DATSUN 210 1979 Service Manual

Manufacturer: DATSUN, Model Year: 1979, Model line: 210, Model: DATSUN 210 1979Pages: 548, PDF Size: 28.66 MB

Page 411 of 548

Engine

Control

Fuel

Exhaust

Systems

Note

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

400C

I040F

or

above

A

sealant

hardened

at

400

C

I040F

or

above

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

beoomes

hardened

because

of

low

temperatures

warm

the

sealant

FE

13

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

the

tube

at

a

temperature

of

over

400C

I040F

for

a

long

period

of

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

Page 412 of 548

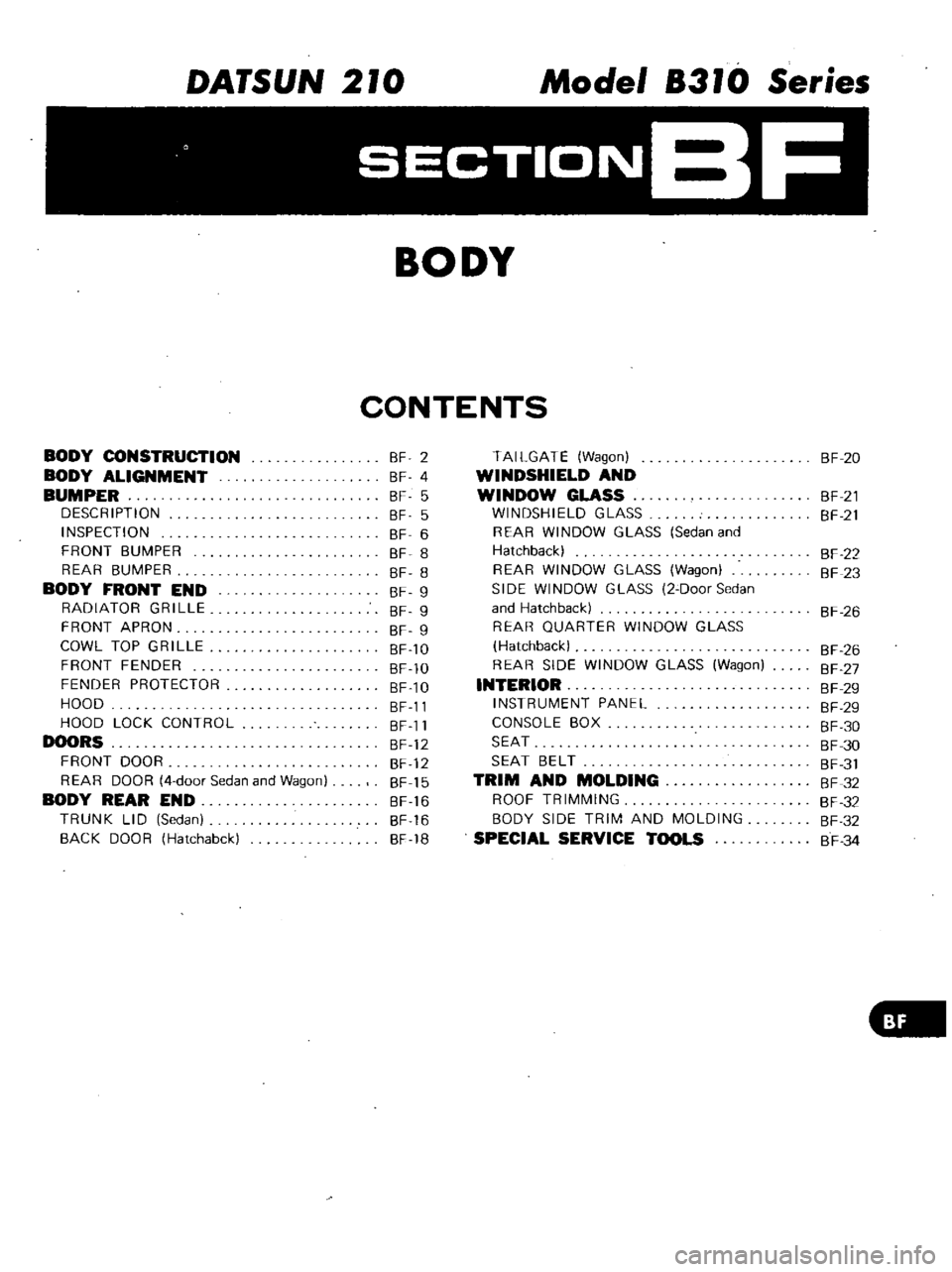

DATSUN

210

Model

8310

Series

F

BODY

CONSTRUCTION

BODY

ALIGNMENT

BUMPER

DESCRIPTION

INSPECTION

FRONT

BUMPER

REAR

BUMPER

BODY

FRONT

END

RADIATOR

GRILLE

FRONT

APRON

COWL

TOP

GRILLE

FRONT

FENDER

FENDER

PROTECTOR

HOOD

HOOD

LOCK

CONTROL

DOORS

FRONT

DOOR

REAR

DOOR

4

door

Sedan

and

Wagon

BODY

REAR

END

TRUNK

LID

Sedan

SAC

K

000

R

Hatchabck

BODY

CONTENTS

BF

2

BF

4

BF

5

BF

5

BF

6

BF

8

SF

8

BF

9

BF

9

BF

9

BF

10

BF

10

BF

10

BF

11

BF

11

BF

12

BF

12

BF

15

BF

16

BF

16

BF

18

TAILGATE

Wagon

WINDSHIELD

AND

WINDOW

GLASS

WINDSHIELD

GLASS

REAR

WINDOW

GLASS

Sedan

and

Hatchback

REAR

WINDOW

GLASS

Wagon

SIDE

WINDOW

GLASS

2

Door

Sedan

and

Hatchback

REAR

QUARTER

WINDOW

GLASS

Hatchback

REAR

SIDE

WINDOW

GLASS

Wagon

INTERIOR

INSTRUMENT

PANEL

CONSOLE

BOX

SEAT

SEAT

BELT

TRIM

AND

MOLDING

ROOF

TRIMMING

BODY

SIDE

TRIM

AND

MOLDING

SPECIAL

SERVICE

TOOLS

BF

20

8F

21

SF

21

BF

22

SF

23

BF

26

BF

26

BF

27

SF

29

BF

29

SF

30

BF

30

BF

31

SF

32

BF

32

BF

32

BF

34

Page 413 of 548

Body

BODY

CONSTRUCTION

Z3

Section

C

Section

F

Section

D

I

Section

E

w

Section

B

Section

A

Section

G

fTIf

Section

H

Fig

BF

l

Body

Construction

S

dan

BF512B

BF

2

Page 414 of 548

Body

Section

D

Section

C

Section

F

L

Section

E

Section

G

Wi

Section

B

Section

A

ionl

Fig

BF

2

Bod

C

BF5138

Y

onstruction

H

atchback

iii

c

II

Section

G

Section

E

Section

F

Section

A

Section

B

J

Section

J

Section

I

Fig

BF

3

B

d

BF514B

o

y

Construe

tion

W

agon

Section

H

BF

3

Page 415 of 548

Xl

ii

b

l

b

l

0

c

tD

s

1

E

tD

h

Section

A

A

rL

Section

B

B

i

Section

C

C

Section

D

D

Center

line

of

rear

axle

f

front

axle

Center

line

0

34

1

725

67

91

1

34

1

SprIng

I

850

33

46

bracket

40

1

57

360

43

6

1

7t

7

t4

17

474

635

28

1

10

r

r

w

1

I

I

s

i

I

t

I

JI

VI

o

c

It

t

r

1

0

I

I

0

I

g

0

O

f

loll

I

O

0

0

0

eo

0

c

J

l

0

LLtL

J

00

t

tJ

Zv

v

w

t

r

I

b

r

c

L

eu

k

142

44

96

III

18

90

639

25

16

JI

I

L

t

F

ont

eat

bracket

bumper

1

43

2

r

I

I

39

1

701

ine

mount

bracke

A

1

55

II

Rear

ens

0

I

Front

floor

ember

I

r

From

seat

cro

J

L

j

35

5

0

20

d

e

D

D

r

l

3

B

c

r

C

C

0

r

r

1

5

I

o

I

Lower

link

0

b

acket

i

0

0

1

Upper

link

r

bracket

847

33

35

55

217

L

H

1

81

2340

1

931

J

36

65

R

H

46

92

13

r

943

37

13

720

28

35

696

2740

78

2

95

J

I

Shock

absorber

bracket

O

ow

Front

side

member

0

I

t

C

II

f

TlIIUI

J

I

U9

135

68

1

38

58

l

5

31

2

681

1

50

2

28

J

L

H

30

1

18

505

R

H

27

1

06

19

88

f

i

Rear

floor

9

r

00

8

1

Wagon

aJ

o

o

f

C5

z

3

m

z

4

CD

o

0

Page 416 of 548

DESCRIPTION

The

front

and

rear

bumpers

consist

essentially

of

a

center

bumper

two

side

bumpers

and

two

shock

absorbers

The

bumper

is

attached

to

the

side

member

through

a

gas

filled

strut

type

shock

absorber

at

each

end

to

effectively

absorb

the

energy

of

a

collision

upon

ilnpact

The

side

bumper

is

constructed

with

a

steel

insert

panel

and

porous

urethane

rubber

The

urethane

rubber

FRONT

BUMPER

I

I

Body

BUMPER

section

reduces

to

a

nummum

the

possibility

of

damaging

the

car

body

when

the

bumper

is

involved

in

a

collision

CAUTION

The

shock

ebsorber

is

filled

with

a

high

pressure

gn

and

should

not

be

disassembled

drilled

or

exposed

to

In

open

flame

CAUTION

LABEL

Pasted

on

shock

absorbers

x

DANGER

i

t

e

e

e

t

I

Contents

under

pressure

Don

t

take

apart

puncture

apply

heat

or

fira

3S

mm

1

38

in

BF

5

1

Front

center

bumper

2

Over

rider

3

Side

bumper

4

Bumper

mounting

bracket

5

Center

bumper

brace

6

Bumper

rainforce

7

Sight

shield

8

Shock

absorber

9

Bumper

attaching

bolt

BF738B

Fig

BF

5

Front

Bumper

Page 417 of 548

Body

REAR

BUMPER

sP

9

4

h

m

O

1Doo

ter

bumper

1

Rear

ceo

2

Over

rider

3

Side

bumper

brace

4

Center

bumpe

mg

bracket

5

Bumper

moun

6

Bame

plate

r

reinforce

7

Bumpe

ld

Wagon

only

8

Sight

shl

9

Shock

absor

bolt

10

Bumper

atta

mg

BF739B

BF

6

Rear

Bump

r

Fig

INSPECTION

To

inspect

condition

of

bumper

tilize

the

follow

and

shock

absor

e

d

proceed

in

the

h

t

asaguld

mg

c

ar

Good

the

chart

order

indicated

m

Good

Measure

shock

absorber

dimensions

Good

Measure

h

ck

bumper

No

good

bumper

height

Visually

c

e

appearance

Adjust

d

bumper

No

goo

height

Check

shock

No

good

absOrber

operation

compressed

and

expanded

Replace

od

shock

No

go

absorber

Good

BF

6

Page 418 of 548

Bumper

height

I

Place

car

on

a

flat

surface

under

curb

weight

condition

Tires

must

be

inflated

to

rated

pressure

2

Measure

height

above

ground

of

bumper

at

two

mounting

locations

as

shown

in

Figs

BF

7

and

BF

8

3

If

bumper

height

is

not

within

the

specification

loosen

shock

ab

sorber

attaching

bolts

and

nuts

Then

adjust

bumper

height

After

adjust

ment

tighten

bolts

and

nuts

securely

Front

bumper

height

H

360

to

408

mm

14

17

to

16

06

in

Rear

bumper

height

H

Sedan

and

Hatchback

391

to

433

mm

15

39

to

17

05

in

Wagon

376

to

418

mm

14

BO

to

16

46

in

Sedan

and

Hatchback

Body

I

J

S

H

I

BF740B

Fig

BF

7

Front

Bumper

Height

Wagon

O

J

H

j

BF741B

Fig

BF

8

Rear

Bumper

Height

BF

7

Page 419 of 548

Body

2

Length

of

shock

absorber

Front

shock

absorber

I

164

6

46

q

j

0

I

0

0

67

2

64

Rear

shock

absorber

G

riA

l

yll

L

J

J

Unit

mm

in

3

Checking

shock

absorber

I

Place

car

in

front

of

a

wall

Apply

hand

brake

and

place

wheel

chocks

securely

2

Place

a

jack

between

wall

and

extend

jack

approximately

20

mm

0

79

in

The

bumper

should

move

approxilnately

50

mm

I

97

in

back

ward

through

shock

absorber

opera

tion

See

Fig

BF

IO

Note

Use

a

jack

with

y

of

more

than

600

kg

I

3231b

94

3

70

rL

I

i

r

T

l

f

L

W

67

2

64

1

8F742B

Fig

BF

9

Length

of

Shock

Absorber

3

Make

sure

bumper

returns

to

its

original

position

when

jack

is

re

tracted

Note

When

replacing

shock

absorb

ers

make

Sure

they

are

of

the

same

type

and

rating

and

manufactured

by

the

same

maker

4

For

rear

bumper

utilize

the

same

procedures

as

described

for

front

bumper

f

BF7438

1

Front

bumper

2

Jack

3

Wheel

chock

Fig

BF

10

Checking

Shock

Abaorber

Function

BF

8

FRONT

BUMPER

REMOVAL

AND

INSTALLATION

1

Loosen

bolts

attaching

front

bumper

to

shock

absorbers

and

re

move

bumper

See

Fig

BF

5

2

Loosen

bolts

attaching

shock

ab

sorbers

to

radia

tor

core

support

and

side

members

and

remove

shock

absorbers

3

Install

shock

absorbers

and

front

bumper

in

reverse

order

of

removal

and

adjust

bumper

height

as

shown

in

Fig

BF

7

fj

Tightening

torque

Front

bumper

Bumper

to

shock

absorber

attaching

bolt

6

0

to

8

0

kg

m

43

to

58

ft

Ib

Shock

absorber

to

body

attaching

bolt

and

nut

front

0

93

to

1

2

kg

m

6

7

to

B

7

ft

Ibl

attaching

bolt

and

nut

sida

1

9

to

2

5

kg

m

14

to

18

ft

b

REAR

BUMPER

REMOVAL

AND

INSTALLATION

1

Loosen

bolts

attaching

rear

bumper

to

shock

absorbers

and

re

move

rear

bumper

See

Fig

BF

6

2

Loosen

bolts

and

nuts

attaching

shock

absorbers

to

side

members

and

remove

shock

absorbers

3

Install

shock

absorbers

an

rear

bumper

in

reverse

order

of

removal

and

adjust

rear

bumper

height

as

shown

in

Fig

BF

B

fj

Tightening

torque

Rear

bumper

Bumper

to

shock

absorber

attaching

bolt

rear

6

0

to

8

0

kg

m

43

to

58

ft

b

Shock

absorber

to

body

attaching

bolt

and

nut

rear

0

93

to

1

2

kg

m

6

7

to

8

7

ft

b

attaching

bolt

and

nut

side

6

0

to

BoO

kg

m

43

to

58

ft

b

Page 420 of 548

RADIATOR

GRILLE

REMOVAL

AND

INSTALLATION

I

Open

hood

2

Remove

radiator

grille

attaching

screws

3

Detach

radiator

grille

from

front

end

of

car

4

Disconnect

front

combination

lamp

connectors

Then

remove

radia

tor

grille

S

Installation

is

in

the

reverse

order

of

removal

Note

a

Radiator

grille

is

made

of

plastic

so

do

not

use

excessive

force

b

Take

care

to

keep

any

oil

away

from

radiator

grille

FRONT

APRON

REMOVAL

AND

INSTALLATION

1

Remove

screws

attaching

front

apron

to

front

fender

2

Remove

screws

attaching

front

apron

to

hood

lock

stay

3

Remove

screws

attaching

front

apron

to

radiator

core

support

4

Remove

screws

attaching

front

apron

to

bracket

S

Installation

is

in

the

reverse

order

of

removal

Body

BODY

FRONT

END

8F7448

Fig

BF

11

Removing

RadiIJtor

Grille

S

1

i

oo

1

0

ole

I

Q

I

f

J

0

0

i

I

g

nl

o

A

BF

9

4

1

J

n

Jf

rf

BF745B

Fig

BF

12

Remouing

Front

Apron