NISSAN X-TRAIL 2003 Electronic Repair Manual

X-TRAIL 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57402/w960_57402-0.png

NISSAN X-TRAIL 2003 Electronic Repair Manual

Trending: key battery, air suspension, spare tire location, brake sensor, tire size, engine oil, steering wheel adjustment

Page 2751 of 3066

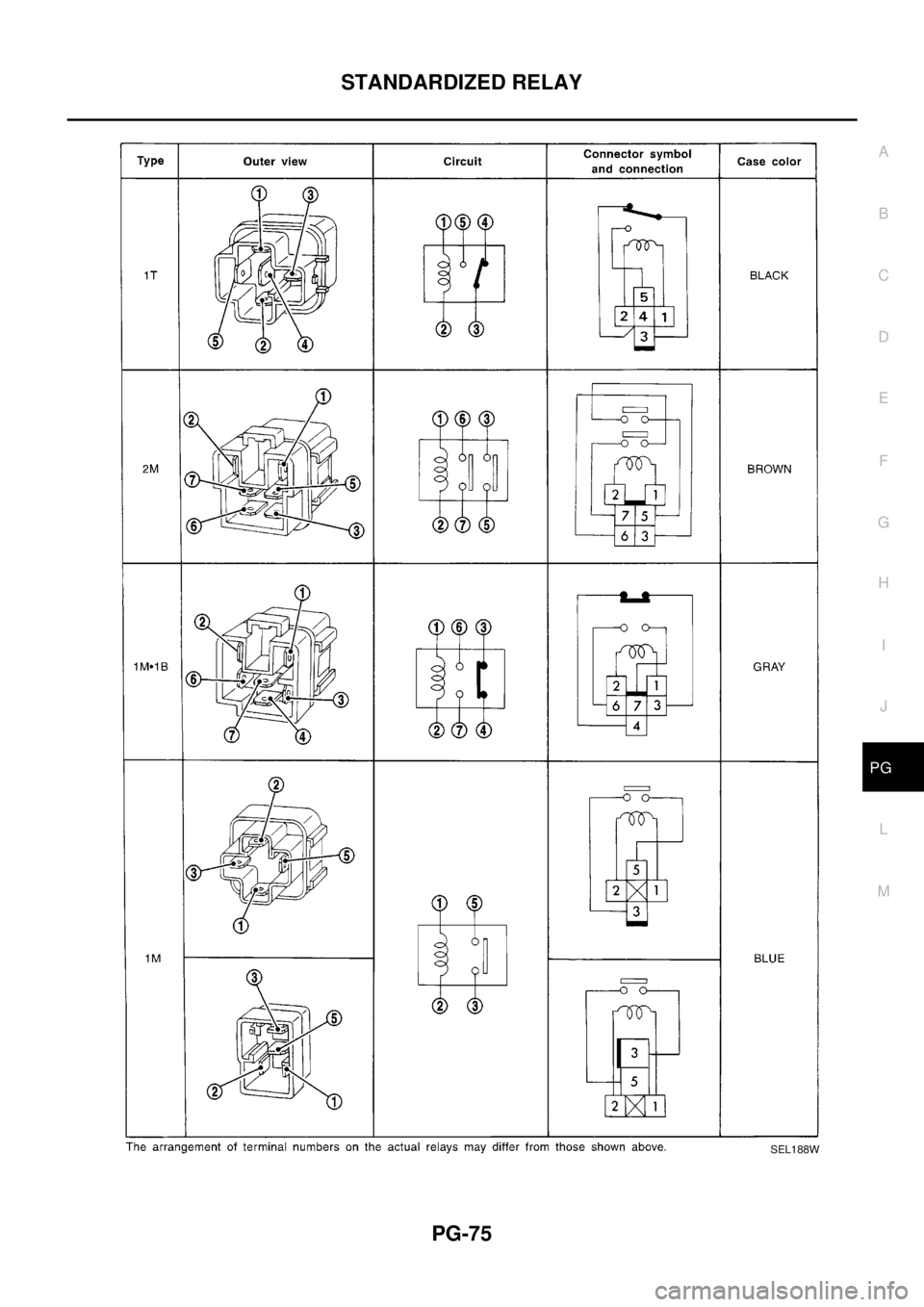

STANDARDIZED RELAY

PG-75

C

D

E

F

G

H

I

J

L

MA

B

PG

SEL188W

Page 2752 of 3066

PG-76

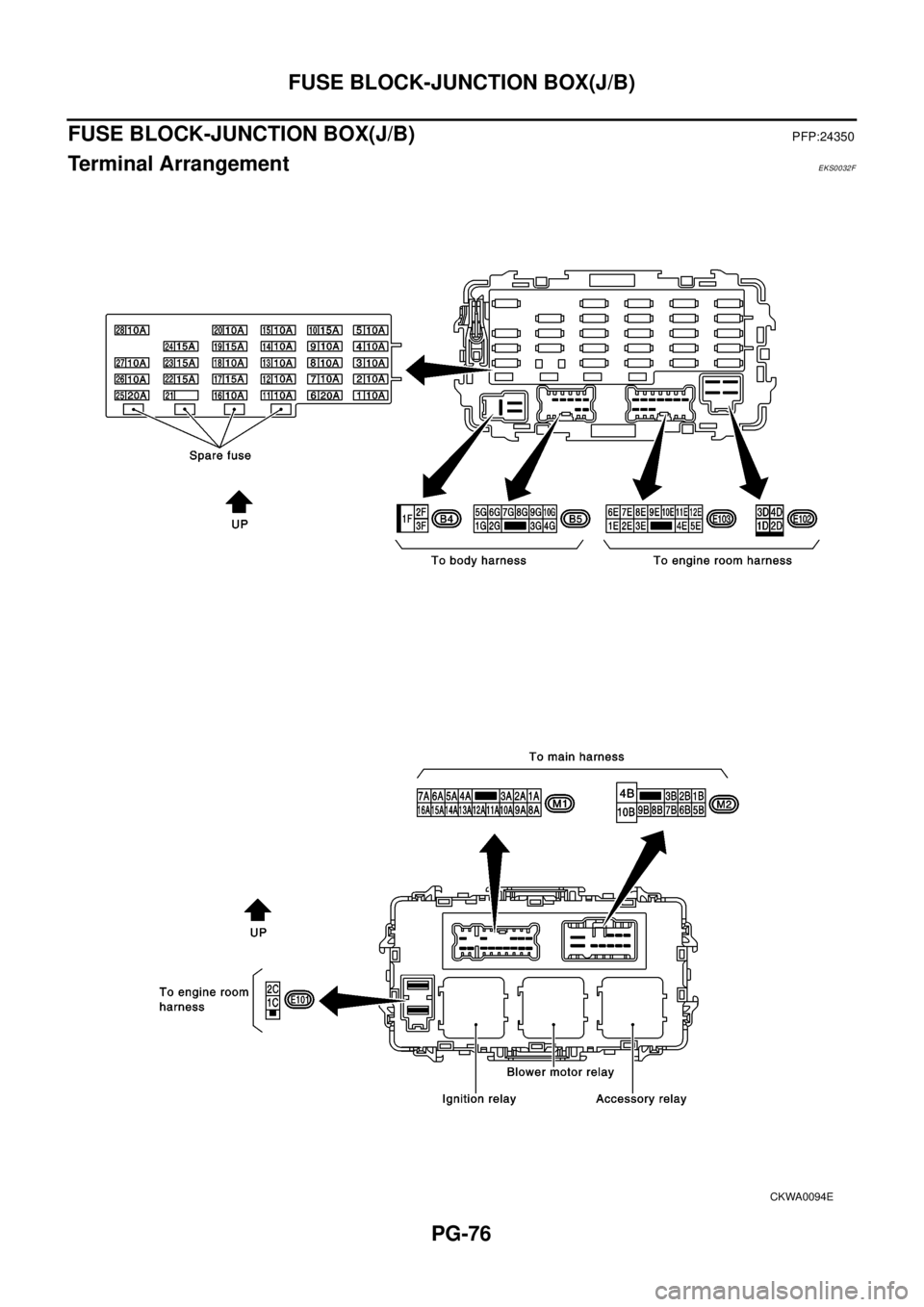

FUSE BLOCK-JUNCTION BOX(J/B)

FUSE BLOCK-JUNCTION BOX(J/B)

PFP:24350

Terminal ArrangementEKS0032F

CKWA0094E

Page 2753 of 3066

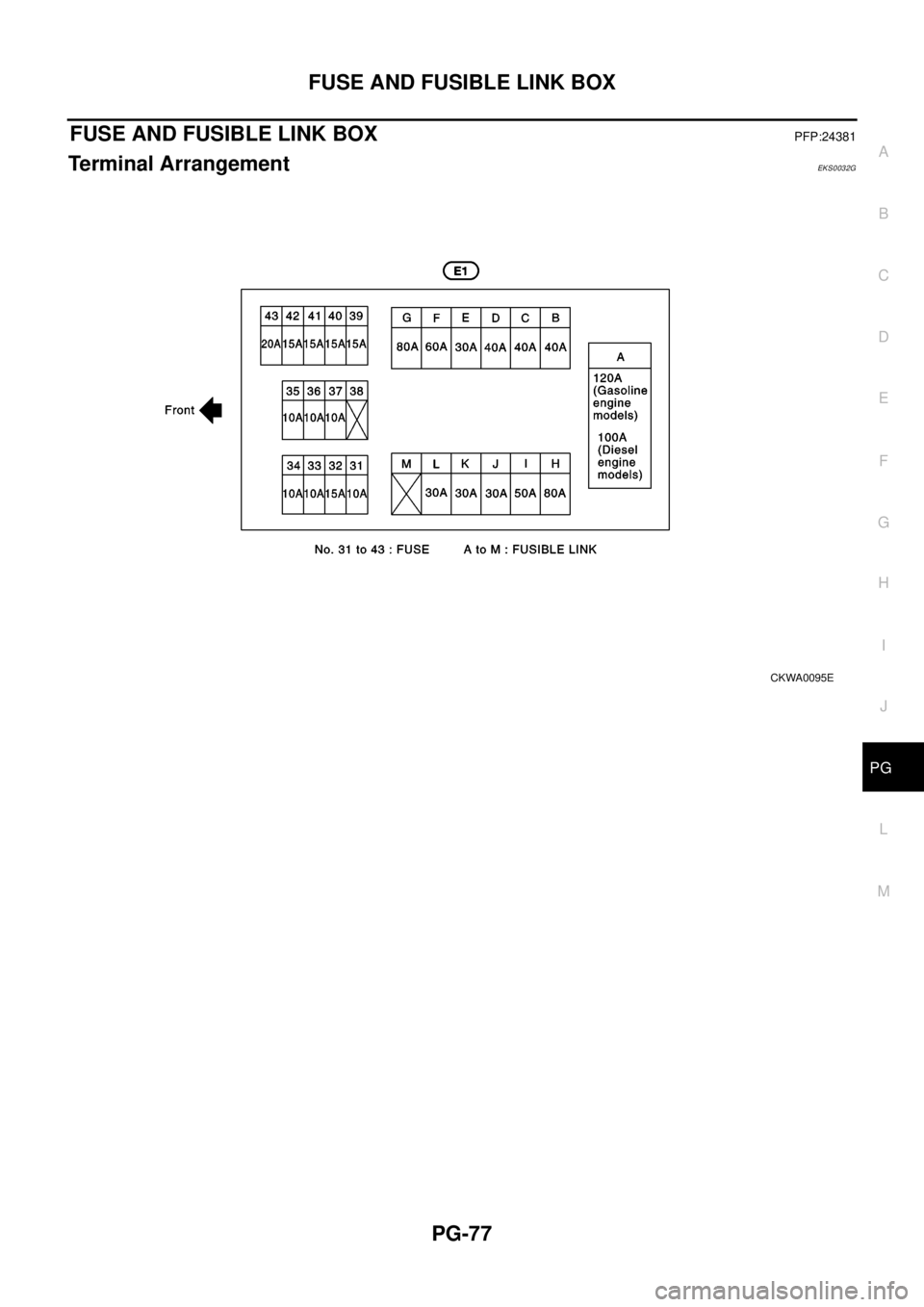

FUSE AND FUSIBLE LINK BOX

PG-77

C

D

E

F

G

H

I

J

L

MA

B

PG

FUSE AND FUSIBLE LINK BOXPFP:24381

Terminal ArrangementEKS0032G

CKWA0095E

Page 2754 of 3066

PG-78

FUSE AND FUSIBLE LINK BOX

Page 2755 of 3066

PR-1

PROPELLER SHAFT

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION

A

B

PR

PROPELLER SHAFT

REAR PROPELLER SHAFT ...................................... 2

On-Vehicle Inspection .............................................. 2

PROPELLER SHAFT RUNOUT INSPECTION..... 2

APPEARANCE AND NOISE INSPECTION .......... 2

Removal and Installation .......................................... 3

REMOVAL ............................................................. 3

INSPECTION AFTER REMOVAL ......................... 3

INSTALLATION ..................................................... 3SERVICE DATA AND SPECIFICATIONS (SDS) ........ 5

General Specifications .............................................. 5

Propeller Shaft Axial Play ......................................... 5

Propeller Shaft Vibration ........................................... 5

Page 2756 of 3066

PR-2

REAR PROPELLER SHAFT

REAR PROPELLER SHAFT

PFP:37000

On-Vehicle InspectionEDS00051

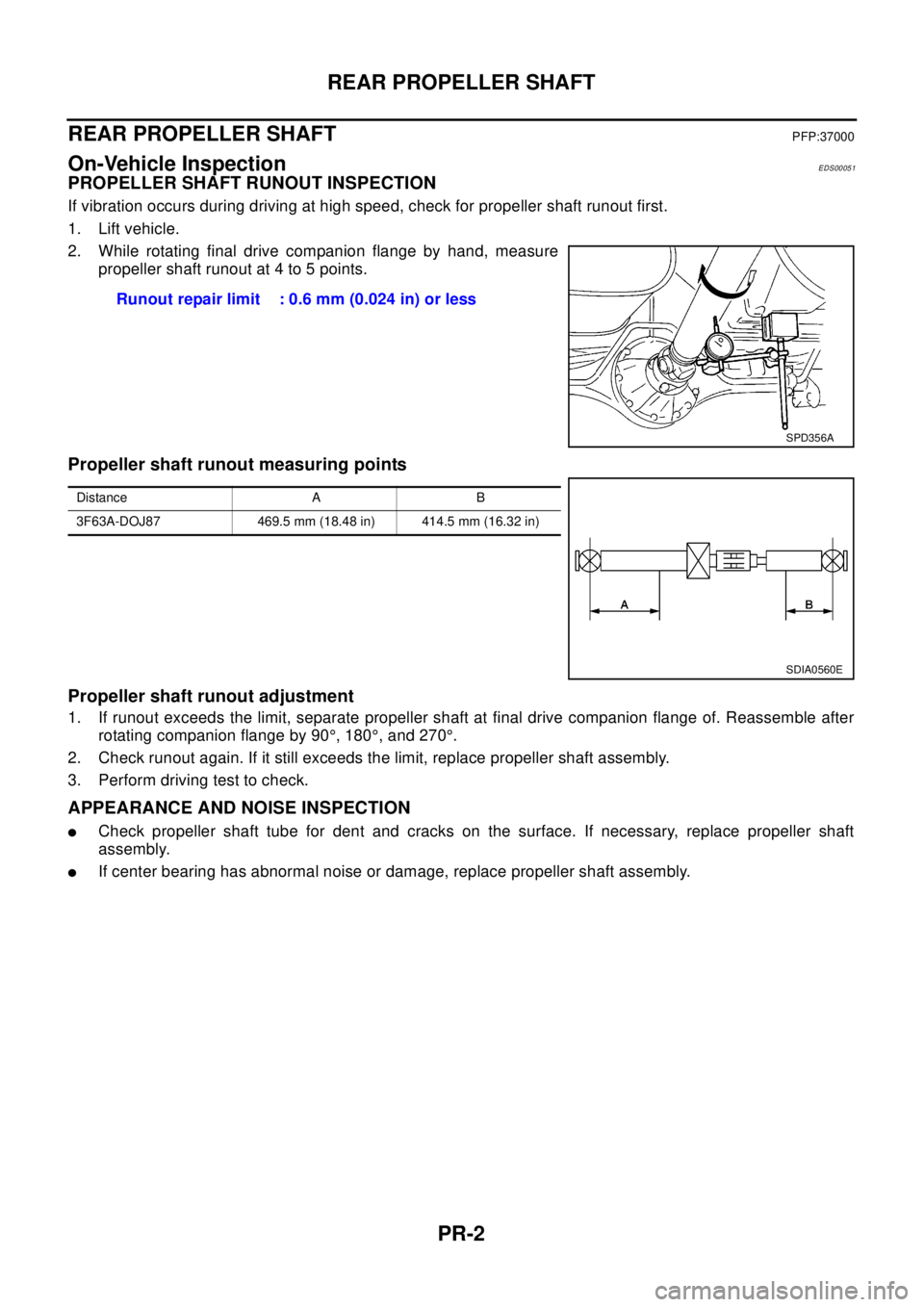

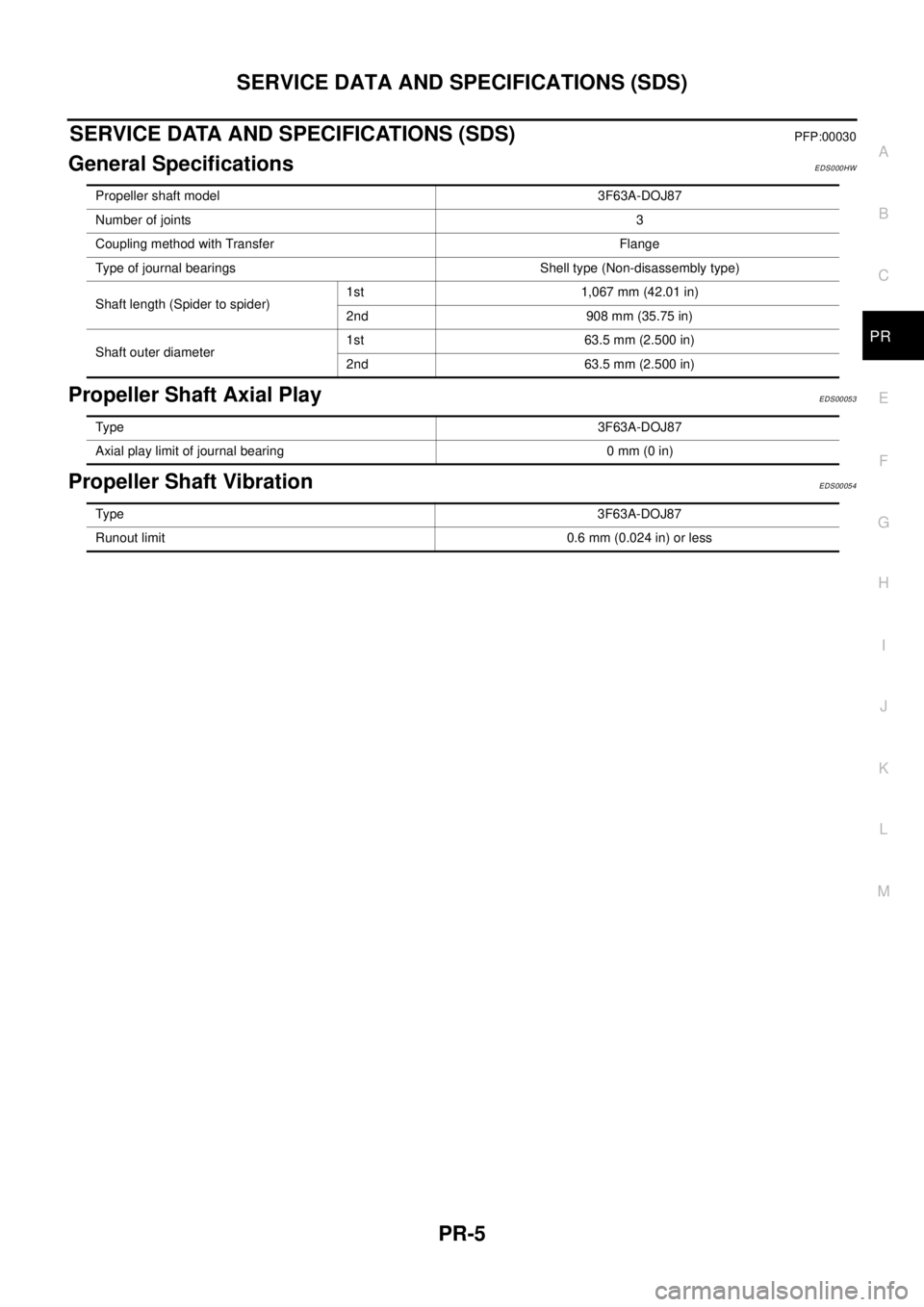

PROPELLER SHAFT RUNOUT INSPECTION

If vibration occurs during driving at high speed, check for propeller shaft runout first.

1. Lift vehicle.

2. While rotating final drive companion flange by hand, measure

propeller shaft runout at 4 to 5 points.

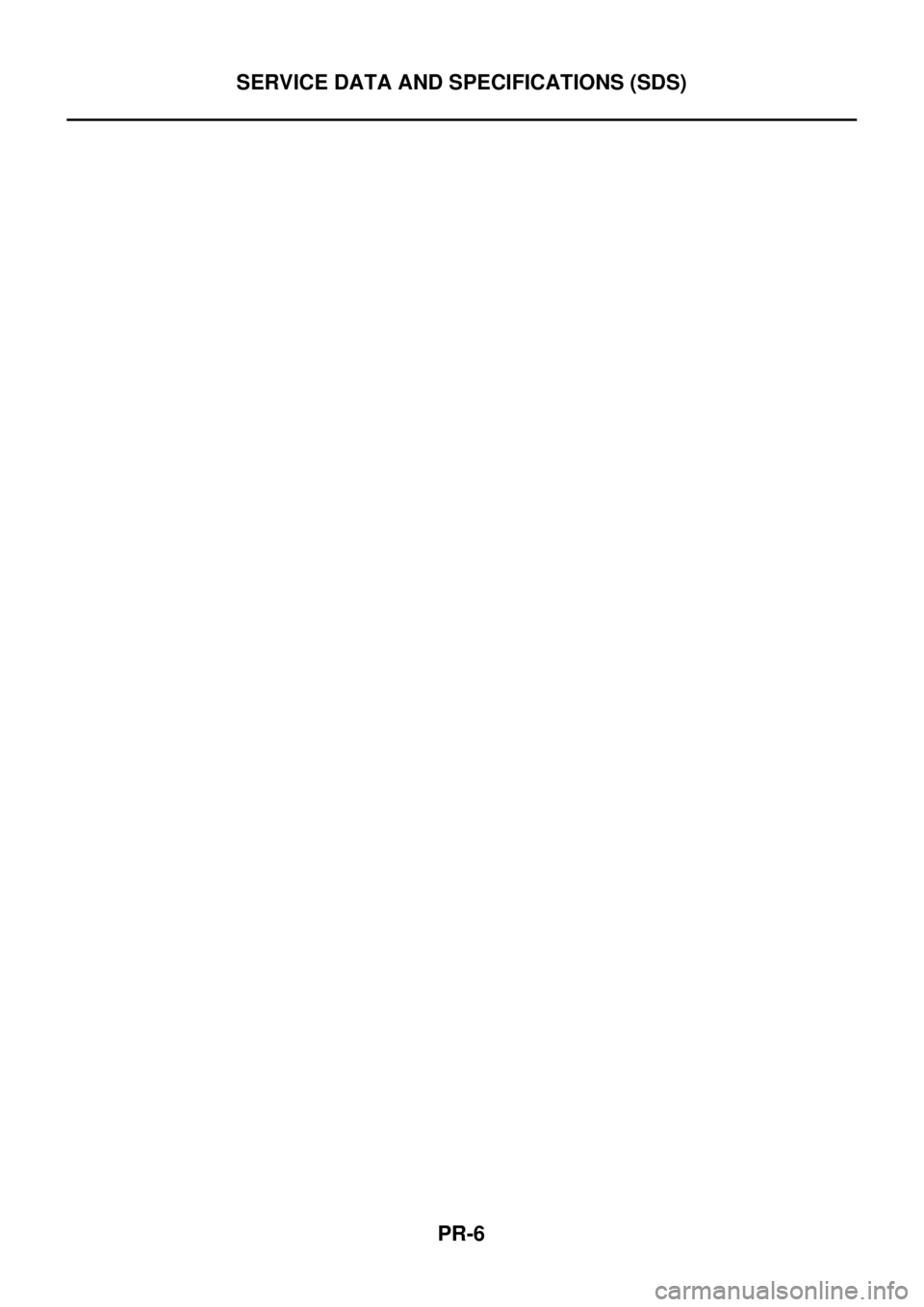

Propeller shaft runout measuring points

Propeller shaft runout adjustment

1. If runout exceeds the limit, separate propeller shaft at final drive companion flange of. Reassemble after

rotating companion flange by 90°, 180°, and 270°.

2. Check runout again. If it still exceeds the limit, replace propeller shaft assembly.

3. Perform driving test to check.

APPEARANCE AND NOISE INSPECTION

lCheck propeller shaft tube for dent and cracks on the surface. If necessary, replace propeller shaft

assembly.

lIf center bearing has abnormal noise or damage, replace propeller shaft assembly.Runout repair limit : 0.6 mm (0.024 in) or less

SPD356A

Distance A B

3F63A-DOJ87 469.5 mm (18.48 in) 414.5 mm (16.32 in)

SDIA0560E

Page 2757 of 3066

REAR PROPELLER SHAFT

PR-3

C

E

F

G

H

I

J

K

L

MA

B

PR

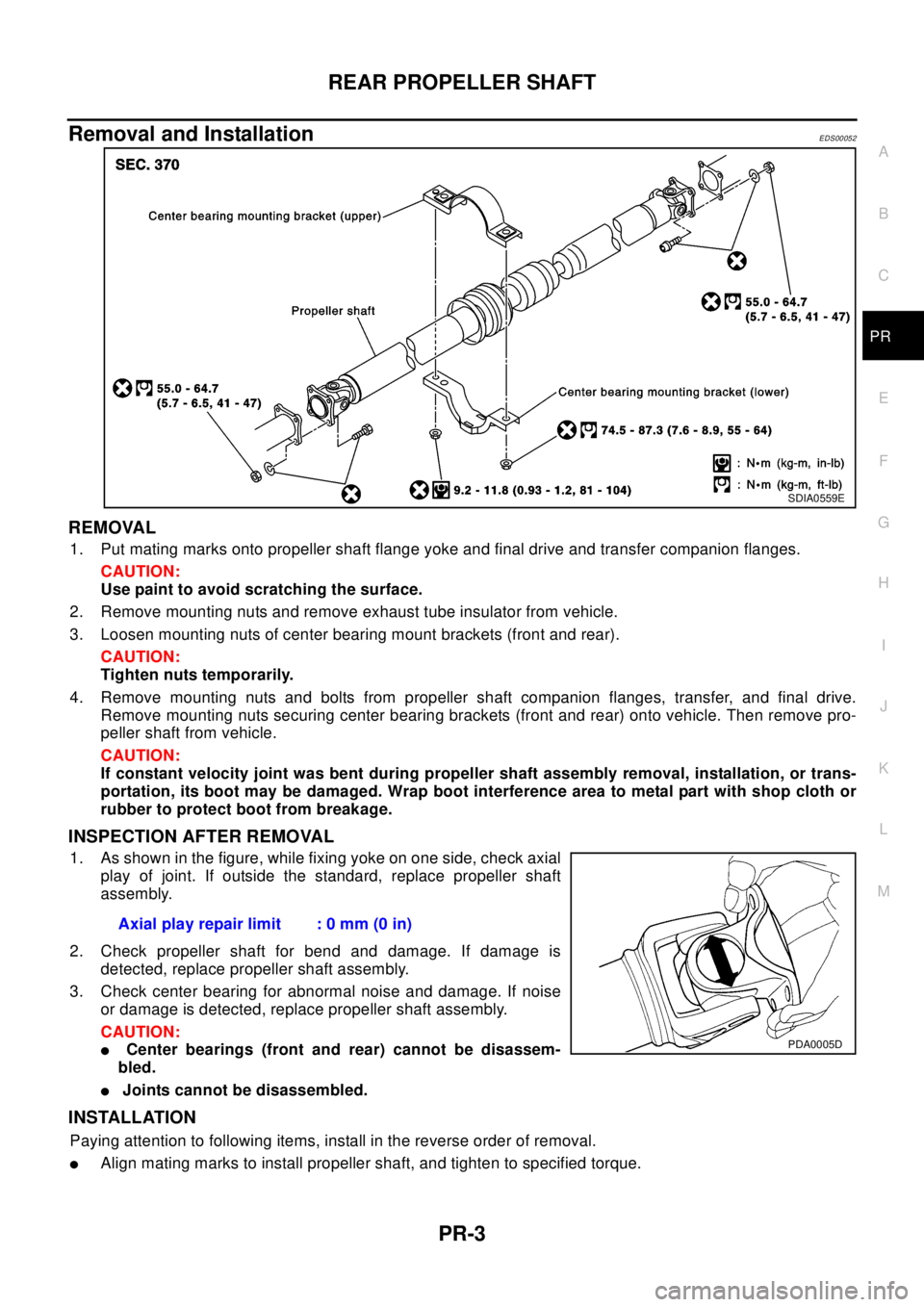

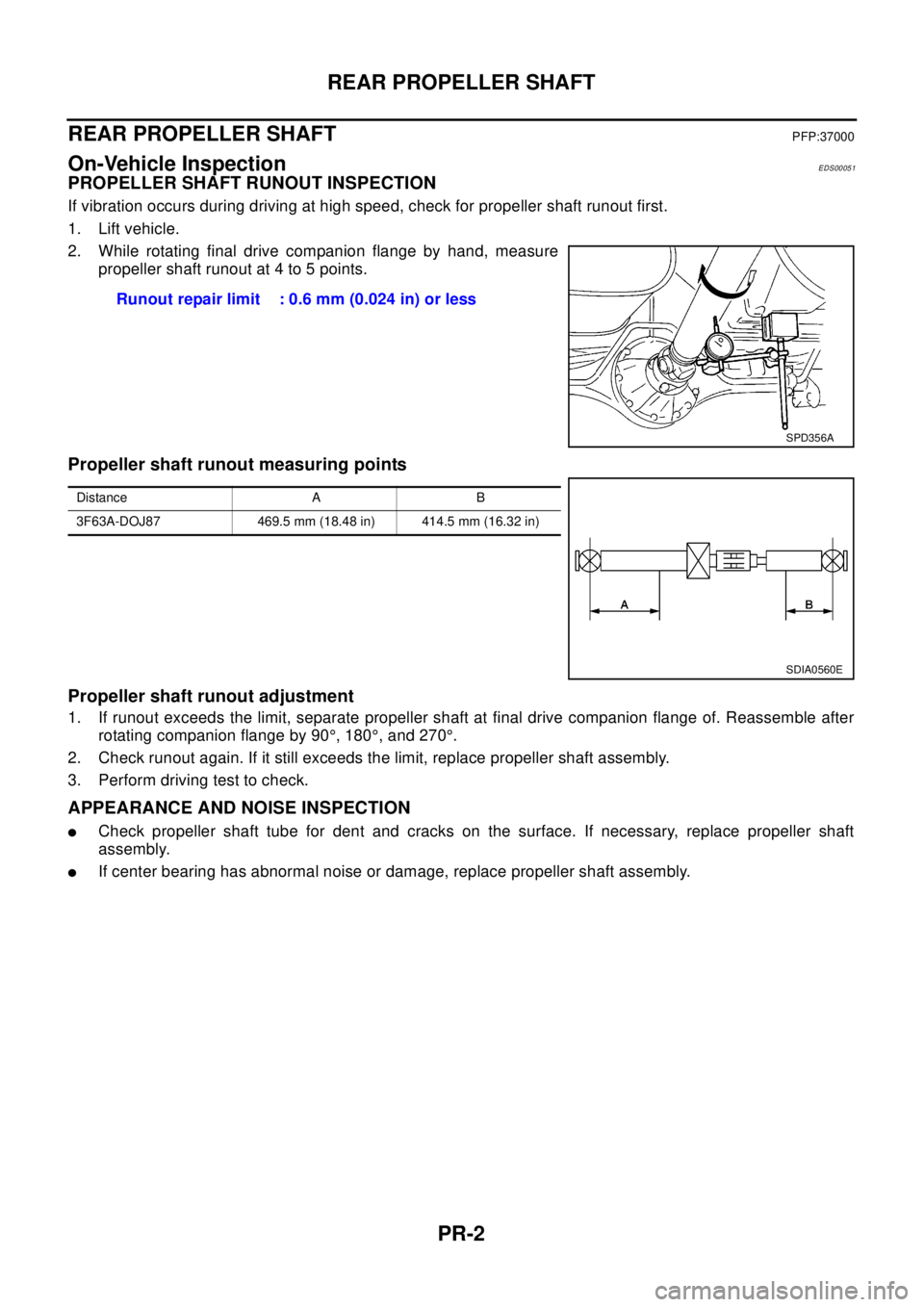

Removal and InstallationEDS00052

REMOVAL

1. Put mating marks onto propeller shaft flange yoke and final drive and transfer companion flanges.

CAUTION:

Use paint to avoid scratching the surface.

2. Remove mounting nuts and remove exhaust tube insulator from vehicle.

3. Loosen mounting nuts of center bearing mount brackets (front and rear).

CAUTION:

Tighten nuts temporarily.

4. Remove mounting nuts and bolts from propeller shaft companion flanges, transfer, and final drive.

Remove mounting nuts securing center bearing brackets (front and rear) onto vehicle. Then remove pro-

peller shaft from vehicle.

CAUTION:

If constant velocity joint was bent during propeller shaft assembly removal, installation, or trans-

portation, its boot may be damaged. Wrap boot interference area to metal part with shop cloth or

rubber to protect boot from breakage.

INSPECTION AFTER REMOVAL

1. As shown in the figure, while fixing yoke on one side, check axial

play of joint. If outside the standard, replace propeller shaft

assembly.

2. Check propeller shaft for bend and damage. If damage is

detected, replace propeller shaft assembly.

3. Check center bearing for abnormal noise and damage. If noise

or damage is detected, replace propeller shaft assembly.

CAUTION:

lCenter bearings (front and rear) cannot be disassem-

bled.

lJoints cannot be disassembled.

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

lAlign mating marks to install propeller shaft, and tighten to specified torque.

SDIA0559E

Axial play repair limit : 0 mm (0 in)

PDA0005D

Page 2758 of 3066

PR-4

REAR PROPELLER SHAFT

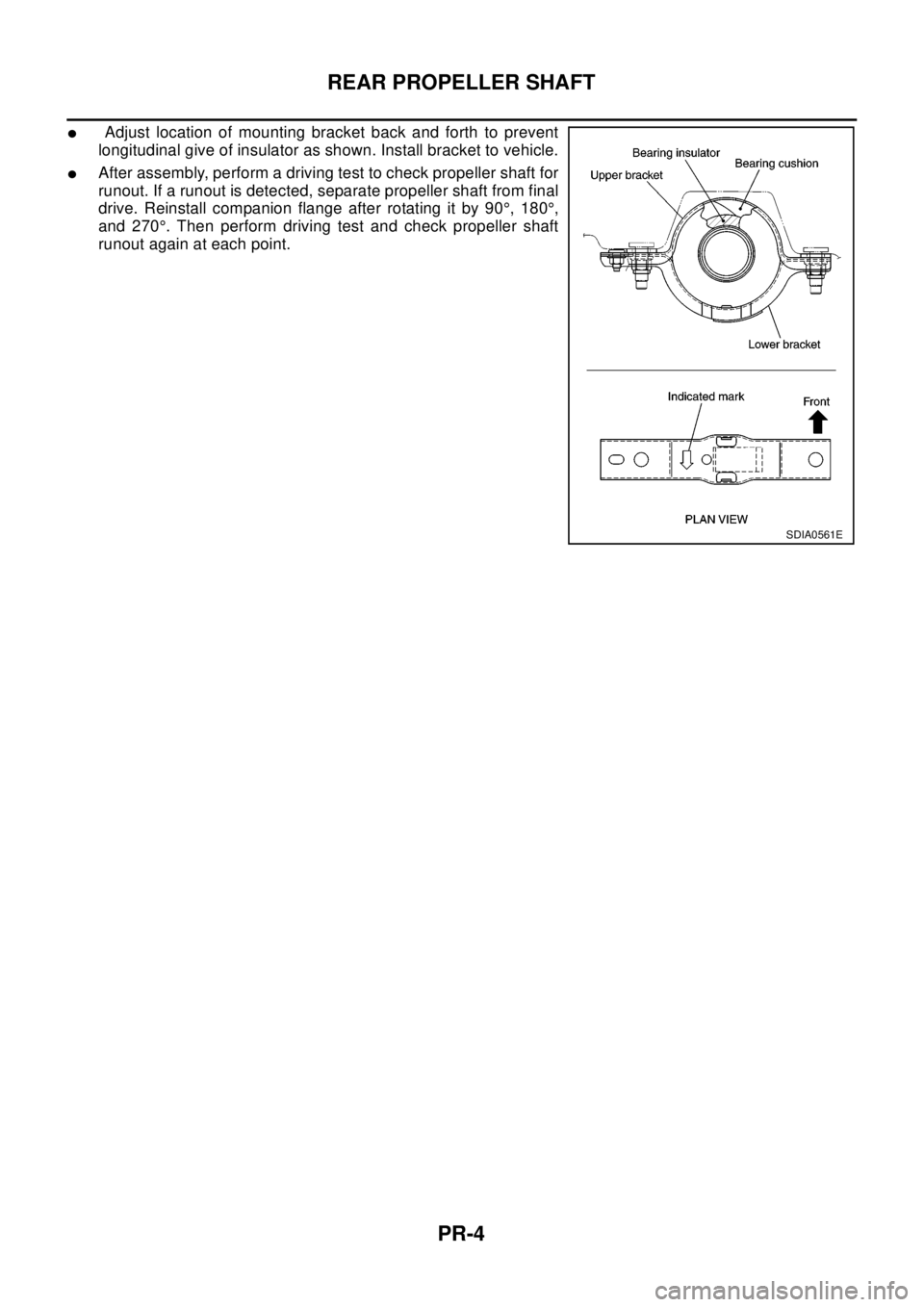

lAdjust location of mounting bracket back and forth to prevent

longitudinal give of insulator as shown. Install bracket to vehicle.

lAfter assembly, perform a driving test to check propeller shaft for

runout. If a runout is detected, separate propeller shaft from final

drive. Reinstall companion flange after rotating it by 90°,180°,

and 270°. Then perform driving test and check propeller shaft

runout again at each point.

SDIA0561E

Page 2759 of 3066

SERVICE DATA AND SPECIFICATIONS (SDS)

PR-5

C

E

F

G

H

I

J

K

L

MA

B

PR

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

General SpecificationsEDS000HW

Propeller Shaft Axial PlayEDS00053

Propeller Shaft VibrationEDS00054

Propeller shaft model 3F63A-DOJ87

Number of joints3

Coupling method with Transfer Flange

Type of journal bearings Shell type (Non-disassembly type)

Shaft length (Spider to spider)1st 1,067 mm (42.01 in)

2nd 908 mm (35.75 in)

Shaft outer diameter1st 63.5 mm (2.500 in)

2nd 63.5 mm (2.500 in)

Ty pe3F63A-DOJ87

Axial play limit of journal bearing 0 mm (0 in)

Ty pe3F63A-DOJ87

Runout limit 0.6 mm (0.024 in) or less

Page 2760 of 3066

PR-6

SERVICE DATA AND SPECIFICATIONS (SDS)

Trending: wheelbase, fuses, fuel filter location, height, battery capacity, octane, diagram