RENAULT KANGOO 1997 KC / 1.G Sheet Metal Work Workshop Manual

Manufacturer: RENAULT, Model Year: 1997, Model line: KANGOO, Model: RENAULT KANGOO 1997 KC / 1.GPages: 255

Page 1 of 255

77 11 194 280JULY 1997Edition Anglaise

Sheet Metal Work

The repair methods given by the manufacturer in this document are based on the

technical specifications current when it was prepared.

The methods may be modified as a result of changes introduced by the

manufacturer in the production of the various component units and accessories

from which his vehicles are constructed."All copyrights reserved by Renault.

Copying or translating, in part or in full, of this document or use of the service part

reference numbering system is forbidden without the prior written authority of

Renault.

CRenault 1997

GENERAL

LOWER STRUCTURE

UPPER FRONT STRUCTURE

UPPER SIDE STRUCTURE

UPPER REAR STRUCTURE

TOP OF BODY

SIDE OPENING ELEMENTS

NON-SIDE OPENING ELEMENTS

Page 2 of 255

EXPLODED VIEW

PRB4008

Page 3 of 255

Contents

GENERAL

Dimensions

Engine and equipment

Identification

Means of lifting

Towing

Using symbols

Key to symbols

Description of Parts (exploded)

Opening clearances

Collision fault finding

Sub- frame dimensions

Repair bench

Special tooling

Part Number of special tooling40-1

40-2

40-4

40-6

40-8

40-9

40-11

40-12

40-15

40-22

40-25

40-27

40-38

40-38

LOWER STRUCTURE

41- 1

41- 5

41-10

41-13

41-17

41-21

41-26

41-29

41-33

41-36

41-39

41-41

41-44

41-51

41-53

41-55

41-58

41-60

41-62

41-63

41-67

41-68

41-71UPPER FRONT STRUCTUREPage Page40

41

42

Sheet metal work

UPPER SIDE STRUCTURE43

AFront end lower cross member

BFront side member, front section

CFront side member closure panel

DFront half unit

EFront side cross member

FFront side member, rear section

GFront mounting of sub frame

HSill panel closure panel

ICross member under front seat

JSide floor

KTunnel

LRear floor, front section

MRear floor, rear section (part

section)

NFront cross member of rear floor,

front section

ORear floor stiffener

PRear end cross member

QRear absorber reinforcement

RRear side member extension

SRear side member, part section

TComplete rear side member

URear floor centre cross member

VSeat anchoring reinforcement

WRear floor unit42-1

42-2

42-5

42-8

42-12

42-17

42-24

42-28

42-32

42-34 AFront wing

BHeadlight carrier panel

CCowl side panel (pillar lining)

part section

DUpper reinforcement of cowl side

panel

EWheel arch, front section

FWheel arch

GPlenum chamber

HWindscreen aperture lower cross

member

ISteering column mounting

JBulkhead

43-1

43-6

43-9

43-14

43-19

43-23

43-25 AFront pillar

BWindscreen pillar

C Front pillar lining/Cowl side panel

DCentre pillar / sill panel

ECentre pillar lower reinforcement /

door pillar

FSill panel reinforcement

GLeft hand side sill panel

UPPER REAR STRUCTURE

44

44-1

44-9

44-17

44-26

44-30

44-33

44-38

44-41 ARear wing panel

BSide panel

CSide panel lining

DRoof stretcher lining

ERear inner wheel arch

FLights mounting side panel rain

channel

GRear wing panel extension

HRear end panel

Page 4 of 255

Contents

NON-SIDE OPENING ELEMENTS48

TOP OF BODY

SIDE OPENING ELEMENTS45

47

45-1

45-7

45-8

45-9 ARoof

BRoof front cross member

CRoof centre cross member

DRoof rear cross member

47-1

47-2

47-6

47-8

47-11

47-14

48-1

48-2

48-3

48-4

48-5 ABonnet

BBonnet hinge

CRear opening doors

D Tailgate

ERoof flap AFront door

BFront door panel

CFront door stiffener

DSide door

ESide door panel

FSide door stiffener

Page 5 of 255

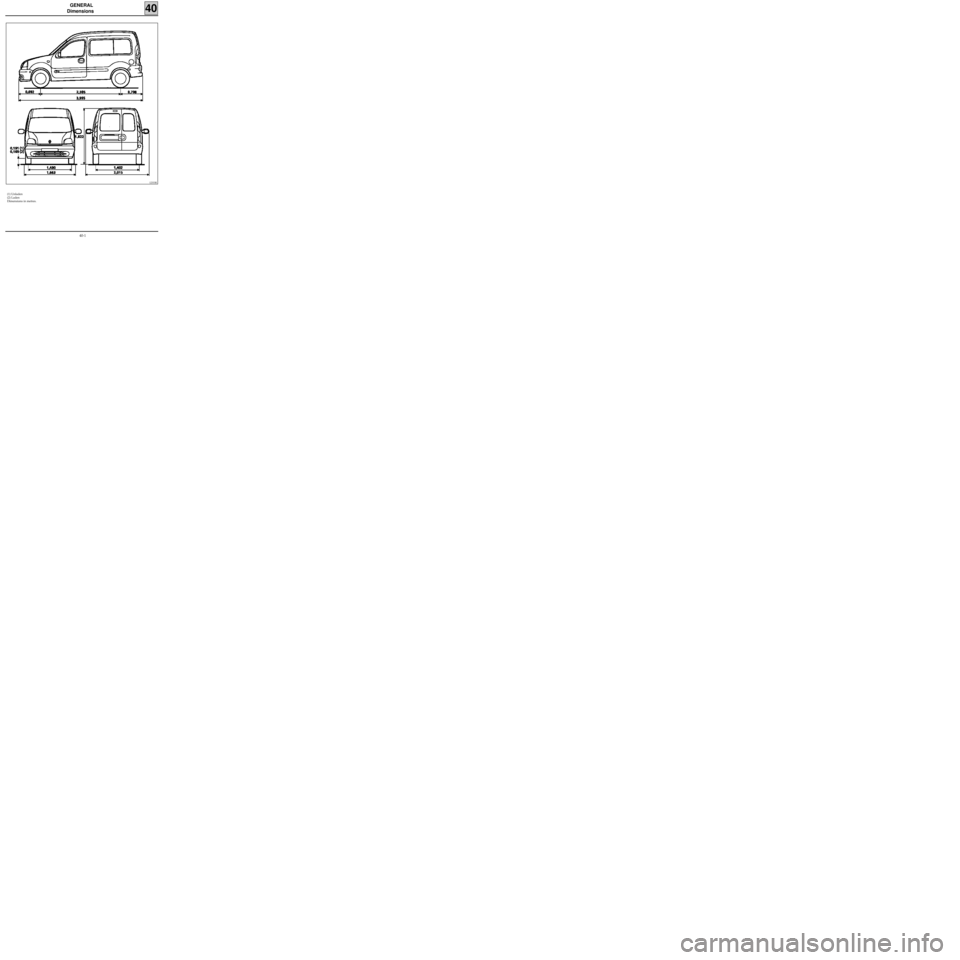

GENERAL

Dimensions

(1) Unladen

(2) Laden

Dimensions in metres.

40

12333R

40-1

Page 6 of 255

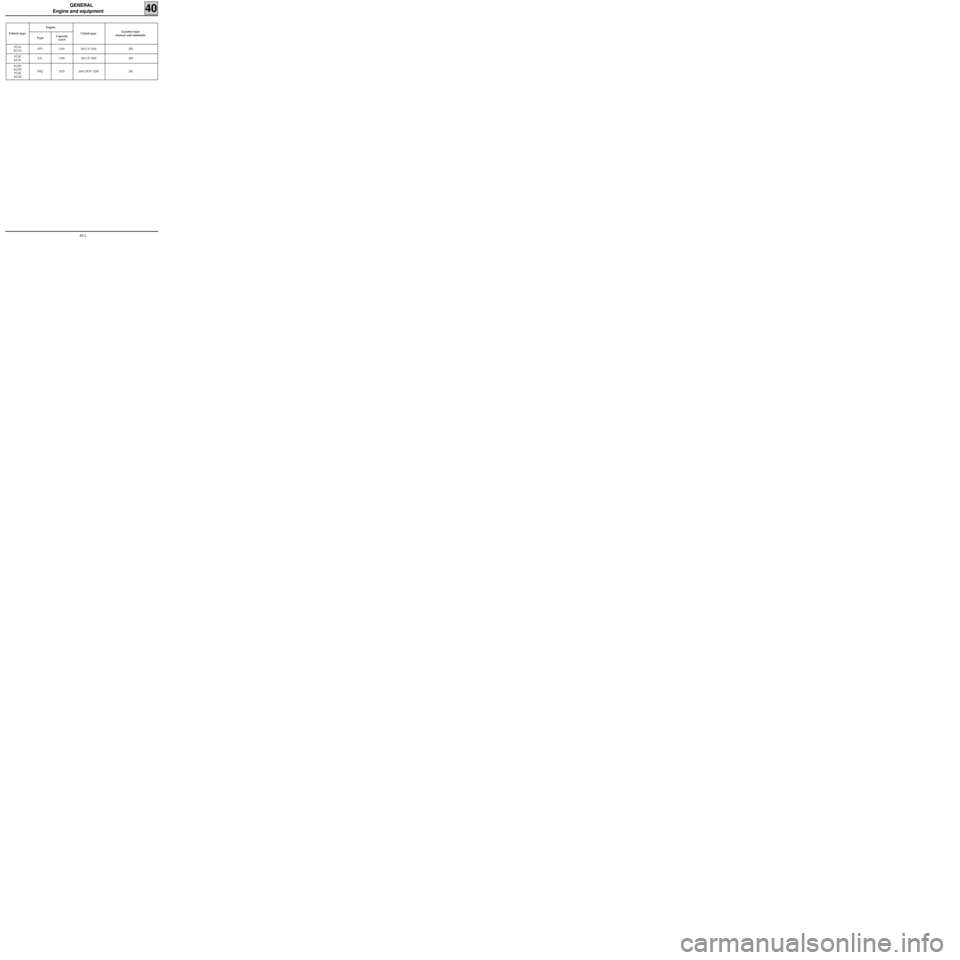

GENERAL

Engine and equipment

40

Vehicle type Engine

TypeCapacity

(cm

3)Clutch type Gearbox type

manual and automatic

FC0A

KC0AD7F 1149 180 CP 3300 JB1

FC0C

KC0CE7J 1390 180 CP 3300 JB3

FC0D

KC0D

FC0E

KC0EF8Q 1870 200 CPOV 3250 JB1

40-2

Page 7 of 255

GENERAL

Engine and equipment

40

SPECIFIC BODYWORK FEATURES

Driver’s airbag

Passenger’s and driver’s airbag

Height adjustable front head restraint

Height adjustable and tiltable front head restraint

Rear parcel shelf

Luggage compartment net

Electric one touch windows

Heated electric rear view mirrors

Heated screen + timed windscreen wiper

Heated front seats

Front seat driver emergency exit

Rear bench seat 1/1

Rear bench seat 1/3 - 2/3

Cabin rack without stop

Headlining

Boot carpet

Parcel shelf luggage cover

Two front fog lights in bumper

(excluding F8 AC PAS)Pay load 600 kg

Pay load 625 to 710 kg depending on

engine/equipment

Pay load 800 kg

Glazed, sliding side door and rear opening doors

or glazed tailgate

Sliding side door (reflective glass)

Sliding side door (panel)

Rear door, panel

Rear door, glazed

Opening doors, panels

Opening doors, glazed

Tailgate

Opaque roof flap (excluding tailgate)

Glazed roof flap (excluding tailgate)

Fixed side window (meaning glazed side door)

Sliding side window

Fixed rear quarter panel (meaning the glazed

sliding side door )

Heat insulating windscreen (with air conditioning)

2 point rear centre seat belt

3 point rear centre seat belt

40-3

Page 8 of 255

GENERAL

Identification

40

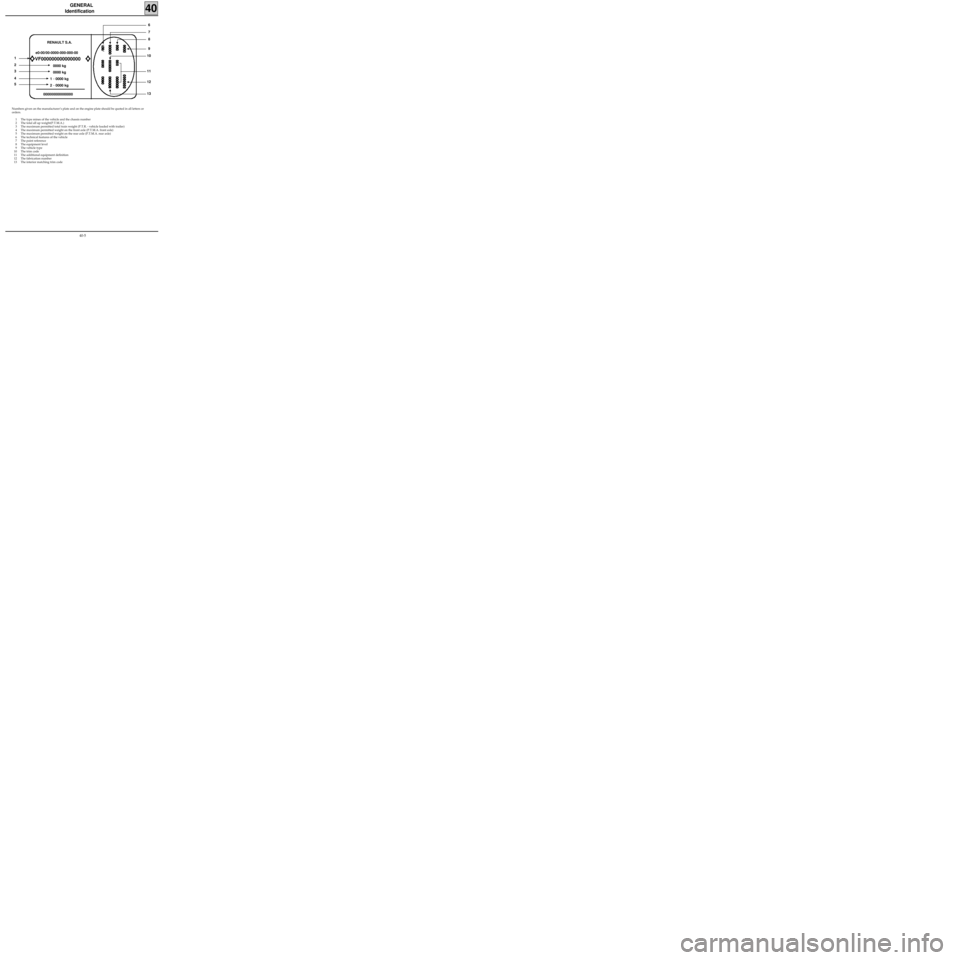

POSITIONING OF VEHICLE IDENTIFICATION PLATE

It is located at the bottom of the right hand side

centre pillar.

13187R

40-4

Page 9 of 255

GENERAL

Identification

40

Numbers given on the manufacturer’s plate and on the engine plate should be quoted in all letters or

orders.

1 The type mines of the vehicle and the chassis number

2 The total all up weight(P.T.M.A.)

3 The maximum permitted total train weight (P.T.R. - vehicle loaded with trailer)

4 The maximum permitted weight on the front axle (P.T.M.A. front axle)

5 The maximum permitted weight on the rear axle (P.T.M.A. rear axle)

6 The technical features of the vehicle

7 The paint reference

8 The equipment level

9 The vehicle type

10 The trim code

11 The additional equipment definition

12 The fabrication number

13 The interior matching trim code

e0-00/00-0000-000-000-00

VF000000000000000

0000 kg

0000 kg

1

- 0000 kg

2

- 0000 kg

000000000000000RENAULT S.A.

1

2

3

4

5

8 7

6

9

10

13

12 11

40-5

Page 10 of 255

GENERAL

Means of lifting

40

AXLE STANDS

To place the vehicle on axle stands, they MUSTbe

placed:

- either under the reinforcements provided for

lifting the vehicle with the jack which forms

part of the vehicle equipment,

- or under the points behind the reinforcements.

Rear positioning of the axle stands can be carried

out by lifting the vehicle from the side.

Safety symbol (special precautions to be taken when carrying out operations).

SPECIAL TOOLING REQUIRED

Cha. 280 -02 Adaptable cross piece for trolley

jack

Cha. 408 -01

or Adaptable socket for trolley jack

Cha. 408 -02

If a trolley jack is used, appropriate axle

stands must always be used.

The vehicle MUST NOT be lifted by supporting its

weight under the front suspension arms, or under

the V section rear axle.

According to the type of trolley jack, use sockets

Cha. 408-01 or Cha. 408-02 to position the cross

piece Cha. 280-02.

To lift at the front or rear, take the weight under

the vehicle jacking points.

LIFTING FROM THE SIDE WITH A TROLLEY JACK

Use cross piece Cha. 280-02.

Take the weight under the valance at the front

door.

Position the flange correctly in the cross member

groove.

12333-2G

12274-1R

85679-1G15

40-6