DODGE NEON 1999 Service Repair Manual

Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 781 of 1200

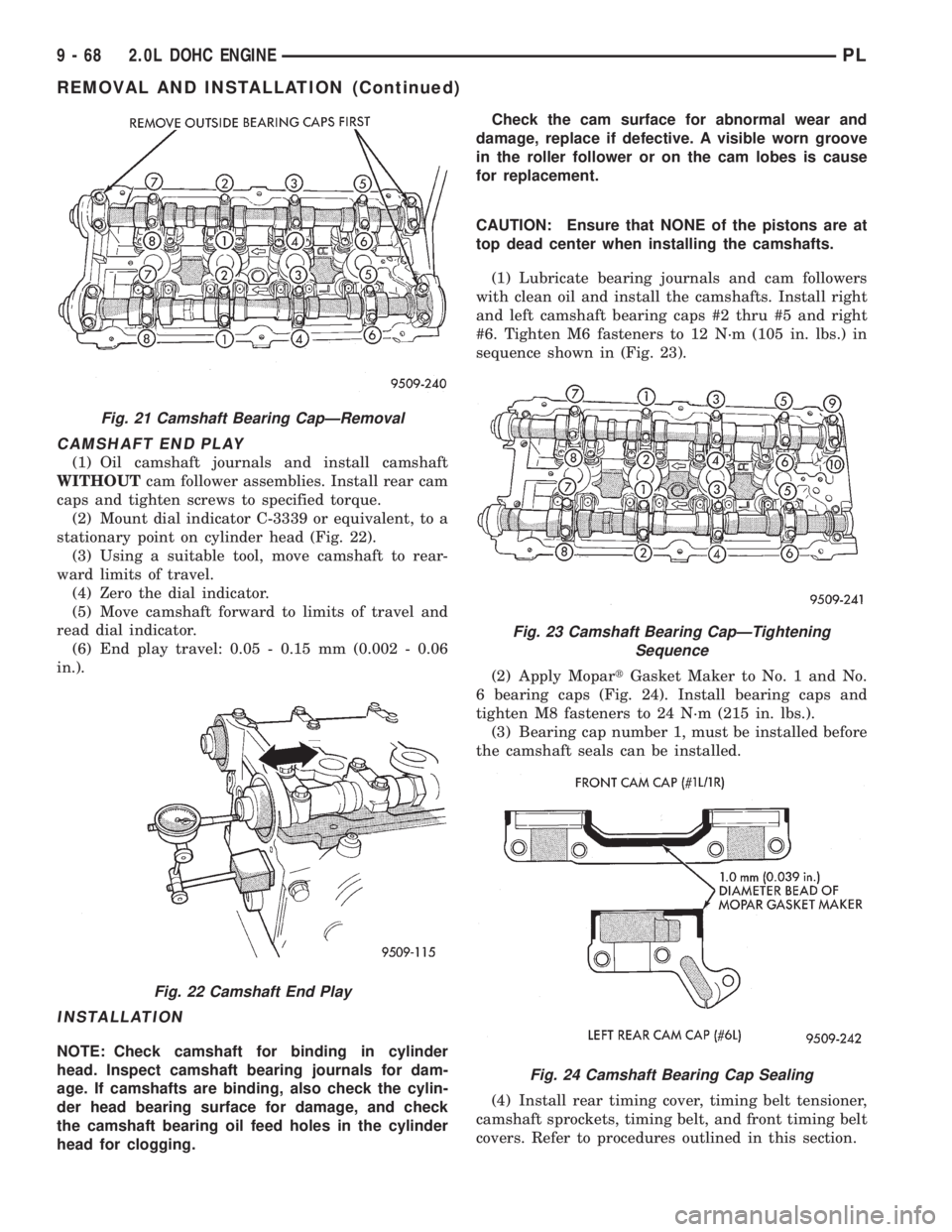

CAMSHAFT END PLAY

(1) Oil camshaft journals and install camshaft

WITHOUTcam follower assemblies. Install rear cam

caps and tighten screws to specified torque.

(2) Mount dial indicator C-3339 or equivalent, to a

stationary point on cylinder head (Fig. 22).

(3) Using a suitable tool, move camshaft to rear-

ward limits of travel.

(4) Zero the dial indicator.

(5) Move camshaft forward to limits of travel and

read dial indicator.

(6) End play travel: 0.05 - 0.15 mm (0.002 - 0.06

in.).

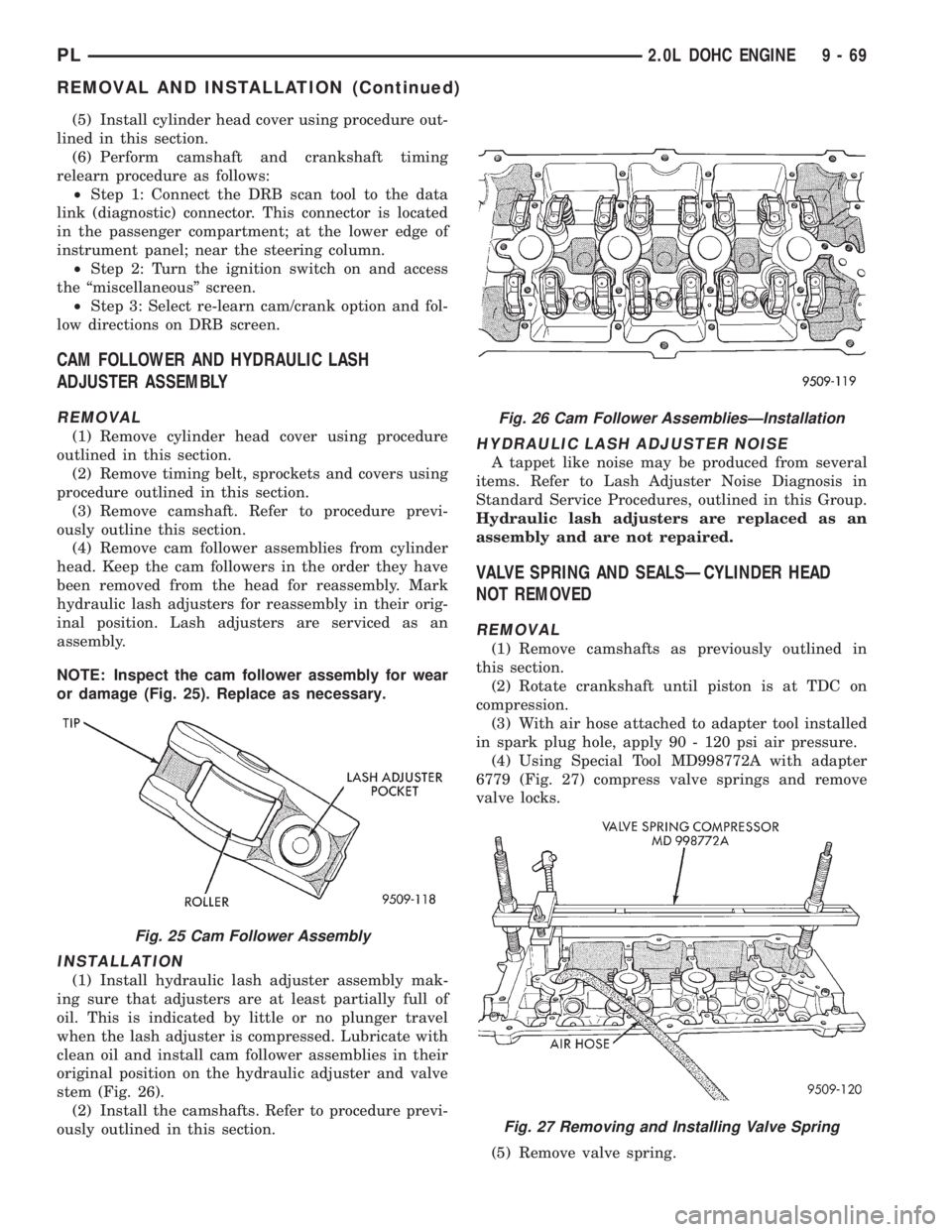

INSTALLATION

NOTE: Check camshaft for binding in cylinder

head. Inspect camshaft bearing journals for dam-

age. If camshafts are binding, also check the cylin-

der head bearing surface for damage, and check

the camshaft bearing oil feed holes in the cylinder

head for clogging.Check the cam surface for abnormal wear and

damage, replace if defective. A visible worn groove

in the roller follower or on the cam lobes is cause

for replacement.

CAUTION: Ensure that NONE of the pistons are at

top dead center when installing the camshafts.

(1) Lubricate bearing journals and cam followers

with clean oil and install the camshafts. Install right

and left camshaft bearing caps #2 thru #5 and right

#6. Tighten M6 fasteners to 12 N´m (105 in. lbs.) in

sequence shown in (Fig. 23).

(2) Apply MopartGasket Maker to No. 1 and No.

6 bearing caps (Fig. 24). Install bearing caps and

tighten M8 fasteners to 24 N´m (215 in. lbs.).

(3) Bearing cap number 1, must be installed before

the camshaft seals can be installed.

(4) Install rear timing cover, timing belt tensioner,

camshaft sprockets, timing belt, and front timing belt

covers. Refer to procedures outlined in this section.

Fig. 21 Camshaft Bearing CapÐRemoval

Fig. 22 Camshaft End Play

Fig. 23 Camshaft Bearing CapÐTightening

Sequence

Fig. 24 Camshaft Bearing Cap Sealing

9 - 68 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 782 of 1200

(5) Install cylinder head cover using procedure out-

lined in this section.

(6) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Step 1: Connect the DRB scan tool to the data

link (diagnostic) connector. This connector is located

in the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Step 2: Turn the ignition switch on and access

the ªmiscellaneousº screen.

²Step 3: Select re-learn cam/crank option and fol-

low directions on DRB screen.

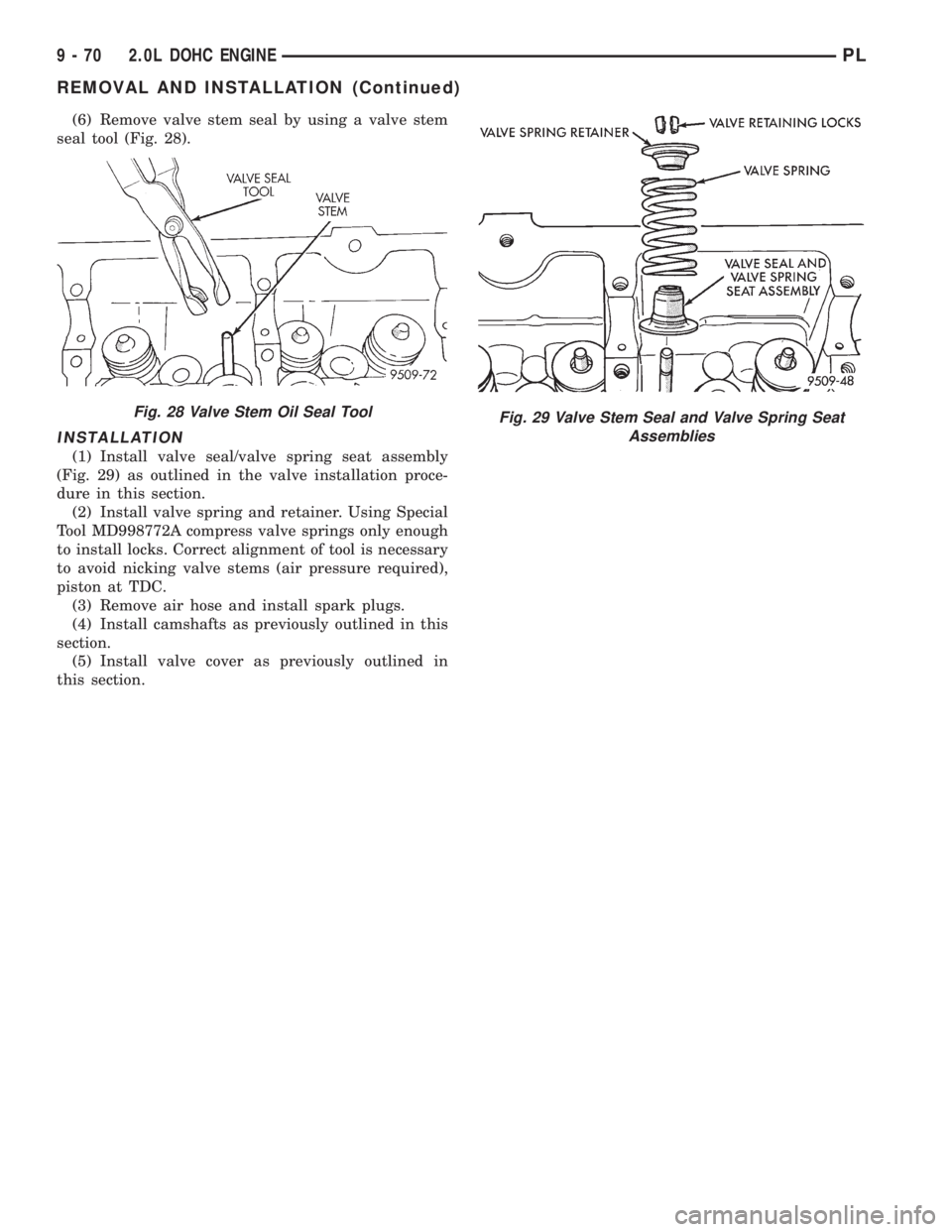

CAM FOLLOWER AND HYDRAULIC LASH

ADJUSTER ASSEMBLY

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Remove timing belt, sprockets and covers using

procedure outlined in this section.

(3) Remove camshaft. Refer to procedure previ-

ously outline this section.

(4) Remove cam follower assemblies from cylinder

head. Keep the cam followers in the order they have

been removed from the head for reassembly. Mark

hydraulic lash adjusters for reassembly in their orig-

inal position. Lash adjusters are serviced as an

assembly.

NOTE: Inspect the cam follower assembly for wear

or damage (Fig. 25). Replace as necessary.

INSTALLATION

(1) Install hydraulic lash adjuster assembly mak-

ing sure that adjusters are at least partially full of

oil. This is indicated by little or no plunger travel

when the lash adjuster is compressed. Lubricate with

clean oil and install cam follower assemblies in their

original position on the hydraulic adjuster and valve

stem (Fig. 26).

(2) Install the camshafts. Refer to procedure previ-

ously outlined in this section.

HYDRAULIC LASH ADJUSTER NOISE

A tappet like noise may be produced from several

items. Refer to Lash Adjuster Noise Diagnosis in

Standard Service Procedures, outlined in this Group.

Hydraulic lash adjusters are replaced as an

assembly and are not repaired.

VALVE SPRING AND SEALSÐCYLINDER HEAD

NOT REMOVED

REMOVAL

(1) Remove camshafts as previously outlined in

this section.

(2) Rotate crankshaft until piston is at TDC on

compression.

(3) With air hose attached to adapter tool installed

in spark plug hole, apply 90 - 120 psi air pressure.

(4) Using Special Tool MD998772A with adapter

6779 (Fig. 27) compress valve springs and remove

valve locks.

(5) Remove valve spring.

Fig. 25 Cam Follower Assembly

Fig. 26 Cam Follower AssembliesÐInstallation

Fig. 27 Removing and Installing Valve Spring

PL2.0L DOHC ENGINE 9 - 69

REMOVAL AND INSTALLATION (Continued)

Page 783 of 1200

(6) Remove valve stem seal by using a valve stem

seal tool (Fig. 28).

INSTALLATION

(1) Install valve seal/valve spring seat assembly

(Fig. 29) as outlined in the valve installation proce-

dure in this section.

(2) Install valve spring and retainer. Using Special

Tool MD998772A compress valve springs only enough

to install locks. Correct alignment of tool is necessary

to avoid nicking valve stems (air pressure required),

piston at TDC.

(3) Remove air hose and install spark plugs.

(4) Install camshafts as previously outlined in this

section.

(5) Install valve cover as previously outlined in

this section.

Fig. 28 Valve Stem Oil Seal ToolFig. 29 Valve Stem Seal and Valve Spring Seat

Assemblies

9 - 70 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 784 of 1200

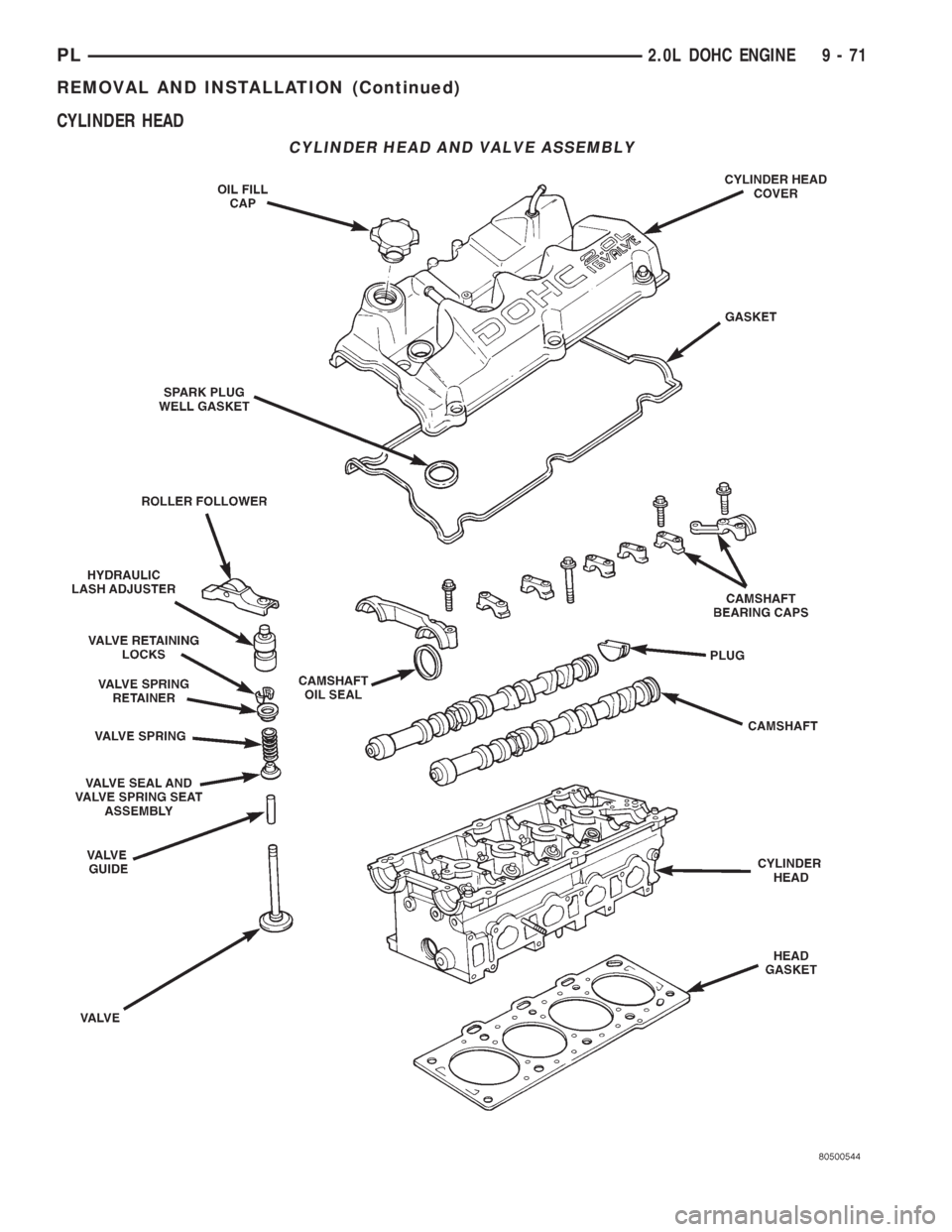

CYLINDER HEAD

CYLINDER HEAD AND VALVE ASSEMBLY

PL2.0L DOHC ENGINE 9 - 71

REMOVAL AND INSTALLATION (Continued)

Page 785 of 1200

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System.

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System.

(3) Remove air cleaner duct and air cleaner, dis-

connect all vacuum lines, electrical wiring and fuel

line from fuel rail and throttle body.

(4) Remove throttle linkage.

(5) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.

(8) Remove power steering pump assembly and set

aside.

(9) Disconnect coil pack wiring connector and

remove coil pack from engine.

(10) Remove cam sensor and fuel injectors wiring

connectors.

(11) Remove timing belt, timing belt tensioner, and

camshaft sprocket. Refer to procedure outlined in

this section.

(12) Remove inner timing belt cover.

(13) Remove cylinder head cover.

(14) Remove camshaft and cam follower assem-

blies. Refer to Camshaft Service for removal proce-

dure outlined in this section.

(15) Remove cylinder head bolts.

CAUTION: Use only a plastic scraper to remove

gasket material on the aluminum head sealing sur-

faces to prevent damage to cylinder head.

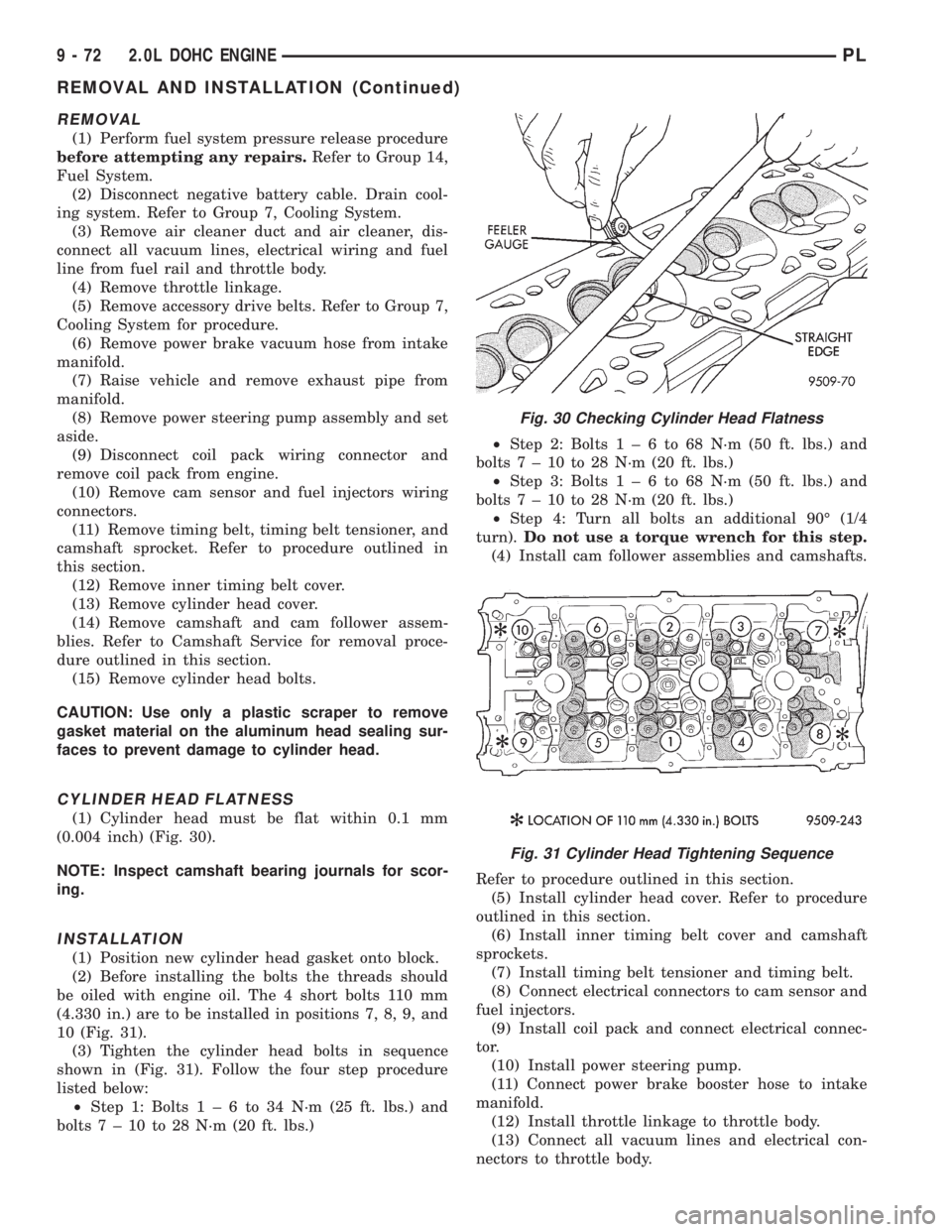

CYLINDER HEAD FLATNESS

(1) Cylinder head must be flat within 0.1 mm

(0.004 inch) (Fig. 30).

NOTE: Inspect camshaft bearing journals for scor-

ing.

INSTALLATION

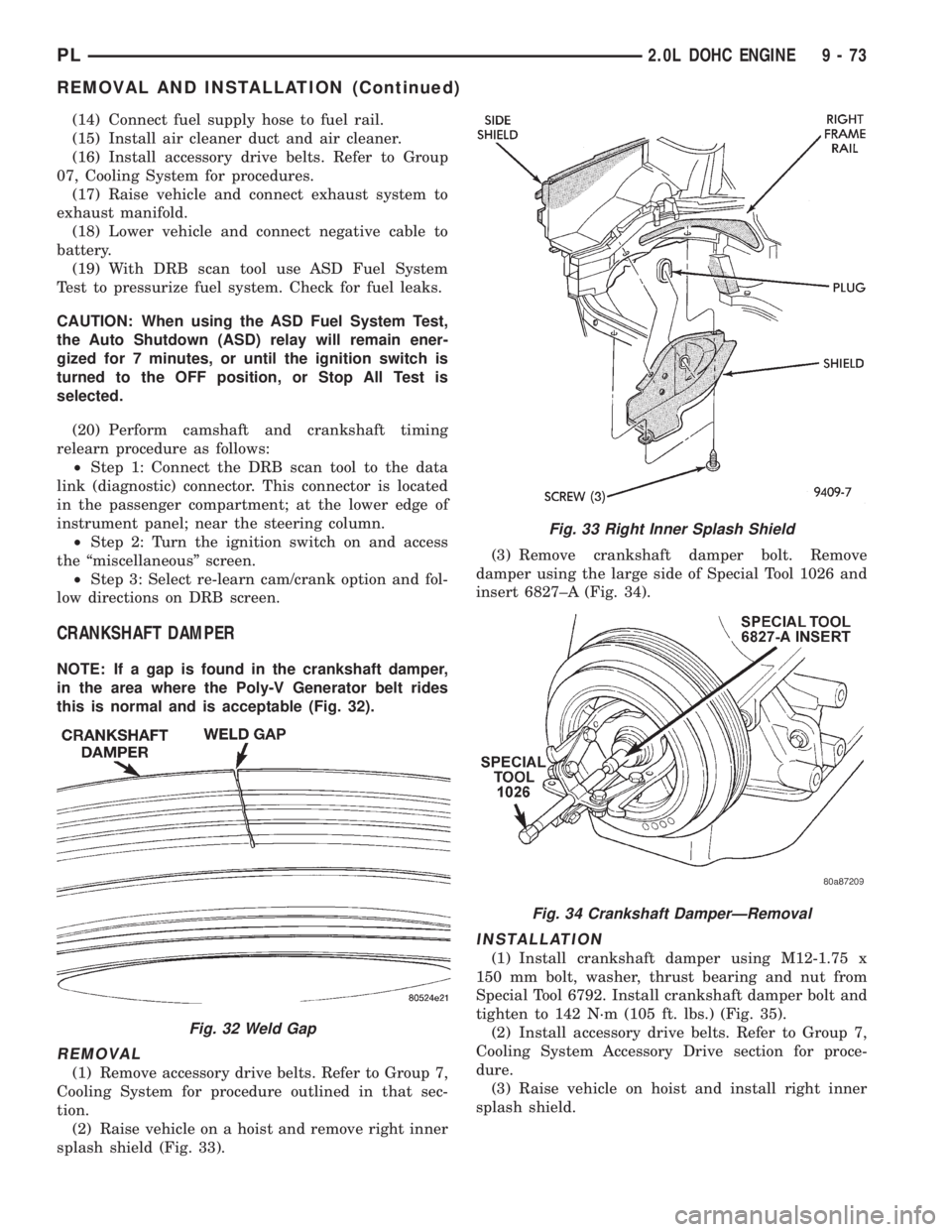

(1) Position new cylinder head gasket onto block.

(2) Before installing the bolts the threads should

be oiled with engine oil. The 4 short bolts 110 mm

(4.330 in.) are to be installed in positions 7, 8, 9, and

10 (Fig. 31).

(3) Tighten the cylinder head bolts in sequence

shown in (Fig. 31). Follow the four step procedure

listed below:

²Step 1: Bolts1±6to34N´m(25ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)²Step 2: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 3: Bolts1±6to68N´m(50ft.lbs.) and

bolts7±10to28N´m(20ft.lbs.)

²Step 4: Turn all bolts an additional 90É (1/4

turn).Do not use a torque wrench for this step.

(4) Install cam follower assemblies and camshafts.

Refer to procedure outlined in this section.

(5) Install cylinder head cover. Refer to procedure

outlined in this section.

(6) Install inner timing belt cover and camshaft

sprockets.

(7) Install timing belt tensioner and timing belt.

(8) Connect electrical connectors to cam sensor and

fuel injectors.

(9) Install coil pack and connect electrical connec-

tor.

(10) Install power steering pump.

(11) Connect power brake booster hose to intake

manifold.

(12) Install throttle linkage to throttle body.

(13) Connect all vacuum lines and electrical con-

nectors to throttle body.

Fig. 30 Checking Cylinder Head Flatness

Fig. 31 Cylinder Head Tightening Sequence

9 - 72 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 786 of 1200

(14) Connect fuel supply hose to fuel rail.

(15) Install air cleaner duct and air cleaner.

(16) Install accessory drive belts. Refer to Group

07, Cooling System for procedures.

(17) Raise vehicle and connect exhaust system to

exhaust manifold.

(18) Lower vehicle and connect negative cable to

battery.

(19) With DRB scan tool use ASD Fuel System

Test to pressurize fuel system. Check for fuel leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes, or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

(20) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Step 1: Connect the DRB scan tool to the data

link (diagnostic) connector. This connector is located

in the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Step 2: Turn the ignition switch on and access

the ªmiscellaneousº screen.

²Step 3: Select re-learn cam/crank option and fol-

low directions on DRB screen.

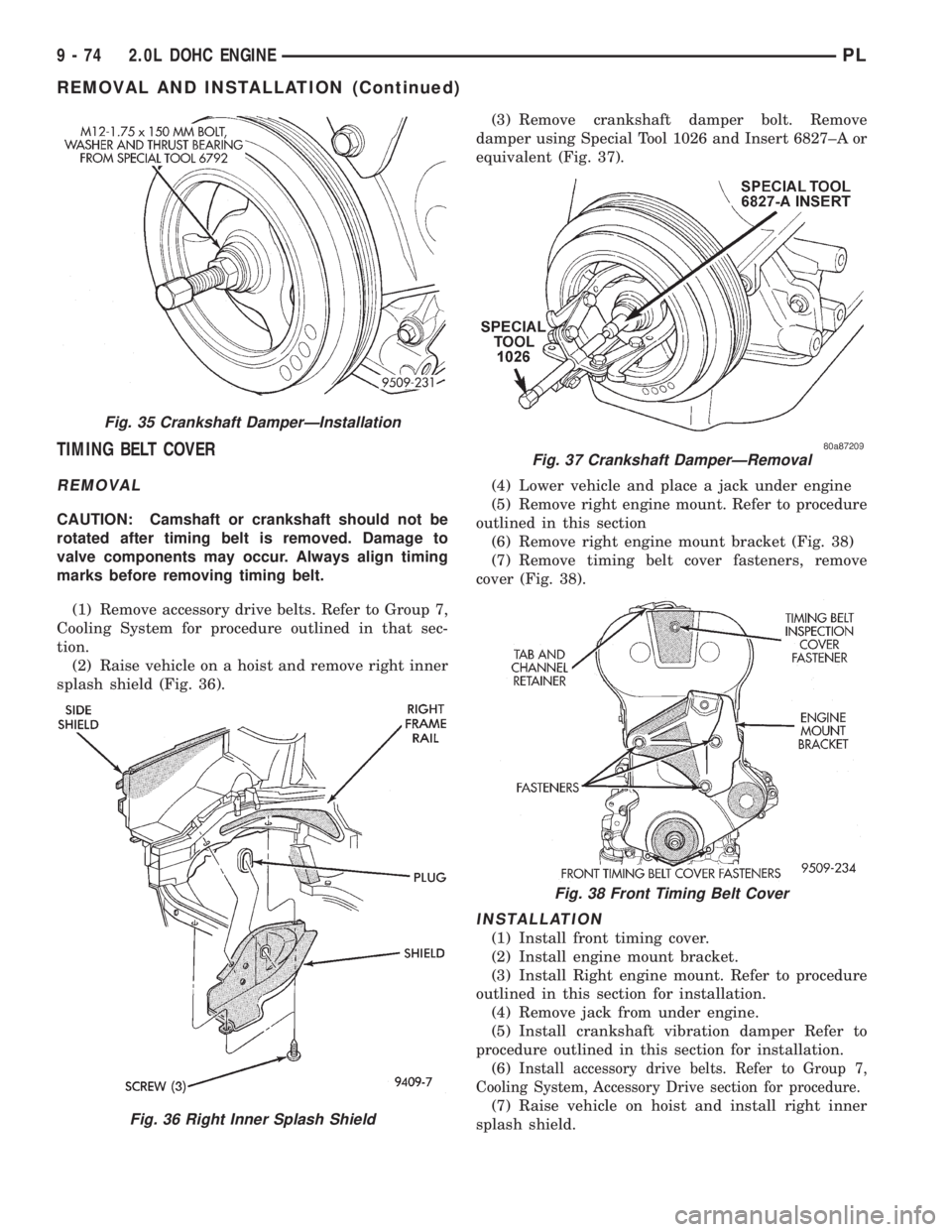

CRANKSHAFT DAMPER

NOTE: If a gap is found in the crankshaft damper,

in the area where the Poly-V Generator belt rides

this is normal and is acceptable (Fig. 32).

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Raise vehicle on a hoist and remove right inner

splash shield (Fig. 33).(3) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827±A (Fig. 34).

INSTALLATION

(1) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 35).

(2) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive section for proce-

dure.

(3) Raise vehicle on hoist and install right inner

splash shield.

Fig. 32 Weld Gap

Fig. 33 Right Inner Splash Shield

Fig. 34 Crankshaft DamperÐRemoval

PL2.0L DOHC ENGINE 9 - 73

REMOVAL AND INSTALLATION (Continued)

Page 787 of 1200

TIMING BELT COVER

REMOVAL

CAUTION: Camshaft or crankshaft should not be

rotated after timing belt is removed. Damage to

valve components may occur. Always align timing

marks before removing timing belt.

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Raise vehicle on a hoist and remove right inner

splash shield (Fig. 36).(3) Remove crankshaft damper bolt. Remove

damper using Special Tool 1026 and Insert 6827±A or

equivalent (Fig. 37).

(4) Lower vehicle and place a jack under engine

(5) Remove right engine mount. Refer to procedure

outlined in this section

(6) Remove right engine mount bracket (Fig. 38)

(7) Remove timing belt cover fasteners, remove

cover (Fig. 38).

INSTALLATION

(1) Install front timing cover.

(2) Install engine mount bracket.

(3) Install Right engine mount. Refer to procedure

outlined in this section for installation.

(4) Remove jack from under engine.

(5) Install crankshaft vibration damper Refer to

procedure outlined in this section for installation.

(6)

Install accessory drive belts. Refer to Group 7,

Cooling System, Accessory Drive section for procedure.

(7) Raise vehicle on hoist and install right inner

splash shield.

Fig. 35 Crankshaft DamperÐInstallation

Fig. 36 Right Inner Splash Shield

Fig. 37 Crankshaft DamperÐRemoval

Fig. 38 Front Timing Belt Cover

9 - 74 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 788 of 1200

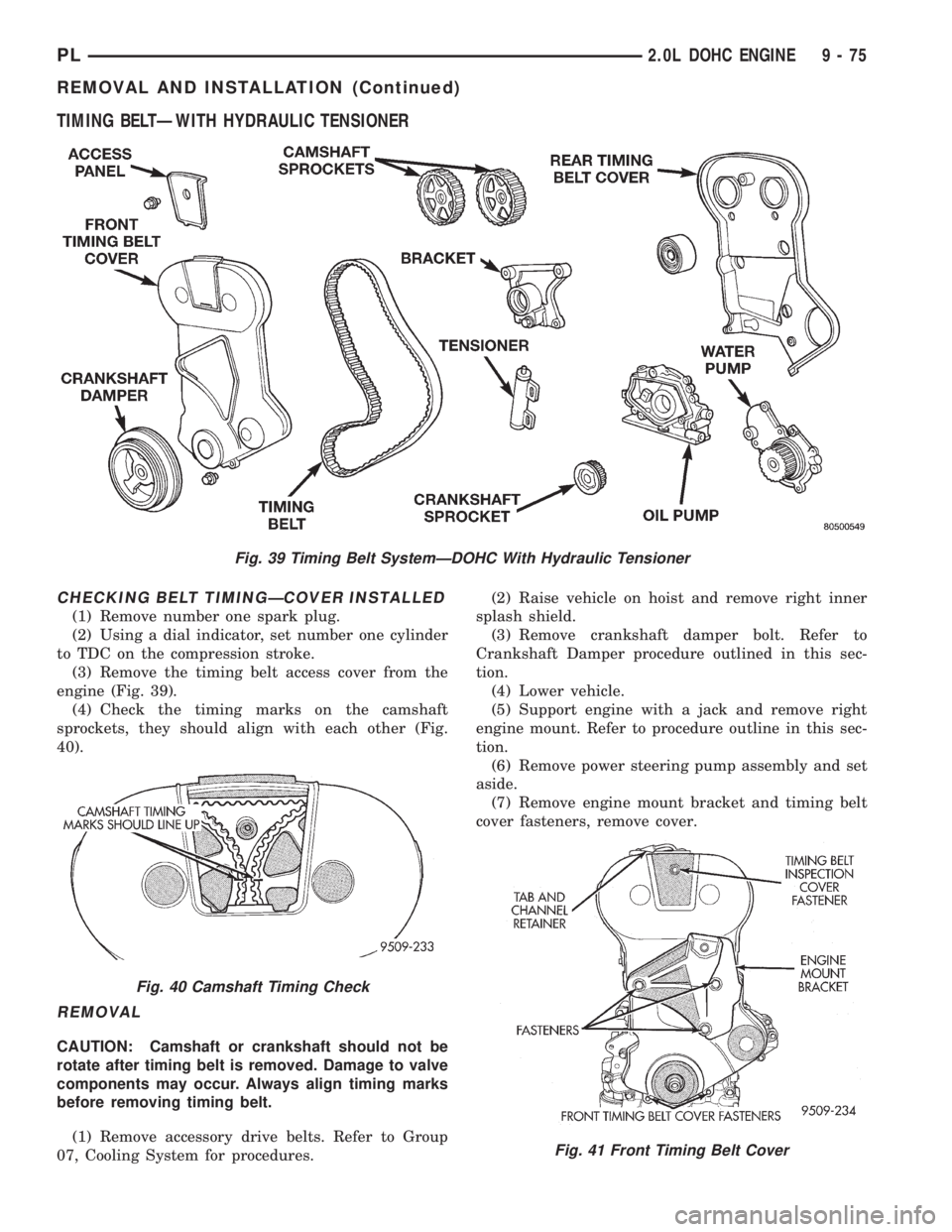

TIMING BELTÐWITH HYDRAULIC TENSIONER

CHECKING BELT TIMINGÐCOVER INSTALLED

(1) Remove number one spark plug.

(2) Using a dial indicator, set number one cylinder

to TDC on the compression stroke.

(3) Remove the timing belt access cover from the

engine (Fig. 39).

(4) Check the timing marks on the camshaft

sprockets, they should align with each other (Fig.

40).

REMOVAL

CAUTION: Camshaft or crankshaft should not be

rotate after timing belt is removed. Damage to valve

components may occur. Always align timing marks

before removing timing belt.

(1) Remove accessory drive belts. Refer to Group

07, Cooling System for procedures.(2) Raise vehicle on hoist and remove right inner

splash shield.

(3) Remove crankshaft damper bolt. Refer to

Crankshaft Damper procedure outlined in this sec-

tion.

(4) Lower vehicle.

(5) Support engine with a jack and remove right

engine mount. Refer to procedure outline in this sec-

tion.

(6) Remove power steering pump assembly and set

aside.

(7) Remove engine mount bracket and timing belt

cover fasteners, remove cover.

Fig. 39 Timing Belt SystemÐDOHC With Hydraulic Tensioner

Fig. 40 Camshaft Timing Check

Fig. 41 Front Timing Belt Cover

PL2.0L DOHC ENGINE 9 - 75

REMOVAL AND INSTALLATION (Continued)

Page 789 of 1200

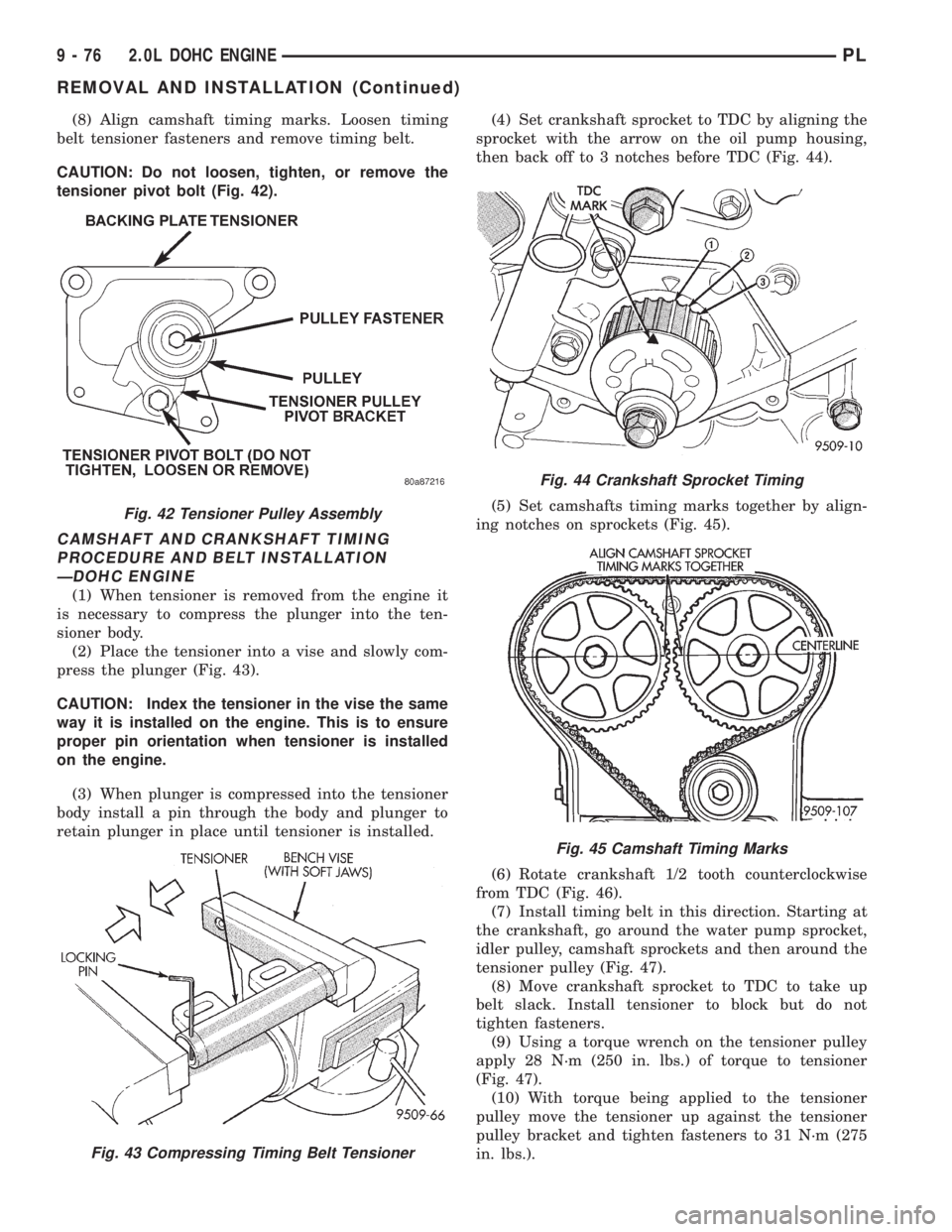

(8) Align camshaft timing marks. Loosen timing

belt tensioner fasteners and remove timing belt.

CAUTION: Do not loosen, tighten, or remove the

tensioner pivot bolt (Fig. 42).

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATION

ÐDOHC ENGINE

(1) When tensioner is removed from the engine it

is necessary to compress the plunger into the ten-

sioner body.

(2) Place the tensioner into a vise and slowly com-

press the plunger (Fig. 43).

CAUTION: Index the tensioner in the vise the same

way it is installed on the engine. This is to ensure

proper pin orientation when tensioner is installed

on the engine.

(3) When plunger is compressed into the tensioner

body install a pin through the body and plunger to

retain plunger in place until tensioner is installed.(4) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 44).

(5) Set camshafts timing marks together by align-

ing notches on sprockets (Fig. 45).

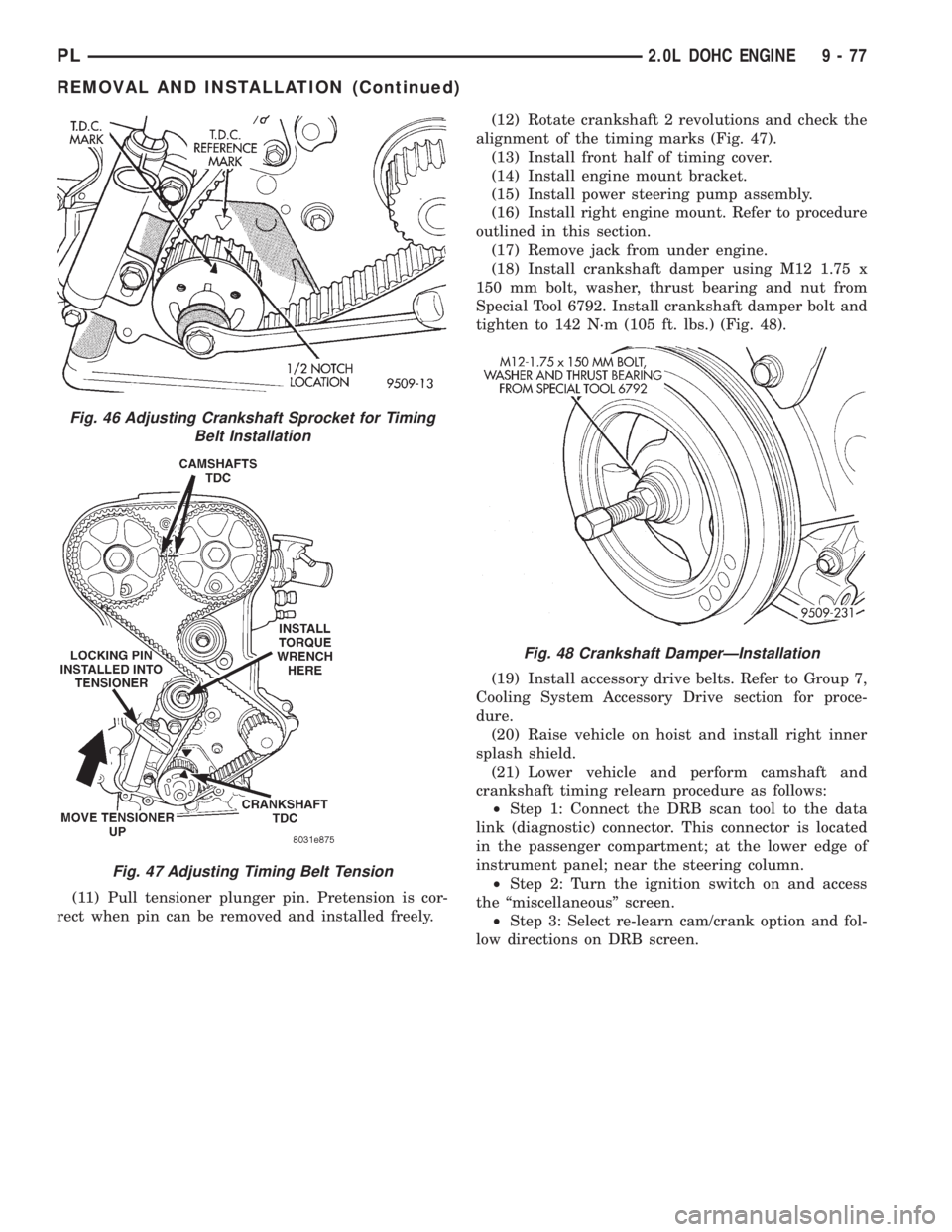

(6) Rotate crankshaft 1/2 tooth counterclockwise

from TDC (Fig. 46).

(7) Install timing belt in this direction. Starting at

the crankshaft, go around the water pump sprocket,

idler pulley, camshaft sprockets and then around the

tensioner pulley (Fig. 47).

(8) Move crankshaft sprocket to TDC to take up

belt slack. Install tensioner to block but do not

tighten fasteners.

(9) Using a torque wrench on the tensioner pulley

apply 28 N´m (250 in. lbs.) of torque to tensioner

(Fig. 47).

(10) With torque being applied to the tensioner

pulley move the tensioner up against the tensioner

pulley bracket and tighten fasteners to 31 N´m (275

in. lbs.).

Fig. 42 Tensioner Pulley Assembly

Fig. 43 Compressing Timing Belt Tensioner

Fig. 44 Crankshaft Sprocket Timing

Fig. 45 Camshaft Timing Marks

9 - 76 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 790 of 1200

(11) Pull tensioner plunger pin. Pretension is cor-

rect when pin can be removed and installed freely.(12) Rotate crankshaft 2 revolutions and check the

alignment of the timing marks (Fig. 47).

(13) Install front half of timing cover.

(14) Install engine mount bracket.

(15) Install power steering pump assembly.

(16) Install right engine mount. Refer to procedure

outlined in this section.

(17) Remove jack from under engine.

(18) Install crankshaft damper using M12 1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 48).

(19) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive section for proce-

dure.

(20) Raise vehicle on hoist and install right inner

splash shield.

(21) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Step 1: Connect the DRB scan tool to the data

link (diagnostic) connector. This connector is located

in the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Step 2: Turn the ignition switch on and access

the ªmiscellaneousº screen.

²Step 3: Select re-learn cam/crank option and fol-

low directions on DRB screen.

Fig. 46 Adjusting Crankshaft Sprocket for Timing

Belt Installation

Fig. 47 Adjusting Timing Belt Tension

Fig. 48 Crankshaft DamperÐInstallation

PL2.0L DOHC ENGINE 9 - 77

REMOVAL AND INSTALLATION (Continued)