MITSUBISHI SPYDER 1990 Service Repair Manual

Manufacturer: MITSUBISHI, Model Year: 1990, Model line: SPYDER, Model: MITSUBISHI SPYDER 1990Pages: 2103, PDF Size: 68.98 MB

Page 1911 of 2103

B O D Y ,

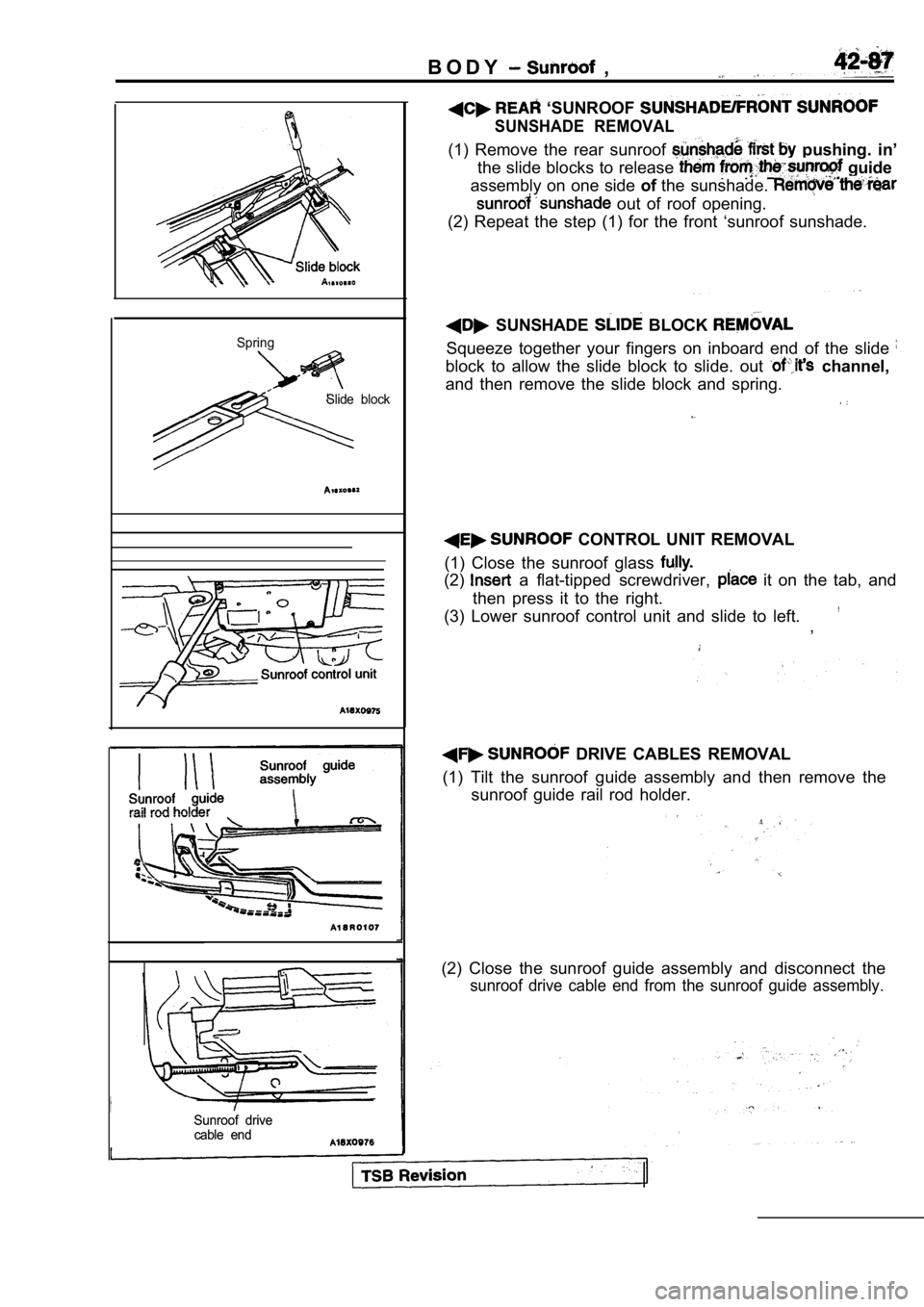

SpringSlide block

Sunroof drive

Sunroof drive

cable end

cable end

‘SUNROOF

SUNSHADE REMOVAL

(1) Remove the rear sunroof pushing. in’

the slide blocks to release

guide

assembly on one side ofthe sunshade.

out of roof opening.

(2) Repeat the step (1) for the front ‘sunroof suns hade.

SUNSHADE BLOCK

Squeeze together your fingers on inboard end of the slide

block to allow the slide block to slide. out channel,

and then remove the slide block and spring.

CONTROL UNIT REMOVAL

(1) Close the sunroof glass

(2) a flat-tipped screwdriver, it on the tab, and

then press it to the right.

(3) Lower sunroof control unit and slide to left.

,

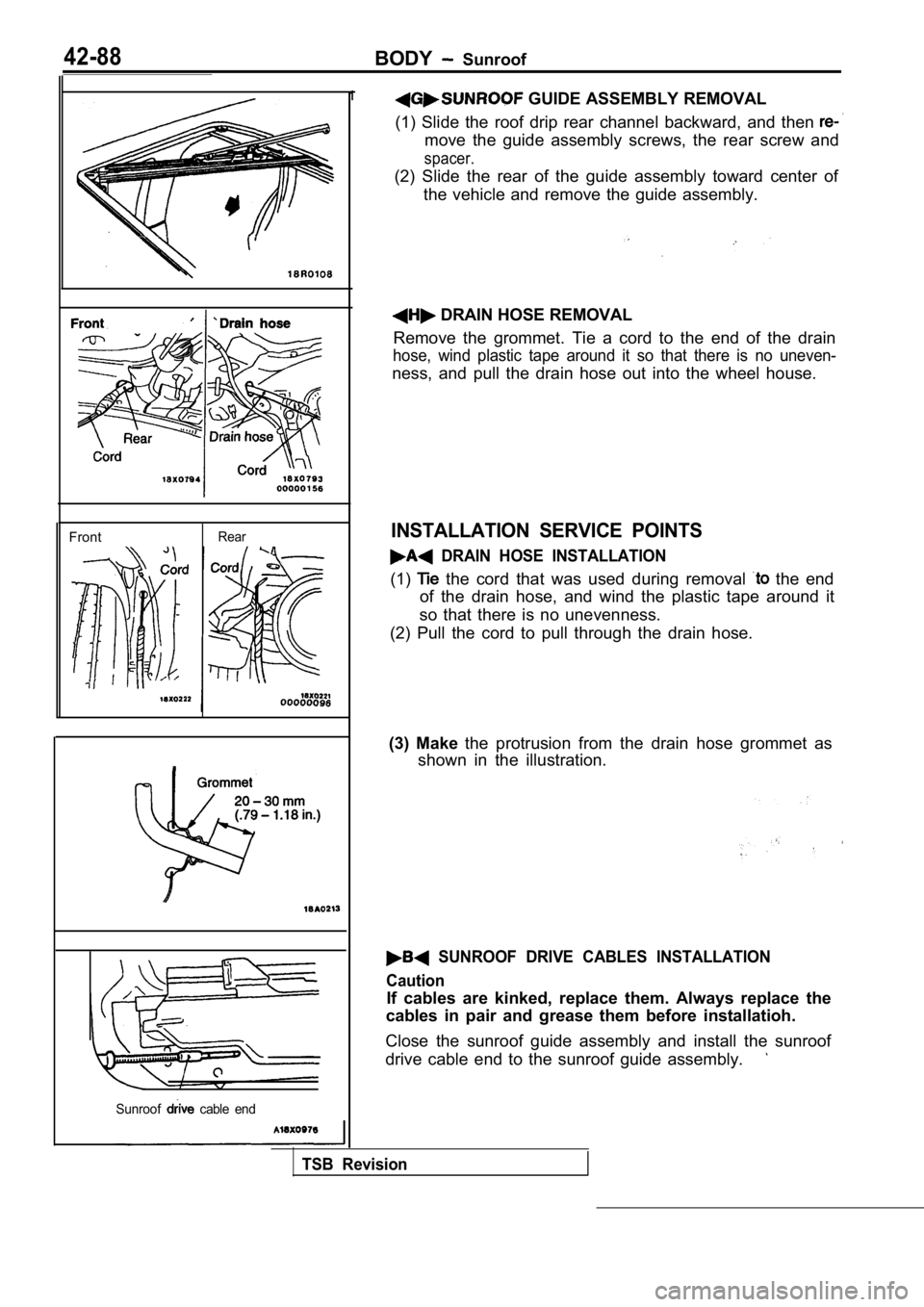

DRIVE CABLES REMOVAL

(1) Tilt the sunroof guide assembly and then remove the

sunroof guide rail rod holder.

(2) Close the sunroof guide assembly and disconnect the

sunroof drive cable end from the sunroof guide assembly.

Page 1912 of 2103

42-88BODY Sunroof

Front

Rear

Sunroof

cable end

1 GUIDE ASSEMBLY REMOVAL

(1) Slide the roof drip rear channel backward, and then

move the guide assembly screws, the rear screw and

spacer.

(2) Slide the rear of the guide assembly toward cen ter of

the vehicle and remove the guide assembly.

DRAIN HOSE REMOVAL

Remove the grommet. Tie a cord to the end of the dr ain

hose, wind plastic tape around it so that there is no uneven-

ness, and pull the drain hose out into the wheel ho use.

INSTALLATION SERVICE POINTS

DRAIN HOSE INSTALLATION

(1) the cord that was used during removal the end

of the drain hose, and wind the plastic tape around it

so that there is no unevenness.

(2) Pull the cord to pull through the drain hose.

(3) Make the protrusion from the drain hose grommet as

shown in the illustration.

SUNROOF DRIVE CABLES INSTALLATION

Caution

If cables are kinked, replace them. Always replace the

cables in pair and grease them before installatioh.

Close the sunroof guide assembly and install the su nroof

drive cable end to the sunroof guide assembly.

TSB Revision

Page 1913 of 2103

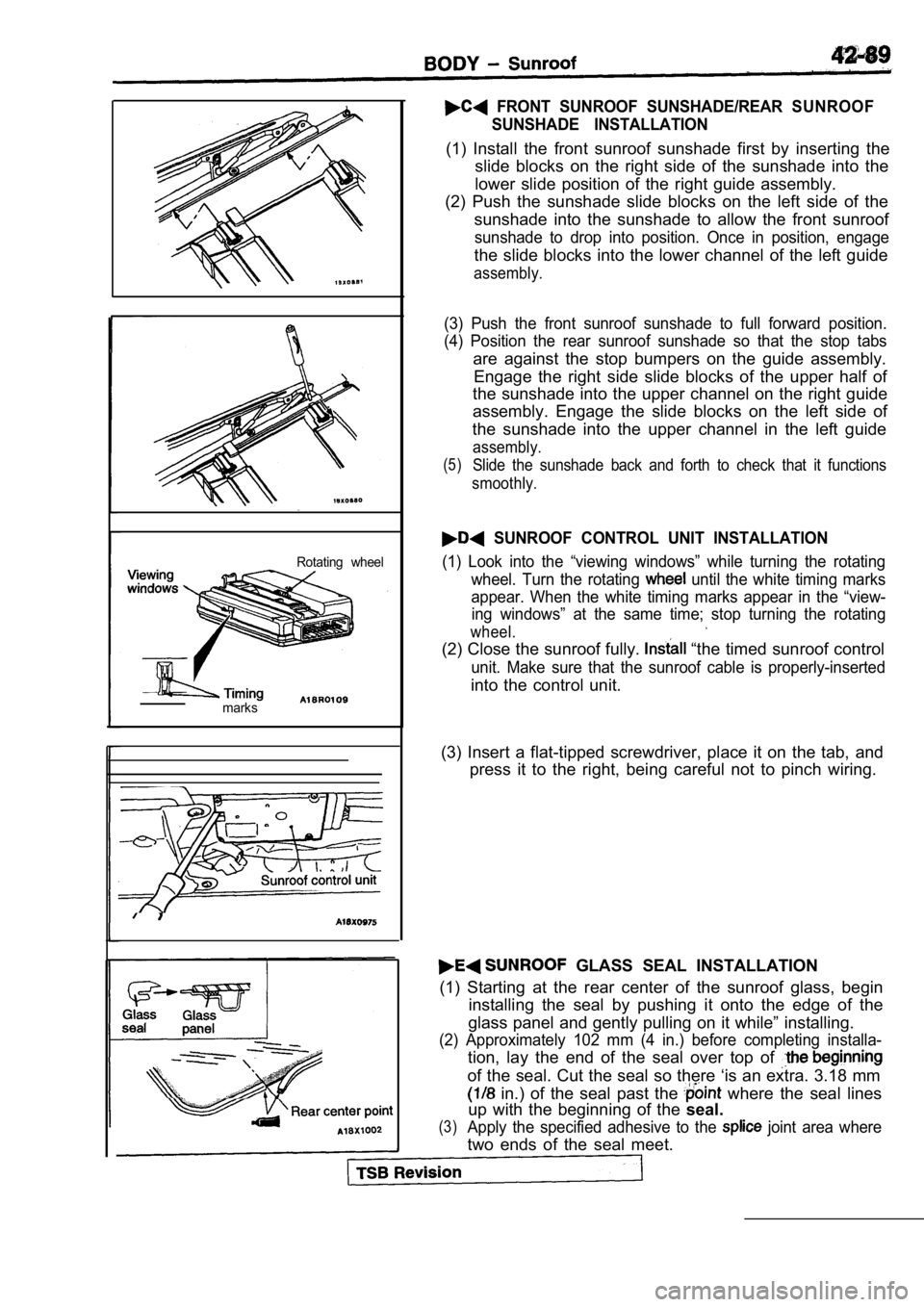

Rotating wheel

marks

FRONT SUNROOF SUNSHADE/REAR SUNROOF SUNSHADE INSTALLATION

(1) Install the front sunroof sunshade first by ins erting the

slide blocks on the right side of the sunshade into the

lower slide position of the right guide assembly.

(2) Push the sunshade slide blocks on the left side of the

sunshade into the sunshade to allow the front sunro of

sunshade to drop into position. Once in position, engage

the slide blocks into the lower channel of the left guide

assembly.

(3) Push the front sunroof sunshade to full forward position.

(4) Position the rear sunroof sunshade so that the stop tabs

are against the stop bumpers on the guide assembly.

Engage the right side slide blocks of the upper hal f of

the sunshade into the upper channel on the right gu ide

assembly. Engage the slide blocks on the left side of

the sunshade into the upper channel in the left gui de

assembly.

(5)Slide the sunshade back and forth to check that it functions

smoothly.

SUNROOF CONTROL UNIT INSTALLATION

(1) Look into the “viewing windows” while turning t he rotating

wheel. Turn the rotating

until the white timing marks

appear. When the white timing marks appear in the “ view-

ing windows” at the same time; stop turning the rot ating

wheel.

(2) Close the sunroof fully. “the timed sunroof control

unit. Make sure that the sunroof cable is properly-inserted

into the control unit.

(3) Insert a flat-tipped screwdriver, place it on t he tab, and

press it to the right, being careful not to pinch w iring.

GLASS SEAL INSTALLATION

(1) Starting at the rear center of the sunroof glas s, begin

installing the seal by pushing it onto the edge of the

glass panel and gently pulling on it while” install ing.

(2) Approximately 102 mm (4 in.) before completing installa-

tion, lay the end of the seal over top of

of the seal. Cut the seal so there ‘is an extra. 3.18 mm

in.) of the seal past the where the seal lines

up with the beginning of the seal.

(3)Apply the specified adhesive to the joint area where

two ends of the seal meet.

Page 1914 of 2103

BODY Sunroof

Specified adhesive:Loctite 410 Black Toughened Instant Adhesive or

equivalent. .

(4) With the approximately 102 mm (4 the seal unat-

tached, push two ends of the seal together at glue joint.

(5) Install remainder of the seal by pushing onto

the edge of the glass panel. The 3.18 mm of extra

seal material should strengthen the seal at the splice

joint.

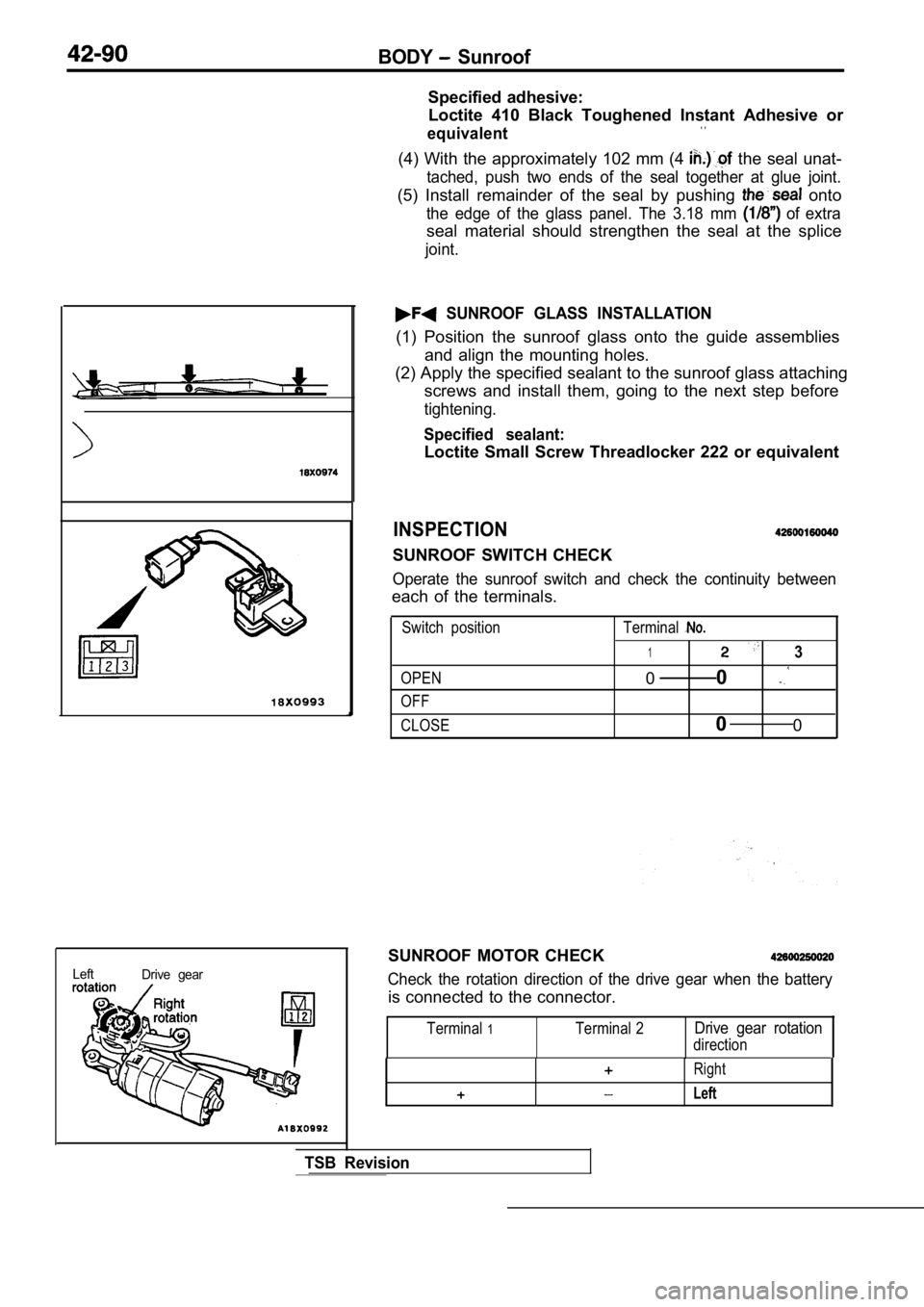

Left

Drive gear

SUNROOF GLASS INSTALLATION

(1) Position the sunroof glass onto the guide assem blies

and align the mounting holes.

(2) Apply the specified sealant to the sunroof glas s attaching

screws and install them, going to the next step bef ore

tightening.

Specified sealant:

Loctite Small Screw Threadlocker 222 or equivalent

INSPECTION

SUNROOF SWITCH CHECK

Operate the sunroof switch and check the continuity between

each of the terminals.

Switch position

OPEN

OFF Terminal

13

0

0

CLOSE0

0

SUNROOF MOTOR CHECK

Check the rotation direction of the drive gear when the battery

is connected to the connector.

Terminal1Terminal 2Drive gear rotation

direction

TSB Revision

Right

Left

Page 1915 of 2103

BODY Convertible Top

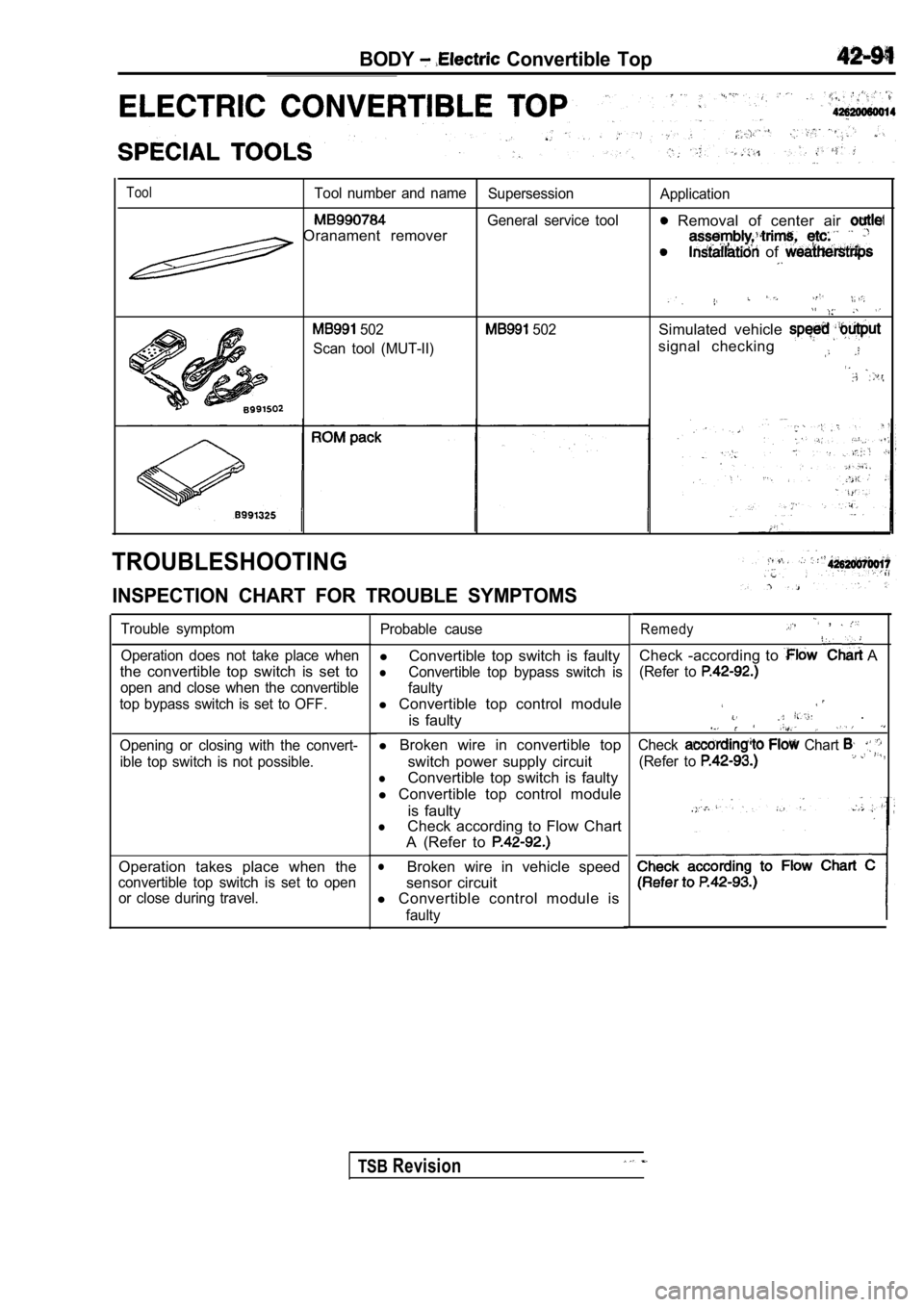

ToolTool number and nameSupersessionApplication

General service tool Removal of center air Oranament remover

of

502

Scan tool (MUT-II) 502Simulated vehicle

signal checking

TROUBLESHOOTING

INSPECTION CHART FOR TROUBLE SYMPTOMS

Trouble symptom

Operation does not take place when

the convertible top switch is set to

open and close when the convertible

top bypass switch is set to OFF.

Opening or closing with the convert- ible top switch is not possible.

Operation takes place when the

convertible top switch is set to openor close during travel. Probable cause

l

Convertible top switch is faulty

lConvertible top bypass switch is

faulty

l Convertible top control module

is faulty

l Broken wire in convertible top

switch power supply circuit

lConvertible top switch is faulty

l Convertible top control module

is faulty

lCheck according to Flow Chart

A (Refer to

lBroken wire in vehicle speed

sensor circuit

l Convertible control module is

faulty

Remedy ,

Check -according to A

(Refer to

.

Check Chart

(Refer to ,

TSBRevision

Page 1916 of 2103

BODY Electric Convertible , .

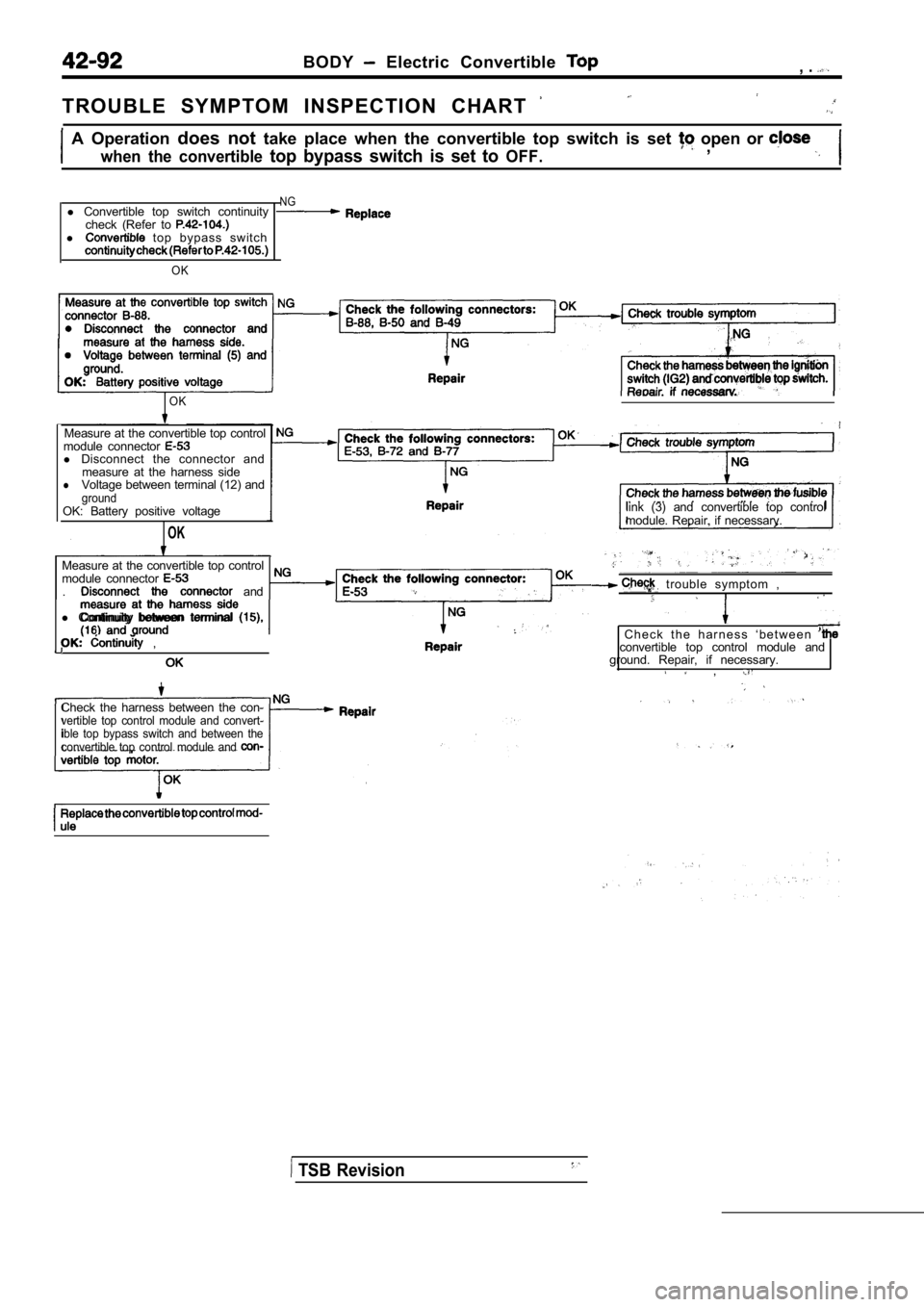

T R O U B L E S Y M P T O M I N S P E C T I O N C H A R T

A Operation does not take place when the convertible top switch is set open or

when the convertible top bypass switch is set to OFF. ,

l Convertible top switch continuity

check (Refer to

l top bypass switch

OK

NG

OK

Measure at the convertible top control

module connector

l Disconnect the connector and

measure at the harness side

lVoltage between terminal (12) andgroundOK: Battery positive voltage

OK

link (3) and convertible top control

module. Repair, if necessary.

Measure at the convertible top control

module connector

. and

l Continuity between terminal

,

Check the harness between the con-vertible top control module and convert-

ible top bypass switch and between the

convertible top control module and

trouble symptom ,

C h e c k t h e h a r n e s s ‘ b e t w e e n convertible top control module and

ground. Repair, if necessary.

,

TSB Revision

Page 1917 of 2103

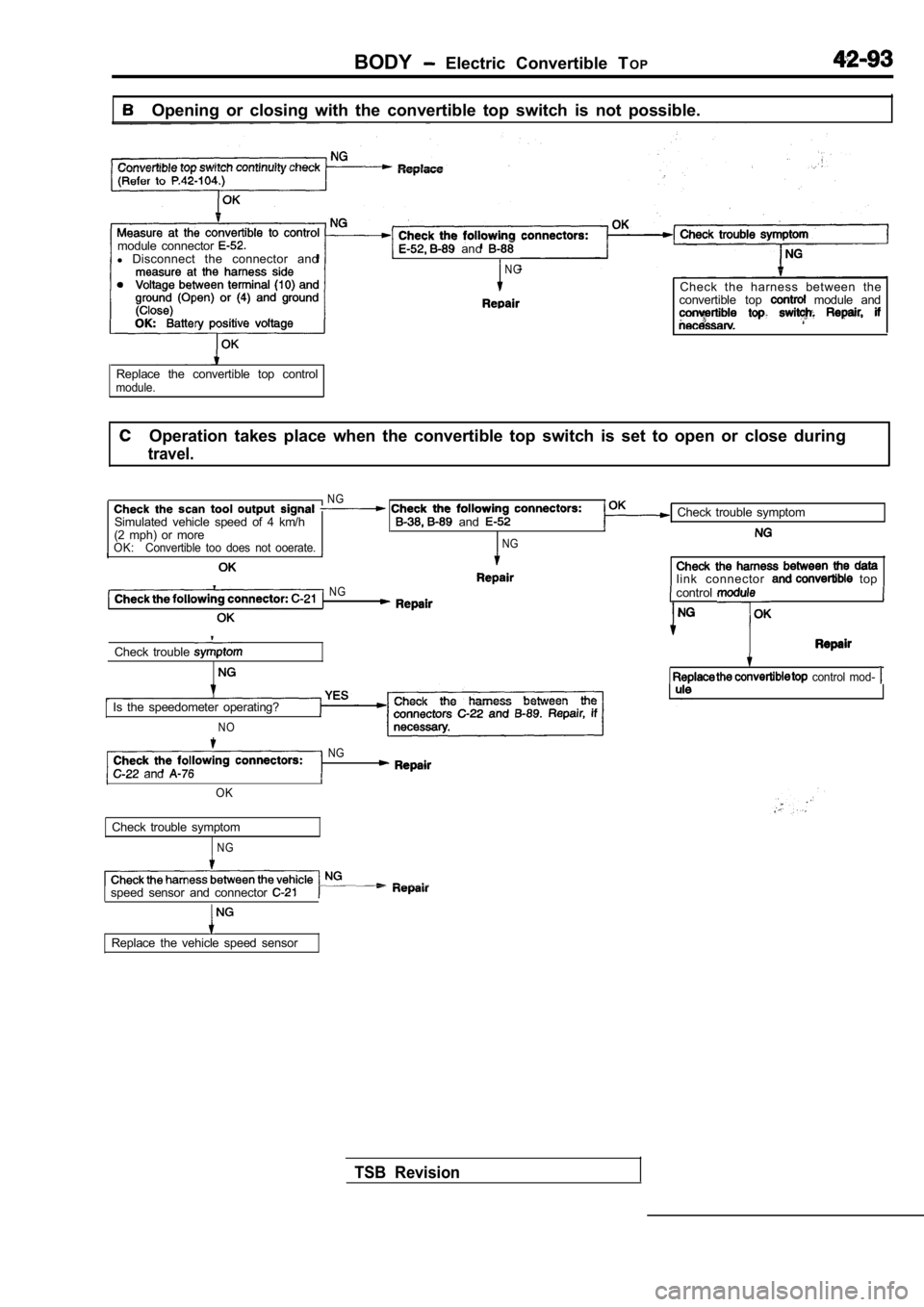

BODY Electric Convertible TOP

Opening or closing with the convertible top switch is not possible.

module connector

l Disconnect the connector and and

Replace the convertible top controlmodule.

N G

Check the harness between the

convertible top module and

Operation takes place when the convertible top swit ch is set to open or close during

travel.

NG

Simulated vehicle speed of 4 km/h and (2 mph) or moreOK: Convertible too does not ooerate.NG

Check trouble symptom

link connector topNG control

Check trouble

control mod-

Is the speedometer operating?

N O

NG

and

TSB Revision

OK

Check trouble symptom

N G

speed sensor and connector

Replace the vehicle speed sensor

Page 1918 of 2103

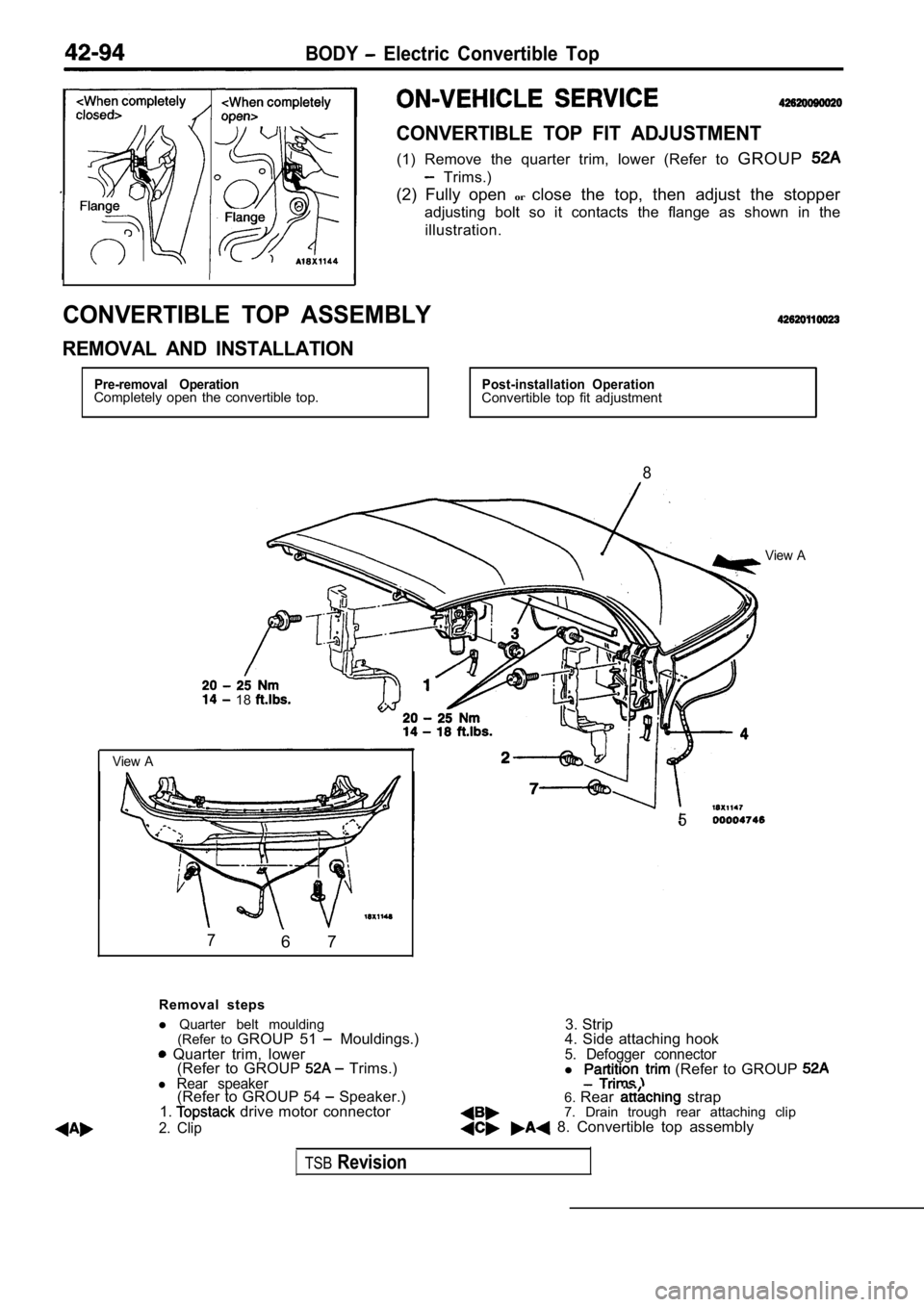

BODY Electric Convertible Top

CONVERTIBLE TOP FIT ADJUSTMENT

(1) Remove the quarter trim, lower (Refer to GROUP

Trims.)

(2) Fully open orclose the top, then adjust the stopper

adjusting bolt so it contacts the flange as shown in the

illustration.

CONVERTIBLE TOP ASSEMBLY

REMOVAL AND INSTALLATION

Pre-removal OperationCompletely open the convertible top.Post-installation OperationConvertible top fit adjustment

8

View A

18

View A

76 7

5

Removal steps

3. Strip

l

Quarter belt moulding

(Refer to GROUP 51

Mouldings.) Quarter trim, lower

(Refer to GROUP Trims.)l Rear speaker(Refer to GROUP 54 Speaker.)

1. drive motor connector

2. Clip

4. Side attaching hook5. Defogger connectorl (Refer to GROUP

6. Rear strap

7. Drain trough rear attaching clip

8. Convertible top assembly

TSBRevision

Page 1919 of 2103

BODY Electric Convertible

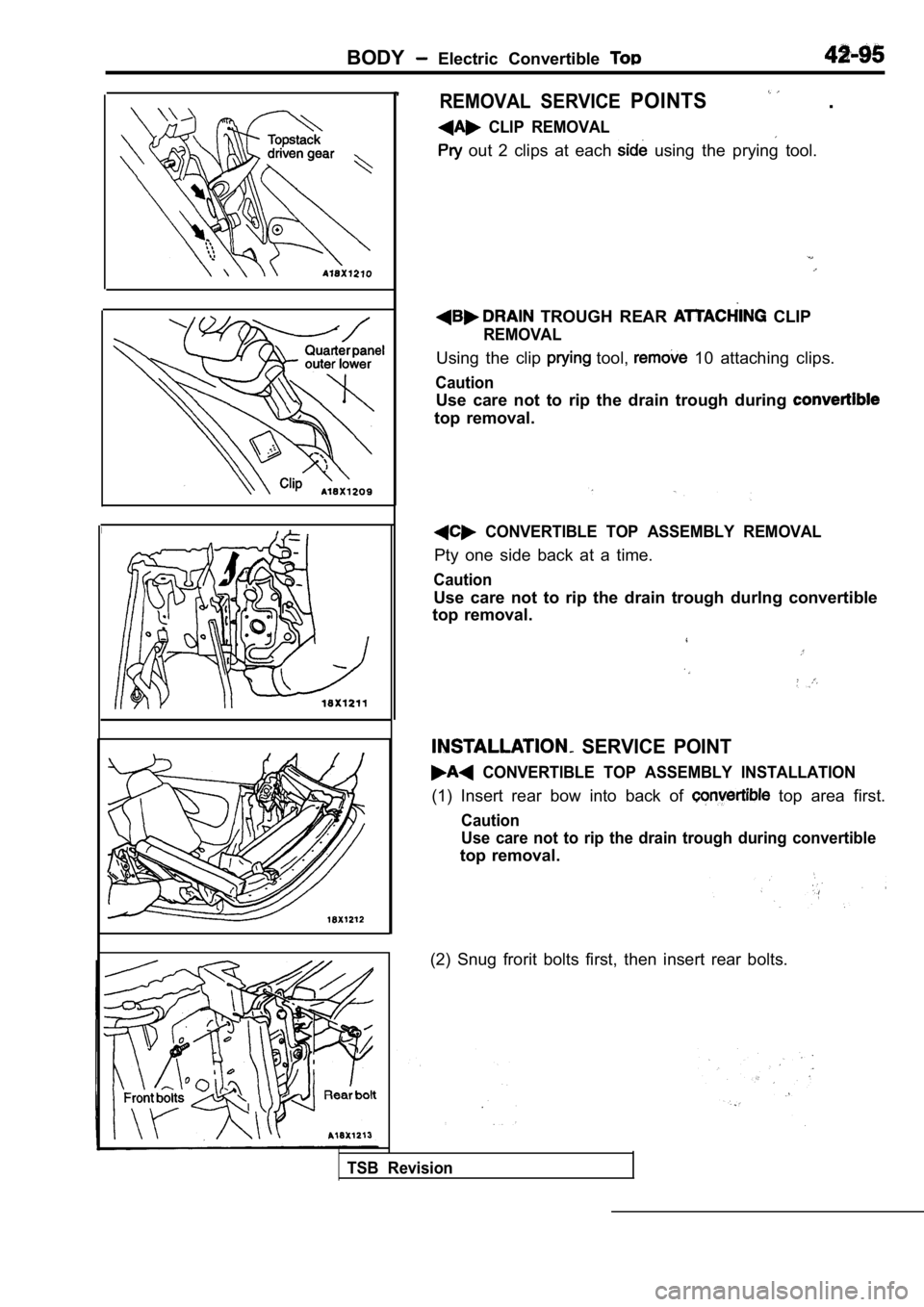

REMOVAL SERVICE POINTS .

CLIP REMOVAL

out 2 clips at each using the prying tool.

TROUGH REAR CLIP

REMOVAL

Using the clip tool, 10 attaching clips.

Caution

Use care not to rip the drain trough during

top removal.

CONVERTIBLE TOP ASSEMBLY REMOVAL

Pty one side back at a time.

Caution

Use care not to rip the drain trough durlng convertible

top removal.

TSB Revision

SERVICE POINT

CONVERTIBLE TOP ASSEMBLY INSTALLATION

(1) Insert rear bow into back of top area first.

Caution

Use care not to rip the drain trough during convert ible

top removal.

(2) Snug frorit bolts first, then insert rear bolts .

Page 1920 of 2103

42-96BODY Electric Convertible

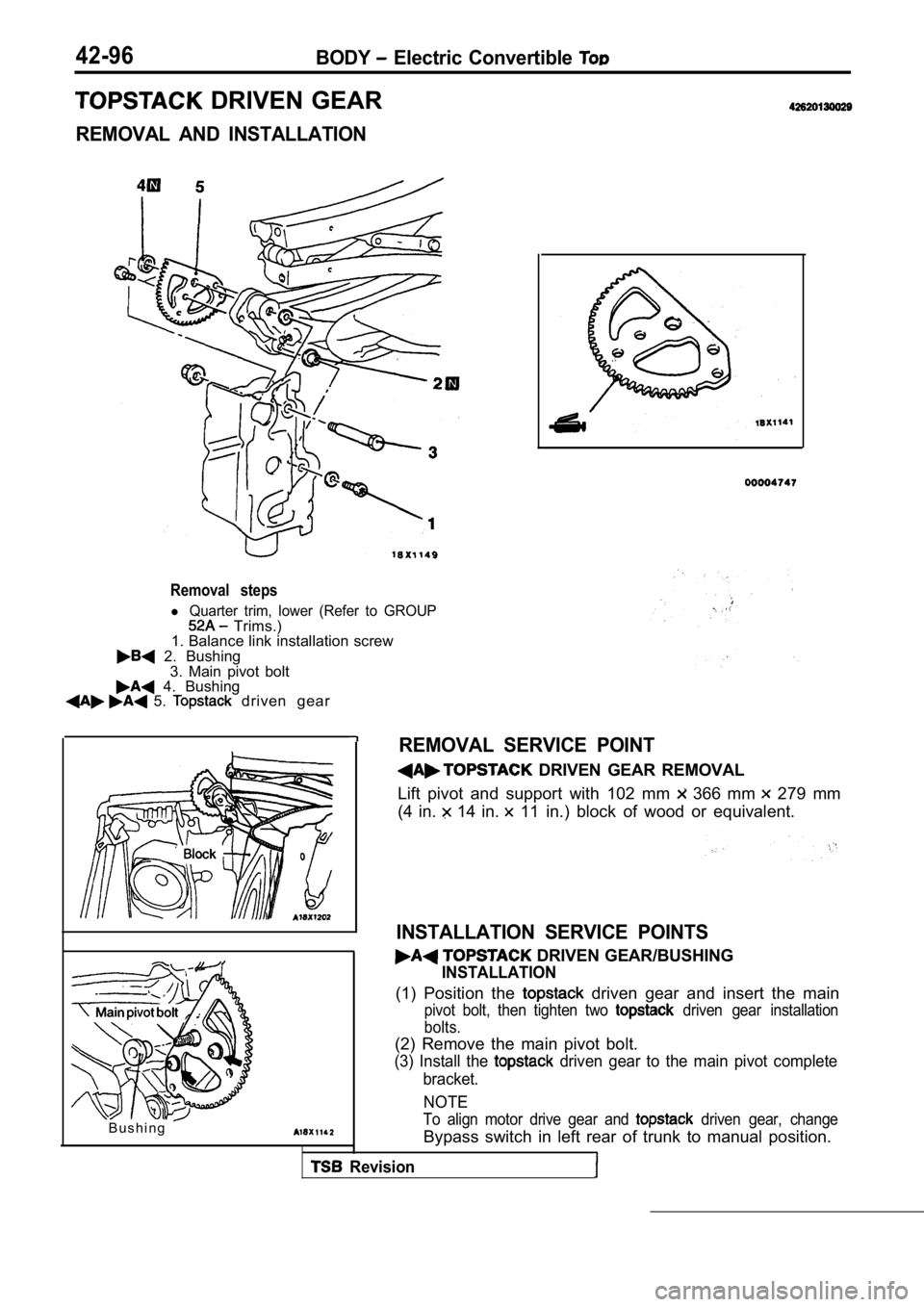

DRIVEN GEAR

REMOVAL AND INSTALLATION

Removal steps

l Quarter trim, lower (Refer to GROUP Trims.)

1. Balance link installation screw

2. Bushing

3. Main pivot bolt

4. Bushing 5. driven gear

B u s h i n g

REMOVAL SERVICE POINT

DRIVEN GEAR REMOVAL

Lift pivot and support with 102 mm

366 mm 279 mm

(4 in.

14 in. 11 in.) block of wood or equivalent.

INSTALLATION SERVICE POINTS

DRIVEN GEAR/BUSHING

INSTALLATION

(1) Position the driven gear and insert the main

pivot bolt, then tighten two driven gear installation

bolts.

(2) Remove the main pivot bolt.

(3) Install the driven gear to the main pivot complete

bracket.

NOTE

To align motor drive gear and driven gear, change

Bypass switch in left rear of trunk to manual posit ion.

Revision