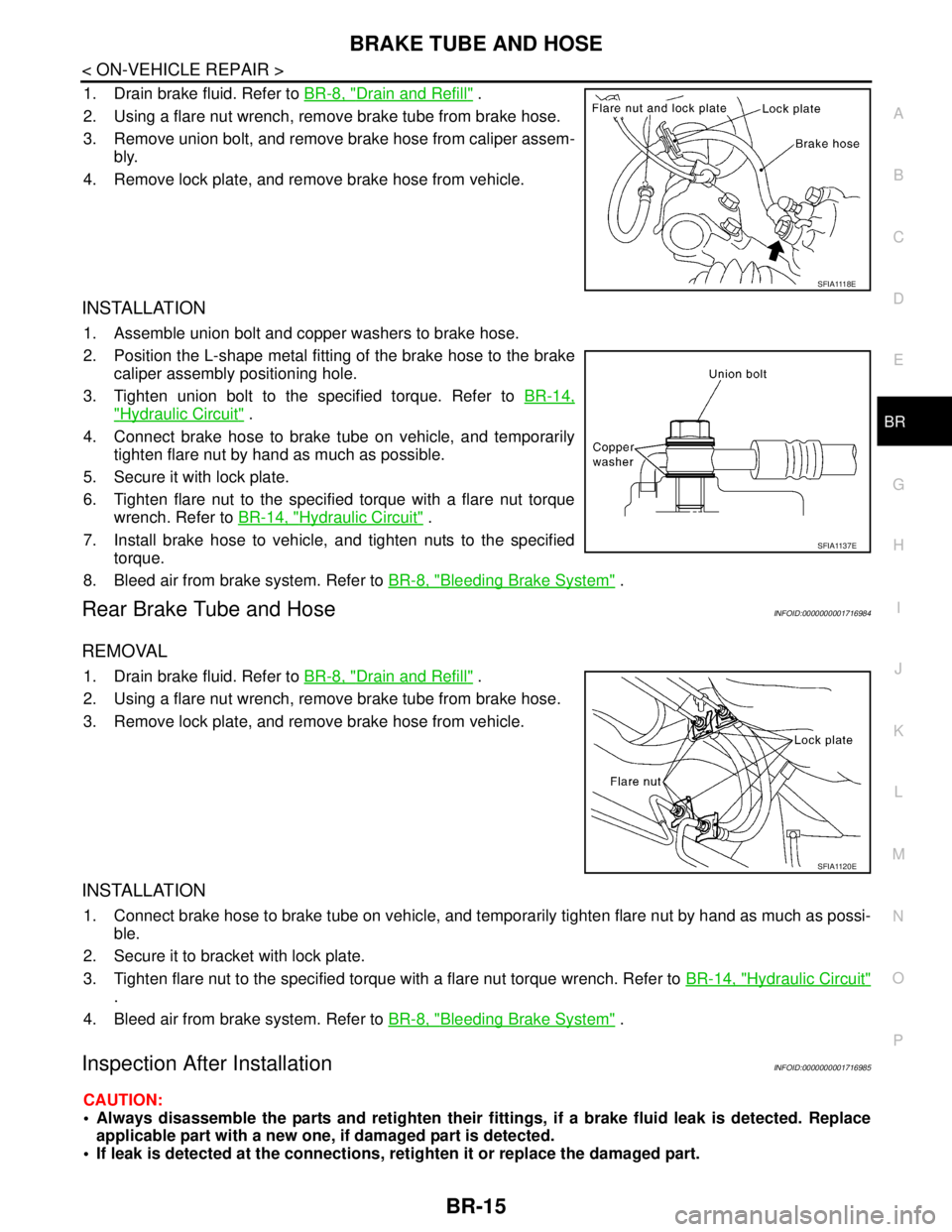

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove union bolt, and remove brake hose from caliper assem-

bly.

4. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Assemble union bolt and copper washers to brake hose.

2. Position the L-shape metal fitting of the brake hose to the brake

caliper assembly positioning hole.

3. Tighten union bolt to the specified torque. Refer to BR-14,

"Hydraulic Circuit" .

4. Connect brake hose to brake tube on vehicle, and temporarily

tighten flare nut by hand as much as possible.

5. Secure it with lock plate.

6. Tighten flare nut to the specified torque with a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

7. Install brake hose to vehicle, and tighten nuts to the specified

torque.

8. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

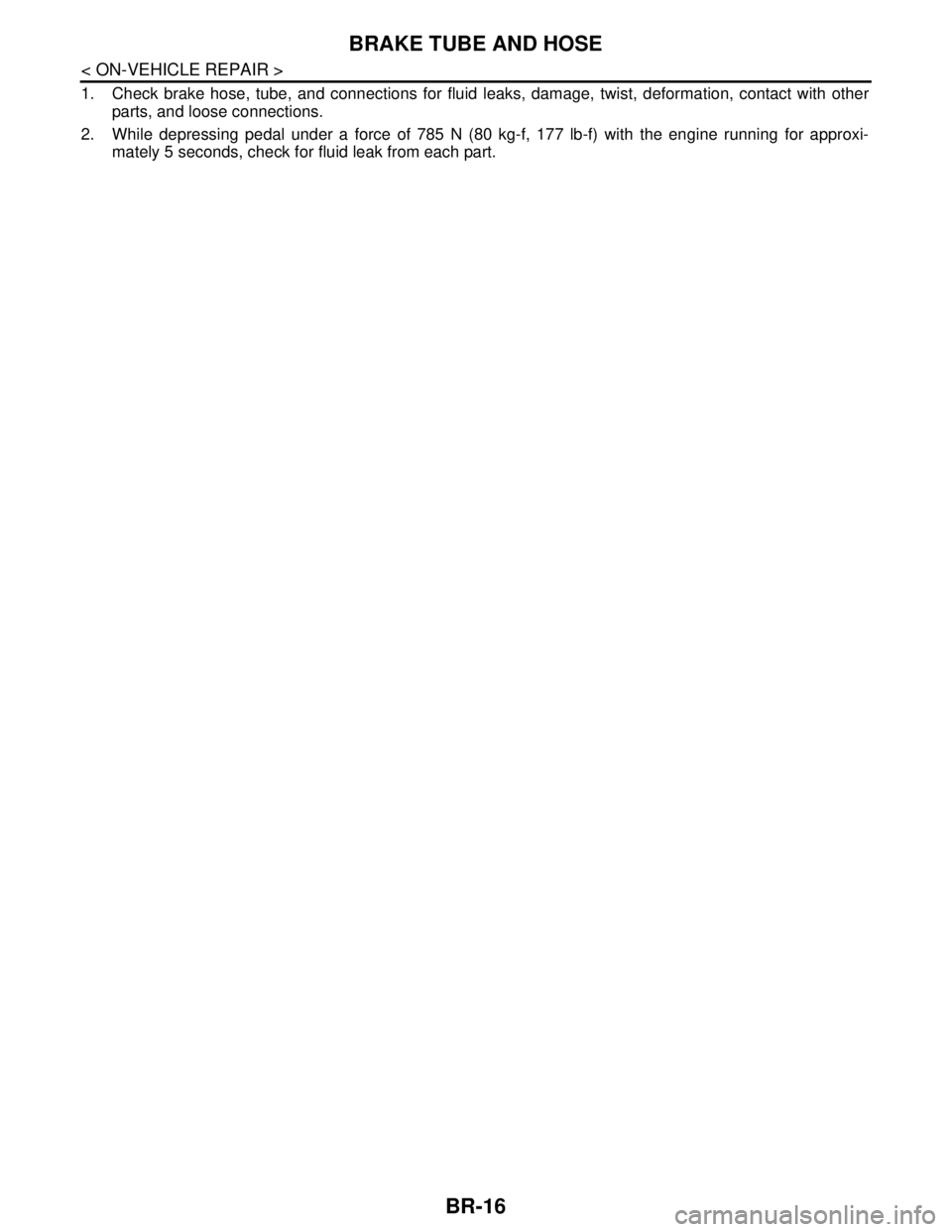

Rear Brake Tube and HoseINFOID:0000000001716984

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Using a flare nut wrench, remove brake tube from brake hose.

3. Remove lock plate, and remove brake hose from vehicle.

INSTALLATION

1. Connect brake hose to brake tube on vehicle, and temporarily tighten flare nut by hand as much as possi-

ble.

2. Secure it to bracket with lock plate.

3. Tighten flare nut to the specified torque with a flare nut torque wrench. Refer to BR-14, "

Hydraulic Circuit"

.

4. Bleed air from brake system. Refer to BR-8, "

Bleeding Brake System" .

Inspection After InstallationINFOID:0000000001716985

CAUTION:

Always disassemble the parts and retighten their fittings, if a brake fluid leak is detected. Replace

applicable part with a new one, if damaged part is detected.

If leak is detected at the connections, retighten it or replace the damaged part.

S F I A 111 8 E

SFIA1137E

SFIA1120E

Page 208 of 5883

BR-16

< ON-VEHICLE REPAIR >

BRAKE TUBE AND HOSE

1. Check brake hose, tube, and connections for fluid leaks, damage, twist, deformation, contact with other

parts, and loose connections.

2. While depressing pedal under a force of 785 N (80 kg-f, 177 lb-f) with the engine running for approxi-

mately 5 seconds, check for fluid leak from each part.

Page 209 of 5883

DUAL PROPORTIONING VALVE

BR-17

< ON-VEHICLE REPAIR >

C

D

E

G

H

I

J

K

L

MA

B

BR

N

O

P

DUAL PROPORTIONING VALVE

Removal and InstallationINFOID:0000000001726771

Removal

1. Disconnect brake lines from dual proportioning valve.

Mark brake lines for installation.

2. Remove dual proportioning valve bolt and dual proportioning valve.

3. Remove two bolts and bracket.

Installation

Installation is in the reverse order of removal.

When installing brake lines to the dual proportioning valve, tighten to specifications. Refer to BR-14,

"Hydraulic Circuit".

InspectionINFOID:0000000001726772

CAUTION:

Carefully monitor brake fluid level at master cylinder.

Use the recommended new brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on paint areas, wash it away with water immediately.

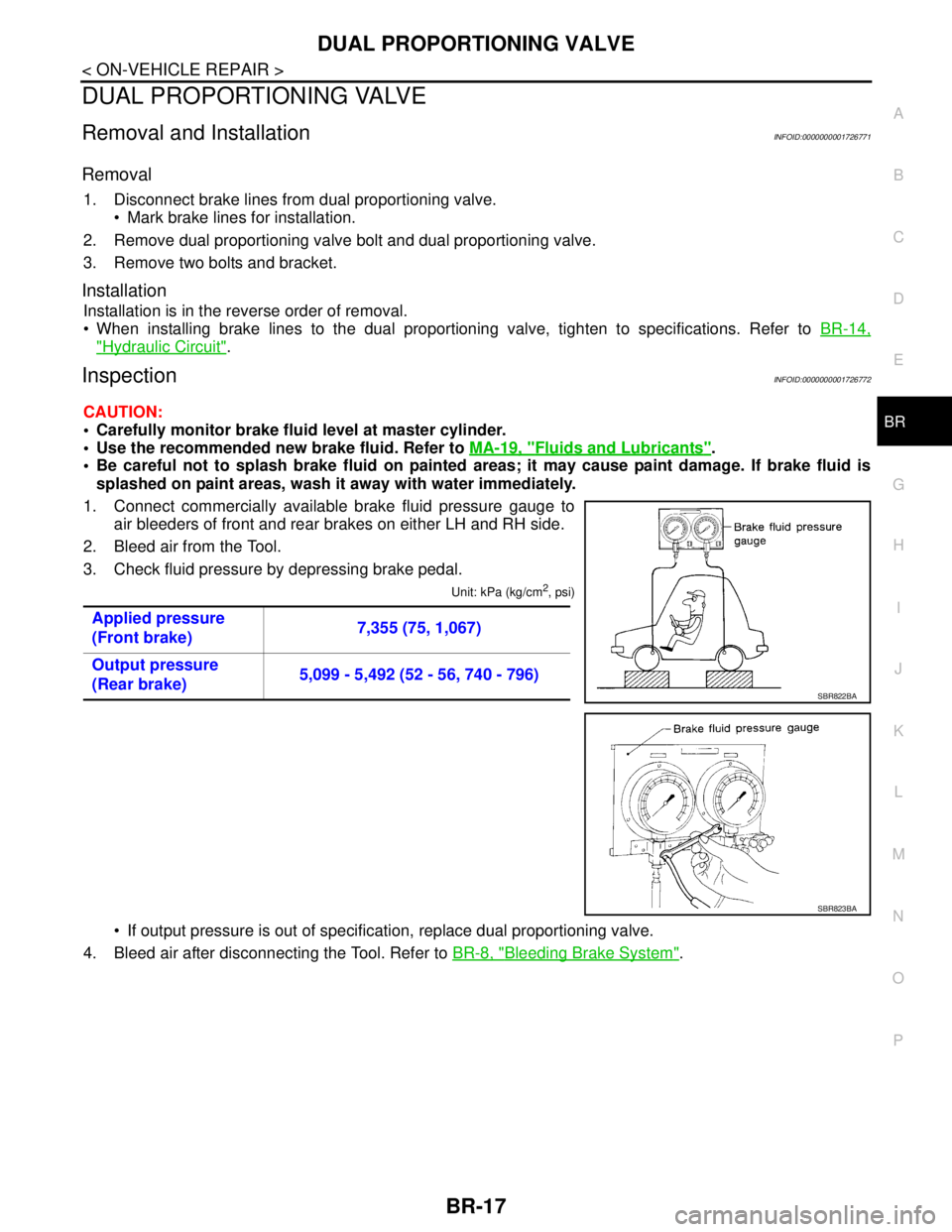

1. Connect commercially available brake fluid pressure gauge to

air bleeders of front and rear brakes on either LH and RH side.

2. Bleed air from the Tool.

3. Check fluid pressure by depressing brake pedal.

Unit: kPa (kg/cm2, psi)

If output pressure is out of specification, replace dual proportioning valve.

4. Bleed air after disconnecting the Tool. Refer to BR-8, "

Bleeding Brake System". Applied pressure

(Front brake)7,355 (75, 1,067)

Output pressure

(Rear brake)5,099 - 5,492 (52 - 56, 740 - 796)

SBR822BA

SBR823BA

Page 210 of 5883

BR-18

< ON-VEHICLE REPAIR >

BRAKE MASTER CYLINDER

BRAKE MASTER CYLINDER

On-Board InspectionINFOID:0000000001716996

LEAK INSPECTION

Check for leaking in a master cylinder installation surface, a reservoir tank installation surface, and brake

tube connections.

Removal and InstallationINFOID:0000000001716997

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe them with cloth and wash it away with water.

REMOVAL

1. Drain brake fluid. Refer to BR-8, "Drain and Refill" .

2. Remove battery. Refer to PG-6, "

Removal and Installation" .

3. Remove air duct and air cleaner. Refer to EM-27, "

Removal and Installation" (HR16DE), EM-154,

"Removal and Installation" (MR18DE), EM-269, "Removal and Installation" (K9K).

4. Disconnect brake fluid level switch harness connector.

5. Using a flare nut wrench, remove brake tube from master cylinder.

6. Remove master cylinder assembly nuts, and remove master cylinder assembly from vehicle..

INSTALLATION

CAUTION:

Refill using recommended brake fluid. Refer to MA-19, "

Fluids and Lubricants".

Never reuse drained brake fluid.

Check if the rod of primary piston has dust or scratches.

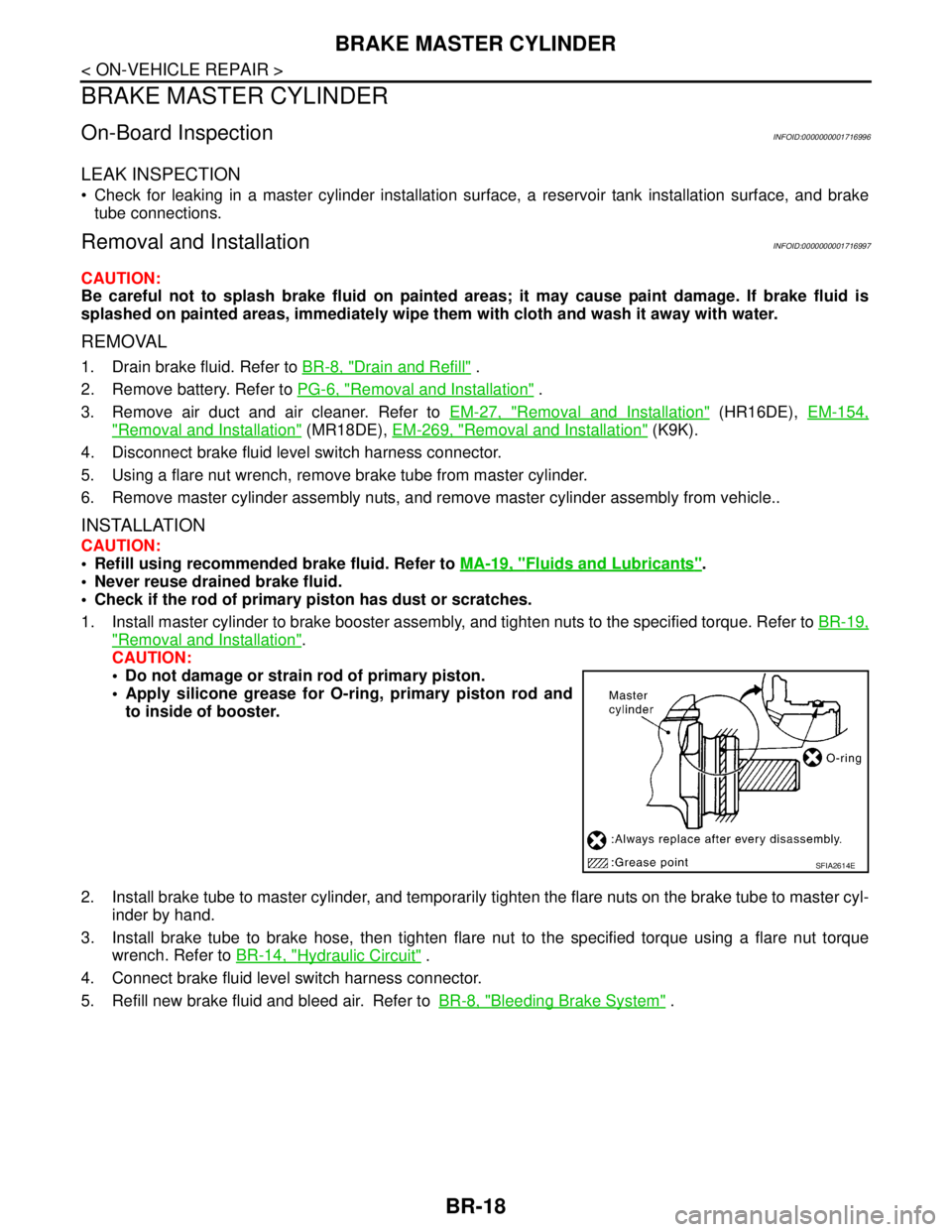

1. Install master cylinder to brake booster assembly, and tighten nuts to the specified torque. Refer to BR-19,

"Removal and Installation".

CAUTION:

Do not damage or strain rod of primary piston.

Apply silicone grease for O-ring, primary piston rod and

to inside of booster.

2. Install brake tube to master cylinder, and temporarily tighten the flare nuts on the brake tube to master cyl-

inder by hand.

3. Install brake tube to brake hose, then tighten flare nut to the specified torque using a flare nut torque

wrench. Refer to BR-14, "

Hydraulic Circuit" .

4. Connect brake fluid level switch harness connector.

5. Refill new brake fluid and bleed air. Refer toBR-8, "

Bleeding Brake System" .

SFIA2614E