NISSAN X-TRAIL 2003 Electronic Owner's Guide

Manufacturer: NISSAN, Model Year: 2003, Model line: X-TRAIL, Model: NISSAN X-TRAIL 2003Pages: 3066, PDF Size: 51.47 MB

Page 31 of 3066

OVERALL SYSTEM

AT-25

D

E

F

G

H

I

J

K

L

MA

B

AT

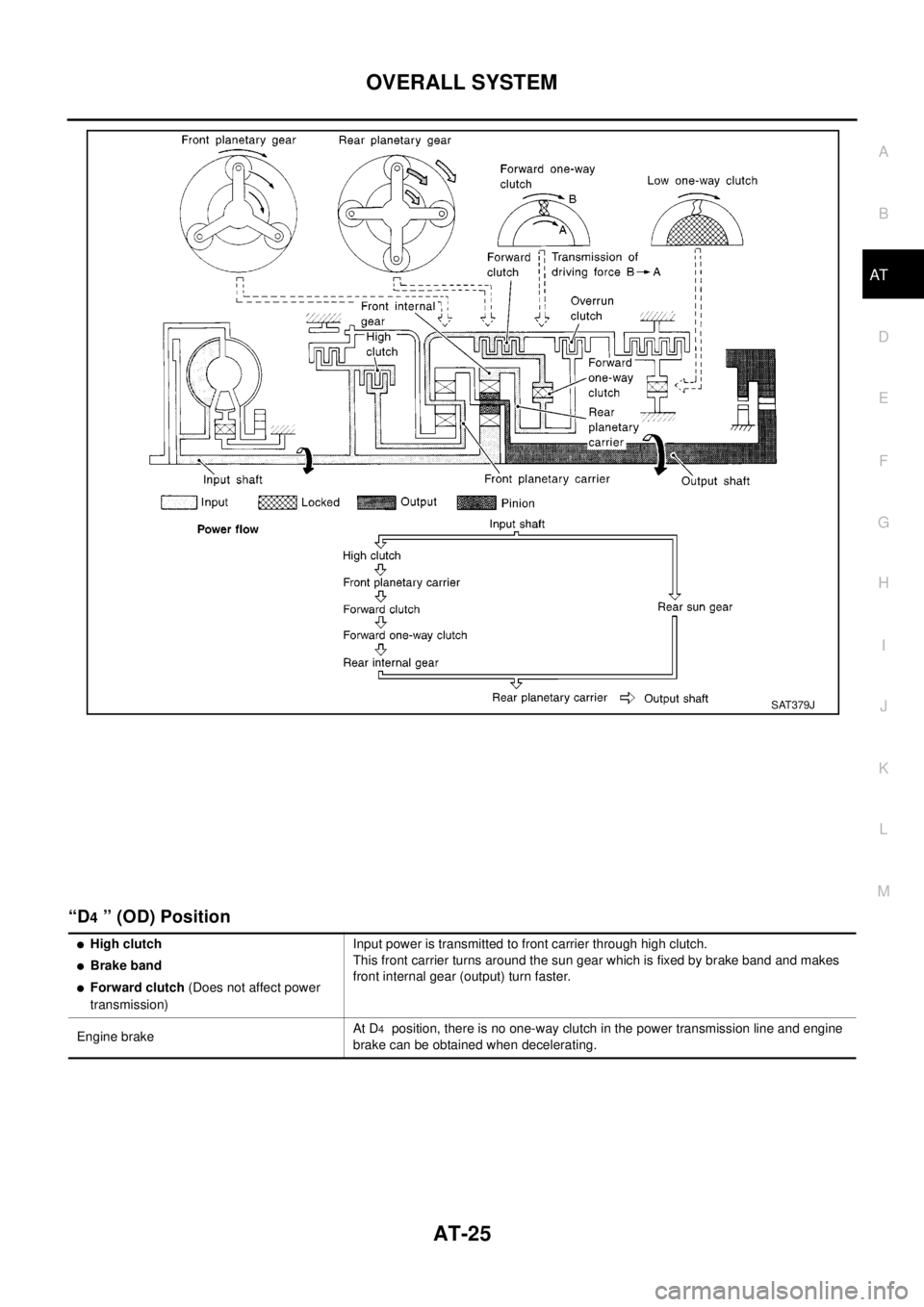

“D4” (OD) Position

SAT379J

lHigh clutch

lBrake band

lForward clutch(Does not affect power

transmission)Input power is transmitted to front carrier through high clutch.

This front carrier turns around the sun gear which is fixed by brake band and makes

front internal gear (output) turn faster.

Engine brakeAt D

4position, there is no one-way clutch in the power transmission line and engine

brake can be obtained when decelerating.

Page 32 of 3066

AT-26

OVERALL SYSTEM

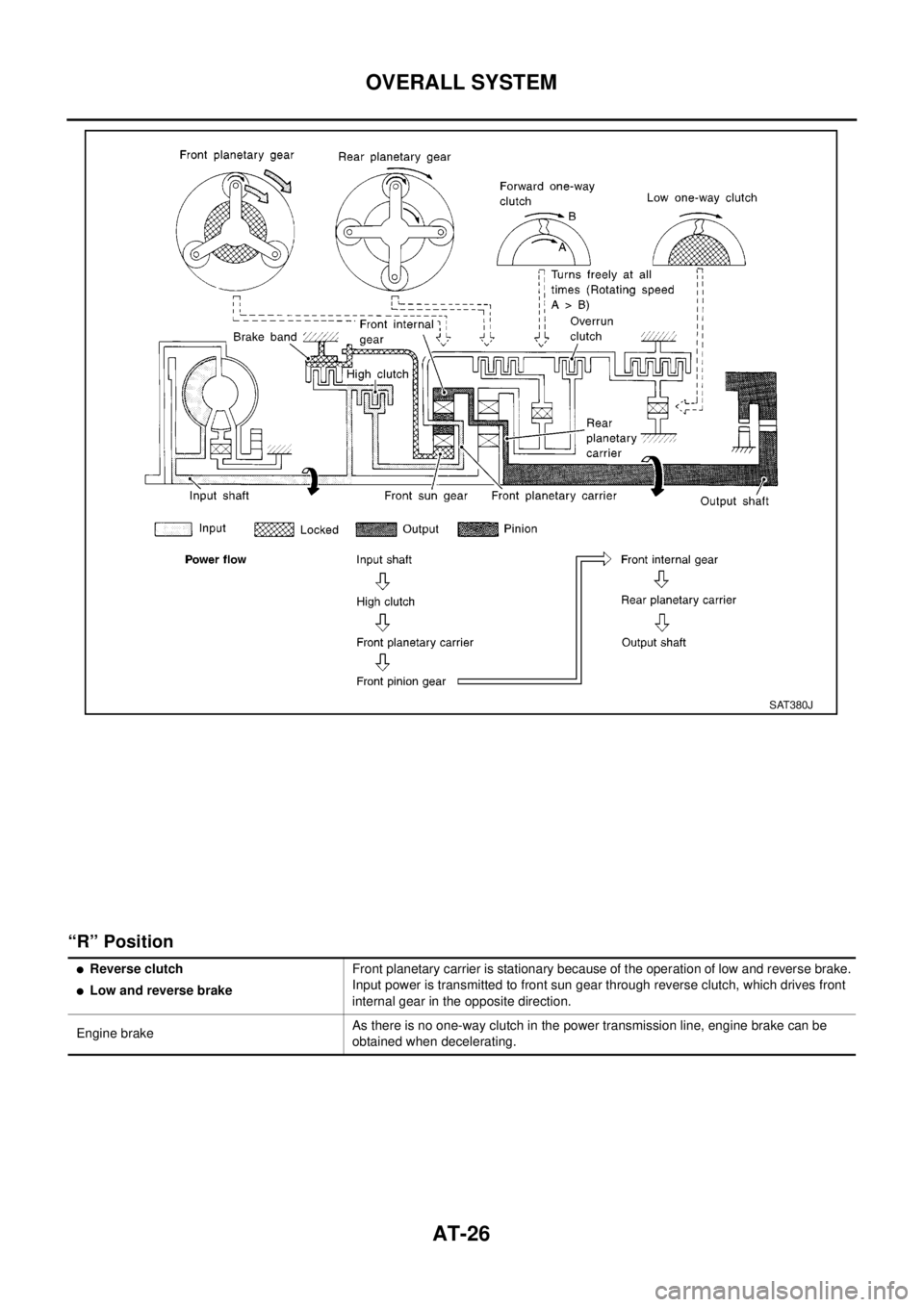

“R” Position

SAT380J

lReverse clutch

lLow and reverse brakeFront planetary carrier is stationary because of the operation of low and reverse brake.

Input power is transmitted to front sun gear through reverse clutch, which drives front

internal gear in the opposite direction.

Engine brakeAs there is no one-way clutch in the power transmission line, engine brake can be

obtained when decelerating.

Page 33 of 3066

OVERALL SYSTEM

AT-27

D

E

F

G

H

I

J

K

L

MA

B

AT

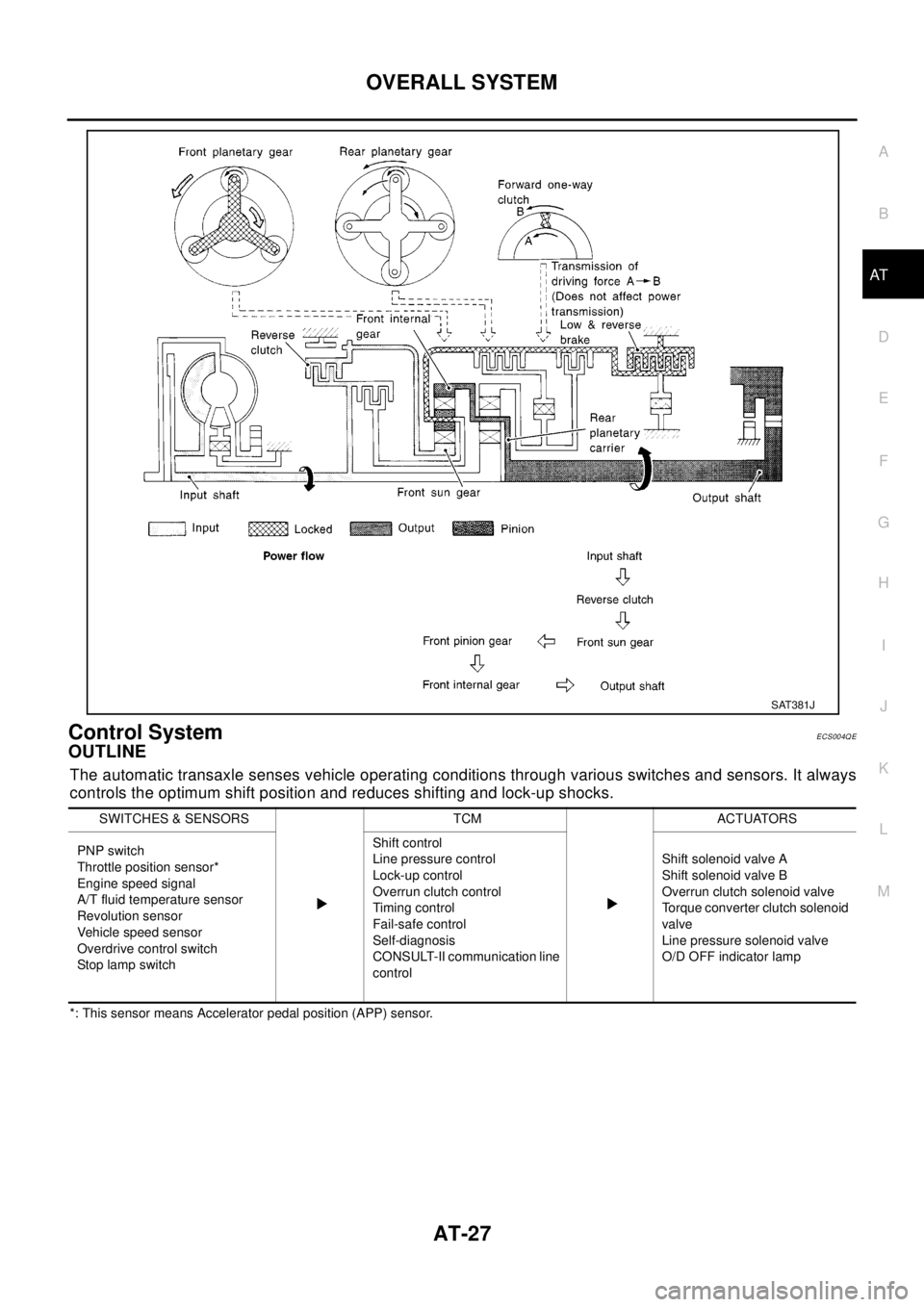

Control SystemECS004QE

OUTLINE

The automatic transaxle senses vehicle operating conditions through various switches and sensors. It always

controls the optimum shift position and reduces shifting and lock-up shocks.

*: This sensor means Accelerator pedal position (APP) sensor.

SAT381J

SWITCHES & SENSORS TCM ACTUATORS

PNP switch

Throttle position sensor*

Engine speed signal

A/T fluid temperature sensor

Revolution sensor

Vehicle speed sensor

Overdrive control switch

Stop la mp s witchShift control

Line pressure control

Lock-up control

Overrunclutchcontrol

Timing control

Fail-safe control

Self-diagnosis

CONSULT-II communication line

controlShift solenoid valve A

Shift solenoid valve B

Overrun clutch solenoid valve

Torque converter clutch solenoid

valve

Line pressure solenoid valve

O/D OFF indicator lamp

Page 34 of 3066

AT-28

OVERALL SYSTEM

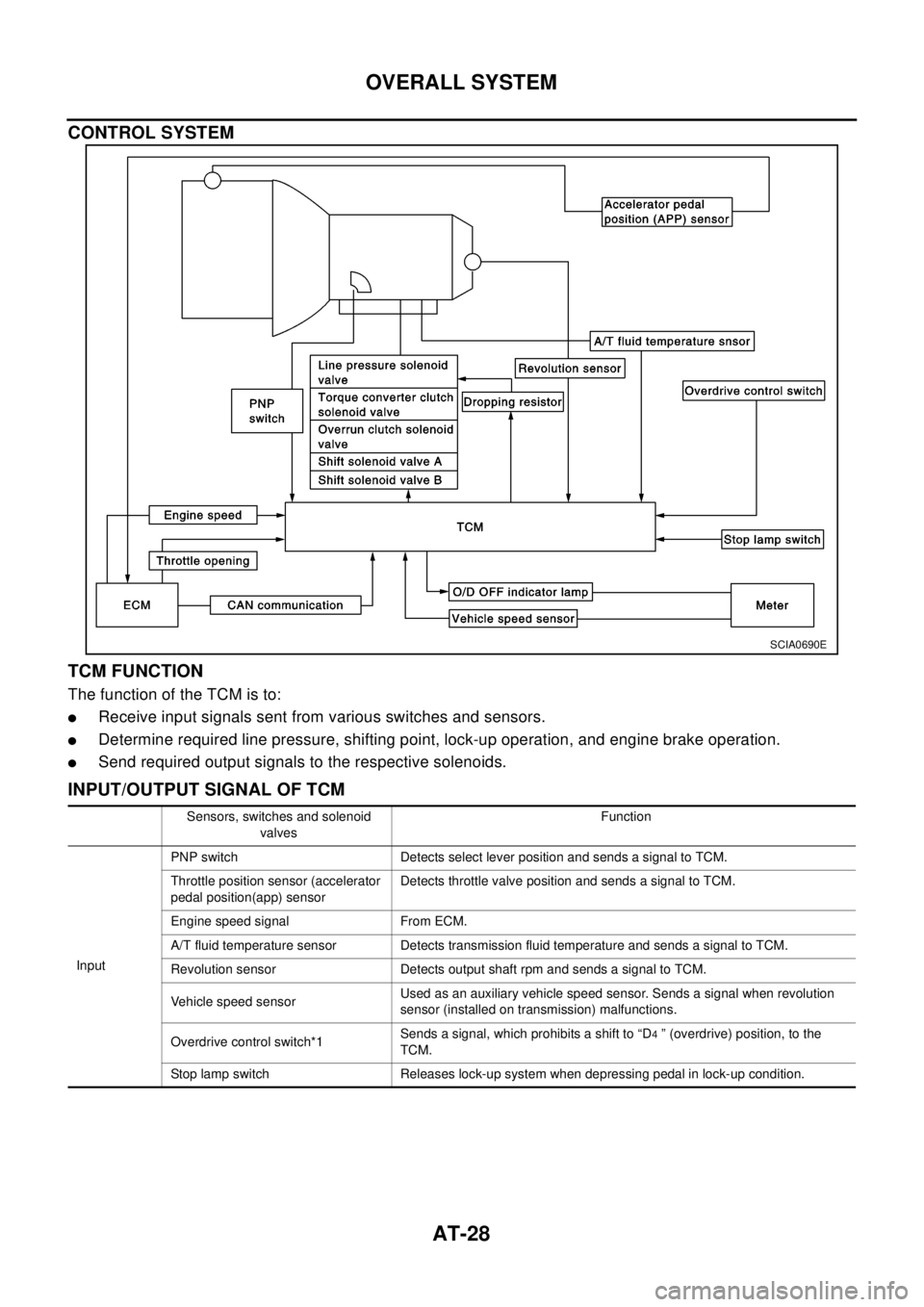

CONTROL SYSTEM

TCM FUNCTION

ThefunctionoftheTCMisto:

lReceive input signals sent from various switches and sensors.

lDetermine required line pressure, shifting point, lock-up operation, and engine brake operation.

lSend required output signals to the respective solenoids.

INPUT/OUTPUT SIGNAL OF TCM

SCIA0690E

Sensors, switches and solenoid

valvesFunction

InputPNP switch Detects select lever position and sends a signal to TCM.

Throttle position sensor (accelerator

pedal position(app) sensorDetects throttle valve position and sends a signal to TCM.

Engine speed signal From ECM.

A/T fluid temperature sensor Detects transmission fluid temperature and sends a signal to TCM.

Revolution sensor Detects output shaft rpm and sends a signal to TCM.

Vehicle speed sensorUsed as an auxiliary vehicle speed sensor. Sends a signal when revolution

sensor (installed on transmission) malfunctions.

Overdrive control switch*1Sends a signal, which prohibits a shift to “D

4” (overdrive) position, to the

TCM.

Stop lamp switch Releases lock-up system when depressing pedal in lock-up condition.

Page 35 of 3066

OVERALL SYSTEM

AT-29

D

E

F

G

H

I

J

K

L

MA

B

AT

Control MechanismECS004QF

LINE PRESSURE CONTROL

TCM has various line pressure control characteristics to match the driving conditions.

An ON-OFF duty signal is sent to the line pressure solenoid valve based on TCM characteristics.

Hydraulic pressure on the clutch and brake is electronically controlled through the line pressure solenoid valve

to accommodate engine torque. This results in smooth shift operation.

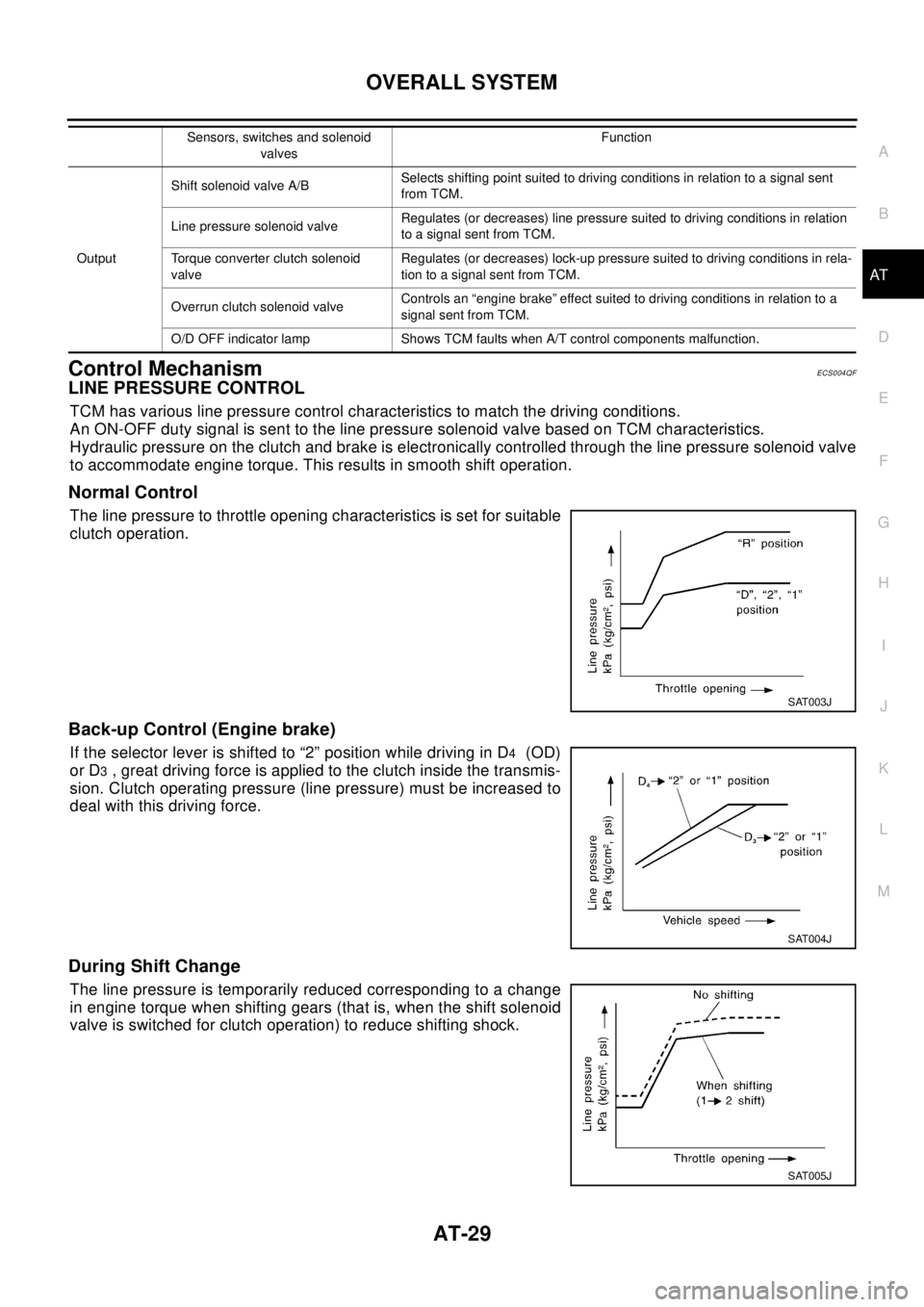

Normal Control

The line pressure to throttle opening characteristics is set for suitable

clutch operation.

Back-up Control (Engine brake)

If the selector lever is shifted to “2” position while driving in D4(OD)

or D

3, great driving force is applied to the clutch inside the transmis-

sion. Clutch operating pressure (line pressure) must be increased to

deal with this driving force.

During Shift Change

The line pressure is temporarily reduced corresponding to a change

in engine torque when shifting gears (that is, when the shift solenoid

valve is switched for clutch operation) to reduce shifting shock.

OutputShift solenoid valve A/BSelects shifting point suited to driving conditions in relation to a signal sent

from TCM.

Line pressure solenoid valveRegulates (or decreases) line pressure suited to driving conditions in relation

to a signal sent from TCM.

Torque converter clutch solenoid

valveRegulates (or decreases) lock-up pressure suited to driving conditions in rela-

tion to a signal sent from TCM.

Overrun clutch solenoid valveControls an “engine brake” effect suited to driving conditions in relation to a

signal sent from TCM.

O/D OFF indicator lamp Shows TCM faults when A/T control components malfunction.Sensors, switches and solenoid

valvesFunction

SAT003J

SAT004J

SAT005J

Page 36 of 3066

AT-30

OVERALL SYSTEM

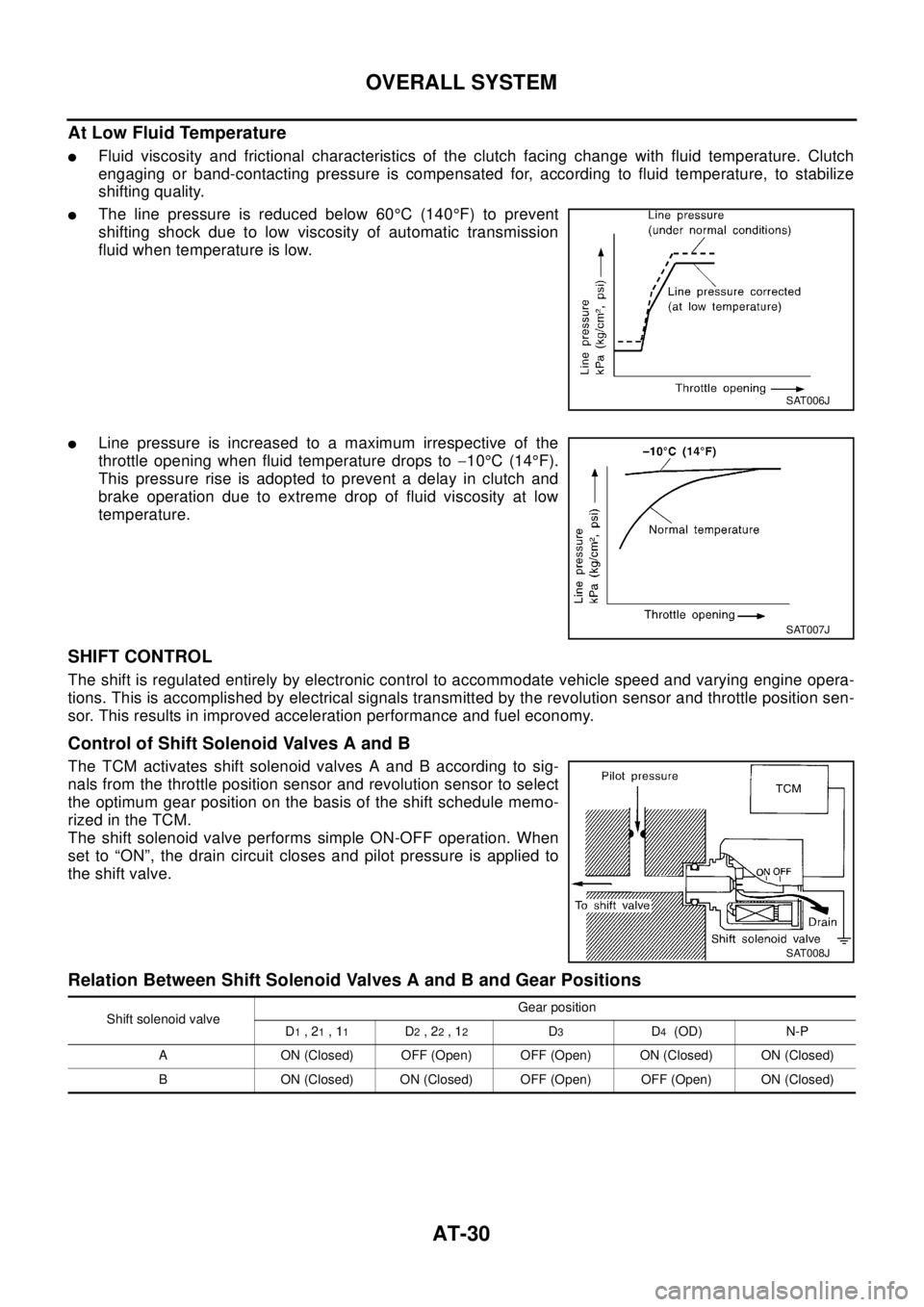

At Low Fluid Temperature

lFluid viscosity and frictional characteristics of the clutch facing change with fluid temperature. Clutch

engaging or band-contacting pressure is compensated for, according to fluid temperature, to stabilize

shifting quality.

lThe line pressure is reduced below 60°C(140°F) to prevent

shifting shock due to low viscosity of automatic transmission

fluid when temperature is low.

lLine pressure is increased to a maximum irrespective of the

throttle opening when fluid temperature drops to-10°C(14°F).

This pressure rise is adopted to prevent a delay in clutch and

brake operation due to extreme drop of fluid viscosity at low

temperature.

SHIFT CONTROL

The shift is regulated entirely by electronic control to accommodate vehicle speed and varying engine opera-

tions. This is accomplished by electrical signals transmitted by the revolution sensor and throttle position sen-

sor. This results in improved acceleration performance and fuel economy.

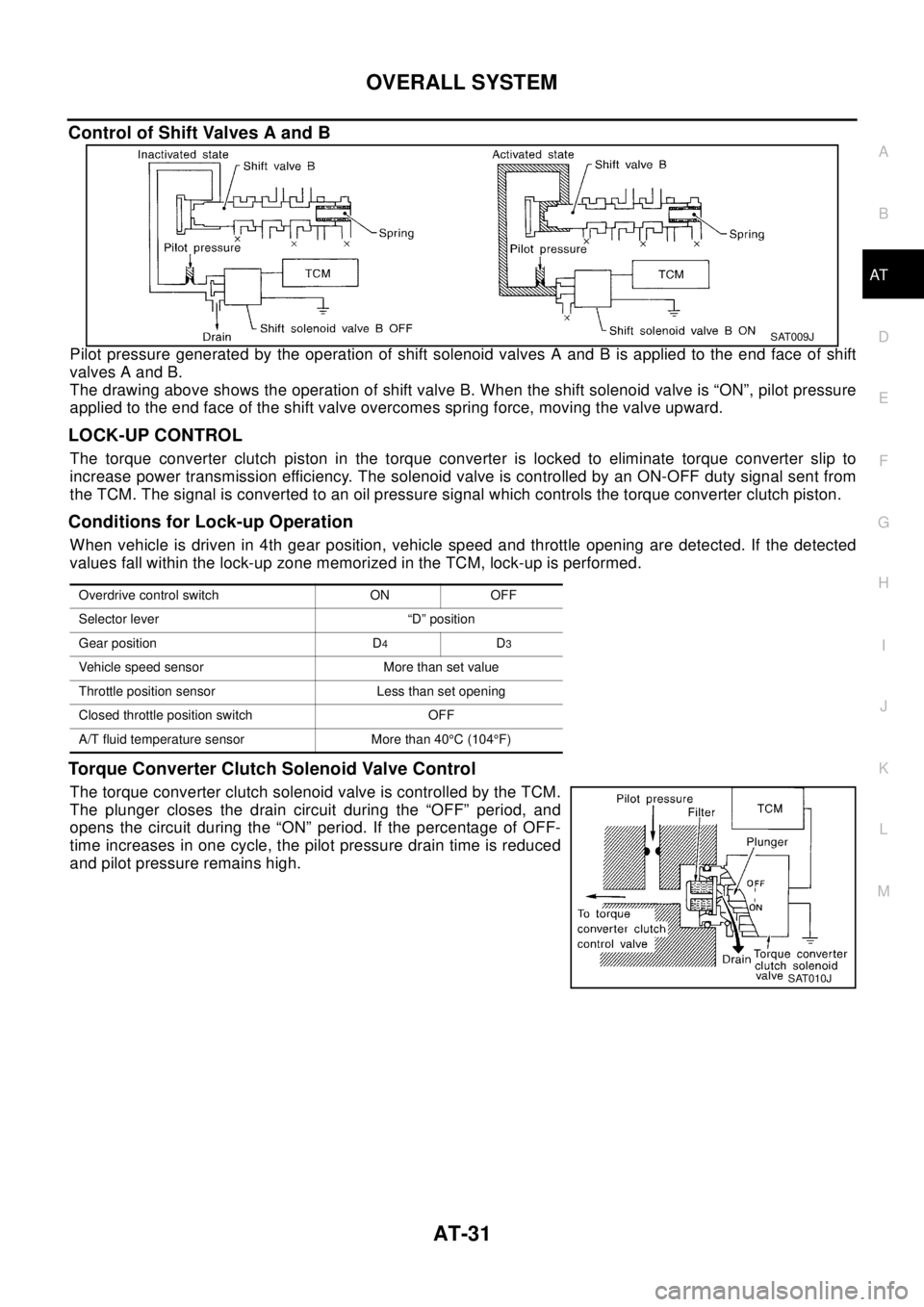

Control of Shift Solenoid Valves A and B

The TCM activates shift solenoid valves A and B according to sig-

nals from the throttle position sensor and revolution sensor to select

the optimum gear position on the basis of the shift schedule memo-

rizedintheTCM.

The shift solenoid valve performs simple ON-OFF operation. When

set to “ON”, the drain circuit closes and pilot pressure is applied to

the shift valve.

Relation Between Shift Solenoid Valves A and B and Gear Positions

SAT006J

SAT007J

SAT008J

Shift solenoid valveGear position

D1,21,11D2,22,12D3D4(OD) N-P

A ON (Closed) OFF (Open) OFF (Open) ON (Closed) ON (Closed)

B ON (Closed) ON (Closed) OFF (Open) OFF (Open) ON (Closed)

Page 37 of 3066

OVERALL SYSTEM

AT-31

D

E

F

G

H

I

J

K

L

MA

B

AT

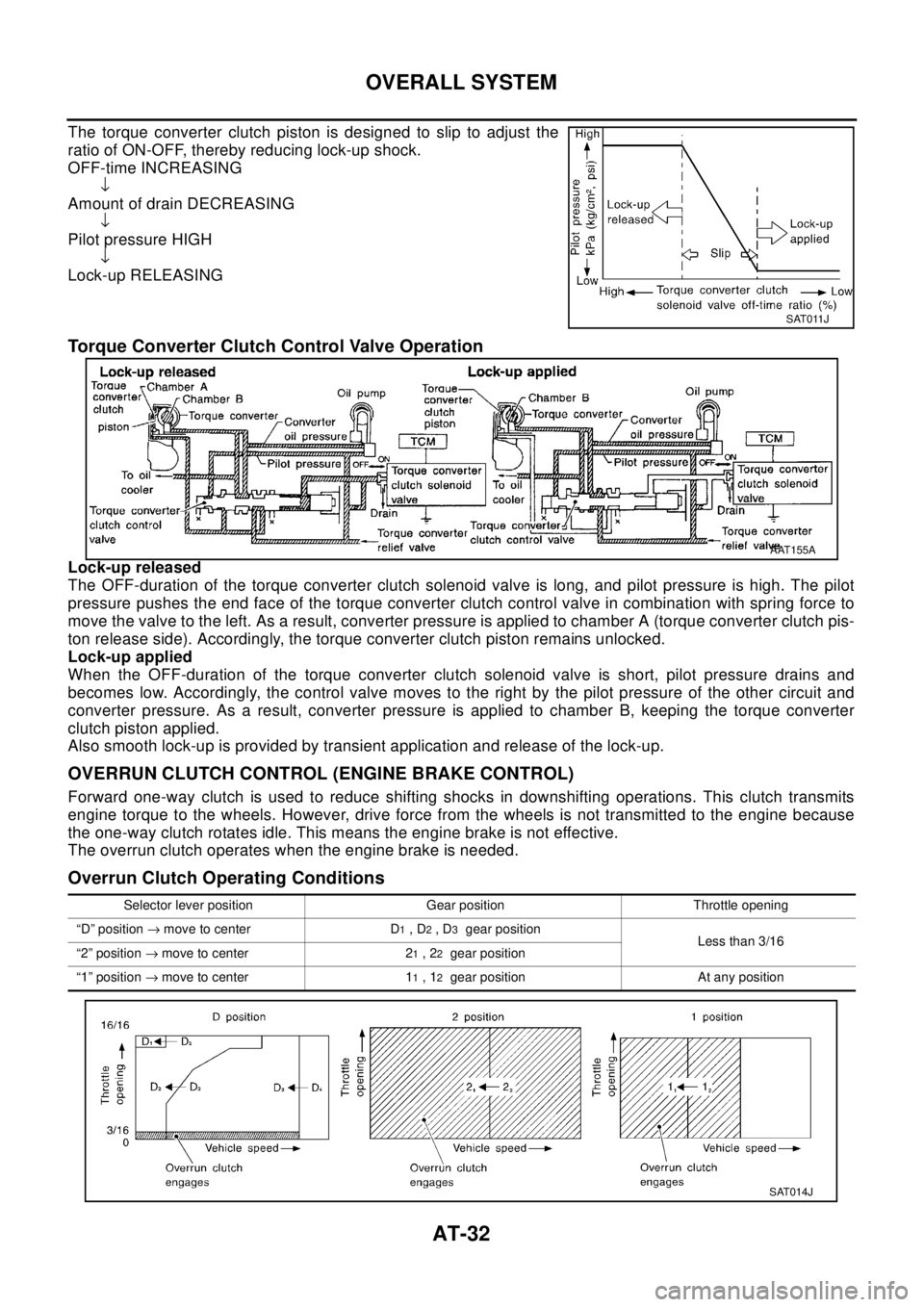

Control of Shift Valves A and B

Pilot pressure generated by the operation of shift solenoid valves A and B is applied to the end face of shift

valves A and B.

The drawing above shows the operation of shift valve B. When the shift solenoid valve is “ON”, pilot pressure

applied to the end face of the shift valve overcomes spring force, moving the valve upward.

LOCK-UP CONTROL

The torque converter clutch piston in the torque converter is locked to eliminate torque converter slip to

increase power transmission efficiency. The solenoid valve is controlled by an ON-OFF duty signal sent from

the TCM. The signal is converted to an oil pressure signal which controls the torque converter clutch piston.

Conditions for Lock-up Operation

When vehicle is driven in 4th gear position, vehicle speed and throttle opening are detected. If the detected

values fall within the lock-up zone memorized in the TCM, lock-up is performed.

Torque Converter Clutch Solenoid Valve Control

The torque converter clutch solenoid valve is controlled by the TCM.

The plunger closes the drain circuit during the “OFF” period, and

opens the circuit during the “ON” period. If the percentage of OFF-

time increases in one cycle, the pilot pressure drain time is reduced

and pilot pressure remains high.

SAT009J

Overdrive control switch ON OFF

Selector lever “D” position

Gear position D

4D3

Vehicle speed sensor More than set value

Throttle position sensor Less than set opening

Closed throttle position switch OFF

A/T fluid temperature sensor More than 40°C(104°F)

SAT010J

Page 38 of 3066

AT-32

OVERALL SYSTEM

The torque converter clutch piston is designed to slip to adjust the

ratio of ON-OFF, thereby reducing lock-up shock.

OFF-time INCREASING

¯

Amount of drain DECREASING

¯

Pilot pressure HIGH

¯

Lock-up RELEASING

Torque Converter Clutch Control Valve Operation

Lock-up released

The OFF-duration of the torque converter clutch solenoid valve is long, and pilot pressure is high. The pilot

pressure pushes the end face of the torque converter clutch control valve in combination with spring force to

move the valve to the left. As a result, converter pressure is applied to chamber A (torque converter clutch pis-

ton release side). Accordingly, the torque converter clutch piston remains unlocked.

Lock-up applied

When the OFF-duration of the torque converter clutch solenoid valve is short, pilot pressure drains and

becomes low. Accordingly, the control valve moves to the right by the pilot pressure of the other circuit and

converter pressure. As a result, converter pressure is applied to chamber B, keeping the torque converter

clutch piston applied.

Also smooth lock-up is provided by transient application and release of the lock-up.

OVERRUN CLUTCH CONTROL (ENGINE BRAKE CONTROL)

Forward one-way clutch is used to reduce shifting shocks in downshifting operations. This clutch transmits

engine torque to the wheels. However, drive force from the wheels is not transmitted to the engine because

the one-way clutch rotates idle. This means the engine brake is not effective.

The overrun clutch operates when the engine brake is needed.

Overrun Clutch Operating Conditions

SAT011J

AAT155A

Selector lever position Gear position Throttle opening

“D” position®move to center D

1,D2,D3gear position

Less than 3/16

“2” position®move to center 2

1,22gear position

“1” position®move to center 1

1,12gear position At any position

SAT014J

Page 39 of 3066

OVERALL SYSTEM

AT-33

D

E

F

G

H

I

J

K

L

MA

B

AT

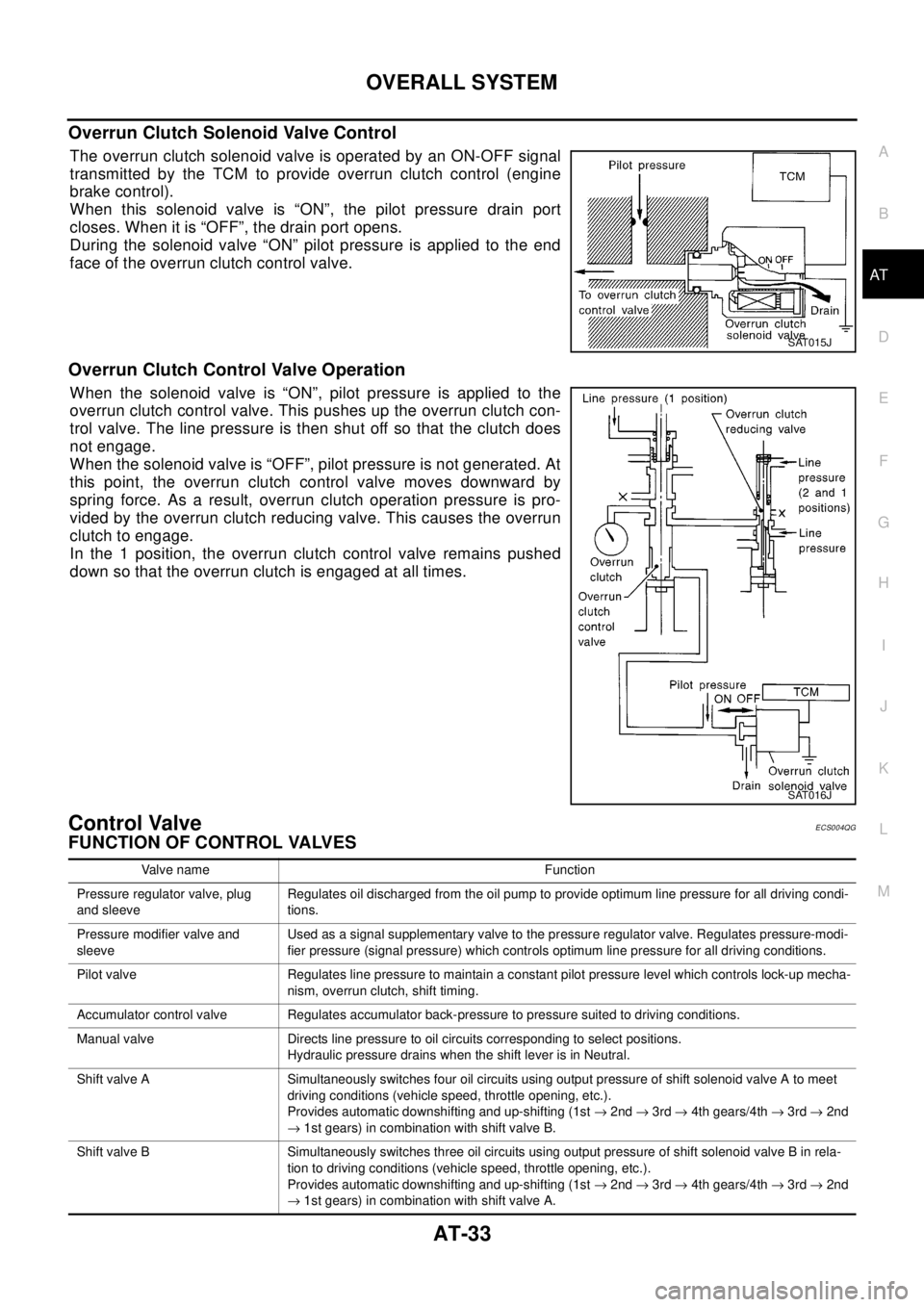

Overrun Clutch Solenoid Valve Control

TheoverrunclutchsolenoidvalveisoperatedbyanON-OFFsignal

transmitted by the TCM to provide overrun clutch control (engine

brake control).

When this solenoid valve is “ON”, the pilot pressure drain port

closes. When it is “OFF”, the drain port opens.

During the solenoid valve “ON” pilot pressure is applied to the end

face of the overrun clutch control valve.

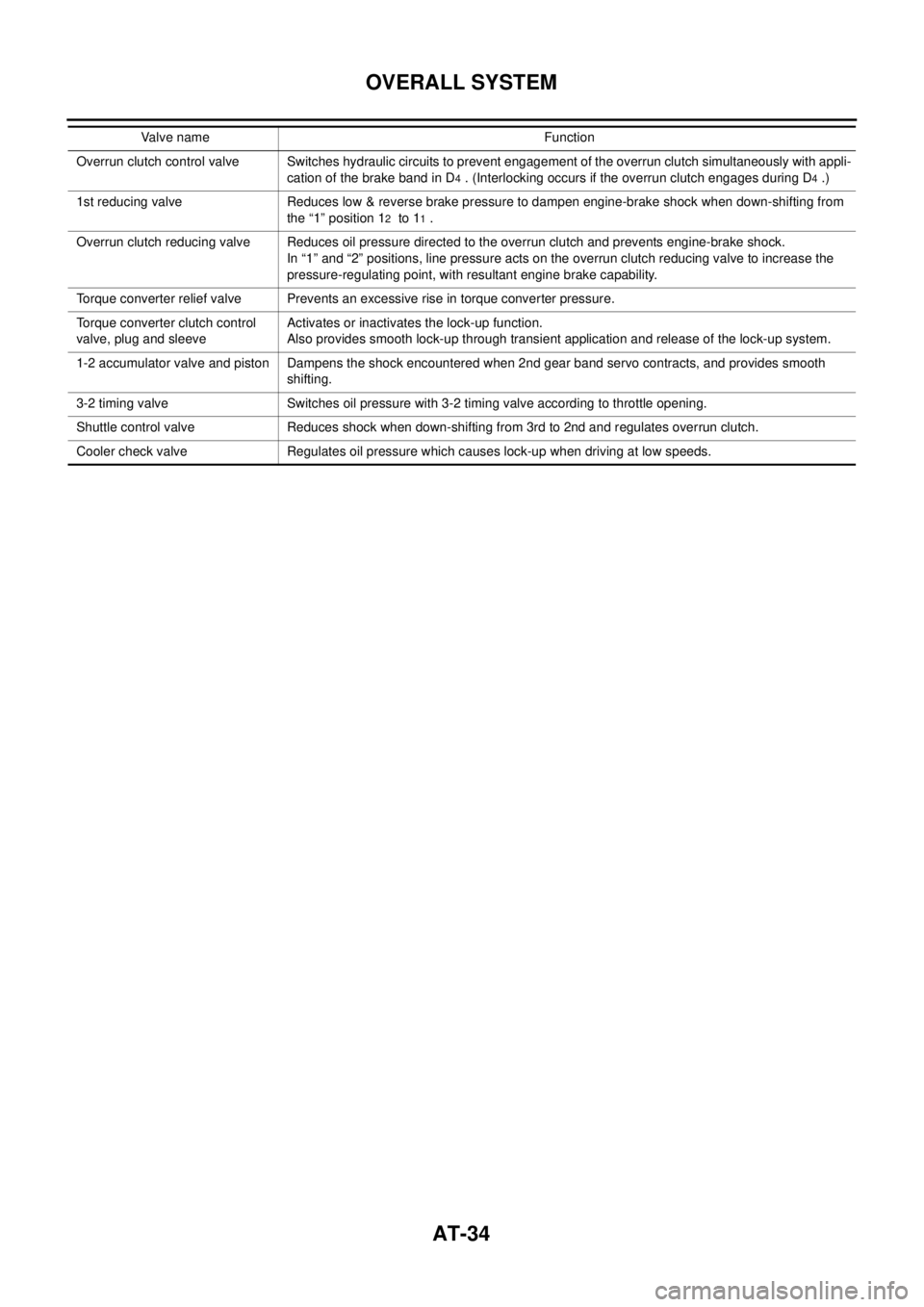

Overrun Clutch Control Valve Operation

When the solenoid valve is “ON”, pilot pressure is applied to the

overrun clutch control valve. This pushes up the overrun clutch con-

trol valve. The line pressure is then shut off so that the clutch does

not engage.

When the solenoid valve is “OFF”, pilot pressure is not generated. At

this point, the overrun clutch control valve moves downward by

spring force. As a result, overrun clutch operation pressure is pro-

vided by the overrun clutch reducing valve. This causes the overrun

clutch to engage.

In the 1 position, the overrun clutch control valve remains pushed

down so that the overrun clutch is engaged at all times.

Control ValveECS004QG

FUNCTION OF CONTROL VALVES

SAT015J

SAT016J

Valve name Function

Pressure regulator valve, plug

and sleeveRegulates oil discharged from the oil pump to provide optimum line pressure for all driving condi-

tions.

Pressure modifier valve and

sleeveUsed as a signal supplementary valve to the pressure regulator valve. Regulates pressure-modi-

fier pressure (signal pressure) which controls optimum line pressure for all driving conditions.

Pilot valve Regulates line pressure to maintain a constant pilot pressure level which controls lock-up mecha-

nism, overrun clutch, shift timing.

Accumulator control valve Regulates accumulator back-pressure to pressure suited to driving conditions.

Manual valve Directs line pressure to oil circuits corresponding to select positions.

Hydraulic pressure drains when the shift lever is in Neutral.

Shift valve A Simultaneously switches four oil circuits using output pressure of shift solenoid valve A to meet

driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st®2nd®3rd®4th gears/4th®3rd®2nd

®1st gears) in combination with shift valve B.

Shift valve B Simultaneously switches three oil circuits using output pressure of shift solenoid valve B in rela-

tion to driving conditions (vehicle speed, throttle opening, etc.).

Provides automatic downshifting and up-shifting (1st®2nd®3rd®4th gears/4th®3rd®2nd

®1st gears) in combination with shift valve A.

Page 40 of 3066

AT-34

OVERALL SYSTEM

Overrun clutch control valve Switches hydraulic circuits to prevent engagement of the overrun clutch simultaneously with appli-

cation of the brake band in D

4. (Interlocking occurs if the overrun clutch engages during D4.)

1st reducing valve Reduces low & reverse brake pressure to dampen engine-brake shock when down-shifting from

the “1” position 1

2to 11.

Overrun clutch reducing valve Reduces oil pressure directed to the overrun clutch and prevents engine-brake shock.

In “1” and “2” positions, line pressure acts on the overrun clutch reducing valve to increase the

pressure-regulating point, with resultant engine brake capability.

Torque converter relief valve Prevents an excessive rise in torque converter pressure.

Torque converter clutch control

valve, plug and sleeveActivates or inactivates the lock-up function.

Also provides smooth lock-up through transient application and release of the lock-up system.

1-2 accumulator valve and piston Dampens the shock encountered when 2nd gear band servo contracts, and provides smooth

shifting.

3-2 timing valve Switches oil pressure with 3-2 timing valve according to throttle opening.

Shuttle control valve Reduces shock when down-shifting from 3rd to 2nd and regulates overrun clutch.

Cooler check valve Regulates oil pressure which causes lock-up when driving at low speeds.Valve name Function