OPEL GT-R 1973 Service Manual

Manufacturer: OPEL, Model Year: 1973, Model line: GT-R, Model: OPEL GT-R 1973Pages: 625, PDF Size: 17.22 MB

Page 251 of 625

49- 201973 OPEL SERVICE MANUAL

IN.LB. TORQUE

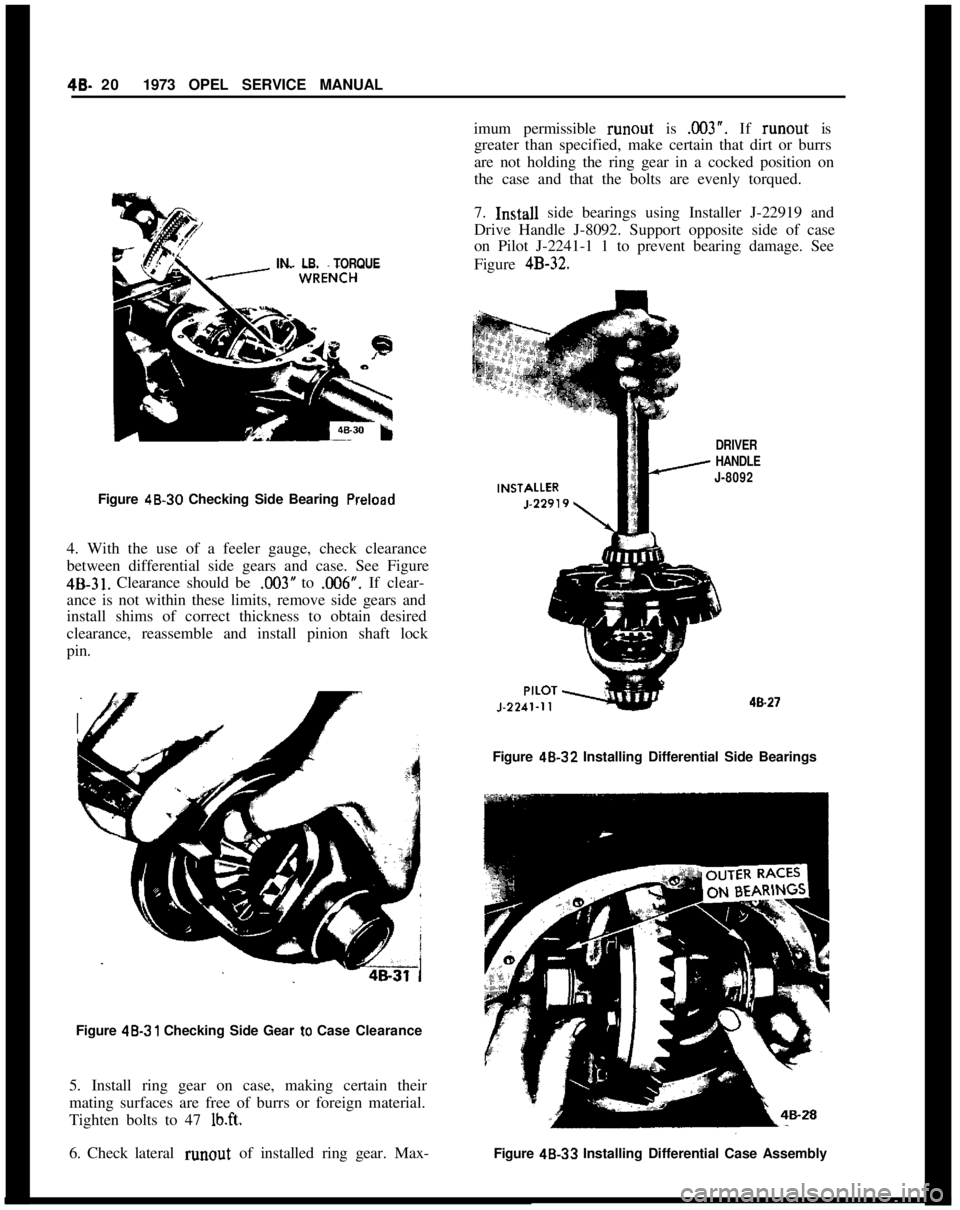

Figure 48.30 Checking Side Bearing Preload

4. With the use of a feeler gauge, check clearance

between differential side gears and case. See Figure

4B-31. Clearance should be ,003” to X106”. If clear-

ance is not within these limits, remove side gears and

install shims of correct thickness to obtain desired

clearance, reassemble and install pinion shaft lock

pin.

Figure 48.31 Checking Side Gear to Case Clearance

5. Install ring gear on case, making certain their

mating surfaces are free of burrs or foreign material.

Tighten bolts to 47

lb.ft.

6. Check lateral runout of installed ring gear. Max- imum permissible

runout is X03”. If runout is

greater than specified, make certain that dirt or burrs

are not holding the ring gear in a cocked position on

the case and that the bolts are evenly torqued.

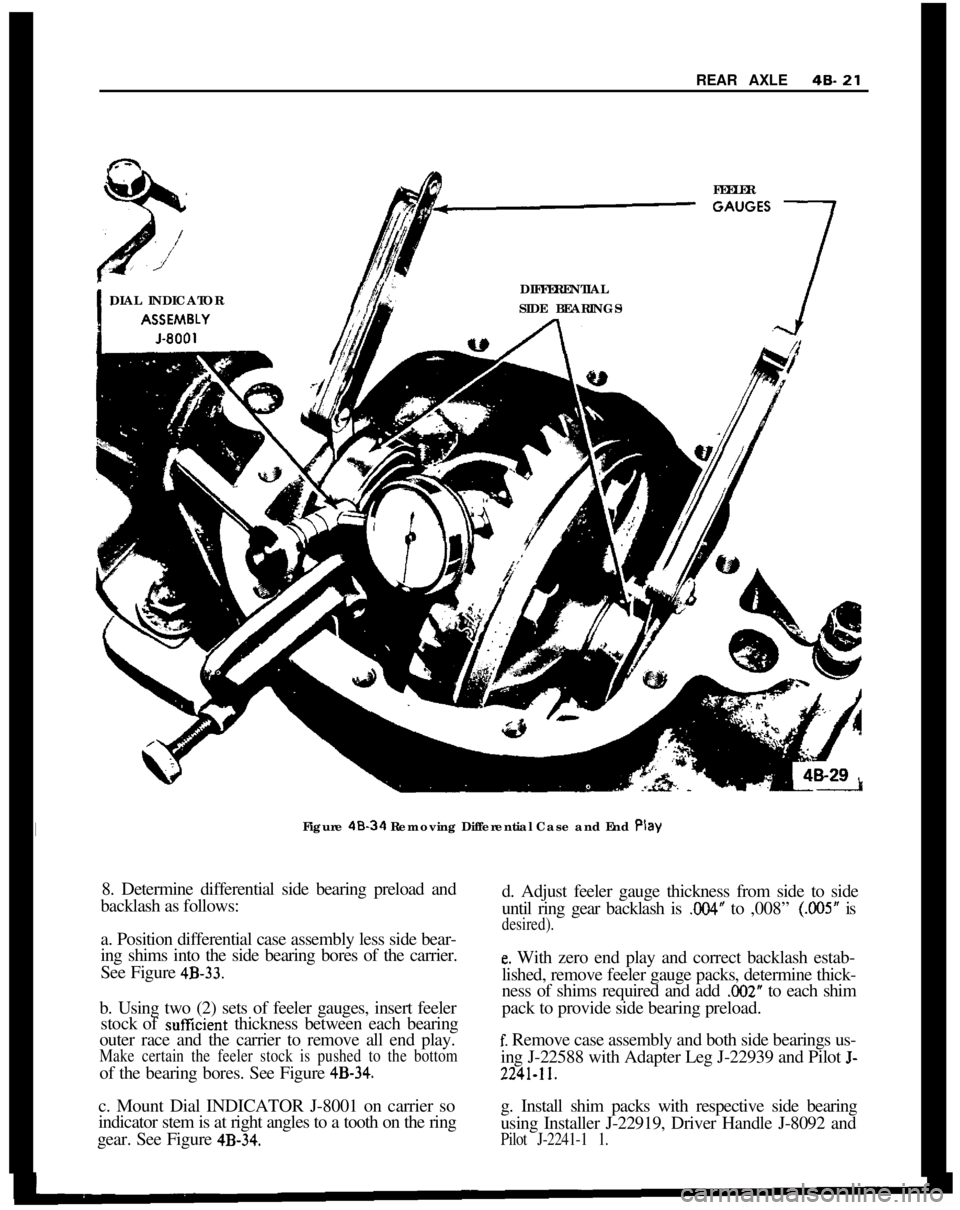

7.

Imtall side bearings using Installer J-22919 and

Drive Handle J-8092. Support opposite side of case

on Pilot J-2241-1 1 to prevent bearing damage. See

Figure

4B-32.

DRIVER

HANDLE

J-8092

4B.27

Figure 48-32 Installing Differential Side Bearings

Figure

48.33 Installing Differential Case Assembly

Page 252 of 625

REAR AXLE48.21FEELER

DIFFERENTIAL

DIAL INDICATOR

SIDE BEARINGS

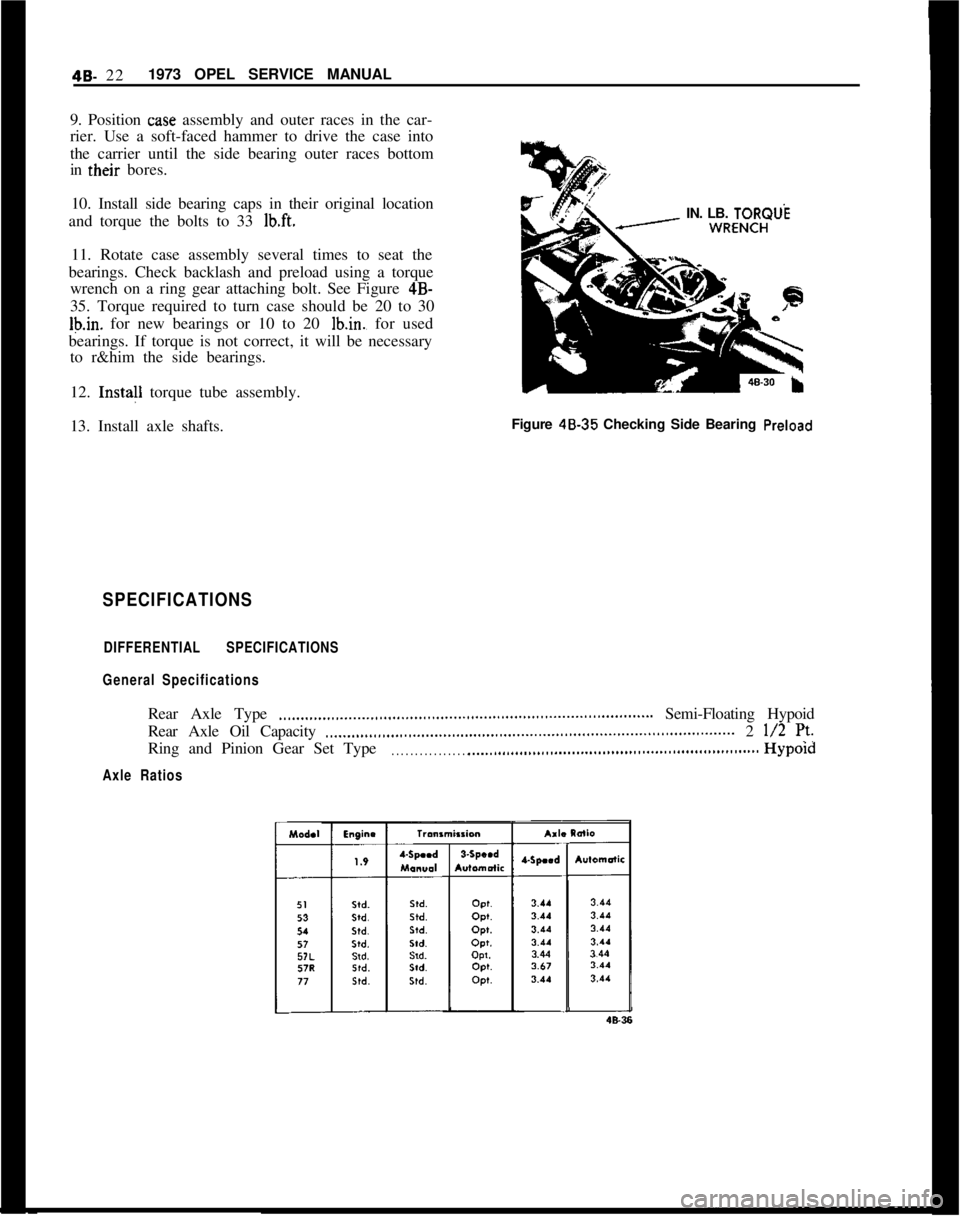

Figure 48.34 Removing Differential Case and End

Play8. Determine differential side bearing preload and

backlash as follows:d. Adjust feeler gauge thickness from side to side

until ring gear backlash is

004” to ,008” (.005” is

desired).a. Position differential case assembly less side bear-

ing shims into the side bearing bores of the carrier.

See Figure

4B-33.b. Using two (2) sets of feeler gauges, insert feeler

stock of sufficient thickness between each bearing

outer race and the carrier to remove all end play.

Make certain the feeler stock is pushed to the bottomof the bearing bores. See Figure

4B-34.

e. With zero end play and correct backlash estab-

lished, remove feeler gauge packs, determine thick-

ness of shims required and add

.002” to each shim

pack to provide side bearing preload.

f. Remove case assembly and both side bearings us-

ing J-22588 with Adapter Leg J-22939 and Pilot

J-

2241-11.c. Mount Dial INDICATOR J-8001 on carrier sog. Install shim packs with respective side bearing

indicator stem is at right angles to a tooth on the ring

using Installer J-22919, Driver Handle J-8092 and

gear. See Figure

4B-34.Pilot J-2241-1 1.

Page 253 of 625

48. 221973 OPEL SERVICE MANUAL

9. Position

case assembly and outer races in the car-

rier. Use a soft-faced hammer to drive the case into

the carrier until the side bearing outer races bottom

in their bores.

10. Install side bearing caps in their original location

and torque the bolts to 33

lb.ft.IN. LB. TORQUL

11. Rotate case assembly several times to seat the

bearings. Check backlash and preload using a torque

wrench on a ring gear attaching bolt. See Figure 4B-

35. Torque required to turn case should be 20 to 30

Ib.in. for new bearings or 10 to 20 lb.in., for used

bearings. If torque is not correct, it will be necessary

to r&him the side bearings.

12. Insta!l torque tube assembly.

13. Install axle shafts.Figure 48.35 Checking Side Bearing

Preload

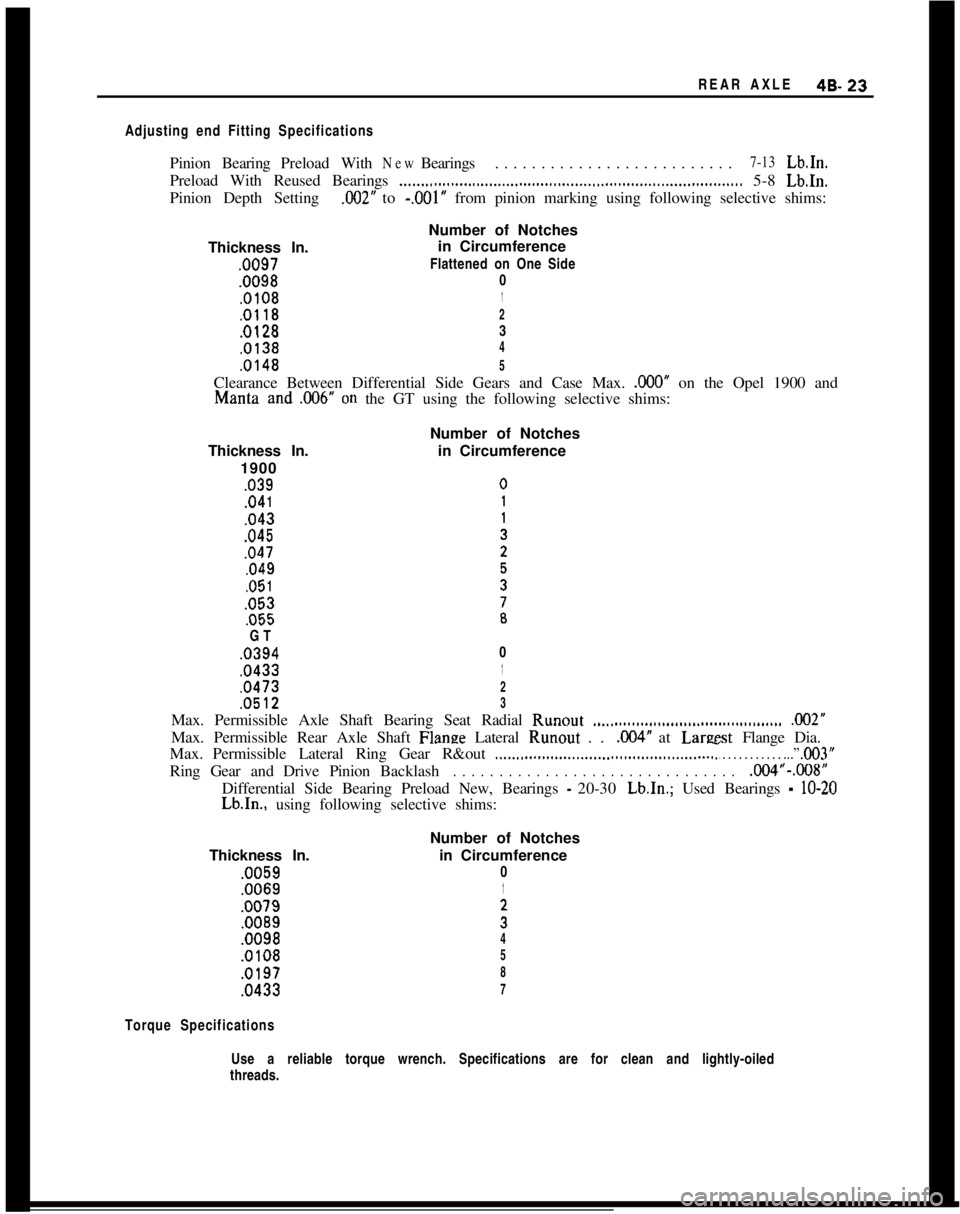

SPECIFICATIONS

DIFFERENTIAL SPECIFICATIONS

General SpecificationsRear Axle Type

.,,...,,,...,,_...._..,,...,,,...,,,....,,.,...,,.,,...,,..,,,........................ Semi-Floating Hypoid

Rear Axle Oil Capacity

..____,,...,,,...,.,..,............,,..,,..,,................................................. 2 l/2 7’.Ring and Pinion Gear Set Type

. . . . . . . . . . . . . . . . . .._................................................................Hypold

Axle Ratios

Page 254 of 625

REAR AXLE49.23

Adjusting end Fitting SpecificationsPinionBearingPreloadWith

NewBearings. . . . . . . . . . . . . . . . . . . . . . . . . .7-13Lb.In.

Preload With Reused Bearings

__.._..I...................,.................,,...................,,............ 5-8 Lb.In.

Pinion Depth Setting

.002” to -.OOl’ from pinion marking using following selective shims:

Number of Notches

Thickness In.in Circumference.0097Flattened on One Side

.00980

.01081

.01182

.01283

.01384

.01485Clearance Between Differential Side Gears and Case Max.

,000” on the Opel 1900 andManta and

,006” on the GT using the following selective shims:

Thickness In.

1900

,039.04

1,043,045,047,049.05

1,053,055

GT

.0394

.0433

.0473Number of Notches

in Circumference

0

1

2

.05123Max. Permissible Axle Shaft Bearing Seat Radial Runout

.._......................................... ,002”Max. Permissible Rear Axle Shaft Flanze Lateral Runout . .

,004” at Lareest Flange Dia.

Max.Permissible Lateral Ring Gear R&out

._.._,,.........._.....,........................... T . . . . . . . . . . . ...” ,003”RingGearandDrivePinionBacklash

. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .,004”-.008”

Differential Side Bearing Preload New, Bearings

- 20-30 Lb.In.; Used Bearings - lo-20Lb.In., using following selective shims:

Thickness In..0059.0069

.0079

.0089

.0098

.0108

.0197

.0433Number of Notches

in Circumference

0

1

;

4

5

8

7

Torque SpecificationsUse a reliable torque wrench. Specifications are for clean and lightly-oiled

threads.

Page 255 of 625

49- 241973 OPEL SERVICE MANUAL

Torque

Lb.Ft.

1.9Nut and BoltPropshaft to Drive Pinion Shaft Extension Flange

......11

NutFlange

toDriveShaftExtension........................................87

BoltRing Gear to Case................................................................

BoltSideBearingCaptoCarrier.............................................i;

BoltDifferentialHousingCover.................................................22

NutTrackRodAttaching(GT)....................................................40

Nut and BoltStabilizer

RodtoRearAxleShackle................................25

BoltStabilizer Rod to Body........................................................15

NutTrack Rod to Rear Axle (Opal1900 & Manta)..............76

NutTrack Rod to Side Member (Opel 1900 & Manta)......22

10 MM Bolt Nut

....................................................................................................................368 MM Bolt Nut

......................................................................................................................156 MM Bolt Nut

........................................................................................................................5

Page 256 of 625

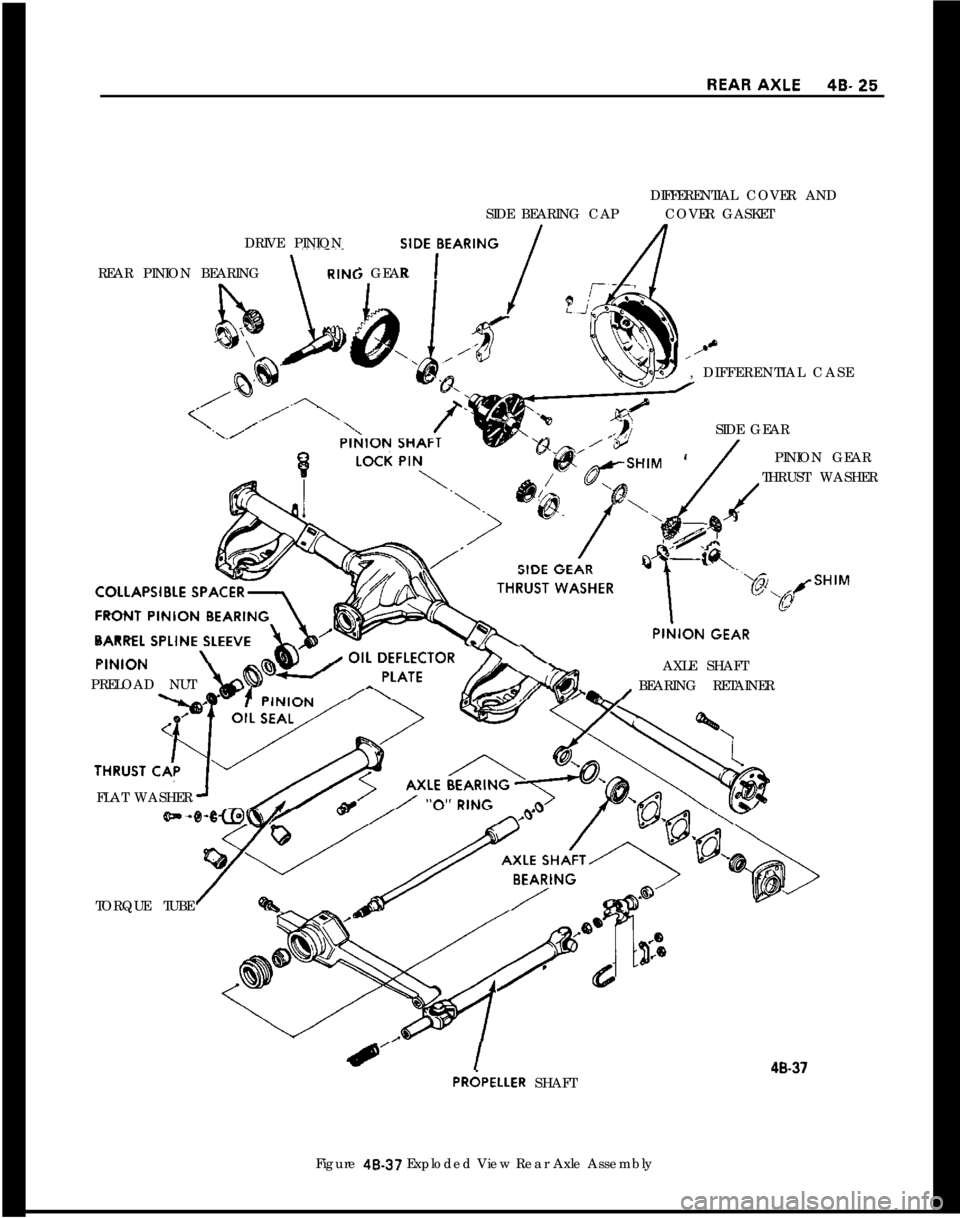

DIFFERENTIAL COVER AND

SIDE BEARING CAPCOVER GASKET

DRIVE PINIONSlDE,BEARlNG /; GEAR REAR PINION BEARINGx

\PRELOAD NUT, DIFFERENTIAL CASE

SIDE GEAR

PINION GEAR

THRUST WASHER

AXLE SHAFT

BEARING RETAINER

FLAT WASHER

TORQUE TUBE40.37PRdPELLER SHAFT

Figure 48-37 Exploded View Rear Axle Assembly

Page 257 of 625

MM Inches.Ol.ocQ4

.02.ooot?

.03.OOlZ

.04.0016

.05.0020

.06.0024

.07.0028

.08.0032

.09.0035

.lO.0039

.ll.0043

.12.ow7

.I3.0051

.14.0055

.15.0059

.16.OM3

.17JO67

.18.0071

.19.0075

.20JO79

.21.0083

.22.0087MM InchesMM InchesMM InchesMM InchesMM Inches

23.0091A4.0173.65.025637.03439.354324

.0095.45.0177.66II260233.034710.3937

.25Al098.46.0181.67.0264.89.0350

.26.0102.47.0185.68.0268.90.035411.4331

.27.0106.48.0186.69~3272-12.4724

.28.OllO.49.0193.70.0276.91.035813.5118

.29.0114.50.0197.92I136214.5512

.30.0118.71.0280.93.036615.5906-

[email protected]

.31.0122.52.0205.73.0287.95.037417.6693

.32.0126.53.cRo9.74.0291.96.037818.7087

.33.0130.54ml3*75*0295.97.038219.7480

.34.0134.55.0217.76SE’99.98.038620.7874

.35.0138.56.0221.77.0303.99a390

.36.0142.57.0224.78.03071.00.039421.8268

.37.0146.58.0228.79.031122.8661

.38.0150.59.023230.03151.039423.9055

.39.0154.60.02362.078724.9449

.40.0158.81.03203.118125.9&13

22.0323

4.1575261.0236

.61.024033.03275.1969271.0630

.41.0161.623244.&I.0331

6.2362281.1024

.42.0165.63.0246.85.03357.2756291.1417

.43.016954.0252.86.03398.3150301.1811

* (one MM = .0394”; one inch = 25.4 MM)4538

Figure 48-38 Conversion Table

- Millimeter to Inch Equivalent

Page 258 of 625

IREAR AXLE48.27J-21691-6

J-22935

J-22936

J-22919J-22931J-8872J-2241-1 I J-7818

J-22938J-24093

J-22937

J-22588Figure

48.39 Differential Special Tools

Page 259 of 625

Page 260 of 625

BRAKES

GROUP 5

Section

5A

5B

5C

Title

Brake Booster and

Master Cylinder

Disc Brakes

.._.__.._____

Drum Brakes. . . . . . . . . . . . .

Page No.

5A- 2

5B-10

5C-22