NISSAN X-TRAIL 2003 Electronic Repair Manual

X-TRAIL 2003

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57402/w960_57402-0.png

NISSAN X-TRAIL 2003 Electronic Repair Manual

Trending: fuse chart, coolant temperature, clock reset, heating, fuel cap release, air conditioning, steering

Page 2891 of 3066

CHARGING SYSTEM

SC-19

C

D

E

F

G

H

I

J

L

MA

B

SC

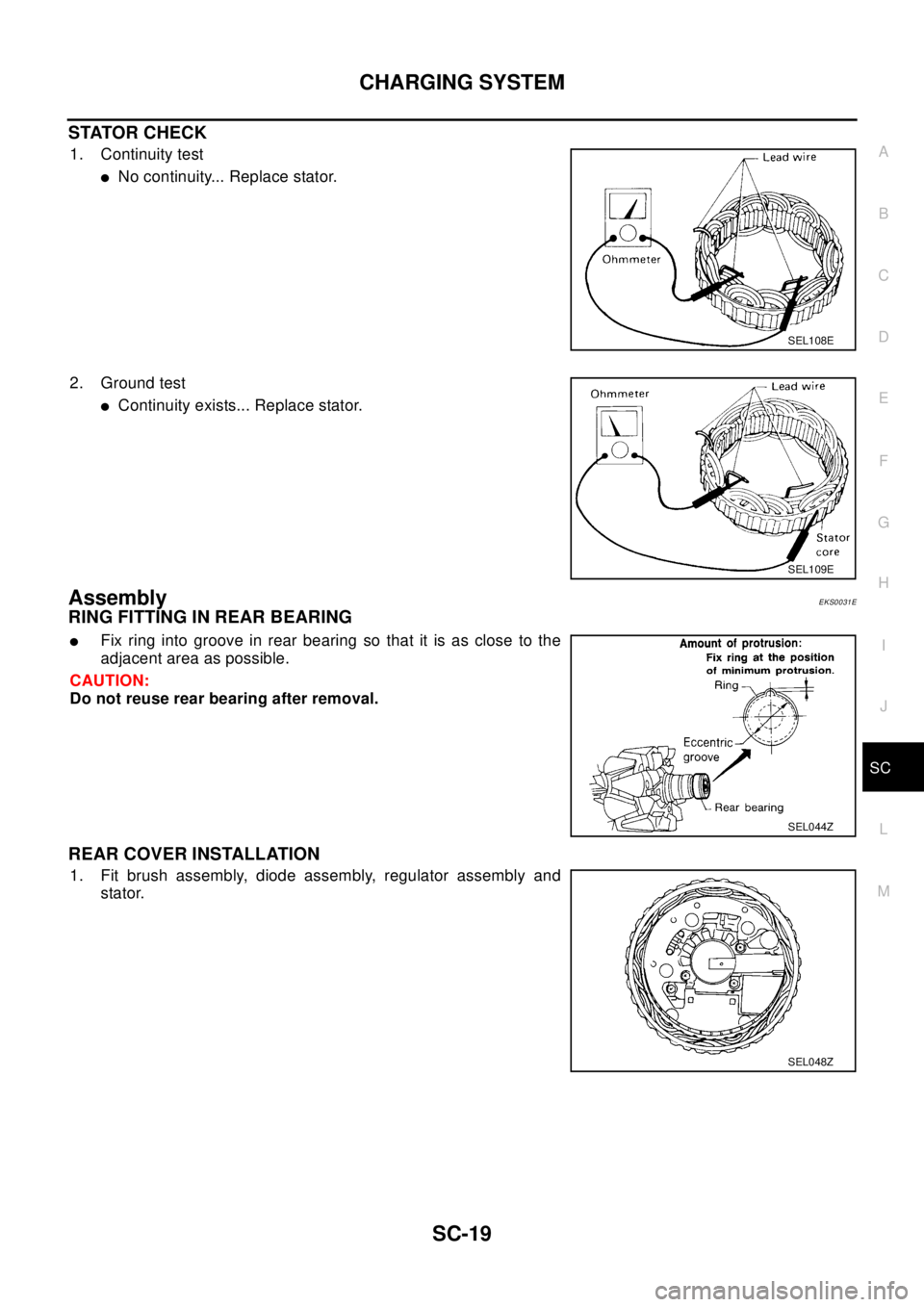

STATOR CHECK

1. Continuity test

lNo continuity... Replace stator.

2. Ground test

lContinuity exists... Replace stator.

AssemblyEKS0031E

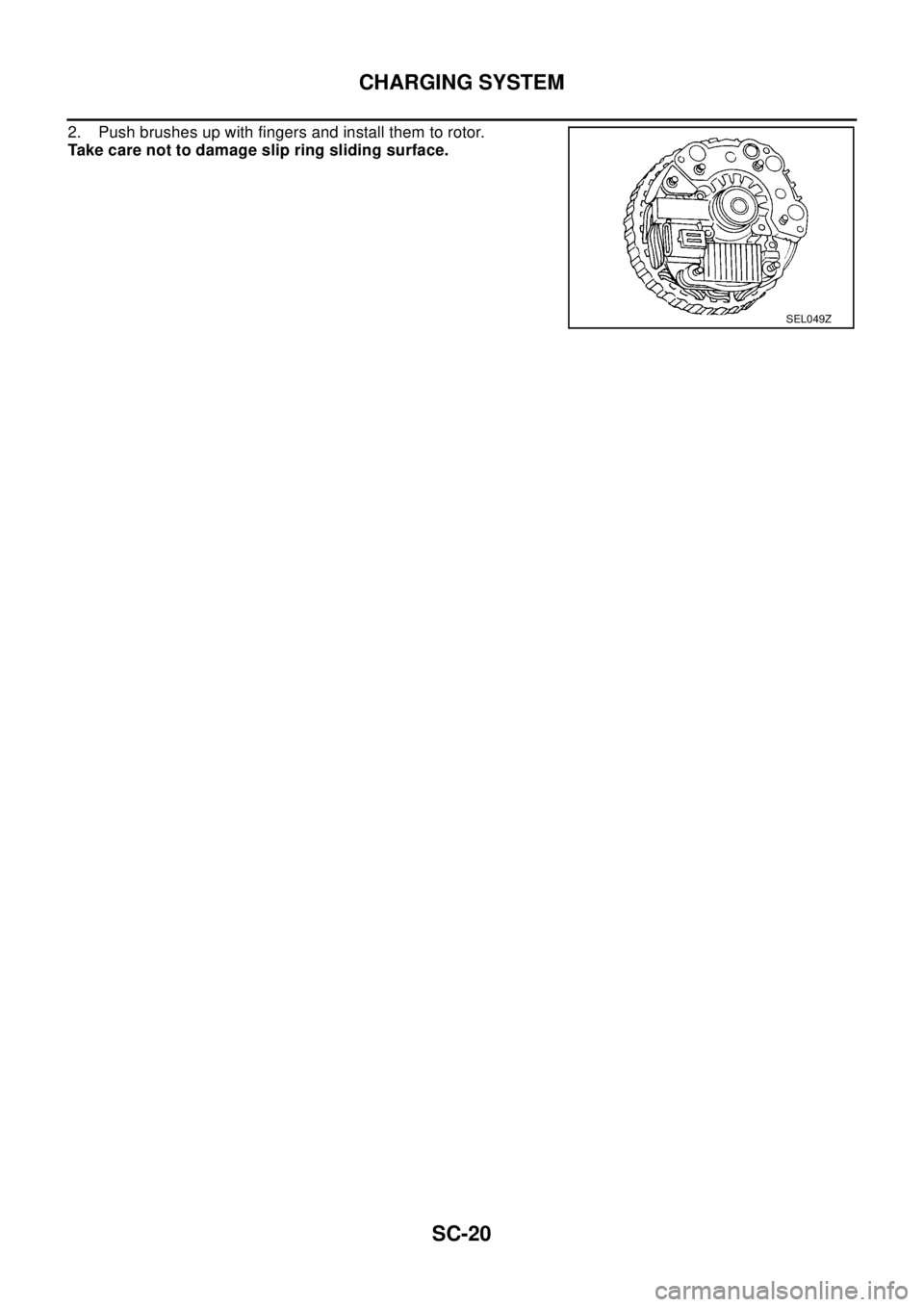

RING FITTING IN REAR BEARING

lFix ring into groove in rear bearing so that it is as close to the

adjacent area as possible.

CAUTION:

Do not reuse rear bearing after removal.

REAR COVER INSTALLATION

1. Fit brush assembly, diode assembly, regulator assembly and

stator.

SEL108E

SEL109E

SEL044Z

SEL048Z

Page 2892 of 3066

SC-20

CHARGING SYSTEM

2. Push brushes up with fingers and install them to rotor.

Take care not to damage slip ring sliding surface.

SEL049Z

Page 2893 of 3066

STARTING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

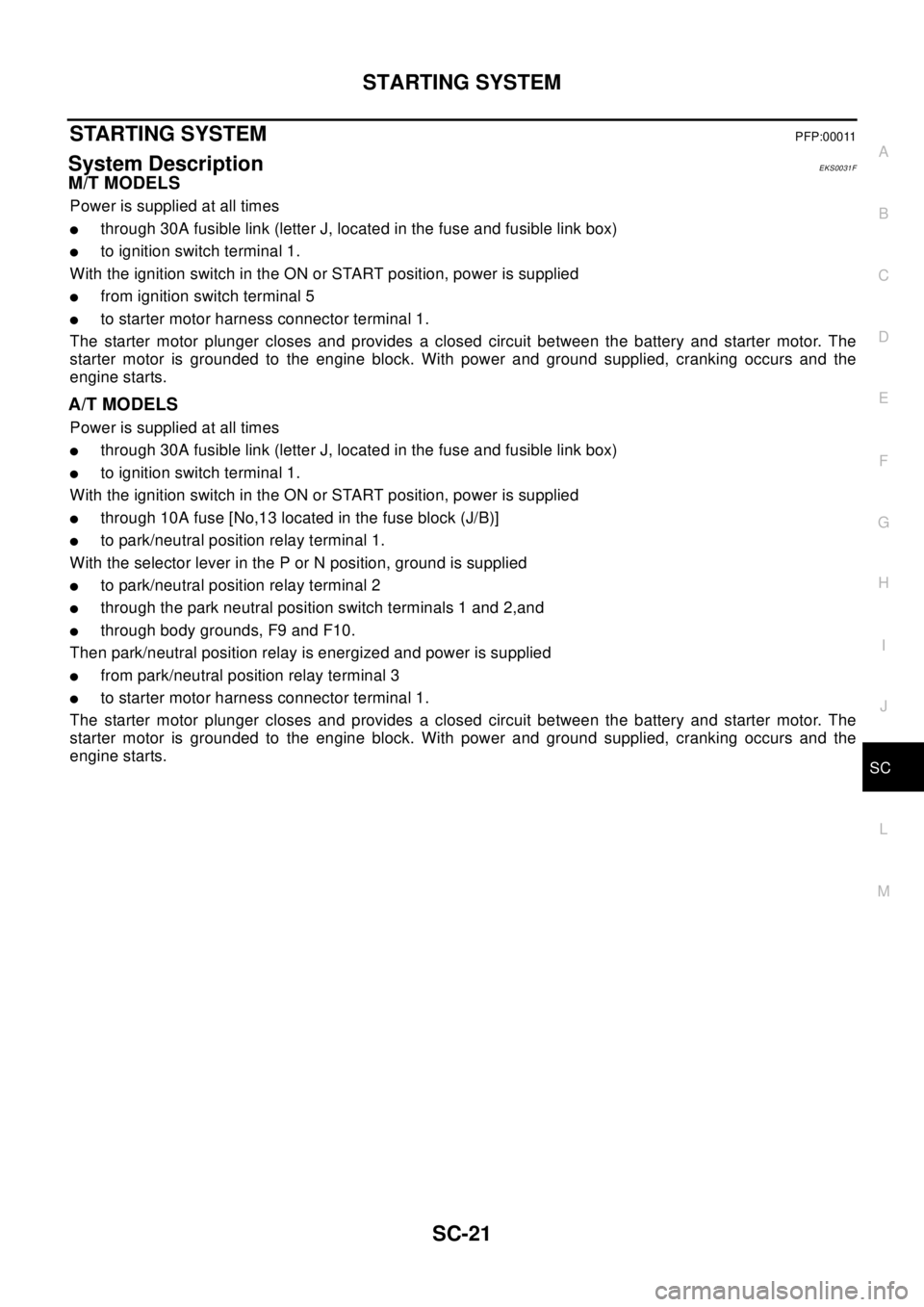

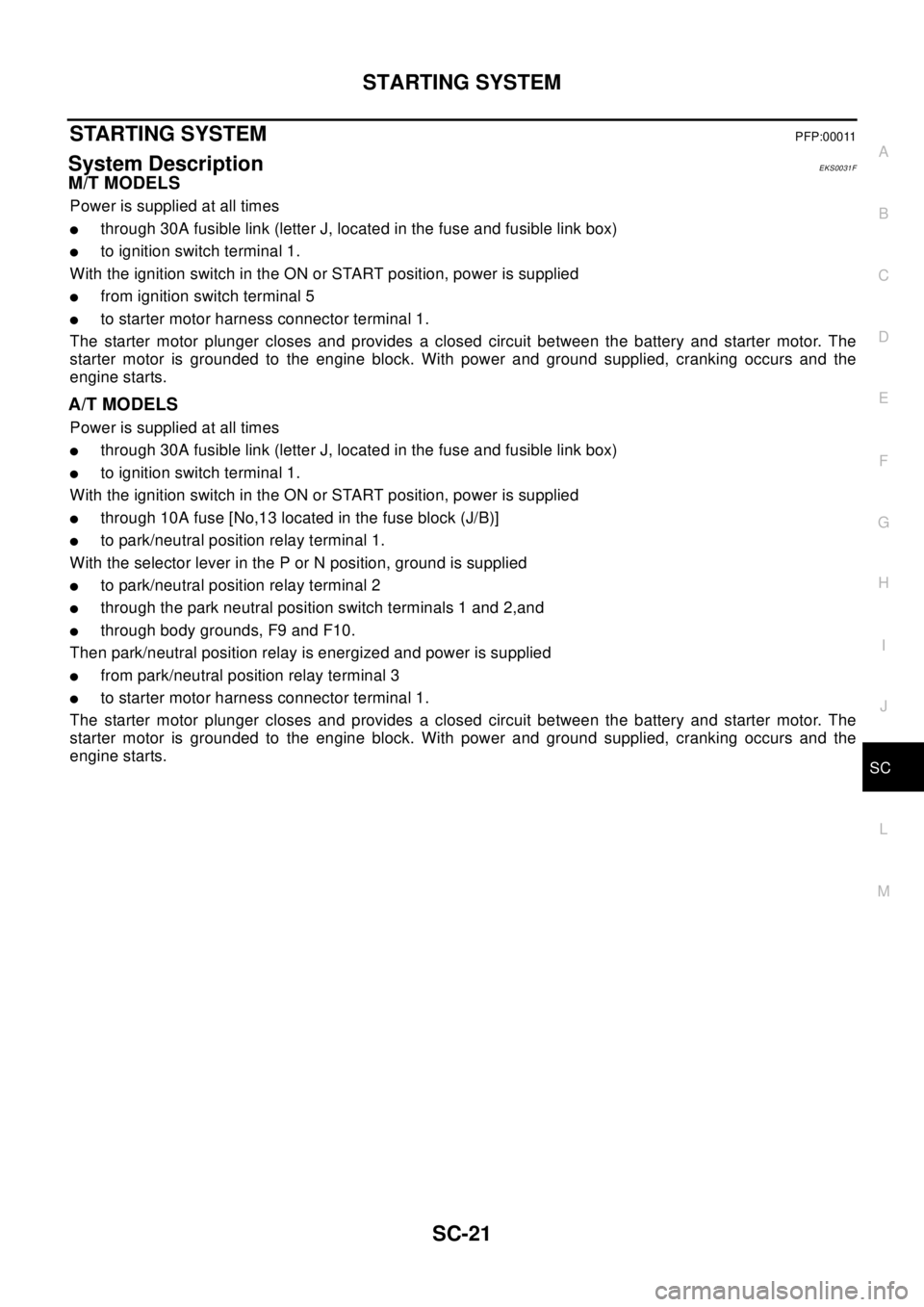

STARTING SYSTEMPFP:00011

System DescriptionEKS0031F

M/T MODELS

Power is supplied at all times

lthrough 30A fusible link (letter J, located in the fuse and fusible link box)

lto ignition switch terminal 1.

With the ignition switch in the ON or START position, power is supplied

lfrom ignition switch terminal 5

lto starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

A/T MODELS

Power is supplied at all times

lthrough 30A fusible link (letter J, located in the fuse and fusible link box)

lto ignition switch terminal 1.

With the ignition switch in the ON or START position, power is supplied

lthrough 10A fuse [No,13 located in the fuse block (J/B)]

lto park/neutral position relay terminal 1.

With the selector lever in the P or N position, ground is supplied

lto park/neutral position relay terminal 2

lthrough the park neutral position switch terminals 1 and 2,and

lthrough body grounds, F9 and F10.

Then park/neutral position relay is energized and power is supplied

lfrom park/neutral position relay terminal 3

lto starter motor harness connector terminal 1.

The starter motor plunger closes and provides a closed circuit between the battery and starter motor. The

starter motor is grounded to the engine block. With power and ground supplied, cranking occurs and the

engine starts.

Page 2894 of 3066

SC-22

STARTING SYSTEM

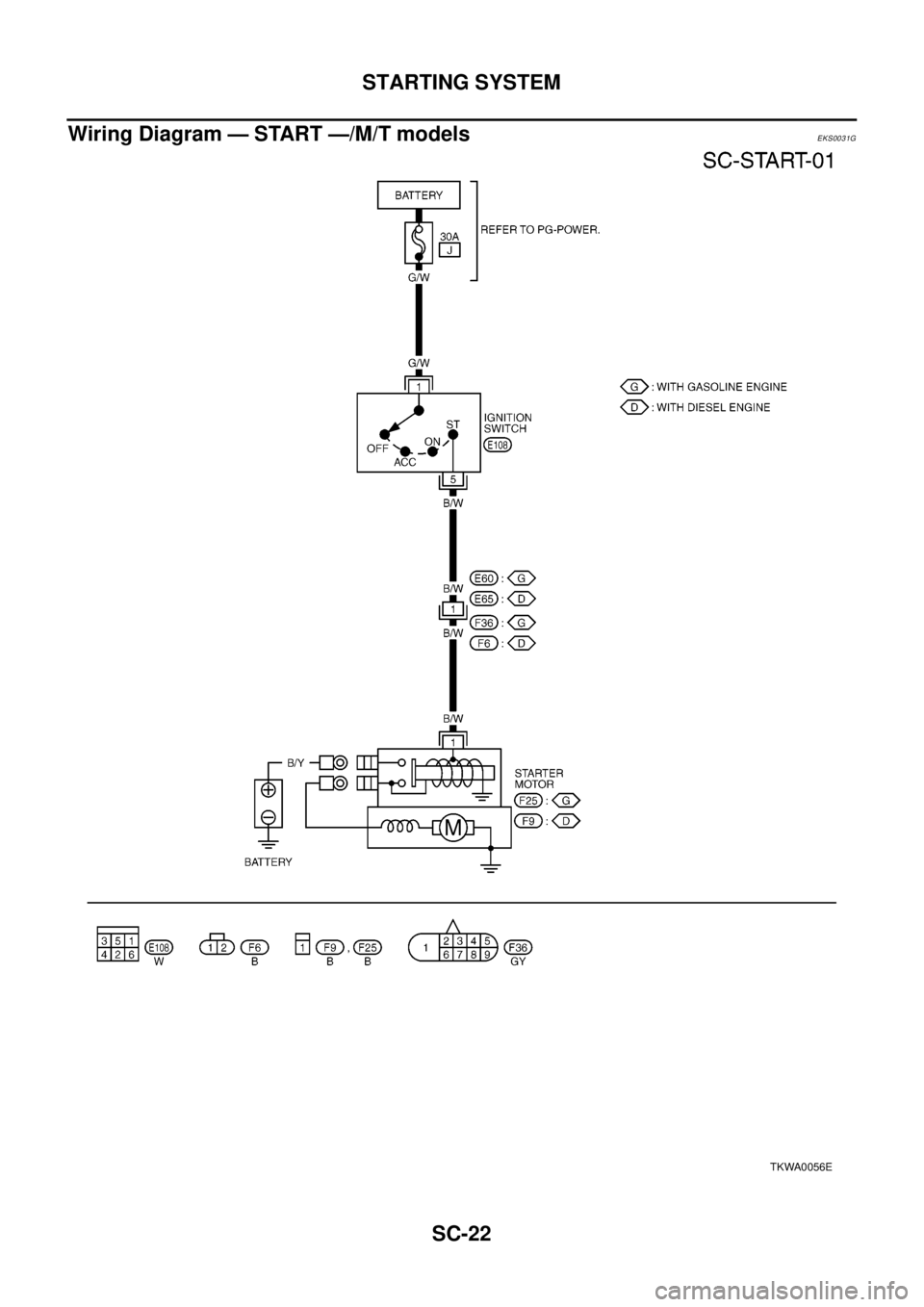

Wiring Diagram — START —/M/T models

EKS0031G

TKWA0056E

Page 2895 of 3066

STARTING SYSTEM

SC-23

C

D

E

F

G

H

I

J

L

MA

B

SC

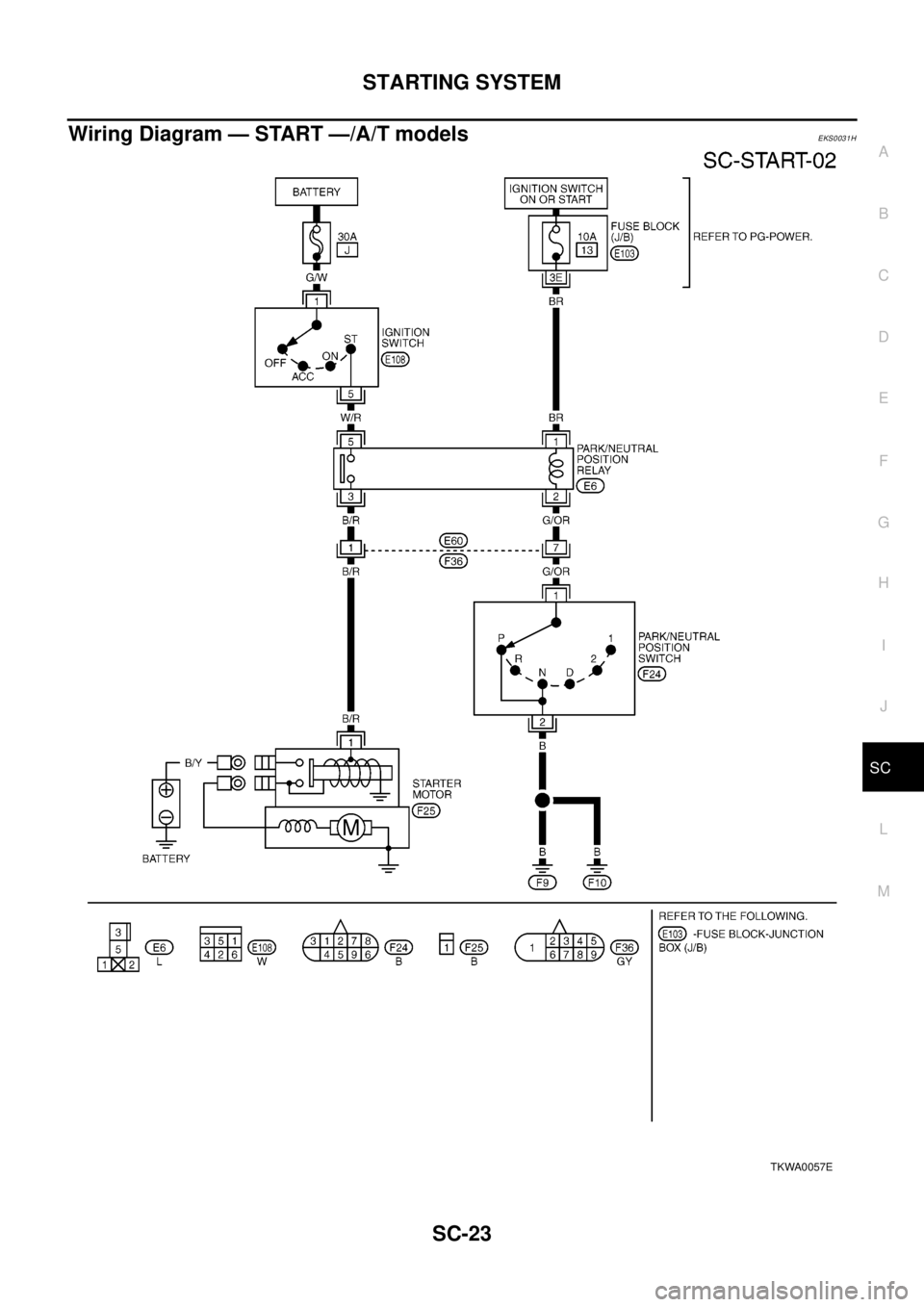

Wiring Diagram — START —/A/T modelsEKS0031H

TKWA0057E

Page 2896 of 3066

SC-24

STARTING SYSTEM

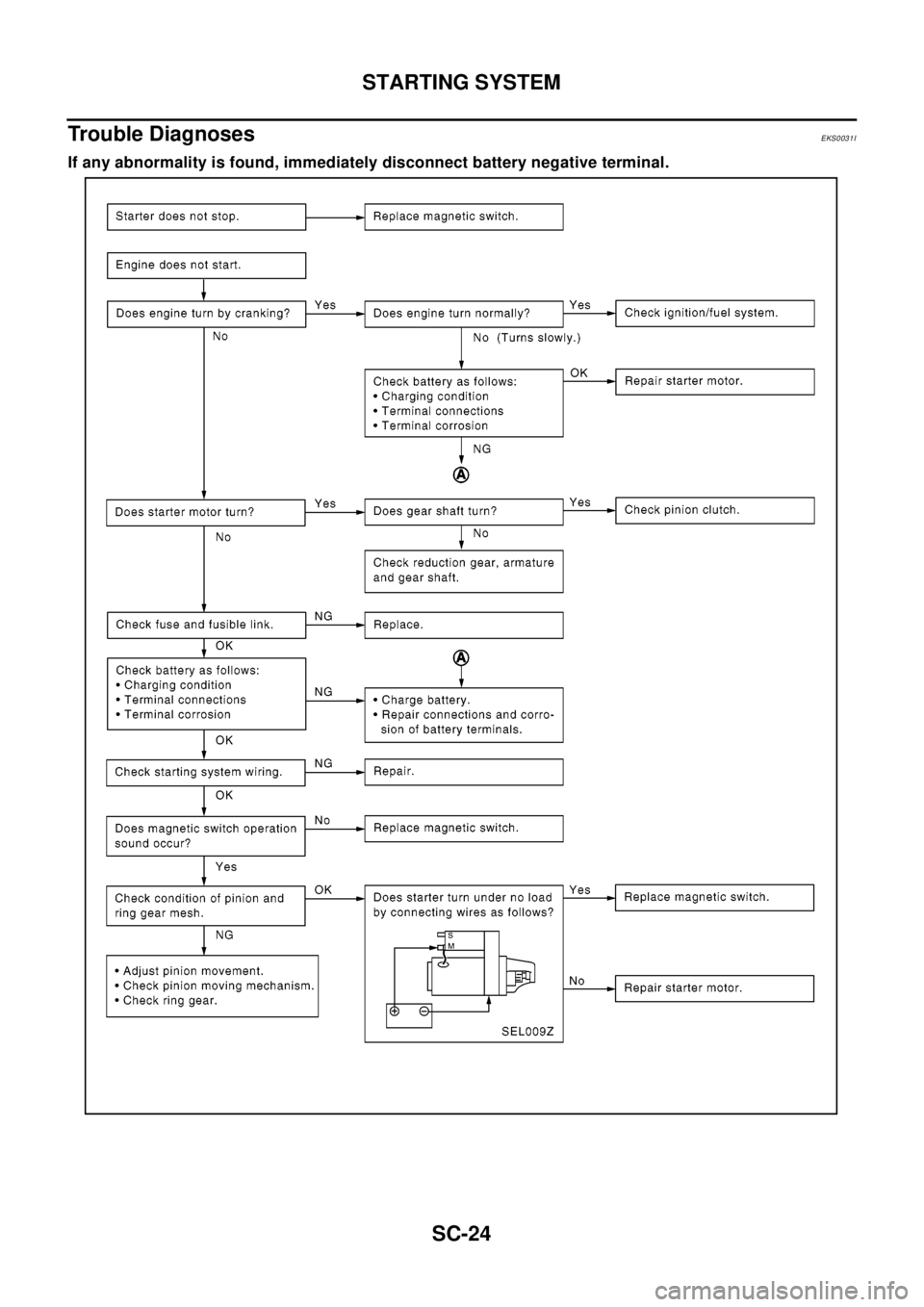

Trouble Diagnoses

EKS0031I

If any abnormality is found, immediately disconnect battery negative terminal.

Page 2897 of 3066

STARTING SYSTEM

SC-25

C

D

E

F

G

H

I

J

L

MA

B

SC

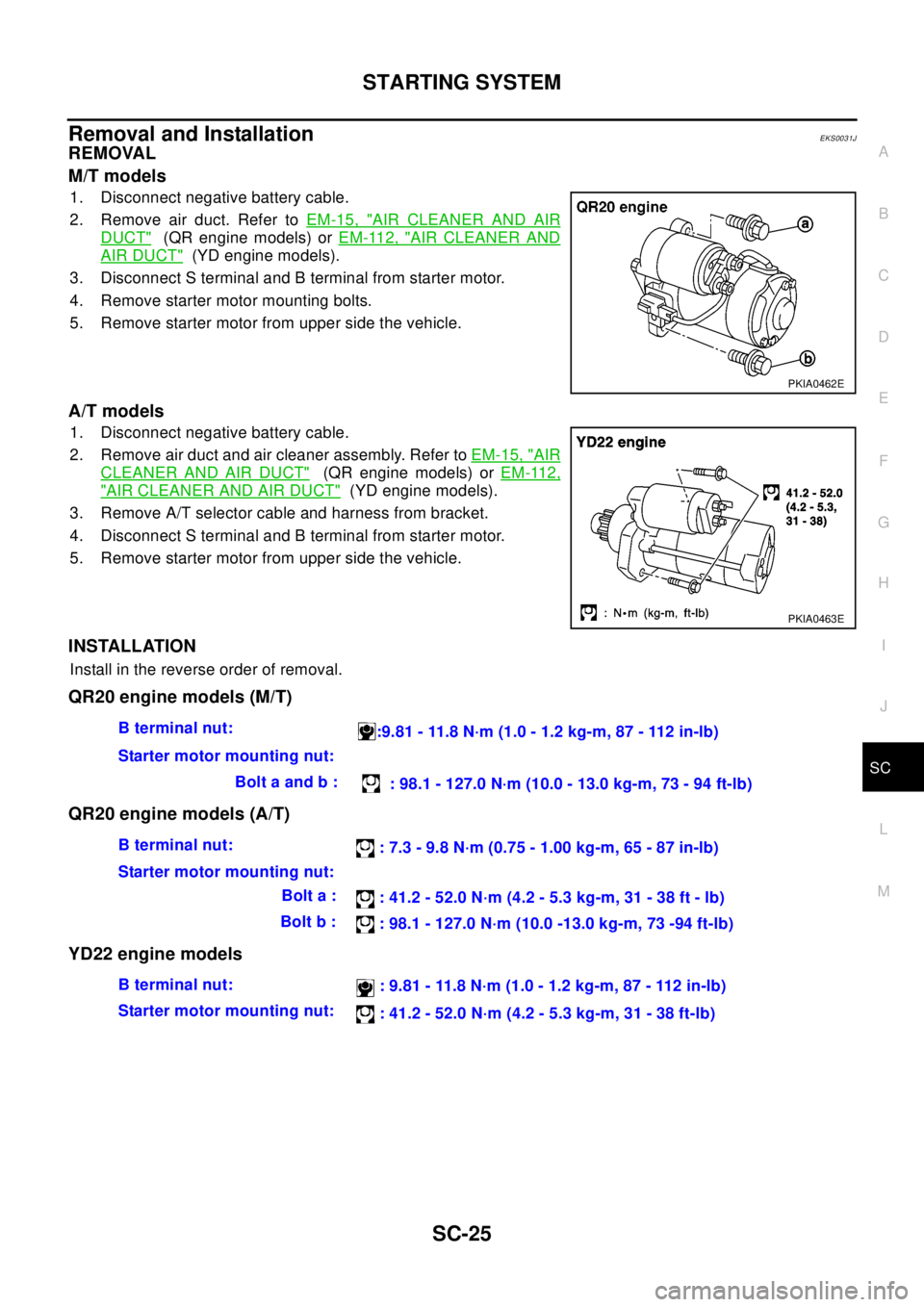

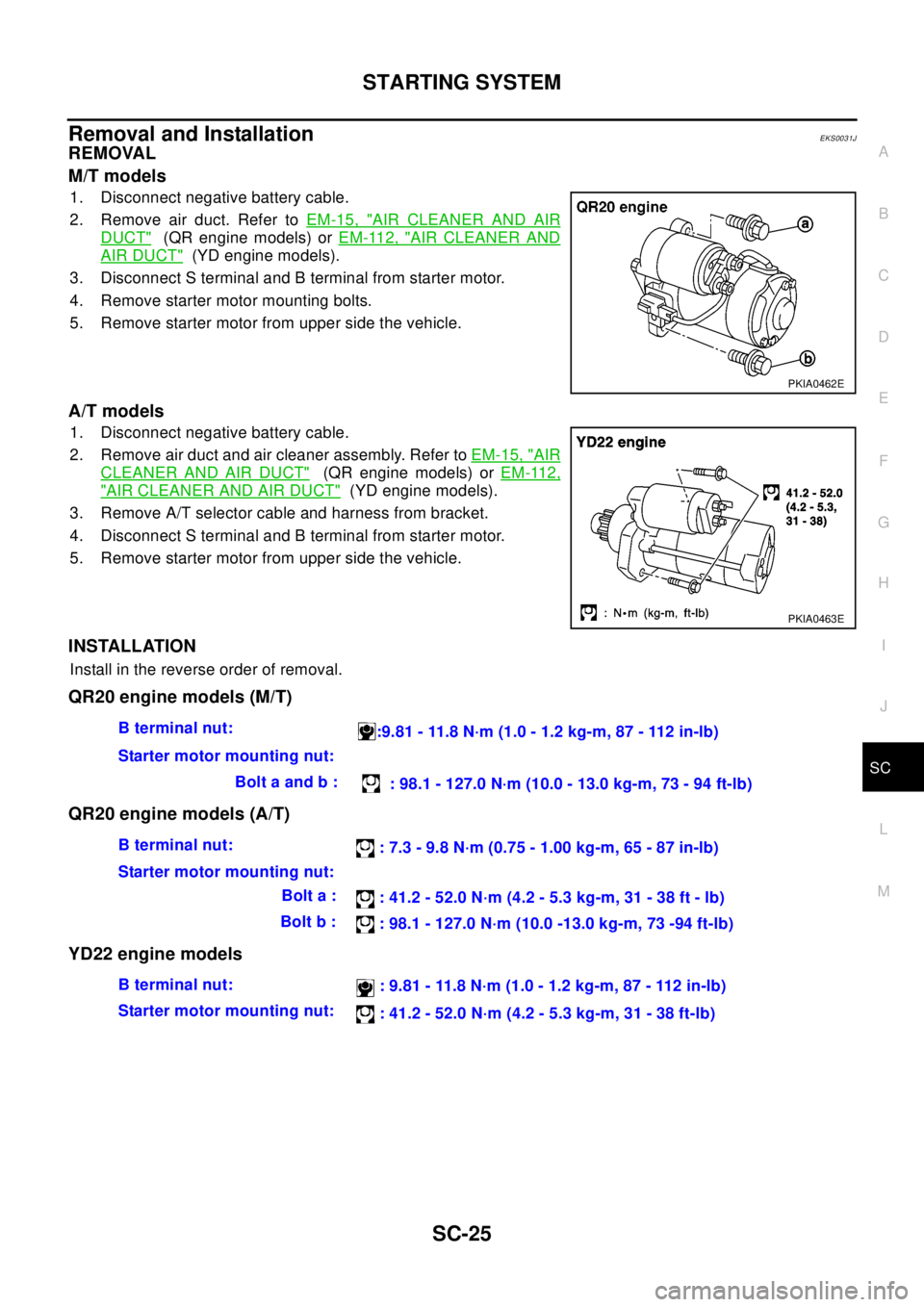

Removal and InstallationEKS0031J

REMOVAL

M/T models

1. Disconnect negative battery cable.

2. Remove air duct. Refer toEM-15, "

AIR CLEANER AND AIR

DUCT"(QR engine models) orEM-112, "AIR CLEANER AND

AIR DUCT"(YD engine models).

3. Disconnect S terminal and B terminal from starter motor.

4. Remove starter motor mounting bolts.

5. Remove starter motor from upper side the vehicle.

A/T models

1. Disconnect negative battery cable.

2. Remove air duct and air cleaner assembly. Refer toEM-15, "

AIR

CLEANER AND AIR DUCT"(QR engine models) orEM-112,

"AIR CLEANER AND AIR DUCT"(YD engine models).

3. Remove A/T selector cable and harness from bracket.

4. Disconnect S terminal and B terminal from starter motor.

5. Remove starter motor from upper side the vehicle.

INSTALLATION

Install in the reverse order of removal.

QR20 engine models (M/T)

QR20 engine models (A/T)

YD22 engine models

PKIA0462E

PKIA0463E

Bterminalnut:

:9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting nut:

Bolt a and b :

: 98.1 - 127.0 N·m (10.0 - 13.0 kg-m, 73 - 94 ft-lb)

Bterminalnut:

: 7.3 - 9.8 N·m (0.75 - 1.00 kg-m, 65 - 87 in-lb)

Starter motor mounting nut:

Bolt a :

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft - lb)

Bolt b :

: 98.1 - 127.0 N·m (10.0 -13.0 kg-m, 73 -94 ft-lb)

Bterminalnut:

: 9.81 - 11.8 N·m (1.0 - 1.2 kg-m, 87 - 112 in-lb)

Starter motor mounting nut:

: 41.2 - 52.0 N·m (4.2 - 5.3 kg-m, 31 - 38 ft-lb)

Page 2898 of 3066

SC-26

STARTING SYSTEM

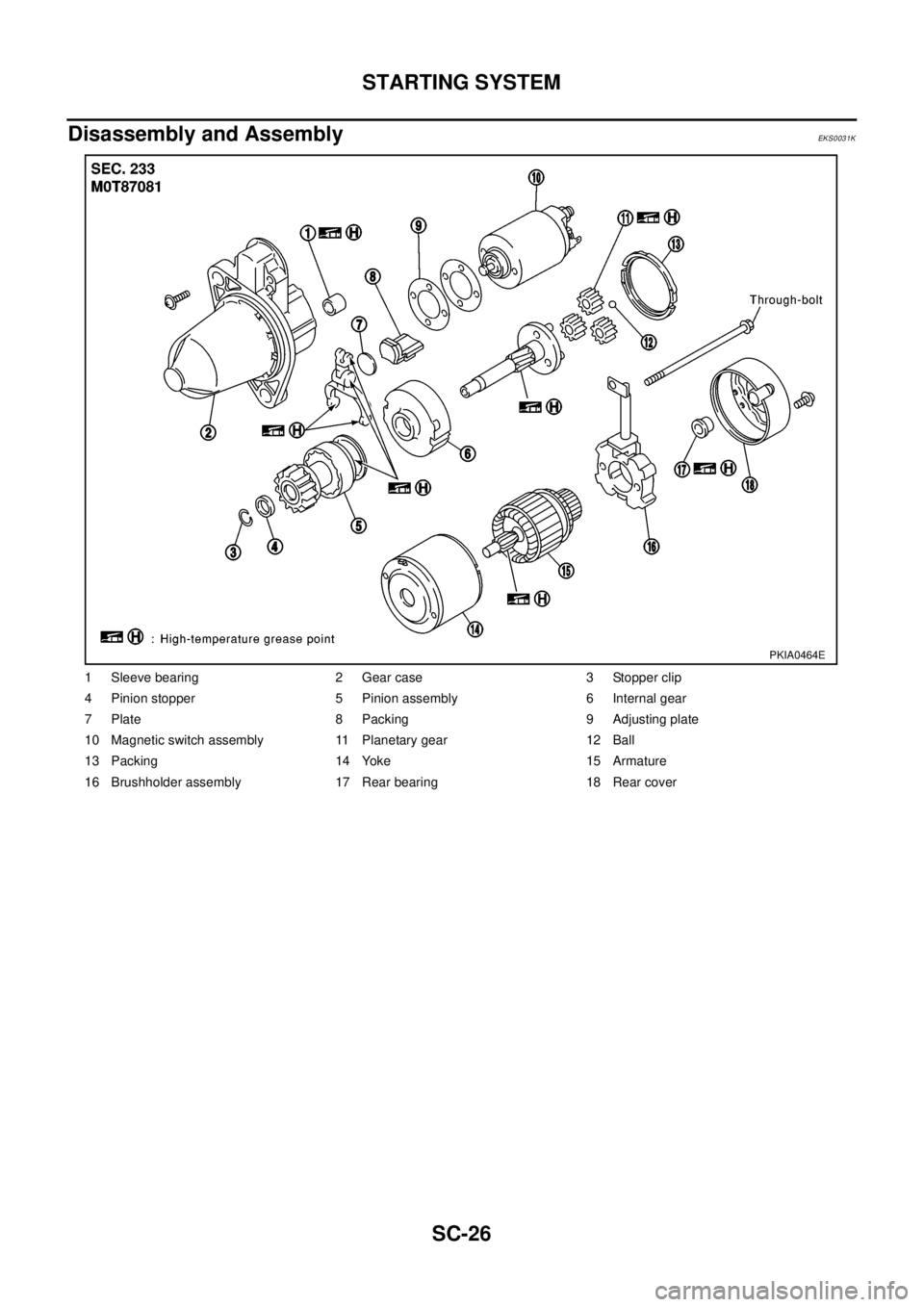

Disassembly and Assembly

EKS0031K

1 Sleeve bearing 2 Gear case 3 Stopper clip

4 Pinion stopper 5 Pinion assembly 6 Internal gear

7 Plate 8 Packing 9 Adjusting plate

10 Magnetic switch assembly 11 Planetary gear 12 Ball

13 Packing 14 Yoke 15 Armature

16 Brushholder assembly 17 Rear bearing 18 Rear cover

PKIA0464E

Page 2899 of 3066

STARTING SYSTEM

SC-27

C

D

E

F

G

H

I

J

L

MA

B

SC

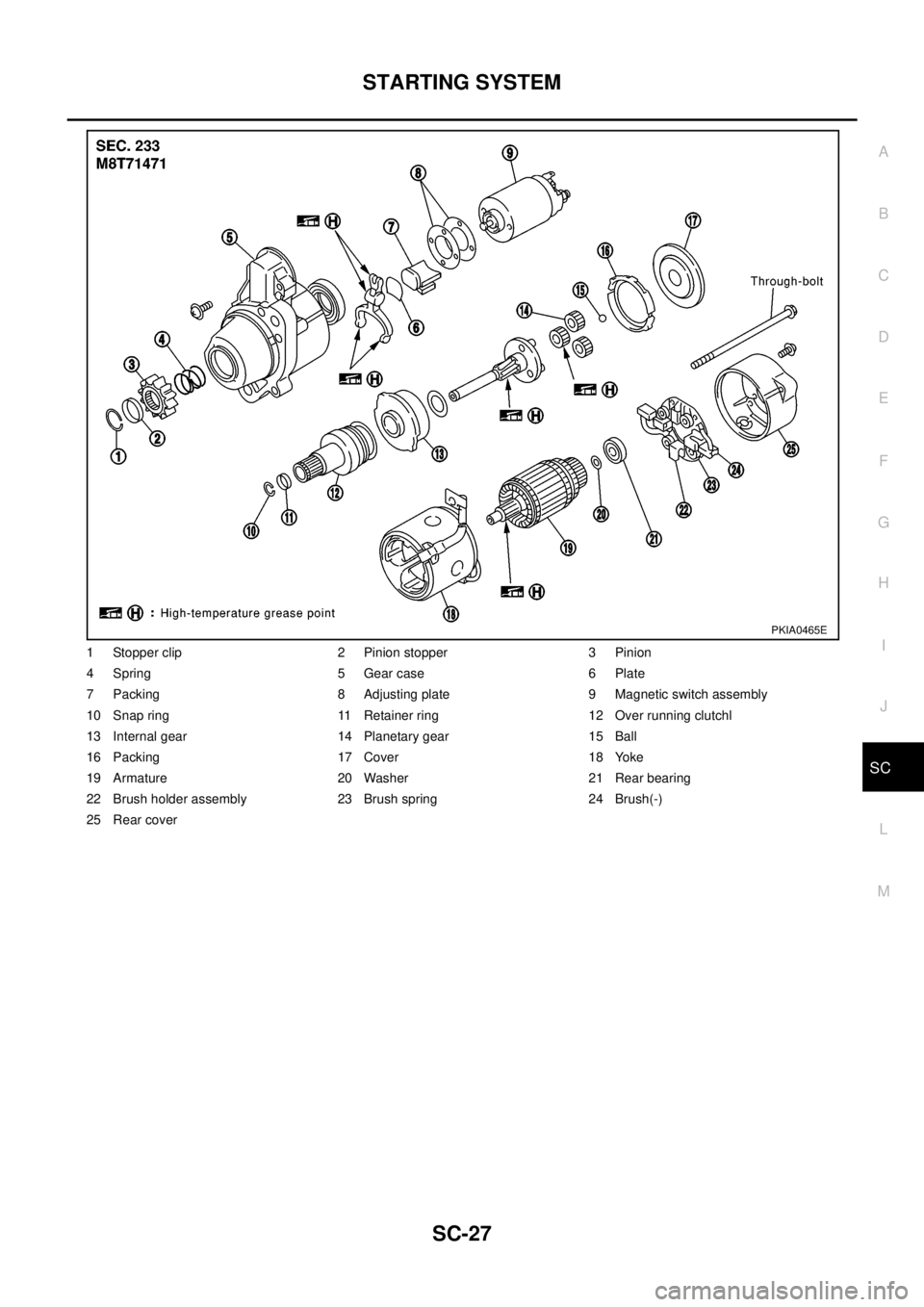

1 Stopper clip 2 Pinion stopper 3 Pinion

4 Spring 5 Gear case 6 Plate

7 Packing 8 Adjusting plate 9 Magnetic switch assembly

10 Snap ring 11 Retainer ring 12 Over running clutchl

13 Internal gear 14 Planetary gear 15 Ball

16 Packing 17 Cover 18 Yoke

19 Armature 20 Washer 21 Rear bearing

22 Brush holder assembly 23 Brush spring 24 Brush(-)

25 Rear cover

PKIA0465E

Page 2900 of 3066

SC-28

STARTING SYSTEM

Inspection

EKS0031L

MAGNETIC SWITCH CHECK

lBefore starting to check, disconnect battery ground cable.

lDisconnect “M” terminal of starter motor.

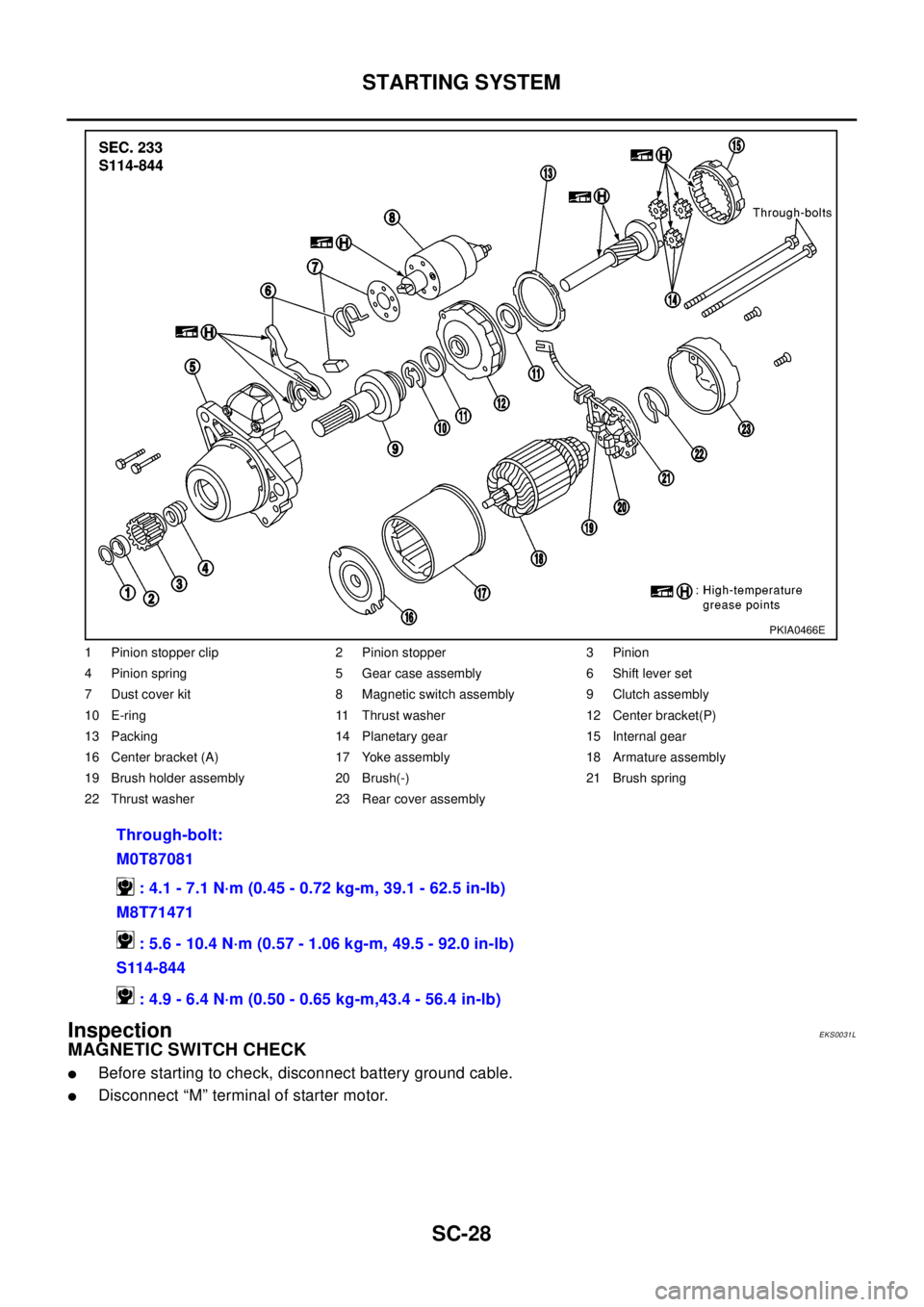

1 Pinion stopper clip 2 Pinion stopper 3 Pinion

4 Pinion spring 5 Gear case assembly 6 Shift lever set

7 Dust cover kit 8 Magnetic switch assembly 9 Clutch assembly

10 E-ring 11 Thrust washer 12 Center bracket(P)

13 Packing 14 Planetary gear 15 Internal gear

16 Center bracket (A) 17 Yoke assembly 18 Armature assembly

19 Brush holder assembly 20 Brush(-) 21 Brush spring

22 Thrust washer 23 Rear cover assembly

Through-bolt:

M0T87081

: 4.1 - 7.1 N·m (0.45 - 0.72 kg-m, 39.1 - 62.5 in-lb)

M8T71471

: 5.6 - 10.4 N·m (0.57 - 1.06 kg-m, 49.5 - 92.0 in-lb)

S114-844

: 4.9 - 6.4 N·m (0.50 - 0.65 kg-m,43.4 - 56.4 in-lb)

PKIA0466E

Trending: air filter, brake, headlamp, radio antenna, oil temperature, air bleeding, CD player