NISSAN X-TRAIL 2003 Electronic Repair Manual

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 2291 of 3066

GI-38

LIFTING POINT

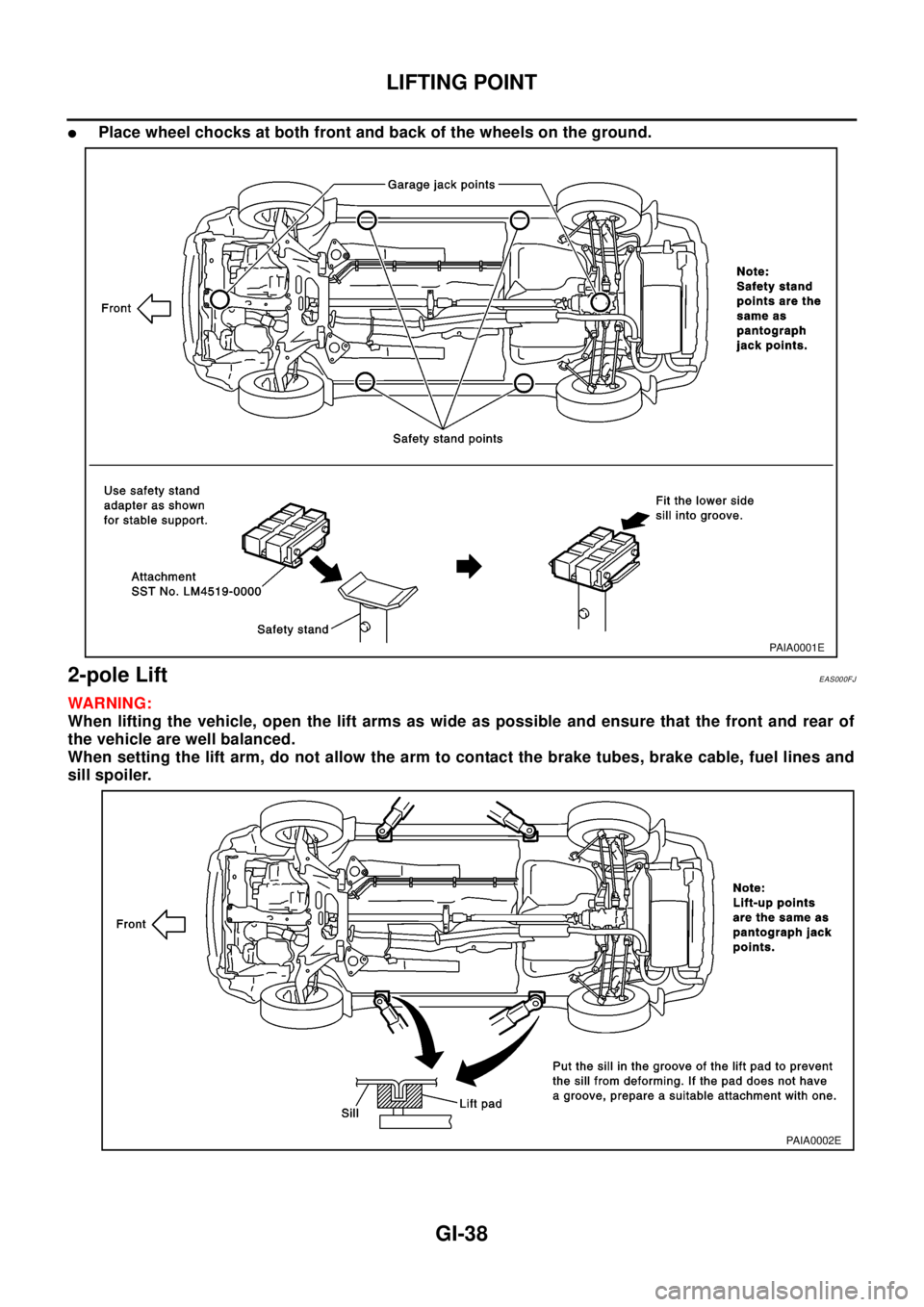

lPlace wheel chocks at both front and back of the wheels on the ground.

2-pole LiftEAS000FJ

WAR NIN G:

When lifting the vehicle, open the lift arms as wide as possible and ensure that the front and rear of

the vehicle are well balanced.

When setting the lift arm, do not allow the arm to contact the brake tubes, brake cable, fuel lines and

sill spoiler.

PAIA0001E

PAIA0002E

Page 2292 of 3066

LIFTING POINT

GI-39

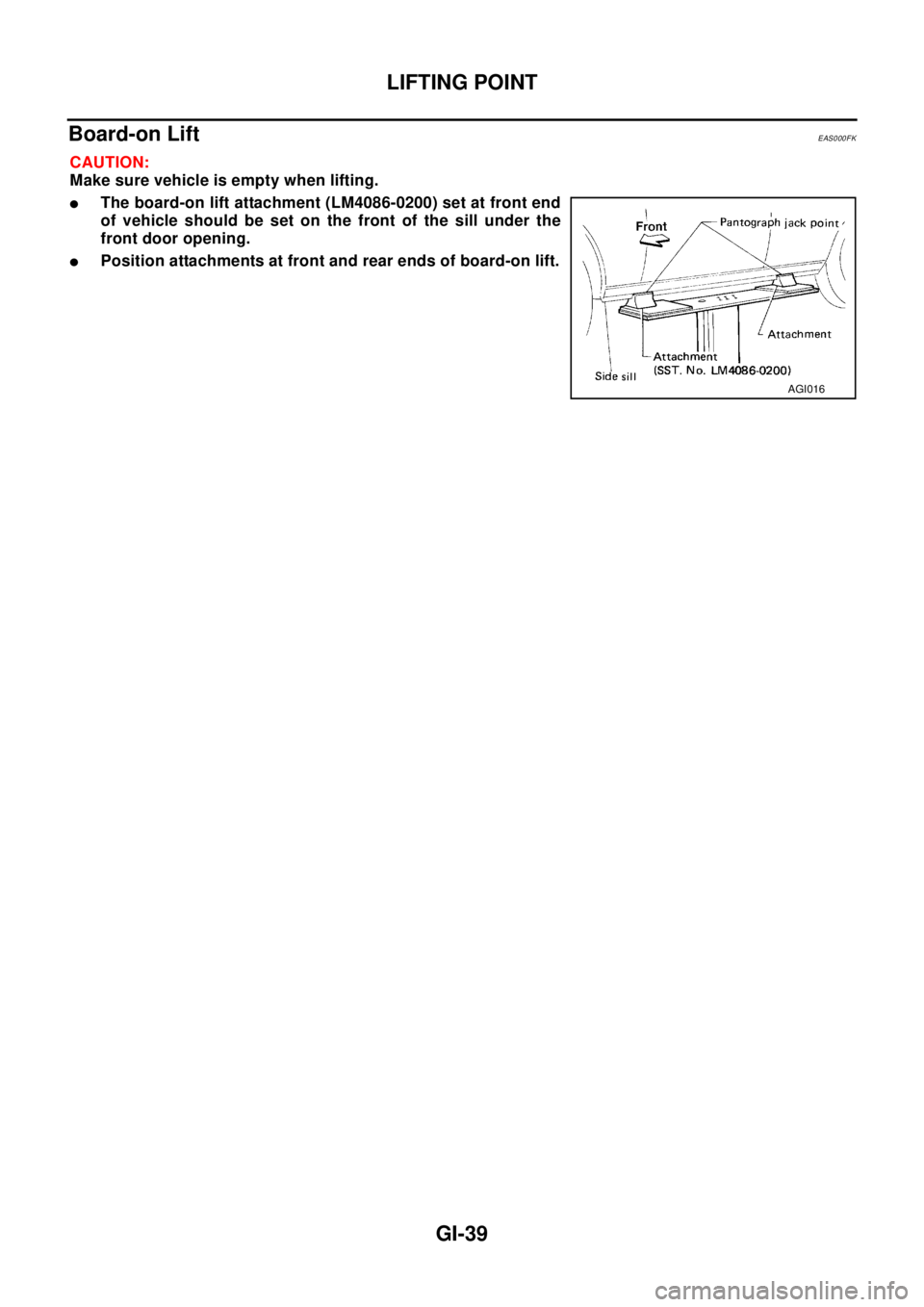

Board-on LiftEAS000FK

CAUTION:

Make sure vehicle is empty when lifting.

lThe board-on lift attachment (LM4086-0200) set at front end

of vehicle should be set on the front of the sill under the

front door opening.

lPosition attachments at front and rear ends of board-on lift.

AGI016

Page 2293 of 3066

GI-40

TOW TRUCK TOWING

TOW TRUCK TOWING

PFP:00000

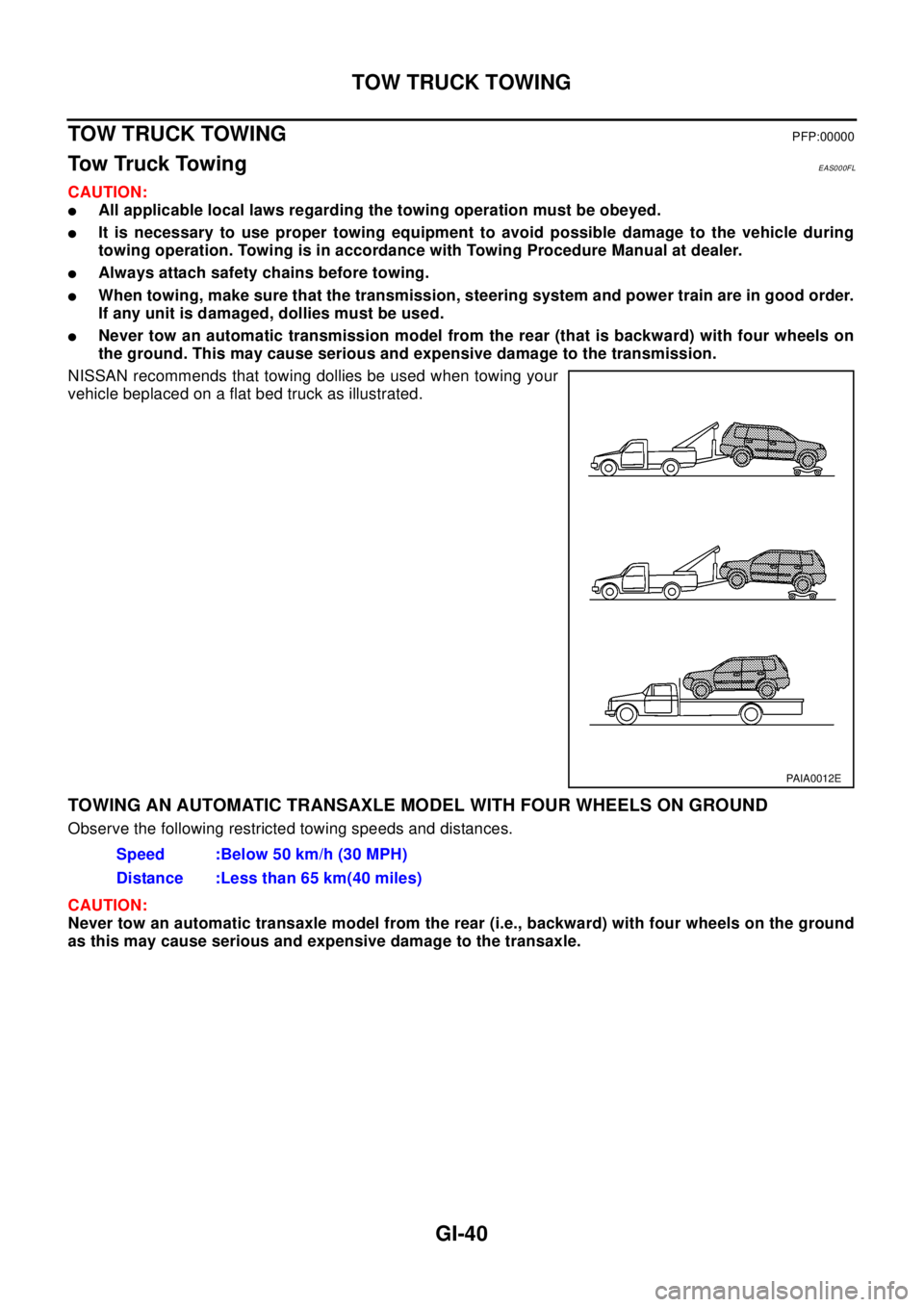

To w Tr u c k To w i n gEAS000FL

CAUTION:

lAll applicable local laws regarding the towing operation must be obeyed.

lIt is necessary to use proper towing equipment to avoid possible damage to the vehicle during

towing operation. Towing is in accordance with Towing Procedure Manual at dealer.

lAlways attach safety chains before towing.

lWhen towing, make sure that the transmission, steering system and power train are in good order.

If any unit is damaged, dollies must be used.

lNever tow an automatic transmission model from the rear (that is backward) with four wheels on

the ground. This may cause serious and expensive damage to the transmission.

NISSAN recommends that towing dollies be used when towing your

vehicle beplaced on a flat bed truck as illustrated.

TOWING AN AUTOMATIC TRANSAXLE MODEL WITH FOUR WHEELS ON GROUND

Observe the following restricted towing speeds and distances.

CAUTION:

Never tow an automatic transaxle model from the rear (i.e., backward) with four wheels on the ground

as this may cause serious and expensive damage to the transaxle.

PAIA0012E

Speed :Below 50 km/h (30 MPH)

Distance :Less than 65 km(40 miles)

Page 2294 of 3066

TOW TRUCK TOWING

GI-41

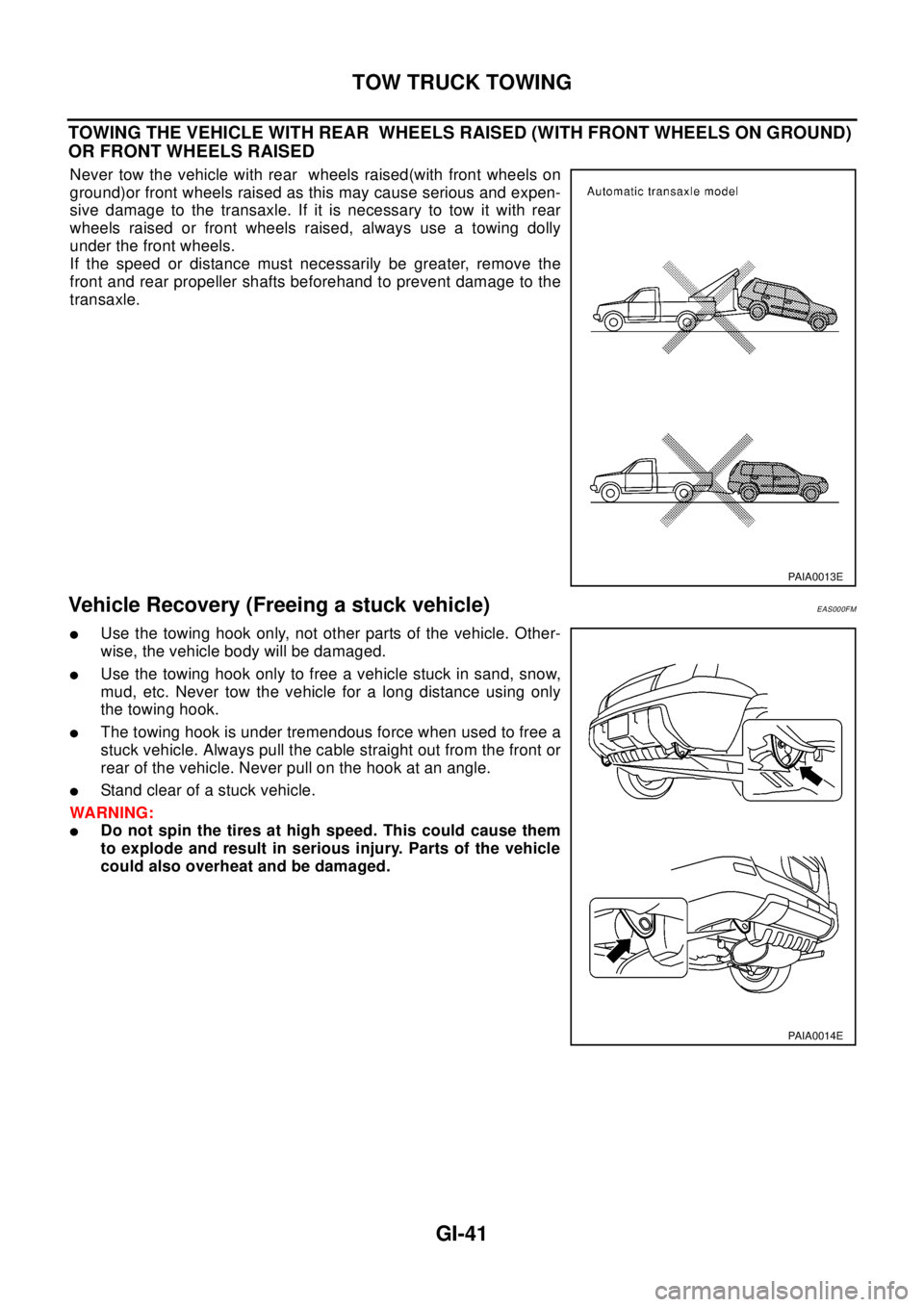

TOWING THE VEHICLE WITH REAR WHEELS RAISED (WITH FRONT WHEELS ON GROUND)

OR FRONT WHEELS RAISED

Never tow the vehicle with rear wheels raised(with front wheels on

ground)or front wheels raised as this may cause serious and expen-

sive damage to the transaxle. If it is necessary to tow it with rear

wheels raised or front wheels raised, always use a towing dolly

under the front wheels.

If the speed or distance must necessarily be greater, remove the

front and rear propeller shafts beforehand to prevent damage to the

transaxle.

Vehicle Recovery (Freeing a stuck vehicle)EAS000FM

lUse the towing hook only, not other parts of the vehicle. Other-

wise, the vehicle body will be damaged.

lUse the towing hook only to free a vehicle stuck in sand, snow,

mud, etc. Never tow the vehicle for a long distance using only

the towing hook.

lThe towing hook is under tremendous force when used to free a

stuck vehicle. Always pull the cable straight out from the front or

rear of the vehicle. Never pull on the hook at an angle.

lStand clear of a stuck vehicle.

WA RN ING:

lDo not spin the tires at high speed. This could cause them

to explode and result in serious injury. Parts of the vehicle

could also overheat and be damaged.

PAIA0013E

PAIA0014E

Page 2295 of 3066

GI-42

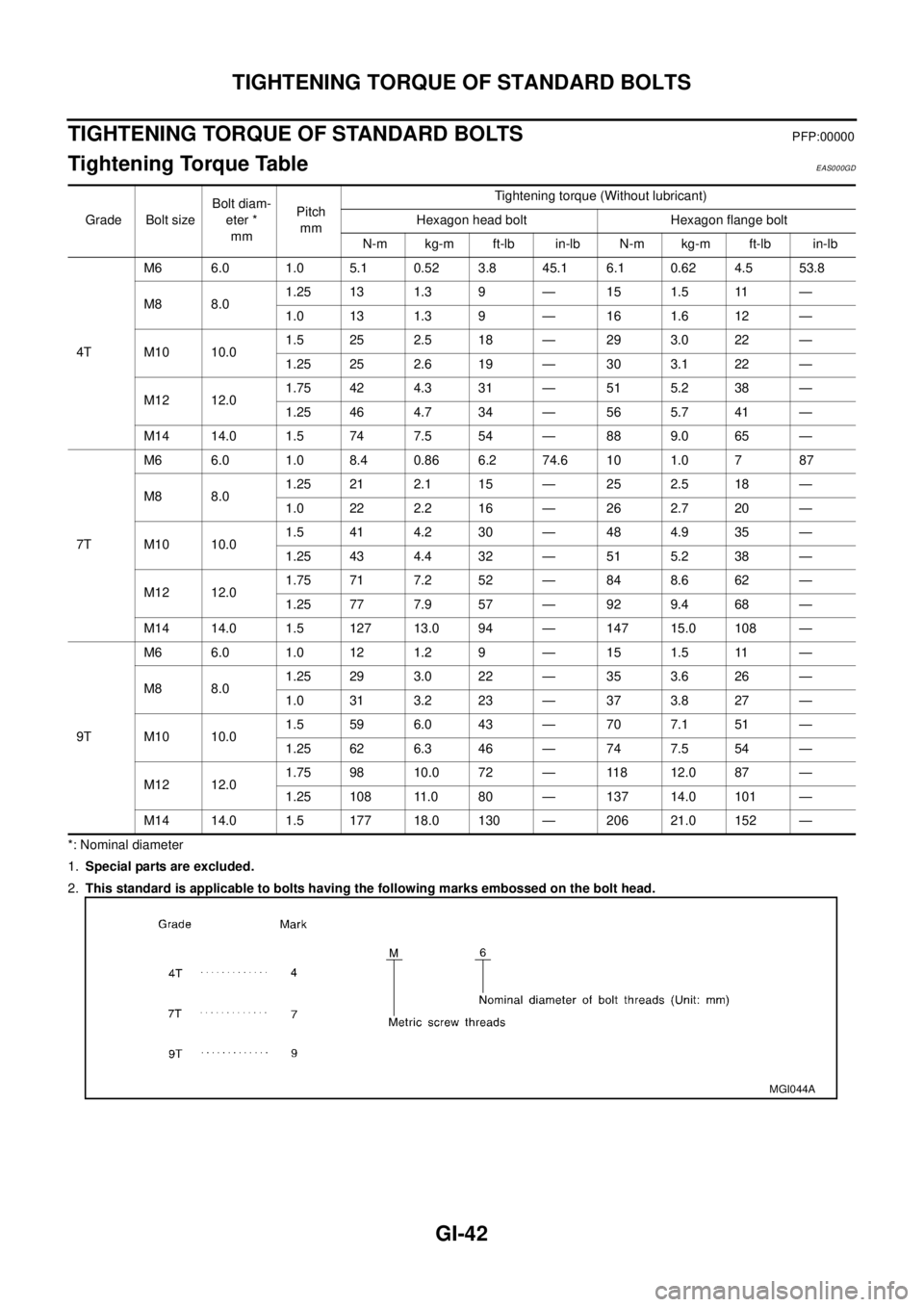

TIGHTENING TORQUE OF STANDARD BOLTS

TIGHTENING TORQUE OF STANDARD BOLTS

PFP:00000

Tightening Torque TableEAS000GD

*: Nominal diameter

1.Special parts are excluded.

2.This standard is applicable to bolts having the following marks embossed on the bolt head. Grade Bolt sizeBolt diam-

eter *

mmPitch

mmTightening torque (Without lubricant)

Hexagon head bolt Hexagon flange bolt

N-m kg-m ft-lb in-lb N-m kg-m ft-lb in-lb

4TM6 6.0 1.0 5.1 0.52 3.8 45.1 6.1 0.62 4.5 53.8

M8 8.01.25 13 1.3 9 — 15 1.5 11 —

1.0 13 1.3 9 — 16 1.6 12 —

M10 10.01.5 25 2.5 18 — 29 3.0 22 —

1.25 25 2.6 19 — 30 3.1 22 —

M12 12.01.75 42 4.3 31 — 51 5.2 38 —

1.25 46 4.7 34 — 56 5.7 41 —

M14 14.0 1.5 74 7.5 54 — 88 9.0 65 —

7TM6 6.0 1.0 8.4 0.86 6.2 74.6 10 1.0 7 87

M8 8.01.25 21 2.1 15 — 25 2.5 18 —

1.0 22 2.2 16 — 26 2.7 20 —

M10 10.01.5 41 4.2 30 — 48 4.9 35 —

1.25 43 4.4 32 — 51 5.2 38 —

M12 12.01.75 71 7.2 52 — 84 8.6 62 —

1.25 77 7.9 57 — 92 9.4 68 —

M14 14.0 1.5 127 13.0 94 — 147 15.0 108 —

9TM6 6.0 1.0 12 1.2 9 — 15 1.5 11 —

M8 8.01.25 29 3.0 22 — 35 3.6 26 —

1.0 31 3.2 23 — 37 3.8 27 —

M10 10.01.5 59 6.0 43 — 70 7.1 51 —

1.25 62 6.3 46 — 74 7.5 54 —

M12 12.01.75 98 10.0 72 — 118 12.0 87 —

1.25 108 11.0 80 — 137 14.0 101 —

M14 14.0 1.5 177 18.0 130 — 206 21.0 152 —

MGI044A

Page 2296 of 3066

IDENTIFICATION INFORMATION

GI-43

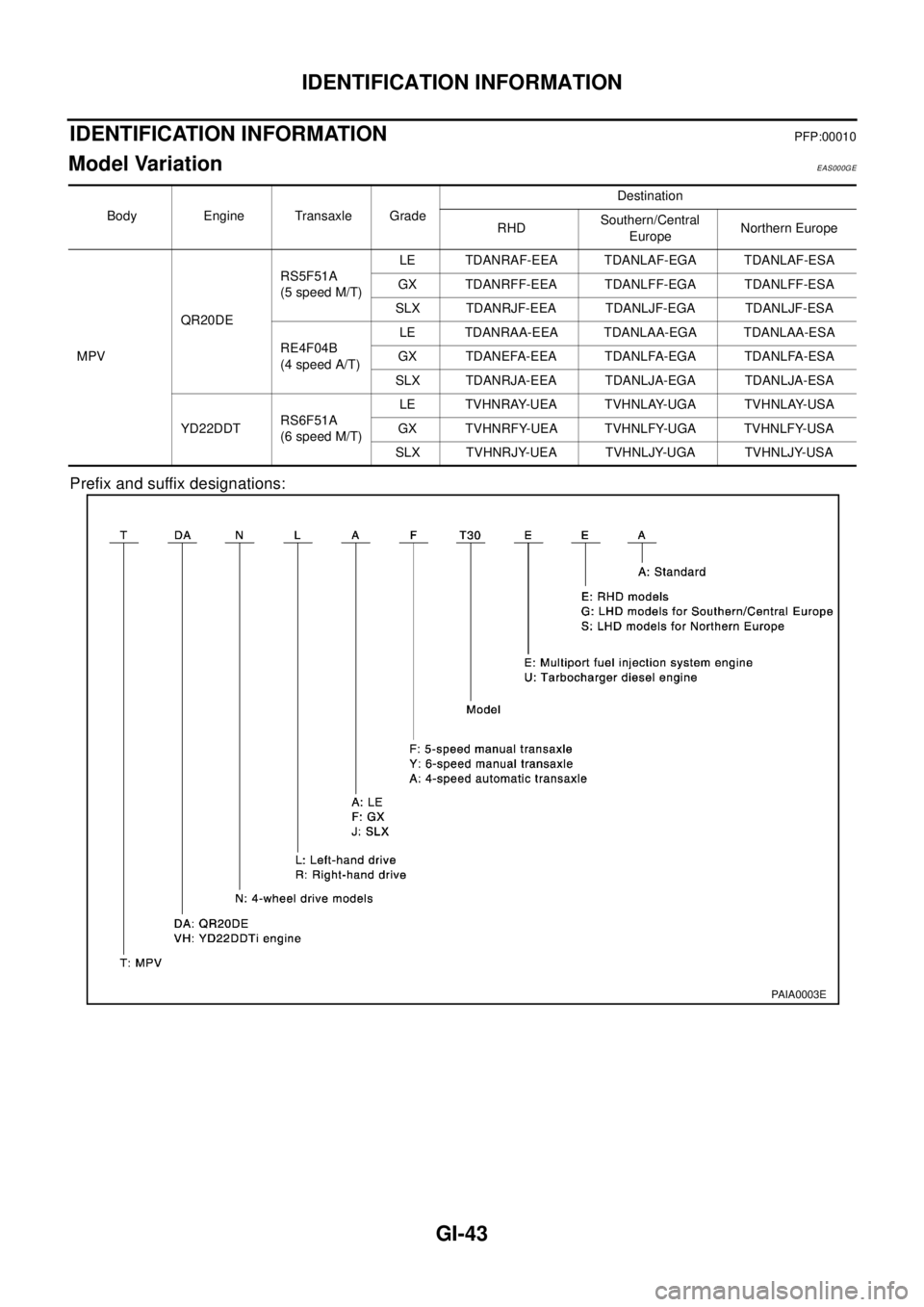

IDENTIFICATION INFORMATIONPFP:00010

Model VariationEAS000GE

Prefix and suffix designations:

Body Engine Transaxle GradeDestination

RHDSouthern/Central

EuropeNorthern Europe

MPVQR20DERS5F51A

(5 speed M/T)LE TDANRAF-EEA TDANLAF-EGA TDANLAF-ESA

GX TDANRFF-EEA TDANLFF-EGA TDANLFF-ESA

SLX TDANRJF-EEA TDANLJF-EGA TDANLJF-ESA

RE4F04B

(4 speed A/T)LE TDANRAA-EEA TDANLAA-EGA TDANLAA-ESA

GX TDANEFA-EEA TDANLFA-EGA TDANLFA-ESA

SLX TDANRJA-EEA TDANLJA-EGA TDANLJA-ESA

YD22DDTRS6F51A

(6 speed M/T)LE TVHNRAY-UEA TVHNLAY-UGA TVHNLAY-USA

GX TVHNRFY-UEA TVHNLFY-UGA TVHNLFY-USA

SLX TVHNRJY-UEA TVHNLJY-UGA TVHNLJY-USA

PAIA0003E

Page 2297 of 3066

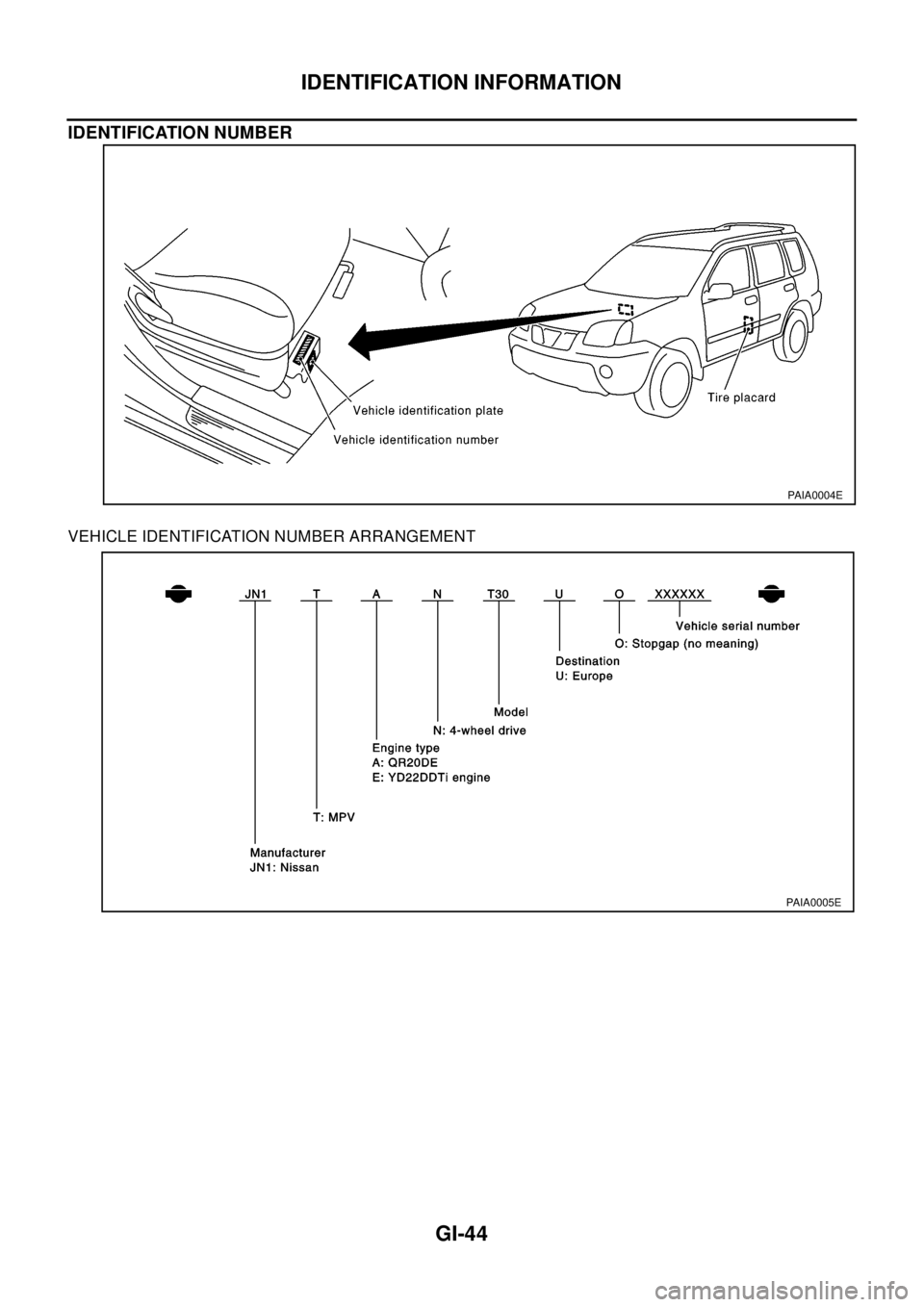

GI-44

IDENTIFICATION INFORMATION

IDENTIFICATION NUMBER

VEHICLE IDENTIFICATION NUMBER ARRANGEMENT

PAIA0004E

PAIA0005E

Page 2298 of 3066

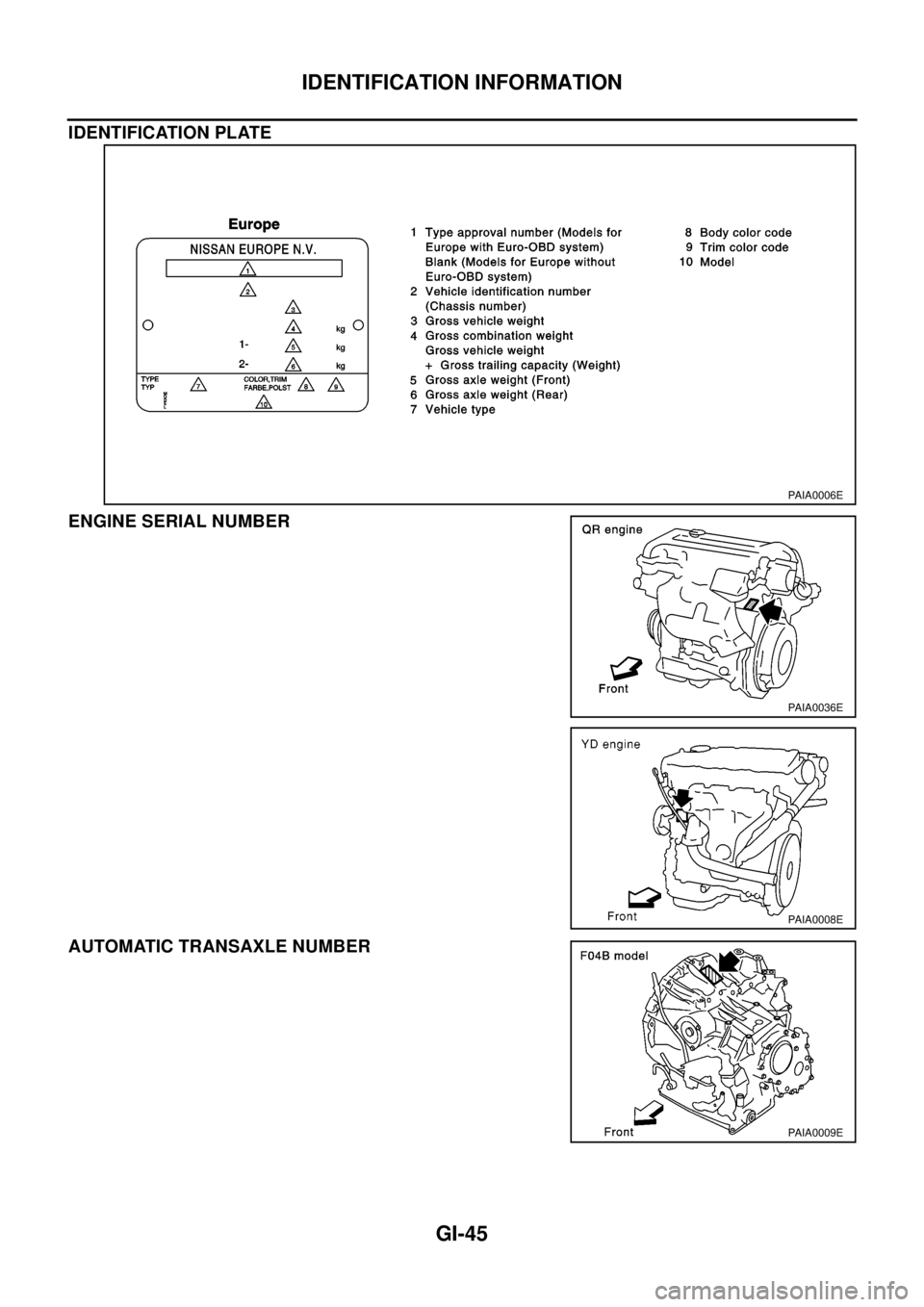

IDENTIFICATION INFORMATION

GI-45

IDENTIFICATION PLATE

ENGINE SERIAL NUMBER

AUTOMATIC TRANSAXLE NUMBER

PAIA0006E

PAIA0036E

PAIA0008E

PAIA0009E

Page 2299 of 3066

GI-46

IDENTIFICATION INFORMATION

MANUAL TRANSAXLE NUMBER

DimensionsEAS000GF

Unit: mm(in)

Wheels & TiresEAS000GG

PAIA0010E

Overall length 4,510

Overall width 1,765

Overall height 1,675 (Standard), 1,750 (With Rear spoiler)

Front tread 1,530

Rear tread 1,530

Wheelbase 2,625

Conventional Spare

Road wheel/offset mm (in)15´6JJ Steel/40 (1.57)

16´6.5JJ Steel/Aluminum/40 (1.57)Conventional

Tire size215/70 R15

215/65 R16Conventional

Page 2300 of 3066

TERMINOLOGY

GI-47

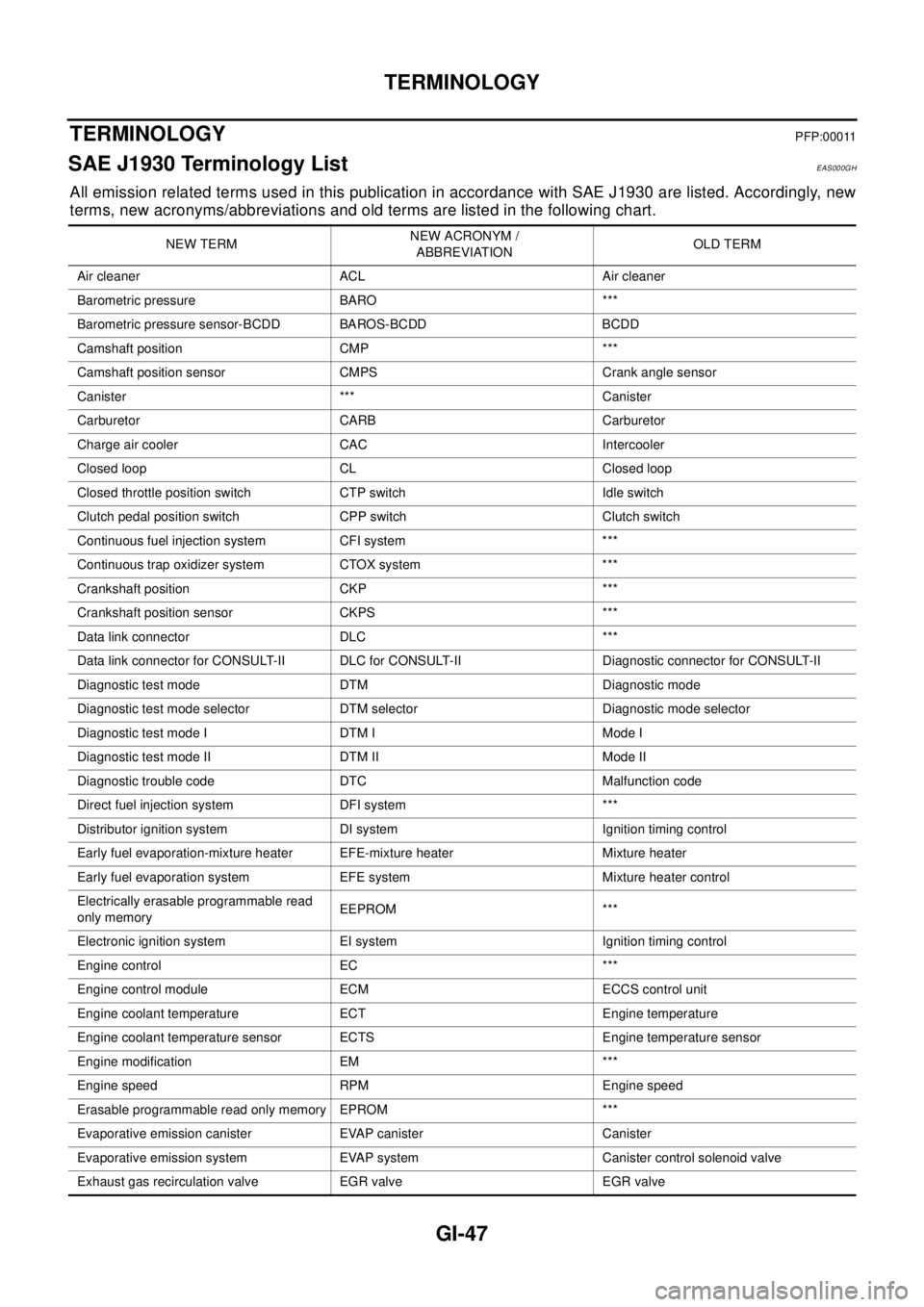

TERMINOLOGYPFP:00011

SAE J1930 Terminology ListEAS000GH

All emission related terms used in this publication in accordance with SAE J1930 are listed. Accordingly, new

terms, new acronyms/abbreviations and old terms are listed in the following chart.

NEW TERMNEW ACRONYM /

ABBREVIATIONOLD TERM

Air cleaner ACL Air cleaner

Barometric pressure BARO ***

Barometric pressure sensor-BCDD BAROS-BCDD BCDD

Camshaft position CMP ***

Camshaft position sensor CMPS Crank angle sensor

Canister *** Canister

Carburetor CARB Carburetor

Charge air cooler CAC Intercooler

Closed loop CL Closed loop

Closed throttle position switch CTP switch Idle switch

Clutch pedal position switch CPP switch Clutch switch

Continuous fuel injection system CFI system ***

Continuous trap oxidizer system CTOX system ***

Crankshaft position CKP ***

Crankshaft position sensor CKPS ***

Data link connector DLC ***

Data link connector for CONSULT-II DLC for CONSULT-II Diagnostic connector for CONSULT-II

Diagnostic test mode DTM Diagnostic mode

Diagnostic test mode selector DTM selector Diagnostic mode selector

Diagnostic test mode I DTM I Mode I

Diagnostic test mode II DTM II Mode II

Diagnostic trouble code DTC Malfunction code

Direct fuel injection system DFI system ***

Distributor ignition system DI system Ignition timing control

Early fuel evaporation-mixture heater EFE-mixture heater Mixture heater

Early fuel evaporation system EFE system Mixture heater control

Electrically erasable programmable read

only memoryEEPROM ***

Electronic ignition system EI system Ignition timing control

Engine control EC ***

Engine control module ECM ECCS control unit

Engine coolant temperature ECT Engine temperature

Engine coolant temperature sensor ECTS Engine temperature sensor

Engine modification EM ***

Engine speed RPM Engine speed

Erasable programmable read only memory EPROM ***

Evaporative emission canister EVAP canister Canister

Evaporative emission system EVAP system Canister control solenoid valve

Exhaust gas recirculation valve EGR valve EGR valve