NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2761 of 3066

PS-1

POWER STEERING SYSTEM

G STEERING

CONTENTS

C

D

E

F

H

I

J

K

L

M

SECTION

A

B

PS

POWER STEERING SYSTEM

PRECAUTIONS .......................................................... 2

Precautions for models with SRS air bag and pre-

tensioner seat belt .................................................... 2

Caution ..................................................................... 2

PREPARATION ........................................................... 3

Special Service Tools ............................................... 3

NOISE, VIBRATION, AND HARSHNESS (NVH)

TROUBLESHOOTING ................................................ 4

NVH Trouble shooting Chart .................................... 4

POWER STEERING FLUID ........................................ 5

Checking Fluid Level ................................................ 5

Checking Fluid Leak ................................................. 5

Bleeding Hydraulic System ...................................... 5

STEERING WHEEL .................................................... 6

On-Vehicle Inspection and Service .......................... 6

PLAY INSPECTION .............................................. 6

NEUTRAL POSITION INSPECTION .................... 6

STEERING TORQUE CHECK .............................. 6

STEERING ANGLE INSPECTION ........................ 6

Removal and Installation .......................................... 7

REMOVAL ............................................................. 7

INSTALLATION ..................................................... 7

STEERING COLUMN ................................................. 9

Removal and Installation .......................................... 9

REMOVAL OF LOWER JOINT AND HOLE

COVER ................................................................. 9

INSTALLATION OF LOWER JOINT AND HOLE

COVER ................................................................. 9

REMOVAL OF STEERING COLUMN ASSEM-

BLY ........................................................................ 9

INSTALLING STEERING COLUMN ASSEMBLY... 10

Disassembly and Assembly ................................... 10

DISASSEMBLY ................................................... 10

INSPECTION AFTER DISASSEMBLY. ...............11

ASSEMBLY ..........................................................11

POWER STEERING GEAR AND LINKAGE ............ 12

Removal and Installation ........................................ 12

REMOVAL ........................................................... 12

INSTALLATION ................................................... 12Components ........................................................... 14

MODEL PR24AD ................................................. 14

Disassembly and Assembly .................................... 15

DISASSEMBLY ................................................... 15

PINION GEAR ROTATION TORQUE ADJUST-

MENT .................................................................. 16

INSPECTION AFTER DISASSEMBLY ................ 16

ASSEMBLY ......................................................... 17

POWER STEERING OIL PUMP ............................... 23

On-Vehicle Inspection and Service ......................... 23

OIL PUMP PULLEY HYDRAULIC PRESSURE

INSPECTION ...................................................... 23

Removal and Installation (QR20DE engine model)... 23

REMOVAL ........................................................... 23

INSTALLATION ................................................... 23

Disassembly and Assembly(QR20DE engine

model) ..................................................................... 24

INSPECTION BEFORE DISASSEMBLY ............. 24

DISASSEMBLY ................................................... 24

INSPECTION AFTER DISASSEMBLY ................ 25

ASSEMBLY ......................................................... 25

Removal and Installation (YD22DDTi engine

model) ..................................................................... 28

Disassembly and Assembly (YD22DDTi engine

model) ..................................................................... 29

INSPECTION BEFORE DISASSEMBLY ............. 29

DISASSEMBLY ................................................... 30

INSPECTION AFTER DISASSEMBLY ................ 31

ASSEMBLY ......................................................... 31

HYDRAULIC LINE .................................................... 33

Removal and Installation ........................................ 33

SERVICE DATA AND SPECIFICATIONS (SDS) ...... 35

Wheel ..................................................................... 35

Steering Angle ........................................................ 35

Steering Column ..................................................... 35

Steering Linkage ..................................................... 35

Steering Gear ......................................................... 36

Oil Pump ................................................................. 36

Steering Fluid .......................................................... 36

Page 2762 of 3066

PS-2

PRECAUTIONS

PRECAUTIONS

PFP:00001

Precautions for models with SRS air bag and pre-tensioner seat beltEGS00048

WAR NIN G:

lBefore removing and installing components and harnesses of SRS air bag and seat belt pre-ten-

sioner system, turn ignition switch OFF, disconnect battery ground cable, and wait at least 3 min-

utes. (This discharges electricity held in the air bag sensor unit's additional power circuit.)

lDo not use pneumatic or electric tools to remove and install the components.

lDo not solder SRS air bag and seat belt pre-tensioner system harnesses when making repairs.

Make sure harness is not pinched and there is no contact with other components.

lWhen checking the SRS air bag and the seat belt pre-tensioner circuit or the components of each

system, do not use an electric tester such as a circuit tester. (This is to prevent accidental trigger-

ing caused by the weak electric current of a tester.)

lNever insert foreign material (such as a screwdriver) in the air bag module and pre-tensioner seat

belt connectors. (The units may be actuated by mistake by static electricity.)

lSeat belt pre-tensioner and SRS air bag harnesses can be distinguished from other harnesses by

their yellow connectors.

lWhen servicing, refer to “SB Seat Belt” and “SRS Air Bag” for safety.

CautionEGS00049

lAlways follow the warnings and the cautions below in disassembly procedures:

–Work in a clean, dust-free place. No dust proof device is necessary.

–Clean outside of unit before disassembly.

–Clean parts to be disassembled. Be careful not to allow any dirt or other foreign materials to enter or con-

tact with parts.

–Assemble disassembled parts properly, following order shown in manual. If work has been suspended in

the middle of assembly, place a clean cover over parts. This will prevent them from being contaminated.

–Use paper towels when removing dirt and other foreign materials. Cloth shop towels can leave lint on

cleaned parts that might affect operation of parts.

–Clean disassembled parts (except rubber parts) with kerosene. Drain oil by blowing with air or absorbing

with shop papers.

–Before assembling, apply Nissan power steering fluid to O-rings and seals.

–Replace gaskets and O-rings with new ones. Be careful not to damage any O-rings, oil seals, and gaskets

during assembly.

lIf following part is scratched after disassembly of steering pump, replace applicable part: case, rear body,

side plate, pulley, rotor, vane, or flow control valve

lMark source of fluid leak with a white marker for identification.

lSeals and copper washers must not be reused.

Page 2763 of 3066

PREPARATION

PS-3

C

D

E

F

H

I

J

K

L

MA

B

PS

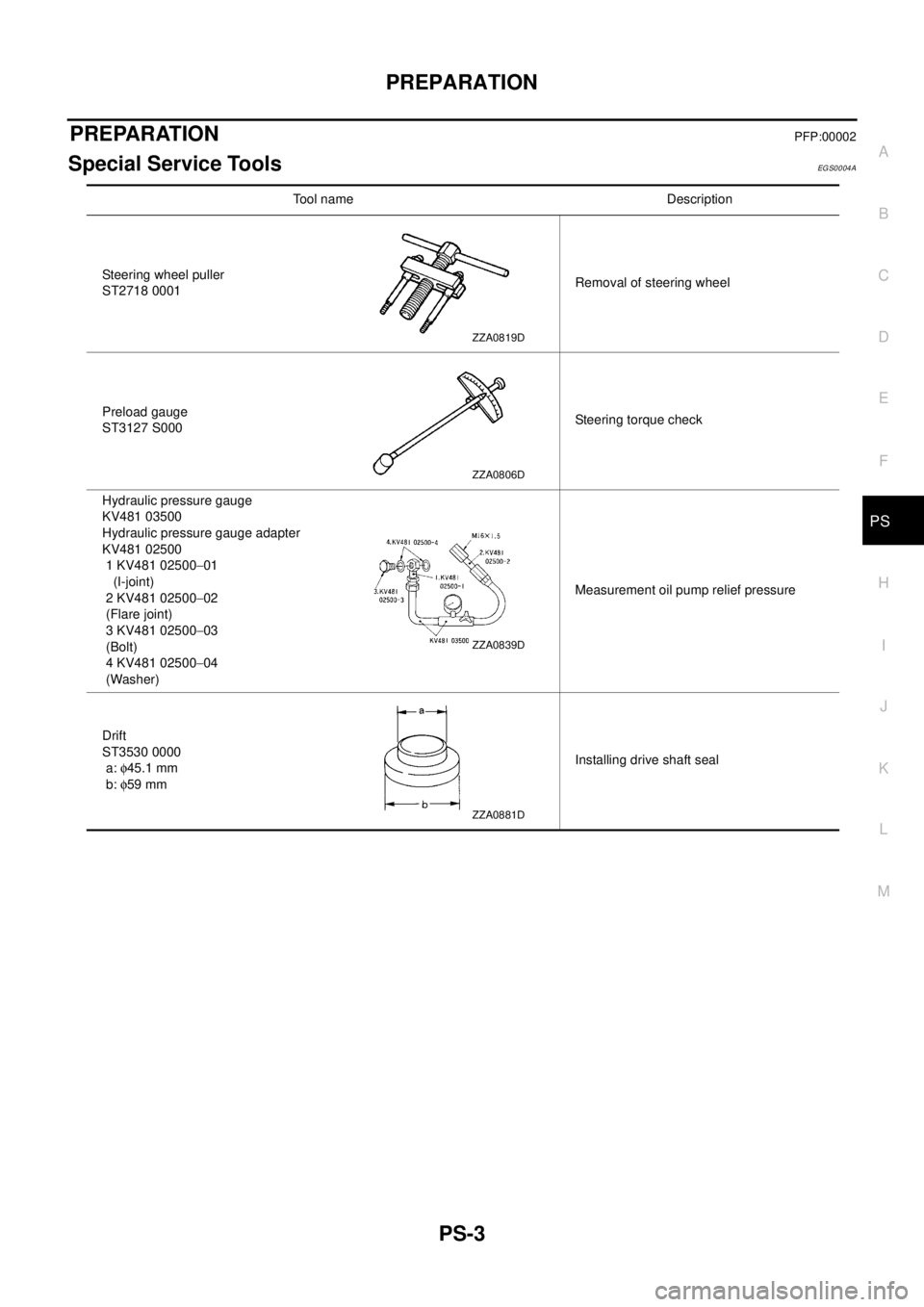

PREPARATIONPFP:00002

Special Service ToolsEGS0004A

Tool name Description

Steering wheel puller

ST2718 0001Removal of steering wheel

Preload gauge

ST3127 S000Steering torque check

Hydraulic pressure gauge

KV481 03500

Hydraulic pressure gauge adapter

KV481 02500

1 KV481 02500-01

(I-joint)

2 KV481 02500-02

(Flare joint)

3 KV481 02500-03

(Bolt)

4 KV481 02500-04

(Washer)Measurement oil pump relief pressure

Drift

ST3530 0000

a:f45.1 mm

b:f59 mmInstalling drive shaft seal

ZZA0819D

ZZA0806D

ZZA0839D

ZZA0881D

Page 2764 of 3066

PS-4

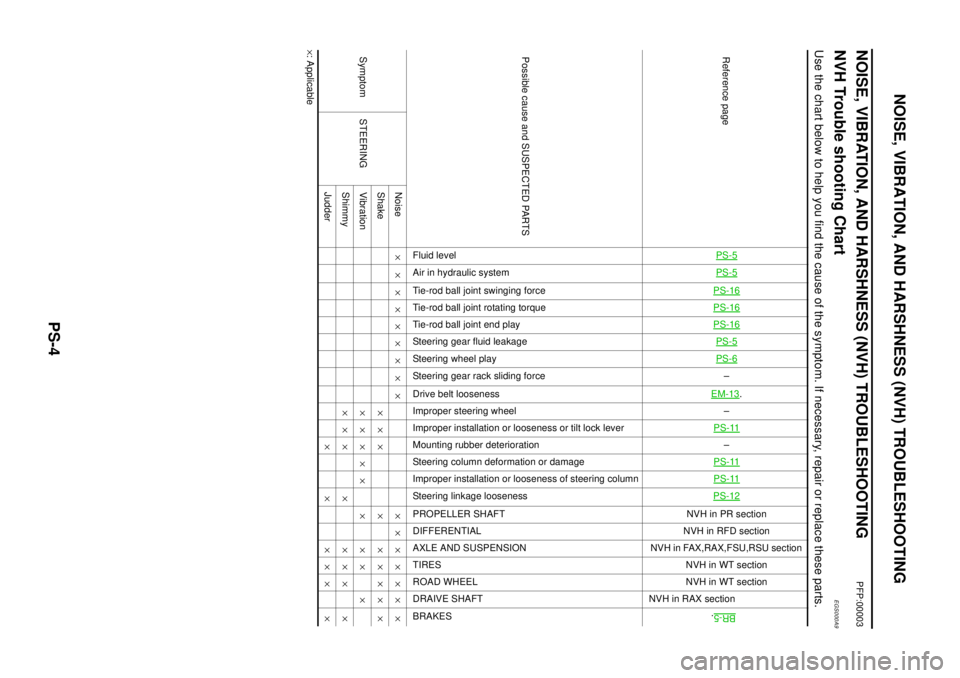

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

NOISE, VIBRATION, AND HARSHNESS (NVH) TROUBLESHOOTING

PFP:00003

NVH Trouble shooting ChartEGS000A9

Use the chart below to help you find the cause of the symptom. If necessary, repair or replace these parts.

´: ApplicableReference page

PS-5PS-5PS-16PS-16PS-16PS-5PS-6–

EM-13

.

–

PS-11

–

PS-11PS-11PS-12

NVHinPRsection

NVH in RFD section

NVH in FAX,RAX,FSU,RSU section

NVH in WT section

NVH in WT section

NVH in RAX section

BR-5

.

Possible cause and SUSPECTED PARTS

Fluid level

Air in hydraulic system

Tie-rod ball joint swinging force

Tie-rod ball joint rotating torque

Tie-rod ball joint end play

Steering gear fluid leakage

Steering wheel play

Steering gear rack sliding force

Drive belt looseness

Improper steering wheel

Improper installation or looseness or tilt lock lever

Mounting rubber deterioration

Steering column deformation or damage

Improper installation or looseness of steering column

Steering linkage looseness

PROPELLER SHAFT

DIFFERENTIAL

AXLE AND SUSPENSION

TIRES

ROAD WHEEL

DRAIVE SHAFT

BRAKES

Symptom STEERINGNoise´ ´ ´´´´´ ´ ´ ´´´´´´ ´

Shake´´´ ´ ´´´´ ´

Vibration´´´´´ ´ ´´ ´

Shimmy´´´ ´ ´´´ ´

Judder´ ´ ´´´ ´

Page 2765 of 3066

POWER STEERING FLUID

PS-5

C

D

E

F

H

I

J

K

L

MA

B

PS

POWER STEERING FLUIDPFP:KLF20

Checking Fluid LevelEGS0004B

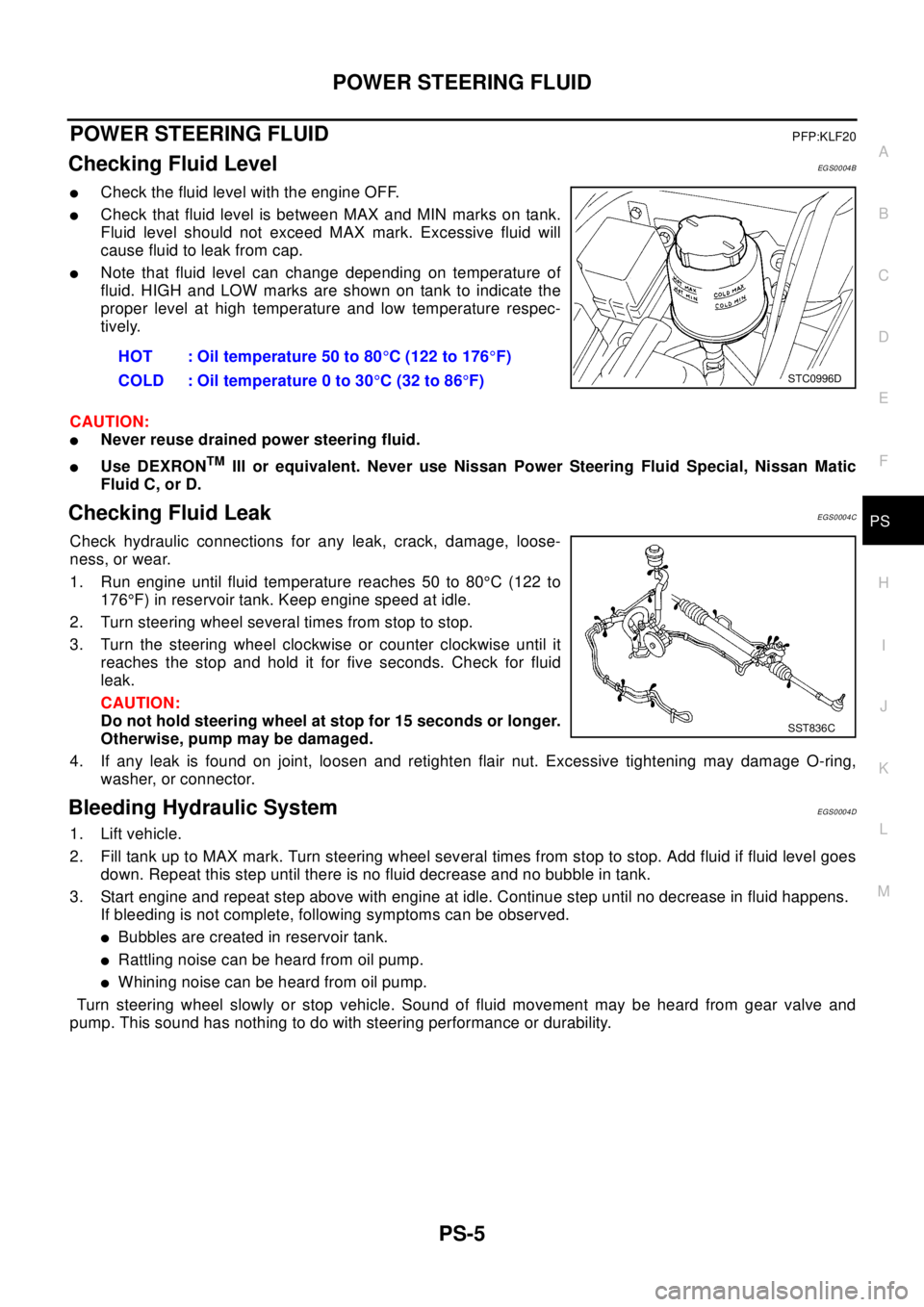

lCheck the fluid level with the engine OFF.

lCheck that fluid level is between MAX and MIN marks on tank.

Fluid level should not exceed MAX mark. Excessive fluid will

cause fluid to leak from cap.

lNote that fluid level can change depending on temperature of

fluid. HIGH and LOW marks are shown on tank to indicate the

proper level at high temperature and low temperature respec-

tively.

CAUTION:

lNever reuse drained power steering fluid.

lUse DEXRONTMIII or equivalent. Never use Nissan Power Steering Fluid Special, Nissan Matic

Fluid C, or D.

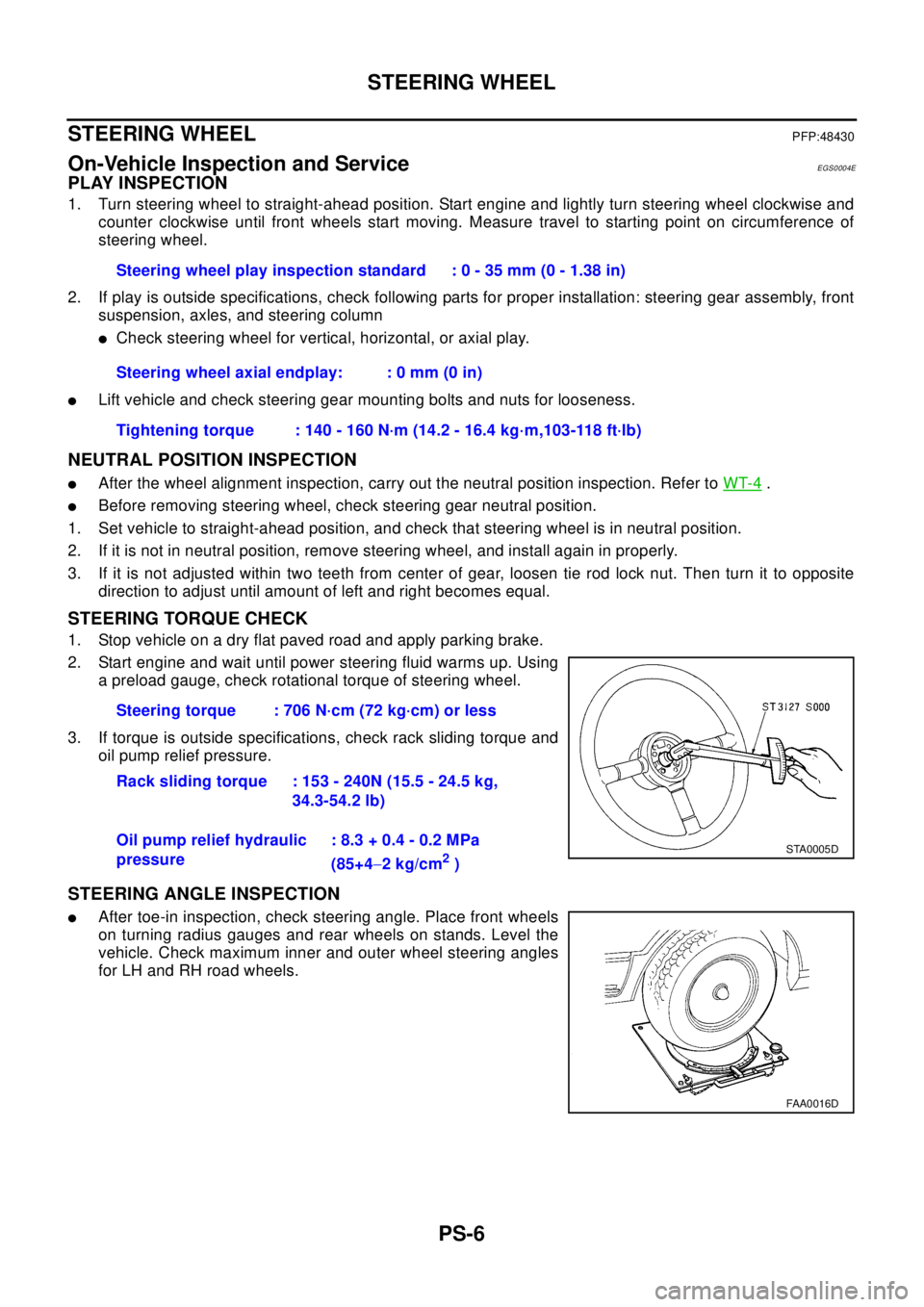

Checking Fluid LeakEGS0004C

Check hydraulic connections for any leak, crack, damage, loose-

ness, or wear.

1. Run engine until fluid temperature reaches 50 to 80°C (122 to

176°F) in reservoir tank. Keep engine speed at idle.

2. Turn steering wheel several times from stop to stop.

3. Turn the steering wheel clockwise or counter clockwise until it

reaches the stop and hold it for five seconds. Check for fluid

leak.

CAUTION:

Do not hold steering wheel at stop for 15 seconds or longer.

Otherwise, pump may be damaged.

4. If any leak is found on joint, loosen and retighten flair nut. Excessive tightening may damage O-ring,

washer, or connector.

Bleeding Hydraulic SystemEGS0004D

1. Lift vehicle.

2. Fill tank up to MAX mark. Turn steering wheel several times from stop to stop. Add fluid if fluid level goes

down. Repeat this step until there is no fluid decrease and no bubble in tank.

3. Start engine and repeat step above with engine at idle. Continue step until no decrease in fluid happens.

If bleeding is not complete, following symptoms can be observed.

lBubbles are created in reservoir tank.

lRattling noise can be heard from oil pump.

lWhiningnoisecanbeheardfromoilpump.

Turn steering wheel slowly or stop vehicle. Sound of fluid movement may be heard from gear valve and

pump. This sound has nothing to do with steering performance or durability.HOT : Oil temperature 50 to 80°C (122 to 176°F)

COLD : Oil temperature 0 to 30°C(32to86°F)

STC0996D

SST836C

Page 2766 of 3066

PS-6

STEERING WHEEL

STEERING WHEEL

PFP:48430

On-Vehicle Inspection and ServiceEGS0004E

PLAY INSPECTION

1. Turn steering wheel to straight-ahead position. Start engine and lightly turn steering wheel clockwise and

counter clockwise until front wheels start moving. Measure travel to starting point on circumference of

steering wheel.

2. If play is outside specifications, check following parts for proper installation: steering gear assembly, front

suspension, axles, and steering column

lCheck steering wheel for vertical, horizontal, or axial play.

lLift vehicle and check steering gear mounting bolts and nuts for looseness.

NEUTRAL POSITION INSPECTION

lAfter the wheel alignment inspection, carry out the neutral position inspection. Refer toWT-4.

lBefore removing steering wheel, check steering gear neutral position.

1. Set vehicle to straight-ahead position, and check that steering wheel is in neutral position.

2. If it is not in neutral position, remove steering wheel, and install again in properly.

3. If it is not adjusted within two teeth from center of gear, loosen tie rod lock nut. Then turn it to opposite

direction to adjust until amount of left and right becomes equal.

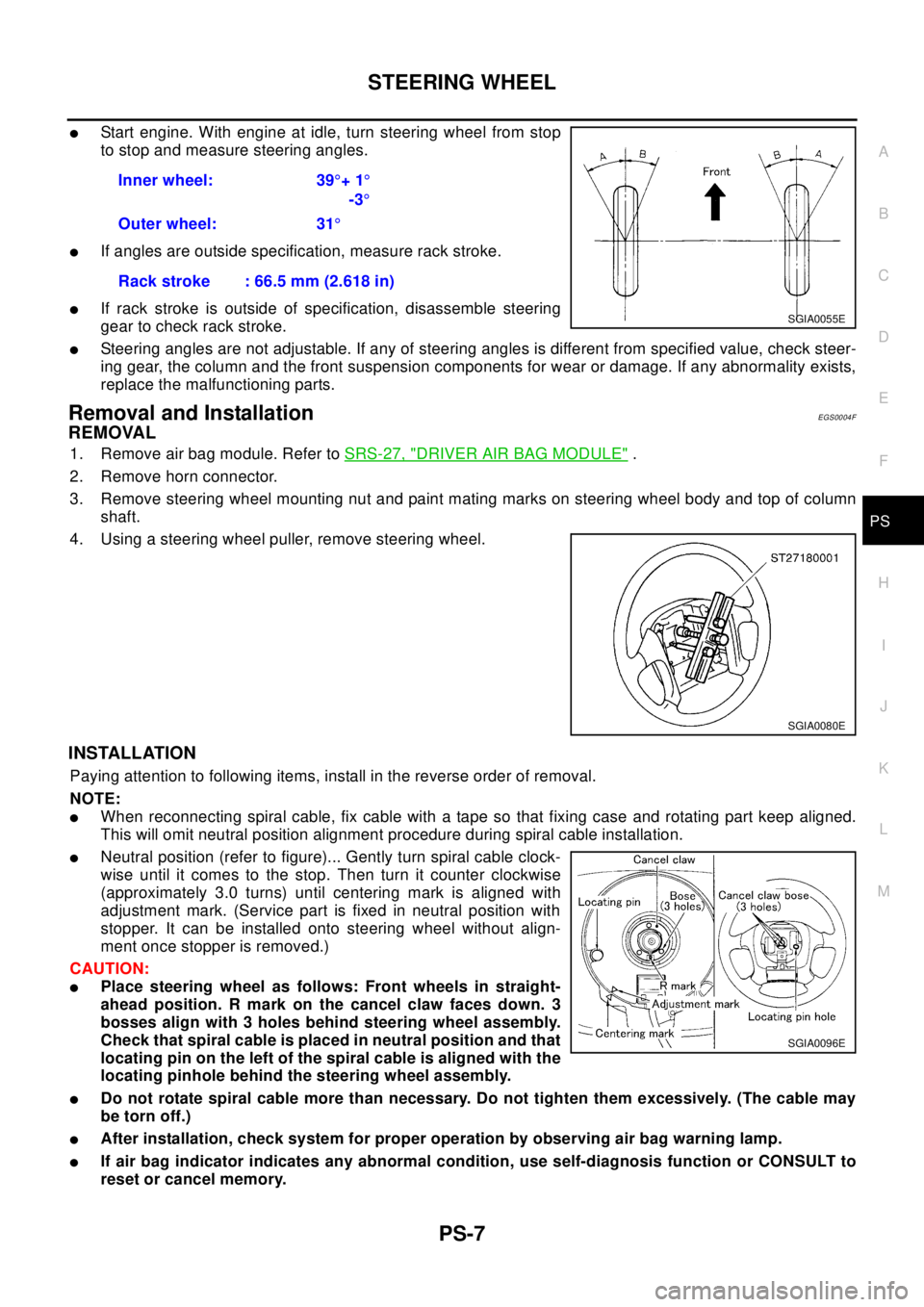

STEERING TORQUE CHECK

1. Stop vehicle on a dry flat paved road and apply parking brake.

2. Start engine and wait until power steering fluid warms up. Using

a preload gauge, check rotational torque of steering wheel.

3. If torque is outside specifications, check rack sliding torque and

oil pump relief pressure.

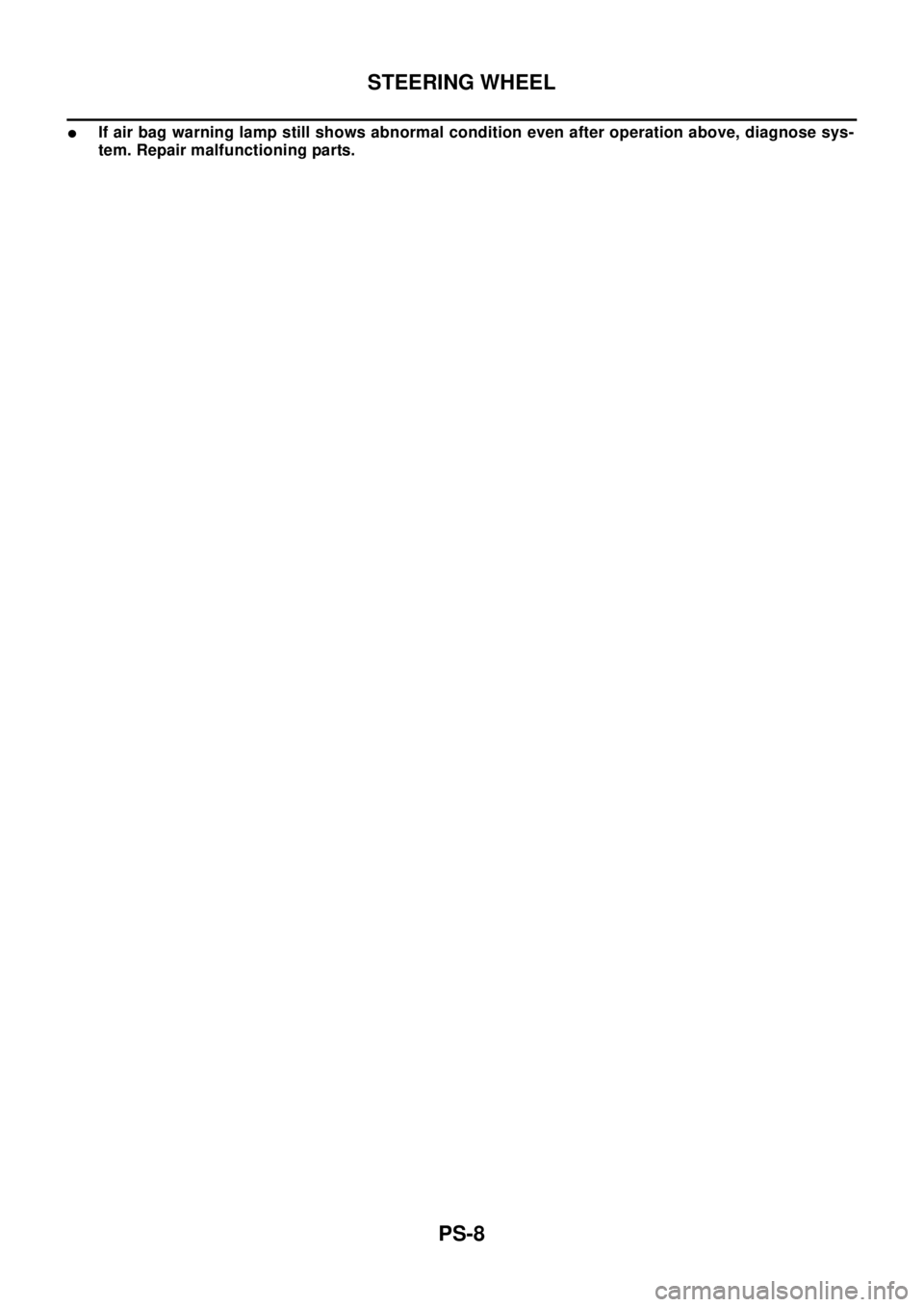

STEERING ANGLE INSPECTION

lAfter toe-in inspection, check steering angle. Place front wheels

on turning radius gauges and rear wheels on stands. Level the

vehicle. Check maximum inner and outer wheel steering angles

for LH and RH road wheels.Steering wheel play inspection standard : 0 - 35 mm (0 - 1.38 in)

Steering wheel axial endplay: : 0 mm (0 in)

Tightening torque : 140 - 160 N·m (14.2 - 16.4 kg·m,103-118 ft·lb)

Steering torque : 706 N·cm (72 kg·cm) or less

Rack sliding torque : 153 - 240N (15.5 - 24.5 kg,

34.3-54.2 lb)

Oil pump relief hydraulic

pressure: 8.3 + 0.4 - 0.2 MPa

(85+4-2kg/cm

2)

STA0005D

FAA0016D

Page 2767 of 3066

STEERING WHEEL

PS-7

C

D

E

F

H

I

J

K

L

MA

B

PS

lStart engine. With engine at idle, turn steering wheel from stop

to stop and measure steering angles.

lIf angles are outside specification, measure rack stroke.

lIf rack stroke is outside of specification, disassemble steering

gear to check rack stroke.

lSteering angles are not adjustable. If any of steering angles is different from specified value, check steer-

ing gear, the column and the front suspension components for wear or damage. If any abnormality exists,

replace the malfunctioning parts.

Removal and InstallationEGS0004F

REMOVAL

1. Remove air bag module. Refer toSRS-27, "DRIVER AIR BAG MODULE".

2. Remove horn connector.

3. Remove steering wheel mounting nut and paint mating marks on steering wheel body and top of column

shaft.

4. Using a steering wheel puller, remove steering wheel.

INSTALLATION

Paying attention to following items, install in the reverse order of removal.

NOTE:

lWhen reconnecting spiral cable, fix cable with a tape so that fixing case and rotating part keep aligned.

This will omit neutral position alignment procedure during spiral cable installation.

lNeutral position (refer to figure)... Gently turn spiral cable clock-

wise until it comes to the stop. Then turn it counter clockwise

(approximately 3.0 turns) until centering mark is aligned with

adjustment mark. (Service part is fixed in neutral position with

stopper. It can be installed onto steering wheel without align-

ment once stopper is removed.)

CAUTION:

lPlace steering wheel as follows: Front wheels in straight-

ahead position. R mark on the cancel claw faces down. 3

bosses align with 3 holes behind steering wheel assembly.

Check that spiral cable is placed in neutral position and that

locating pin on the left of the spiral cable is aligned with the

locating pinhole behind the steering wheel assembly.

lDo not rotate spiral cable more than necessary. Do not tighten them excessively. (The cable may

be torn off.)

lAfter installation, check system for proper operation by observing air bag warning lamp.

lIf air bag indicator indicates any abnormal condition, use self-diagnosis function or CONSULT to

reset or cancel memory.Inner wheel: 39°+1°

-3°

Outer wheel: 31°

Rack stroke : 66.5 mm (2.618 in)

SGIA0055E

SGIA0080E

SGIA0096E

Page 2768 of 3066

PS-8

STEERING WHEEL

lIf air bag warning lamp still shows abnormal condition even after operation above, diagnose sys-

tem. Repair malfunctioning parts.

Page 2769 of 3066

STEERING COLUMN

PS-9

C

D

E

F

H

I

J

K

L

MA

B

PS

STEERING COLUMNPFP:48810

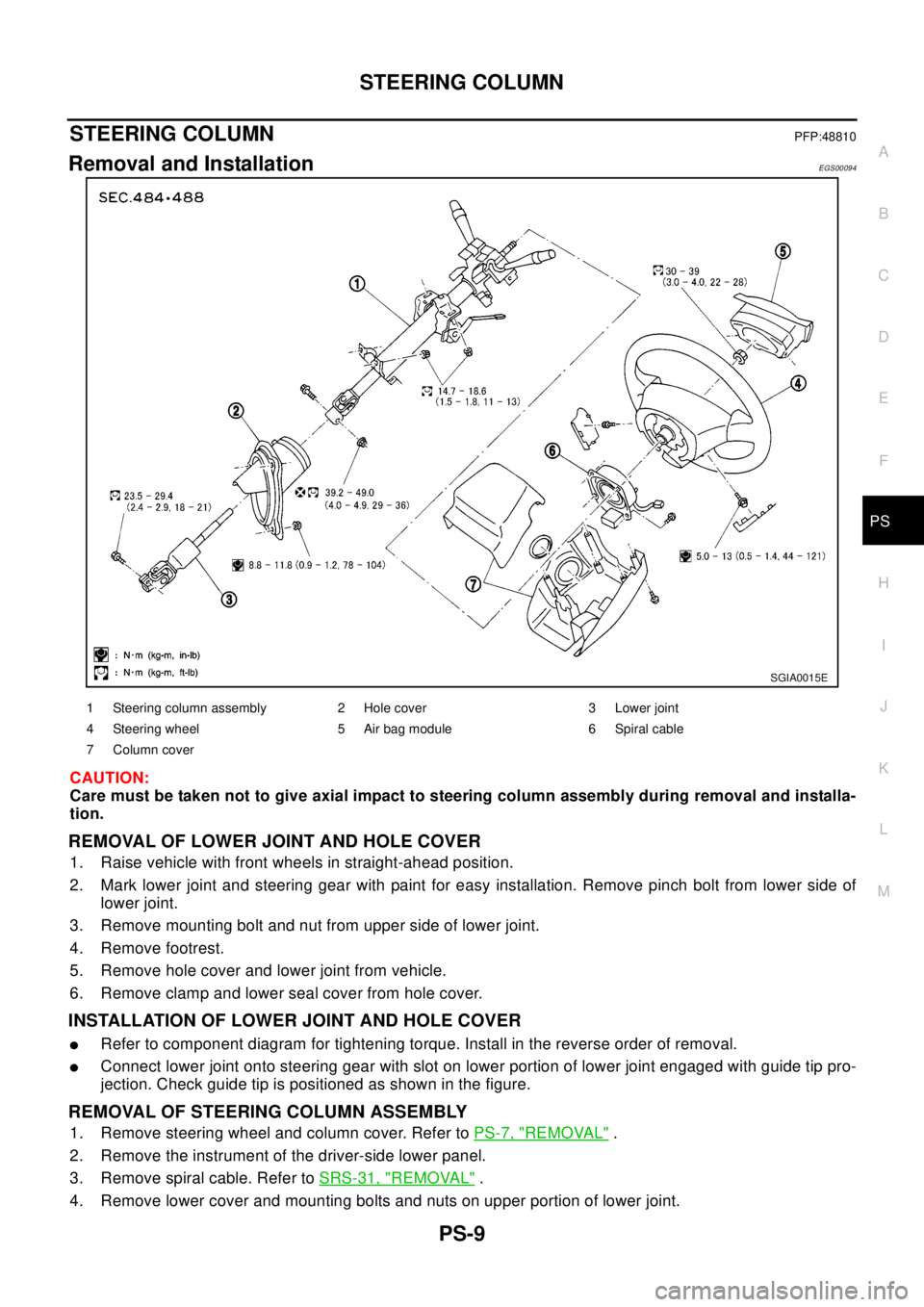

Removal and InstallationEGS00094

CAUTION:

Care must be taken not to give axial impact to steering column assembly during removal and installa-

tion.

REMOVAL OF LOWER JOINT AND HOLE COVER

1. Raise vehicle with front wheels in straight-ahead position.

2. Mark lower joint and steering gear with paint for easy installation. Remove pinch bolt from lower side of

lower joint.

3. Remove mounting bolt and nut from upper side of lower joint.

4. Remove footrest.

5. Remove hole cover and lower joint from vehicle.

6. Remove clamp and lower seal cover from hole cover.

INSTALLATION OF LOWER JOINT AND HOLE COVER

lRefer to component diagram for tightening torque. Install in the reverse order of removal.

lConnect lower joint onto steering gear with slot on lower portion of lower joint engaged with guide tip pro-

jection. Check guide tip is positioned as shown in the figure.

REMOVAL OF STEERING COLUMN ASSEMBLY

1. Remove steering wheel and column cover. Refer toPS-7, "REMOVAL".

2. Remove the instrument of the driver-side lower panel.

3. Remove spiral cable. Refer toSRS-31, "

REMOVAL".

4. Remove lower cover and mounting bolts and nuts on upper portion of lower joint.

SGIA0015E

1 Steering column assembly 2 Hole cover 3 Lower joint

4 Steering wheel 5 Air bag module 6 Spiral cable

7 Column cover

Page 2770 of 3066

PS-10

STEERING COLUMN

5. Remove the key interlock cable from the steering column assembly. Refer toAT- 4 5 2 , "Removal".

6. Remove clamp and connector from steering column assembly.

7. Remove steering column assembly mounting nut and remove steering column assembly from vehicle.

CAUTION:

Do not deform lower bracket on steering column assembly during removal or installation.

INSTALLING STEERING COLUMN ASSEMBLY

lInstallation procedure should be used with steering lock unlocked.

1. Position on steering column assembly, and install steering column assembly to vehicle with mounting

nuts.

2. Attach mounting bolts and nuts on upper portion of lower joint.

CAUTION:

Do not reuse mounting nuts.

3. Connect clamp and connector.

4. Connect key interlock cable to steering column assembly. Refer toAT-453, "

Installation"

5. Connect spiral cable. Refer toSRS-32, "INSTALLATION".

6. Install instrument lower driver panel.

7. Install steering wheel and column cover. Refer toPS-7, "

INSTALLATION".

CAUTION:

After installation, turn steering wheel. Be sure it turns smoothly with no disinterred condition,

binding, noise or excessive steering effort.

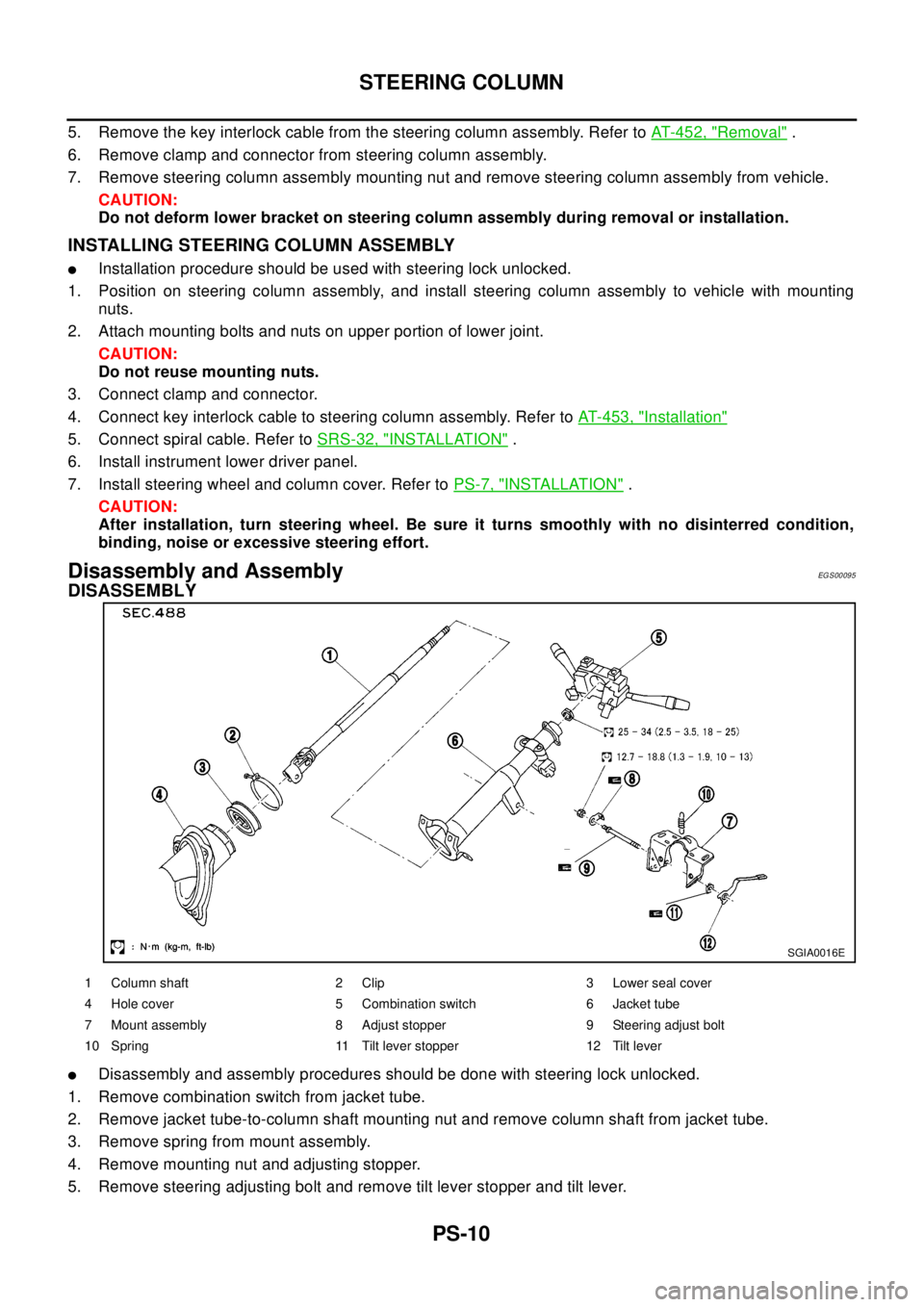

Disassembly and AssemblyEGS00095

DISASSEMBLY

lDisassembly and assembly procedures should be done with steering lock unlocked.

1. Remove combination switch from jacket tube.

2. Remove jacket tube-to-column shaft mounting nut and remove column shaft from jacket tube.

3. Remove spring from mount assembly.

4. Remove mounting nut and adjusting stopper.

5. Remove steering adjusting bolt and remove tilt lever stopper and tilt lever.

SGIA0016E

1 Column shaft 2 Clip 3 Lower seal cover

4 Hole cover 5 Combination switch 6 Jacket tube

7 Mount assembly 8 Adjust stopper 9 Steering adjust bolt

10 Spring 11 Tilt lever stopper 12 Tilt lever