NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2791 of 3066

POWER STEERING OIL PUMP

PS-31

C

D

E

F

H

I

J

K

L

MA

B

PS

INSPECTION AFTER DISASSEMBLY

lIf pulley is cracked or deformed, replace it.

lIf an oil leak is found around pulley shaft oil seal, replace the seal.

lIf serration on pulley or pulley shaft is deformed or worn, replace it.

ASSEMBLY

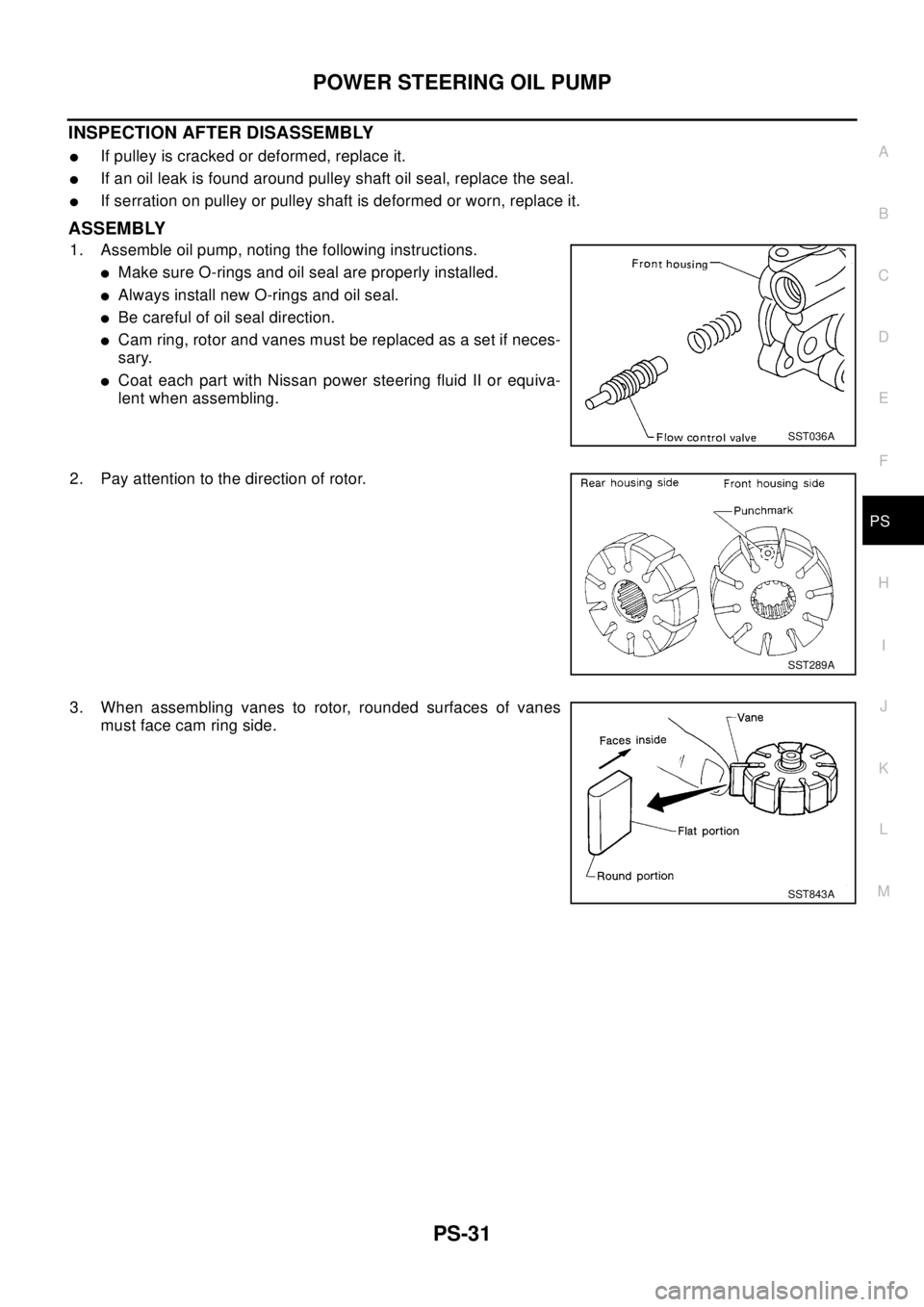

1. Assemble oil pump, noting the following instructions.

lMake sure O-rings and oil seal are properly installed.

lAlways install new O-rings and oil seal.

lBe careful of oil seal direction.

lCam ring, rotor and vanes must be replaced as a set if neces-

sary.

lCoat each part with Nissan power steering fluid II or equiva-

lent when assembling.

2. Pay attention to the direction of rotor.

3. When assembling vanes to rotor, rounded surfaces of vanes

must face cam ring side.

SST036A

SST289A

SST843A

Page 2792 of 3066

PS-32

POWER STEERING OIL PUMP

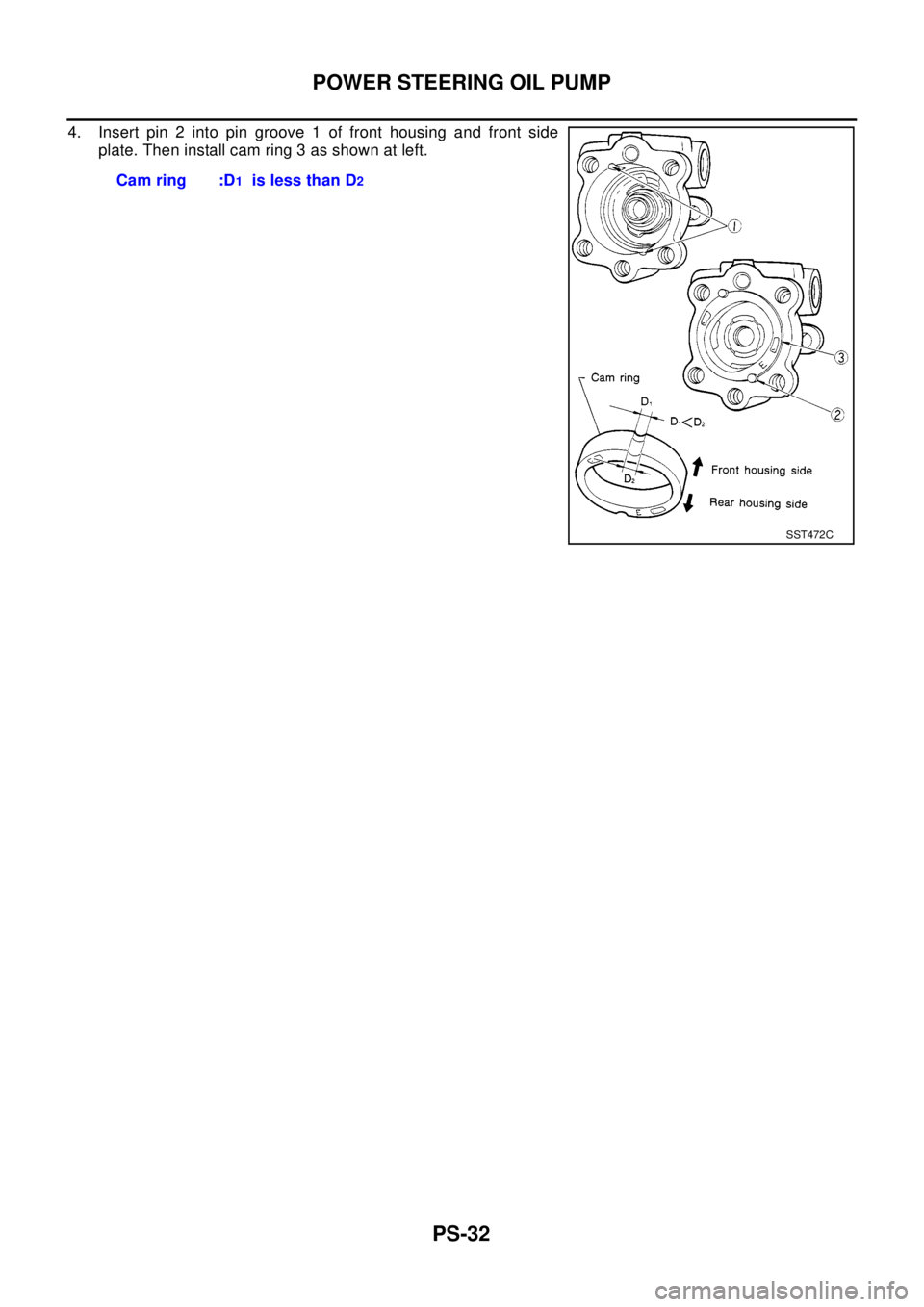

4. Insert pin 2 into pin groove 1 of front housing and front side

plate. Then install cam ring 3 as shown at left.

Cam ring :D

1is less than D2

SST472C

Page 2793 of 3066

HYDRAULIC LINE

PS-33

C

D

E

F

H

I

J

K

L

MA

B

PS

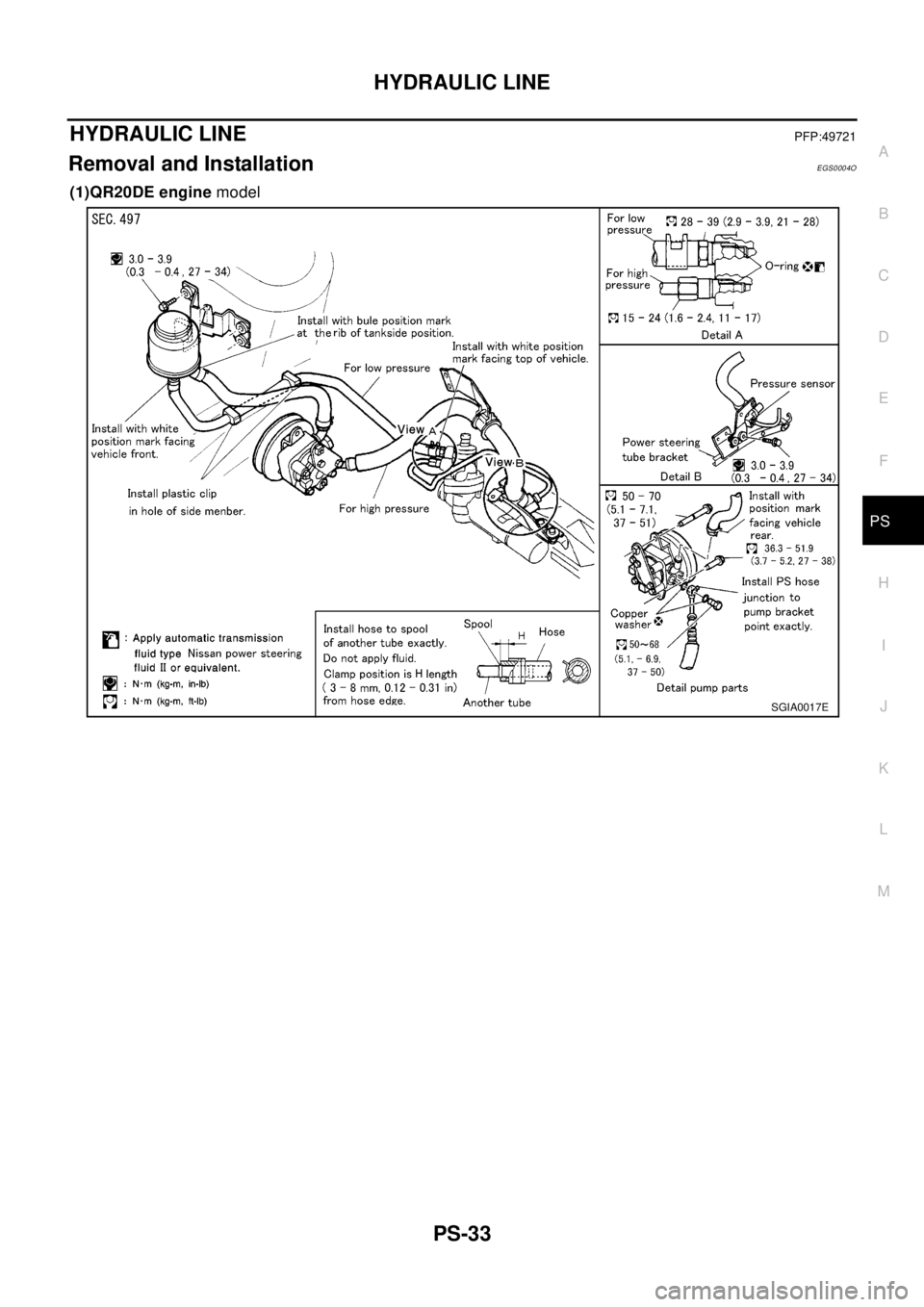

HYDRAULIC LINEPFP:49721

Removal and InstallationEGS0004O

(1)QR20DE enginemodel

SGIA0017E

Page 2794 of 3066

PS-34

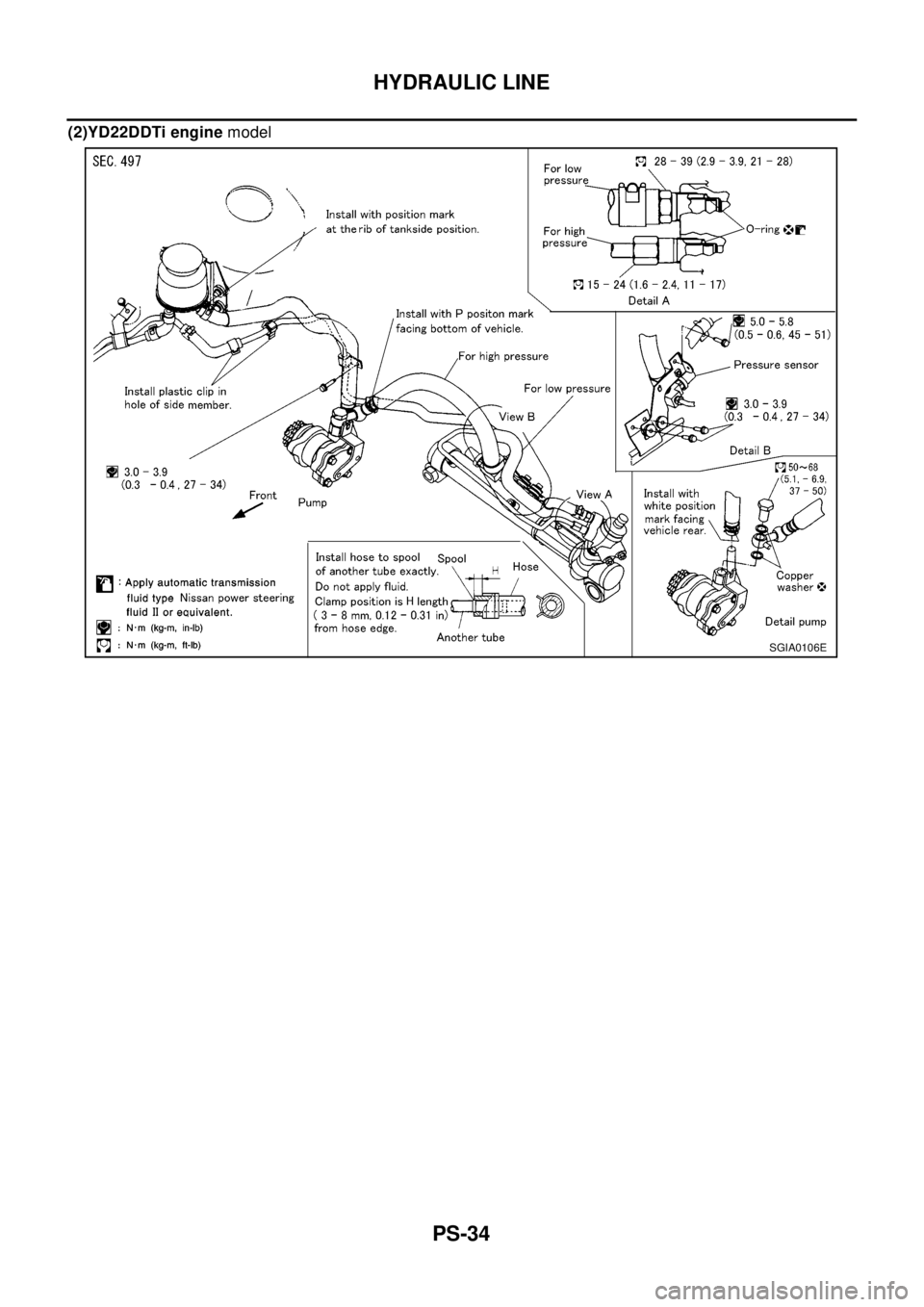

HYDRAULIC LINE

(2)YD22DDTi enginemodel

SGIA0106E

Page 2795 of 3066

SERVICE DATA AND SPECIFICATIONS (SDS)

PS-35

C

D

E

F

H

I

J

K

L

MA

B

PS

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

WheelEGS0004P

Steering AngleEGS0004Q

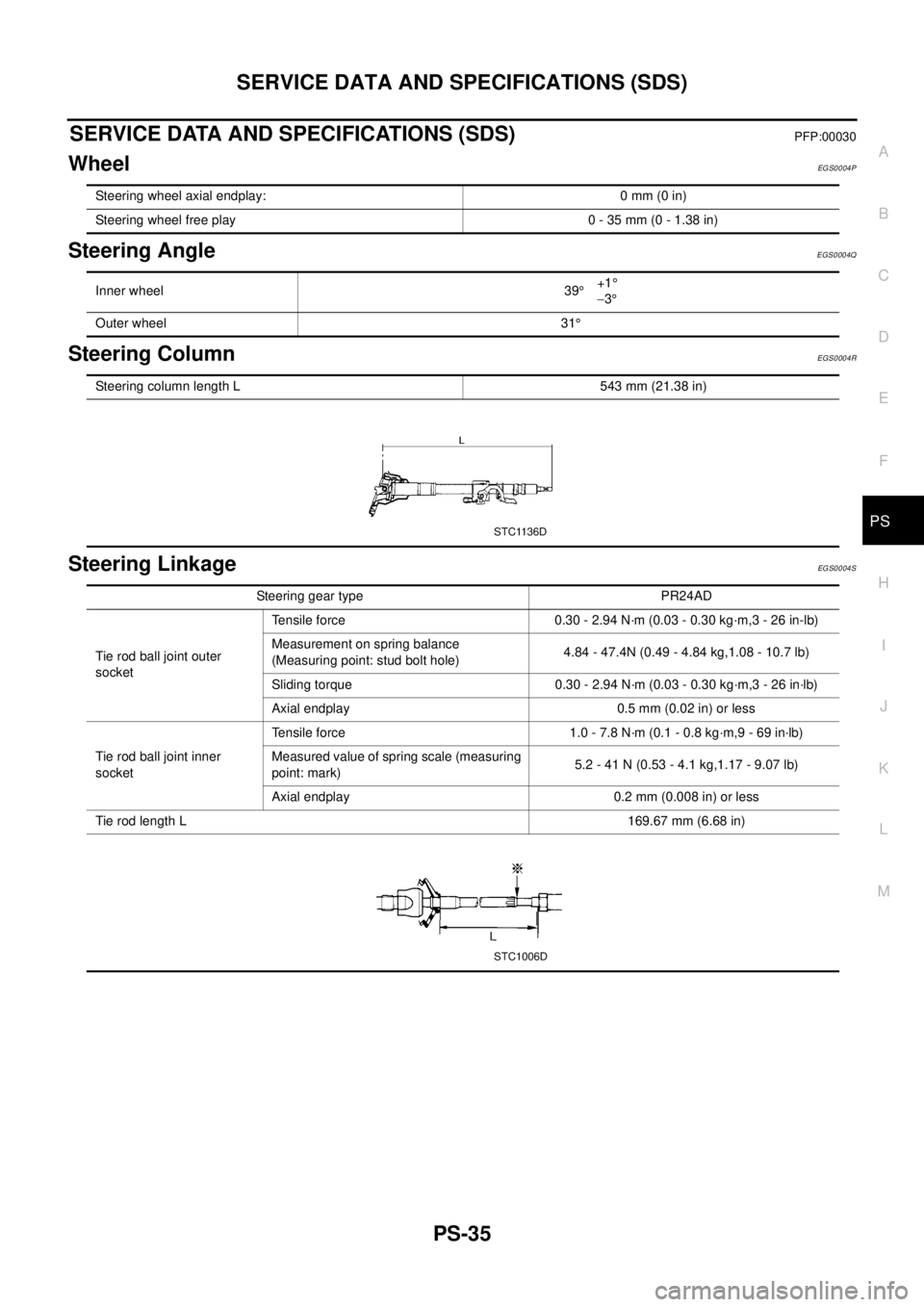

Steering ColumnEGS0004R

Steering LinkageEGS0004S

Steering wheel axial endplay: 0 mm (0 in)

Steering wheel free play 0 - 35 mm (0 - 1.38 in)

Inner wheel 39°+1°

-3°

Outer wheel 31°

Steering column length L 543 mm (21.38 in)

STC1136D

Steering gear type PR24AD

Tie rod ball joint outer

socketTensile force 0.30 - 2.94 N·m (0.03 - 0.30 kg·m,3 - 26 in-lb)

Measurement on spring balance

(Measuring point: stud bolt hole)4.84 - 47.4N (0.49 - 4.84 kg,1.08 - 10.7 lb)

Sliding torque 0.30 - 2.94 N·m (0.03 - 0.30 kg·m,3 - 26 in·lb)

Axial endplay 0.5 mm (0.02 in) or less

Tie rod ball joint inner

socketTensile force 1.0 - 7.8 N·m (0.1 - 0.8 kg·m,9 - 69 in·lb)

Measured value of spring scale (measuring

point: mark)5.2 - 41 N (0.53 - 4.1 kg,1.17 - 9.07 lb)

Axial endplay 0.2 mm (0.008 in) or less

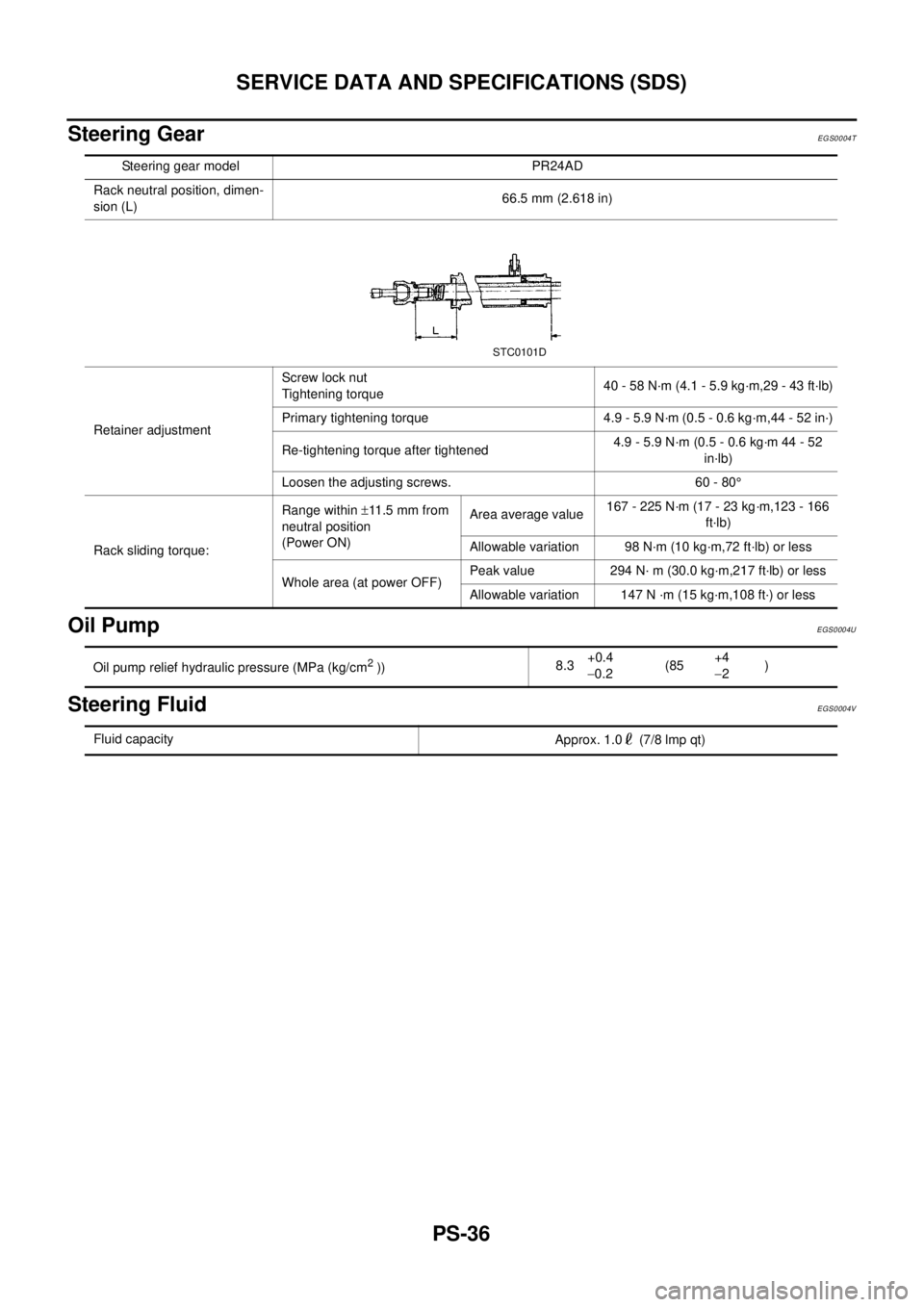

Tie rod length L169.67 mm (6.68 in)

STC1006D

Page 2796 of 3066

PS-36

SERVICE DATA AND SPECIFICATIONS (SDS)

Steering Gear

EGS0004T

Oil PumpEGS0004U

Steering FluidEGS0004V

Steering gear model PR24AD

Rack neutral position, dimen-

sion (L)66.5 mm (2.618 in)

Retainer adjustmentScrew lock nut

Tightening torque40 - 58 N·m (4.1 - 5.9 kg·m,29 - 43 ft·lb)

Primary tightening torque 4.9 - 5.9 N·m (0.5 - 0.6 kg·m,44 - 52 in·)

Re-tightening torque after tightened4.9 - 5.9 N·m (0.5 - 0.6 kg·m 44 - 52

in·lb)

Loosen the adjusting screws. 60 - 80°

Rack sliding torque:Range within±11 .5 m m f r o m

neutral position

(Power ON)Area average value167 - 225 N·m (17 - 23 kg·m,123 - 166

ft·lb)

Allowable variation 98 N·m (10 kg·m,72 ft·lb) or less

Whole area (at power OFF)Peak value 294 N· m (30.0 kg·m,217 ft·lb) or less

Allowable variation 147 N ·m (15 kg·m,108 ft·) or less

STC0101D

Oil pump relief hydraulic pressure (MPa (kg/cm2))8.3+0.4

-0.2(85+4

-2)

Fluid capacity

Approx. 1.0 (7/8 lmp qt)

Page 2797 of 3066

RAX-1

REAR AXLE

D DRIVELINE/AXLE

CONTENTS

C

E

F

G

H

I

J

K

L

M

SECTION

A

B

RAX

REAR AXLE

PRECAUTIONS .......................................................... 2

Caution ..................................................................... 2

Precautions for Brake System .................................. 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

Commercial Service Tools ........................................ 4

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 5

NVH Troubleshooting Chart ..................................... 5

WHEEL HUB (4WD) ................................................... 6

On-Vehicle Inspection .............................................. 6

REAR WHEEL BEARING ..................................... 6

Removal and Installation .......................................... 6

REMOVAL ............................................................. 6INSTALLATION ..................................................... 7

Disassembly and Assembly ...................................... 7

DISASSEMBLY ..................................................... 7

INSPECTION AFTER DISASSEMBLY .................. 8

ASSEMBLY ........................................................... 8

REAR DRIVE SHAFT ................................................. 9

Removal and Installation .......................................... 9

REMOVAL ............................................................. 9

INSPECTION AFTER REMOVAL ......................... 9

INSTALLATION ..................................................... 9

Disassembly and Assembly .................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY ................ 11

ASSEMBLY ......................................................... 12

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 15

Wheel Bearing ........................................................ 15

Drive Shaft .............................................................. 15

Page 2798 of 3066

RAX-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

CautionEDS00060

Observe the following precautions when disassembling and servicing drive shaft.

lPerform work in a location which is as dust-free and dirt-free as possible.

lBefore disassembling and servicing, clean the outside of parts.

lThe disassembly and service location must be clean. Care must be taken to prevent parts from becoming

dirty and to prevent the entry of foreign objects.

lDisassembled parts must be carefully reassembled in the correct order. If work is interrupted, a clean

cover must be placed over parts.

lPaper shop cloths must be used. Fabric shop cloths must not be used because of the danger of lint adher-

ing to parts.

lDisassembled parts (except for rubber parts) should be cleaned with kerosene which shall be removed by

blowing with air or wiping with paper shop cloths.

Precautions for Brake SystemEDS0 00 I2

lWhen installing rubber parts, final tightening must be carried out

under unladen condition* with tires on ground.

*: Fuel, radiator coolant and engine oil full. Spare tire, jack,

hand tools and mats in designated positions.

lUse flare nut wrench when removing or installing brake tubes.

lAfter installing removed suspension parts, check wheel align-

ment and adjust if necessary.

lAlways torque brake lines when installing.

SBR686C

Page 2799 of 3066

PREPARATION

RAX-3

C

E

F

G

H

I

J

K

L

MA

B

RAX

PREPARATIONPFP:00002

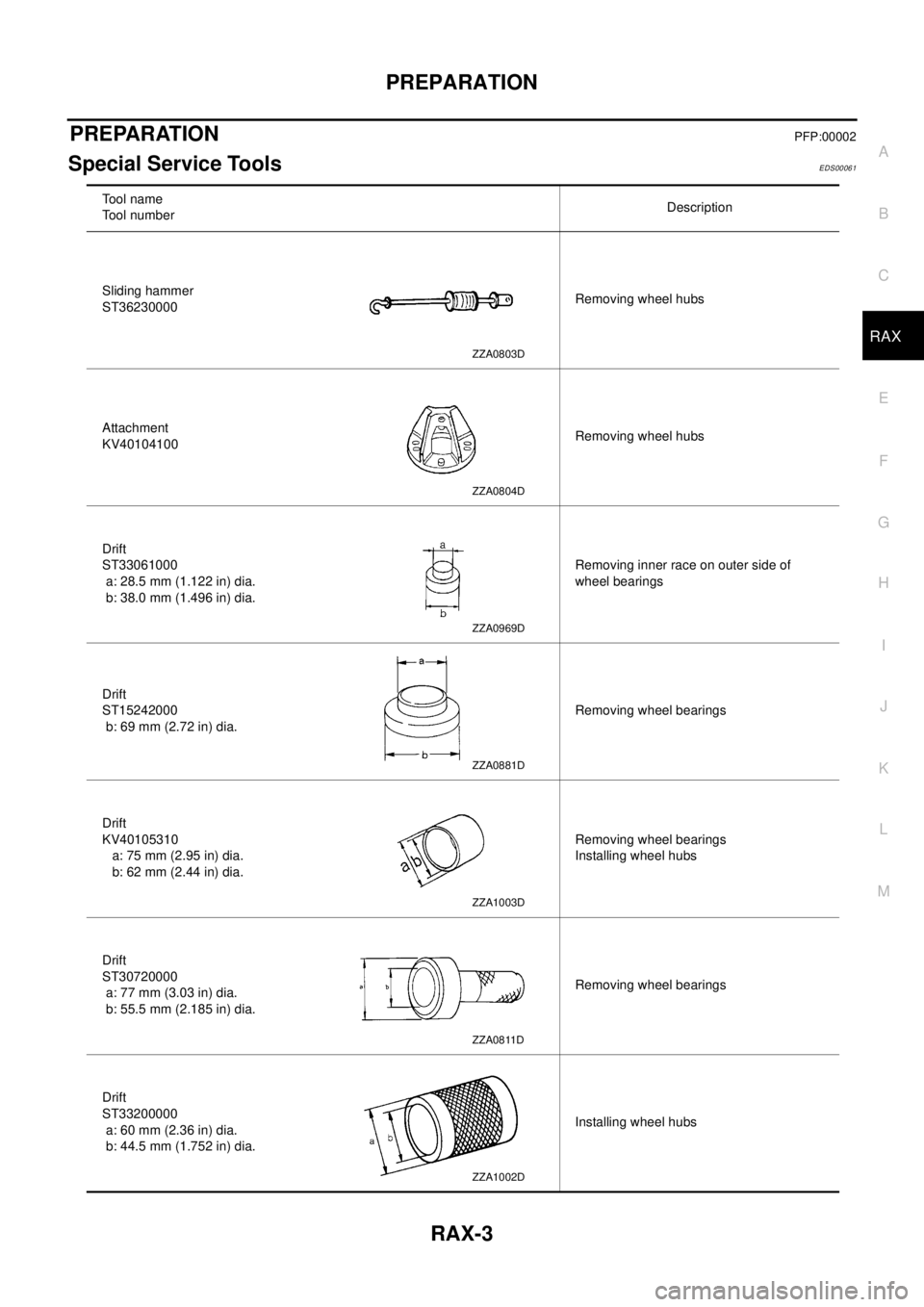

Special Service ToolsEDS00061

To o l n a m e

Tool numberDescription

Sliding hammer

ST36230000Removing wheel hubs

Attachment

KV40104100Removing wheel hubs

Drift

ST33061000

a: 28.5 mm (1.122 in) dia.

b: 38.0 mm (1.496 in) dia.Removing inner race on outer side of

wheel bearings

Drift

ST15242000

b: 69 mm (2.72 in) dia.Removing wheel bearings

Drift

KV40105310

a: 75 mm (2.95 in) dia.

b: 62 mm (2.44 in) dia.Removing wheel bearings

Installing wheel hubs

Drift

ST30720000

a: 77 mm (3.03 in) dia.

b: 55.5 mm (2.185 in) dia.Removing wheel bearings

Drift

ST33200000

a: 60 mm (2.36 in) dia.

b: 44.5 mm (1.752 in) dia.Installing wheel hubs

ZZA0803D

ZZA0804D

ZZA0969D

ZZA0881D

ZZA1003D

ZZA0811D

ZZA1002D

Page 2800 of 3066

RAX-4

PREPARATION

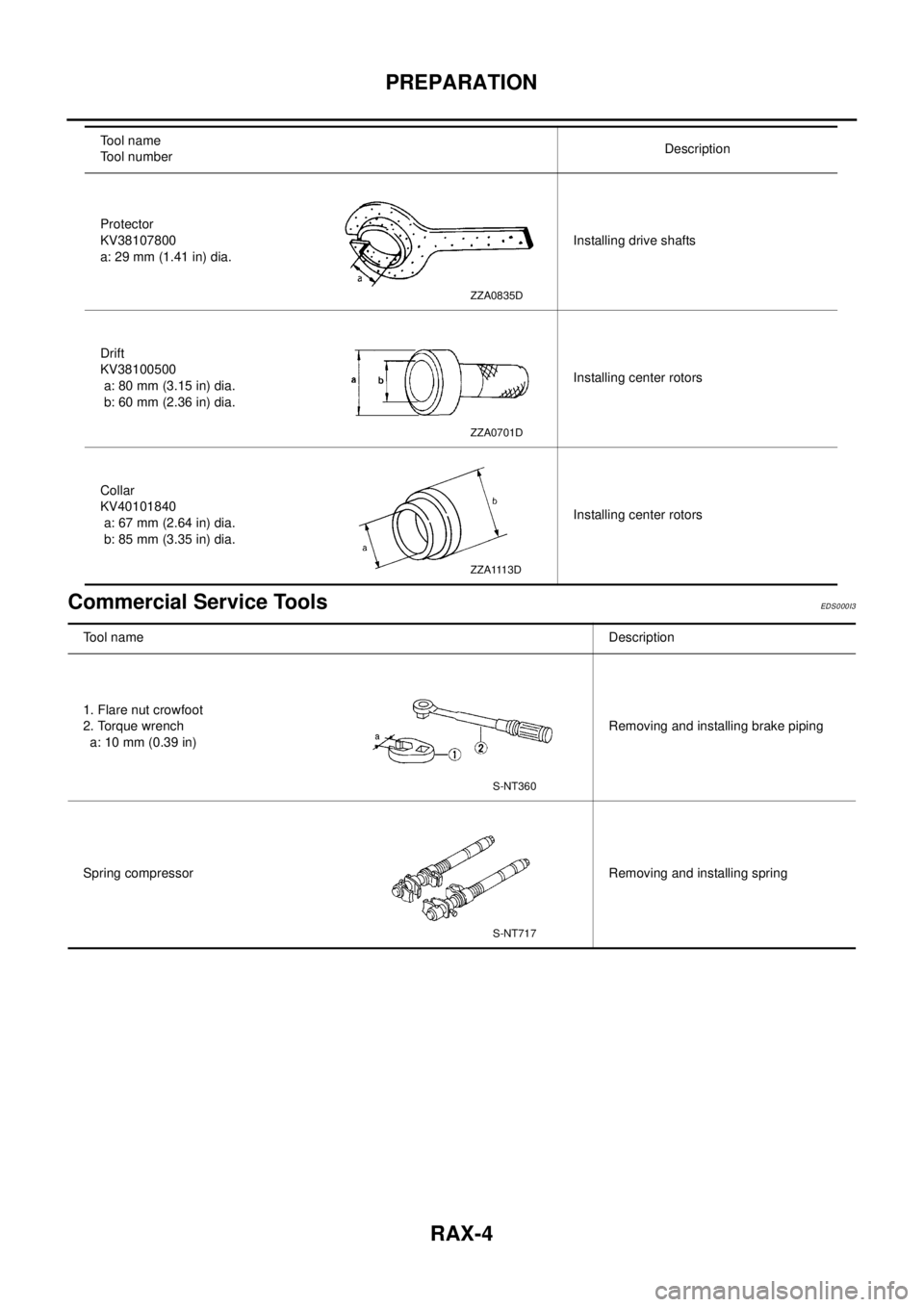

Commercial Service Tools

EDS0 00 I3

Protector

KV38107800

a: 29 mm (1.41 in) dia.Installing drive shafts

Drift

KV38100500

a: 80 mm (3.15 in) dia.

b: 60 mm (2.36 in) dia.Installing center rotors

Collar

KV40101840

a: 67 mm (2.64 in) dia.

b: 85 mm (3.35 in) dia.Installing center rotors Tool name

Tool numberDescription

ZZA0835D

ZZA0701D

ZZA1113D

Tool nameDescription

1. Flare nut crowfoot

2. Torque wrench

a: 10 mm (0.39 in)Removing and installing brake piping

Spring compressor Removing and installing spring

S-NT360

S-NT717