MAZDA 626 1987 Workshop Manual

Manufacturer: MAZDA, Model Year: 1987, Model line: 626, Model: MAZDA 626 1987Pages: 1865, PDF Size: 94.35 MB

Page 651 of 1865

4C EXHAUST SYSTEM (LEADED FUEL)

REMOVAL AND INSTALLATION

1. Remove in the sequence shown in the figure.

2. Install in the reverse order of removal.

Torque Specifications

1. Main silencer

2. Middle pipe

3. No. 2 pre-silencer

76G04C-165

4. No. 1 pre-silencer

5. Bracket

6. Front pipe

4C—90

Page 652 of 1865

CONTROL SYSTEM 4C

CONTROL SYSTEM

Throttle sensor

Solenoid Solenoid Idle valve valve switch (VIC) (PRC)

Solenoid

valve

control)*

Solenoid valve

'(No.1 purge control)*1

E/L control unit

Engine control unit

Control relay

Injector

Knock sensor* -

Water thermo

switch*1

"1...Unleaded fuel

*2...Leaded fuel

Oxygen Distributor Water thermo sensor*1 sensor

Clutch switch

Oxygen sensor

relay*1

Solenoid valve

(EGR)*1

/ Solenoid valve 7 (ISC)

Air flow sensor

Neutral switch

76G04C-166

The control system consists of the input devices and the engine control unit. The control unit controls

the fuel injection amount (EGI), fuel injection pressure, bypass air amount, ignition timing, switch moni-

tor function, and fail-safe function.

4C-91

Page 653 of 1865

4C CONTROL SYSTEM

RELATIONSHIP CHART

Output Devices

and

Input Devices (Unleaded fuel)

IGNITION SWITCH

(ON POSION) X X X X X O X X X X X X X X O

TEST CONNECTOR X X X O X X X X X X X X X O X

ELECTRICAL LOAD CONTROL UNIT X X X o X X X X X X X X X X X

P/S PRESSURE SWITCH X X X o X X X X X X X X X X X

A/C SWITCH X X X o X X X X X X X X O X X

IGNITION SWITCH

(STA POSITION) O O X o O X X X X O X X X O X

NEUTRAL

AND

CLUTCH SWITCH O X X o X X X X X X X X X X X

OXYGEN SENSOR o X X X X X X X X X X X X X X

WATER THERMO

SWITCH (RADIATOR) o X X X X X X X o X X X X X X

INTAKE

AIR

THERMO SENSOR X X X X X X X X X O X X X X X

WATER

THERMO SENSOR o X X o X X o o O O X X X O o

IDLE SWITCH o X X o X X X X X o X X X O X

THROTTLE SENSOR o X X X X X X X O X X X X o X

AIR FLOW SENSOR o X X X X X X o X X X X X o O

Ne SIGNAL o o X O o X X O O O o o X o O

G SIGNAL X O X X X X X X X X X X X X X

\

INPUT

DEVICE

OUTPUT

DEVICE

FUEL

INJECTION

AMOUNT FUEL

INJECTION

TIMING

AIR

VALVE

ISC

VALVE

FUEL

PUMP

CONTROL

MAIN

POWER

CONTROL

SOLENOID

VALVE

(No.1

PURGE)

SOLENOID

VALVE

(No.2

PURGE)

SOLENOID

VALVE

(EGR)

SOLENOID

VALVE

(PRESSURE

REGULATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INERTIA

CONTROL)

OXYGEN

SENSOR

RELAY

I A/C

RELAY

IGNITER

AIR

FLOW

SENSOR

(BURN-OFF)

\

INPUT

DEVICE

OUTPUT

DEVICE

INJECTOR

BAC

VALVE

CONTROL

RELAY

SOLENOID

VALVE

(No.1

PURGE)

SOLENOID

VALVE

(No.2

PURGE)

SOLENOID

VALVE

(EGR)

SOLENOID

VALVE

(PRESSURE

REGULATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INERTIA

CONTROL)

OXYGEN

SENSOR

RELAY

I A/C

RELAY

IGNITER

AIR

FLOW

SENSOR

(BURN-OFF)

76G04C-167

4C—92

Page 654 of 1865

CONTROL SYSTEM 4C

Output Devices and In put Devices (Leaded fuel)

IGNITION SWITCH

(ON POSITION) X X X X X O X X X X O

TEST CONNECTOR X X X O X X X X X O X

KNOCK SENSOR X X X X X X X X X o X

ELECTRICAL LOAD

CONTROL UNIT X X X O X X X X X X X

P/S PRESSURE SWITCH X X X o X X X X X X X

A/C SWITCH X X X o X X X X O X X

IGNITION SWITCH (STA POSITION) O O X o O X O X X O X

NEUTRAL AND

CLUTCH SWITCH O X X o X X X X X X X

INTAKE AIR THERMO SENSOR X X X X X X O X X X X

WATER THERMO SENSOR O X X o X X O X X O o

IDLE SWITCH o X X o X X o X X O X

VARIABLE RESISTOR (IN AIR FLOW SENSOR) o X X X X X X X X X X

AIR FLOW SENSOR o X X X X X X X X O O

Ne SIGNAL o o X O o X O o X o O

G SIGNAL X O X X X X X X X X X

INPUT

DEVICE

OUTPUT

DEVICE

FUEL

INJECTION

AMOUNT

FUEL

INJECTION

TIMING

AIR

VALVE

ISC

VALVE

FUEL

PUMP

CONTROL

MAIN

POWER

CONTROL

SOLENOID

VALVE

(PRESSURE

REGULATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INERTIA

CONTROL)

A/C

RELAY

IGNITER

AIR

FLOW

SENSOR

(BURN-OFF)

INPUT

DEVICE

OUTPUT

DEVICE

INJECTOR

BAC

VALVE

CONTROL

RELAY

SOLENOID

VALVE

(PRESSURE

REGULATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INERTIA

CONTROL)

A/C

RELAY

IGNITER

AIR

FLOW

SENSOR

(BURN-OFF)

76G04C-168

4C—93

Page 655 of 1865

4C CONTROL SYSTEM

Output Devices

and

Engine Conditions (Unleaded fuel)

REMARK

*

Above

7,000

rpm:

fuel

cut

'Coolant

temp.:

below

50°C

(122°F)

41 Coolant

temp:

below

70°C

(158°F)

*2 Engine

speed

above

1,700

rpm

*3 Engine

speed:

1,500—3,500

rpm

*

During

hot

start

only

*

Engine

speed:

above

5,200

rpm

'Engine

speed:

above

3,000

rpm

'Delays

0.5

second

IGN:

ON

(ENGINE

NOT RUNNING)

No

injection

No bypass OFF

(main

fuel

pump

not

operated)

OFF

OFF

z

1

IDLE

(THROTTLE

VALVE

FULLY CLOSED)

Rich

and

i

lean

Sequential

(once

per

two

revolutions)

OFF

o en C3 UJ

z

"After

start-

ing:

ON

(Vacuum

cut) OFF

o

DECELE-

RATION

'Fuel

cut

L

Small

amount

of

bypass

air

N (1st

stage

operate:

o

o Ho 3 O CO CD > CO >

>; CO

CO c o

c o o

HEAVY

LOAD

•ST c

Closed

Small

amount

of

bypass

air

-co-CD CO

N (1st

stage

operate:

In CD 2? 03 a. o CD o> CO to "O c

*3 OFF (EGR)

o Ho 3 O CO CD > CO >

03 k-o CO c 03 CO z o *

CD c O) c 03 c o

c o o a 3

ACCELE-

RATION

Rich

o •*—• 3 o > CD

O

Small

amount

of

bypass

air

03 Q. O Q. E 3

ON

O

In CD 2? 03 a. o CD o> CO to "O c

ON

(EGR cut)

:F (Vacuum

to

pressure

regulatt

03 3 -C CO o

c 03 CS3 > X o o

z o * CO •o c CD Q. CD T3

C CO CD o "O 3= O c: 3 CO

LL LL o

MEDIUM

LOAD

WARM

Rich

and lean

|

Q. CD O

CD D

C CO E

CVJ.

z o fS *

*3 OFF (EGR)

:F (Vacuum

to

pressure

regulatt

E 3 3

c 03 i t 3 G, LL LL

T3 CD O c CO > "O <

C CO CD o "O 3= O c: 3 CO

LL LL o

MEDIUM

LOAD

COLD

ro

c CD 3 cr

z O "a CD a? CD CL o

F (2nd

stage

not

operated)

:F (Vacuum

to

pressure

regulatt

z o * O «

WARMING

UP

(DURING

IDLE)

Rich

CD CO c CD Q-O

o

c 3 CO O CO E CO

o c

stage

not

operated)

tr O UJ

z o

O

LL z

Fixed

at

BTDC

12°

CRANKING

(COLD

ENGINE)

1

group

(twice

per

revolution)

CO

«

CD urn i CO

CO

LL LL O

LL O * « o o

LL LL o

Fixed

at

BTDC

6°

z o

SOLENOID

VALVE

(PRESSURE

REGU-

LATOR

CONTROL)

CC

o z o o iii z

o z 111

OUTPUT

DEVICE

FUEL

INJECTION

AMOUNT FUEL

INJECTION

TIMING

AIR

VALVE

'

ISC

VALVE

FUEL

PUMP

CONTROL

MAIN

POWER

CONTROL

SOLENOID

VALVE

(No.1

PURGE)

SOLENOID

VALVE

(NO.2

PURGE)

SOLENOID

VALVE

(EGR)

SOLENOID

VALVE

(PRESSURE

REGU-

LATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INE

TIA

CONTROL)

> <

Ul oc oc o

£T u. O 1 z oc 3 m

oc o

OUTPUT

DEVICE

INJECTOR

BAC

VALVE

CONTROL

RELAY

SOLENOID

VALVE

(No.1

PURGE)

SOLENOID

VALVE

(NO.2

PURGE)

SOLENOID

VALVE

(EGR)

SOLENOID

VALVE

(PRESSURE

REGU-

LATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INE

TIA

CONTROL)

tn z Ul (0 z Ul o >-X o

A/C

RELAY

IGNITER

z Ul (O

=5 o

IL oc <

76G04C-169

4C—94

Page 656 of 1865

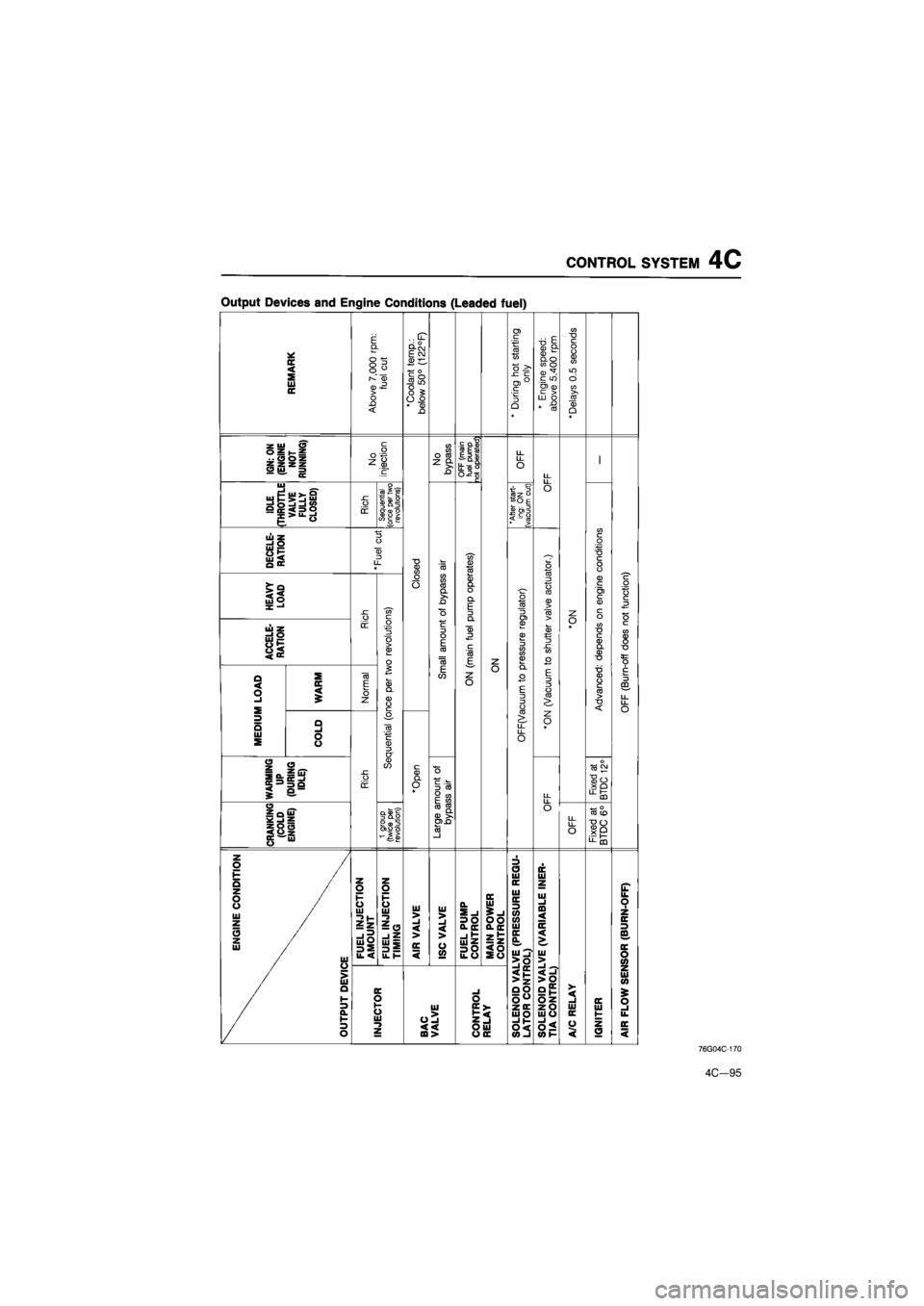

CONTROL SYSTEM

4C

Output Devices

and

Engine Conditions (Leaded fuel)

REMARK

E Q

O O O r-»" CD > o n <

fuel

cut

'Coolant

temp.:

below

50°

(122°F)

*

During

hot

starting

only

*

Engine

speed:

above

5,400

rpm

'Delays

0.5

seconds

IGN:

ON

(ENGINE

I

NOT

RUNNING)

o

z

injection

No

bypass

OFF

(main

fuel

pump

not

operated)

OFF

LL

I

IDLE

(THROTTLE

VALVE

FULLY

CLOSED)

Rich

I

Sequential (once

per

two

revolutions)

"After

start-

ing:

ON

(vacuum

cut)

O

DECELE-

RATION

i

i

'Fuel

cut

•o CD CO "co" CD ts o to 3 o CO CD > CO

CO c o

c o o

HEAVY

LOAD

sz "co" c

O o CO CO CO Q. >. -O

O

CD Q. O CL E CL ® D

C CO F

o 08 3 u> £ CD 3 CO 0) CD

o to 3 o CO CD > CO

z

B

ACCELE-RATION

ir o 3 0 > CD 1 O

C

O E CO

"CO

CD Q. O CL E CL ® D

C CO F

z

o 08 3 u> £ CD 3 CO 0) CD

CD e 3 SZ CO o

O * CO

c CD CL CD T3

c CO 8 "D

'

MEDIUM

LOAD

WARM

Normal

CD Q. CD O

E CO

z

O

o o_ O

E

3 3

o CO ^ LL LL O

E 3 3 O CO

•o

c

3

m

LL LL o

'

MEDIUM

LOAD

COLD

.H C CD 3 CT

o_ O

E

3 3

o CO ^ LL LL O

z

o *

WARMING

UP

(DURING

IDLE)

Rich

CD CO

*Open

B

3

CO

O

CO

E

<®

LL

Fixed

at

BTDC

12°

CRANKING

(COLD

ENGINE)

1

group

(twice

per

revolution)

CO

«

0)

>,

u>n w-CO

o

OFF

Fixed

at

BTDC

6°

ENGINE

CONDITION

OUTPUT

DEVICE

FUEL

INJECTION

AMOUNT

'

FUEL

INJECTION

TIMING

AIR

VALVE

ISC

VALVE

FUEL

PUMP

CONTROL MAIN

POWER

CONTROL

SOLENOID

VALVE

(PRESSURE

REGU-

LATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INER-

TIA

CONTROL)

(T ik 0 1 z DC 3

ffl

OC o tn

OUTPUT

DEVICE

INJECTOR

BAC

VALVE

CONTROL

RELAY

SOLENOID

VALVE

(PRESSURE

REGU-

LATOR

CONTROL)

SOLENOID

VALVE

(VARIABLE

INER-

TIA

CONTROL)

A/C

RELAY

IGNITER

Z Ul tn

£ o

ik DC <

76G04C-170

4C—95

Page 657 of 1865

4C CONTROL SYSTEM

EGI MAIN FUSE

Inspection

Check the continuity of EGI main fuse.

69G04A-161

CONTROL RELAY

Power Supply Circuit

1. Check that a "clicking" sound is heard at the con-

trol relay when turning the ignition switch ON and

OFF.

Note

The control relay is located under the center

console.

76G04C-171

2. Apply 12V to the 2B terminal and ground the 2D

terminal of the control relay.

3. Check voltage at the terminals with an voltmeter.

terminal

Terminals Grounded Not grounded

2C 12V OV

2E 12V OV

76G04C-172

From EGI From '9' From Ig. main fuse switch (ON) / switch

(ST)

To C/U / 9round To main To injector fuel Pump

Fuel Pump Circuit

1. Apply 12V and a ground to the terminals described

below and check the terminals with an ohmmeter

or voltmeter.

Terminal applied 12V

Terminal

grounded

Terminal checked

Correct condition

1B 1D 2F-1A Continuity

2F 1C 1A ADDrox.12V

76G04C-173

4C-96

Page 658 of 1865

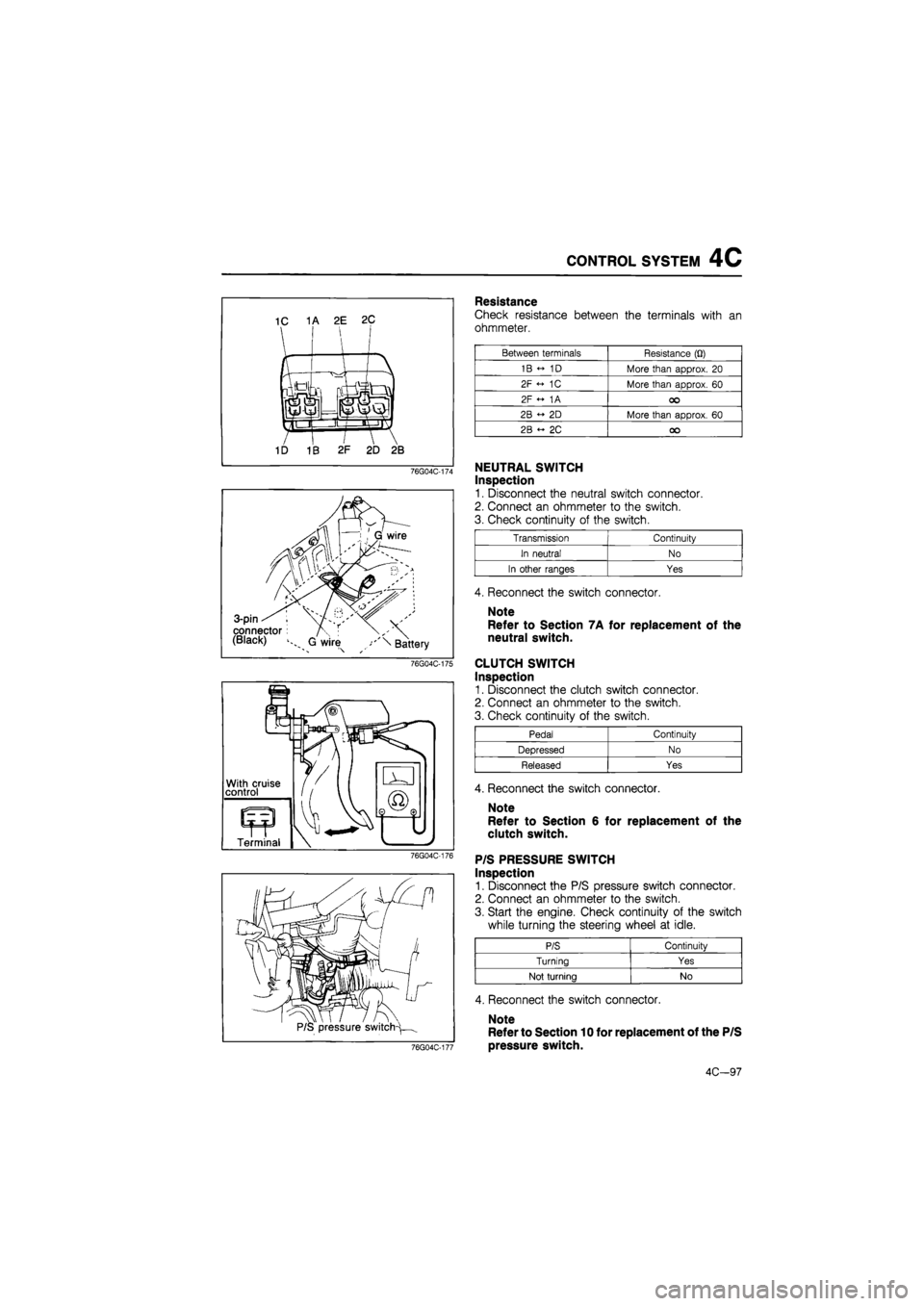

CONTROL SYSTEM 4C

Resistance

Check resistance between the terminals with an

ohmmeter.

Between terminals Resistance (Q)

1B « 1D More than approx. 20

2F <- 1C More than approx. 60

2F « 1A oo

2B « 2D More than approx. 60

2B ~ 2C oo

NEUTRAL SWITCH

Inspection

1. Disconnect the neutral switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Transmission Continuity

In neutral No

In other ranges Yes

4. Reconnect the switch connector.

Note

Refer to Section 7A for replacement of the

neutral switch.

CLUTCH SWITCH

Inspection

1. Disconnect the clutch switch connector.

2. Connect an ohmmeter to the switch.

3. Check continuity of the switch.

Pedal Continuity

Depressed No

Released Yes

4. Reconnect the switch connector.

Note

Refer to Section 6 for replacement of the

clutch switch.

P/S PRESSURE SWITCH

Inspection

1. Disconnect the P/S pressure switch connector.

2. Connect an ohmmeter to the switch.

3. Start the engine. Check continuity of the switch

while turning the steering wheel at idle.

P/S Continuity

Turning Yes

Not turning No

4. Reconnect the switch connector.

Note

Refer to Section 10 for replacement of the P/S

pressure switch.

4C-97

Page 659 of 1865

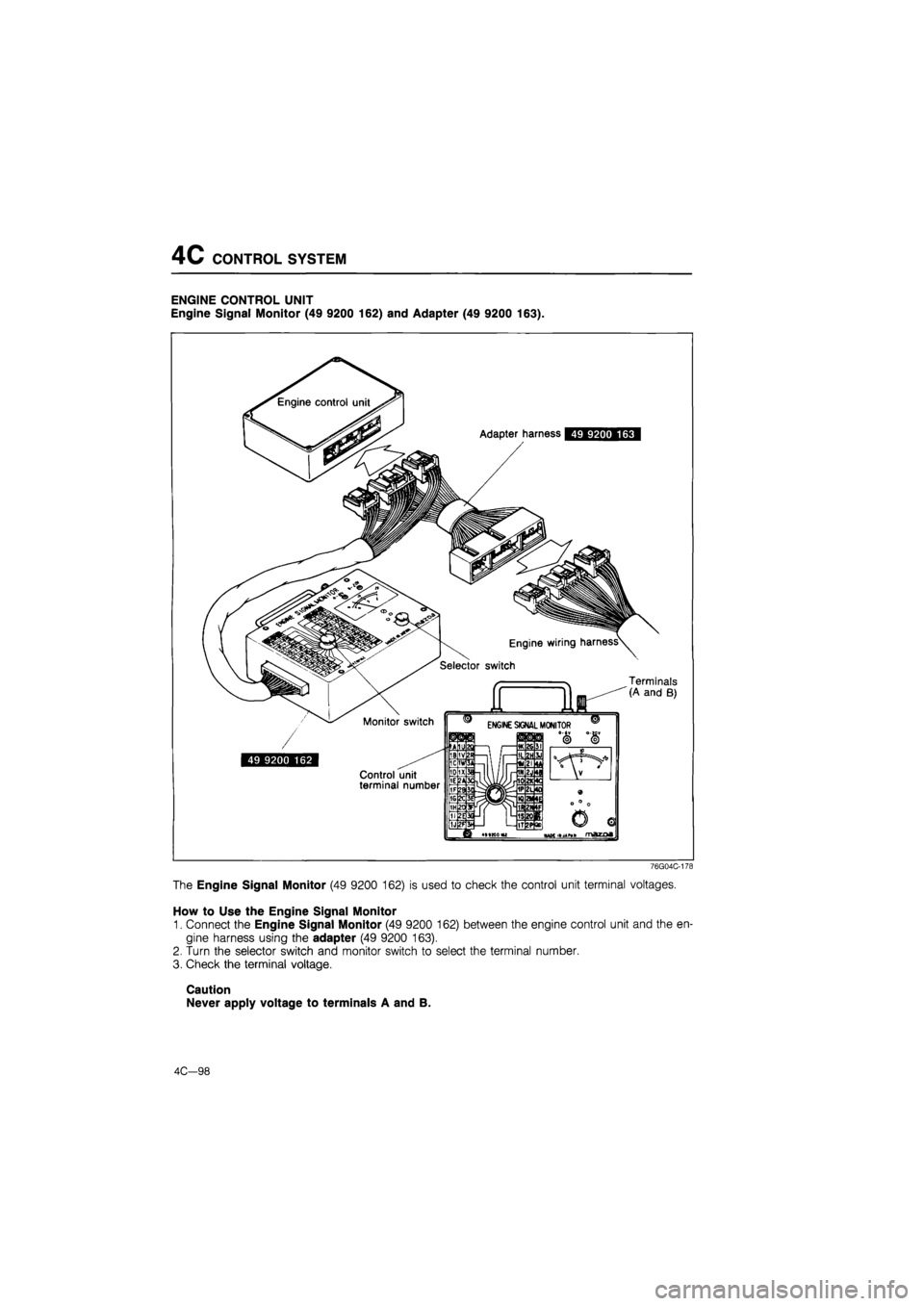

4C CONTROL SYSTEM

ENGINE CONTROL UNIT

Engine Signal Monitor (49 9200 162) and Adapter (49 9200 163).

Adapter harness 49 9200 163

Engine wiring harness^

Selector switch

' —

Monitor switch

49 9200 162

Control unit terminal number

Terminals (A and B)

Q IIIM«I

76G04C-178

The Engine Signal Monitor (49 9200 162) is used to check the control unit terminal voltages.

How to Use the Engine Signal Monitor

1. Connect the Engine Signal Monitor (49 9200 162) between the engine control unit and the en-

gine harness using the adapter (49 9200 163).

2. Turn the selector switch and monitor switch to select the terminal number.

3. Check the terminal voltage.

Caution

Never apply voltage to terminals A and B.

4C—98

Page 660 of 1865

CONTROL SYSTEM 4C

Terminal Voltage

If the input and output devices wiring are normal, but the engine control unit terminal voltage is incor-

rect, replace the engine control unit.

Terminal Input Output Connection to Voltage (After warming-up) Remark Terminal Input Output Connection to Ign: ON Idle Remark

1A — — — — — —

1B o Self-Diagnosis Checker (Code No.)

For 3sec. after ignition switch OFF ->• ON: below 2.5V (Buzzer sounds) After 3sec.: approx. 12V (Buzzer does not sound)

• Using Self-Diagnosis Check-er and test con-nector grounded • Buzzer sounds: below 2.5V • Buzzer does not sound: approx. 12V

1C o

Solenoid valve (Variable inertia control) Approx. 12V

Above 5200 rpm (Unleaded fuel) or 5400 rpm (Leaded fuel): Below 2.5V

1D o Self-Diagnosis Checker (Monitor lamp)

For 3sec.after igni-tion switch OFF -» ON:

approx. 5V (light il-luminates)

After 3sec.: approx. 12V (light does not illuminate)

(Test connector grounded) approx. 5V (Test connector not grounded) Monitor lamp ON: approx. 5V Monitor lamp OFF: approx. 12V

With Self-Diagnosis

Checker

1E O Idle switch Accelerator pedal released: OV

Accelerator pedal depressed: approx. 12V

1F o A/C relay A/C switch ON: below 2.5V

A/C switch OFF: approx. 12V Blower motor ON

1G O Neutral or clutch switch

In-gear condition Clutch pedal depressed: approx. 12V Clutch pedal released: OV

MTX (Neutral: con-stant approx. 12V)

1H

(U/F) o Water thermo

switch

Approx. 12V Radiator temp.: be-low 17°C (63°R 1H

(U/F) o Water thermo

switch OV Radiator temp.:

above 17°C (63°F)

11 o Electrical load control unit E/L switch ON: below 2.5V

E/L switch OFF: approx. 10—12V

Electrical load: Rear defroster switch

Headlight switch Blower motor switch (3rd & 4th position) Electrical fan switch

1J — — — — —

1K o P/S pressure

switch

Constant approx.

12V

P/S ON: below 2.5V P/S OFF: approx. 12V

1L o A/C switch A/C switch ON: below 2.5V A/C switch OFF: aDDrox. 12V Blower motor: ON

1M o Distributor

(Ne signal) OV or 5V Approx. 2.0V

1N o Distributor (G signal) OV or 5V Approx. 1.2V

Note

Terminals labeled "U/F" are only for unleaded fuel.

4C-99