LEXUS LS430 2003 Factory Repair Manual

Manufacturer: LEXUS, Model Year: 2003,

Model line: LS430,

Model: LEXUS LS430 2003

Pages: 4500, PDF Size: 87.45 MB

LEXUS LS430 2003 Factory Repair Manual

LS430 2003

LEXUS

LEXUS

https://www.carmanualsonline.info/img/36/57050/w960_57050-0.png

LEXUS LS430 2003 Factory Repair Manual

Trending: parking brake, boot, bulb, air suspension, tail light replacement, electronic modulated, Rear control Arm

Page 3481 of 4500

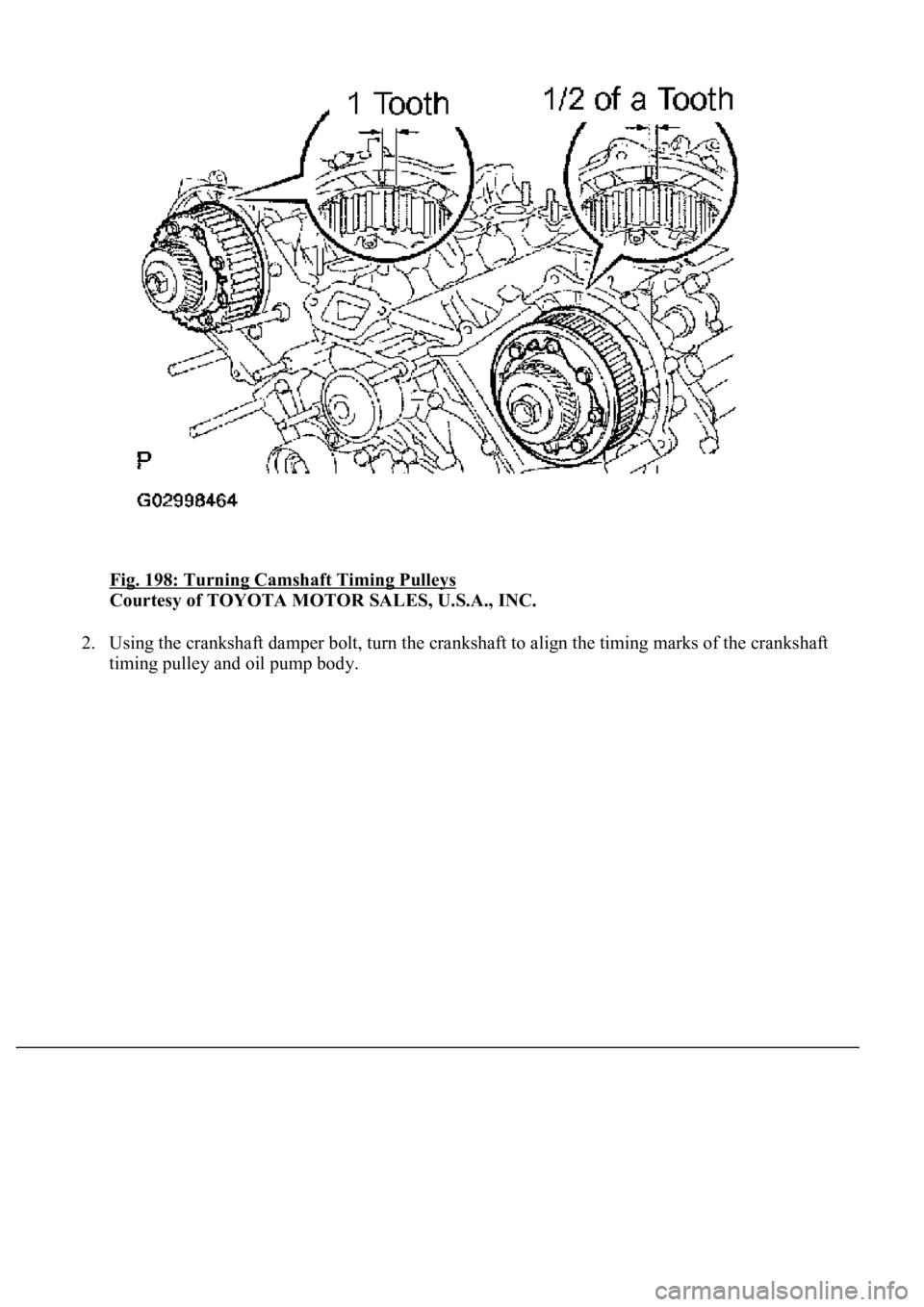

Fig. 198: Turning Camshaft Timing Pulleys

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

2. Using the crankshaft damper bolt, turn the crankshaft to align the timing marks of the crankshaft

timin

g pulley and oil pump body.

Page 3482 of 4500

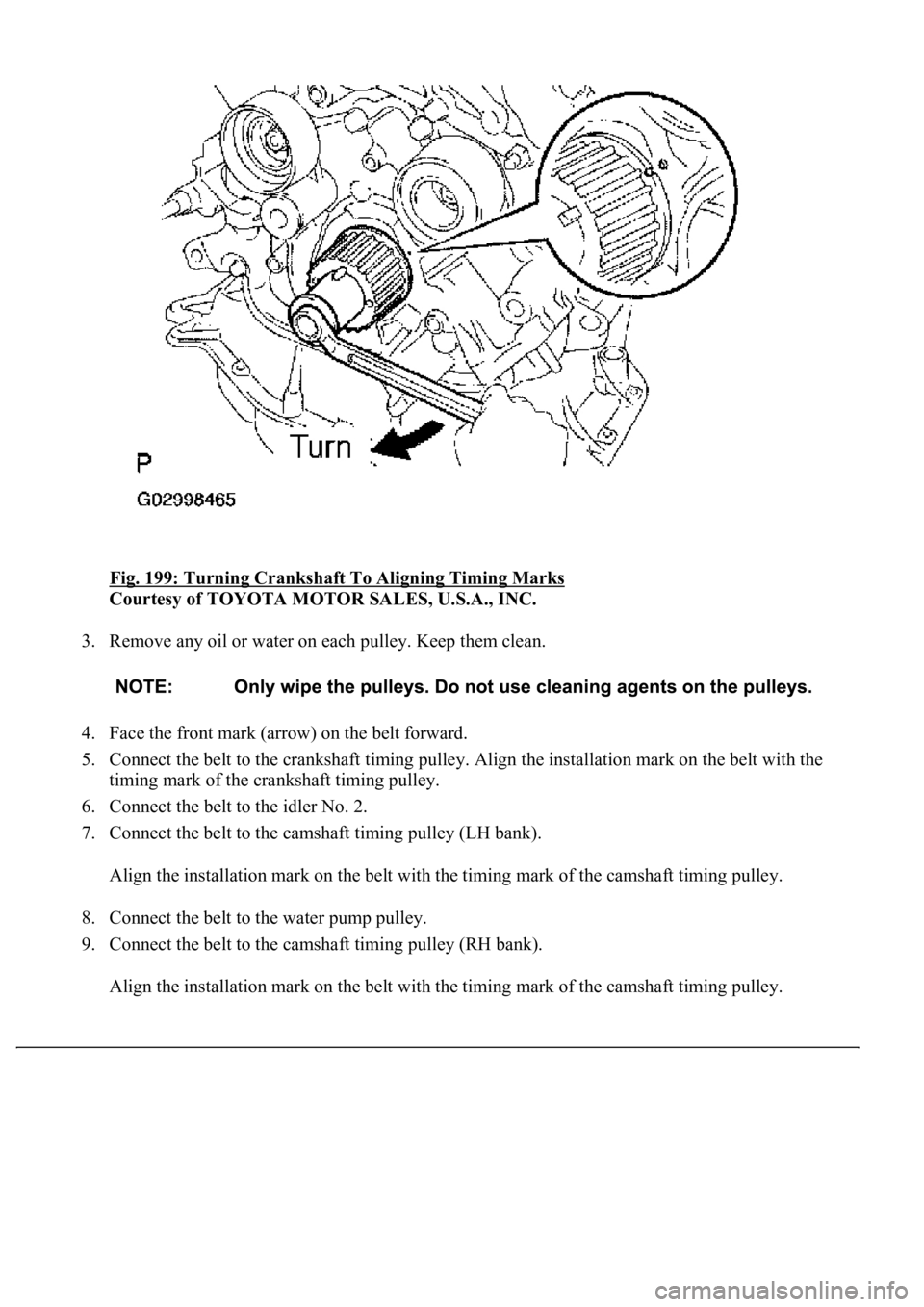

Fig. 199: Turning Crankshaft To Aligning Timing Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

3. Remove any oil or water on each pulley. Keep them clean.

4. Face the front mark (arrow) on the belt forward.

5. Connect the belt to the crankshaft timing pulley. Align the installation mark on the belt with the

timing mark of the crankshaft timing pulley.

6. Connect the belt to the idler No. 2.

7. Connect the belt to the camshaft timing pulley (LH bank).

Align the installation mark on the belt with the timing mark of the camshaft timing pulley.

8. Connect the belt to the water pump pulley.

9. Connect the belt to the camshaft timing pulley (RH bank).

Align the installation mark on the belt with the timing mark of the camshaft timing pulley.

Page 3483 of 4500

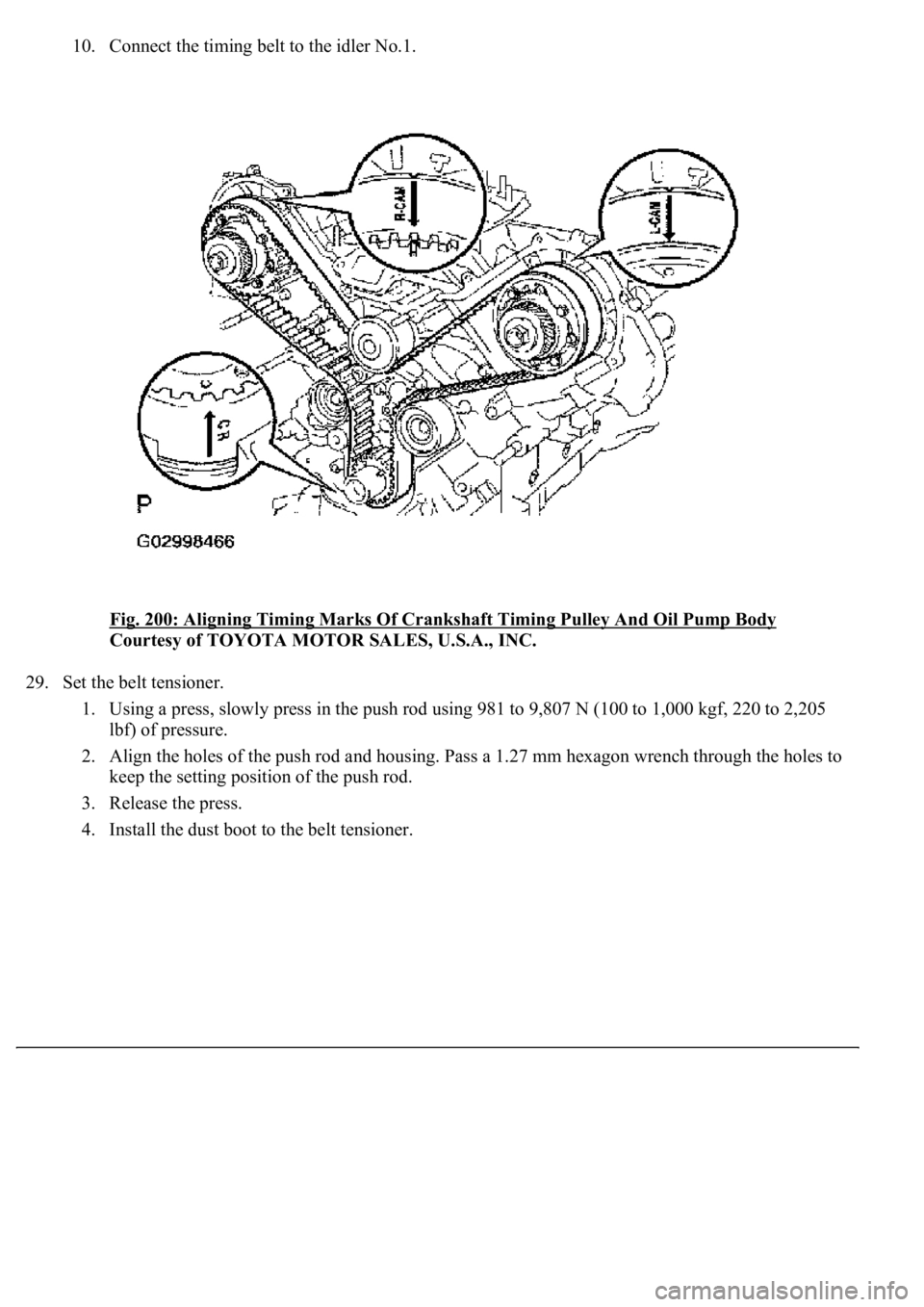

10. Connect the timing belt to the idler No.1.

Fig. 200: Aligning Timing Marks Of Crankshaft Timing Pulley And Oil Pump Body

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

29. Set the belt tensioner.

1. Using a press, slowly press in the push rod using 981 to 9,807 N (100 to 1,000 kgf, 220 to 2,205

lbf) of pressure.

2. Align the holes of the push rod and housing. Pass a 1.27 mm hexagon wrench through the holes to

keep the setting position of the push rod.

3. Release the press.

4. Install the dust boot to the belt tensioner.

Page 3484 of 4500

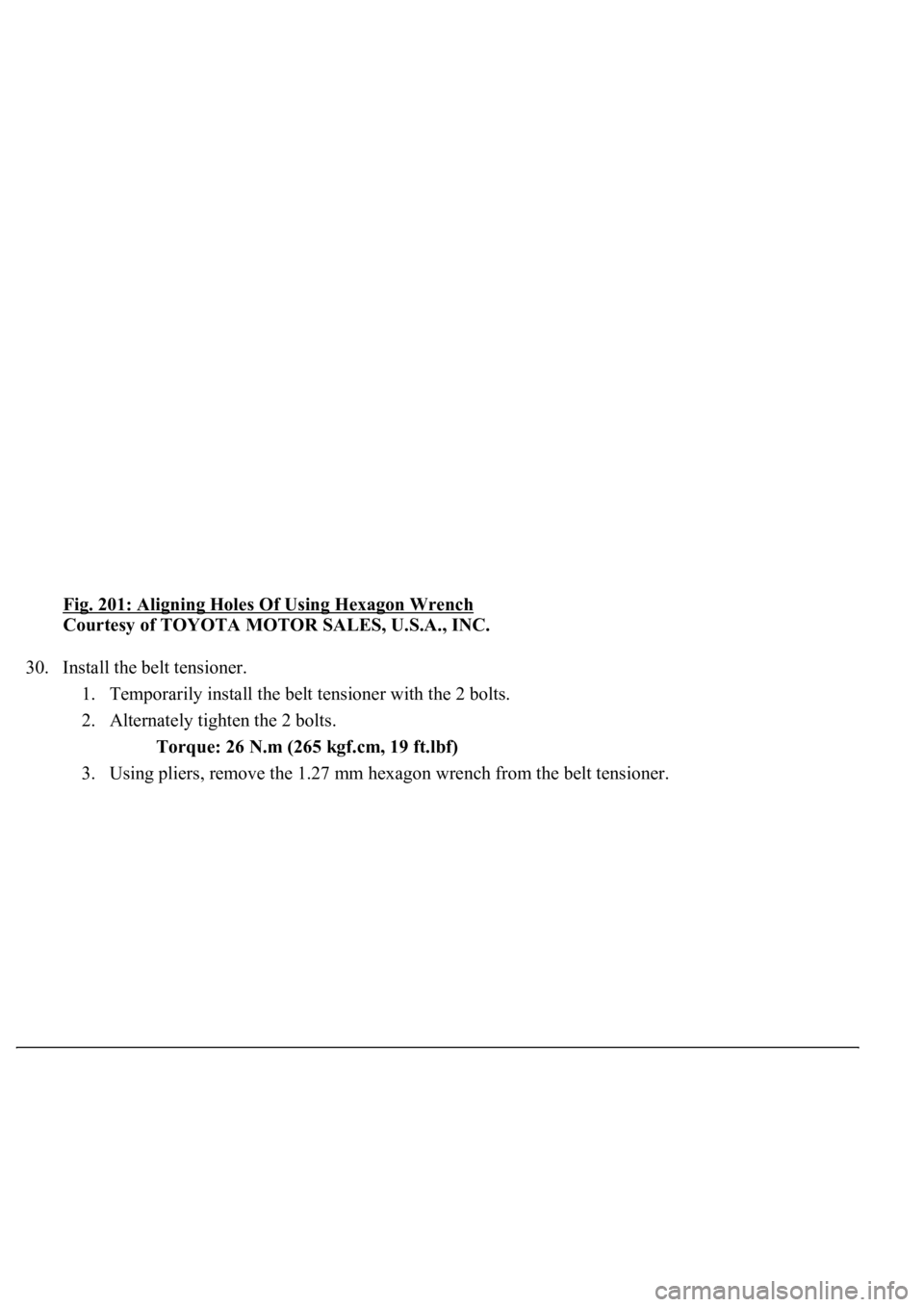

Fig. 201: Aligning Holes Of Using Hexagon Wrench

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

30. Install the belt tensioner.

1. Temporarily install the belt tensioner with the 2 bolts.

2. Alternately tighten the 2 bolts.

Torque: 26 N.m (265 kgf.cm, 19 ft.lbf)

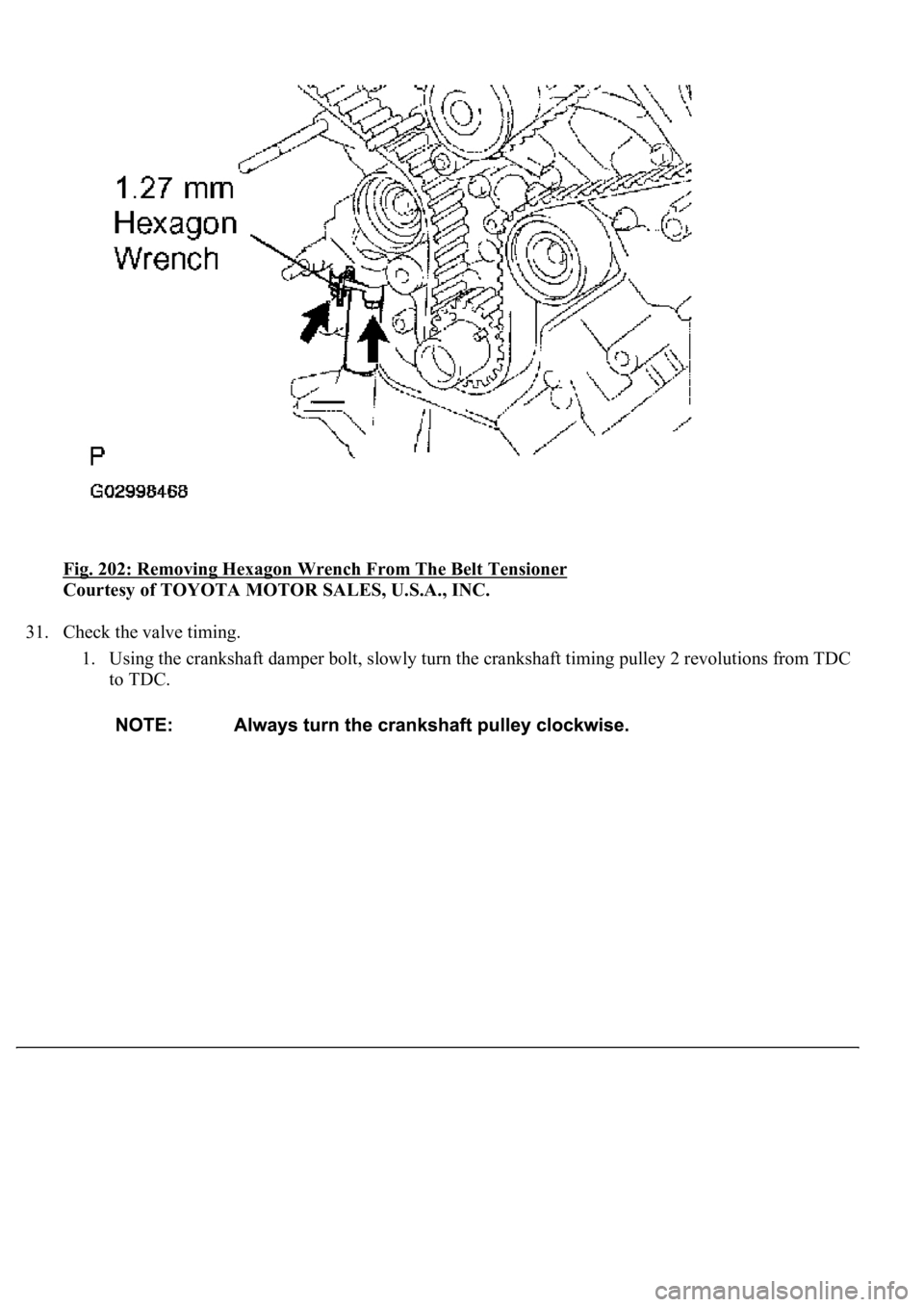

3. Usin

g pliers, remove the 1.27 mm hexagon wrench from the belt tensioner.

Page 3485 of 4500

<0029004c004a00110003001500130015001d000300350048005000520059004c0051004a0003002b0048005b0044004a005200510003003a0055004800510046004b0003002900550052005000030037004b0048000300250048004f005700030037004800

510056004c0052005100480055[

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

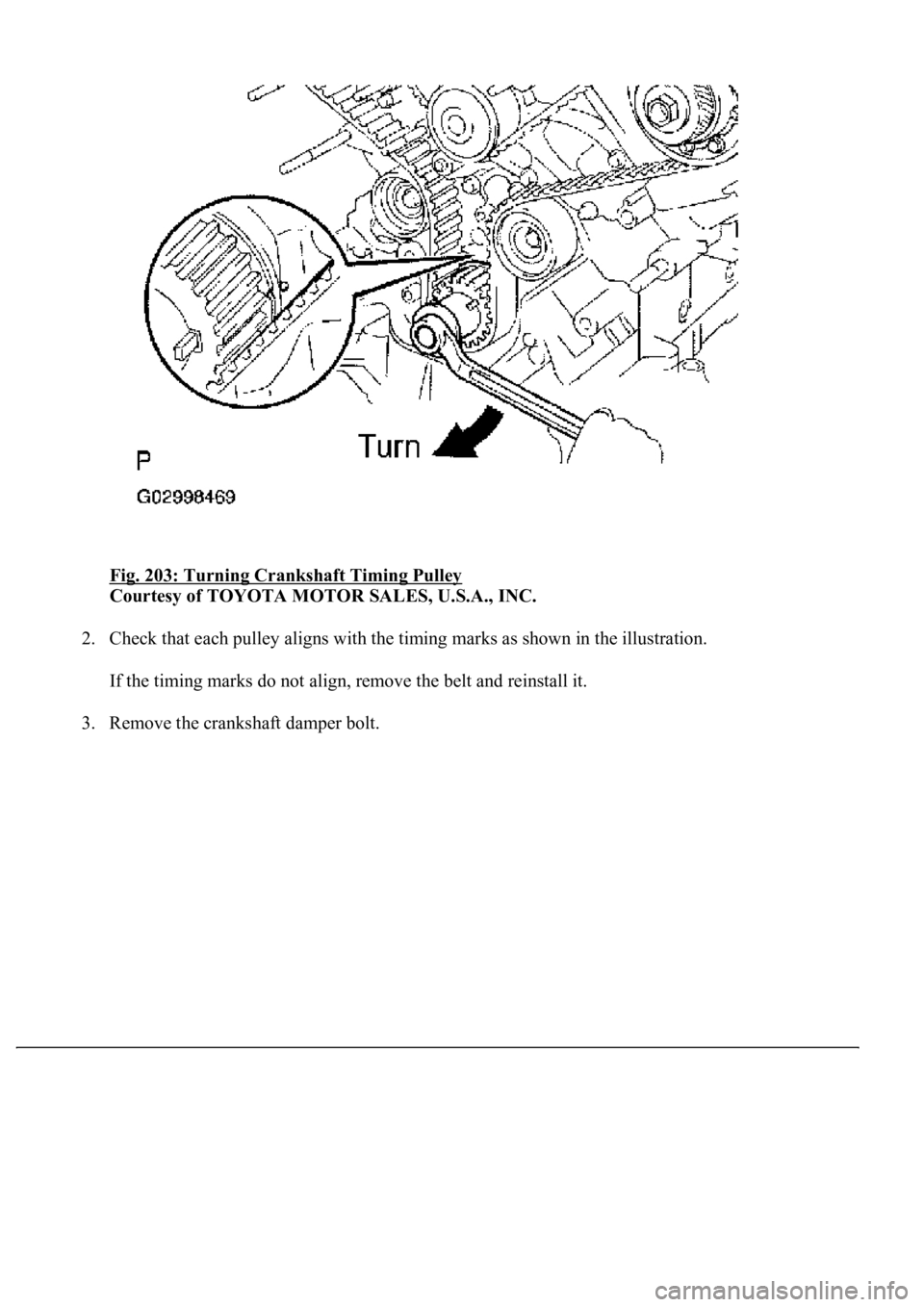

31. Check the valve timing.

1. Using the crankshaft damper bolt, slowly turn the crankshaft timing pulley 2 revolutions from TDC

to TDC.

Page 3486 of 4500

Fig. 203: Turning Crankshaft Timing Pulley

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

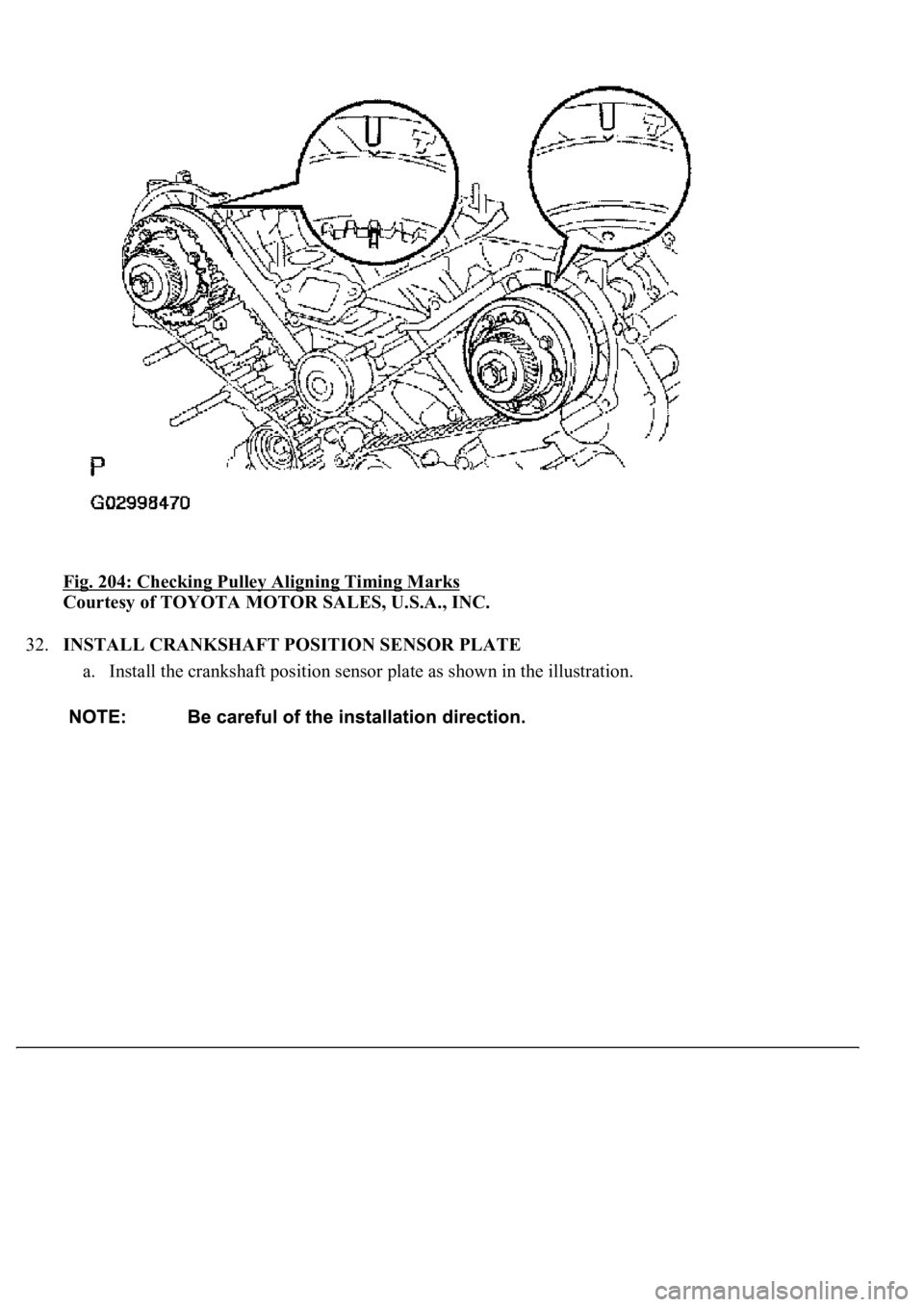

2. Check that each pulley aligns with the timing marks as shown in the illustration.

If the timing marks do not align, remove the belt and reinstall it.

3. Remove the crankshaft damper bolt.

Page 3487 of 4500

Fig. 204: Checking Pulley Aligning Timing Marks

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

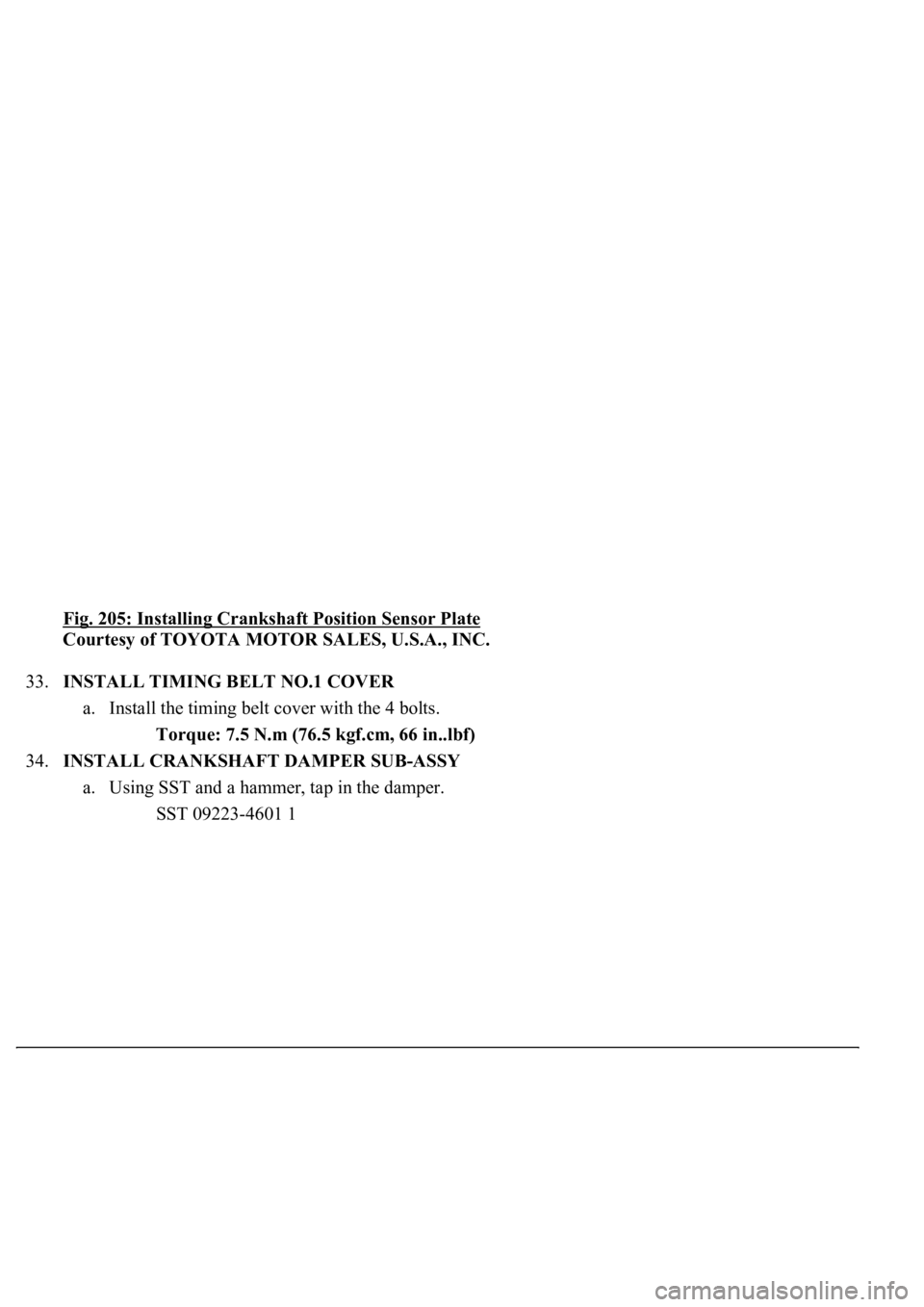

32.INSTALL CRANKSHAFT POSITION SENSOR PLATE

a. Install the crankshaft position sensor plate as shown in the illustration.

Page 3488 of 4500

Fig. 205: Installing Crankshaft Position Sensor Plate

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

33.INSTALL TIMING BELT NO.1 COVER

a. Install the timing belt cover with the 4 bolts.

Torque: 7.5 N.m (76.5 kgf.cm, 66 in..lbf)

34.INSTALL CRANKSHAFT DAMPER SUB-ASSY

a. Using SST and a hammer, tap in the damper.

SST 09223-4601 1

Page 3489 of 4500

Fig. 206: Taping Damper Using SST And Hammer

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

b. Using SST, install the damper bolt.

SST 09213-7001 1, 09330-00021

Torque: 245 N.m (2,500 kgf.cm, 181 ft.lbf)

c. Ali

gn the pulley set key with the key groove of the crankshaft damper.

Page 3490 of 4500

Fig. 207: Installing Damper Bolt Using SST

Courtesy of TOYOTA MOTOR SALES, U.S.A., INC.

35.INSTALL IDLER PULLEY ASSY

a. Install the idler with the 2 bolts and 2 nuts.

Torque:

32 N.m (326 kgf.cm, 24 ft.lbf) for 14 mm head bolt A

16 N.m (163 kgf.cm, 12 ft.lbf) for 12 mm head bolt B

Trending: automatic transmission fluid, airbag, adding oil, ABS, B2620, Expansion Valve, oil filter