MAZDA PROTEGE 1992 Workshop Manual

Manufacturer: MAZDA, Model Year: 1992, Model line: PROTEGE, Model: MAZDA PROTEGE 1992Pages: 1164, PDF Size: 81.9 MB

Page 211 of 1164

ASSEMBLY 82

CYLINDER HEAD

Torque Specifications

11.3-l 4.2 N.m

(1.15-1.45 m-kg, loo-126 In-lb) 4.9-8.6 N.m

(50-90 cm-kg, 43-76 In-lb)

I I I I -

I I I . 7.6-11 N.m JOURNALS AND

-CAM FACES

(60-I 10 cm-kg, 69-96 in-lb) BOLT THREADS

AND SEAL FACES

5.9-6.6 N.m

(60-90 cm-kg, 52-76 in-lb)

a .e..IC..T .*-*.a

I

UHYKtl NtW

.g~fET NEW

. *

-96 cm-kg,

N.rn (m-kg, &lb)

Valve Seal

03UOB2-1

1. Assemble the SST so that depth L is as specified.

Depth L: 19.b20.0mm (0.780-0.787 in)

B2-79

Page 212 of 1164

62 ASSEMBLY

I OWOBX-21!

I CYLINDER HEAD SIDE

05UOBX-2

I

05UOBX-21 6

i

17

05UOBX-2

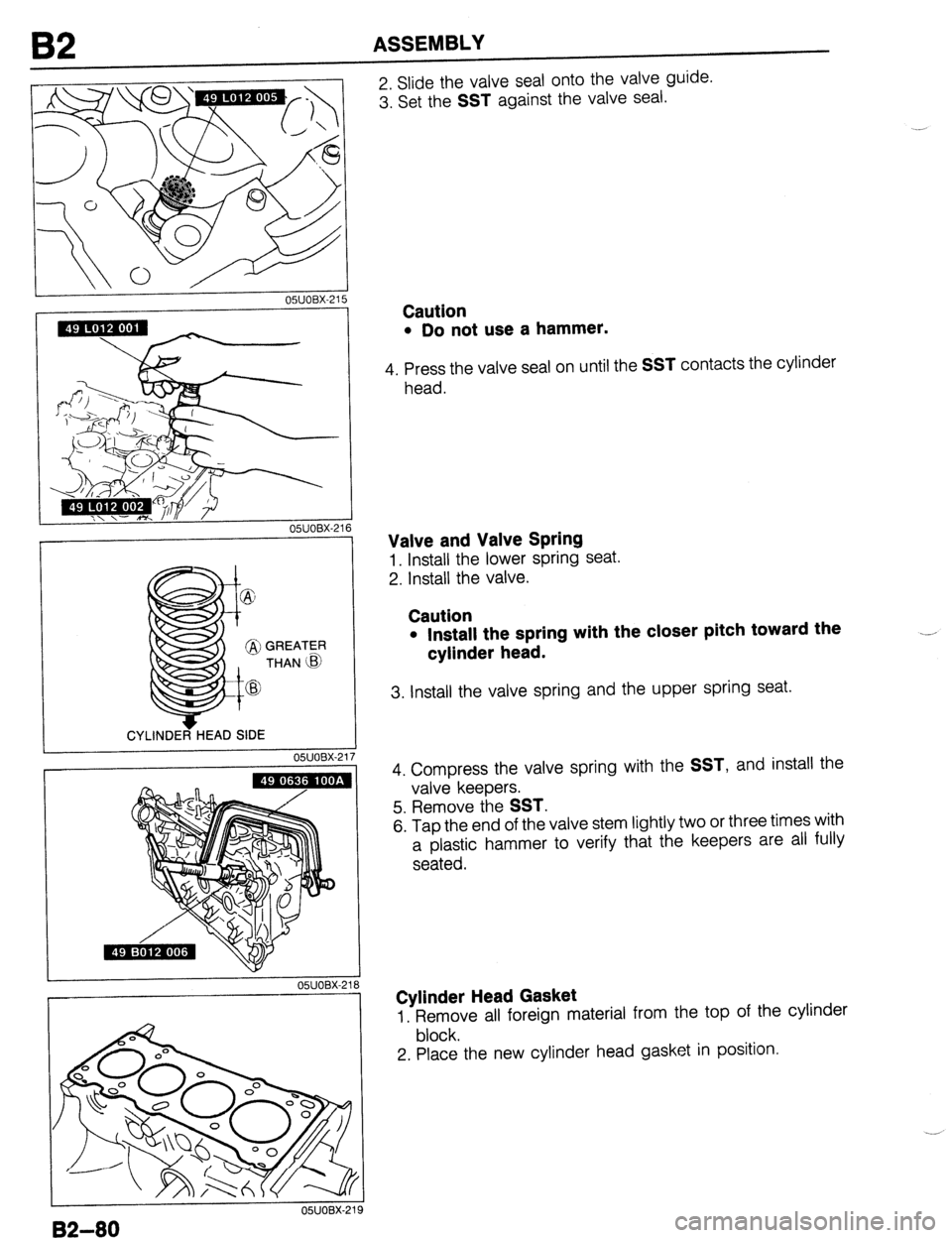

2. Slide the valve seal onto the valve guide.

3. Set the

SST against the valve seal.

Caution

l Do not use a hammer.

4. Press the valve seal on until the SST contacts the cylinder

head.

Valve and Valve Spring

1. Install the lower spring seat.

2. Install the valve.

Caution

l Install the spring with the closer pitch toward the

cylinder head. .---

3. Install the valve spring and the upper spring seat.

4. Compress the valve spring with the

SST, and install the

valve keepers.

5. Remove the

SST.

6. Tap the end of the valve stem lightly two or three times with

a plastic hammer to verify that the keepers are all fully

seated.

Cylinder Head Gasket

1. Remove all foreign material from the top of the cylinder

block.

2. Place the new cylinder head gasket in position.

82-80

Page 213 of 1164

ASSEMBLY

05UOBX-221

I 0311082-10

Cylinder Head

1. Install the cylinder head.

2. Apply clean engine oil to the bolt threads and seat faces.

3. Tighten the cylinder head bolts in two or three steps in the

order shown.

Tightening torque:

76-61 Nsrn (7.7-8.3 m-kg, 56-60 ft-lb)

Water Thermoswitch, Heat Gauge Unit

1. Install the water thermoswitch.

Tightening torque:

5.9-8.8 N#m (60-90 cm-kg, 52-78 in-lb)

2. Install the heat gauge unit.

Tightening torque:

6.4-9.3 N.m (65-95 cm-kg, 56-82 in-lb)

Thermostat, Thermostat Cover

1. Remove all foreign material from the thermostat cover

mounting surface.

2. Install the thermostat with the jiggle pin facing upward.

Caution

l The printed side of the gasket must face the ther-

mostat.

3. Install a new gasket and the thermostat cover.

Tightening torque:

19-26 N-m (1.9-2.6 m-kg, 14-19 ft-lb)

HLA

1. Apply clean engine oil to the friction surfaces.

2. If the HLA are being reused, install them in the position from

which they were removed.

3. Verify that the HLA move smoothly in their bores.

05UOBX.223

B2-81

Page 214 of 1164

B2 ASSEMBLY

DlSTRlBUfOR

DRIVE GROOVE

-- 03umx-01

-

05UOBX-05

--____--

udOBX-056

---I

Camshaft

Note

l The exhaust camshaft is grooved for the distribu-

tor drive.

1. Apply clean engine oil to the camshaft journals and bearings.

2. Install the camshaft in position.

Caution

l Do not allow any sealant on the camshaft journal

surfaces.

3. Apply silicone sealant to the shaded areas shown in the

figure.

4. Install the camshaft caps according to the cap number and

arrow mark.

5. Install the camshaft cap bolts and tighten them in two or

three steps in the order shown in the figure.

Tightening torque:

11.3-14.2 Nlm (1.15-l .45 m-kg, loo-126 in-lb)

6. Apply a small amount of clean engine oil to the lip of a new

camshaft oil seal.

7. Push the oil seal slightly in by hand.

Caution

l The oil seal must be tapped in until it is flush with

the edge of the camshaft cap.

8. Tap the oil seal in evenly with a suitable pipe and a hammer.

Oil seal outer diameter: 48mm (1.89 in)

Seal Plate

1. Install the seal plate on the cylinder head.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 69-95 in-lb)

~,. ,

03”oEm10:

B2-82

Page 215 of 1164

ASSEMBLY 82

DOWEL PIN

23UOB2-042

03UOB2-1 OL Camshaft Pulley

1. Turn the camshafts until the camshaft dowel pins face

straight up.

2. Install the camshaft pulleys with the

I mark (intake side) or

the E mark (exhaust side) straight up.

3. Install the camshaft pulley lock bolts.

4. Hold the camshaft with a wrench at hexagonal portion.

5. Tighten the camshaft pulley lock bolt.

Tightening torque:

49-61 N.m (5.0-6.2 m-kg, 36-45 ft-lb)

Cylinder Head Cover

1. Apply silicone sealant to the shaded areas shown in the

figure.

2. Install the cylinder head cover.

Tightening torque:

4.9-6.6 N.m (50-90 cm-kg, 43-76 in-lb)

82-83

Page 216 of 1164

B2 ASSEMBLY

TIMING BELT

Torque Specifications

7.6-11 N:m

(60-l 10 cm-kg,

69-95 in-lb) \

-kg, 69-95 in-lb)

37-52

(3.8-5.3, 27-38)

157-167 (16-17, 116-123)

?.a--11 N-m

(60-110 cm-kg, 69-95 in-lb) /

12-17 (1.25-1.76, 9-13)

N-m (m-kg, ft-it

03UOB2.1

Idler

1. Install the idler.

Tightening torque:

37-52 N.m (3.8-5.3 m-kg, 27-38 ft-lb)

Tensioner and Tensioner Spring

1. Install the tensioner and the tensioner spring.

2. Temporarily secure the tensioner with the spring fully ex-

tended.

-’

o5uoBx-229

02-84

Page 217 of 1164

ASSEMBLY

13EOB2.03

13EOB2-03.

3 1

03UOB2-111

23UOB2-04: 3

Timing Belt

1. Verify that the timing belt pulley mark is aligned with the tim-

ing mark.

2. Verify that the camshaft pulley marks are aligned with the

seal plate marks.

3. Install the timing belt so that there is no looseness at the

idler side or between the camshaft pulleys.

4. Install the pulley boss and pulley lock bolt.

Caution

l Do not turn the crankshaft counterclockwise.

5. Turn the crankshaft two turns clockwise and face the pin

on the pulley boss upright.

6. Verify that the camshaft pulley marks are aligned with the

seal plate marks.

If not aligned, remove the timing belt and repeat from ten-

sioner installation.

7. Turn the crankshaft 1 and 5/6 turns clockwise, and align

the timing belt pulley mark with the tension set mark for prop-

er timing belt tension adjustment.

8. Loosen the tensioner lock bolt to apply tension to the tim-

ing belt.

9. Tighten the tensioner lock bolt.

Tightening torque:

37-52 N-m (3.8-5.3 m-kg, 27-38 ft-lb)

10. Turn the crankshaft 2 and l/6 turns clockwise and verify

that the timing marks are correctly aligned.

B2-85

Page 218 of 1164

I 23UOB2-044

82 ASSEMBLY

DEFLECTION CHECKING POlNT

--; 11. Measure the timing belt deflection by applying moderate

oressure (98 N, 10 kg, 22 lb) midway between the two cam-

shaft pulleys.

If the deflection is not correct, repeat from Step 7 above.

Deflection:

9.0-11.5mm (0.35-0.45 in) at 98 N (10 kg, 22 lb)

Timing Belt Cover

1. Install the lower, middle, and upper covers.

Tightening torque:

7.8-11 N.m (80- ,110 cm-kg, 69-95 in-lb)

I 13EOB2-037

82-86

Pulley lock bolt

1. Hold the flywheel (MIX) or drive plate (ATX) with the SST

and tighten the pulley lock bolt.

Tlghtening torque:

157-167 N.m (16-17 m-kg, 116-123 ft-lb)

Cankshaft pully

1. Install the crankshaft pulley.

2. Install the plate.

3. Tighten the pulley bolts.

Tightening torque:

12-17 N-m (1.25-l -75 m-kg, 9-13 ft-lb)

Water Pump Pulley

1. Install the water pump pulley.

Tightening torque:

7.8-11 N*m (80-110 cm-kg, 69-95 in-lb)

Page 219 of 1164

ASSEMBLY B2

AUXILIARY PARTS

Toraue Specifications

19-25 19-25

O-RING, NEW

(1.9-2.6, 14-19) (1.9-2.6, 14-19)

-

I 19-25

mfi GASKET. NEW (1.9-2.6, 14-19)

37-52

(33-5.3, 27-38)

(3.8-5.3, 27-38)

7.8-11 N.m /

(80-110 cm-kg, 69-95 in-lb)

N.m (m-kg, A-lb)

.-. 05UOBX-23

Engine Hanger

1. Install the front and rear engine hangers.

OYJOBX-238

Tightening torque:

37-52 N*m (3.8-5.3 m-kg, 27-38 ft-lb)

82-87

Page 220 of 1164

82 ASSEMBLY

Oil Level Gauge Pipe Stay

1. Install the oil level gauge pipe stay.

Tightening torque:

7.8-l 1 N-m (80-l 10 cm-kg, 89-95 in-lb)

Oil Level Gauge

1. Install the level gauge.

Spark Plug

1, Install the spark plugs.

Tightening torque:

15-23 N*m (1.5-2.3 m-kg, 11-17 ft-lb)

Oil Pressure Switch

1. Install the oil pressure switch.

Tightening torque:

12-18 N-m (120-180 cm-kg, 104-156 in-lb)

Oil Cooler

1. Remove all foreign material from the oil cooler mounting

surface.

2. Apply a small amount of clean engine oil to the rubber seal

of the oil cooler.

3. Install the oil cooler with paint mark (white) facing up.

4. Tighten the oil cooler lock nut.

Tightening torque:

29-39 N.m (3.0-4.0 m-kg, 22-29 ft-lb)

5. Connect the harness to oil pressure switch.

Oil Filter

1. Remove all foreign material from the oil filter mounting

surface.

2. Apply a small amount of clean engine oil to the rubber seal

of the oil filter.

3. Install the oil filter and tighten it by hand until the rubber

seal contacts the base.

4. Tighten the filter 1 and 116 turns with a filter wrench. --_