NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 661 of 3066

TROUBLE DIAGNOSIS

ATC-83

C

D

E

F

G

H

I

K

L

MA

B

AT C

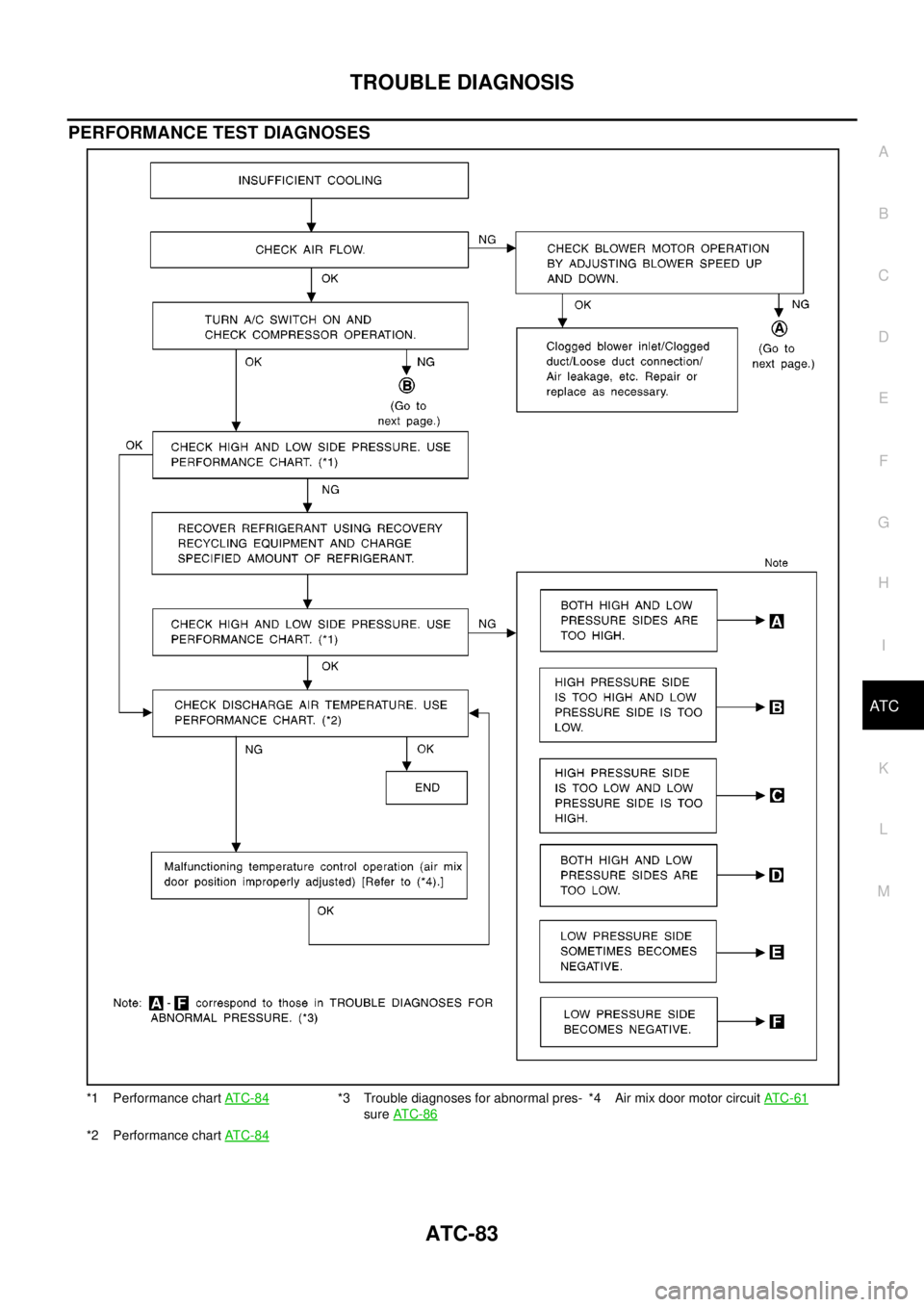

PERFORMANCE TEST DIAGNOSES

*1 Performance chartAT C - 8 4*3 Trouble diagnoses for abnormal pres-

sureAT C - 8 6*4 Air mix door motor circuitAT C - 6 1

*2 Performance chartAT C - 8 4

Page 662 of 3066

ATC-84

TROUBLE DIAGNOSIS

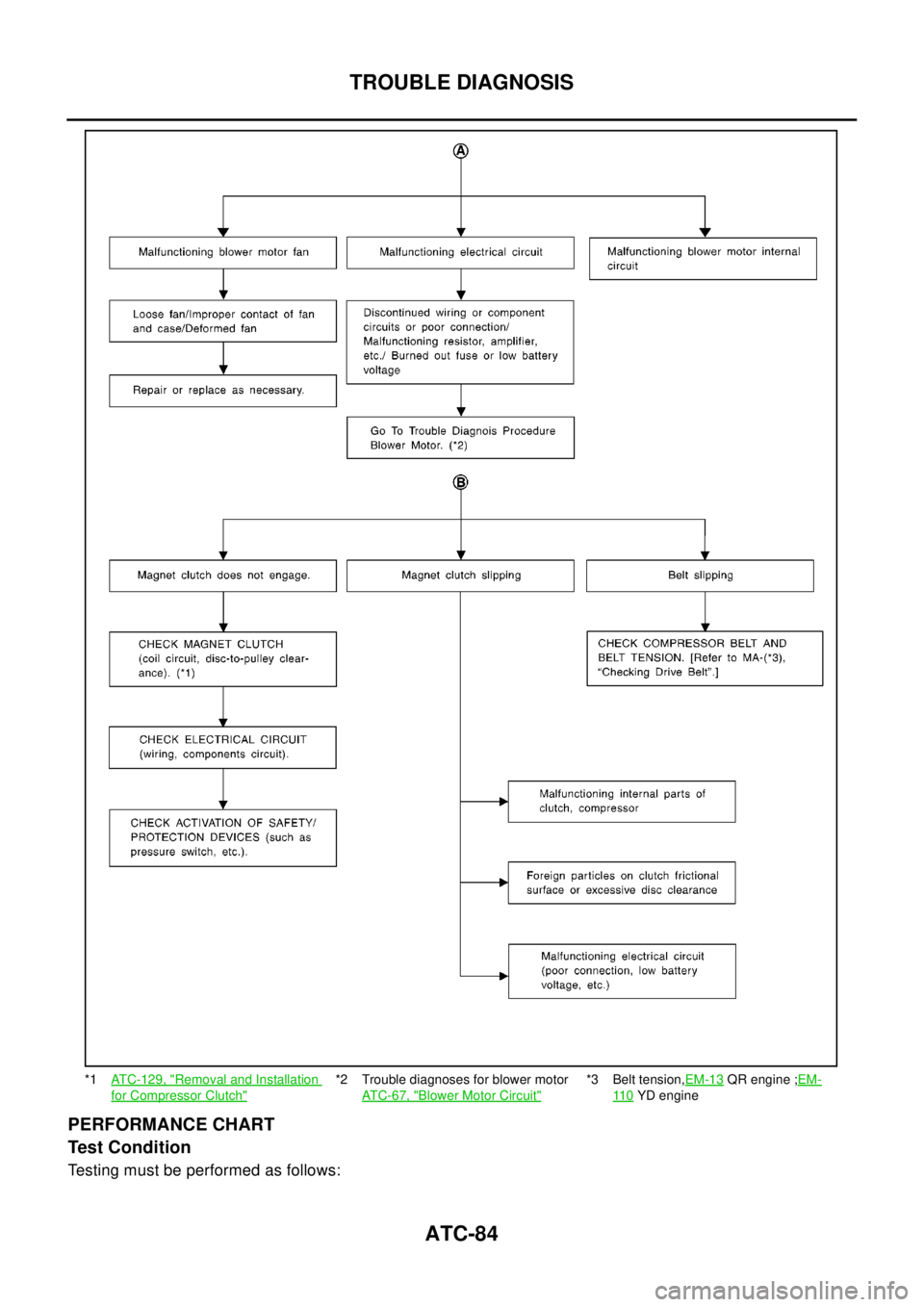

PERFORMANCE CHART

Test Condition

Testing must be performed as follows:

*1ATC-129, "Removal and Installation

for Compressor Clutch"

*2 Trouble diagnoses for blower motor

AT C - 6 7 , "

Blower Motor Circuit"

*3 Belt tension,EM-13QR engine ;EM-

11 0YD engine

Page 663 of 3066

TROUBLE DIAGNOSIS

ATC-85

C

D

E

F

G

H

I

K

L

MA

B

AT C

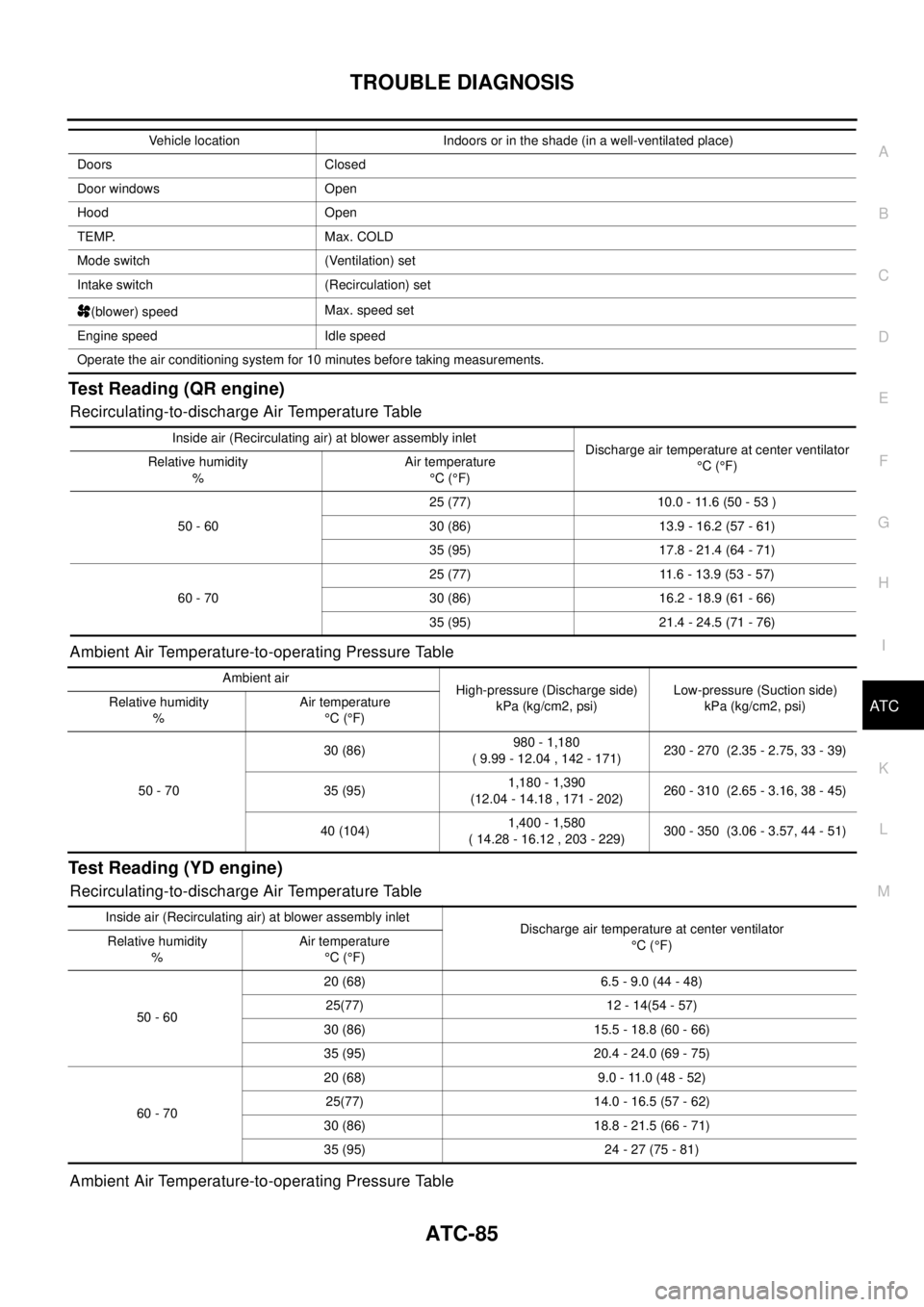

Test Reading (QR engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Test Reading (YD engine)

Recirculating-to-discharge Air Temperature Table

Ambient Air Temperature-to-operating Pressure Table

Vehicle location Indoors or in the shade (in a well-ventilated place)

Doors Closed

Door windows Open

Hood Open

TEMP. Max. COLD

Mode switch (Ventilation) set

Intake switch (Recirculation) set

(blower) speedMax. speed set

Engine speed Idle speed

Operate the air conditioning system for 10 minutes before taking measurements.

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C(°F) Relative humidity

%Air temperature

°C(°F)

50 - 6025 (77) 10.0 - 11.6 (50 - 53 )

30 (86) 13.9 - 16.2 (57 - 61)

35 (95) 17.8 - 21.4 (64 - 71)

60 - 7025 (77) 11.6 - 13.9 (53 - 57)

30 (86) 16.2 - 18.9 (61 - 66)

35 (95) 21.4 - 24.5 (71 - 76)

Ambient air

High-pressure (Discharge side)

kPa (kg/cm2, psi)Low-pressure (Suction side)

kPa (kg/cm2, psi) Relative humidity

%Air temperature

°C(°F)

50 - 7030 (86)980 - 1,180

( 9.99 - 12.04 , 142 - 171)230 - 270 (2.35 - 2.75, 33 - 39)

35 (95)1,180 - 1,390

(12.04 - 14.18 , 171 - 202)260 - 310 (2.65 - 3.16, 38 - 45)

40 (104)1,400 - 1,580

( 14.28 - 16.12 , 203 - 229)300 - 350 (3.06 - 3.57, 44 - 51)

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature at center ventilator

°C(°F) Relative humidity

%Air temperature

°C(°F)

50 - 6020 (68) 6.5 - 9.0 (44 - 48)

25(77) 12 - 14(54 - 57)

30 (86) 15.5 - 18.8 (60 - 66)

35 (95) 20.4 - 24.0 (69 - 75)

60 - 7020 (68) 9.0 - 11.0 (48 - 52)

25(77) 14.0 - 16.5 (57 - 62)

30 (86) 18.8 - 21.5 (66 - 71)

35 (95) 24 - 27 (75 - 81)

Page 664 of 3066

ATC-86

TROUBLE DIAGNOSIS

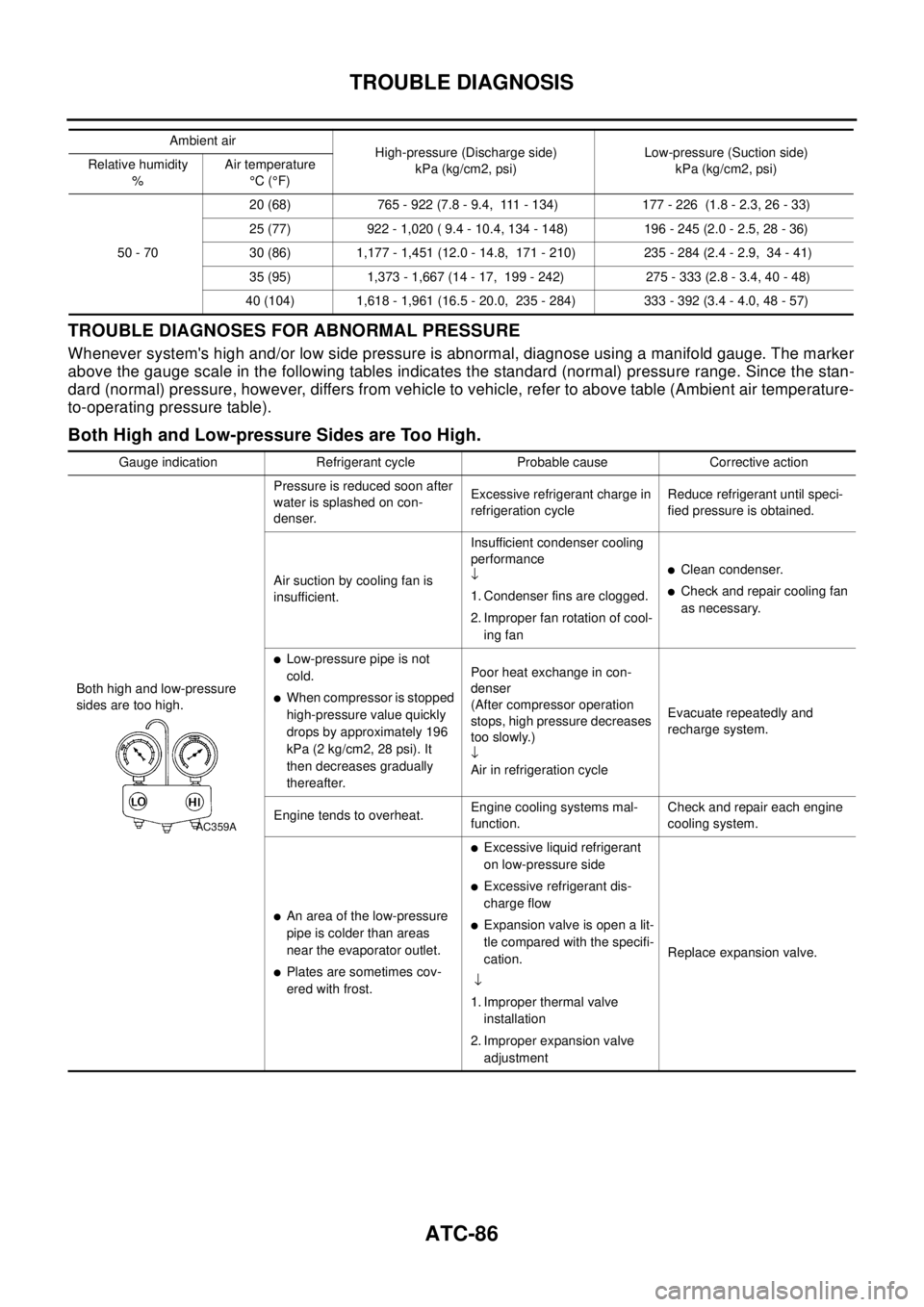

TROUBLE DIAGNOSES FOR ABNORMAL PRESSURE

Whenever system's high and/or low side pressure is abnormal, diagnose using a manifold gauge. The marker

above the gauge scale in the following tables indicates the standard (normal) pressure range. Since the stan-

dard (normal) pressure, however, differs from vehicle to vehicle, refer to above table (Ambient air temperature-

to-operating pressure table).

Both High and Low-pressure Sides are Too High.

Ambient air

High-pressure (Discharge side)

kPa (kg/cm2, psi)Low-pressure (Suction side)

kPa (kg/cm2, psi) Relative humidity

%Air temperature

°C(°F)

50 - 7020 (68) 765 - 922 (7.8 - 9.4, 111 - 134) 177 - 226 (1.8 - 2.3, 26 - 33)

25 (77) 922 - 1,020 ( 9.4 - 10.4, 134 - 148) 196 - 245 (2.0 - 2.5, 28 - 36)

30 (86) 1,177 - 1,451 (12.0 - 14.8, 171 - 210) 235 - 284 (2.4 - 2.9, 34 - 41)

35 (95) 1,373 - 1,667 (14 - 17, 199 - 242) 275 - 333 (2.8 - 3.4, 40 - 48)

40 (104) 1,618 - 1,961 (16.5 - 20.0, 235 - 284) 333 - 392 (3.4 - 4.0, 48 - 57)

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high and low-pressure

sides are too high.Pressure is reduced soon after

water is splashed on con-

denser.Excessive refrigerant charge in

refrigeration cycleReduce refrigerant until speci-

fied pressure is obtained.

Air suction by cooling fan is

insufficient.Insufficient condenser cooling

performance

¯

1. Condenser fins are clogged.

2. Improper fan rotation of cool-

ing fan

lClean condenser.

lCheck and repair cooling fan

as necessary.

lLow-pressure pipe is not

cold.

lWhen compressor is stopped

high-pressure value quickly

drops by approximately 196

kPa (2 kg/cm2, 28 psi). It

then decreases gradually

thereafter.Poor heat exchange in con-

denser

(After compressor operation

stops, high pressure decreases

too slowly.)

¯

Air in refrigeration cycleEvacuate repeatedly and

recharge system.

Engine tends to overheat.Engine cooling systems mal-

function.Check and repair each engine

cooling system.

lAn area of the low-pressure

pipe is colder than areas

near the evaporator outlet.

lPlates are sometimes cov-

ered with frost.

lExcessive liquid refrigerant

on low-pressure side

lExcessive refrigerant dis-

charge flow

lExpansion valve is open a lit-

tle compared with the specifi-

cation.

¯

1. Improper thermal valve

installation

2. Improper expansion valve

adjustmentReplace expansion valve.

AC359A

Page 665 of 3066

TROUBLE DIAGNOSIS

ATC-87

C

D

E

F

G

H

I

K

L

MA

B

AT C

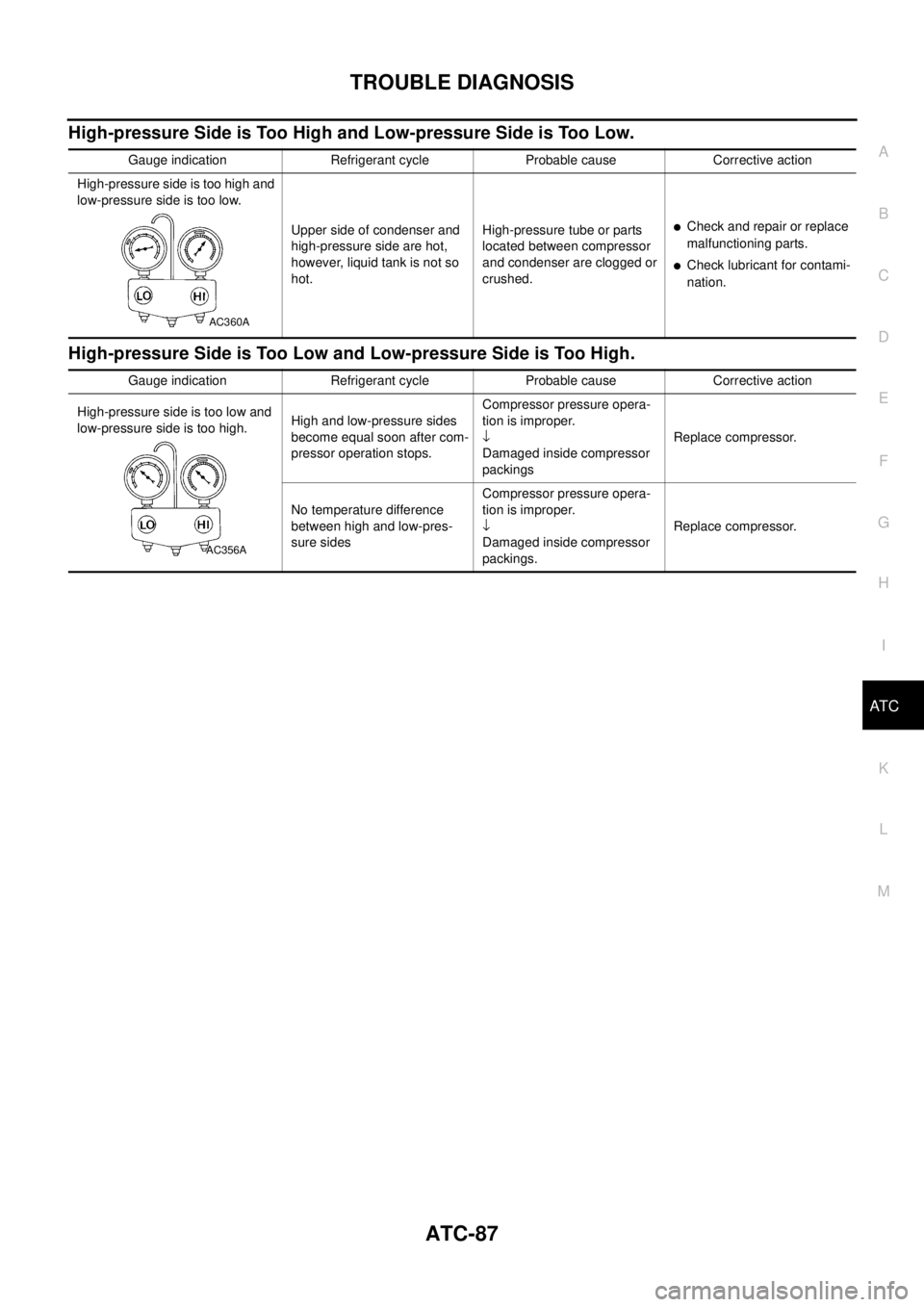

High-pressure Side is Too High and Low-pressure Side is Too Low.

High-pressure Side is Too Low and Low-pressure Side is Too High.

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too high and

low-pressure side is too low.

Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts

located between compressor

and condenser are clogged or

crushed.

lCheck and repair or replace

malfunctioning parts.

lCheck lubricant for contami-

nation.

AC360A

Gauge indication Refrigerant cycle Probable cause Corrective action

High-pressure side is too low and

low-pressure side is too high.High and low-pressure sides

become equal soon after com-

pressor operation stops.Compressor pressure opera-

tion is improper.

¯

Damaged inside compressor

packingsReplace compressor.

No temperature difference

between high and low-pres-

sure sidesCompressor pressure opera-

tion is improper.

¯

Damaged inside compressor

packings.Replace compressor.

AC356A

Page 666 of 3066

ATC-88

TROUBLE DIAGNOSIS

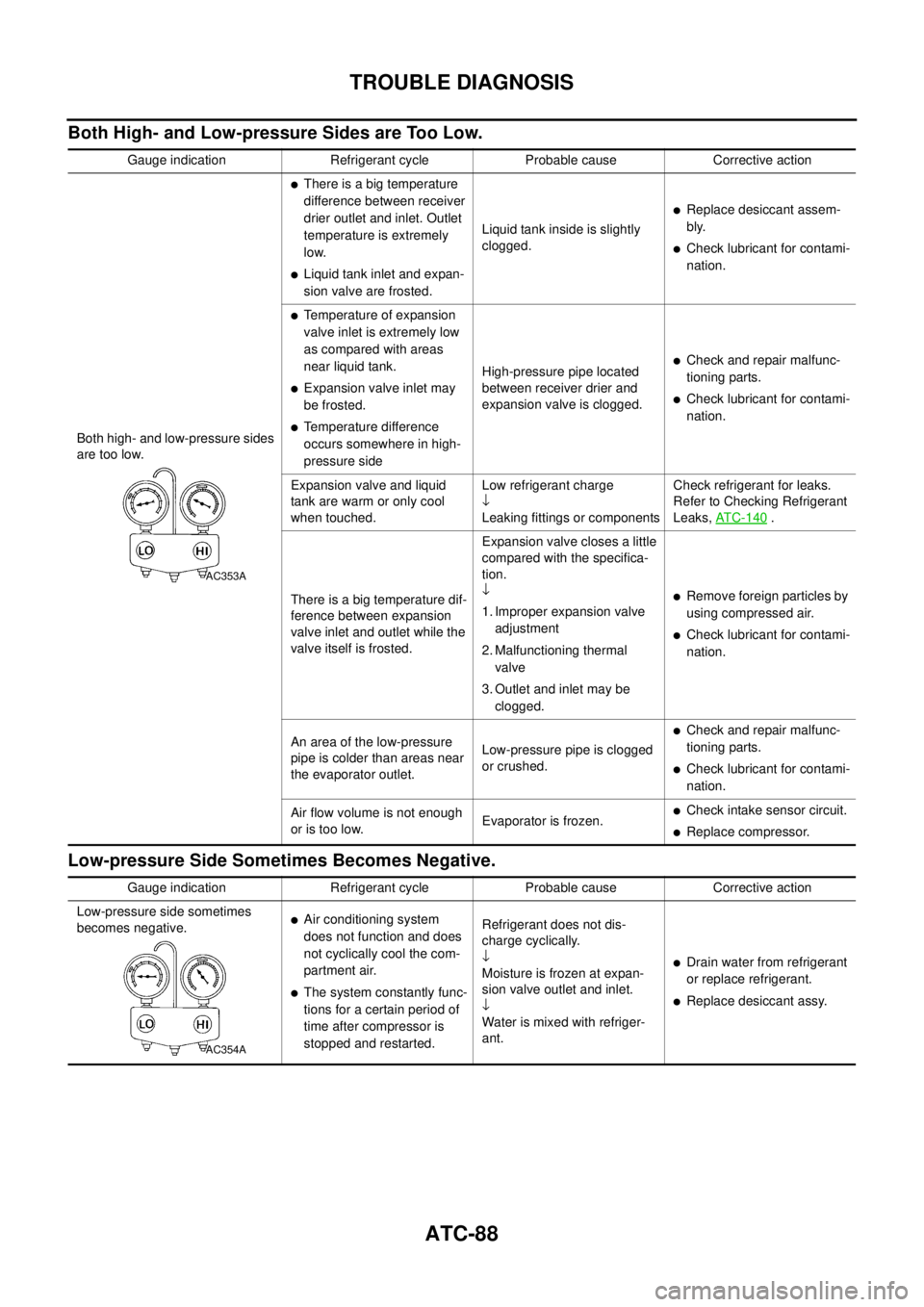

Both High- and Low-pressure Sides are Too Low.

Low-pressure Side Sometimes Becomes Negative.

Gauge indication Refrigerant cycle Probable cause Corrective action

Both high- and low-pressure sides

are too low.

lThere is a big temperature

difference between receiver

drier outlet and inlet. Outlet

temperature is extremely

low.

lLiquid tank inlet and expan-

sion valve are frosted.Liquid tank inside is slightly

clogged.

lReplace desiccant assem-

bly.

lCheck lubricant for contami-

nation.

lTemperature of expansion

valve inlet is extremely low

as compared with areas

near liquid tank.

lExpansion valve inlet may

be frosted.

lTemperature difference

occurs somewhere in high-

pressure sideHigh-pressure pipe located

between receiver drier and

expansion valve is clogged.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Expansion valve and liquid

tank are warm or only cool

when touched.Low refrigerant charge

¯

Leaking fittings or componentsCheck refrigerant for leaks.

Refer to Checking Refrigerant

Leaks,AT C - 1 4 0

.

There is a big temperature dif-

ference between expansion

valve inlet and outlet while the

valve itself is frosted.Expansion valve closes a little

compared with the specifica-

tion.

¯

1. Improper expansion valve

adjustment

2. Malfunctioning thermal

valve

3. Outlet and inlet may be

clogged.

lRemove foreign particles by

using compressed air.

lCheck lubricant for contami-

nation.

An area of the low-pressure

pipe is colder than areas near

the evaporator outlet.Low-pressure pipe is clogged

or crushed.

lCheck and repair malfunc-

tioning parts.

lCheck lubricant for contami-

nation.

Air flow volume is not enough

or is too low.Evaporator is frozen.

lCheck intake sensor circuit.

lReplace compressor.

AC353A

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side sometimes

becomes negative.

lAir conditioning system

does not function and does

not cyclically cool the com-

partment air.

lThe system constantly func-

tions for a certain period of

time after compressor is

stopped and restarted.Refrigerant does not dis-

charge cyclically.

¯

Moisture is frozen at expan-

sion valve outlet and inlet.

¯

Water is mixed with refriger-

ant.

lDrain water from refrigerant

or replace refrigerant.

lReplace desiccant assy.

AC354A

Page 667 of 3066

TROUBLE DIAGNOSIS

ATC-89

C

D

E

F

G

H

I

K

L

MA

B

AT C

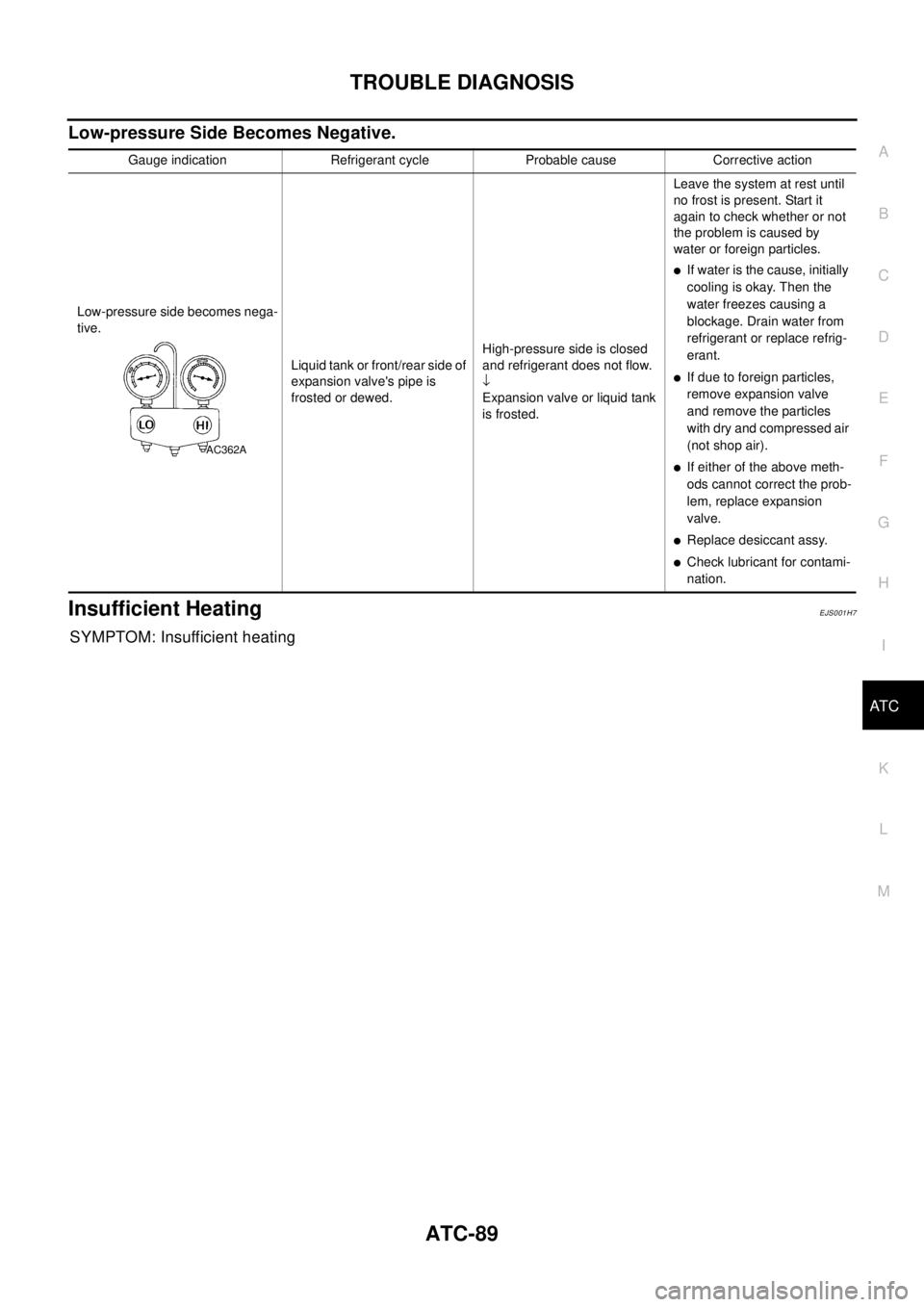

Low-pressure Side Becomes Negative.

Insufficient HeatingEJS001H7

SYMPTOM: Insufficient heating

Gauge indication Refrigerant cycle Probable cause Corrective action

Low-pressure side becomes nega-

tive.

Liquid tank or front/rear side of

expansion valve's pipe is

frosted or dewed.High-pressure side is closed

and refrigerant does not flow.

¯

Expansion valve or liquid tank

is frosted.Leave the system at rest until

no frost is present. Start it

again to check whether or not

the problem is caused by

water or foreign particles.

lIf water is the cause, initially

cooling is okay. Then the

water freezes causing a

blockage. Drain water from

refrigerant or replace refrig-

erant.

lIf due to foreign particles,

remove expansion valve

and remove the particles

with dry and compressed air

(not shop air).

lIf either of the above meth-

ods cannot correct the prob-

lem, replace expansion

valve.

lReplace desiccant assy.

lCheck lubricant for contami-

nation.

AC362A

Page 668 of 3066

ATC-90

TROUBLE DIAGNOSIS

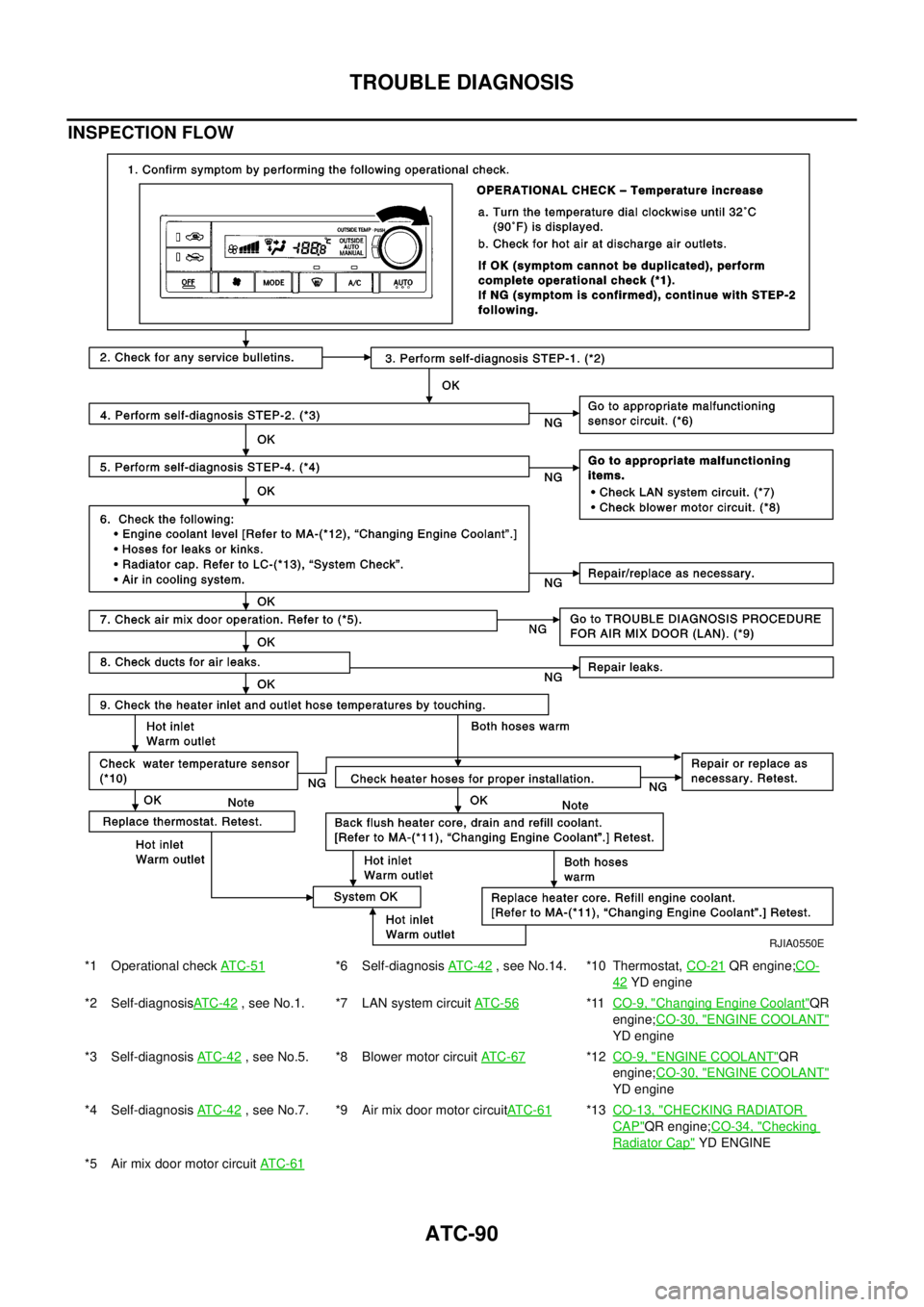

INSPECTION FLOW

*1 Operational checkAT C - 5 1*6 Self-diagnosisAT C -4 2, see No.14. *10 Thermostat,CO-21QR engine;CO-

42YD engine

*2 Self-diagnosisAT C -4 2

, see No.1. *7 LAN system circuitAT C - 5 6*11CO-9, "Changing Engine Coolant"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*3 Self-diagnosisAT C - 4 2

, see No.5. *8 Blower motor circuitAT C - 6 7*12CO-9, "ENGINE COOLANT"QR

engine;CO-30, "

ENGINE COOLANT"

YD engine

*4 Self-diagnosisAT C - 4 2

, see No.7. *9 Air mix door motor circuitAT C - 6 1*13CO-13, "CHECKING RADIATOR

CAP"QR engine;CO-34, "Checking

Radiator Cap"YD ENGINE

*5 Air mix door motor circuitAT C - 6 1

RJIA0550E

Page 669 of 3066

TROUBLE DIAGNOSIS

ATC-91

C

D

E

F

G

H

I

K

L

MA

B

AT C

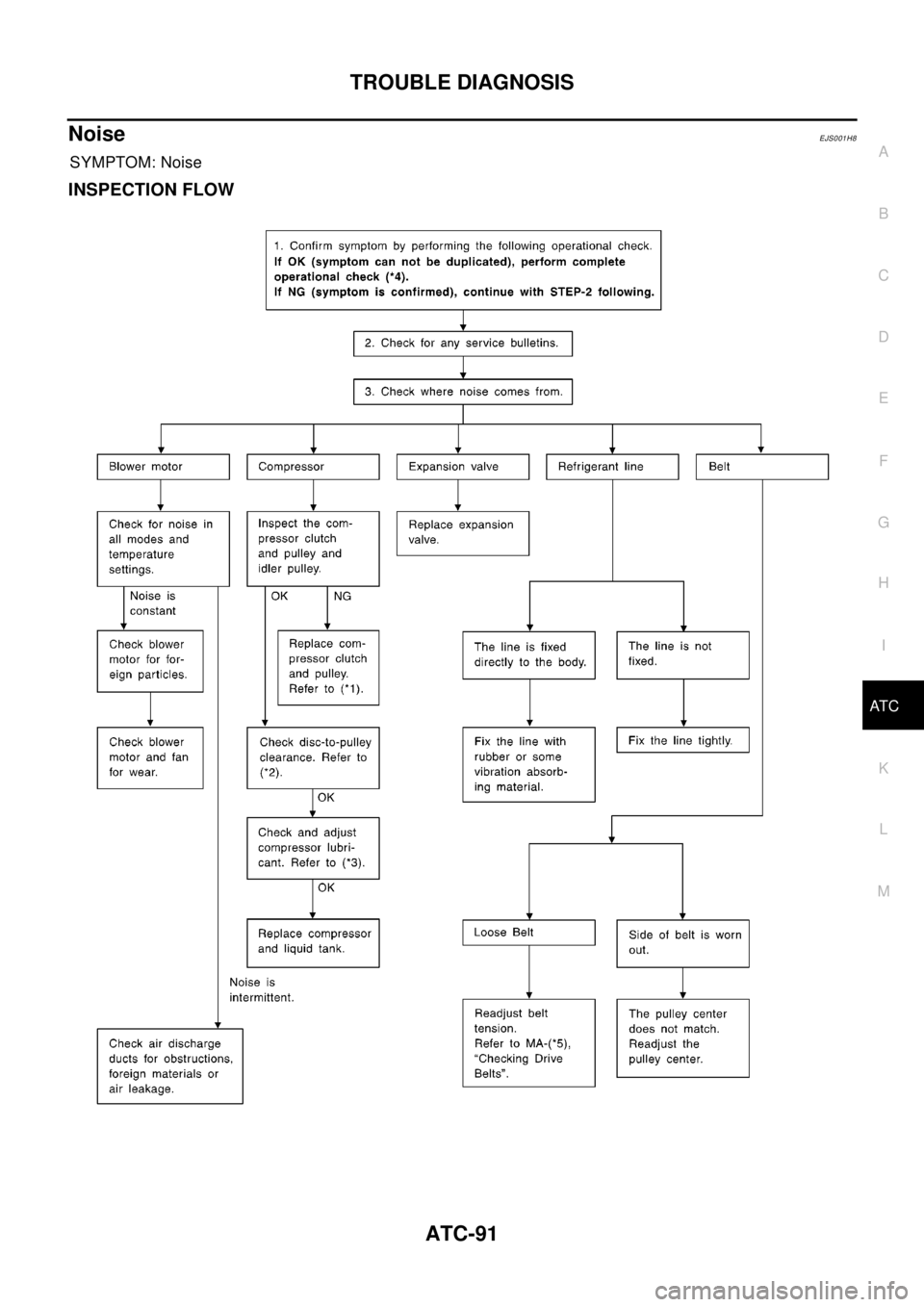

NoiseEJS001H8

SYMPTOM: Noise

INSPECTION FLOW

Page 670 of 3066

ATC-92

TROUBLE DIAGNOSIS

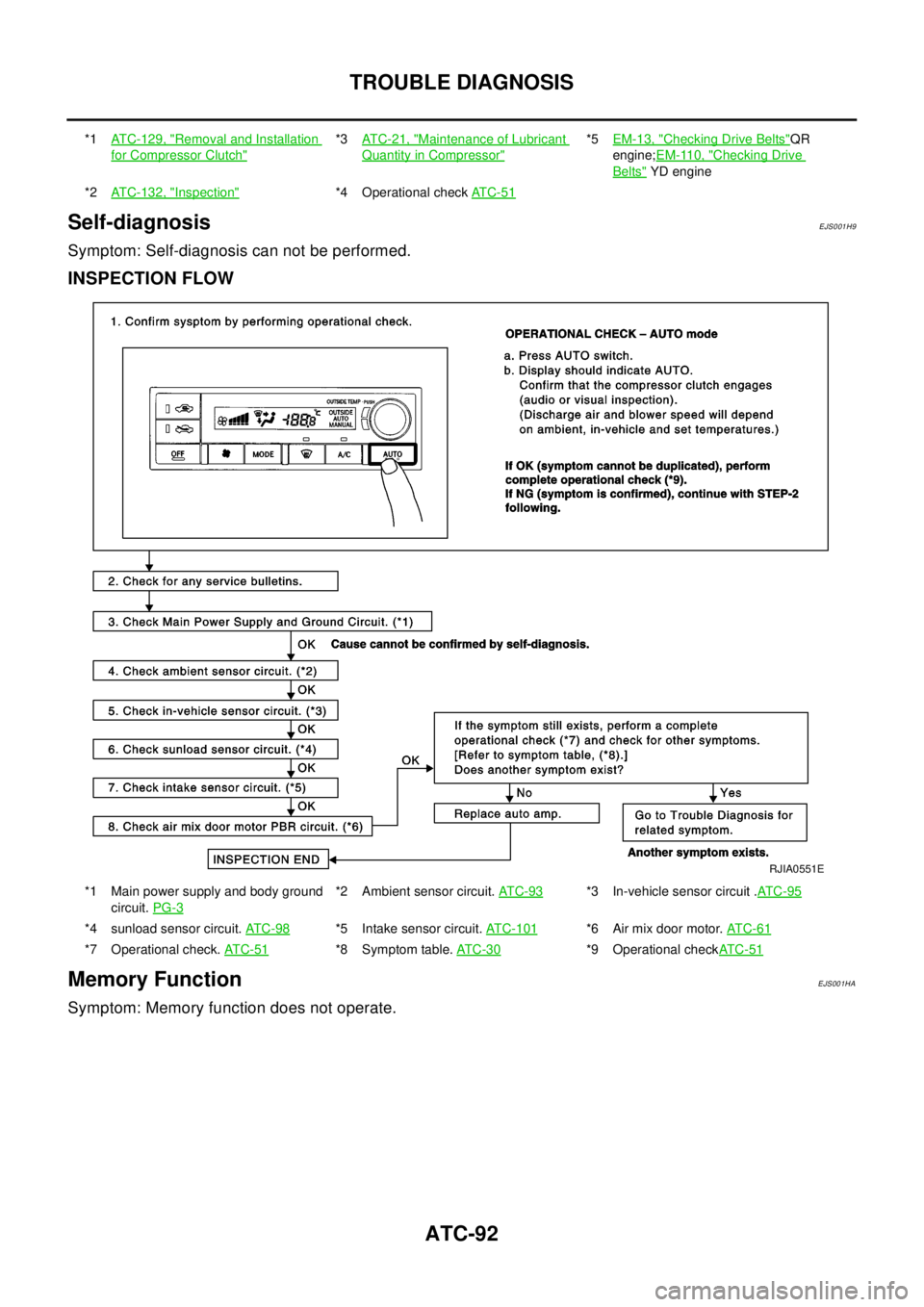

Self-diagnosis

EJS001H9

Symptom: Self-diagnosis can not be performed.

INSPECTION FLOW

Memory FunctionEJS001HA

Symptom: Memory function does not operate.

*1ATC-129, "Removal and Installation

for Compressor Clutch"

*3AT C - 2 1 , "Maintenance of Lubricant

Quantity in Compressor"

*5EM-13, "Checking Drive Belts"QR

engine;EM-110, "

Checking Drive

Belts"YD engine

*2ATC-132, "

Inspection"*4 Operational checkAT C - 5 1

*1 Main power supply and body ground

circuit.PG-3*2 Ambient sensor circuit.AT C - 9 3*3 In-vehicle sensor circuit .AT C - 9 5

*4 sunload sensor circuit.AT C - 9 8*5 Intake sensor circuit.AT C - 1 0 1*6 Air mix door motor.AT C - 6 1

*7 Operational check.AT C - 5 1*8 Symptom table.AT C -3 0*9 Operational checkAT C - 5 1

RJIA0551E