ISUZU KB P190 2007 Workshop Repair Manual

Manufacturer: ISUZU, Model Year: 2007, Model line: KB P190, Model: ISUZU KB P190 2007Pages: 6020, PDF Size: 70.23 MB

Page 2871 of 6020

Engine Mechanical – V6 Page 6A1–94

Page 6A1–94

3.12 Camshaft Cover

Remove

1 Remove the intake manifold assembly, refer to 3.10 Intake Manifold Assembly – Complete .

2 For the left-hand side, remove the evaporative (EVAP) emission canister purge solenoid, refer to Section 6C1-3 Engine Management – V6 – Service Operations.

3 Remove the two bolts (1) attaching the engine wiring harness former to the rear of the cylinder heads.

4 Unclip the transmission v ent tube (2) from the engine

wiring harness.

Figure 6A1 – 61

5 Disconnect the oxygen sensor wiring harness connector (1) from the engine wiring harness (2), left-

hand shown, right-hand similar.

Figure 6A1 – 62

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2872 of 6020

Engine Mechanical – V6 Page 6A1–95

Page 6A1–95

6 Remove the bolt (1) attaching the ground connector

(2) to the cylinder head.

7 Fro the left-hand side, disconnect the engine coolant temperature (ECT) sensor wiring connector (3).

8 Unclip the engine wiring harness retaining lugs from the side of the camshaft cover.

Figure 6A1 – 63

9 For the right-hand side, remove the engine wiring harness retaining clip (1) from the engine control

module (ECM) bracket (2).

Figure 6A1 – 64

10 Disconnect the camshaft position (CMP) sensor wiring connector (1).

11 Unclip the engine wiring harness retaining lug (3) from the front of the camshaft cover.

12 Remove the ignition coil assemblies; refer to Section 6C1-3 Engine Management – V6 – Service

Operations .

13 Move the engine wiring harness clear of the camshaft cover.

Figure 6A1 – 65

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2873 of 6020

Engine Mechanical – V6 Page 6A1–96

Page 6A1–96

14 Remove the bolt (1), 13 places, attaching the camshaft

cover (2) to the cylinder head (3).

15 Remove the cover and discard the seal.

Figure 6A1 – 66

16 Install Tool No. EN-46101 (1) to the spark plug tubes of the cylinder head to prevent entry of dirt into the

combustion chamber.

Figure 6A1 – 67

Clean and Inspect

Safety glasses must be worn when using

compressed air.

1 Clean the camshaft cover with suitable cleaning solvent and blow dry with compressed air.

2 Inspect the cover for cracking and distortion.

3 Check the spark plug tube seals for damage.

4 If the camshaft cover is damaged in any way that will affect it’s performance to seal and stop the ingress of dirt, replace the camshaft cover.

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2874 of 6020

Engine Mechanical – V6 Page 6A1–97

Page 6A1–97

Reinstall

Reinstallation of the camshaft cover assembly is the reverse of the removal procedure, noting the following:

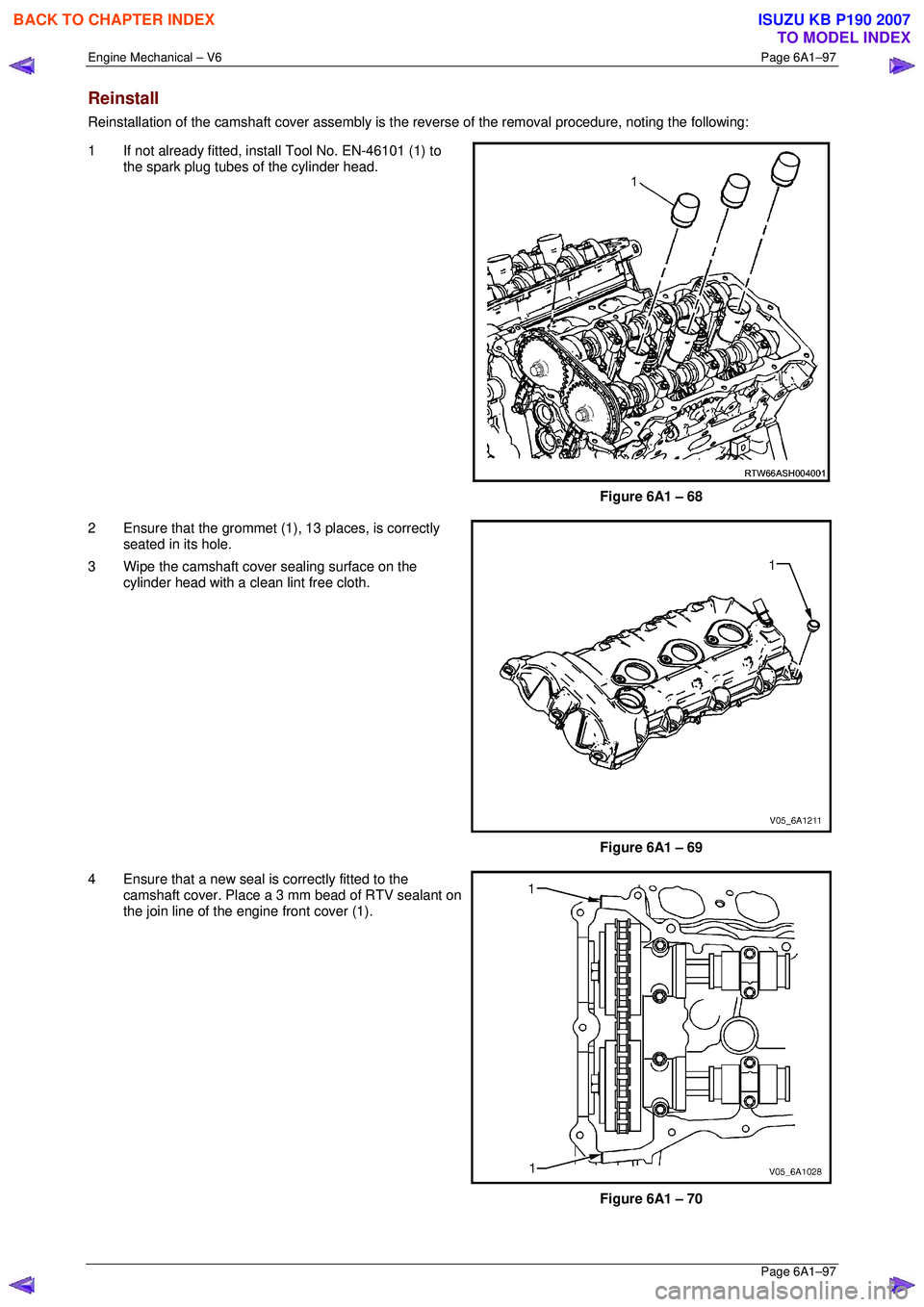

1 If not already fitted, install Tool No. EN-46101 (1) to the spark plug tubes of the cylinder head.

Figure 6A1 – 68

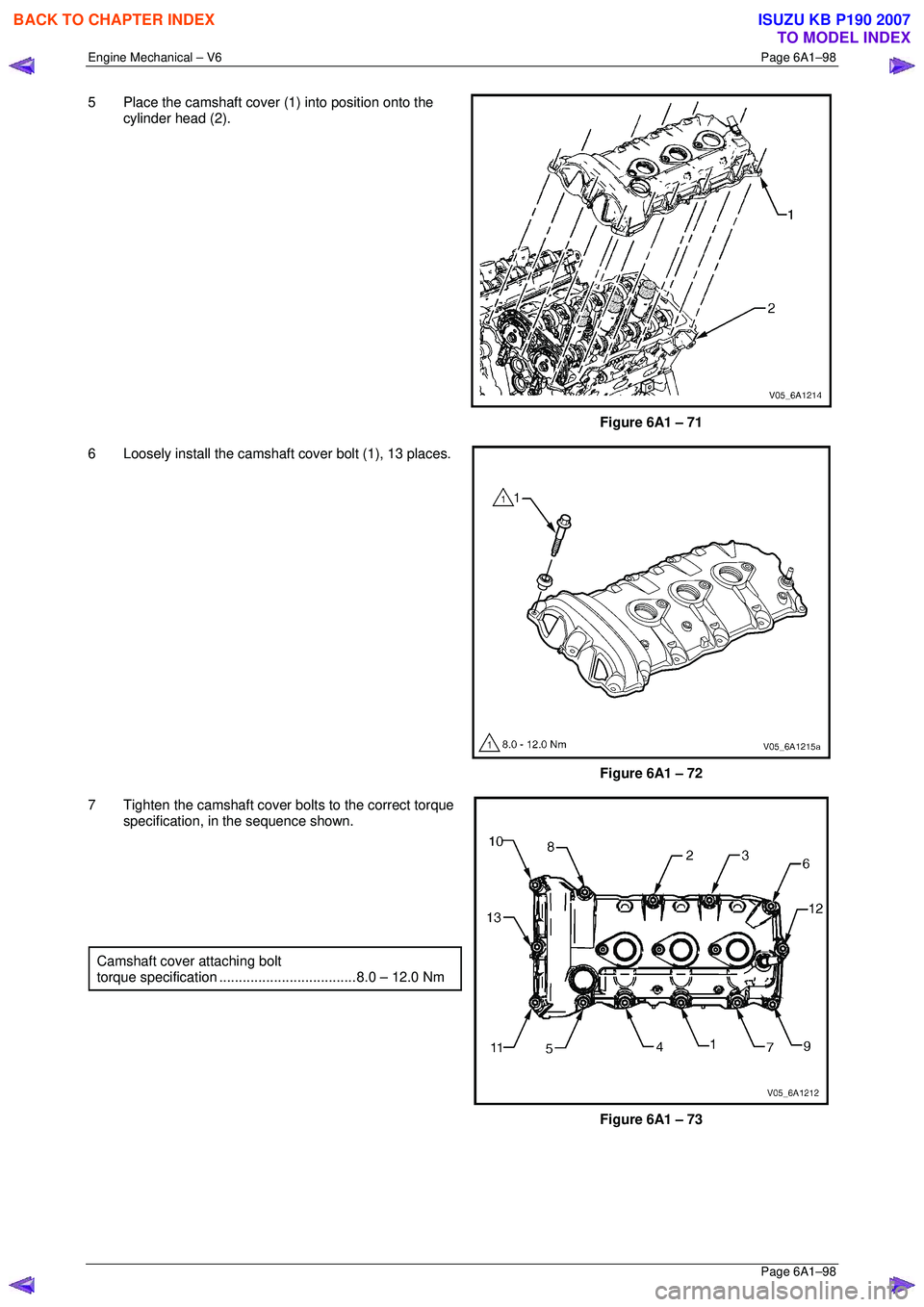

2 Ensure that the grommet (1), 13 places, is correctly seated in its hole.

3 Wipe the camshaft cover sealing surface on the cylinder head with a clean lint free cloth.

Figure 6A1 – 69

4 Ensure that a new seal is correctly fitted to the camshaft cover. Place a 3 mm bead of RTV sealant on

the join line of the engine front cover (1).

Figure 6A1 – 70

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2875 of 6020

Engine Mechanical – V6 Page 6A1–98

Page 6A1–98

5 Place the camshaft cover (1) into position onto the

cylinder head (2).

Figure 6A1 – 71

6 Loosely install the camshaft cover bolt (1), 13 places.

Figure 6A1 – 72

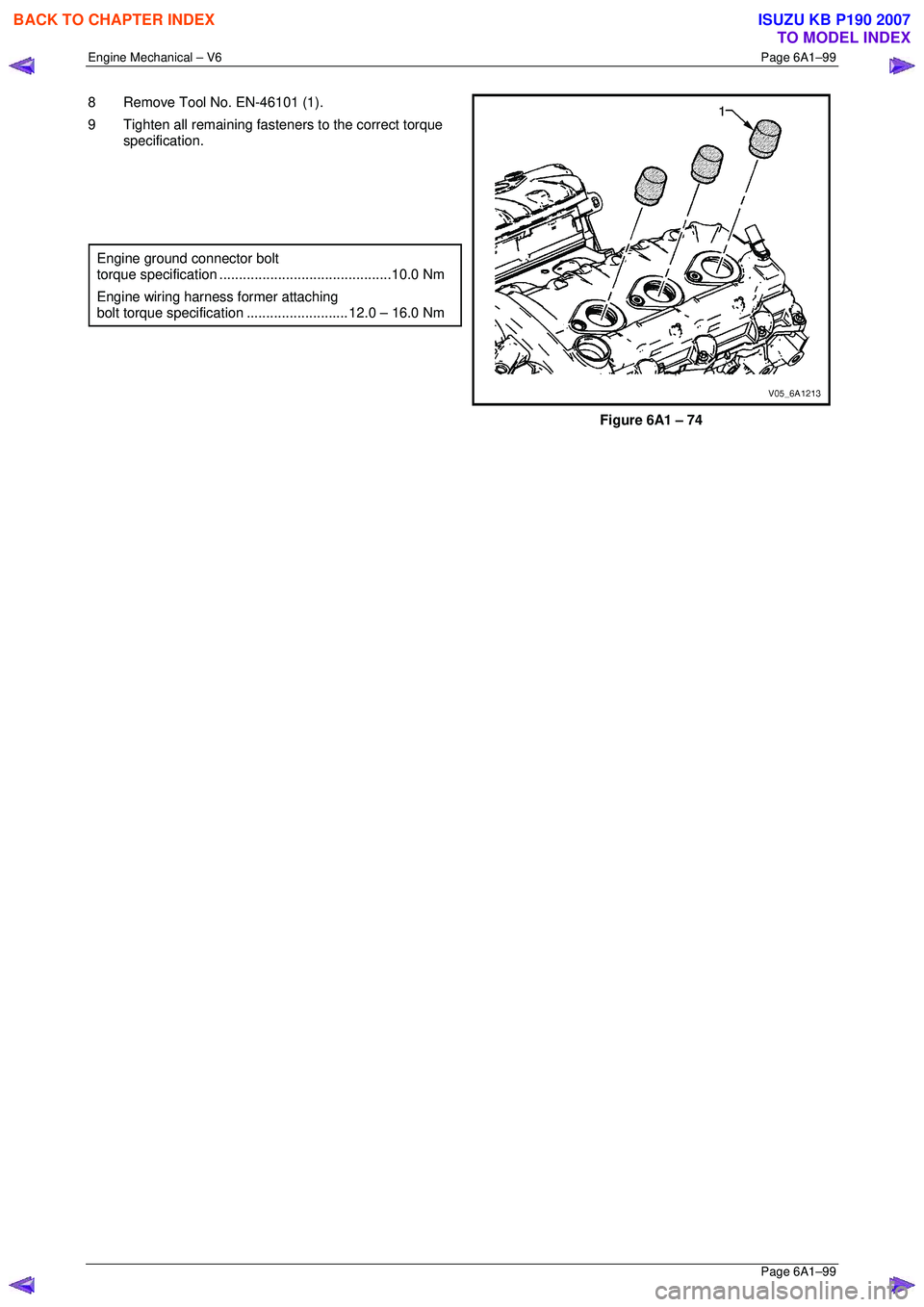

7 Tighten the camshaft cover bolts to the correct torque specification, in the sequence shown.

Camshaft cover attaching bolt

torque specificatio n ................................... 8. 0 – 12.0 Nm

Figure 6A1 – 73

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2876 of 6020

Engine Mechanical – V6 Page 6A1–99

Page 6A1–99

8 Remove Tool No. EN-46101 (1).

9 Tighten all remaining fasteners to the correct torque specification.

Engine ground connector bolt

torque specificat ion ............................................ 10.0 Nm

Engine wiring harness former attaching

bolt torque specification .......................... 12.0 – 16.0 Nm

Figure 6A1 – 74

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2877 of 6020

Engine Mechanical – V6 Page 6A1–100

Page 6A1–100

3.13 Crankshaft Balancer Assembly

Remove

1 Remove the accessory drive belt, refer to 3.5 Accessory Drive Belt.

2 Remove the starter motor, refer to Section 6D1-2 Starting System.

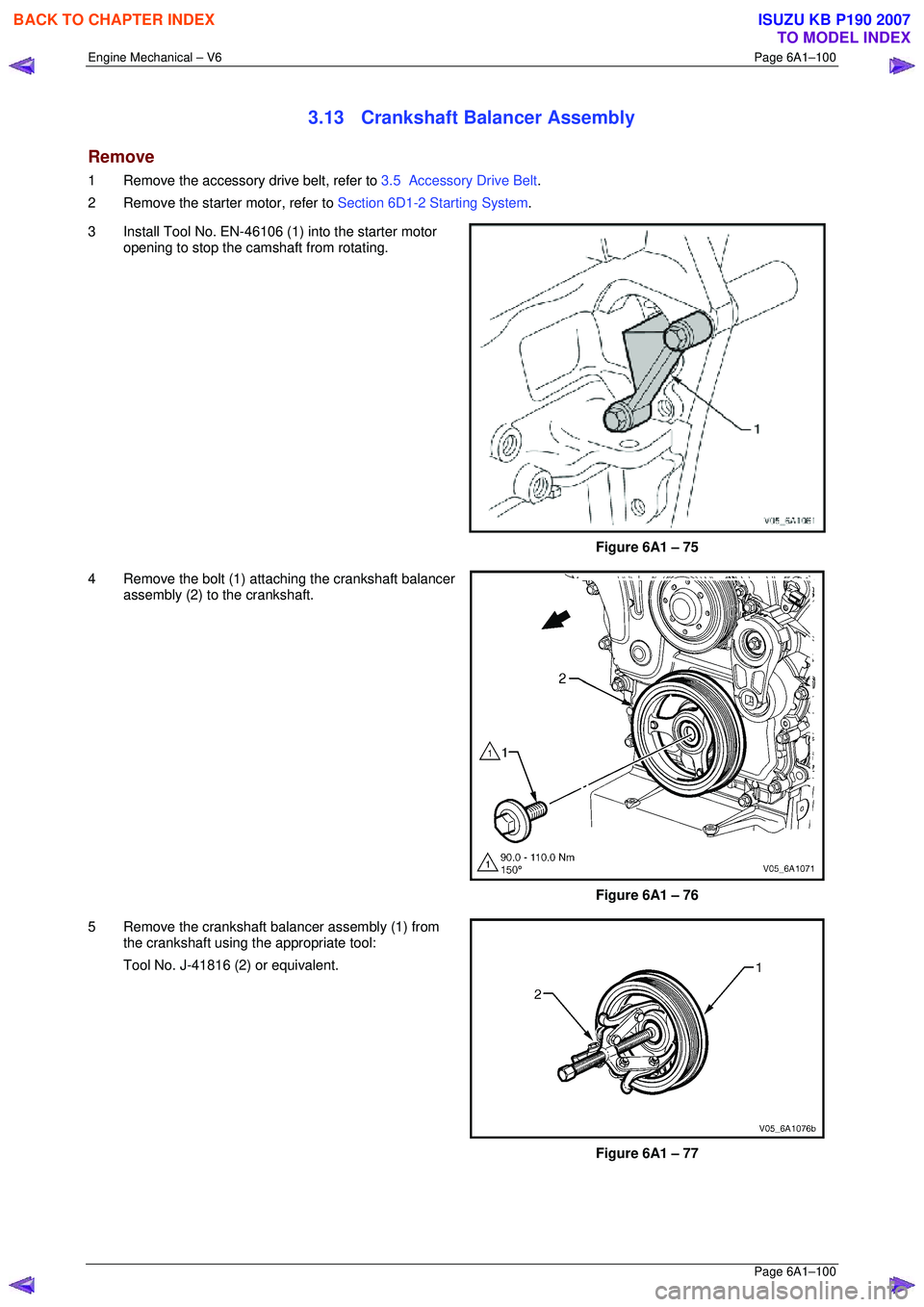

3 Install Tool No. EN-46106 (1) into the starter motor opening to stop the camshaft from rotating.

Figure 6A1 – 75

4 Remove the bolt (1) attaching the crankshaft balancer assembly (2) to the crankshaft.

Figure 6A1 – 76

5 Remove the crankshaft balancer assembly (1) from the crankshaft using the appropriate tool:

Tool No. J-41816 (2) or equivalent.

Figure 6A1 – 77

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2878 of 6020

Engine Mechanical – V6 Page 6A1–101

Page 6A1–101

Clean and Inspect

1 Using a suitable non-corrosive cleaning solvent and a soft bristled parts cleaning brush, clean the crankshaft

balancer assembly.

Safety glasses must be worn when using

compressed air.

2 Dry the crankshaft balancer assembly using compressed air.

3 Inspect the crankshaft balancer assemb ly for the following fault conditions:

• Hub to crankshaft inner surface for wear or damage,

• Sealing surface for wear, grooving or scoring,

• Rubber ring between the hub and the pulley for wear, chunking and general deterioration, and

• Drive belt ribs of the pulley for damage.

Reinstall

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer must be installed onto a

dry seal.

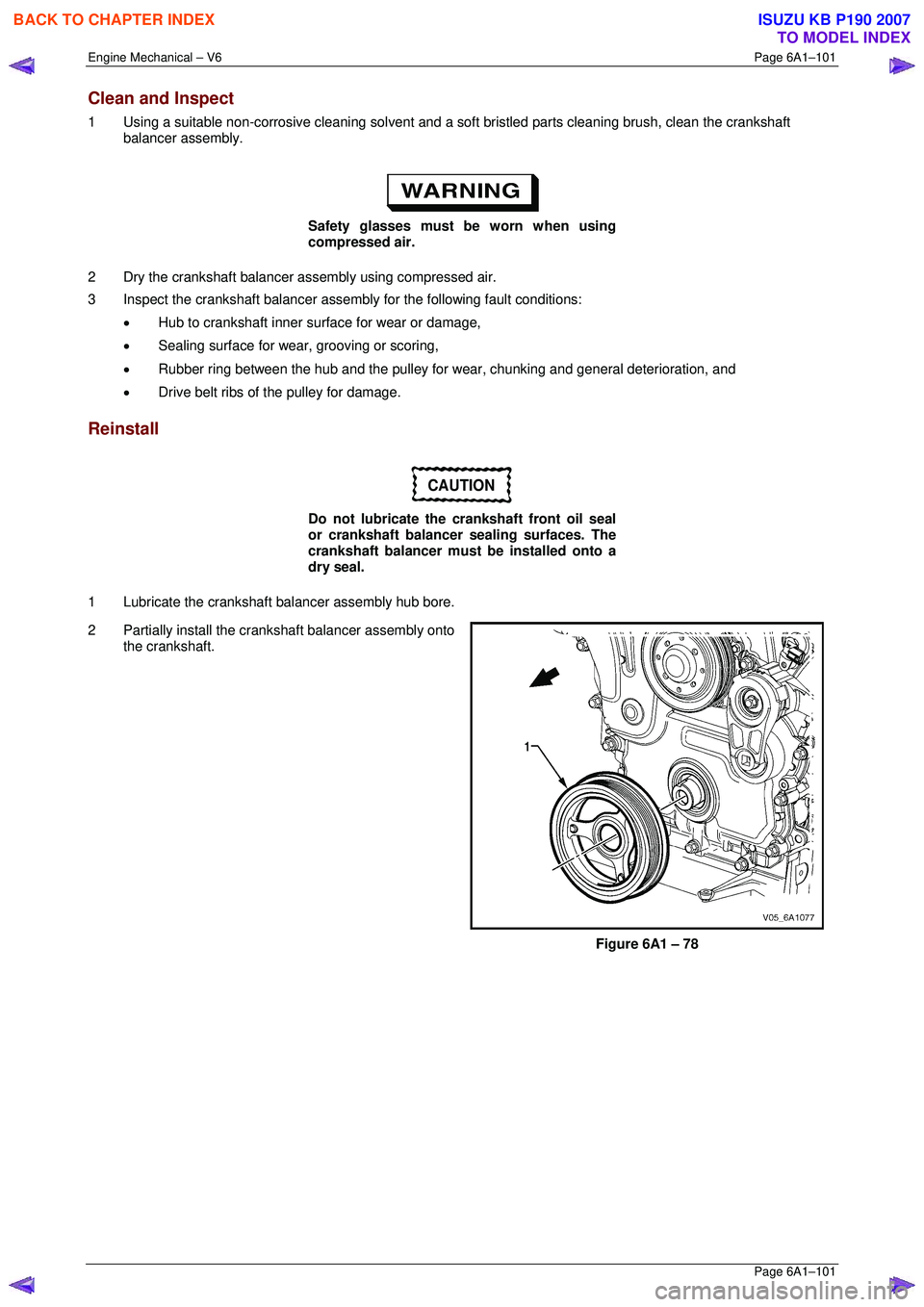

1 Lubricate the crankshaft balancer assembly hub bore.

2 Partially install the crankshaft balancer assembly onto the crankshaft.

Figure 6A1 – 78

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2879 of 6020

Engine Mechanical – V6 Page 6A1–102

Page 6A1–102

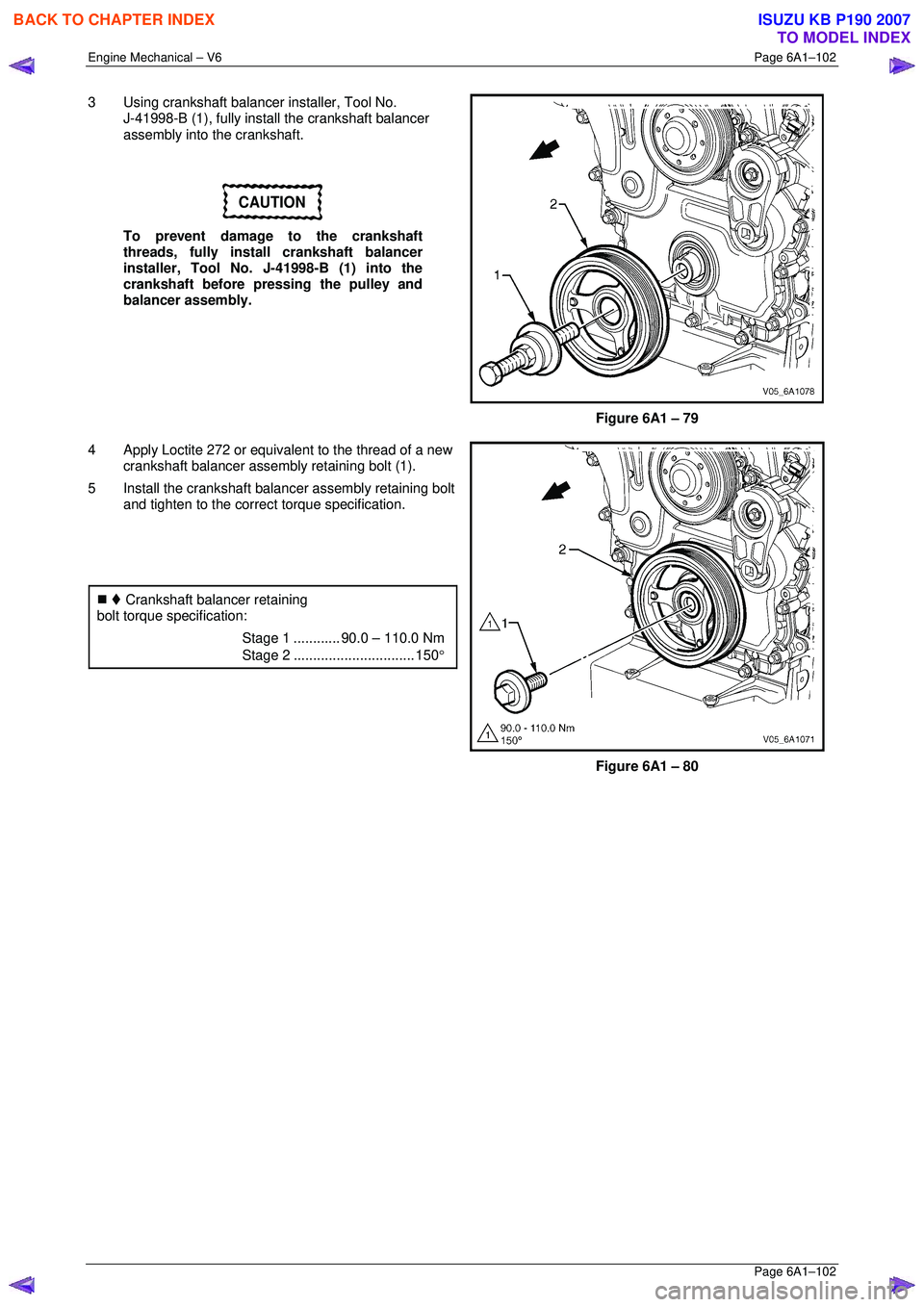

3 Using crankshaft balancer installer, Tool No.

J-41998-B (1), fully install the crankshaft balancer

assembly into the crankshaft.

CAUTION

To prevent damage to the crankshaft

threads, fully install crankshaft balancer

installer, Tool No. J-41998-B (1) into the

crankshaft before pressing the pulley and

balancer assembly.

Figure 6A1 – 79

4 Apply Loctite 272 or equivalent to the thread of a new crankshaft balancer assembly retaining bolt (1).

5 Install the crankshaft balancer assembly retaining bolt and tighten to the correct torque specification.

�„ Crankshaft balancer retaining

bolt torque specification:

Stage 1............ 90.0 – 110.0 Nm

Stage 2 ............................... 150°

Figure 6A1 – 80

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007

Page 2880 of 6020

Engine Mechanical – V6 Page 6A1–103

Page 6A1–103

3.14 Crankshaft Front Seal

Replace

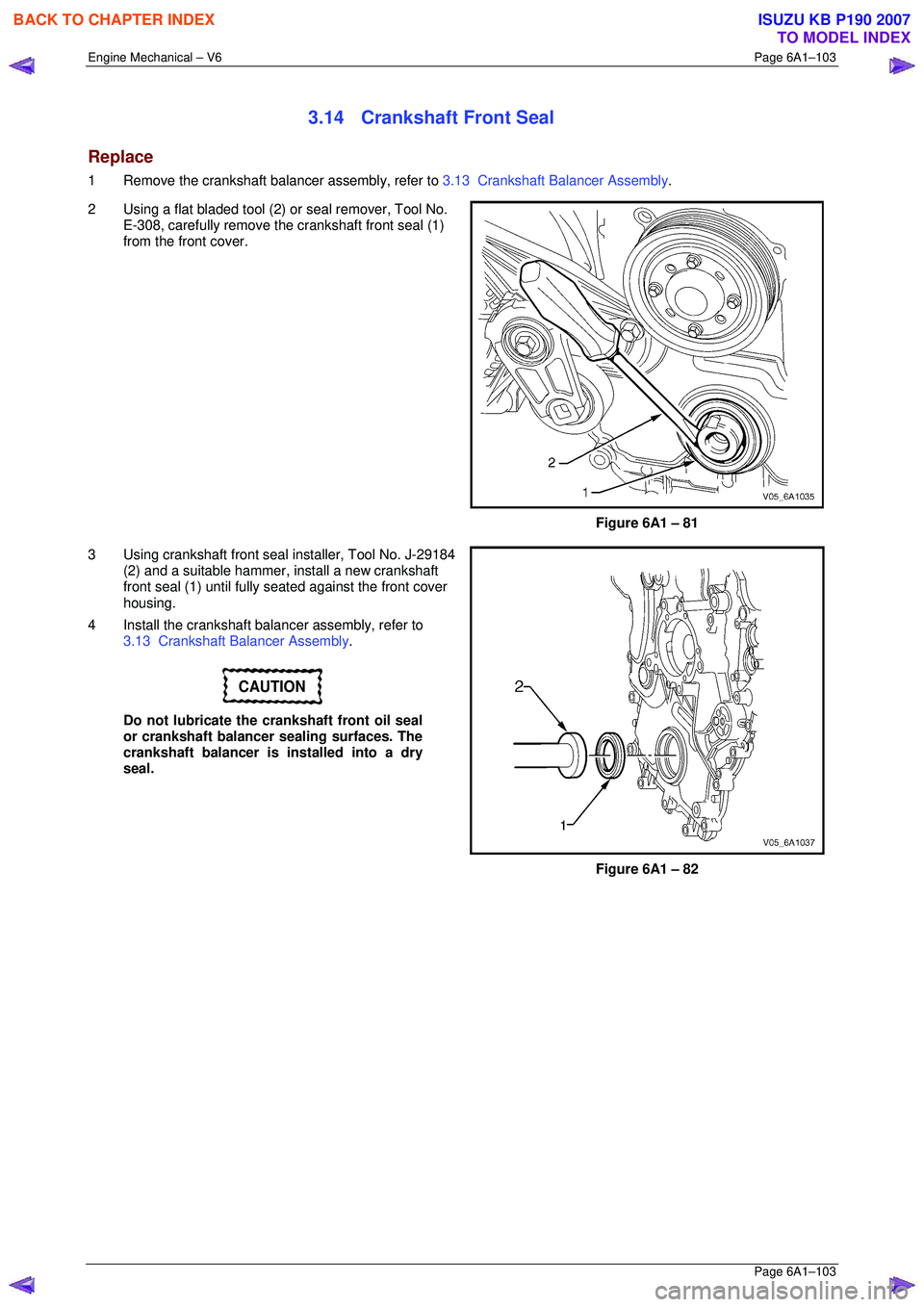

1 Remove the crankshaft balancer assembly, refer to 3.13 Crankshaft Balancer Assembly .

2 Using a flat bladed tool (2) or seal remover, Tool No. E-308, carefully remove the crankshaft front seal (1)

from the front cover.

Figure 6A1 – 81

3 Using crankshaft front seal installer, Tool No. J-29184 (2) and a suitable hammer, install a new crankshaft

front seal (1) until fully s eated against the front cover

housing.

4 Install the crankshaft balanc er assembly, refer to

3.13 Crankshaft Balancer Assembly .

CAUTION

Do not lubricate the crankshaft front oil seal

or crankshaft balancer sealing surfaces. The

crankshaft balancer is installed into a dry

seal.

Figure 6A1 – 82

BACK TO CHAPTER INDEX

TO MODEL INDEX

ISUZU KB P190 2007