NISSAN TERRANO 2004 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2004, Model line: TERRANO, Model: NISSAN TERRANO 2004Pages: 1833, PDF Size: 53.42 MB

Page 301 of 1833

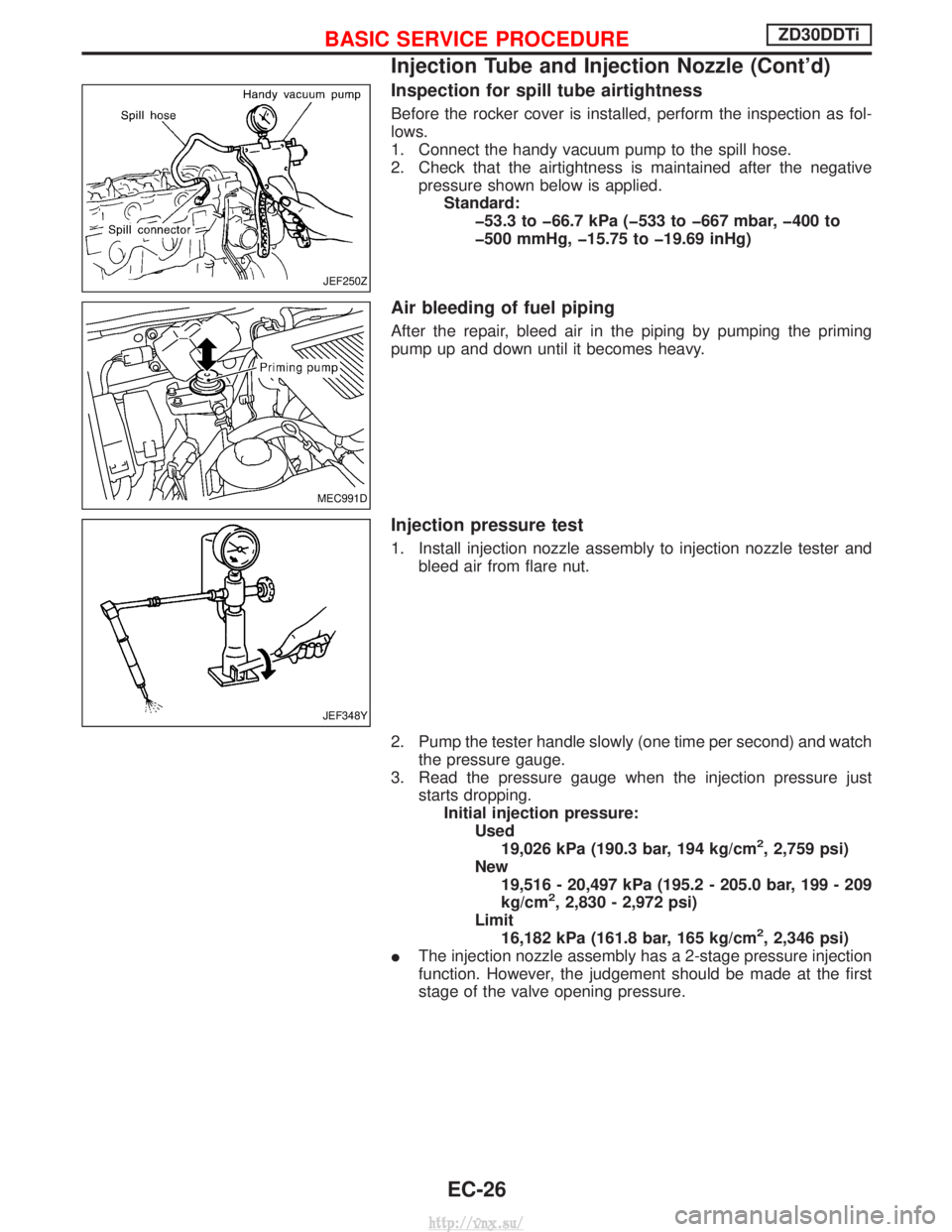

Inspection for spill tube airtightness

Before the rocker cover is installed, perform the inspection as fol-

lows.

1. Connect the handy vacuum pump to the spill hose.

2. Check that the airtightness is maintained after the negativepressure shown below is applied.Standard: þ53.3 to þ66.7 kPa (þ533 to þ667 mbar, þ400 to

þ500 mmHg, þ15.75 to þ19.69 inHg)

Air bleeding of fuel piping

After the repair, bleed air in the piping by pumping the priming

pump up and down until it becomes heavy.

Injection pressure test

1. Install injection nozzle assembly to injection nozzle tester andbleed air from flare nut.

2. Pump the tester handle slowly (one time per second) and watch the pressure gauge.

3. Read the pressure gauge when the injection pressure just starts dropping.Initial injection pressure: Used19,026 kPa (190.3 bar, 194 kg/cm

2, 2,759 psi)

New 19,516 - 20,497 kPa (195.2 - 205.0 bar, 199 - 209

kg/cm

2, 2,830 - 2,972 psi)

Limit 16,182 kPa (161.8 bar, 165 kg/cm

2, 2,346 psi)

I The injection nozzle assembly has a 2-stage pressure injection

function. However, the judgement should be made at the first

stage of the valve opening pressure.

JEF250Z

MEC991D

JEF348Y

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-26

http://vnx.su/

Page 302 of 1833

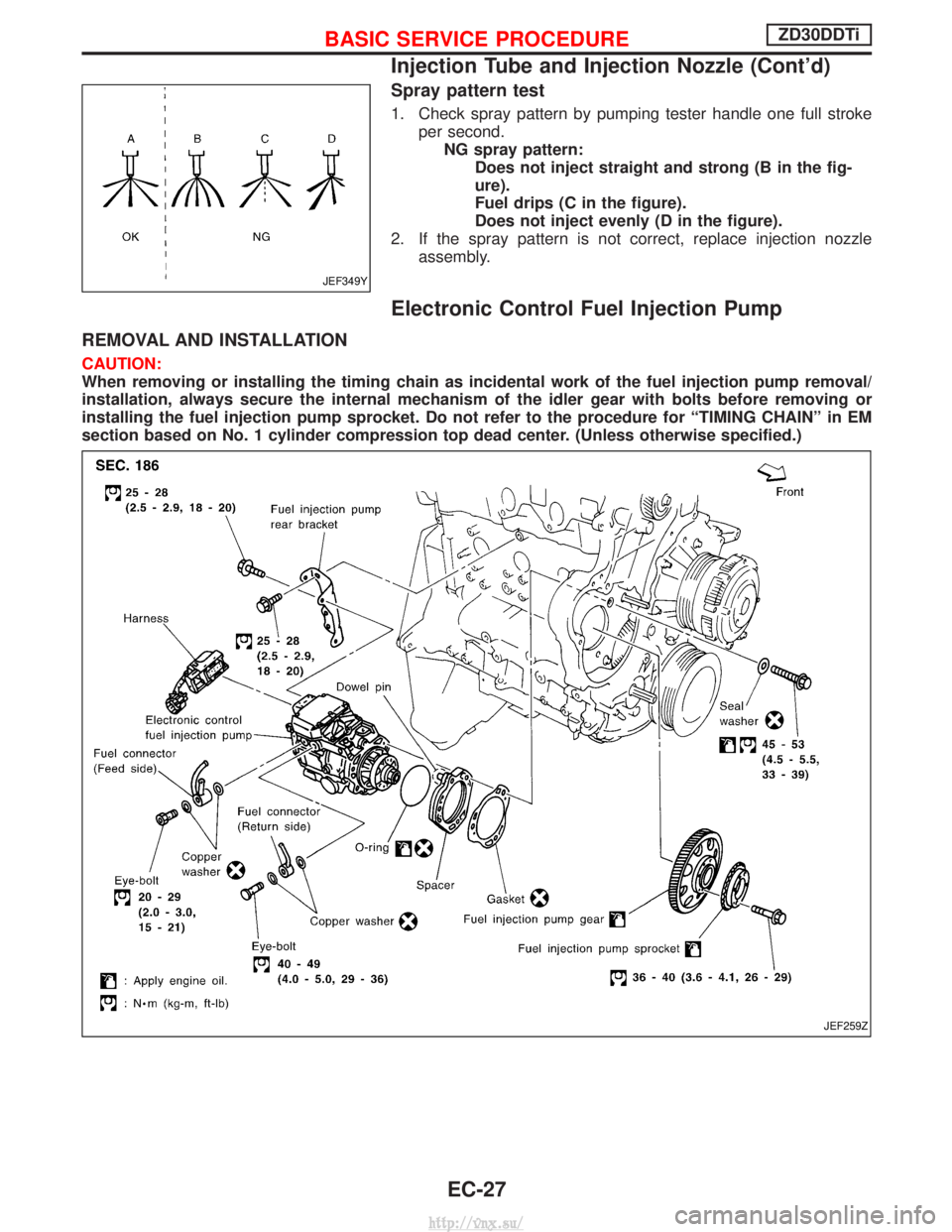

Spray pattern test

1. Check spray pattern by pumping tester handle one full strokeper second.NG spray pattern: Does not inject straight and strong (B in the fig-

ure).

Fuel drips (C in the figure).

Does not inject evenly (D in the figure).

2. If the spray pattern is not correct, replace injection nozzle assembly.

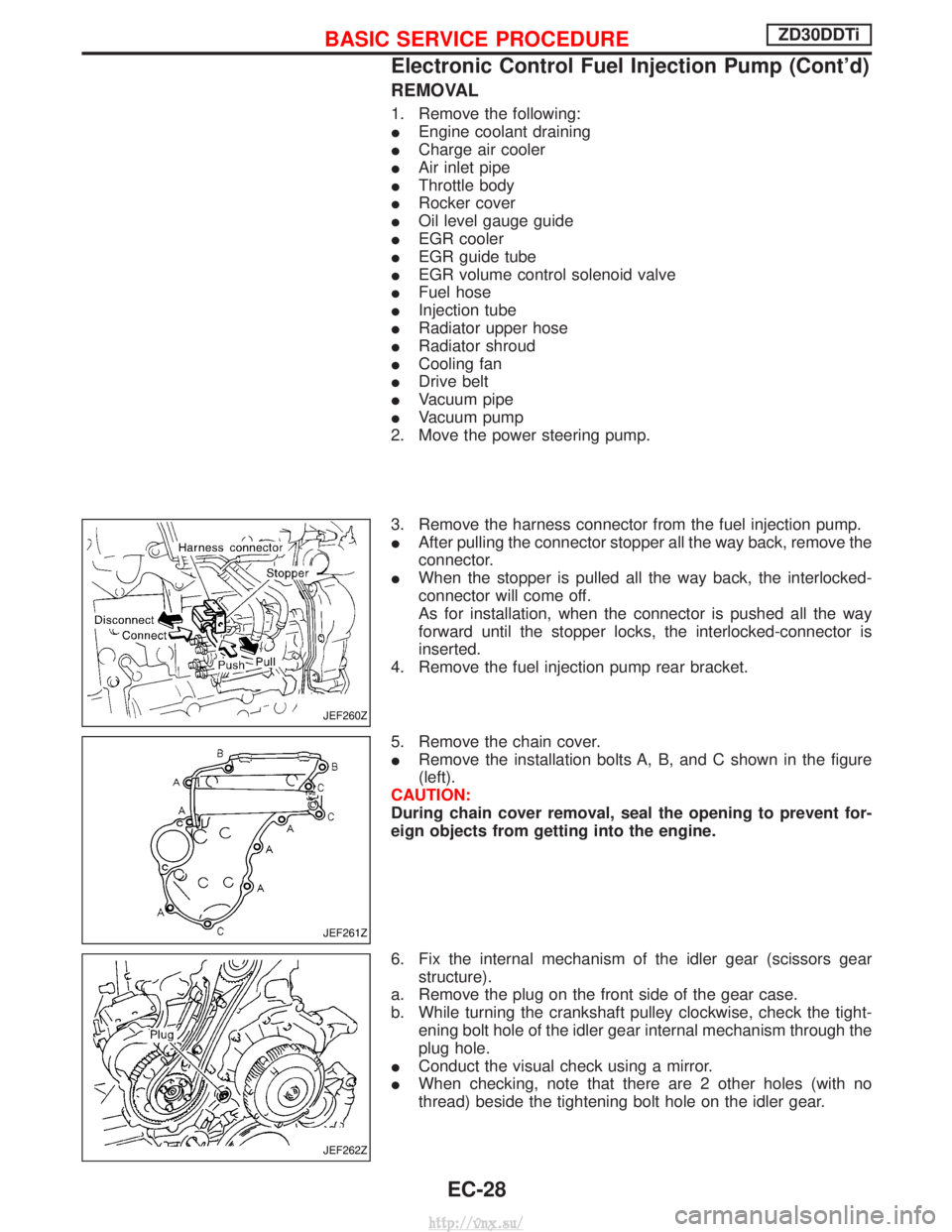

Electronic Control Fuel Injection Pump

REMOVAL AND INSTALLATION

CAUTION:

When removing or installing the timing chain as incidental work of the fuel injection pump removal/

installation, always secure the internal mechanism of the idler gear with bolts before removing or

installing the fuel injection pump sprocket. Do not refer to the procedure for ªTIMING CHAINº in EM

section based on No. 1 cylinder compression top dead center. (Unless otherwise specified.)

JEF349Y

JEF259Z

BASIC SERVICE PROCEDUREZD30DDTi

Injection Tube and Injection Nozzle (Cont'd)

EC-27

http://vnx.su/

Page 303 of 1833

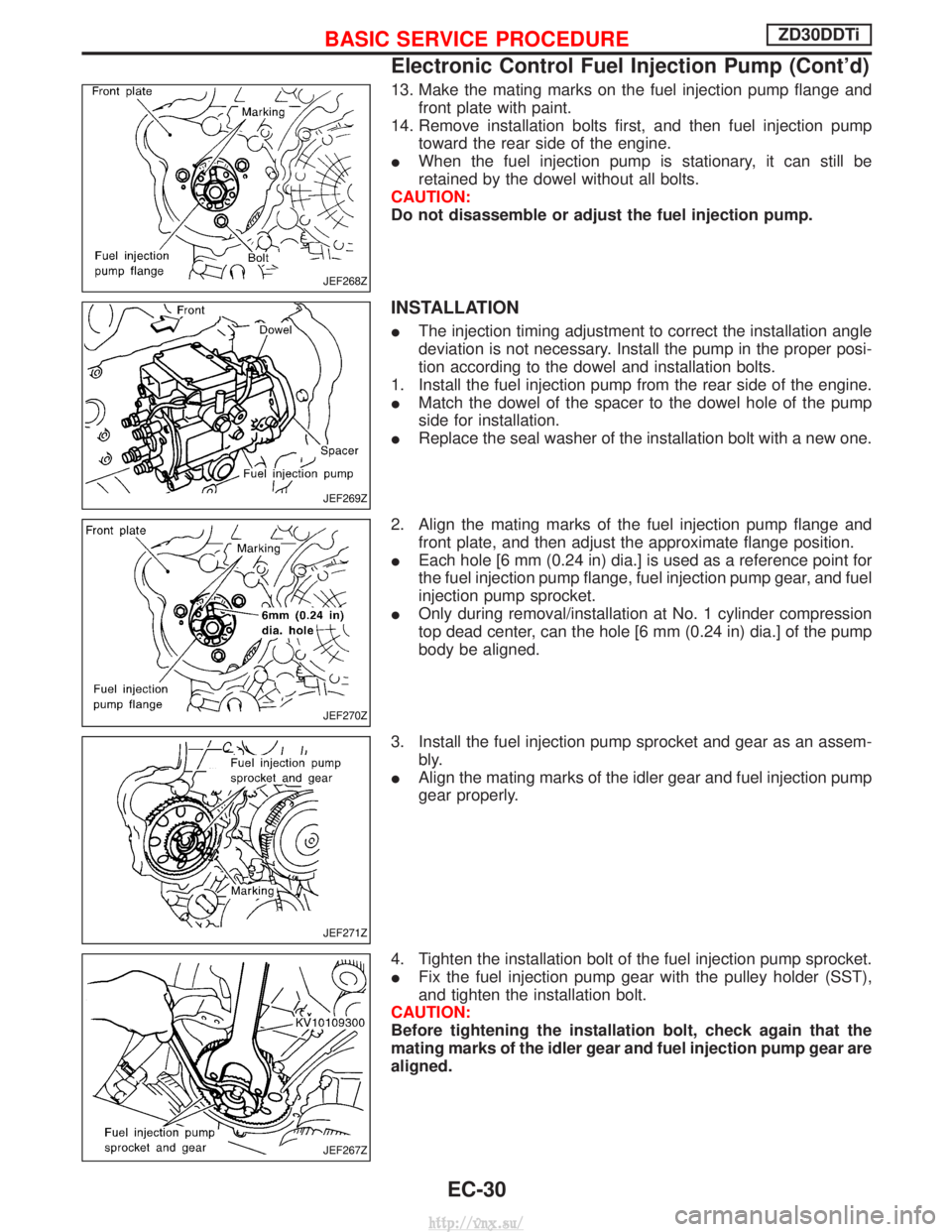

REMOVAL

1. Remove the following:

IEngine coolant draining

I Charge air cooler

I Air inlet pipe

I Throttle body

I Rocker cover

I Oil level gauge guide

I EGR cooler

I EGR guide tube

I EGR volume control solenoid valve

I Fuel hose

I Injection tube

I Radiator upper hose

I Radiator shroud

I Cooling fan

I Drive belt

I Vacuum pipe

I Vacuum pump

2. Move the power steering pump.

3. Remove the harness connector from the fuel injection pump.

I After pulling the connector stopper all the way back, remove the

connector.

I When the stopper is pulled all the way back, the interlocked-

connector will come off.

As for installation, when the connector is pushed all the way

forward until the stopper locks, the interlocked-connector is

inserted.

4. Remove the fuel injection pump rear bracket.

5. Remove the chain cover.

I Remove the installation bolts A, B, and C shown in the figure

(left).

CAUTION:

During chain cover removal, seal the opening to prevent for-

eign objects from getting into the engine.

6. Fix the internal mechanism of the idler gear (scissors gear structure).

a. Remove the plug on the front side of the gear case.

b. While turning the crankshaft pulley clockwise, check the tight- ening bolt hole of the idler gear internal mechanism through the

plug hole.

I Conduct the visual check using a mirror.

I When checking, note that there are 2 other holes (with no

thread) beside the tightening bolt hole on the idler gear.

JEF260Z

JEF261Z

JEF262Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-28

http://vnx.su/

Page 304 of 1833

![NISSAN TERRANO 2004 Service Repair Manual c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

fi NISSAN TERRANO 2004 Service Repair Manual c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

fi](/img/5/57394/w960_57394-303.png)

c. Install the tightening bolt [Part No.: 81-20620-28, thread diam-eter: M6, under head: 20 mm (0.79 in), pitch: 1.0 mm (0.039 in)]

to the idler gear tightening bolt hole, and tighten to the speci-

fied torque:

: 2.5 - 3.4 N ×m (0.25 - 0.35 kg-m, 22 - 30 in-lb)

CAUTION:

I To protect the idler gear from damage, do not use the sub-

stitute part for the tightening bolt.

I Hereafter, do not turn the crankshaft to avoid hitting tight-

ening bolt head against the gear case.

I Do not remove the idler gear tightening bolt before instal-

lations of the timing chain and related parts are completed.

7. Make mating marks on the cam sprocket, fuel injection pump sprocket, and timing chain with paint.

8. Make mating marks on the fuel injection pump gear and idler gear with paint.

9. Remove the chain tensioner.

(1) Loosen the upper and lower installation bolts.

(2) While holding the chain tensioner by hand, remove the upper installation bolt to release the spring tension.

(3) Remove the lower installation bolt first, and then the chain ten- sioner.

I Since the chain tensioner does not have a mechanism to pre-

vent the plunger pop-out, watch out for the fall of the plunger

and spring. (Return prevention mechanism is available.)

10. Remove the timing chain slack guide.

11. Remove the cam sprocket and timing chain at the same time.

I Make mating marks on each sprocket and timing chain.

I Hold the hexagon head of the camshaft on the exhaust mani-

fold side, and loosen the cam sprocket installation bolt.

CAUTION:

Do not loosen the installation bolt using a chain tension.

12. Remove the fuel injection pump sprocket and gear as an assembly.

I Fix the fuel injection pump gear with the pulley holder (SST),

and loosen the installation bolt for removal.

I Try not to move the pump shaft when removing.

I Connect the sprocket and gear with a dowel pin, and tighten

them together with the installation bolt.

JEF263Z

JEF264Z

JEF265Z

JEF266Z

JEF267Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-29

http://vnx.su/

Page 305 of 1833

13. Make the mating marks on the fuel injection pump flange andfront plate with paint.

14. Remove installation bolts first, and then fuel injection pump toward the rear side of the engine.

I When the fuel injection pump is stationary, it can still be

retained by the dowel without all bolts.

CAUTION:

Do not disassemble or adjust the fuel injection pump.

INSTALLATION

I The injection timing adjustment to correct the installation angle

deviation is not necessary. Install the pump in the proper posi-

tion according to the dowel and installation bolts.

1. Install the fuel injection pump from the rear side of the engine.

I Match the dowel of the spacer to the dowel hole of the pump

side for installation.

I Replace the seal washer of the installation bolt with a new one.

2. Align the mating marks of the fuel injection pump flange and front plate, and then adjust the approximate flange position.

I Each hole [6 mm (0.24 in) dia.] is used as a reference point for

the fuel injection pump flange, fuel injection pump gear, and fuel

injection pump sprocket.

I Only during removal/installation at No. 1 cylinder compression

top dead center, can the hole [6 mm (0.24 in) dia.] of the pump

body be aligned.

3. Install the fuel injection pump sprocket and gear as an assem- bly.

I Align the mating marks of the idler gear and fuel injection pump

gear properly.

4. Tighten the installation bolt of the fuel injection pump sprocket.

I Fix the fuel injection pump gear with the pulley holder (SST),

and tighten the installation bolt.

CAUTION:

Before tightening the installation bolt, check again that the

mating marks of the idler gear and fuel injection pump gear are

aligned.

JEF268Z

JEF269Z

JEF270Z

JEF271Z

JEF267Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-30

http://vnx.su/

Page 306 of 1833

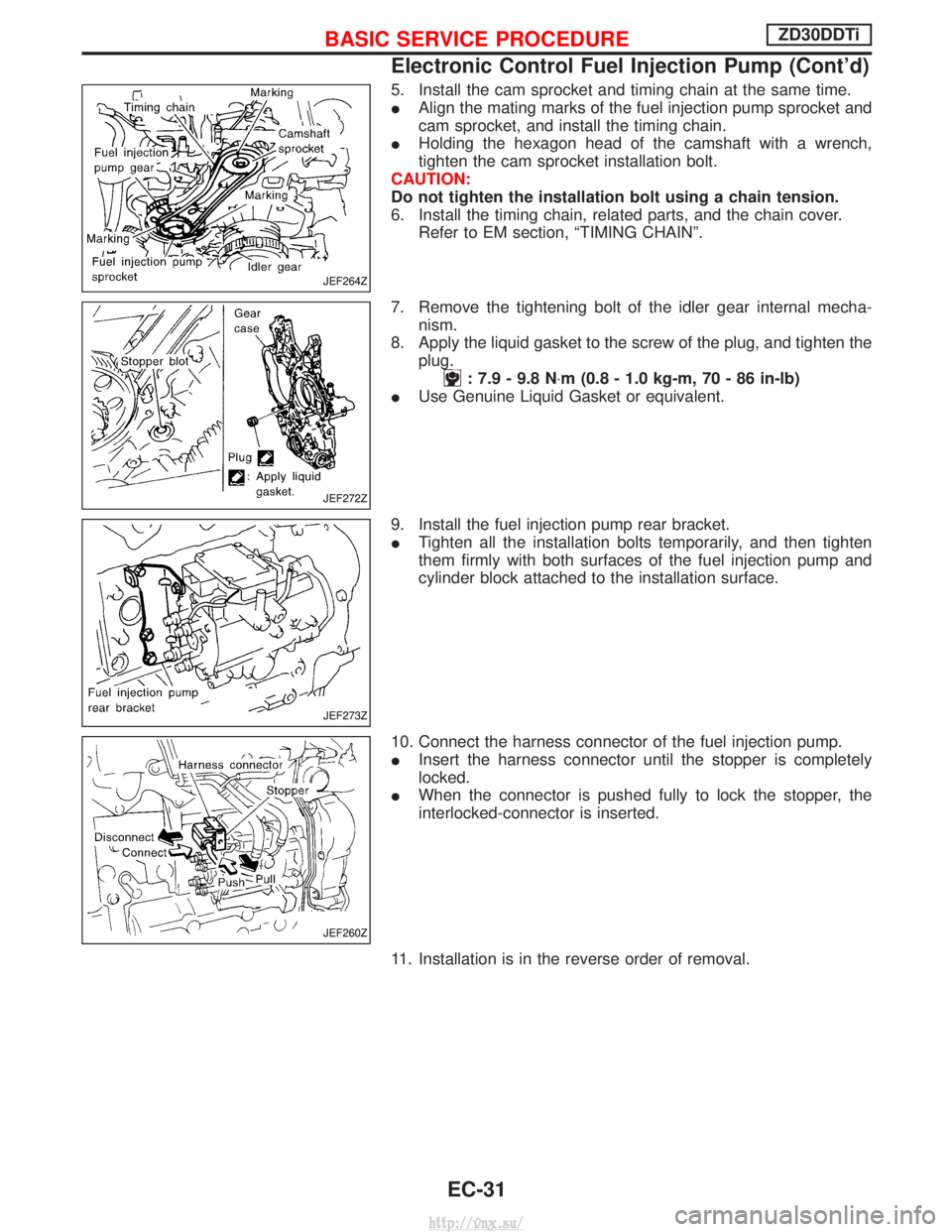

5. Install the cam sprocket and timing chain at the same time.

IAlign the mating marks of the fuel injection pump sprocket and

cam sprocket, and install the timing chain.

I Holding the hexagon head of the camshaft with a wrench,

tighten the cam sprocket installation bolt.

CAUTION:

Do not tighten the installation bolt using a chain tension.

6. Install the timing chain, related parts, and the chain cover. Refer to EM section, ªTIMING CHAINº.

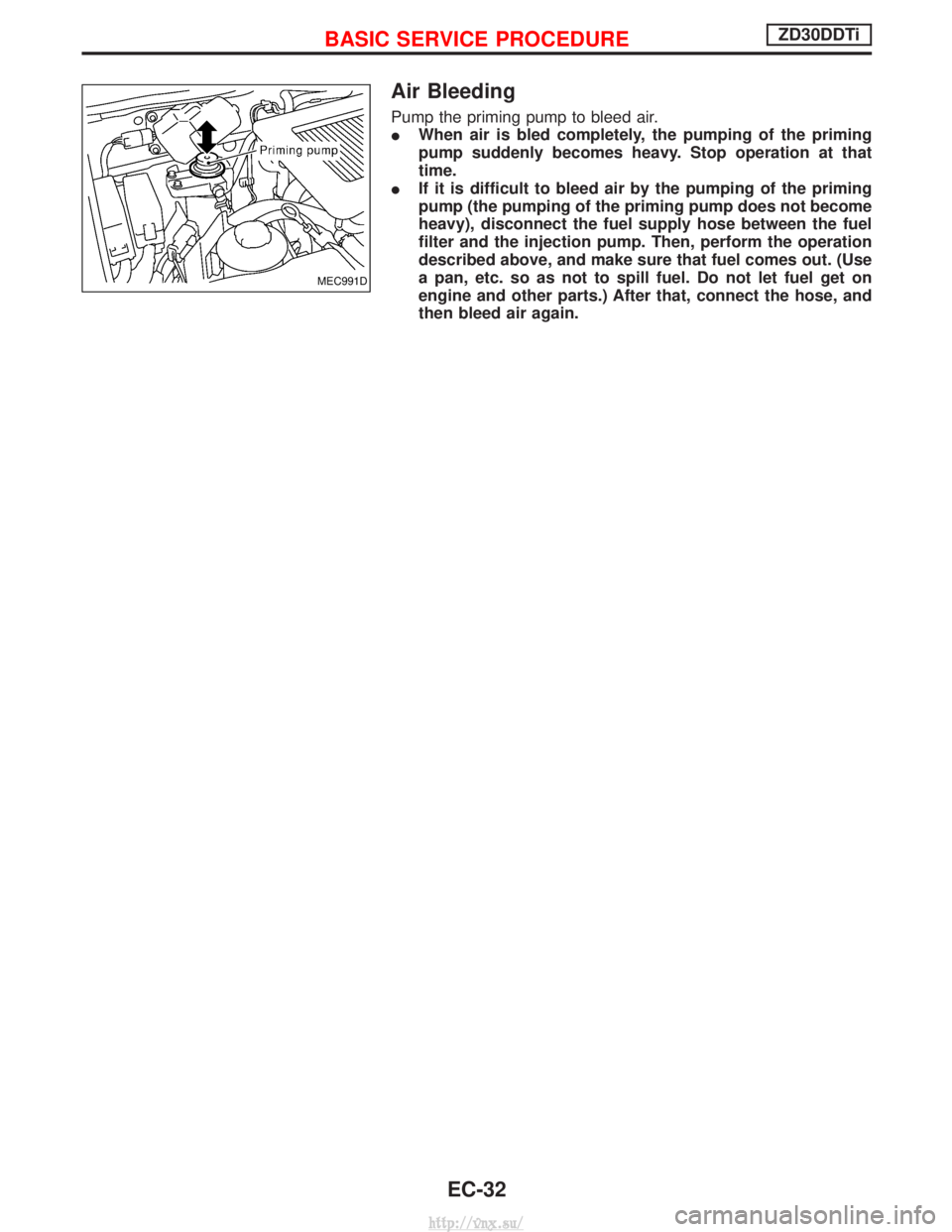

7. Remove the tightening bolt of the idler gear internal mecha- nism.

8. Apply the liquid gasket to the screw of the plug, and tighten the plug.

: 7.9 - 9.8 N ×m (0.8 - 1.0 kg-m, 70 - 86 in-lb)

I Use Genuine Liquid Gasket or equivalent.

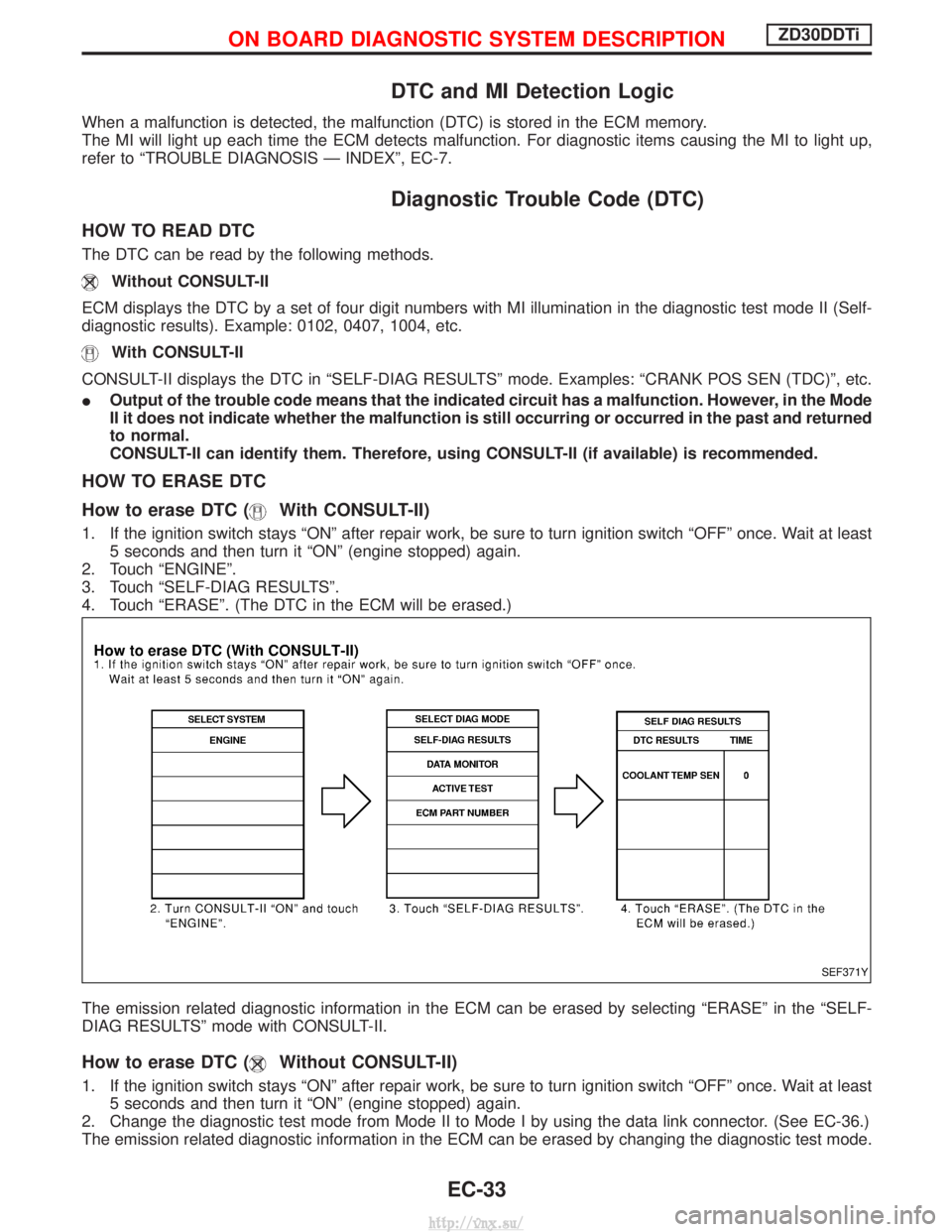

9. Install the fuel injection pump rear bracket.

I Tighten all the installation bolts temporarily, and then tighten

them firmly with both surfaces of the fuel injection pump and

cylinder block attached to the installation surface.

10. Connect the harness connector of the fuel injection pump.

I Insert the harness connector until the stopper is completely

locked.

I When the connector is pushed fully to lock the stopper, the

interlocked-connector is inserted.

11. Installation is in the reverse order of removal.

JEF264Z

JEF272Z

JEF273Z

JEF260Z

BASIC SERVICE PROCEDUREZD30DDTi

Electronic Control Fuel Injection Pump (Cont'd)

EC-31

http://vnx.su/

Page 307 of 1833

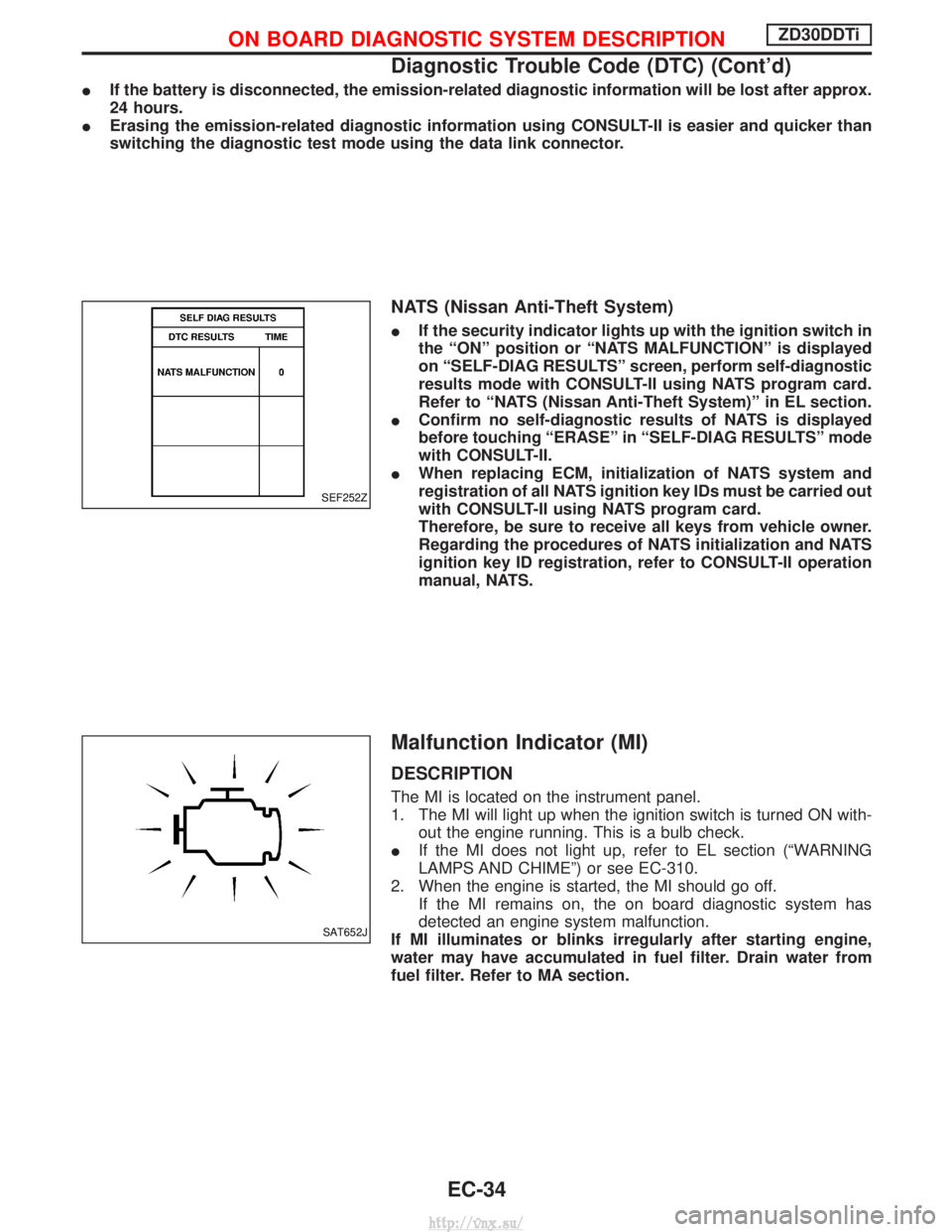

Air Bleeding

Pump the priming pump to bleed air.

IWhen air is bled completely, the pumping of the priming

pump suddenly becomes heavy. Stop operation at that

time.

I If it is difficult to bleed air by the pumping of the priming

pump (the pumping of the priming pump does not become

heavy), disconnect the fuel supply hose between the fuel

filter and the injection pump. Then, perform the operation

described above, and make sure that fuel comes out. (Use

a pan, etc. so as not to spill fuel. Do not let fuel get on

engine and other parts.) After that, connect the hose, and

then bleed air again.

MEC991D

BASIC SERVICE PROCEDUREZD30DDTi

EC-32

http://vnx.su/

Page 308 of 1833

DTC and MI Detection Logic

When a malfunction is detected, the malfunction (DTC) is stored in the ECM memory.

The MI will light up each time the ECM detects malfunction. For diagnostic items causing the MI to light up,

refer to ªTROUBLE DIAGNOSIS Ð INDEXº, EC-7.

Diagnostic Trouble Code (DTC)

HOW TO READ DTC

The DTC can be read by the following methods.

Without CONSULT-II

ECM displays the DTC by a set of four digit numbers with MI illumination in the diagnostic test mode II (Self-

diagnostic results). Example: 0102, 0407, 1004, etc.

With CONSULT-II

CONSULT-II displays the DTC in ªSELF-DIAG RESULTSº mode. Examples: ªCRANK POS SEN (TDC)º, etc.

I Output of the trouble code means that the indicated circuit has a malfunction. However, in the Mode

II it does not indicate whether the malfunction is still occurring or occurred in the past and returned

to normal.

CONSULT-II can identify them. Therefore, using CONSULT-II (if available) is recommended.

HOW TO ERASE DTC

How to erase DTC (

With CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least

5 seconds and then turn it ªONº (engine stopped) again.

2. Touch ªENGINEº.

3. Touch ªSELF-DIAG RESULTSº.

4. Touch ªERASEº. (The DTC in the ECM will be erased.)

The emission related diagnostic information in the ECM can be erased by selecting ªERASEº in the ªSELF-

DIAG RESULTSº mode with CONSULT-II.

How to erase DTC (Without CONSULT-II)

1. If the ignition switch stays ªONº after repair work, be sure to turn ignition switch ªOFFº once. Wait at least 5 seconds and then turn it ªONº (engine stopped) again.

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See EC-36.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

SEF371Y

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

EC-33

http://vnx.su/

Page 309 of 1833

IIf the battery is disconnected, the emission-related diagnostic information will be lost after approx.

24 hours.

I Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

IIf the security indicator lights up with the ignition switch in

the ªONº position or ªNATS MALFUNCTIONº is displayed

on ªSELF-DIAG RESULTSº screen, perform self-diagnostic

results mode with CONSULT-II using NATS program card.

Refer to ªNATS (Nissan Anti-Theft System)º in EL section.

I Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº mode

with CONSULT-II.

I When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried out

with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle owner.

Regarding the procedures of NATS initialization and NATS

ignition key ID registration, refer to CONSULT-II operation

manual, NATS.

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON with-

out the engine running. This is a bulb check.

I If the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-310.

2. When the engine is started, the MI should go off. If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-34

http://vnx.su/

Page 310 of 1833

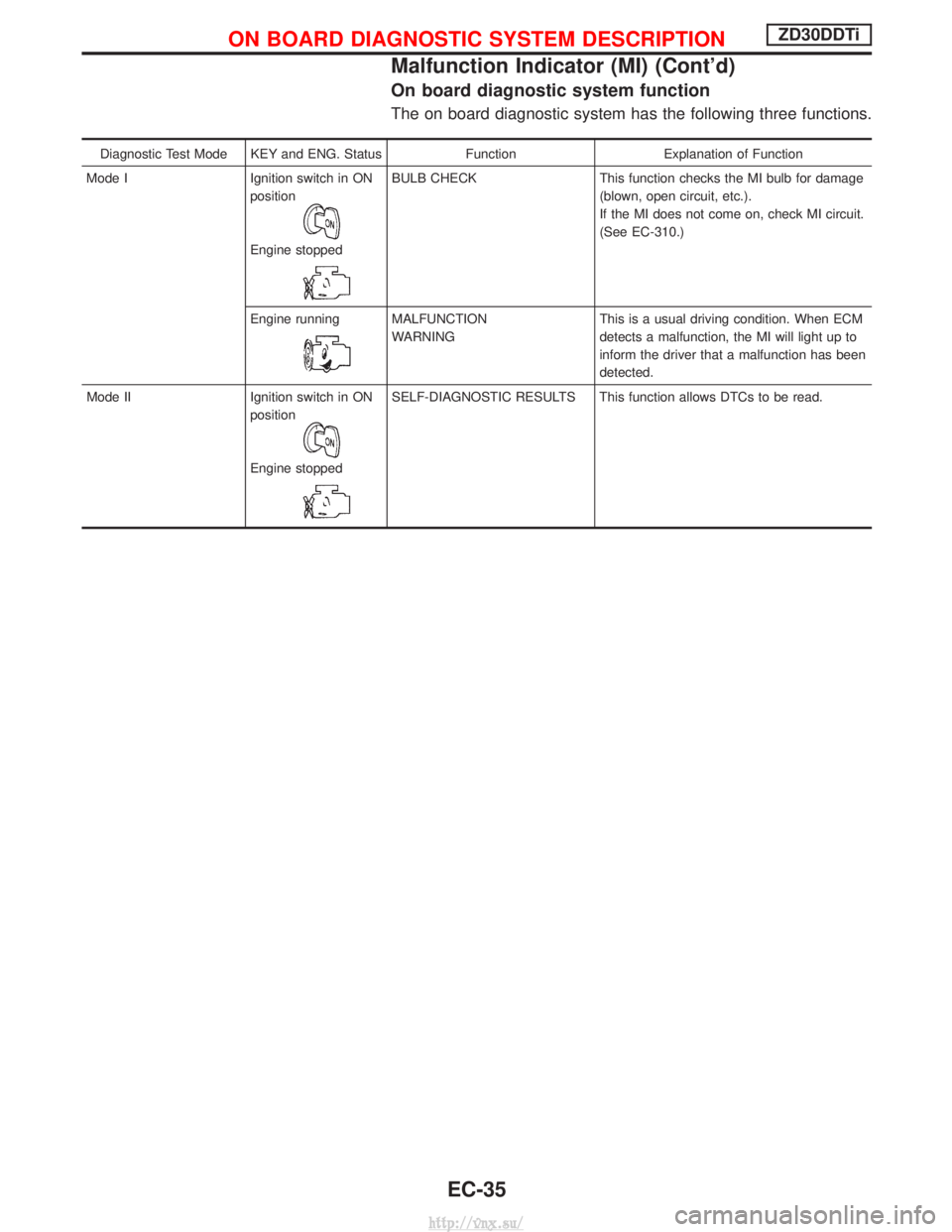

On board diagnostic system function

The on board diagnostic system has the following three functions.

Diagnostic Test Mode KEY and ENG. StatusFunctionExplanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-310.)

Engine running

MALFUNCTION

WARNING This is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-35

http://vnx.su/